The Environmental Impacts of Façade Renovation: A Case Study of an Office Building

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Office Building

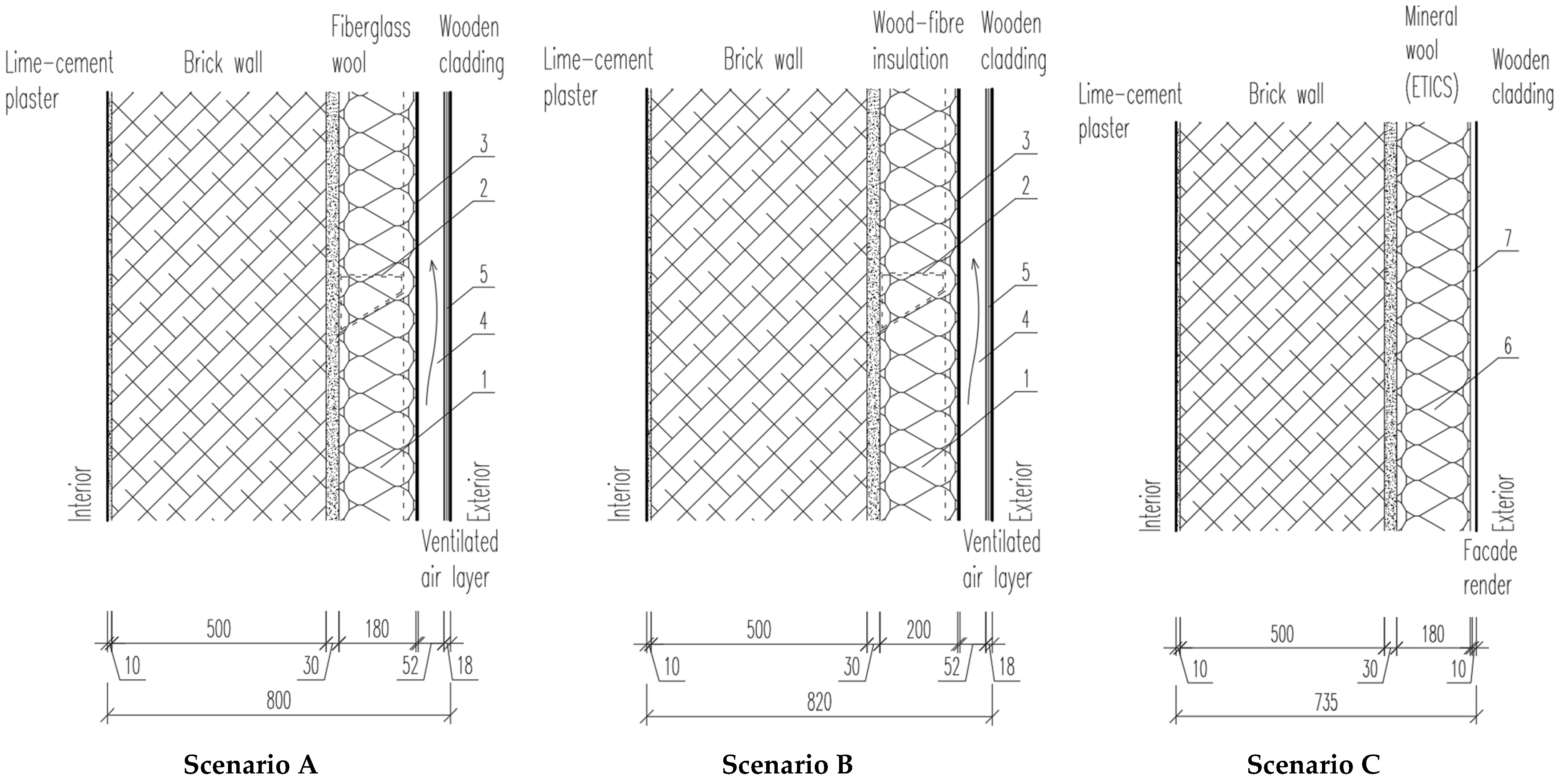

2.2. Scenarios Analysed

2.3. Methodology of the Study

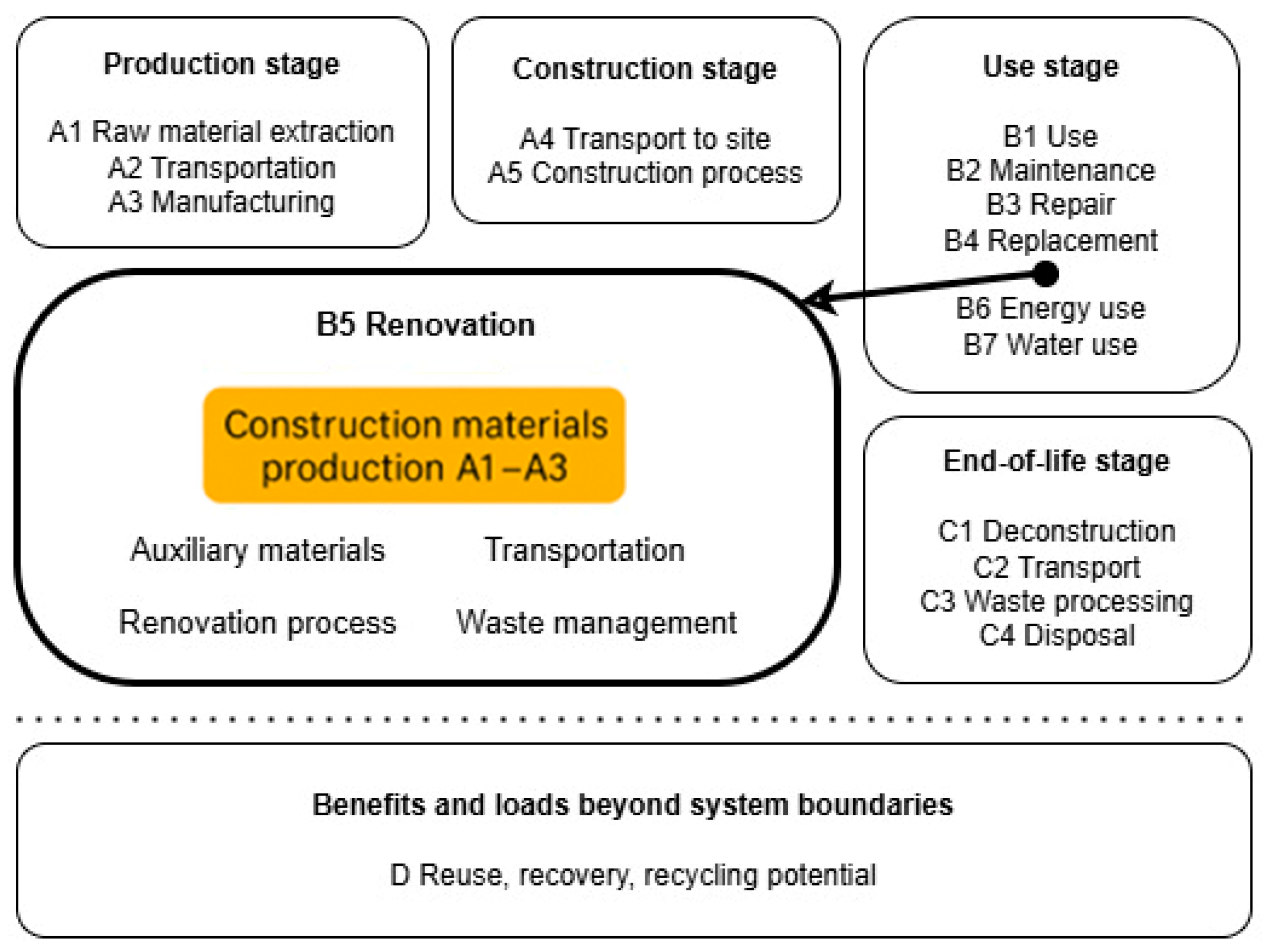

2.3.1. Life Cycle Inventory

2.3.2. Life Cycle Impact Assessment

2.3.3. Proposal of an Integrated Evaluation Framework—Composite Environmental Index (CEI)

3. Results

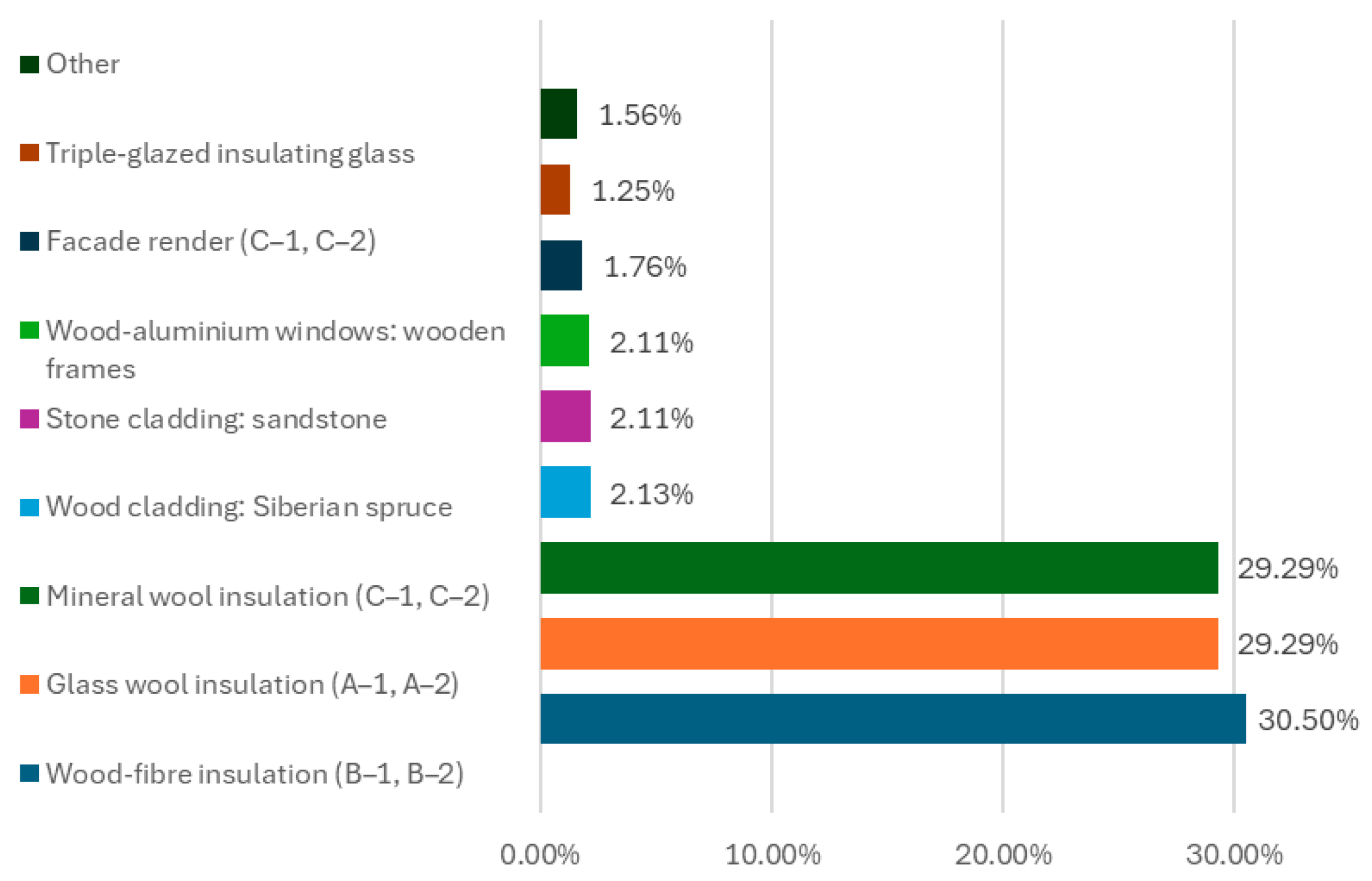

3.1. Mass and Volumetric Distribution of Materials

3.2. Influence of Window Type

3.3. Influence of Façade Type

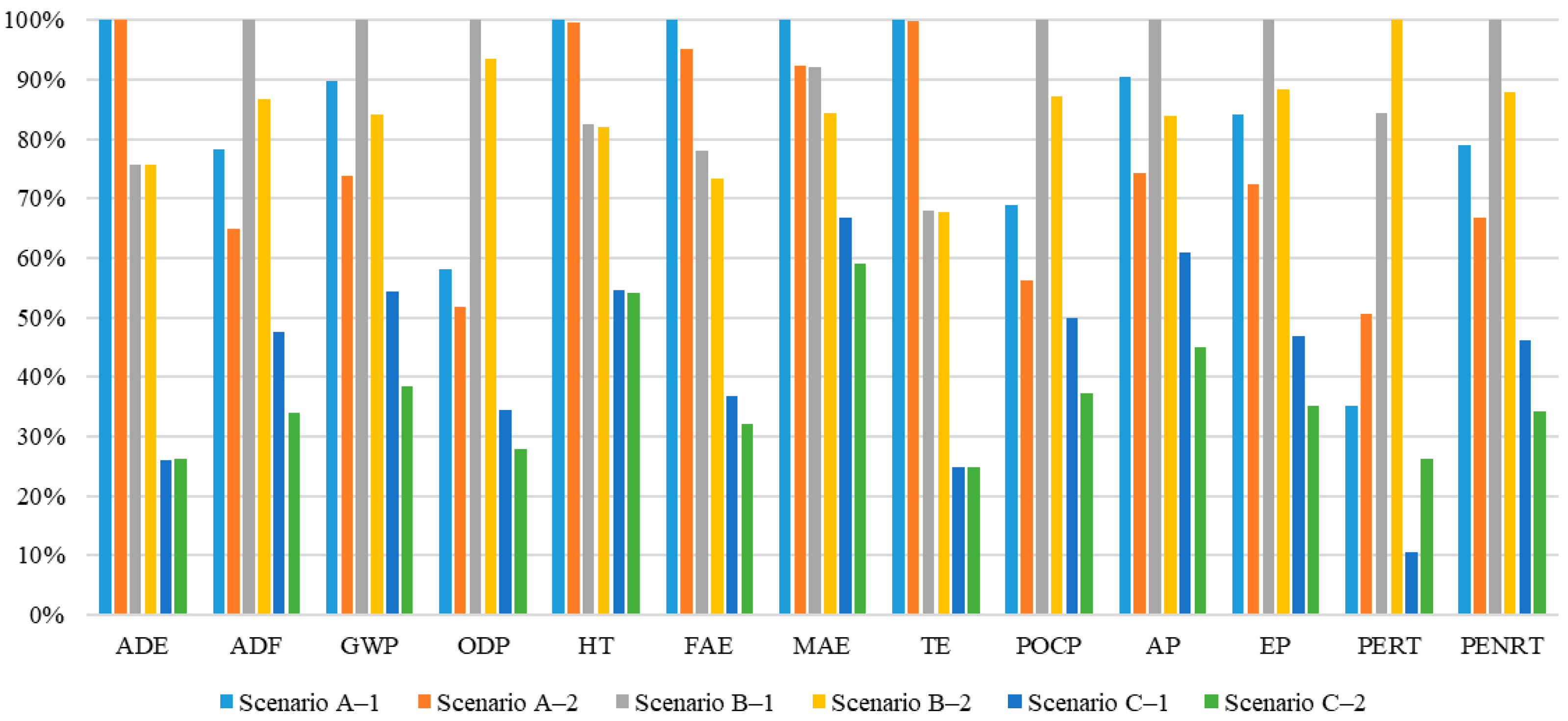

3.4. Normalisation Results

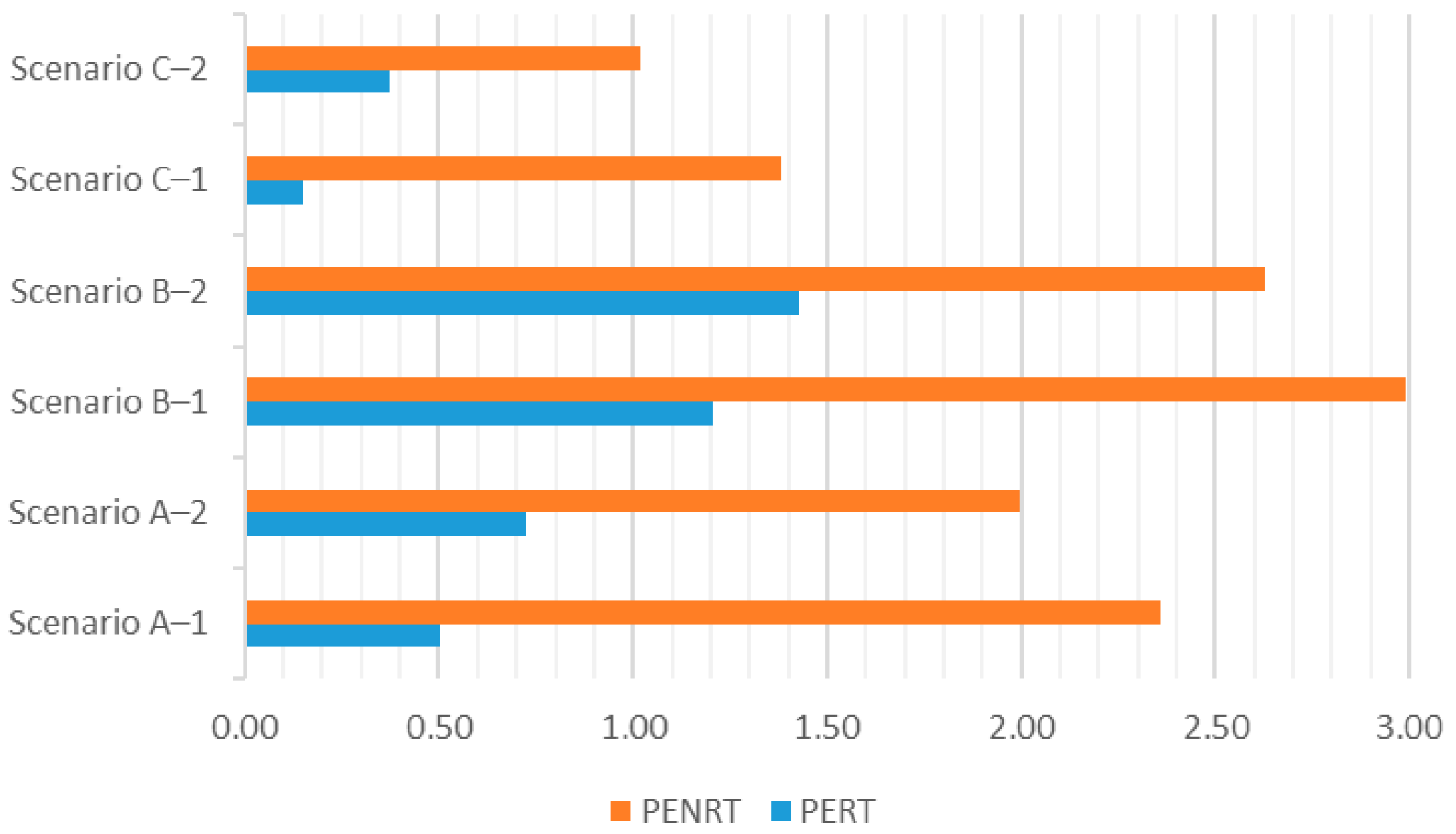

3.5. Primary Energy Share

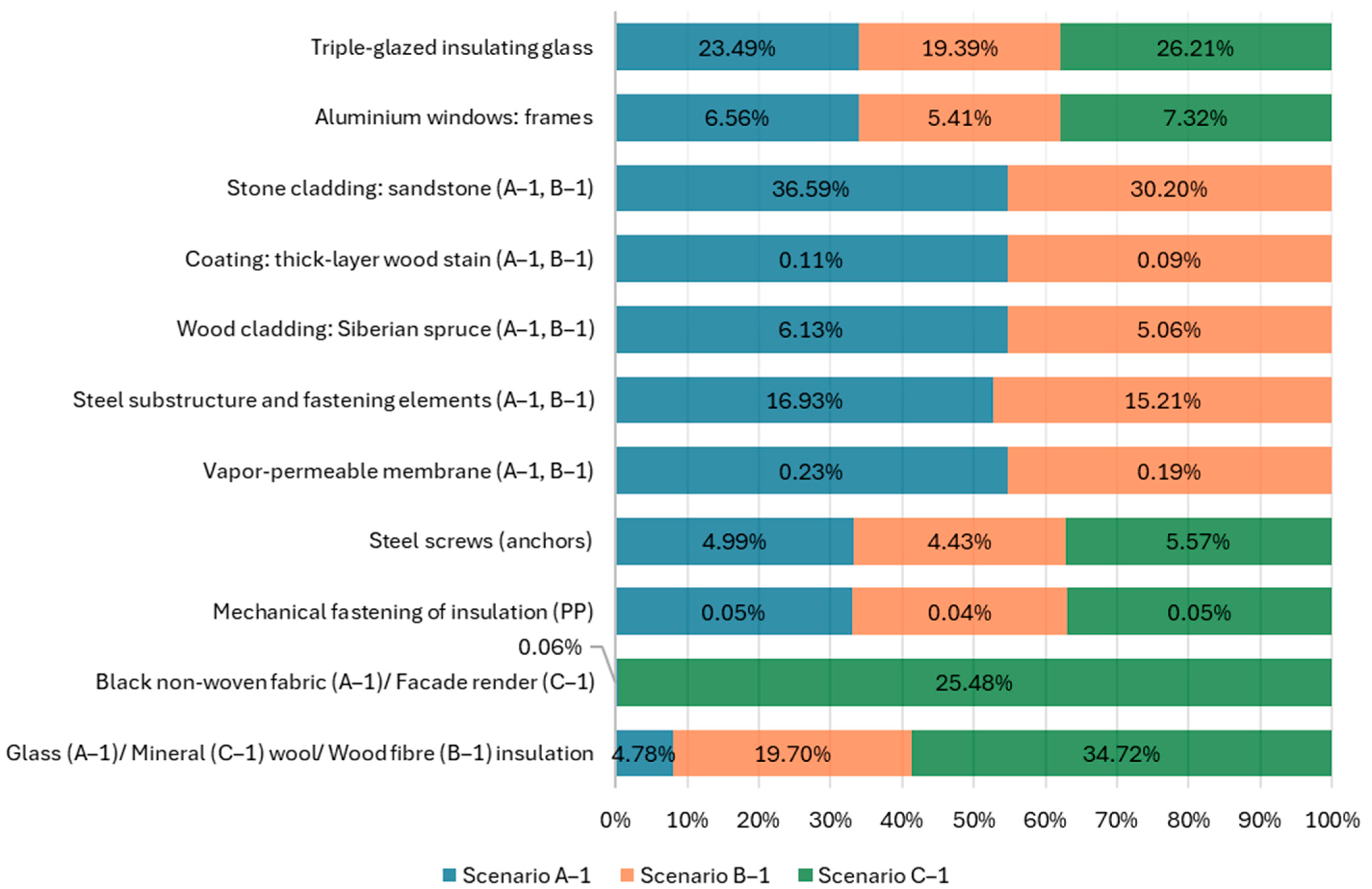

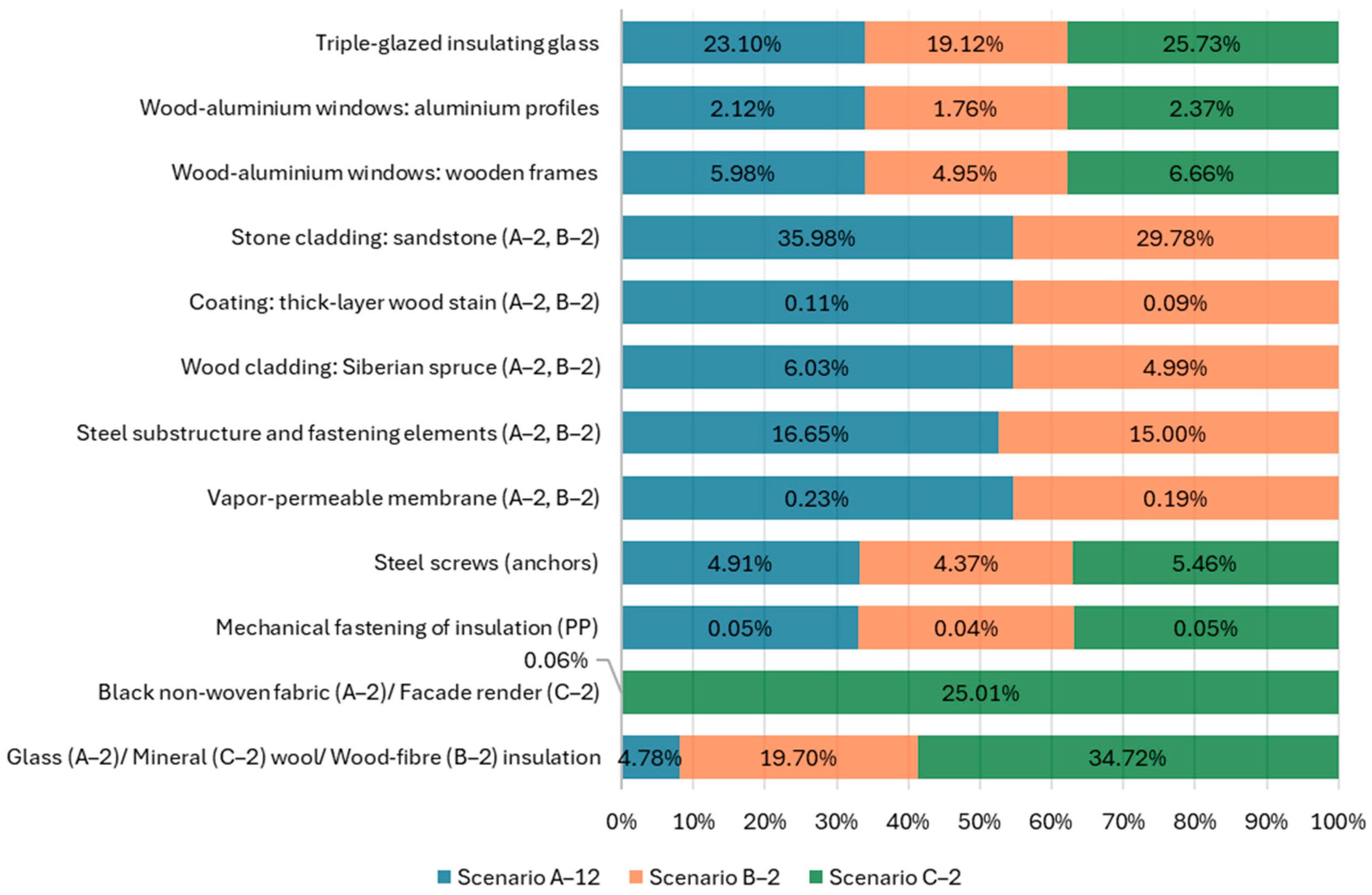

3.6. Proportional Impact of Construction Elements

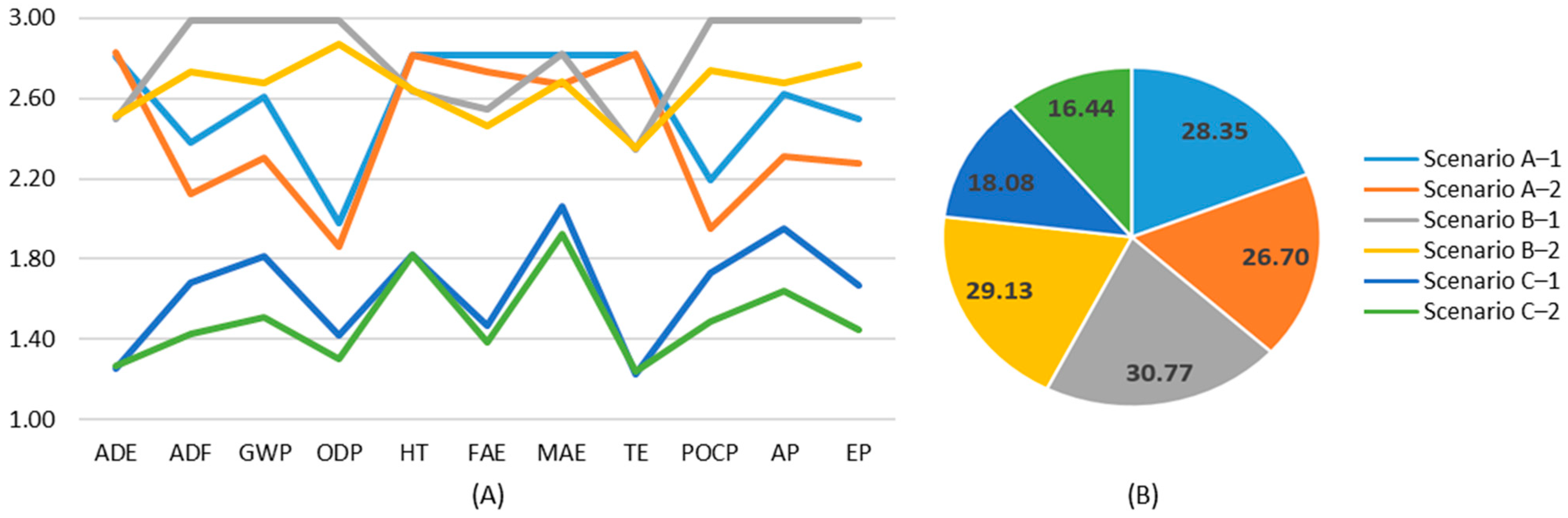

3.7. Composite Environmental Index (CEI) Assessment

3.8. Uncertainty Assessment

3.9. Limitations of the Study

4. Discussion

5. Conclusions

- Wood–aluminium windows (scenarios A–2, B–2 and C–2) have a lower impact than aluminium windows (scenarios A–1, B–1 and C–1) in the categories ADF, GWP, ODP, FAE, MAE, POCP, AP, and EP, and a comparable impact in the categories ADE, HT, and TE;

- The building façade in scenario A (A–1 and A–2) shows the worst performance in the categories ADE, HT, FAE, MAE, and TE;

- Scenario B performs the worst in the categories ADF, GWP, ODP, POCP, AP, and EP;

- Scenario C (C–1 and C–2) exhibits the most favourable environmental performance, showing the lowest impact in all assessed categories;

- Based on the assessment, the contact façade system using mineral wool and façade render (ETICS), in combination with wood–aluminium windows (scenario C–2), is clearly identified as the most environmentally favourable variant across all evaluated categories.

- The application of the composite environmental index (CEI) revealed that façade composition has a more significant impact on overall environmental performance than window type, with scenario C–2 emerging as the most favourable option and scenario B–2 as the least, based on cumulative index values.

- Uncertainty analysis revealed that HT and TE categories are unreliable, so further validation is needed when using these values for direct decision-making. On the other hand, the results of GWP, AP and ODP showed the highest reliability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Impact Category | Unit | Scenario A–1 | Scenario A–2 | Scenario B–1 | Scenario B–2 | Scenario C–1 | Scenario C–2 |

|---|---|---|---|---|---|---|---|

| ADE | g Sb eq | 3.11 | 3.12 | 2.36 | 2.36 | 0.81 | 0.82 |

| ADF | GJ | 2.11 | 1.75 | 2.70 | 2.34 | 1.28 | 0.92 |

| GWP | kg CO2 eq | 202.56 | 166.58 | 225.53 | 189.54 | 122.43 | 86.44 |

| ODP | mg CFC-11 eq | 1.37 | 1.22 | 2.36 | 2.21 | 0.81 | 0.66 |

| HT | t 1,4-DB eq | 3.81 | 3.79 | 3.14 | 3.12 | 2.07 | 2.06 |

| FAE | kg 1,4-DB eq | 656.40 | 625.12 | 512.63 | 481.35 | 241.33 | 210.05 |

| MAE | kt 1,4-DB eq | 1.22 | 1.13 | 1.13 | 1.03 | 0.82 | 0.72 |

| TE | kg 1,4-DB eq | 81.58 | 81.49 | 55.38 | 55.30 | 20.32 | 20.23 |

| POCP | g C2H4 eq | 51.50 | 41.93 | 74.67 | 65.09 | 37.30 | 27.73 |

| AP | kg SO2 eq | 1.02 | 0.84 | 1.13 | 0.95 | 0.69 | 0.51 |

| EP | g PO43-eq | 281.21 | 241.85 | 334.46 | 295.10 | 156.54 | 117.18 |

| PERT | GJ | 0.50 | 0.72 | 1.21 | 1.43 | 0.15 | 0.37 |

| PENRT | GJ | 2.36 | 2.00 | 2.99 | 2.63 | 1.38 | 1.02 |

References

- Hesse, T.; Braungardt, S. EU 2040 Climate Target: Contributions of the Buildings Sector; Oeko Institute: Freiburg, Germany, 2024. [Google Scholar]

- Österbring, M.; Mata, É.; Thuvander, L.; Wallbaum, H. Explorative life-cycle assessment of renovating existing urban housing-stocks. Build. Environ. 2019, 165, 106391. [Google Scholar] [CrossRef]

- Gkatzogias, K.; Veljkovic, A.; Pohoryles, D.; Tsionis, G.; Bournas, D.; Crowley, H.; Norlén, H.; Butenweg, C.; Gervasio, H.; Manfredi, V.; et al. Policy Practice and Regional Impact Assessment for Building Renovation—REEBUILD: Integrated Techniques for the Seismic Strengthening and Energy Efficiency of Existing Buildings; Gkatzogias, K., Tsionis, G., Eds.; Publications Office of the European Union: Luxembourg, 2022; JRC131250. [Google Scholar] [CrossRef]

- European Commission. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Berg, F.; Fuglseth, M. Life cycle assessment and historic buildings: Energy-efficiency refurbishment versus new construction in Norway. J. Archit. Conserv. 2018, 24, 152–167. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life Cycle Assessment (LCA) of Building Refurbishment: A Literature Review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Technical Committee ISO/TC 207. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO/TC 207/SC 5. ISO: Geneva, Switzerland, 2006.

- Fahlstedt, O.; Rasmussen, N.F.; Temeljotov-Salaj, A.; Huang, L.; Bohne, A.R. Building renovations and life cycle assessment—A scoping literature review. Renew. Sustain. Energy Rev. 2024, 203, 114774. [Google Scholar] [CrossRef]

- Fahlstedt, O.; Temeljotov-Salaj, A.; Lohne, J.; Bohne, A.R. Holistic assessment of carbon abatement strategies in building refurbishment literature—A scoping review. Renew. Sustain. Energy Rev. 2022, 167, 112636. [Google Scholar] [CrossRef]

- Bragadin, A.M.; Guardigli, L.; Calistri, C.; Ferrante, A. Demolishing or Renovating? Life Cycle Analysis in the Design Process for Building Renovation: The ProGETonE Case. Sustainability 2023, 15, 8614. [Google Scholar] [CrossRef]

- Rabani, M.; Madesaa, B.H.; Ljungström, M.; Aamodt, L.; Løvvold, S.; Nord, N. Life cycle analysis of GHG emissions from the building retrofitting: The case of a Norwegian office building. Build. Environ. 2021, 204, 108159. [Google Scholar] [CrossRef]

- Bragadin, A.M.; Calistri, M.; Predari, G. LCA-based strategic evaluation for building renovation construction projects. In Proceedings of the 12th Nordic Conference on Construction Economics and Organisation, Trondheim, Norway, 30–31 May 2024. [Google Scholar]

- Chandrasekaran, V.; Dvarioniene, J.; Vitkute, A.; Gecevicius, G. Environmental Impact Assessment of Renovated Multi-Apartment Building Using LCA Approach: Case Study from Lithuania. Sustainability 2021, 13, 1542. [Google Scholar] [CrossRef]

- Hasik, V.; Escott, E.; Bates, R.; Carlisle, S.; Faircloth, B.; Bilec, M.M. Comparative whole-building life cycle assessment of renovation and new construction. Build. Environ. 2019, 161, 1062018. [Google Scholar] [CrossRef]

- Wrålsen, B.; O’Born, R.; Skaar, C.H. Life cycle assessment of an ambitious renovation of a Norwegian apartment building to nZEB standard. Energy Build. 2018, 177, 197–206. [Google Scholar] [CrossRef]

- Schaubroeck, S.; Schaubroeck, T.; Baustert, P.; Gibon, T.; Benetto, E. When to replace a product to decrease environmental impact?—A consequential LCA framework and case study on car replacement. Int. J. Life Cycle Assess. 2020, 25, 1500–1521. [Google Scholar] [CrossRef]

- Huuhka, S.; Moisio, M.; Salmio, E.; Köliö, A.; Lahdensivu, J. Renovate or replace? Consequential replacement LCA framework for buildings. Build. Cities 2023, 4, 212–228. [Google Scholar] [CrossRef]

- Kuittinen, M.; Häkkinen, T. Reduced carbon footprints of buildings: New Finnish standards and assessments. Build. Cities 2020, 1, 182–197. [Google Scholar] [CrossRef]

- Lechtenböhmer, S.; Schüring, A. The potential for large-scale savings from insulating residential buildings in the EU. Energy Effic. 2011, 4, 257–270. [Google Scholar] [CrossRef]

- Mišík, M.; Oravcová, V. Energy efficiency of buildings in Central and Eastern Europe: Room for improvement. Energy Effic. 2023, 17, 32. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A.M. Residential Building Envelope Energy Retrofit Methods, Simulation Tools, and Example Projects: A Review of the Literature. Buildings 2022, 12, 954. [Google Scholar] [CrossRef]

- Sojkova, K.; Volf, M.; Lupisek, A.; Bolliger, R.; Vachal, T. Selection of favourable concept of energy retrofitting solution for social housing in the Czech Republic based on economic parameters, greenhouse gases, and primary energy consumption. Sustainability 2019, 11, 6842. [Google Scholar] [CrossRef]

- Motuziene, V.; Juodis, E.S. Simulation based complex energy assessment of office building fenestration. J. Civ. Eng. Manag. 2010, 16, 345–351. [Google Scholar] [CrossRef]

- Košir, M.; Gostiša, T.; Kristl, Ž. Influence of architectural building envelope characteristics on energy performance in Central European climatic conditions. J. Build. Eng. 2018, 15, 278–288. [Google Scholar] [CrossRef]

- Wang, G.; Luo, T.; Luo, H.; Liu, R.; Liu, Y.; Liu, Z. A Comprehensive Review of Building Lifecycle Carbon Emissions and Reduction Approaches. City Built Environ. 2024, 2, 12. [Google Scholar] [CrossRef]

- Obead, R.; Khaddour, L.; D’Amico, B. Historical Building Energy Retrofit Focusing on the Whole Life Cycle Assessment—A Systematic Literature Review. Architecture 2025, 5, 49. [Google Scholar] [CrossRef]

- Favi, C.; Germani, M.; Marconi, M.; Mandolini, M. The Application of Life Cycle Assessment in Buildings: Challenges, and Directions for Future Research. Int. J. Life Cycle Assess. 2022, 27, 1221–1240. [Google Scholar] [CrossRef]

- STN 73 0540-2: 2019; Thermal Protection of Buildings. Thermal Performance of Buildings and Components. Part 2: Functional Requirements. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2019.

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro; PRé Sustainability: Amersfoort, The Netherlands, 2016; Available online: https://pre-sustainability.com/files/2014/05/SimaPro8IntroductionToLCA.pdf (accessed on 20 July 2025).

- Ecoinvent. Ecoinvent v3.11. Available online: https://ecoinvent.org/ecoinvent-v3-11/#webinar-introduction-to-ecoinvent-version-3-11 (accessed on 20 July 2025).

- STN EN 15804+A2 2020; Sustainability of Construction Works. Environmental Product Declarations. Core Rules for the Product Category of Construction Products. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020.

- Moghtadernejad, S.; Chouinard, L.E.; Mirza, M.S. Design strategies using multi-criteria decision-making tools to enhance the performance of building façades. J. Build. Eng. 2020, 30, 101247. [Google Scholar] [CrossRef]

- Tahmasbi, F.; Khdair, I.A.; Aburumman, A.G.; Tahmasebi, M.; Thi, H.N.; Afrand, M. Energy-efficient building façades: A comprehensive review of innovative technologies and sustainable strategies. J. Build. Eng. 2025, 99, 111643. [Google Scholar] [CrossRef]

- Beneito, L.; Konsantinou, T.; Torres-Ramo, J.; Sánches-Ostiz, A. Towards decarbonisation in the built environment: A comparative analysis of conventional vs. industrialised façades in nearly zero-energy building renovations. Energy Build. 2025, 342, 115885. [Google Scholar] [CrossRef]

- Gonçalves, M.; Figueiredo, A.; Almeida, F.S.M.R.; Vicente, R. Dynamic façades in buildings: A systematic review across thermal comfort, energy efficiency and daylight performance. Renew. Sustain. Energy Rev. 2024, 199, 114474. [Google Scholar] [CrossRef]

- Van Gulck, L.; Van de Putte, S.; Delghust, M.; Van den Bossche, N.; Steeman, M. Environmental and financial assessment of façade renovations designed for change: Developing optimal scenarios for apartment buildings in Flanders. Build. Environ. 2020, 183, 107178. [Google Scholar] [CrossRef]

- Apostolopoulos, V.; Mamounakis, I.; Seitaridis, A.; Tagkoulis, N.; Korkoumpas, S.D.; Iliadis, P.; Angelakoglou, K.; Nikolopoulos, N. An integrated life cycle assessment and life cycle costing approach towards sustainable building renovation via a dynamic online tool. Appl. Energy 2023, 334, 120710. [Google Scholar] [CrossRef]

- Gao, J.; Lu, F. Evaluating green policies: A comparative analysis of subsidies and public procurement in green transition. Econ. Anal. Policy 2025, 86, 1675–1694. [Google Scholar] [CrossRef]

- Xue, Q.; Wang, Z.; Chen, Q. Multi-Objective Optimization of Building Design for Life Cycle Cost and CO2 Emissions: A Case Study of a Low-Energy Residential Building in a Severe Cold Climate. Build. Simul. 2022, 15, 83–98. [Google Scholar] [CrossRef]

- Füchsl, S.; Rheude, F.; Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 2022, 5, 10011. [Google Scholar] [CrossRef]

- Pawelzik, P.; Carus, M.; Hotchkiss, J.; Narayan, R.; Selke, S.; Wellisch, M.; Weiss, M.; Wicke, B.; Patel, K.M. Critical aspects in the life cycle assessment (LCA) of bio-based materials Reviewing methodologies and deriving recommendations. Resour. Conserv. Recycl. 2013, 73, 211–228. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Sedláková, A.; Vilčeková, S.; Burák, D.; Tomková, Ž.; Moňoková, A.; Doroudiani, S. Environmental impacts assessment for conversion of an old mill building into a modern apartment building through reconstruction. Build. Environ. 2020, 172, 106734. [Google Scholar] [CrossRef]

- Beylot, A.; Ardente, F.; Sala, S.; Zampori, L. Accounting for the dissipation of abiotic resources in LCA: Status, key challenges and potential way forward. Resour. Conserv. Recycl. 2020, 157, 104748. [Google Scholar] [CrossRef] [PubMed]

- Rey-Álvarez, B.; Silvestre, J.; García-Martínez, A.; Sánchez-Montañés, B. A comparative approach to evaluate the toxicity of building materials through life cycle assessment. Sci. Total Environ. 2024, 912, 168897. [Google Scholar] [CrossRef] [PubMed]

- Rasul, G.M.; Arutla, R.K.L. Environmental impact assessment of green roofs using life cycle assessment. Energy Rep. 2020, 6, 503–508. [Google Scholar] [CrossRef]

- Kobetičová, K.; Černý, R. Terrestrial eutrophication of building materials and buildings: An emerging topic in environmental studies. Sci. Total Environ. 2019, 689, 1316–1328. [Google Scholar] [CrossRef] [PubMed]

- Lebrun, N.M.; Dorber, M.; Verones, F.; Henderson, D.A. Novel Endpoint Characterization Factors for Life Cycle Impact Assessment of Terrestrial Acidification. Ecol. Indic. 2025, 171, 113241. [Google Scholar] [CrossRef]

- JRC Technical Reports. Development of a Weighting Approach for the Environmental Footprint. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC106545/jrc106545_weighting__on_line-1.pdf (accessed on 20 July 2025).

- Beylot, A.; Ardente, F.; Sala, S.; Zampori, L. Development of a Weighting Approach for the Environmental Footprint. JRC Technical Reports. 2020. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC118681 (accessed on 14 July 2025).

- Bribián, Z.I.; Capilla, A.V.; Usón, A.A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Prado, V.; Cinelli, M.; Ter Haar, S.F.; Ravikumar, D.; Heijungs, R.; Guinée, J.; Seager, T.P. Sensitivity to weighting in life cycle impact assessment (LCIA). Int. J. Life Cycle Assess. 2020, 25, 2393–2406. [Google Scholar] [CrossRef]

| Parameter | Total Value |

|---|---|

| Total floor area (A) | 21,553 m2 |

| Volume of heated space (V) | 81,786 m3 |

| Surface area of the thermal envelope | 14,118 m2 |

| Total surface area of the perimeter walls, including window openings | 9545.1 m2 |

| Shape factor (A/V ratio) | 0.26 m2/m3 |

| Scenario | Insulation Type | Façade Finish | Window Type | Insulation Thickness (Brick/Concrete) | Architectural Preservation |

|---|---|---|---|---|---|

| A–1 | Glass wool | Wood + stone cladding | Aluminium | 160 mm/180 mm | Yes |

| A–2 | Glass wool | Wood + stone cladding | Wood–aluminium | 160 mm/180 mm | Yes |

| B–1 | Wood-fibre | Wood + stone cladding | Aluminium | 180 mm/200 mm | Yes |

| B–2 | Wood-fibre | Wood + stone cladding | Wood–aluminium | 180 mm/200 mm | Yes |

| C–1 | Mineral wool (ETICS) | Render | Aluminium | 160 mm/180 mm | No |

| C–2 | Mineral wool (ETICS) | Render | Wood–aluminium | 160 mm/180 mm | No |

| Scenario | Heat Transfer Coefficient U (W∙m−2∙K−1) | Thermal Resistance R (m2∙K∙W−1) | Water Vapor (kg∙m−2∙Year−1) | Phase Shift of Thermal Oscillation Ψ (h) | Thermal Damping Factor ν (-) | |

|---|---|---|---|---|---|---|

| Annual Amount of Condensed Water Vapor | Balance of Annual Amount of Condensed and Evaporated Water Vapor | |||||

| A | 0.189 | 5.093 | – 1 | – 1 | 11.917 | 294.622 |

| B | 0.191 | 5.016 | – 1 | – 1 | 19.724 | 668.808 |

| C | 0.187 | 5.166 | 0.352 | −1.661 2 | 12.941 | 286.827 |

| Parameter | State of the Building | Total Value 1 | Unit |

|---|---|---|---|

| Specific heat loss of the building | Before renovation | 30,918.58 | [W/K] |

| After renovation | 13,776.70 | ||

| Total heat losses | Before renovation | 2,287,340.44 | [kWh/year] |

| After renovation | 1,019,194.02 | ||

| Annual heating energy demand | Before renovation | 1,643,718.55 | [kWh/year] |

| After renovation | 365,051.91 | ||

| Specific heating energy demand | Before renovation | 100.34 | [kWh/m2∙year] |

| After renovation | 22.28 | ||

| Before renovation | 26.80 | [kWh/m3∙year] | |

| After renovation | 5.95 |

| Variant | Material | Unit | Quantity | Bulk Density [kg/Unit] | Mass [kg] 2 |

|---|---|---|---|---|---|

| Scenario A | Glass wool insulation (160 mm) | m3 | 643.54 | 23 | 16,281.46 |

| Glass wool insulation (180 mm) | m3 | 354.29 | 23 | 8963.64 | |

| Black non-woven fabric (bonded to the glass wool insulation) | m2 | 5990.40 | 0.05 | 329.47 | |

| Mechanical fastening of insulation using polypropylene (PP) anchors | m3 | 0.23 | 990 | 245.03 | |

| Steel screws (anchors) | m3 | 3.00 | 7850 | 25,905.00 | |

| Vapor-permeable membrane 1 | m2 | 5990.40 | 0.19 | 1219.05 | |

| Steel substructure and fastening elements for external cladding | m3 | 10.18 | 7850 | 87,936.08 | |

| Wood cladding: Siberian spruce 1 | m3 | 72.40 | 400 | 31,855.03 | |

| Coating: thick layer of wood stain 1 | m3 | 0.48 | 1050 | 557.46 | |

| Stone cladding: sandstone 1 | m3 | 71.97 | 2400 | 190,011.89 | |

| Aluminium windows: frames 1 | m3 | 11.46 | 2700 | 34,047.81 | |

| Triple-glazed insulating glass 1 | m3 | 42.66 | 2600 | 121,997.30 | |

| Wood–aluminium windows: wood frames 1 | m3 | 71.76 | 400 | 31,574.62 | |

| Wood–aluminium windows: aluminium profiles 1 | m3 | 3.78 | 2700 | 11,217.30 | |

| Scenario B | Wood-fibre insulation (180 mm) | m3 | 314.93 | 110 | 38,106.29 |

| Wood-fibre insulation (200 mm) | m3 | 723.98 | 110 | 87,601.34 | |

| Mechanical fastening of insulation using polypropylene (PP) anchors | m3 | 0.25 | 990 | 269.53 | |

| Steel screws (anchors) | m3 | 3.23 | 7850 | 27,847.88 | |

| Steel substructure and fastening elements for external cladding | m3 | 11.08 | 7850 | 95,695.14 | |

| Scenario C | Mineral wool insulation (160 mm) | m3 | 643.54 | 150 | 106,183.44 |

| Mineral wool insulation (180 mm) | m3 | 354.29 | 150 | 58,458.51 | |

| Façade render | m3 | 59.90 | 1800 | 118,609.92 | |

| Mechanical fastening of insulation using polypropylene (PP) anchors | m3 | 0.23 | 990 | 245.03 | |

| Steel screws (anchors) | m3 | 3.00 | 7850 | 25,905.00 |

| Impact Indicator | Impact Category | Description | Unit |

|---|---|---|---|

| ADE | Abiotic depletion of elements | Reduction in non-renewable natural resources—minerals and metals | [kg Sb eq] |

| ADF | Abiotic depletion of fossils | Reduction in non-renewable natural resources—fossil fuels | [MJ] |

| GWP | Global warming potential | Increase in average atmospheric temperature caused by greenhouse gas emissions | [kg CO2 eq] |

| ODP | Ozone depletion potential | Thinning of the ozone layer | [kg CFC-11 eq] |

| HT | Human toxicity | Adverse effect of chemical substances on human health | [kg 1,4-DCB eq] |

| FAE | Freshwater aquatic ecotoxicity | Adverse effect of chemical substances on freshwater, marine, and soil ecosystems | [kg 1,4-DCB eq] |

| MAE | Marine aquatic ecotoxicity | [kg 1,4-DCB eq] | |

| TE | Terrestrial ecotoxicity | [kg 1,4-DCB eq] | |

| POCP | Photochemical ozone creation potential | Pollution due to the presence of unburnt hydrocarbons and nitrogen oxides | [kg C2H4 eq] |

| AP | Acidification potential | Lowering the pH of lakes, rivers, forests, and soils | [kg SO2 eq] |

| EP | Eutrophication potential | Lowering of oxygen content in soils and surface waters | [kg PO43− eq] |

| PERT | Primary energy renewable total | Energy content of renewable and non-renewable resources before its conversion | [GJ] |

| PENRT | Primary energy non-renewable total | [GJ] |

| Impact Category | Scenario A–1 | Scenario A–2 | Scenario B–1 | Scenario B–2 | Scenario C–1 | Scenario C–2 |

|---|---|---|---|---|---|---|

| ADE | 22.20% | 22.90% | 19.40% | 21.80% | 23.50% | 21.60% |

| ADF | 17.50% | 16.30% | 13.90% | 13.70% | 18.90% | 16.60% |

| AP | 12.80% | 14.00% | 12.00% | 11.30% | 13.60% | 12.90% |

| EP | 37.20% | 38.30% | 36.70% | 32.30% | 33.00% | 36.00% |

| FAE | 64.50% | 55.90% | 49.90% | 50.00% | 34.20% | 39.00% |

| GWP | 12.10% | 13.20% | 10.70% | 10.10% | 12.80% | 11.70% |

| HT | 61.40% | 71.00% | 55.00% | 77.60% | 68.30% | 102.00% |

| MAE | 41.60% | 41.50% | 41.20% | 40.50% | 53.40% | 53.70% |

| ODP | 11.80% | 11.90% | 11.50% | 11.80% | 12.50% | 12.60% |

| POCP | 15.40% | 13.70% | 13.10% | 10.90% | 17.20% | 13.50% |

| TE | 176.00% | 407.00% | 235.00% | 812.00% | 339.00% | 1050.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Štompf, P.; Vaňová, R.; Jochim, S. The Environmental Impacts of Façade Renovation: A Case Study of an Office Building. Sustainability 2025, 17, 6766. https://doi.org/10.3390/su17156766

Štompf P, Vaňová R, Jochim S. The Environmental Impacts of Façade Renovation: A Case Study of an Office Building. Sustainability. 2025; 17(15):6766. https://doi.org/10.3390/su17156766

Chicago/Turabian StyleŠtompf, Patrik, Rozália Vaňová, and Stanislav Jochim. 2025. "The Environmental Impacts of Façade Renovation: A Case Study of an Office Building" Sustainability 17, no. 15: 6766. https://doi.org/10.3390/su17156766

APA StyleŠtompf, P., Vaňová, R., & Jochim, S. (2025). The Environmental Impacts of Façade Renovation: A Case Study of an Office Building. Sustainability, 17(15), 6766. https://doi.org/10.3390/su17156766