Abstract

Space exploration and the prospect of developing permanent lunar settlements in the near future will require the need for innovative building construction techniques using locally sourced materials, without the need for excessive input of simple, reusable energy. The Moon’s surface is covered by regolith, a superficial layer of unconsolidated heterogeneous dusty aggregate that covers solid bedrock. This material needs to be agglomerated to create a cohesive composite that can be used as building blocks or bricks. In this study, the OPRH2N’s Lunar Regolith Simulant (LRS) was used and agglomerated with Potato (Solanum tuberosum) Starch (PS) polymer aerogel. Starch was chosen because of its excellent binding properties at very low concentrations. The resulting low-starch-containing LRS/PS aerogel composite bricks (2 and 4 wt%) were tested for their mechanical and thermal insulation performance to evaluate their potential application in lunar building structures. The composite resistance to intense beta-radiation and very large thermal amplitude was investigated to test the bricks’ resistance. This new lightweight and porous material shows promising mechanical and thermal performance, making it a potential candidate for the construction of larger structures, especially in low gravity.

1. Introduction

The late 1960s and early 1970s brought a wave of groundbreaking achievements in space exploration with the space race and the Moon landing. However, the cost of launching material (approximately USD 1 million per kilogram as reported on the NASA website [1]) and equipment from Earth, associated with technological difficulties in developing reliable reusable launchers and waning public interest, put a damper on the initial momentum. Today’s renewed interest in space exploration has sparked ambitious programs to return to, build, and stay on the Moon as a springboard for further planetary explorations to Mars and beyond. One of the key challenges remains using local resources from the Moon. In-situ resource utilization (ISRU) [2] is the practice that promotes the use of local collection and indigenous material instead of bringing it from Earth. The perspective of setting up permanent lunar settlements as a gateway to further space exploration in the near future will require the need for new alternative materials produced in situ, with a particular focus on locally sourced materials as innovative construction materials. The Moon’s surface is covered by regolith [3], constituted of unconsolidated, loose, heterogeneous superficial powdery deposits covering solid pyroxene, olivine, or plagioclase basalt bedrock. It includes dust, broken rocks, and a variety of other minerals. This regolith needs to be agglomerated to make cohesive composites, able to be used to create solid “Lunarcrete” blocks or bricks [4]. These bricks could be used as elements for constructing external protective wall structures over inflatable habitats. They must be sufficiently strong to allow the construction of self-standing walls in high-vacuum and low-gravity environments and insulate the habitats against extreme temperature variations and radiation. The walls should be able to protect the highly exposed lunar surface, which is devoid of a protective magnetic field and atmospheric layer. The Moon’s surface is subjected to the intense solar ionizing radiations and cosmic rays’ relentless aggression, as well as deadly micrometeoritic impacts. The literature related to lunar construction refers to several techniques [5], of which the two main ones implement chemical or thermal processes. The first involves mixing the regolith with a binder or polymer [6]. It requires little on-site energy, but large quantities of binder have to be brought from Earth as a heavy payload; moreover, the pressure and temperature conditions on the lunar surface render these outdoor fabrications and manipulations problematic [7]. The second one revolves around creating sintered or molten regolith as an alternative technical solution. The main advantage is that it only requires regolith and considerable energy, which could potentially be provided by capturing solar energy. The technology needed, such as 3D printing for example, is complex, very expensive, and not necessarily very fast. For example, the process could require up to five hours of work for the manufacturing of a single brick [8]. Roberts et al. [9] recently proposed an interesting composite they called “Starcrete” obtained by compacting regolith simulants under three tons of pressure with various additives, such as MgCl2, acetic acid, Na2CO3, and FeSO4, using various starch polymers as the binder. They assessed the effect of adding in situ produced human excretion, such as urea and saliva, to the material. This technique has the advantage of only using local resources and being less energy-intensive but still requires the use of a heavy press. Benefiting from a long experience in the field of starch composite materials [10,11], we investigated the possibility of creating starch-regolith aerogel composite bricks as a building material, using minimal equipment and process conditions. The choice of potato (Solanum tuberosum) starch (PS) was determined by several factors. It has already been shown that starch has excellent agglomerating properties in many composite materials [10] and can be used at low concentrations. It could either be shipped in payloads or produced in situ from scrubbing the habitat atmosphere’s CO2 in local greenhouses. Potatoes have been suggested as a crop for a regenerative life support system to be grown on regolith and/or base-produced biowastes [12,13]. Potatoes were one of the first vegetables grown in space! Seed potato production was first tested aboard the Columbia Space Shuttle Microgravity Lab during the Oct. 1995 STS-73 mission [14]. This fast-growing crop can capture carbon dioxide very efficiently from space habitat and transform it into useful organic matter such as starch polysaccharides in high yields, while regenerating precious oxygen, with very little solar energy and water input. Even if the presence of water on the Moon has been known for a long time [15], the discovery of very important quantities in the form of ice in permanently shadowed craters at the south poles and almost everywhere in the subsoil is more recent [16], the extraction of which is also well referenced [17]. The water could also simply come from recycling gray waters and residues from the life support systems on which potatoes could be grown in greenhouse reconstituted soil [18,19] lit by LEDs or optic fibers, conveyed sunlight. Therefore, in addition to providing alternative sustenance, the cultivation of potato plants would be an essential part of maintaining life in the habitat [20]. In previous studies, we have shown that (PS) is a very efficient binder for various aggregates to create valuable large cohesive porous aerogel materials in the shape of bricks or panels [20,21,22,23,24]. In the present study, OPRH2N’s Lunar Regolith Simulant (LRS) was used and agglomerated with PS polymer hydrogel to create an LRS-bonded aerogel, or what should be more accurately called a “vacuogel” composite when used in the atmosphere-depleted Moon environment. In the literature, numerous LRS have been tested to mimic lunar regolith for experimentation, mainly based on volcanic scoria [25,26] or powdered Archean Anorthosite. In the present work, LRS was agglomerated with PS polymer hydrogel at various concentrations and molded in brick-shaped molds. The resulting LRS-PS gel composites were dried by different methods (air, oven, or freeze-drying), providing composite aerogels with distinct densities, porosities, physicochemical, and engineering properties. The freeze-drying process was chosen, as it only requires very low temperature and pressure, conditions that are easily reproducible on the Moon’s surface at low energy cost, using particularly low payload equipment. Moreover, it allows complete recovery of the precious water used in the fabrication process in a purified form. The resulting LRS composite bricks were tested for their mechanical and thermal insulation performances to study their potential in lunar building applications. The behavior of the composite towards extreme temperature variations and beta-radiation was also investigated. The aim of this work was to add alternative solutions to building lunar structures using ISRU-available material and the minimum of shipped equipment. This work shows that, despite the extreme conditions prevailing on the Moon, the novel combination of lunar soil and a simple organic compound can withstand and help protect future inhabitants of lunar missions. To this end, the thermal properties and ability to withstand radiation and temperature variations on the mechanical strength of samples were tested.

2. Materials and Methods

2.1. Composition and Granulometry of LRS

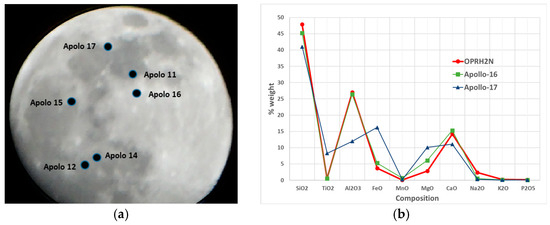

OPRH2N is the general simulant of lunar Highlands regolith produced by Off Planet Research (98201 Everett, Washington, DC, USA) by mixing the basaltic feedstock from Arizona and Archean Anorthosite from the Ontario Precambrian shield in Canada in a 7:3 ratio to simulate average composition and particle sizes of regolith collected during the Apollo 16 and 17 missions [27,28,29]. The composition of this simulant mimics that of the general nearside highlands, which is similar to that of the Apollo 16 mission, as shown in Figure 1 and Table 1.

Figure 1.

(a) Localization of Apollo’s mission (Photo credit F. Bogard 2025); (b) Comparison of LRS composition.

Table 1.

OPRH2N composition (Off Planet Research).

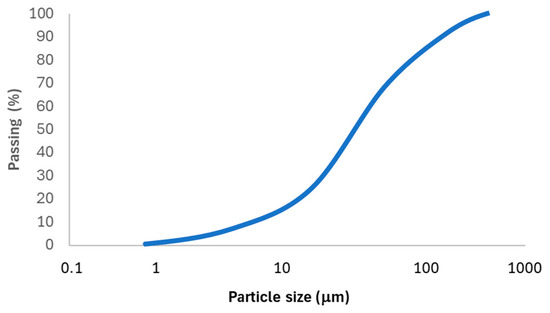

The LRS granulometry was measured by sifting through a series of 1 to 0.25 mm sieves, and the finest portion passing the 250 µm screen was analyzed by laser granulometry [30]. Figure 2 presents the associated cumulative curve.

Figure 2.

Cumulative particle size distribution of OPRH2N.

Particle size distribution plays a role in the fabrication process and the properties of the obtained composite. The finer the particles, the higher the cohesivity, notably due to the increased surface area of contact, which will have an impact on the preparation of the brick [31].

2.2. LRS Brick Preparation

The Potato Starch (PS) used in this study was provided by Tereos (Haussimont, France). Two compositions with varying starch content were tested, namely LRS-PS2 and LRS-PS4 for 2 and 4 wt% PS dry base, respectively.

The choice of these PS contents was dictated by technical processing constraints. It was observed that beyond 5 wt%, the viscosity of the LRS/gel mixture drastically increases, which degrades its workability. Similarly, below 1 wt% starch content, the composite was discarded prior to mechanical testing, in view of its brittle behavior.

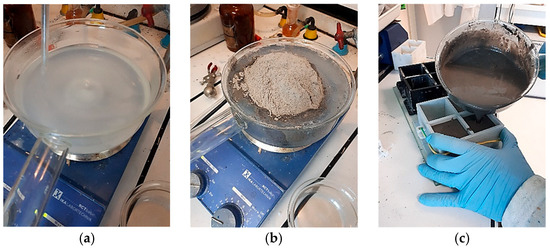

In typical LRS-PS sample preparation, a formulation was prepared by mixing 4 or 8 g of PS in 200 mL of water. The starch suspension was heated to boiling under vigorous mechanical stirring until the mixture turned into a clear viscous paste. The paste was cooled to 70–80 °C, then 200 g of LRS was added rapidly, and the mixture was stirred to a homogeneous paste as shown in Figure 3. The gel was obtained by boiling a starch suspension in water with constant and vigorous mechanical stirring until the mixture turned into a viscous paste. The hot LRS/PS gel mix was poured into specific molds to create 50 × 50 × 50 mm3 samples. The prepared samples were cooled to 50 °C before being frozen to −30 °C. The frozen samples were pulled out of the molds and freeze-dried at 0.6 mbar in a Heto Power Dry LL3000 freeze dryer vacuum chamber. No shrinkage phenomenon was observed in the obtained freeze-dried LRS-PS samples.

Figure 3.

Sample preparation: (a) starch gel mixture; (b) addition of regolith; (c) molding.

2.3. Density and Porosity of LRS and LRS-PS2/4

The bulk density of the composite material is the ratio of the sample mass to the bulk volume, which includes the volume of the solids and voids, calculated as:

where m (kg) is the mass of the aggregates and V (m3) is the volume taken up by the aggregates. The different bulk densities measured on the final samples are presented in Table 2. The skeletal density of the composite material represents the density of the solids without the voids; it was determined for LRS and LRS-PS2/4 samples using the cyclohexane/pycnometer method described by Bourdot et al. [32]. In short, a given mass of dried sample was placed in a pycnometer filled with cyclohexane to 2/3 of the total volume in such a manner that the entire sample was entirely covered with cyclohexane. The system was placed under reflux for six cycles of 30 min of boiling and cooling (10 min); during these cycles, air escaped from the sample cavities, leaving the pores, and was gradually replaced by cyclohexane. After cooling at room temperature, the pycnometer is filled and plugged with the stopper, ensuring no bubbles are trapped. The system was then weighed with an accuracy of 1 × 10−4 g. The skeletal density is calculated as follows:

where is the skeletal density, is the density of the cyclohexane, Ms is the mass of the sample, M1 is the mass of the pycnometer filled with cyclohexane alone, and M2 is the mass of the pycnometer with cyclohexane and the sample.

Table 2.

Physical properties of LRS and LRS-PS composites.

The porosity was calculated as:

In the experiments, the porosity of the composite samples was found to be close to 50%.

2.4. Thermal Tests

To evaluate the thermal resistance of the starch binder, an attempt was made to simulate the thermal conditions prevailing on the Moon. To this end, three different sets of tests were carried out on separate samples. A first set of samples was subjected to thermal fatigue in the form of 10 temperature rises and falls (between −40 and +170 °C), noted as LRS-PS2c and LRS-PS4c. A second set was subjected to a +150 °C plateau for 15 days (corresponding to half a lunar day). A third set of samples was exposed to a brutal cooling to the core (visual control) in liquid nitrogen at −196 °C, followed immediately by a 30-min stay at 150 °C in a muffle furnace. The aim was not only to demonstrate the resistance of the LRS-PS composite against thermally induced stresses at the Moon’s surface but also to show that our unique combination (LRS-PS) exhibits satisfactory thermal insulation properties, resulting in energy savings at the habitat scale [33].

2.4.1. Thermal Properties

For insulation materials, thermal conductivity (λ), diffusivity a, and specific heat capacity Cp are the most important parameters. In the context of thermal insulation, the thermal conductivity λ of a material is defined as its ability to conduct heat. For a homogeneous material, the higher the thermal conductivity, the more heat the material allows for pass through; conversely, the lower the conductivity, the more insulating the material. The thermal diffusivity “a” is the capacity of a material to transmit heat inside through itself, more or less rapidly. The lower the thermal diffusivity inside a material, the longer the heat transfer will be and the better the thermal inertia. The specific heat capacity Cp [J/(kg·K)] delineates the amount of energy needed to raise the temperature of 1 kg of material by 1 K (=1 °C). Thermal properties were assessed using a thermal characteristic analyzer (ISOMET 2114 (Applied Precision s.r.o., Bratislava, Slovakia)) based on heat flux pulses applied to the material surface. These three thermal parameters were measured for three cubic samples (100 × 100 × 100 mm) of each composite formulation, namely, LRS-PS2, LRS-PS4, LRS (OPRH2N), and PS aerogel.

2.4.2. Thermal Fatigue (Cycling)

Given the extremely high vacuum (about 10−12 Pa) surrounding the lunar surface, the amplitude of temperature variations is very high; during the cycle of a lunar day (27 Earth days, 7 h, 43 min, and 12 s), the temperature variation ranges from −180 to 130 °C [25]. This significant temperature variation, which can be rapid during the day/night transition, is approached experimentally by subjecting specimens to thermal cycles (temperature rise and fall at the maximum capacity of the enclosure used, cycle repeated 10 times).

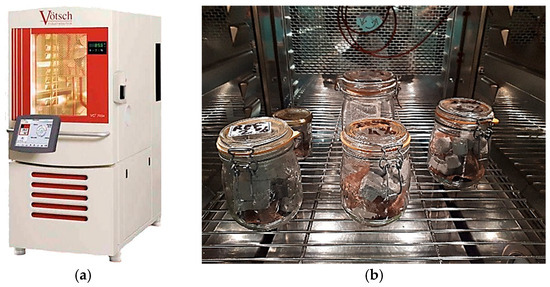

The climatic chamber used, Figure 4, was a Vötsch VC4 with a large temperature range of −42 °C to +180 °C, with a rate of variation of 3.2 K/min for heating and 4 K/min for cooling. Humidity was set to zero, and to ensure no condensation during cycling, samples were placed in sealed glass jars containing activated silica gel to ensure drying conditions.

Figure 4.

Climatic chamber (a); samples in glass jars (b).

2.4.3. Prolonged Thermal Exposure

To simulate the prolonged thermal exposure associated with the lunar day, LRS-PS2 and LRS-PS4 samples were subjected to a constant temperature of 150 °C for a duration of 15 days. This exposure corresponds to half a lunar cycle, specifically the lunar daytime phase. Following the completion of the fabrication process, the specimens were placed in a temperature-controlled furnace maintained at 150 °C for the specified period. Subsequent mechanical testing was performed after the samples were allowed to return to ambient temperature under dry atmospheric conditions.

2.4.4. Thermal Shock to Extreme Temperatures

Since temperature variations can be extreme on the Moon’s surface, a series of thermal shocks was tested by placing the LRS-PS2 and LRS-PS4 samples at 150 °C in a conventional muffle furnace and then sharply cooling them to −196 °C by immersion in liquid nitrogen (Figure 5). The specimens were kept until N2 boiling stopped to ensure core cooling and then placed straight back in the muffle furnace preheated at 150 °C for 30 min. The resulting samples showing no apparent damage were further tested for a mechanical compression test.

Figure 5.

Visualization of the sample cooling process.

2.5. Radiation Exposure

Without a magnetosphere and atmosphere, the lunar surface is subjected to a wide range of radiation types [34]. To investigate the consequences of the composites’ exposure to radiation, prismatic 50 × 50 × 30 mm LRS-PS2 and LRS-PS4 specimens were subjected to intense beta radiation. The beta radiation was chosen because of its penetrating properties in dense material.

The experiment was conducted on a 10 MeV 20 KW electron accelerator on the ION-ISOS facility (Chaumesnil, France, https://www.ionisos.com accessed on 2 March 2025). As soon as they were manufactured, the specimens were sealed in a plastic bag and stored in a controlled atmosphere. They underwent irradiation in these vacuum bags, taped to a tray. An automatic conveyor system fed the specimens into the irradiation chamber, where they passed under the electron beam at an appropriate speed (depending on the selected dose). The samples were subjected to a consecutive series of 8 × 25 KGy irradiations. The dosimeters placed in front and back of the samples indicated a level of dose of 210 ± 3 kGy (2.1 × 105 Sv). The electrons emitted had a single energy level of 9.8 ± 0.2 MeV. No apparent degradation was noticed after the treatment, only a typical slight increase in the temperature of the specimens, observed immediately after the irradiation. The samples were then tested for mechanical resistance.

2.6. Mechanical Testing (Compression Test)

An Instron 34TR50 testing machine, equipped with a 50 kN load cell, was used for compression tests. The tests were performed in the same direction as the specimen compaction, according to the ASTM C109 standard used to determine the compressive properties of hydraulic cement mortars [35] with a rate of 1 mm/min, Figure 6. As soon as they had been manufactured, the samples were stored in a dry place. The prepared dry samples kept in sealed bags were opened just before the start of the compression test. The indoor conditions were 23 °C room temperature and less than 50% relative humidity. Starch aerogels and LRS-PS2 and LRS-PS4 specimens with dimensions 50 × 50 × 50 mm were tested.

Figure 6.

Experimental set-up used for the compressive test on an LRS-PB composite sample.

The apparent tangent Young modulus was determined by using Hooke’s law:

where σ denotes the engineering stress (MPa), E stands for the Young’s modulus, and ε is the engineering strain (mm/mm).

σ = E.ε

These compression tests were carried out on:

- untreated reference specimens LRS-PS2 and LRS-PS4

- thermally cycled specimens (named LRS-PS2c and LRS-PS4c)

- prolonged thermal exposure specimens (named LRS-PS2p and LRS-PS4p)

- thermal shock specimens (named LRS-PS2ts and LRS-PS4ts)

- irradiated specimens (named LRS-PS2r and LRS-PS4r)

Each type of treatment was applied independently. However, on the Moon, stresses such as irradiation, thermal cycling, and day–night transitions occur simultaneously. In an attempt to study the synergy between heat and radiation stress, some specimens were subjected to the combined effect of irradiation and thermal cycling (named LRS-PS2rc and LRS-PS4rc, respectively).

The Young’s modulus was calculated for the six samples and averaged. It was determined from the linear portion of the stress-strain curve, based on the steepest linear section between 25% and 75% of the maximum applied load (within the limit of 10% strain), following ISO844:2021 [36]. The ductility index i′ is an analysis tool used to compare the different formulations and assess the material’s ability to withstand plastic deformation [37]. It is defined as the ratio ε85%/εu, where ε85% is the strain corresponding to 85% of σmax for each test. The table presents the average value obtained from the tested samples.

3. Results and Discussion

3.1. Thermal Properties of Reference Samples (LRS-PS2 and LRS-PS4)

Table 3 sums up the physical properties of LRS and LRS-PS composites.

Table 3.

Mean thermal characteristics of LRS and PS.

Thermal conductivity, diffusivity, and specific heat capacity were measured to ensure reproducibility (mean of 15 measurements), Table 3. Corresponding thermal average values are given in Table 3. It is noticeable that PS aerogel alone has a low thermal conductivity value of 0.066 W/(m·K).

Overall, the heat treatments undergone by samples LRS-PS2 and LRS-PS4 did not affect their structural integrity. The samples did not crack, break, or deform significantly after thermal cycling or thermal shock.

The measured thermal conductivities were 0.159 W/(m·K) for LRS-PS2 and 0.145 W/(m·K) for LRS-PS4. This 8.8% reduction for LRS-PS4 is explained by the fact that there is slightly more porosity in LRS-PS2 (45.5% and 44% for LRS-PS4). Both LRS composites can be considered as good thermal insulators, knowing that greater thickness would further improve thermal resistance and consequently insulation. Compared to previously studied raw earth as a building material, these values are slightly lower than those typically reported (0.5–1.2 W/(m·K)) [37]. Moreover, the conductivity would be even lower in the vacuum moon environment. Thermal conductivity measurements performed on native OPRH2N LRS dropped from 0.246 W/(m·K) to 0.07 W/(m·K) when measured at a pressure of 20 Pa. Thermal diffusivity “a” reflects a material’s ability to store thermal energy and is a key indicator of thermal inertia. Thermal diffusivity is directly related to the phase shift phenomenon across a wall during transient conditions. This phase shift is inversely proportional to thermal diffusivity. Lower thermal diffusivity implies a longer time for the heat front to penetrate the material’s thickness. The values obtained are 0.273 × 10−6 m2/s for LRS-PS2 and 0.212 × 10−6 m2/s for LRS-PS4, translating to a 22.3% decrease. This means that during a lunar sunrise or sunset, the material will attenuate abrupt thermal changes, reducing internal stresses and increasing the durability of the structure in question. This behavior is crucial on the Moon, where there is no atmosphere to moderate transitions. For example, these values indicate a much lower thermal diffusivity than concrete (0.83 × 10−6 m2/s) or Earthen material (0.414 × 10−6 m2/s), making these composites promising for thermal protection. The obtained values of specific heat capacity Cp (J/(kg·K)) are 0.443 kJ/(kg·K) for LRS-PS2 and 0.504 kJ/(kg·K) for LRS-PS4, corresponding to an increase of 12.6%. The starch-enriched composite therefore stores more thermal energy without rapidly rising in temperature, acting as a thermal buffer, able to retain heat during the day and release it slowly at night. This can help stabilize the interior temperature of lunar habitats, reducing the load on thermal regulation systems.

The 4 wt% starch formulation (LRS-PS4) thus combines low conductivity, high thermal capacity, and good inertia–qualities perfectly suited to protecting lunar structures against extreme thermal conditions.

The thermal properties of starch aerogel alone were investigated in a previous study. Thermal conductivity of starch aerogel alone obtained from the dry freezing of 1 dm3 was measured to be 0.065 +/− 0.003. The glass transition temperature of dry starch is known to be around 227 °C [38], whereas for 13% commonly hydrated starch in a 40–75% relative humidity (RH) atmosphere, Tg decreases to 56 °C. In the moon environment, RH is null such that the expected Tg of the starch binder should be about 230 °C, close to its decomposition temperature.

3.2. Aspect of Irradiation and Double Stress (Thermal and Radiation)

Miller et al. [39] have shown that regolith alone is a good substitute for aluminum or carbon for radiation protection. Moreover, Miller et al. [40] indicate that a thin layer of compacted regolith is sufficient to protect against most radiation. The density of the regolith used is important, but at 5 cm thickness and above, 100 MeV radiation can be stopped. As for the starch binder, Sunder et al. [41] have shown that a high dose of gamma radiation up to 200 kGy can create radicals. This can lead to amylopectin hydrolysis, producing shorter dextrins and sugars in the presence of water. In the absence of water, no hydrolysis can happen, even in the presence of radicals. On the other hand, Delville et al. [42] have shown that radicals created on dry starch molecules by UV radiation can lead to crosslinking of the starch polymeric chains.

To analyze the influence of irradiation alone, thermal cycling, thermal shock, prolonged thermal exposure, as well as the combination of irradiation and thermal cycling, mechanical tests have been carried out and presented further in the following section.

3.3. Mechanical Properties, Compression Tests

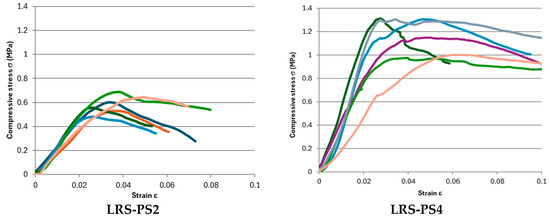

3.3.1. Compression Test on Reference LRS-PS2 and LRS-PS4 Composite

Table 4 presents the mechanical properties of the two reference composites containing 2 wt% and 4 wt% starch. The values of σmax (the maximum stress applied during testing) and εu (the strain corresponding to σmax) are average values calculated from six compression tests; the standard deviation is shown in parentheses.

Table 4.

Mechanical properties of untreated reference specimens.

Table 4 shows the results of compression tests carried out on the 2 wt% and 4 wt% compositions that had not undergone any particular treatment for six specimens. The results show that increasing the starch content improves the strength of the composite, as indicated by the rise in the ductility index i′ from 1.65 for LRS-PS2 to 1.93 for LRS-PS4. An index of 1 typically characterizes brittle behavior, where the material stiffens progressively and then breaks suddenly at its strength limit. The values indicate a shift away from brittle failure, suggesting a plastic behavior that could be beneficial for structural applications. This is likely due to the high porosity (around 50%) of the starch aerogel in both the 2 wt% and 4 wt% formulations. The difference in elasticity is reflected in the slope of the stress–strain curves in Figure 7, where the LRS-PS2 sample exhibits a more abrupt failure than LRS-PS4.

Figure 7.

Compression curves for LRS-PS2 and LRS-PS4.

Additionally, the maximum compressive strength nearly doubles between LRS-PS2 and LRS-PS4 (increasing from 0.58 MPa to 1.18 MPa), consistent with the observed increase in Young’s modulus (23.5 MPa for LRS-PS2 to 43.33 MPa for LRS-PS4, respectively). For both compositions, the peak stress is reached at nearly the same strain εu. The addition of 4 wt% starch provides enhanced plasticity to the regolith while also increasing σmax, an advantageous combination in shaping bricks for construction purposes.

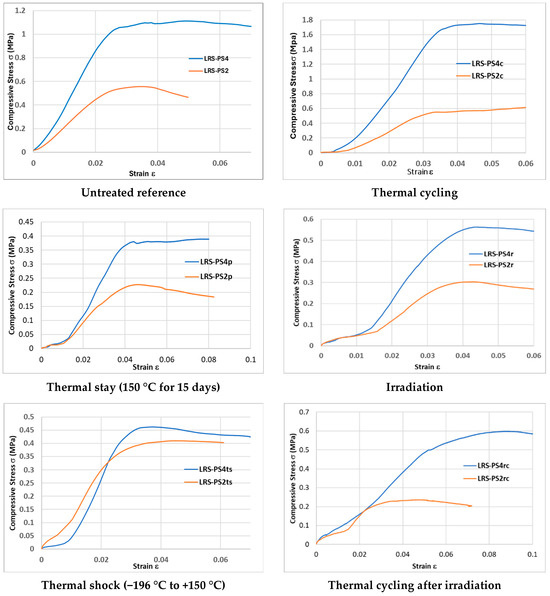

Compression tests performed on the treated composites are presented in Figure 8 for direct comparison with the reference averaged curves (LRS-PS2 and LRS-PS4). Overall, except for the cycling thermal treatment, a decrease in σmax is observed across all treated samples, highlighting the impact of thermal treatment on the starch matrix composites. The ultimate strain εu, corresponding to the strain at maximum stress σmax, falls within the range of 4.0–4.6% for LRS-PS2% and 3.6–9.0% for LRS-PS4%, showing more cohesive and dispersive behavior, respectively. The general decrease in Young’s modulus after treatment suggests structural damage within the material and the onset of relative ductility. The addition of starch to the regolith transforms a loose granular assembly into a cohesive solid, which consequently behaves more like a homogeneous material. Table 5 summarizes the main mechanical characteristics derived from the results in Figure 8.

Figure 8.

Mean compression curves for each treatment undergone by the composites studied.

Table 5.

Mechanical characteristics of 2wt% and 4wt% starch in composites.

3.3.2. Thermal Cycling Tests

It is worth noting that the σmax and E values obtained after thermal cycling are close to the LRS-PS2 ones (only 3% difference). However, a difference for σmax and E can also be noticed between LRS-PS4 and LRS-PS4c (+33%). This can be explained by the specific setup of the thermal cycling test. In this test, specimens were sealed in jars containing drying silica gel as a humidity trap used to prevent condensation during the hot–cold transition. This reduced the specimens’ exposure to ambient humidity, resulting in drier and thus mechanically stronger samples. On the Moon, where vacuum and the absence of moisture prevail, samples would inherently be even drier than in the used lab conditions, suggesting that mechanical properties in situ could exceed those measured in this study.

3.3.3. Prolonged Thermal Exposure Tests

Upon exposure to a prolonged thermal treatment at 150 °C for 15 days, both composites exhibited a marked degradation in their mechanical performance. The maximum stress decreased to 0.39 MPa for LRS-PS4 (−67%) and to 0.23 MPa for LRS-PS2 (−60%), with Young’s modulus showing a similar downward trend. Despite this decline, LRS-PS4 consistently outperforms LRS-PS2. This superior performance is likely attributable to the enhanced thermal stability of the matrix reinforced with 4% starch, which better preserves its mechanical integrity under elevated temperature conditions.

3.3.4. Thermal Shock Tests

The thermal shock, involving a rapid temperature transition from −196 °C to +150 °C, induces a notable degradation of the mechanical properties of the material. The maximum stress decreases to 0.46 MPa for the LRS-PS4 (−61%) formulation and to 0.38 MPa for LRS-PS2 (−60%). Nevertheless, LRS-PS4 maintains a clear mechanical advantage, exhibiting a higher Young’s modulus (24.3 MPa versus 20.5 MPa). This observation indicates that the 4% starch-based composite demonstrates superior resilience under extreme thermal transitions, likely attributable to a more homogeneous distribution of internal stresses within the matrix. However, during these thermal shock tests, it was extremely difficult to keep the specimens protected from ambient humidity and moisture condensation, which might explain some of the observed property loss.

3.3.5. Irradiation Tests

Irradiation of the samples also resulted in a detrimental impact on mechanical performance, although to a lesser extent than the prolonged thermal exposure at 150 °C. LRS-PS4 retained a maximum stress of 0.56 MPa (−53%), whereas LRS-PS2 decreased to 0.30 MPa (−34%). A similar trend was observed for Young’s modulus, with values of 21.4 MPa for LRS-PS4 and 12.9 MPa for LRS-PS2. These findings suggest that the 4% starch formulation exhibits greater resistance to irradiation-induced degradation, likely due to a denser and more cohesive internal structure that offers improved resilience against ionizing damage.

3.3.6. Irradiation and Thermal Cycling Tests

Finally, the most severe treatment, combining irradiation and thermal cycling, highlights the ultimate strength capacity of the materials. LRS-PS4 maintains a maximum stress of 0.67 MPa (−43%), while LRS-PS2 collapses to 0.23 MPa (−60%). The Young’s modulus here is surprisingly higher for LRS-PS2 (18 MPa) than LRS-PS4 (14 MPa), but this can be attributed to increased residual stiffness due to embrittlement, which does not necessarily reflect improved strength. LRS-PS4 retains a better ability to withstand combined space environments, while LRS-PS2 shows critical vulnerability.

To sum up, LRS-PS4% features significantly higher initial mechanical strength and better response to irradiation alone but is more sensitive to rapid thermal cycling. LRS-PS2%, although more modest in terms of strength, exhibits a more homogeneous response and favorable plasticity under thermal stress conditions, which could be relevant for certain non-structural applications where mechanical damping, dimensional stability, and deformation tolerance are priorities. In lunar conditions, the closest test to real-life conditions would be the combination of radiation and day/night thermal cycle. As a result, LRS-PS4 would appear to be the most suitable construction material. These observations suggest that the optimal choice between these two formulations will depend on the type of lunar environment targeted and the intended constructive function of the material. A combined or hybrid approach, adapting the binder ratio to local limitations, could be a relevant avenue for future applications.

3.4. Recycling Properties

The recyclability of the composite was investigated by reconditioning the material after mechanical testing. The crushed untreated specimens were collected, an equivalent amount of initially used water was added, and the mix was heated to 100 °C. The obtained paste was remolded, frozen, and freeze-dried. The obtained samples were tested for mechanical resistance, showing almost identical mechanical properties.

3.5. Limitations

This study aimed to highlight the potential of a novel starch/lunar regolith composite as an alternative or complementary solution for constructing lunar habitats. While the presented results are promising, several limitations must be acknowledged to contextualize the findings and guide future research.

Although individual environmental factors—such as radiation, thermal cycles, or mechanical stresses—were tested independently, real lunar conditions involve their simultaneous and potentially synergistic effects. Reduced gravity, vacuum, ionizing radiation (alpha, beta, gamma, X-ray, solar, and cosmic), and extreme thermal cycling occur together and may interact in nonlinear ways. To achieve realistic performance assessments, future experiments should aim to reproduce these combined conditions as closely as possible.

Another key limitation concerns the fabrication of bricks under lunar conditions. The reduced gravity may significantly affect the agglomeration, setting, and drying processes of starch-based composites. These parameters remain untested and require dedicated investigations in simulated or extrapolated lunar environments.

The long-term behavior of the composite under lunar stressors is still unknown. Accelerated aging protocols that realistically mimic lunar surface exposure over time will be necessary to validate their durability and mechanical integrity. To significantly reduce radiation, thermal aggression, and the problems caused by micrometeorites on our composite materials, one technical solution would be to use a thick layer of ordinary regolith on a brick structure protecting an inflatable habitat, for example.

4. Conclusions

Space exploration and the perspective of the development of permanent lunar settlements in the near future will require the need for locally produced construction materials. In this study, a Lunar Regolith Simulant (LRS) was used as a model material to mimic the chemical, mechanical, particle size distributions, and engineering properties of lunar regolith. This LRS was agglomerated with Potato (Solanum tuberosum) Starch (PS) polymer gel to create a cohesive LRS-PS composite that can be used to create bricks with 2 wt% and 4 wt%. These bricks were tested in an extremely low RH environment for their mechanical and thermal insulation performances and beta-radiation resistance to study their potential application in lunar building applications. The 4 wt% composite presents very interesting compressive mechanical behavior, is resistant enough to be used in a harsh lunar surface environment, and has properties conducive to building large structures, especially in low gravity. These original results suggest that starch, a simple organic binder, can play a key role in the development of efficient lunar bricks, provided its mechanical properties are also sufficient. Further work will enable us to consolidate these results by further improving experimental conditions, for example, by testing resistance to micro-impacts and developing a numerical model to extrapolate the properties of the regolith/starch brick to larger surfaces and thicknesses.

Author Contributions

Conceptualization, C.B. and F.B. (Fabien Beaumont); methodology, F.B. (Fabien Beaumont); validation, G.P., S.M. and F.B. (Fabien Beaumont); investigation, M.L., S.M. and C.B.; resources, M.L. and C.M.; data curation, V.B.; writing—original draft preparation, C.B.; writing—review and editing, F.B. (Fabien Bogard) and C.M.; supervision, F.B. (Fabien Beaumont); project administration, G.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The study did not report any data.

Acknowledgments

The authors wish to thank G. Stockton for proofreading this manuscript and acknowledge the use of ChatGPT 4.0 for language improvement purposes only. The prompt used was “Rephrase to scientific English”.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- NASA Website. Available online: https://www.nasa.gov/commercial-lunar-payload-services/ (accessed on 16 March 2025).

- Sacksteder, K.R.; Sanders, G.B. In-Situ Resource Utilization for Lunar and Mars Exploration (ISRU). In Proceedings of the 14th AIAA Aerospace Science Meeting & Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar] [CrossRef]

- Heiken, G.H.; Vaniman, D.T.; French, B.M. Lunar Sourcebook; Cambridge University Press: Cambridge, UK, 1991. [Google Scholar]

- Beyer, L.A. Lunarcrete—A Novel Approach to Extraterrestrial Construction. In Space Manufacturing 5: Engineering with Lunar and Asterodial Materials, Proceedings of the Seventh Princeton/AIAA/SSI Conference 8–11 May 1985; Faughnan, B., Maryniak, G., Eds.; American Institute of Aeronautics and Astronautics: New York, NY, USA, 1985; p. 172. ISBN 978-0-930403-07-2. [Google Scholar]

- Farries, K.W.; Visintin, P.; Smith, S.T.; van Eyk, P. Sintered or melted regolith for lunar construction: State-of-the-art review and future research directions. Constr. Build. Mater. 2021, 296, 123627. [Google Scholar] [CrossRef]

- Hintze, P.; Curran, J.; Back, T. Lunar surface stabilization via sintering or the use of heat cured polymers. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009. [Google Scholar] [CrossRef]

- Spedding, C.P.; Nuttall, W.J.; Lim, S. Energy requirements of a thermally processed ISRU radiation shield for a lunar habitat. Adv. Space Res. 2020, 65, 2467–2474. [Google Scholar] [CrossRef]

- Fateri, M.; Kaouk, A.; Cowley, A.; Siarov, S.; Palou, M.V.; Gobartt González, F.; Marchant, R.; Cristoforetti, S.; Sperl, M. Feasibility study on additive manufacturing of recyclable objects for space applications. Addit. Manuf. 2018, 24, 400–404. [Google Scholar] [CrossRef]

- Roberts, A.D.; Scrutton, N. Starcrete: A starch-based biocomposite for off-world construction. Open Eng. 2023, 13, 20220390. [Google Scholar] [CrossRef]

- Follain, N.; Joly, C.; Dole, P.; Bliard, C. Mechanical properties of starch-based materials. I. Short review and complementary experimental analysis. J. Appl. Polym. Sci. 2005, 97, 1783–1794. [Google Scholar] [CrossRef]

- Karaky, H.; Maalouf, C.; Bliard, C.; Moussa, T.; El Wakil, N.; Lachi, M.; Polidori, G. Hygrothermal and Acoustical Performance of Starch-Beet Pulp Composites for Building Thermal Insulation. Materials 2018, 11, 1622. [Google Scholar] [CrossRef] [PubMed]

- Ming, D.W.; Henninger, D.L. Use of lunar regolith as a substrate for plant growth. Adv. Space Res. 1994, 14, 435–443. [Google Scholar] [CrossRef]

- Wheeler, R.M.; Tibbitts, T.W. Utilization of potatoes for life support systems in space. IV. Effect of CO2 enrichment. Am. Potato J. 1989, 66, 25–34. [Google Scholar] [CrossRef]

- Brown, C.S.; Tibbitts, T.W.; Croxdale, J.G.; Wheeler, R.M. Potato tuber formation in the spaceflight environment. Life Support Biosph. Sci. 1997, 4, 71–76. [Google Scholar]

- Feldman, W.C.; Maurice, S.; Lawrence, D.J.; Little, R.C.; Lawson, S.L.; Gasnault, O.; Wiens, R.C.; Barraclugh, B.L.; Elphic, R.C.; Pretty-Man, T.H.; et al. Evidence for Water Ice Near the Lunar Poles. J. Geophys. Res. 2001, 106, 23232–23252. [Google Scholar] [CrossRef]

- Deutsch, A.N.; Head, J.W., III; Neumann, G.A. Analyzing the ages of south polar craters on the Moon: Implications for the sources and evolution of surface water ice. Icarus 2020, 336, 113455. [Google Scholar] [CrossRef]

- Sargeant, H.M.; Barber, S.J.; Anand, M.; Abernethy, F.A.J.; Sheridan, S.; Wright, I.P.; Morse, A.D. Hydrogen reduction of lunar samples in a static system for a water production demonstration on the Moon. Planet. Space Sci. 2021, 205, 10528. [Google Scholar] [CrossRef]

- NASA Growing, Plants in Space. 2021. Available online: https://www.nasa.gov/content/growing-plants-in-space (accessed on 16 March 2025).

- Setiawan, G.D.; Treesubsuntorn, C.; Krobthong, S.; Yingchutrakul, Y.; Thiravetyan, P. Using multi-omics approach to investigate the effect of a Moon soil simulant on Vigna radiata seedling root and shoot growth, stress responses, and photosynthesis. Acta Astronaut. 2023, 202, 550–563. [Google Scholar] [CrossRef]

- Wang, S.; Zhan, P.; Li, Y.; Li, J.; Li, X.; Yang, J.; Ji, M.; Li, F.; Zhang, C. Recent advances and future challenges of the starch-based bio-composites for engineering applications. Carbohydr. Polym. 2023, 307, 120627. [Google Scholar] [CrossRef] [PubMed]

- Gibney, E. How to build a Moon base. Nature 2018, 562, 474. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- Harb, E.; Maalouf, C.; Bliard, C.; Tenpierik, M.; Lachi, M.; Bogard, F.; Polidori, G. Thermal performance of starch/beet-pulp composite bricks for building insulation at a wall scale. Case Stud. Constr. Mater. 2023, 18, e01851. [Google Scholar] [CrossRef]

- Badouard, C.; Maalouf, C.; Bliard, C.; Polidori, G.; Bogard, F. Hygric Behavior of Viticulture By-Product Composites for Building Insulation. Material 2022, 15, 815. [Google Scholar] [CrossRef]

- Williams, J.-P.; Paige, D.A.; Greenhagen, B.T.; Sefton-Nash, E. The global surface temperatures of the Moon as measured by the Diviner Lunar Radiometer Experiment. Icarus 2017, 283, 300–325. [Google Scholar] [CrossRef]

- Zhang, T.; C Chao, Z.; Yao, K.; Xu, W.; Zhang, X.; Ding, S.; Liu, Z.; Zhao, Y.; Wang An, B.; Yu, S.; et al. The technology of lunar regolith environment construction on Earth. Acta Astronaut. 2021, 178, 216–232. [Google Scholar] [CrossRef]

- Zhang, X.; Osinski1, G.R.; Newson, T.; Ahmed, A.; Touqan, M.; Joshi, D.; Hill, H. A comparative study of lunar regolith simulants in relation to terrestrial test of lunar exploration missions. In Proceedings of the 50th Lunar and Planetary Science Conference, Woodlands, TX, USA, 18–22 March 2019. LPI Contrib. No. 2132. [Google Scholar]

- Wang, J.; Huntsinger, W.; Lapeyre, J.; Schofield, P.; Agbeworvi, G.; Banerjee, S.; Bullard, J.W. Sintering kinetics and microstructure development of synthetic lunar highlands and mare regolith. Appl. Mater. Today 2024, 37, 102145. [Google Scholar] [CrossRef]

- Morris, R.V. Ferromagnetic resonance and magnetic properties of ALHAS 1005. Geophys. Res. Lett. 1983, 10, 807–808. [Google Scholar] [CrossRef]

- Carrier, D. Lunar soil grain size distribution. In The Moon; 1973; Volume 6, pp. 250–263. [Google Scholar] [CrossRef]

- Collins, P.J.; Edmunson, J.; Fiske, M.; Radlin, A. Materials characterization of various lunar regolith simulants for use in geopolymer lunar concrete. Adv. Space Res. 2022, 69, 3941–3951. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vázquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of a hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Akisheva, Y.; Gourinat, Y. Utilisation of Moon Regolith for Radiation Protection and Thermal Insulation in Permanent Lunar Habitats. Appl. Sci. 2021, 11, 3583. [Google Scholar] [CrossRef]

- Reitz, G.; Berger, T.; Matthiae, D. Radiation exposure in the moon environment. Planet. Space Sci. 2012, 74, 78–83. [Google Scholar] [CrossRef]

- XP P13-901:2022; Blocs de Terre Comprimée Pour Murs et Cloisons: Définitions-Spécifications-Méthodes d’Essais-Conditions de Réception. AFNOR: La Plaine Saint-Denis, France, 2022.

- ISO 844:2021; Rigid Cellular Plastics—Determination of Compression Properties. AFNOR: Saint-Denis, France, 2021.

- Imanzadeh, S.; Jarno, A.; Hibouche, A.; Bouarar, A.; Taibi, S. Ductility analysis of vegetal-fiber reinforced raw earth concrete by mixture design. Constr. Build. Mater. 2020, 239, 117829. [Google Scholar] [CrossRef]

- Mitrus, M. Glass transition temperature of thermoplastic starches. Int. Agrophys. 2005, 19, 237–241. [Google Scholar]

- Miller, J.; Taylor, L.A.; DiGiuseppe, M.; Heilbronn, L.H.; Sanders, G.; Zeitlin, C.J. Radiation shielding properties of lunar regolith and regolith simulant. In Proceedings of the NLSI Lunar Science Conference 2008, Moffett Field, CA, USA, 20–23 July 2008. [Google Scholar]

- Miller, J.; Taylor, L.; Zeitlin, C.; Heilbronn, L.; Guetersloh, S.; DiGiuseppe, M.; Iwata, Y.; Murakami, T. Lunar soil as shielding against space radiation. Radiat. Meas. 2009, 44, 163–167. [Google Scholar] [CrossRef]

- Sunder, M.; Mumbrekar, K.D.; Mazumder, N. Gamma radiation as a modifier of starch—Physicochemical perspective. Curr. Res. Food Sci. 2022, 5, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Delville, J.; Joly, C.; Dole, P.; Bliard, C. Solid state photocrosslinked starch based films: A new family of homogeneous modified starches. Carbohydr. Polym. 2001, 49, 71–81. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).