Red Clay as a Raw Material for Sustainable Masonry Composite Ceramic Blocks

Abstract

1. Introduction

2. Materials and Methods

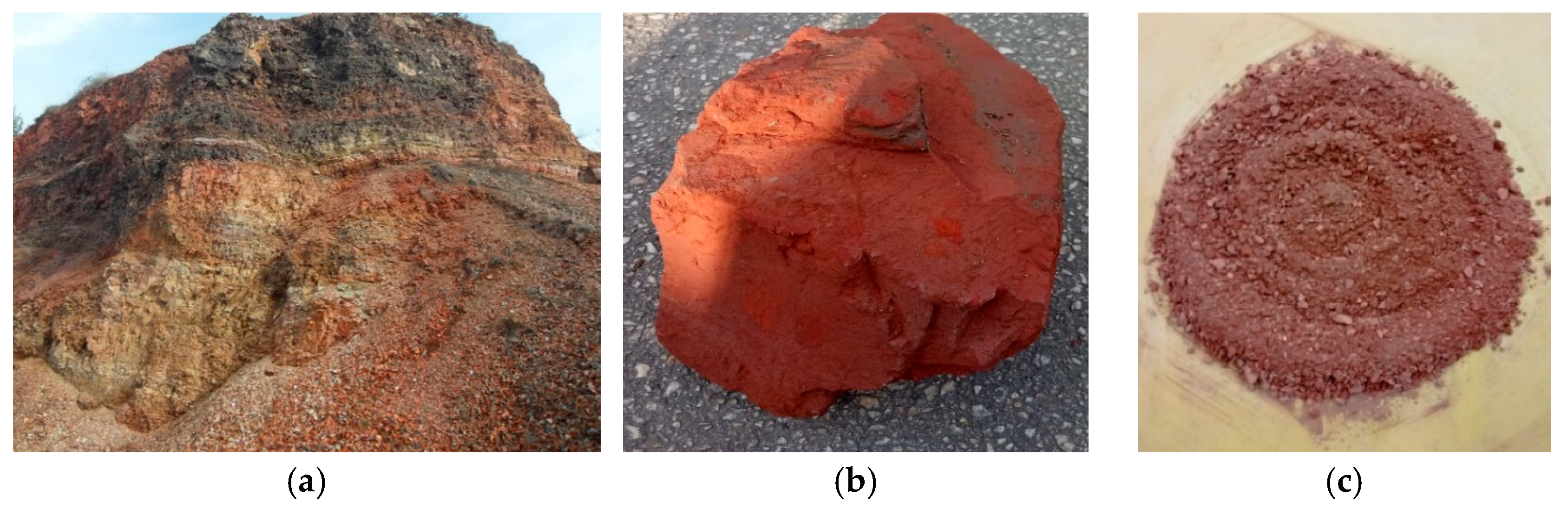

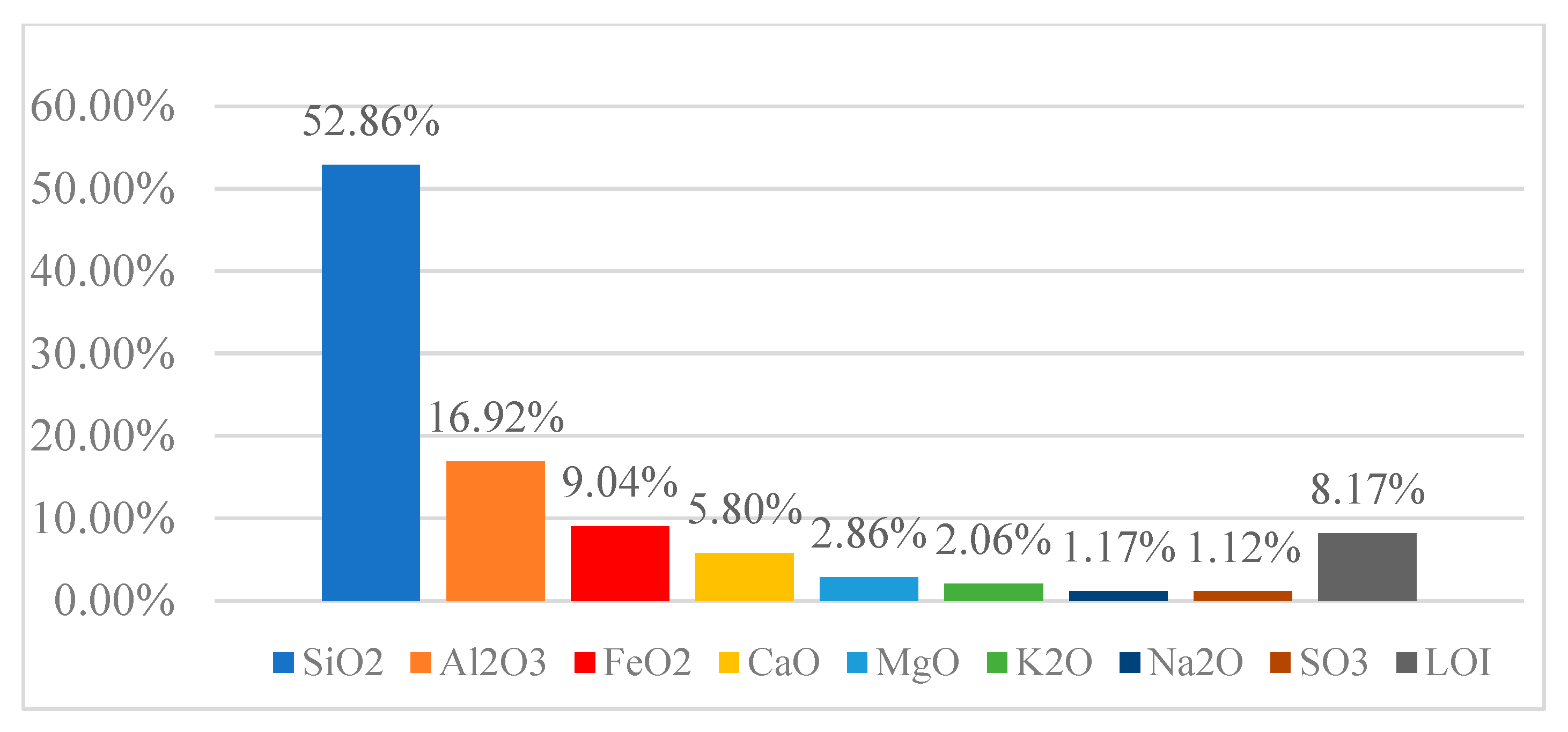

2.1. Mineralogical–Petrographic and Chemical Composition of the Raw Material

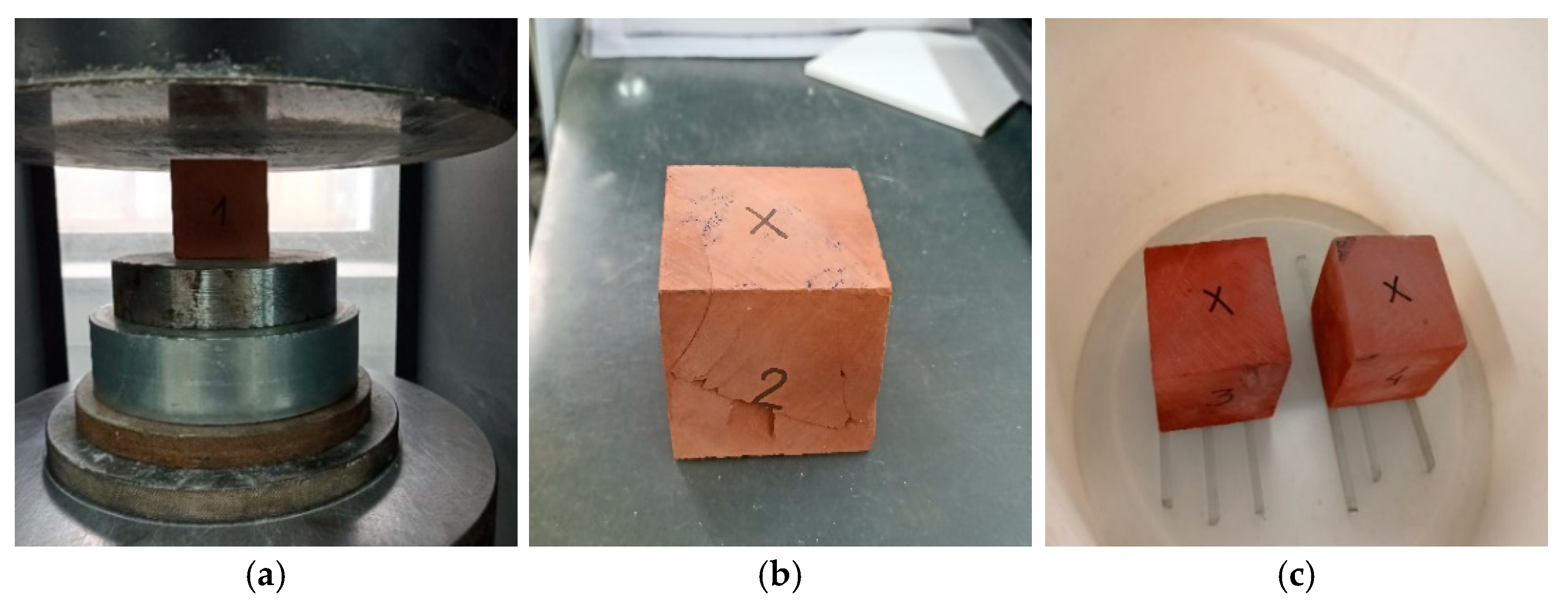

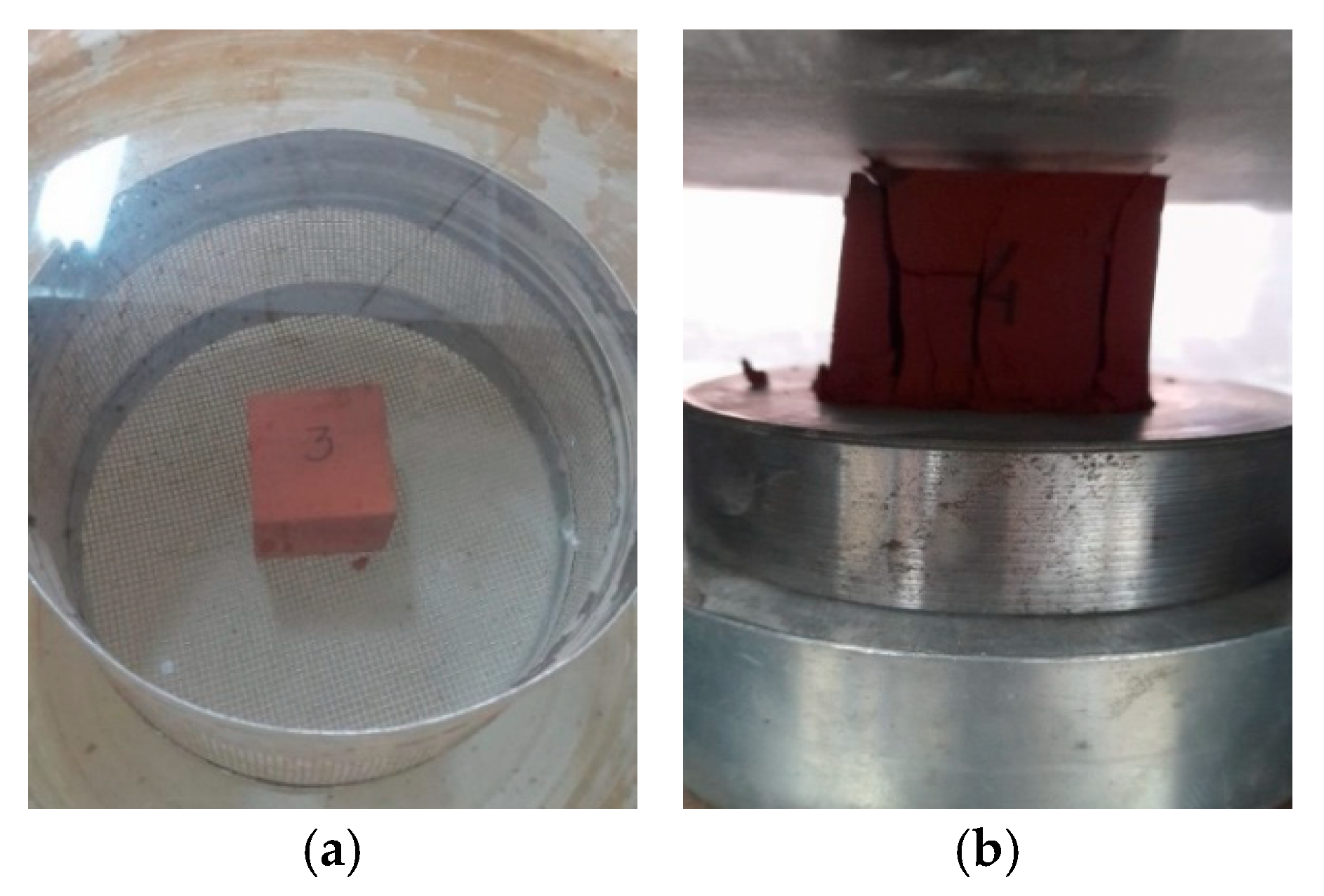

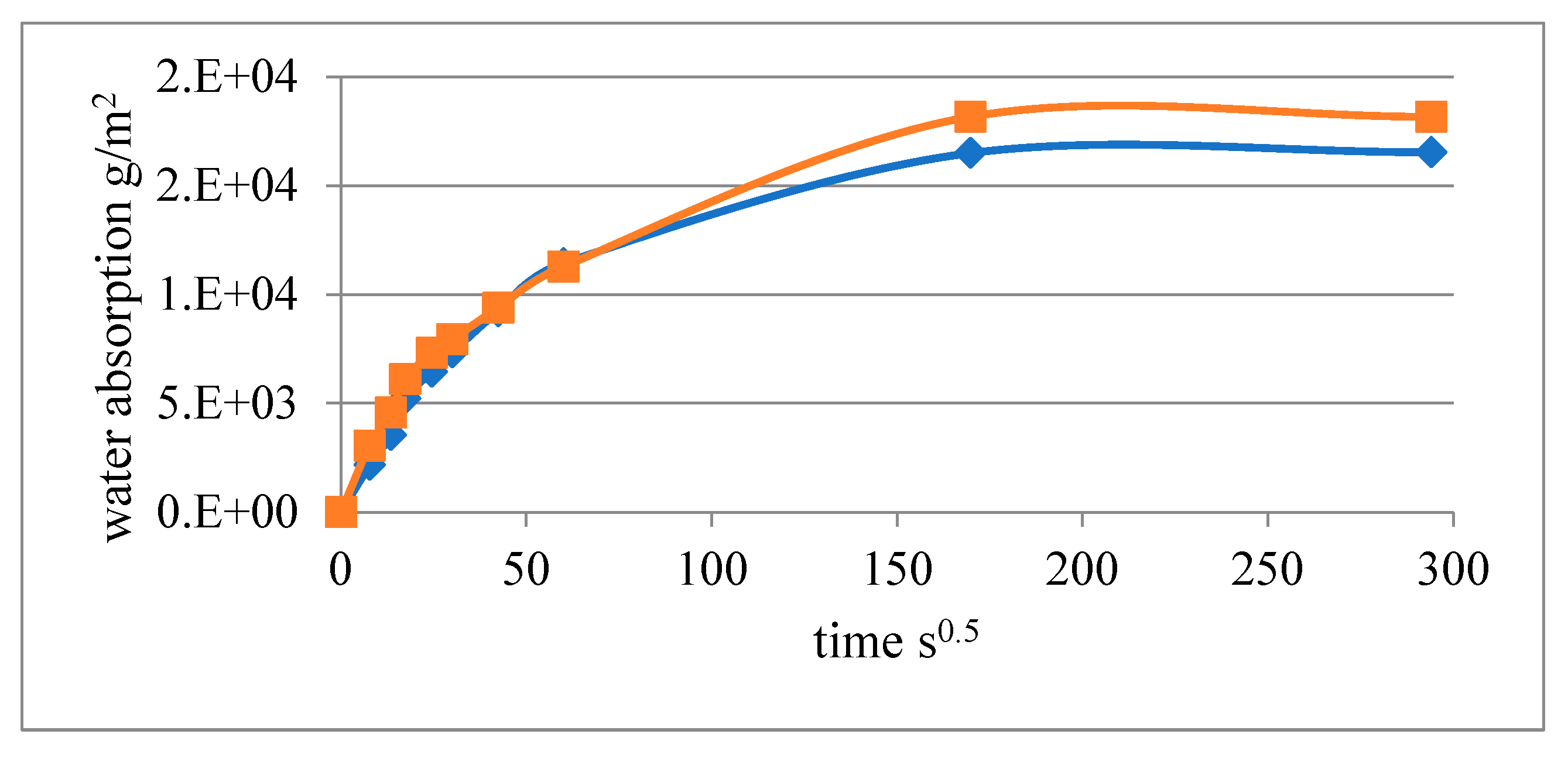

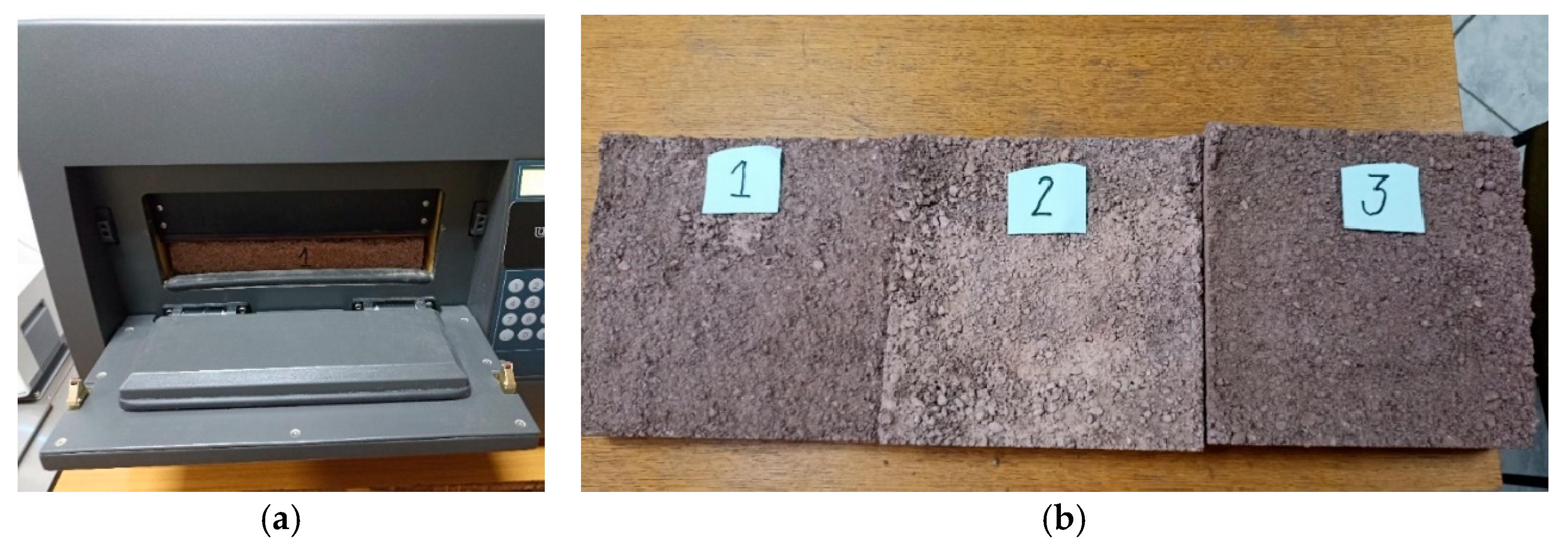

2.2. Physical and Mechanical Properties of Red Solid Clays

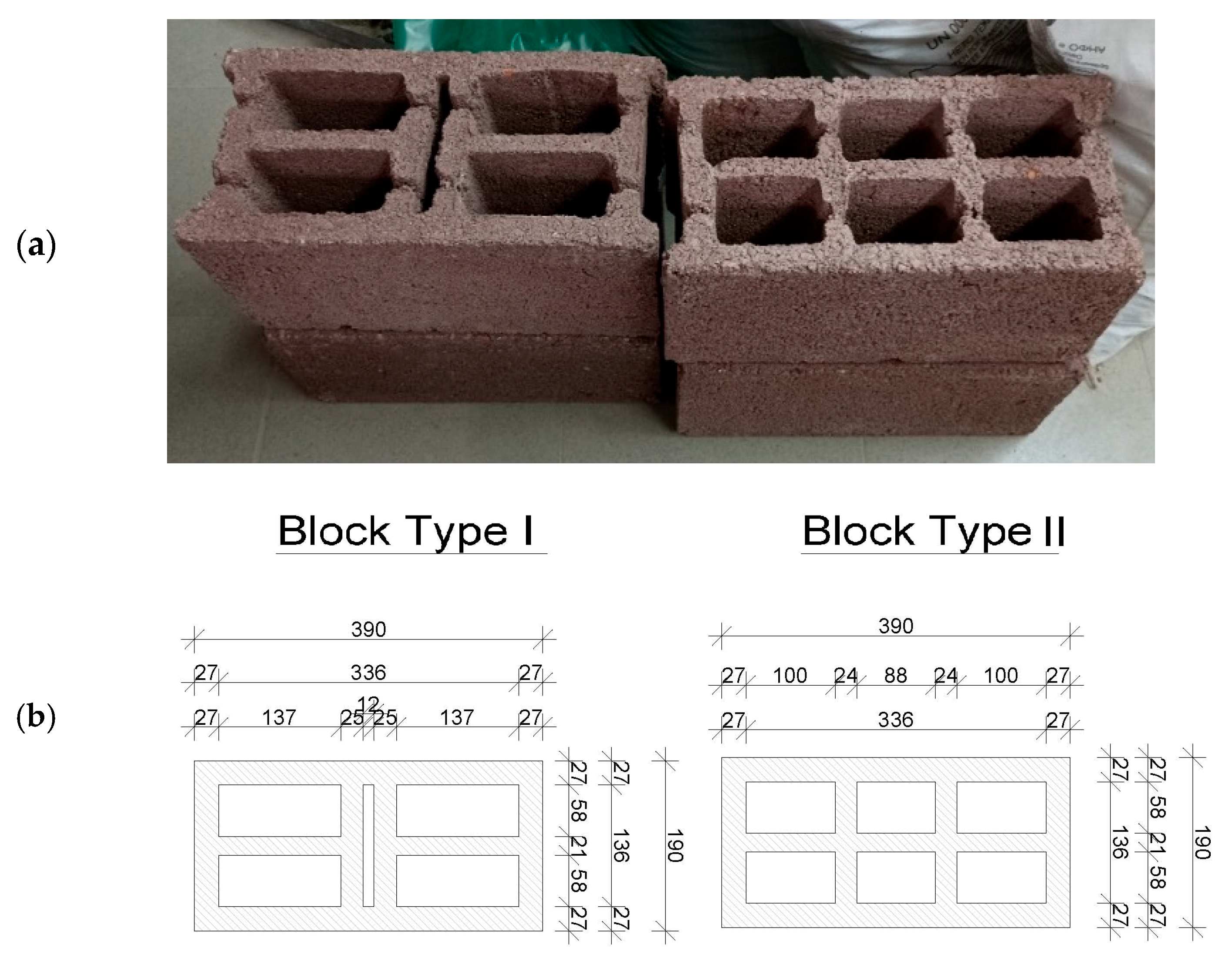

2.3. Composite Masonry Blocks

Materials for Blocks

3. Results and Discussion

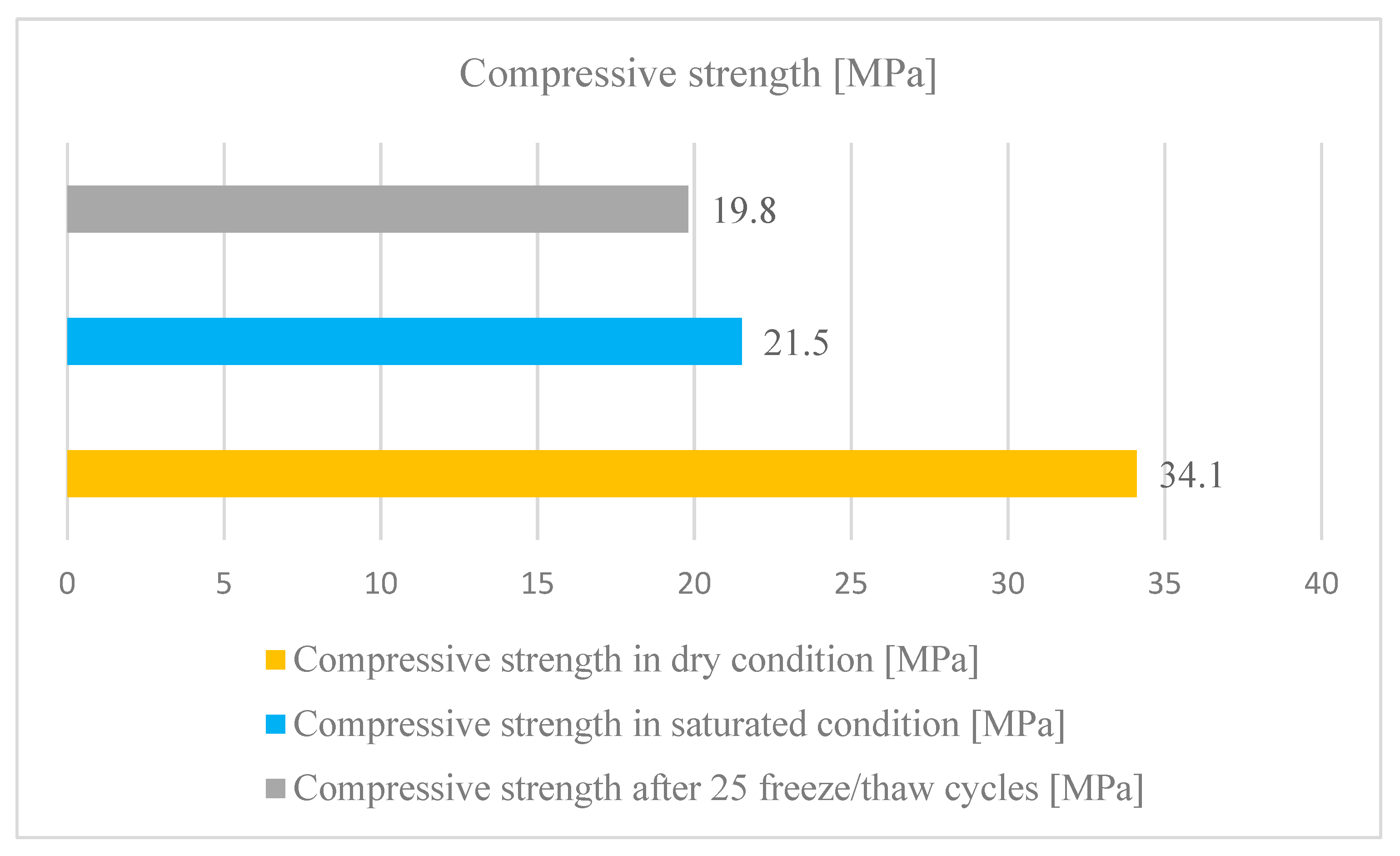

3.1. Physical and Mechanical Properties of the Blocks

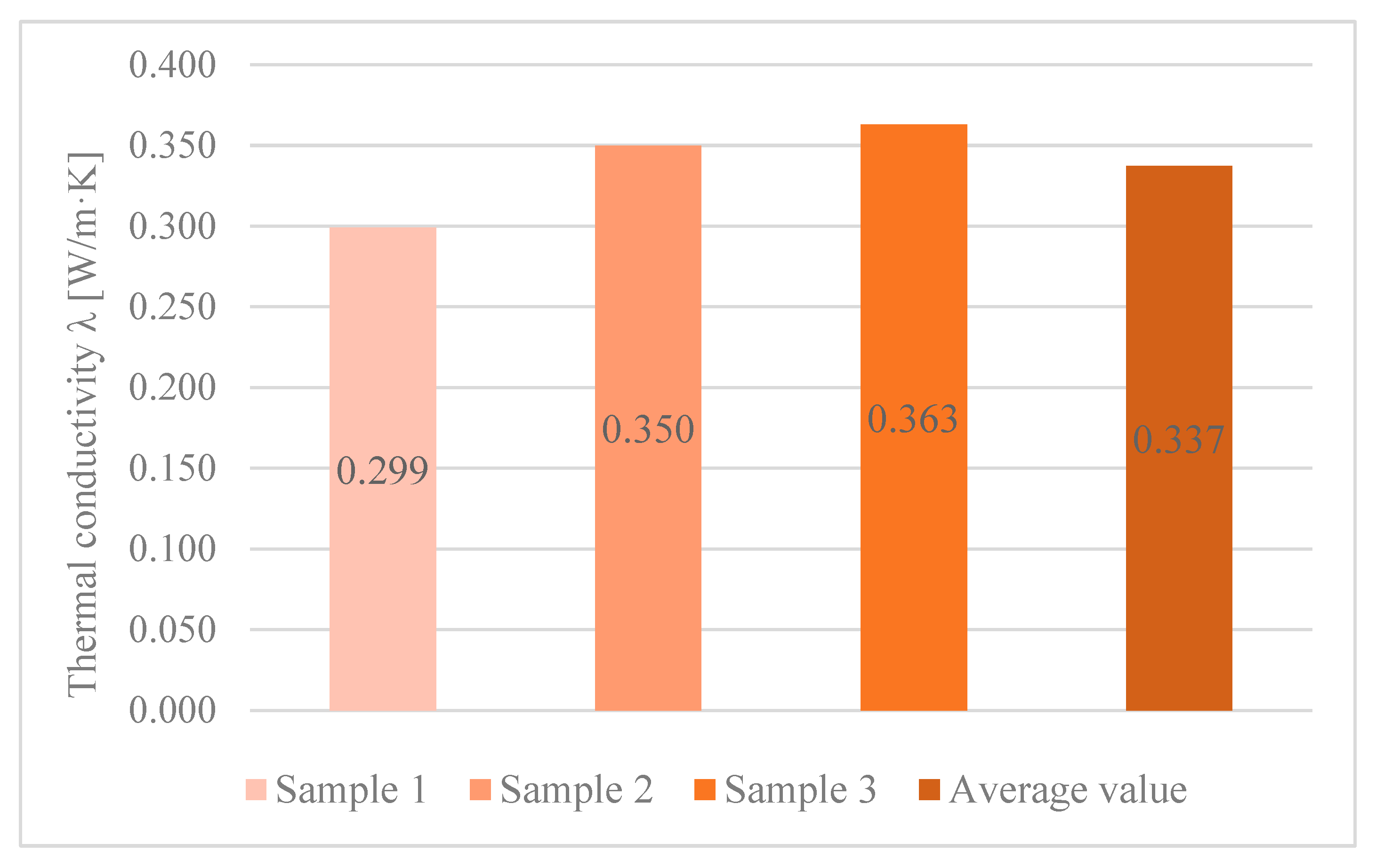

3.2. Thermal Conductivity

3.3. Discussion

3.3.1. Discussion on Results for the Red Solid Clay

3.3.2. Discussion on Results for the Composite Masonry Blocks

4. Conclusions

- -

- Cubes of the naturally baked red solid clay showed a high porosity, low density, high percentage of water absorption, and unexpectedly good strength properties.

- -

- Considering the high percentage of porosity of the red solid clay and the good results of compressive strength, it opens up the possibility of using the material as a building stone, especially in the production of composite masonry blocks.

- -

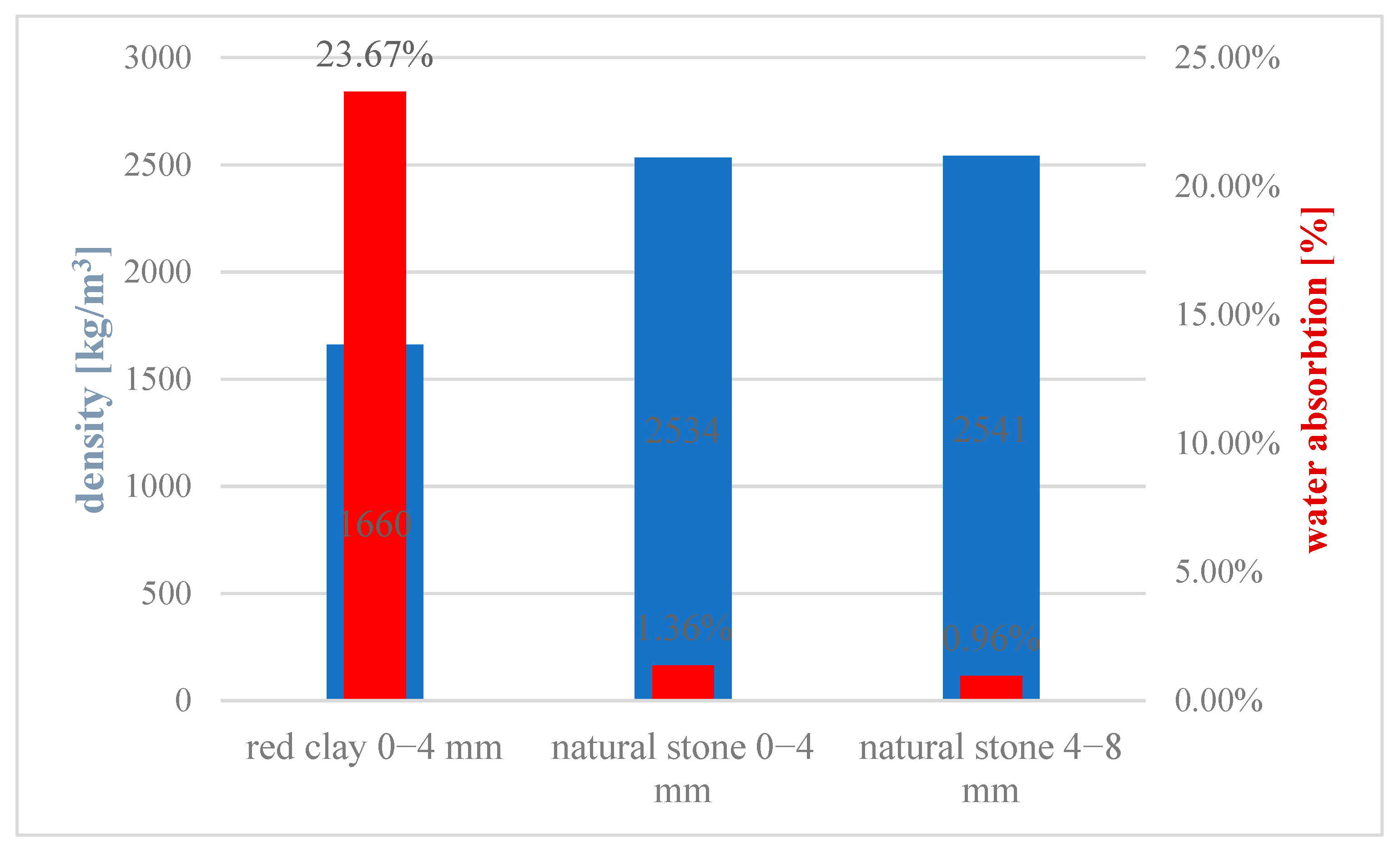

- The density of red solid clay aggregate is significantly lower compared to the density of natural stone aggregate, which is traditionally used for making traditional concrete blocks. Testing proved that water absorption also occurs with a large percentage, i.e., it is much higher compared to the natural aggregate.

- -

- The compressive strength of tested types of composite blocks depends on the net density and the number of chambers (cavities). The five-chamber block (type II) showed better compressive strength than the six-chamber block, in addition to its lower net density. That means the type II block is generally lighter than the type I, yet has a better compressive strength due to the arrangement of the chambers.

- -

- Composite masonry blocks based on red solid clay have good strength-deformable properties, are lighter compared to traditional concrete blocks, and have a high degree of porosity, which certainly brings improved thermal properties.

- -

- Solid red clay composite blocks have a thermal conductivity seven-times lower than traditional concrete blocks and about two-times lower than solid brick. They were shown to be a better insulator than these two traditionally used materials in building construction. Lower thermal conductivity will decrease energy consumption and/or decrease the thickness of the thermal insulation. Energy consumption during the operational period is one of the biggest aspects of sustainability in buildings.

- -

- The composite masonry block with these properties can be used for building non-structural walls in smaller residential buildings, as well as larger industrial buildings, for building chimneys, fence walls, etc.

- -

- One of the advantages is that the blocks are larger in size and make masonry faster and easier, while reducing the use of mortar.

- -

- The negative side is the relatively high degree of water absorption, which makes the blocks unsuitable for use in wet environments. If they are used in humid conditions, they need to be protected with appropriate waterproofing.

- -

- Another limitation of the research presented here is the extent of the physical and mechanical properties of the new material presented here. We are aware that research on alternative materials typically requires more properties to be investigated as well as deeper scientific analysis (evidence) to support and explain the observed properties. The capacity of our research laboratories has been the major limiting factor to undertaking microstructural analysis and/or some simulation work. Our future research will include microstructural investigation (SEM/BSE/EDS, etc.) and related thermal analysis (e.g., TGA) to help explain the relationship between the raw materials, processing, and resulting properties, while simulations and modelling (for strength and thermal properties) will provide further insight and predictive power.

- -

- Furthermore, the potential for sintering or lowering the temperature of firing will contribute to absorption reduction. New ingredients in the recipes need to be tested. Possibly, waste materials can be used as a partial replacement for other aggregate or for binding.

- -

- Life-cycle analysis as a tool for the assessment of sustainability is necessary, in order to calculate the embodied energy and embodied carbon in the material.

- -

- Durability in wet/dry cycling conditions should be improved with waterproof coatings. The choice will depend on further analysis and calculation.

- -

- Geological genesis of the natural rock needs further in-depth investigation and tests. At least, the following tests are recommended: XRF, XRD, Inductively Coupled Plasma Mass Spectrometry (ICP MS), Scanning Electron Microscopy, Magnetic susceptibility, Isotope Analysis, regional geological contextualisation and connection with volcanic areas/centres and sedimentary deposition areas. An approach such as that of Pedersen et al. [38] can be suggested.

- -

- Eventually, a cost–benefit analysis will make the red clay comparable to other alternatives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arenas, N.F.; Shafique, M. Reducing embodied carbon emissions of buildings—A key consideration to meet the net zero target. Sustain. Futures 2024, 7, 100166. [Google Scholar] [CrossRef]

- Myint, N.N.; Shafique, M. Embodied carbon emissions of buildings: Taking a step towards net zero buildings. Case Stud. Constr. Mater. 2024, 20, e03024. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- Al-Ani, T.; Sarapää, O. Clay and Clay Mineralogy; Geological Survey of Finland: Espoo, Finland, 2008. [Google Scholar]

- Mukherjee, S. The Science of Clays; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Lechner, N. Heating, Cooling, Lighting: Sustainable Design Methods for Architects; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Adazabra, A.N.; Viruthagiri, G.; Shanmugam, N. An assessment on the sustainable production of construction clay bricks with spent shea waste as renewable ecological material. J. Environ. Waste Manag. Recycl. 2018, 1, 36–46. [Google Scholar]

- Rasool, A.M.; Hameed, A.; Qureshi, M.U.; Ibrahim, Y.E.; Qazi, A.U.; Sumair, A. Experimental study on strength and endurance performance of burnt clay bricks incorporating marble waste. J. Asian Arch. Build. Eng. 2022, 22, 240–255. [Google Scholar] [CrossRef]

- Nuchnapa, T.; Sopita, M.; Atima, N.; Watchara, S.; Anuvat, S. Enhancing physical-thermal-mechanical properties of fired clay bricks by eggshell as a bio-filler and flux. Sci. Sinter. 2019, 51, 1–13. [Google Scholar]

- Ansari, A.A.; Mangi, S.A.; Khoso, S.; Khatri, K.L.; Solangi, G.S. Latest Development in the Structural Material Consisting of Reinforced Baked Clay. In Proceedings of the 7th International Civil Engineering Congress (ICEC-2015) “Sustainable Development through Advancements in Civil Engineering”, Karachi, Pakistan, 12–13 June 2015; Arif, F., Gazder, U., Lodi, S.H., Eds.; pp. 35–43. [Google Scholar]

- Elaborate for ore reserves of deposit “Crvena Mogila”-Delcevo, GRO Granit—Skopje, Macedonia. 1982.

- Shubbar, A.A.; Sadique, M.; Kot, P.; Atherton, W. Future of clay-based construction materials—A review. Constr. Build. Mater. 2019, 210, 172–187. [Google Scholar] [CrossRef]

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301. [Google Scholar] [CrossRef]

- Kipsanai, J.J.; Wambua, P.M.; Namango, S.S.; Amziane, S. A Review on the Incorporation of Diatomaceous Earth as a Geopolymer-Based Concrete Building Resource. Materials 2022, 15, 7130. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Bernardo, L.F.A. The Use of Waste Ceramic in Concrete: A Review. CivilEng 2024, 5, 482–500. [Google Scholar] [CrossRef]

- Main mining design for surface exploitation of solid clay from deposit “Crvena Mogila”—Delcevo, Mining design bureau “Rudproekt”, Skopje. 1989.

- Jovanovski, M. Elaborate on detailed geological investigations on solid clay at the locality Crvena Mogila in Delchevo. Ss. Cyril and Methodius University, Faculty of Civil Engineering, Skopje. 2011. [Google Scholar]

- Sutar, S.; Patil, P.V.; Ravan, C.V.; Maske, M.M. Study and Review of Ordinary Portland Cement. ASEAN J. Sci. Eng. 2021, 1, 153–160. [Google Scholar] [CrossRef]

- Saidi, T.; Hasan, M. The effect of partial replacement of cement with diatomaceous earth (DE) on the compressive strength and absorption of mortar. J. King Saud Univ.–Eng. Sci. 2020, 34, 250–259. [Google Scholar] [CrossRef]

- Zhang, H.; He, B.; Zhao, B.; Monteiro, P.J.M. Using diatomite as a partial replacement of cement for improving the performance of recycled aggregate concrete (RAC)-Effects and mechanism. Constr. Build. Mater. 2023, 385, 131518. [Google Scholar] [CrossRef]

- MKS EN 1926; Natural Stone Test Methods—Determination of Uniaxial Compressive Strength. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 12371; Natural Stone Test Methods—Determination of Frost Resistance. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2011.

- MKS EN 1925; Natural Stone Test Methods—Determination of Water Absorption Coefficient by Capillarity. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 13755; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 772-1; Methods of Test for Masonry Units Part 1: Determination of Compressive Strength. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2015.

- MKS EN 771-1; Specification for Masonry Units—Part 1: Clay Masonry Units. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2016.

- MKS EN 772-21; Methods of Test for Masonry Units—Part 21: Determination of Water Absorption of Clay and Calcium Silicate Masonry Units by Cold Water Absorption. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2013.

- EN 772-3; Methods of Test for Masonry Units—Part 3: Determination of Net Volume and Percentage of Voids of Clay Masonry Units by Hydrostatic Weighing. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2009.

- MKS ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2016.

- MKS EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2009.

- Debbarma, S.; Ransinchung R.N, G.D.; Dhaka, M. Effects of a Portland cement additive rich in SiO2 and Al2O3 in microstructure densification of RAP incorporated RCCP mixes. Constr. Build. Mater. 2020, 258, 119626. [Google Scholar] [CrossRef]

- Jamal, M.A.; Mohammed, A.S.; Ali, J.A. Modeling the impact of SiO2, Al2O3, CaO, and Fe2O3 on the compressive strength of cement modified with nano-silica and silica fume. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 156. [Google Scholar] [CrossRef]

- Liang, C.F.; Ma, H.; Pan, Y.; Ma, Z.; Duan, Z.; He, Z. Chloride permeability and the caused steel corrosion in the concrete with carbonated recycled aggregate. Constr. Build. Mater. 2019, 218, 506–518. [Google Scholar] [CrossRef]

- Rakhila, Y.; Ezzahi, A.; Elmchaouri, A.; Mestari, A. Synthesis and Characterization of a Red Clay Based New Composite Ceramic Material. Adv. Mater. Phys. Chem. 2018, 8, 295–310. [Google Scholar] [CrossRef]

- Lu, X.; Yu, Q.; Xu, J.; Yue, B.; Sheng, M. Comparative Experimental Study on Strength Properties of Red Clay Modified by Cement and Industrial Solid Waste Powder. Adv. Civ. Eng. 2023, 2023, 6645563. [Google Scholar] [CrossRef]

- Ji, S.; Gu, Q.; Xia, B. Porosity dependence of mechanical properties of solid materials. J. Mater. Sci. 2006, 41, 1757–1768. [Google Scholar] [CrossRef]

- Pedersen, G.K.; Pedersen, S.A.S.; Steffensen, J. Clay content of a clayey diatomite, the Early Eocene Fur Formation, Denmark. Bull. Geol. Soc. Den. 2004, 51, 159–177. [Google Scholar] [CrossRef]

| Oxides | Red Clay (% of Weight) | OPC (% of Weight) [18] |

|---|---|---|

| 52.86 | 17–25 | |

| 16.92 | 3–8 | |

| 9.04 | 0.5–6 | |

| 5.8 | 60–67 | |

| 2.86 | 0.1–4 | |

| 2.06 | 0.5–1.3 | |

| 1.17 | ||

| 1.12 | 1–3 | |

| Heat losses | 8.17 | |

| Total | 100 | 100 |

| Sample | Dimensions [cm] | Mass [g] | Volume [cm3] | Density [kg/m3] | Force [kN] | Compressive Strength [MPa] | Condition | ||

|---|---|---|---|---|---|---|---|---|---|

| d | b | h | m | V | γ | F | |||

| 1 | 5.19 | 5.10 | 5.18 | 188.10 | 137.11 | 1371.90 | 79.00 | 29.85 | Dry |

| 2 | 5.10 | 5.25 | 5.21 | 197.80 | 139.50 | 1417.94 | 102.60 | 38.32 | |

| Average value | 5.15 | 5.18 | 5.20 | 192.95 | 138.30 | 1394.92 | 90.80 | 34.08 | |

| 3 | 5.11 | 5.26 | 5.23 | 209.60 | 140.58 | 1491.02 | 93.80 | 34.90 | Saturated |

| 4 | 4.98 | 5.05 | 5.05 | 146.60 | 127.00 | 1154.31 | 20.10 | 7.99 | |

| Average value | 5.05 | 5.16 | 5.14 | 178.10 | 133.79 | 1322.66 | 56.95 | 21.45 | |

| 5 | 5.05 | 4.96 | 5.02 | 149.90 | 125.74 | 1192.13 | 46.20 | 18.44 | Freeze–thaw |

| 6 | 5.19 | 5.21 | 5.11 | 202.90 | 138.17 | 1468.44 | 57.40 | 21.23 | |

| Average value | 5.12 | 5.09 | 5.07 | 176.40 | 131.96 | 1330.29 | 51.80 | 19.84 | |

| Determination of water absorption coefficient by capillarity—[23] | Sample 3 | [g/m2·s0.5] | 51.2 |

| Sample 4 | [g/m2·s0.5] | 47.5 | |

| Average value | [g/m2·s0.5] | 49.4 |

| Ingredient | Cement | Water | w/c | Additive | Aggregate dmax = 8 mm | ||

|---|---|---|---|---|---|---|---|

| Fine Red Solid Clay Aggregate (Fraction 0–4 mm) | Fine Aggregate (Fraction 0–4 mm) | Fine Aggregate (Fraction 4–8 mm) | |||||

| Quantity | 300 kg | 100 kg | 0.33 | / | 900 kg (50%) | 400 kg (22%) | 500 kg (28%) |

| 1. | Real density | MKS EN 1936 [25] | 1390 | ||

| 2. | Apparent density | 2630 | |||

| 3. | Total porosity | % | 52.85 | ||

| 4. | Open porosity | % | 47.15 |

| Material | Average Compressive Strength [MPa] | Average Net Density [kg/m3] |

|---|---|---|

| Composite block with red solid clay (tested results) | 3.1–4.1 | 1600–1640 |

| Ordinary concrete block | 6.0–9.0 | 1800–2100 |

| Autoclaved lightweight concrete block | 2.5–7.0 | 400–700 |

| Properties | Material | ||

|---|---|---|---|

| Composite Block with red Solid Clay (Tested Results) | Ordinary Concrete Block | Autoclaved Lightweight Concrete Block | |

| Percentage of pores and voids [%] | 44.00–45.28% | 18.50–26.40% | 60.00–80.00% |

| Degree of water absorption [%] | 14.56–20.49% | 4.40–7.55% | 40.00–80.00% |

| Thermal conductivity λ [W/m∙K] | 0.337 | 2.3 | 0.14 |

| Spec. | Compressive Strength | Dry Mass mdry,u | Mass After Soaking | Gross Volume Vg,u | Net Volume Vn,u | Gross Dry Density | Net Dry Density | Water Absorption | Percentage of Pores and Voids |

|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [g] | [g] | [104 mm3] | [104 mm3] | [kg/m3] | [kg/m3] | [%] | [%] | |

| I-1 | 3.00 | 13,178 | 15,114 | 1397 | 812 | 943 | 1622 | 14.69 | 44.48 |

| I-2 | 3.26 | 13,389 | 15,322 | 1381 | 808 | 970 | 1658 | 14.44 | 43.12 |

| Av. block I | 3.1 | - | - | - | - | 956 | 1640 | 14.56 | 44 |

| II-1 | 3.93 | 12,466 | 15,114 | 1390 | 603 | 897 | 1601 | 21.24 | 45.70 |

| II-2 | 4.32 | 12,796 | 15,322 | 1393 | 623 | 919 | 1600 | 19.74 | 44.86 |

| Av. block II | 4.1 | - | - | - | - | 908 | 1601 | 20.49 | 45.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samardzioska, T.; Peshevski, I.; Zileska Pancovska, V.; Golaboski, B.; Jovanovski, M.; Abazi, S. Red Clay as a Raw Material for Sustainable Masonry Composite Ceramic Blocks. Sustainability 2025, 17, 6852. https://doi.org/10.3390/su17156852

Samardzioska T, Peshevski I, Zileska Pancovska V, Golaboski B, Jovanovski M, Abazi S. Red Clay as a Raw Material for Sustainable Masonry Composite Ceramic Blocks. Sustainability. 2025; 17(15):6852. https://doi.org/10.3390/su17156852

Chicago/Turabian StyleSamardzioska, Todorka, Igor Peshevski, Valentina Zileska Pancovska, Bojan Golaboski, Milorad Jovanovski, and Sead Abazi. 2025. "Red Clay as a Raw Material for Sustainable Masonry Composite Ceramic Blocks" Sustainability 17, no. 15: 6852. https://doi.org/10.3390/su17156852

APA StyleSamardzioska, T., Peshevski, I., Zileska Pancovska, V., Golaboski, B., Jovanovski, M., & Abazi, S. (2025). Red Clay as a Raw Material for Sustainable Masonry Composite Ceramic Blocks. Sustainability, 17(15), 6852. https://doi.org/10.3390/su17156852