Abstract

The pursuit of sustainable construction practices has become imperative in the modern era. This paper delves into the research of the properties and application of a specific material called “red clay” from the locality “Crvena Mogila” in Macedonia. A series of laboratory tests were conducted to evaluate the physical, mechanical, and chemical properties of the material. The tested samples show that it is a porous material with low density, high water absorption, and compressive strength in range of 29.85–38.32 MPa. Samples of composite wall blocks were made with partial replacement of natural aggregate with red clay aggregate. Two types of blocks were produced with dimensions of 390 × 190 × 190 mm, with five and six holes. The average compressive strength of the blocks ranges from 3.1 to 4.1 MPa, which depends on net density and the number of holes. Testing showed that these blocks have nearly seven-times-lower thermal conductivity than conventional concrete blocks and nearly twice-lower conductivity than full-fired clay bricks. The general conclusion is that the tested red clay is an economically viable and sustainable material with favourable physical, mechanical, and thermal parameters and can be used as a granular aggregate in the production of composite ceramic blocks.

1. Introduction

Sustainable building materials enable reductions in energy consumption, both during the construction phase of the buildings and throughout their exploitation. Lightweight materials with appropriate insulating properties can reduce the need for heating and cooling, which leads to significant energy savings during the exploitation of buildings. In addition, materials that are produced using renewable energy sources or natural materials requiring short processing before their use can help to reduce the carbon footprint of construction [1,2]. The construction industry is also striving for sustainable building materials because of the potential economic benefits [3]. Energy-efficient buildings lead to lower energy bills for tenants, and the use of sustainable materials can help to reduce waste and save on material costs in the long term. Overall, the construction industry needs energy-efficient building materials which are readily available and require less energy to be produced to meet the pressing environmental and economic challenges and move towards a more sustainable future.

Clay masonry units have played a significant role in construction for thousands of years, due to their outstanding characteristics such as durability, high strength properties, and low production costs. The term “clay” refers to a natural material composed primarily of fine-grained minerals, which with a certain water content becomes plastic, while when drying or firing it becomes solid [4,5]. Clay composites are emerging as promising sustainable construction materials, offering an eco-friendly alternative to conventional building products. Clay retains its high thermal mass when used in composites, which helps to regulate indoor temperatures. This reduces the need for energy-intensive heating and cooling [6]. Additionally, these composites can be produced locally, minimising transportation emissions and promoting the use of regional resources. The low carbon footprint associated with clay composites, along with their recyclability and biodegradability, positions them as a viable solution for creating sustainable, energy-efficient buildings that contribute to a circular economy. Adazabra et al. [7] replaced proportionate amounts of clay materials with 0%, 5%, 10%, 15%, and 20% by weight of spent shea waste to prepare brick samples, contributing to economic firing and improving the thermal properties. Rasool et al. [8] used waste marble powder in varying percentages by weight of clay in an industrial production of bricks, studying their mechanical and durability performance. Adding eggshell powder, Nuchnapa et al. [9] obtained clay brick material with potential use for bricks for construction and thermal insulation. Ansari et al. [10] researched baked clay panels with a proportion of 70:30 of clay/pit sand and proved that it can achieve a strength as good as that of concrete with moderate compression force.

Considering the huge production of different clay-based construction materials, many tests have been carried out around the world on different types of clay. Although they come from different origins and locations around the world, it has been observed that most of the clays used in the production of various clay-based construction materials show a similar percentage range of SiO2, CaO, and Al2O3 [11]. Most of the studies on diatomaceous earth have concentrated on its integration as either a partial cement replacement or a fine aggregate replacement. Diatomaceous earth can be used as a lightweight aggregate in mortar and concrete for insulation purposes because of its unique properties, such as its low density and porous structure, which are desirable for thermal performance, fire resistance, and sound absorption [12,13]. Jwaida et al. made a detailed review of the use of ceramic waste as fine and coarse aggregate in concrete. It was shown that the compressive strength increased by 35% with the replacement of fine brick aggregate. An increase of 3.9% in the compressive strength is found for replacement with 20% of coarse ceramic waste aggregate [14].

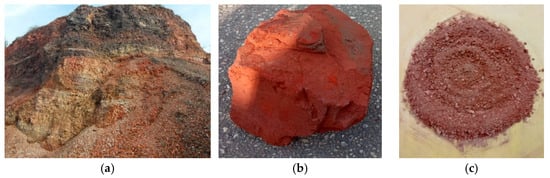

The material presented in this paper is locally known as red baked clay, found at a locality (quarry) called “Crvena Mogila” (Figure 1) in Delcevo Municipality, Macedonia. In 1982 and 1989, initial geological studies and tests of the material properties were performed. Later on, Geological Report [15] and Mining Design [16] were prepared as a basis for the development of a mining project.

Figure 1.

(a) Open cut at locality. (b) Red clay rock. (c) Fine red solid clay aggregate.

The specifics of this material as a possible component for sustainable ceramic composites are related to its geological origin. Namely, different varieties of pelite–alevrolite diatomites, marlstones, and bituminous diatomites were deposited in the wider area, in specific geological conditions during the Neogene [15]. Due to the sedimentation under variable conditions, a formation consisting of layers with different thicknesses is created, ranging from several centimetres to over ten metres. The colour of the sediments varies in wide spectre, from grey white to red to totally black. With red layers dominating, the material obtained the local name “red clay”. There is also a presence of volcanic ash in some of the layers and an indication in the Neogene series that the subbase coal layers have been naturally “baked”. Without going into further detail for its genesis, we consider the material as a predominantly diatomaceous pelite rock made up of fine-grained particles, including clay minerals and diatomaceous earth, with specific thermally induced changes.

With the current development of the construction industry, as well as the intensive construction activity in the region, there is an increasing need to use natural materials that are environmentally friendly and less energy demanding. Therefore, the purpose of this paper is to determine the physical, mechanical, and thermal properties of red clay from the “Crvena Mogila” locality, near Delchevo. The research aims to define the possibility of applying this material as a natural building stone. Furthermore, it explores the area of its application as a raw material for producing composite masonry blocks. The potential advantages of the analysed material can prove its suitability for masonry units. This could offer an opportunity to overcome the problem of a lack of sand aggregate in the wider region of the Crvena Mogila locality. Namely, the sand was previously extracted from the Bregalnica riverbed. Nowadays, the river sand has been restricted by the new national laws and regulations related to sustainable and safe mining. On the other hand, red clay in this locality is abundant, available in sufficient quantities, and easy to extract. This fulfils the prerequisite for the material of interest to be considered a possible composite ceramic material.

2. Materials and Methods

2.1. Mineralogical–Petrographic and Chemical Composition of the Raw Material

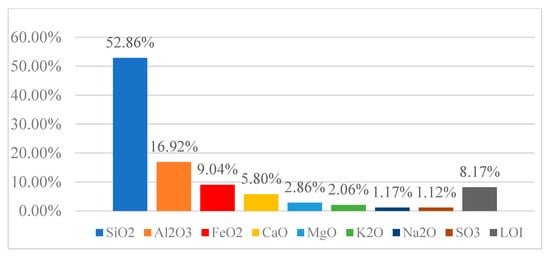

With mineralogical–petrographic, X-ray-structural, and a large number of chemical analyses and tests carried out, the composition of the parent rock from the “Crvena Mogila” locality was determined. Varieties of diatomite, diatomite siltstone pelites, diatomite pelitic siltstones, volcanic ashes, tuffites, and similar varieties have been found in the composition of “red solid clays”. The results of the chemical analysis from the report in [17] are presented in Figure 2 and Table 1.

Figure 2.

Chemical composition of red solid clays from Crvena Mogila locality.

Table 1.

Chemical analysis of red clay from Crvena Mogila locality and OPC.

The results for the red clay, presented in Figure 2 and Table 1, meet the necessary requirements of the material for its intended use in construction. The chemical analysis proves the suitability of this material for the factory production of masonry units. The properties of Ordinary Portland Cement (OPC) are shown in the last column of Table 1, for comparison purposes [18].

Table 1 shows that the percentage of SiO2 and Al2O3 is significantly higher in red clay than in OPC, while the content of CaO is much lower than in OPC. Although this material cannot be used as a substitute for cement, as it has different properties, there have been studies recommending the use of diatomaceous earth for partial replacement of cement [19,20].

2.2. Physical and Mechanical Properties of Red Solid Clays

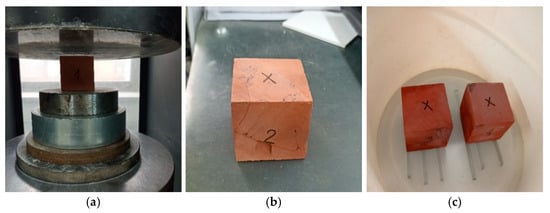

The physical and mechanical properties of the red solid clays were tested for the determination of compressive strength, water absorption, real and apparent density, and frost resistance. For the purpose of determination of the compressive strength, monolithic samples with an irregular shape were saw-cut out of irregular boulders in the laboratory to obtain test samples of the appropriate shape and size according to the applicable standard [21], as shown in Figure 3.

Figure 3.

Irregularly shaped monolithic rock and cubic test samples, 50 × 50 × 50 mm.

Six cubic samples with dimensions of 50 ± 5 mm were made, of which two samples were used to test the compressive strength in a dry state (Figure 4). Before testing, the samples were dried at a temperature of 70 ± 5 °C to a constant mass, i.e., within 24 ± 2 h, there was no difference of 0.1% in the mass. The samples were measured dimensionally and by weight before testing. The uniaxial compressive strength σ for each specimen was expressed by the ratio of the specimen’s load to failure and its cross-sectional area before testing, with Equation (1):

where F is the compression force and A is the cross-section of the sample.

Figure 4.

(a) Compressive strength test. (b) Cracked sample. (c) Samples immersed in water.

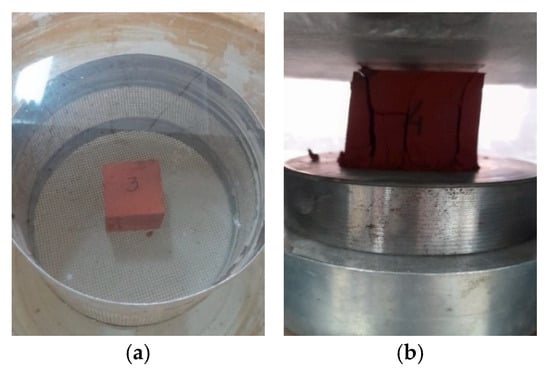

Two water-saturated samples were also tested for compressive strength (Figure 5), as well as two samples after 25 freeze–thaw cycles, in accordance with [22].

Figure 5.

(a) Saturated sample. (b) Failure of saturated sample.

The material is considered stable under frost if the test sample, after a certain number of cycles (25) of freezing and thawing, does not lose more than 5% of its mass as a result of failure and does not reduce in strength by more than 15–25% [22]. The tested samples showed very little damage and a loss of 0.01% of the mass. The obtained results for the compressive strength are presented in Table 2.

Table 2.

Compressive strength of red solid clay samples.

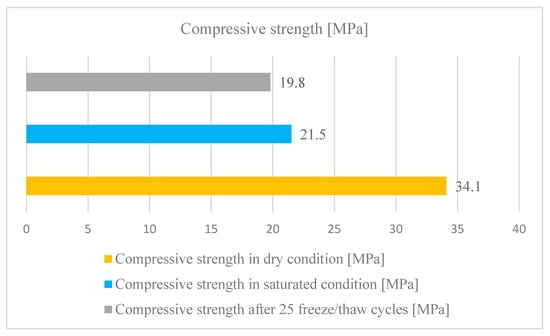

The average values of the compressive strengths of the red solid clay samples in dry and saturated conditions, as well as after 25 freeze/thaw cycles, are presented in Figure 6.

Figure 6.

Average compressive strengths of the red solid clay samples in different conditions.

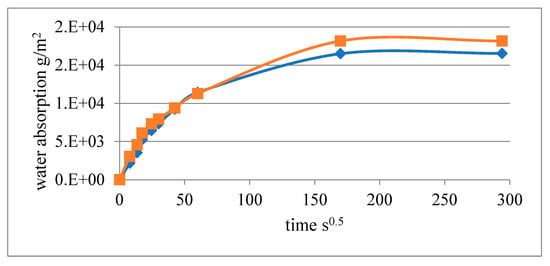

To determine the coefficient of water absorption by capillary rise, the samples were first dried to a constant mass in a fan oven at a temperature of (70 ± 5) °C [23]. Two samples were immersed in a container of water to a (3 ± 1) mm depth of the height of the samples, and this depth was maintained during the complete duration of the test. At time intervals, initially very short then longer, each sample was removed in turn, the submerged portion was lightly dried with a damp cloth to remove any water droplets, weighed to the nearest 0.01 g, and afterwards returned to the water container. The stone was treated as a highly absorbent stone and water absorption readings at 1, 3, 5, 10, 15, 30, 60, 480, and 1440 min were taken. The results of the test are presented in Figure 7, showing the mass of absorbed water in grams divided by the area of the submerged base of the sample in square metres as a function of the square root of time expressed in seconds. The blue and orange lines in Figure 7 represent the water absorption for the two samples.

Figure 7.

Capillary absorption of water of the natural stone for the two tested samples.

The absorption coefficient is calculated according to Equation (2):

where

—mass of dry sample [g];

—successive masses of the sample during the testing [g];

—area of the side immersed in water [m2];

—time elapsed from start of the test to the times at which successive masses mi were measured [s];

—coefficient of water absorption by capillarity perpendicular to stone’s planes of anisotropy [g/m2·s0.5];

—coefficient of water absorption by capillarity parallel to stone’s planes of anisotropy [g/m2·s0.5].

Table 3 below presents the results of water absorption coefficient by capillarity for both samples.

Table 3.

Water absorption coefficient by capillarity.

For determination of the water absorption at atmospheric pressure, the samples previously measured in a dry state were placed in a tank with a provided support, and then tap water was added to half the height of the samples (time t0). At time t0 + (60 ± 5) min, tap water was added until the water level reached three quarters of the height of the samples. Then, at time t0 + (120 ± 5) min, tap water was added, until the samples were fully immersed, namely 25 ± 5 mm of water above the sample, according to the standard. At time t0 + (48 ± 2) h, the samples were removed from the water, quickly wiped with a damp cloth, and then weighed within 1 min to the nearest 0.01 g (mi), according to [24]. The test was continued until a constant mass of the samples. Constant mass is achieved when the difference between two consecutive measurements is no greater than 0.1% of the first of the two masses. The result of the last measurement is the mass of the saturated sample (mS).

The water absorption at atmospheric pressure Ab of each sample was calculated by Equation (3):

—mass of dry sample [g];

—mass of saturated sample (after immersion in water until constant mass is reached) [g];

—water absorption at atmospheric pressure [%].

The result was expressed as a percentage, with an accuracy of 0.1%.

Two of the samples were used for determination of the real and apparent density. Each sample was weighed in a dry state, and then the samples were placed in a glass container with a vacuum pump and the pressure was gradually lowered to (2.0 ± 0.7) kPa = (15 ± 5) mm Hg [25]. Demineralised water at 20 ± 5 °C was slowly introduced into the vessel while the pressure was maintained at 2.0 ± 0.7 kPa. When both samples were submerged, the vessel was returned to atmospheric pressure and the samples were left under water for another 24 ± 2 h at atmospheric pressure. Each sample was weighed under water and the mass in water was recorded, then the sample was quickly wiped with a moistened cloth and the mass of the saturated sample was determined.

After the determination of the real density, both samples were ground until they passed through a 0.063 mm mesh sieve. The samples were dried to a constant mass me and weighed approximately 50 g, with an accuracy of ±0.01 g. A Le Chatelier volumenometer was filled with deionised water to level 0, then the previously measured mass me of the sample was added, divided into five fractions of 10 g each, ensuring that the entire fraction fell into the liquid. The liquid was stirred to disperse the soil sample. Then, the volume of liquid Vs, displaced by the mass me, was read in [mL] to the nearest 0.1 mL. The results are presented in Table 4.

Table 4.

Real and apparent density and total and open porosity of the samples.

2.3. Composite Masonry Blocks

Materials for Blocks

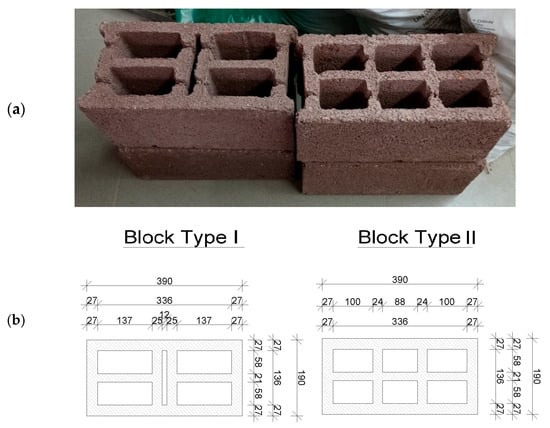

Ten samples of composite masonry blocks were made with the red solid clay as a replacement for the standard sand aggregate. Composite blocks were made in two types: type I with 5 hollows and type II with 6 hollows (Figure 8a,b). The recipe shown in Table 5 was used for the preparation of both types of composite blocks.

Figure 8.

(a) Composite blocks type I with 5 hollows and type II with 6 hollows. (b) Cross-sections of both blocks.

Table 5.

Recipe for composite masonry blocks (1.0 m3).

3. Results and Discussion

3.1. Physical and Mechanical Properties of the Blocks

The determination of compressive strength of both types of composite blocks was performed in accordance with [26]. Capping of the specimens was performed by covering them with a cement and sand mortar, with the mortar expected to achieve a minimum compressive strength when tested. The mortar at the time of testing the specimens shall have attained a strength equal to that of the specimen or 30 N/mm2, whichever is less. The mortar covered both sides of the sample with a minimum thickness of 3 mm over the entire surface, as shown in Figure 9.

Figure 9.

Testing of the compressive strength of composite blocks.

After capping, the samples were tested with a press of measuring range 0–3000 kN at a loading rate of 0.05 MPa. The test surface was perpendicular to the sample surface with dimensions of 390 × 190 mm. A suitable speed/degree of load was applied initially, but when about half of the intended maximum load was applied, the speed was adjusted to reach the maximum load in no less than 1 min. The adopted strength value was then calculated as the average value of the strength of the individual samples with an accuracy of 0.1 MPa.

The determination of net and gross density in the dry condition was performed for both types of blocks [27]. To determine the dry mass of an entire masonry unit, it was necessary to dry the sample to a constant mass , at a temperature of 70 ± 5 °C.

The net density in the dry state was determined by Equation (4):

where

—net dry density (kg/m3);

—the mass of an entire masonry unit after drying to a constant mass [g];

—net volume of the masonry unit [mm3].

When determining the net volume , all depressions and indentations observed during measurement were subtracted from the volume obtained (length × width × height).

The gross volume of the specimens was calculated by subtracting the volume of the perforations, pores, alignments, and incisions required to be filled with mortar.

The gross dry density was calculated according to Equation (5):

where

—gross dry density [kg/m3];

—the mass of an entire masonry unit after drying to a constant mass [g];

—gross volume of the masonry unit [mm3].

For determination of the degree of water absorption of the composite blocks, it was necessary to dry the samples to a constant mass Md in a ventilated oven at a temperature of 105 °C ± 5 °C [28]. Then, the mass of each sample was measured and it was placed in the pool of water, where it was left fully submerged for 24 ± 0.5 h. After removal from the pool, the surface water was removed using a towel and the mass of each sample was measured.

The water absorption of each sample is calculated according to Equation (6):

The results for the water absorption are presented in Table 6.

Table 6.

Compressive strength, net and gross density, water absorption, and percentage of pores and voids of the blocks.

The determination of net and gross volume and percentage of pores of clay masonry units was performed according to [29]. Their dry mass is Mau. After the measurement of the dimensions of the blocks, they were immersed in the pool for at least one hour. When the apparent masses of the water-immersed samples (Mwu), measured by two consecutive measurements at 30 min intervals, differed by less than 0.2%, the samples were removed from the water and the result of the second measurement was recorded as the apparent mass (Mwu). The water was removed from the surface of the specimens with a wet cloth and the weight was determined immediately.

The net volume of the samples was calculated as

where is the density of the water.

The gross volume of the samples was calculated multiplying the length () of the samples:

Hence, the volume of the pores is

With the obtained values, the percentage of pores and cavities was calculated with an accuracy of 1% as

3.2. Thermal Conductivity

Thermal conductivity testing of building materials is an essential process, since it is one of the key parameters for energy efficient building materials. By selecting appropriate materials based on their thermal conductivity, engineers can optimise heat transfer, thereby improving the energy efficiency of buildings.

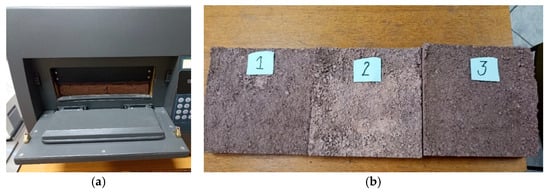

Testing of the thermal conductivity was performed in the laboratory for insulation materials, ceramics, building physics, and chemistry at the Faculty of Civil Engineering in Skopje, using the instrument heat flow meter (HFM) 436/3, showed in Figure 10. The testing was performed according to [30,31]. The instrument has a temperature range of −30 °C to 100 °C and can measure thermal conductivity in a range of 0.005 to 0.5 W/m·K.

Figure 10.

(a) Instrument heat flow meter. (b) Three testing samples.

Three samples were prepared, with dimensions of 30 × 30 cm and thickness up to a maximum of 10 cm. The heat flow (q) through the sample was measured with calibrated heat flux sensors. The test ended when equilibrium was established in the tested sample. The heat flux q(W/m2) is the rate of heat transfer in the x-direction per unit area and is proportional to the temperature gradient (ΔT/Δx) in this direction. The proportionality constant is the heat transfer property of the material, known as thermal conductivity.

where

—temperature difference in the sample;

—sample thickness.

According to the measured dimensions of the samples and their masses, the volume and densities were calculated. The average density of the samples was 1680 kg/m3, which was similar to the density of the masonry blocks.

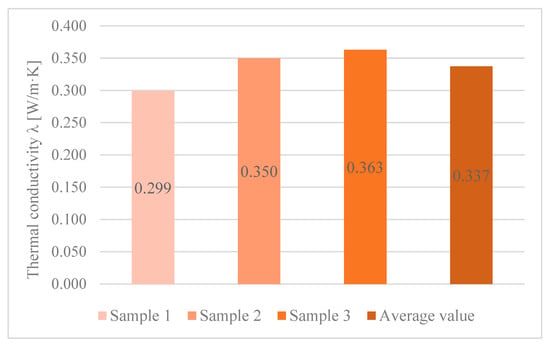

The results for the thermal conductivity are presented in Figure 11. The thermal conductivity does not have a large variation in the three samples with red clay. The calculated average value for λ is 0.337 W/m∙K.

Figure 11.

Thermal conductivity λ of three samples with red clay.

3.3. Discussion

3.3.1. Discussion on Results for the Red Solid Clay

The chemical composition of the red solid clays gives the general picture of the composition and structure of the building stone. The graphic representation of the chemical composition of red solid clays in Figure 1 shows that the tested material has the highest percentage of siliceous dioxide—SiO2, which is characteristic of clays, followed by Al2O3 with a drastically lower percentage. The participation of SiO2 and Al2O3 is suitable in the production of cement mortar and concrete [32,33]. Therefore, composite masonry blocks based on cement and solid clay, for increasing strength, preventing segregation, facilitating installation, improving durability, and reducing cracks caused by shrinkage. The participation of iron FeO2 is found in the form of hematite and very rarely in the form of limonite or magnetite. The presence of iron gives the material its reddish colour. This building material for the production of composite masonry blocks does not contain ingredients that have a detrimental effect on hydration, i.e., the binding and hardening of the cement, nor those that can have a detrimental effect on the hardened composite masonry block.

Since the chloride content is higher than the reference value according to the quality conditions of MKS standards, this aggregate is not suitable for use in concrete production. The presence of chlorides and sulphates is limited due to their aggressive influence, i.e., the corrosion that they can cause on reinforcement in reinforced concrete [34]. Therefore, this building stone cannot be used and does not meet the criteria for use in the production of concrete for reinforced concrete structures. However, this does not preclude the suitability of using the building stone as an aggregate for composite masonry blocks, as they do not use reinforcement that would be at risk of corrosion due to the chloride content.

The summarised results of the tests performed on the physical and mechanical characteristics of the red solid clay (its mass, volume, and density, as well as the compressive strength in three different states) are shown in Table 4. The mean value of the volume mass of red solid clay ranges from 1322.66 kg/m3 to 1394.92 kg/m3, which compares well with other published values for similar clays [35]. The relatively low density of the red clay gives rise to the assumption of a lower compressive strength under different conditions [36].

According to Figure 6, the samples of red solid clay with dimensions of 50 × 50 × 50 mm, tested in a dry condition, show an average compressive strength of 34.1 MPa. This value decreases significantly when the samples are tested in a water-saturated condition; the average compressive strength of the saturated samples is 21.5 MPa, which represents a 37% decrease compared to the average value in the dry condition. This is due to the noticeable difference between the results of compressive strength of samples No. 3 and No. 4. Actually, the mean value is not a true indicator of the real picture in a water-saturated condition. Furthermore, after subjecting the samples to 25 freeze–thaw cycles, the mean compressive strength of the solid stone dropped to 19.8 MPa, which is 42% lower than the value obtained in the dry condition. In general, the results are expected considering that clay as a material under the influence of water becomes plastic and reduces its strength properties [36].

According to Table 4, the real density is 1390 kg/m3, while the apparent density is 2630 kg/m3. This difference between the real and apparent density shows that the material is quite porous, i.e., the percentage of porosity has a high value of 52.85%, mainly open pores. Porosity is proportional to the percentage of water absorption, which is 26.02% for the tested red solid clay.

The general picture of the red solid clay is that it has good strength properties given the high percentage of porosity, low real density, and high percentage of water absorption. Such properties of the material make it ideal for use as an aggregate in non-structural elements, such as composite masonry blocks.

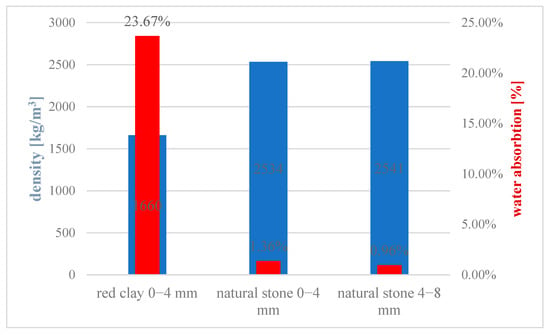

Furthermore, an analysis and comparison was undertaken of the properties of the solid clay aggregate used for this research for the production of composite masonry blocks and those of the natural aggregate. The solid clay aggregate is 53% less dense than the natural aggregate, blue columns in Figure 12.

Figure 12.

Density and water absorption of red solid clay and natural aggregate.

The results of the water absorption tests of the solid clay aggregate and the natural stone aggregate after being saturated for a period of 24 h showed that there is a significant difference in the water absorption of the two materials [red columns in Figure 12]. It was to be expected that the solid clay aggregate would have a higher percentage of water absorption. However, the percentage of water absorption of the solid clay aggregate is 23.67%, which means it is about 17-times higher than the fraction 0/4 mm and about 24-times higher than the 4/8 mm fraction of the natural stone aggregate.

3.3.2. Discussion on Results for the Composite Masonry Blocks

The physical and mechanical properties of the tested ceramic masonry blocks with red solid clay as a partial replacement of the first fraction of the aggregate were analysed and compared to the concrete masonry blocks and autoclaved lightweight concrete blocks [Table 7].

Table 7.

Average compressive strength and density of different type of masonry blocks.

Red solid clay composite masonry blocks have a lower density than traditional concrete blocks, but a higher density than autoclaved concrete blocks. Red solid clay composite masonry block is about 20% lighter than traditional concrete blocks, while being almost 2-times heavier than the autoclaved ones. In terms of compressive strength, the composite masonry block shows similar, albeit slightly weaker, parameters to the autoclaved blocks. However, they have almost two-times-smaller parameter values than the classic concrete block. An increase in density usually means an increase in compressive strength. However, when comparing the test results of blocks of type I and type II, it can be seen that the type II block, although with a lower density than type I, still has a higher compressive strength. This difference is due to the different arrangement of the chambers (cavities) of the blocks. Both block types have the same dimensions 39 × 19 × 19 cm, but the difference is in the number and type of chambers. The type I block has six chambers that are placed longitudinally, and the type II block has five chambers, of which four are longitudinal and one is transverse. This difference in the arrangement of the chambers makes an obvious difference in the compressive strength of the blocks.

The thermal conductivity of the masonry units is one of the most important properties regarding energy efficiency, saving energy, and sustainability in buildings. It is directly connected to the density and porosity of materials. Table 8 shows a comparison of the percentage of pores, degree of water absorption, and thermal conductivity between the composite red solid clay blocks and traditional concrete blocks, as well as autoclave concrete blocks.

Table 8.

Comparison of the percentage of pores, degree of water absorption, and thermal conductivity.

Porosity as a property reflects the compactness of the material. The porosity of the material and the characteristics of the pores affect the properties of the material such as the degree of water absorption, thermal conductivity, frost resistance, strength, acoustic properties, etc. [37]. The composite block with red solid clay has higher values of porosity and absorption than the ordinary concrete block, but lower than the autoclaved blocks. This is due to the highly porous character of the solid clay itself. As the percentage of porosity increases, so does the degree of water absorption. An additional confirmation of this is the test of water absorption under capillary forces.

Regarding the thermal insulation capability, Table 8 presents that the ceramic block of red clay is seven-times better as a thermal insulator than the ordinary concrete block, but almost two-times weaker as an insulator than the aerated concrete blocks.

One of the major limitations of the study presented here is that the results presented are derived using the average of two samples which may not be most representative of the material’s behaviour. Since this was an initial analysis and testing, only a limited number of blocks were made and were used for several different tests (water absorption analysis, compressive strength, freeze–thaw test). Only the most representative results (the most diverse values) of the testing are presented in this paper. Some of the blocks broke during transport to the laboratory, and some test results were among those presented. An appropriate number of samples for testing will be used for further in-depth analysis.

4. Conclusions

The study of the “red clay” from the locality of Crvena Mogila in Macedonia showed that it is a material of specific geological origin. With intention to be used as a sustainable building material, it showed the following properties:

- -

- Cubes of the naturally baked red solid clay showed a high porosity, low density, high percentage of water absorption, and unexpectedly good strength properties.

- -

- Considering the high percentage of porosity of the red solid clay and the good results of compressive strength, it opens up the possibility of using the material as a building stone, especially in the production of composite masonry blocks.

- -

- The density of red solid clay aggregate is significantly lower compared to the density of natural stone aggregate, which is traditionally used for making traditional concrete blocks. Testing proved that water absorption also occurs with a large percentage, i.e., it is much higher compared to the natural aggregate.

- -

- The compressive strength of tested types of composite blocks depends on the net density and the number of chambers (cavities). The five-chamber block (type II) showed better compressive strength than the six-chamber block, in addition to its lower net density. That means the type II block is generally lighter than the type I, yet has a better compressive strength due to the arrangement of the chambers.

- -

- Composite masonry blocks based on red solid clay have good strength-deformable properties, are lighter compared to traditional concrete blocks, and have a high degree of porosity, which certainly brings improved thermal properties.

- -

- Solid red clay composite blocks have a thermal conductivity seven-times lower than traditional concrete blocks and about two-times lower than solid brick. They were shown to be a better insulator than these two traditionally used materials in building construction. Lower thermal conductivity will decrease energy consumption and/or decrease the thickness of the thermal insulation. Energy consumption during the operational period is one of the biggest aspects of sustainability in buildings.

- -

- The composite masonry block with these properties can be used for building non-structural walls in smaller residential buildings, as well as larger industrial buildings, for building chimneys, fence walls, etc.

- -

- One of the advantages is that the blocks are larger in size and make masonry faster and easier, while reducing the use of mortar.

- -

- The negative side is the relatively high degree of water absorption, which makes the blocks unsuitable for use in wet environments. If they are used in humid conditions, they need to be protected with appropriate waterproofing.

- -

- Another limitation of the research presented here is the extent of the physical and mechanical properties of the new material presented here. We are aware that research on alternative materials typically requires more properties to be investigated as well as deeper scientific analysis (evidence) to support and explain the observed properties. The capacity of our research laboratories has been the major limiting factor to undertaking microstructural analysis and/or some simulation work. Our future research will include microstructural investigation (SEM/BSE/EDS, etc.) and related thermal analysis (e.g., TGA) to help explain the relationship between the raw materials, processing, and resulting properties, while simulations and modelling (for strength and thermal properties) will provide further insight and predictive power.

- -

- Furthermore, the potential for sintering or lowering the temperature of firing will contribute to absorption reduction. New ingredients in the recipes need to be tested. Possibly, waste materials can be used as a partial replacement for other aggregate or for binding.

- -

- Life-cycle analysis as a tool for the assessment of sustainability is necessary, in order to calculate the embodied energy and embodied carbon in the material.

- -

- Durability in wet/dry cycling conditions should be improved with waterproof coatings. The choice will depend on further analysis and calculation.

- -

- Geological genesis of the natural rock needs further in-depth investigation and tests. At least, the following tests are recommended: XRF, XRD, Inductively Coupled Plasma Mass Spectrometry (ICP MS), Scanning Electron Microscopy, Magnetic susceptibility, Isotope Analysis, regional geological contextualisation and connection with volcanic areas/centres and sedimentary deposition areas. An approach such as that of Pedersen et al. [38] can be suggested.

- -

- Eventually, a cost–benefit analysis will make the red clay comparable to other alternatives.

The general conclusion is that red solid clay has favourable physical and mechanical parameters. It can be used as a fine aggregate for the production of composite masonry blocks. Crushed red solid clay aggregate makes composite masonry blocks lighter and more energy efficient than traditional concrete blocks and standard masonry bricks.

The red solid clay from the “Crvena Mogila” locality is an economically viable material. The costs for its exploitation are minimal due to the ordinary excavators and loaders for mining. In addition, the material itself is easy to process and can be used in different variants in construction and industry. Further studies are recommended to better understand the geological origin of the material, as well as the definition of material reserves at the locality and the wider area, in order to make advanced economic analyses.

Author Contributions

Conceptualization, T.S.; Methodology, T.S. and I.P.; Validation, B.G.; Formal analysis, T.S. and V.Z.P.; Investigation, B.G., M.J. and S.A.; Resources, I.P.; Data curation, M.J.; Writing—original draft, T.S.; Writing—review & editing, T.S., I.P. and V.Z.P.; Supervision, T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data are contained within the article. The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

This research work has been carried out under the support of the Faculty of Civil Engineering, Ss. Cyril and Methodius University in Skopje, and the laboratory of the construction company “Civil Engineering Institute Makedonija”—Skopje.

Conflicts of Interest

Bojan Golaboski is employed by Civil Engineering Institute Makedonija. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest

References

- Arenas, N.F.; Shafique, M. Reducing embodied carbon emissions of buildings—A key consideration to meet the net zero target. Sustain. Futures 2024, 7, 100166. [Google Scholar] [CrossRef]

- Myint, N.N.; Shafique, M. Embodied carbon emissions of buildings: Taking a step towards net zero buildings. Case Stud. Constr. Mater. 2024, 20, e03024. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- Al-Ani, T.; Sarapää, O. Clay and Clay Mineralogy; Geological Survey of Finland: Espoo, Finland, 2008. [Google Scholar]

- Mukherjee, S. The Science of Clays; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Lechner, N. Heating, Cooling, Lighting: Sustainable Design Methods for Architects; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Adazabra, A.N.; Viruthagiri, G.; Shanmugam, N. An assessment on the sustainable production of construction clay bricks with spent shea waste as renewable ecological material. J. Environ. Waste Manag. Recycl. 2018, 1, 36–46. [Google Scholar]

- Rasool, A.M.; Hameed, A.; Qureshi, M.U.; Ibrahim, Y.E.; Qazi, A.U.; Sumair, A. Experimental study on strength and endurance performance of burnt clay bricks incorporating marble waste. J. Asian Arch. Build. Eng. 2022, 22, 240–255. [Google Scholar] [CrossRef]

- Nuchnapa, T.; Sopita, M.; Atima, N.; Watchara, S.; Anuvat, S. Enhancing physical-thermal-mechanical properties of fired clay bricks by eggshell as a bio-filler and flux. Sci. Sinter. 2019, 51, 1–13. [Google Scholar]

- Ansari, A.A.; Mangi, S.A.; Khoso, S.; Khatri, K.L.; Solangi, G.S. Latest Development in the Structural Material Consisting of Reinforced Baked Clay. In Proceedings of the 7th International Civil Engineering Congress (ICEC-2015) “Sustainable Development through Advancements in Civil Engineering”, Karachi, Pakistan, 12–13 June 2015; Arif, F., Gazder, U., Lodi, S.H., Eds.; pp. 35–43. [Google Scholar]

- Elaborate for ore reserves of deposit “Crvena Mogila”-Delcevo, GRO Granit—Skopje, Macedonia. 1982.

- Shubbar, A.A.; Sadique, M.; Kot, P.; Atherton, W. Future of clay-based construction materials—A review. Constr. Build. Mater. 2019, 210, 172–187. [Google Scholar] [CrossRef]

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301. [Google Scholar] [CrossRef]

- Kipsanai, J.J.; Wambua, P.M.; Namango, S.S.; Amziane, S. A Review on the Incorporation of Diatomaceous Earth as a Geopolymer-Based Concrete Building Resource. Materials 2022, 15, 7130. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Bernardo, L.F.A. The Use of Waste Ceramic in Concrete: A Review. CivilEng 2024, 5, 482–500. [Google Scholar] [CrossRef]

- Main mining design for surface exploitation of solid clay from deposit “Crvena Mogila”—Delcevo, Mining design bureau “Rudproekt”, Skopje. 1989.

- Jovanovski, M. Elaborate on detailed geological investigations on solid clay at the locality Crvena Mogila in Delchevo. Ss. Cyril and Methodius University, Faculty of Civil Engineering, Skopje. 2011. [Google Scholar]

- Sutar, S.; Patil, P.V.; Ravan, C.V.; Maske, M.M. Study and Review of Ordinary Portland Cement. ASEAN J. Sci. Eng. 2021, 1, 153–160. [Google Scholar] [CrossRef]

- Saidi, T.; Hasan, M. The effect of partial replacement of cement with diatomaceous earth (DE) on the compressive strength and absorption of mortar. J. King Saud Univ.–Eng. Sci. 2020, 34, 250–259. [Google Scholar] [CrossRef]

- Zhang, H.; He, B.; Zhao, B.; Monteiro, P.J.M. Using diatomite as a partial replacement of cement for improving the performance of recycled aggregate concrete (RAC)-Effects and mechanism. Constr. Build. Mater. 2023, 385, 131518. [Google Scholar] [CrossRef]

- MKS EN 1926; Natural Stone Test Methods—Determination of Uniaxial Compressive Strength. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 12371; Natural Stone Test Methods—Determination of Frost Resistance. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2011.

- MKS EN 1925; Natural Stone Test Methods—Determination of Water Absorption Coefficient by Capillarity. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 13755; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2010.

- MKS EN 772-1; Methods of Test for Masonry Units Part 1: Determination of Compressive Strength. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2015.

- MKS EN 771-1; Specification for Masonry Units—Part 1: Clay Masonry Units. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2016.

- MKS EN 772-21; Methods of Test for Masonry Units—Part 21: Determination of Water Absorption of Clay and Calcium Silicate Masonry Units by Cold Water Absorption. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2013.

- EN 772-3; Methods of Test for Masonry Units—Part 3: Determination of Net Volume and Percentage of Voids of Clay Masonry Units by Hydrostatic Weighing. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2009.

- MKS ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2016.

- MKS EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. Standardization Institute of the Republic of North Macedonia: Skopje, North Macedonia, 2009.

- Debbarma, S.; Ransinchung R.N, G.D.; Dhaka, M. Effects of a Portland cement additive rich in SiO2 and Al2O3 in microstructure densification of RAP incorporated RCCP mixes. Constr. Build. Mater. 2020, 258, 119626. [Google Scholar] [CrossRef]

- Jamal, M.A.; Mohammed, A.S.; Ali, J.A. Modeling the impact of SiO2, Al2O3, CaO, and Fe2O3 on the compressive strength of cement modified with nano-silica and silica fume. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 156. [Google Scholar] [CrossRef]

- Liang, C.F.; Ma, H.; Pan, Y.; Ma, Z.; Duan, Z.; He, Z. Chloride permeability and the caused steel corrosion in the concrete with carbonated recycled aggregate. Constr. Build. Mater. 2019, 218, 506–518. [Google Scholar] [CrossRef]

- Rakhila, Y.; Ezzahi, A.; Elmchaouri, A.; Mestari, A. Synthesis and Characterization of a Red Clay Based New Composite Ceramic Material. Adv. Mater. Phys. Chem. 2018, 8, 295–310. [Google Scholar] [CrossRef]

- Lu, X.; Yu, Q.; Xu, J.; Yue, B.; Sheng, M. Comparative Experimental Study on Strength Properties of Red Clay Modified by Cement and Industrial Solid Waste Powder. Adv. Civ. Eng. 2023, 2023, 6645563. [Google Scholar] [CrossRef]

- Ji, S.; Gu, Q.; Xia, B. Porosity dependence of mechanical properties of solid materials. J. Mater. Sci. 2006, 41, 1757–1768. [Google Scholar] [CrossRef]

- Pedersen, G.K.; Pedersen, S.A.S.; Steffensen, J. Clay content of a clayey diatomite, the Early Eocene Fur Formation, Denmark. Bull. Geol. Soc. Den. 2004, 51, 159–177. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).