Towards Sustainable Construction: Systematic Review of Lean and Circular Economy Integration

Abstract

1. Introduction

2. Literature Review

2.1. Lean Construction

2.2. Circular Economy

2.3. Synergies, Theoretical Tensions and Gaps

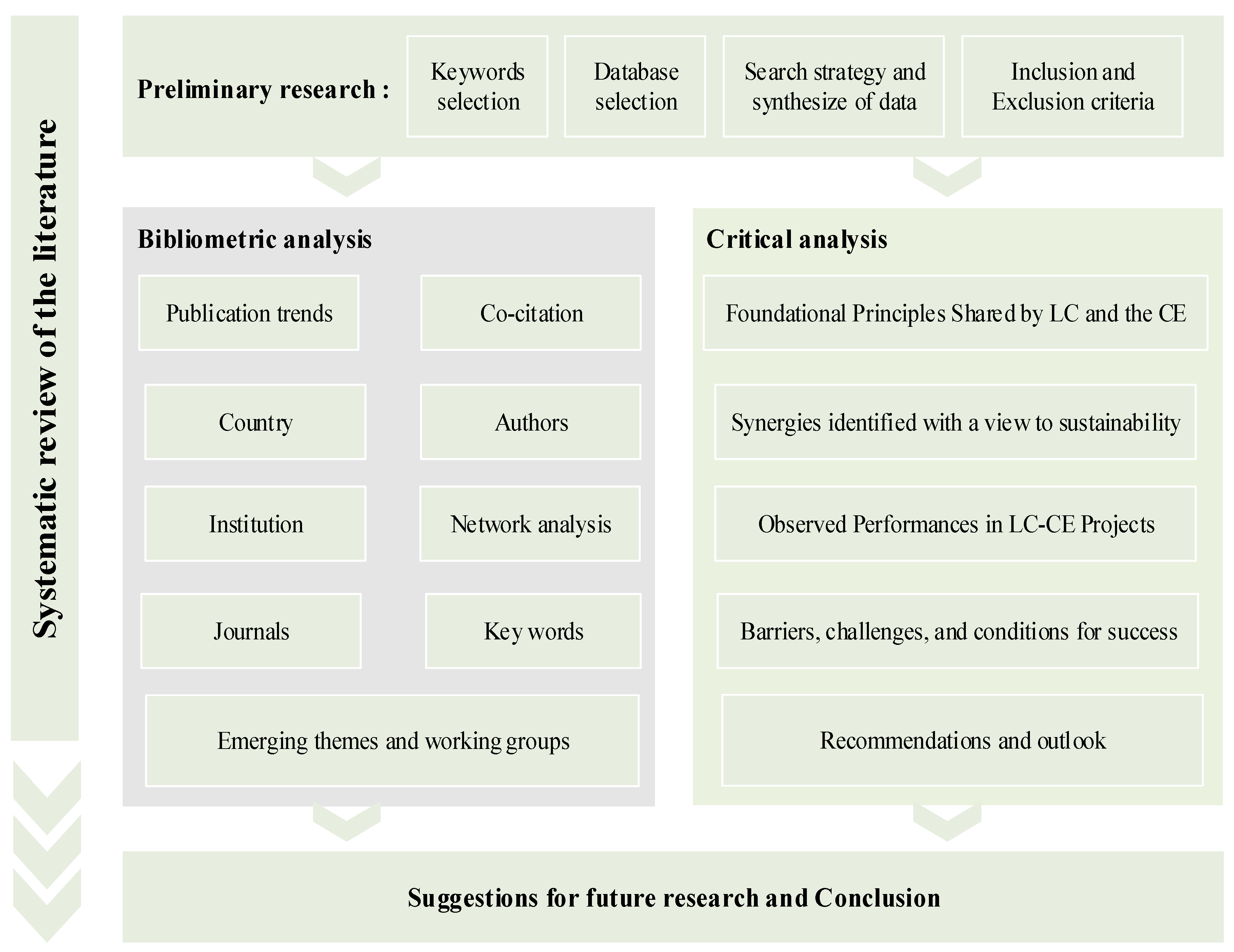

3. Methodology

3.1. Objective

- (i)

- Bibliometric analysis to trace the evolution and intellectual structure.

- (ii)

- Qualitative content analysis to extract thematic insights from selected articles.

“How does the integration of LC principles and CE strategies contribute to improving the efficiency and sustainability of construction projects, and with what observed outcomes?”

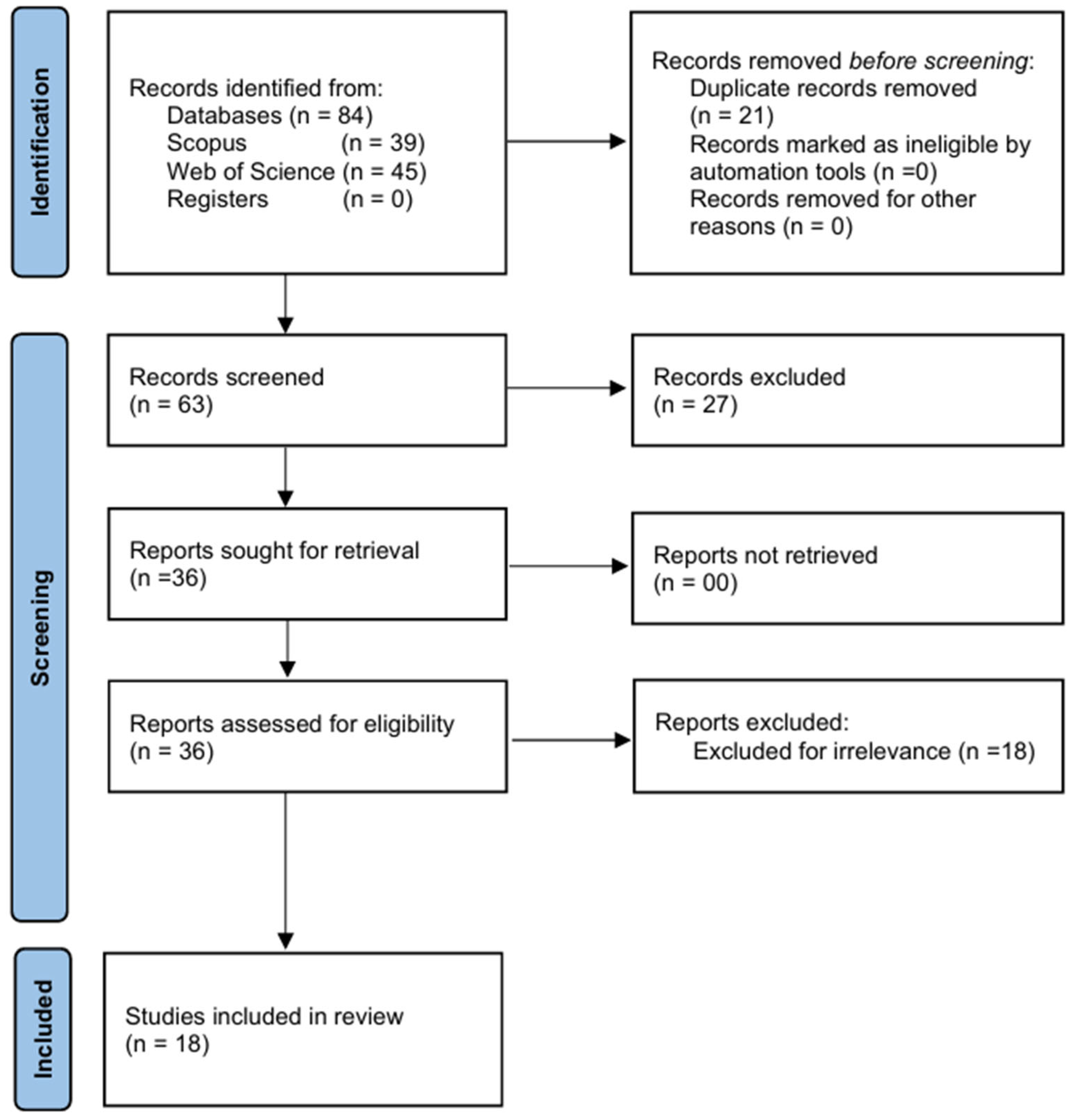

3.2. Literature Search Strategy

- ○

- LC: (“Lean” OR “LPS” OR “VSM” OR “Just-in-Time” OR “JIT” OR “Pull Planning” OR “5S” OR “Standard Work” OR “Takt Time Planning” OR “IPD” OR “A3” OR “Kaizen” OR “Continuous Improvement”);

- ○

- Construction domain: (“Construction” OR “Project” OR “Build*” OR “Housi*” OR “Infrastruct*”);

- ○

- CE: (“Circular Economy” OR “Lifecycle” OR “Circularity”).

3.3. Inclusion and Exclusion Criteria for Publications

3.4. Selection Process and Data Analysis Method

4. Results and Discussion

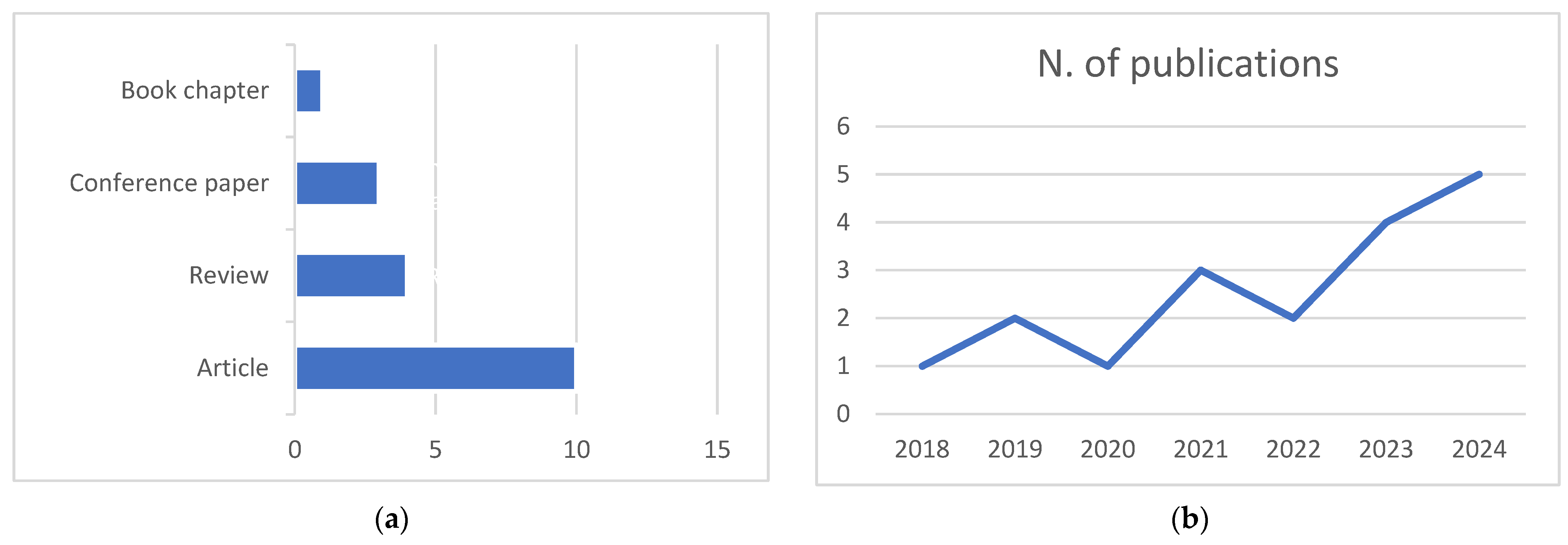

4.1. Quantitative Findings

4.1.1. QR1-1: Chronological Evolution and Publication Trends

4.1.2. QR1-2: Leading Contributors

- Most Influential Authors:

- ○

- M. Marzouk (Cairo University) developed a deconstruction model grounded in the integration of Lean principles with BIM functionalities [35]. His work exemplifies the synergy between digital tools and Lean thinking for optimized demolition processes, a critical component of CE strategies in construction.

- ○

- G.L.F. Benachio (Federal University of Paraná, Brazil) proposed a systematic mapping of the interactions between LC principles and CE practices [14]. His content-based approach provides a reference framework for modeling conceptual convergence, supported by 33 citations.

- ○

- T. Boukherroub (ÉTS Montréal) conducted a field-based study in Quebec focused on maximizing material reuse through Lean-driven deconstruction workflows [25]. Despite a modest citation count (three), the study offers high operational relevance and normative value, particularly in emerging regulatory contexts for circular transitions.

- ○

- S.M. Saradara (Khalifa University) contributed a structured bibliometric and systematic review, culminating in the development of an integrative framework aligning LC, CE, and BIM dimensions [15]. His systemic approach illustrates the field’s evolution toward strategic convergence and multi-scalar planning logics (three citations).

- ○

- J. Du (Shanghai University) employed a scientometric lens to map research on Lean prefabrication within a sustainability-oriented framework [34]. With 52 citations, his analysis identifies dominant research streams, author networks, and emerging themes positioned at the interface of industrial efficiency and environmental objectives.

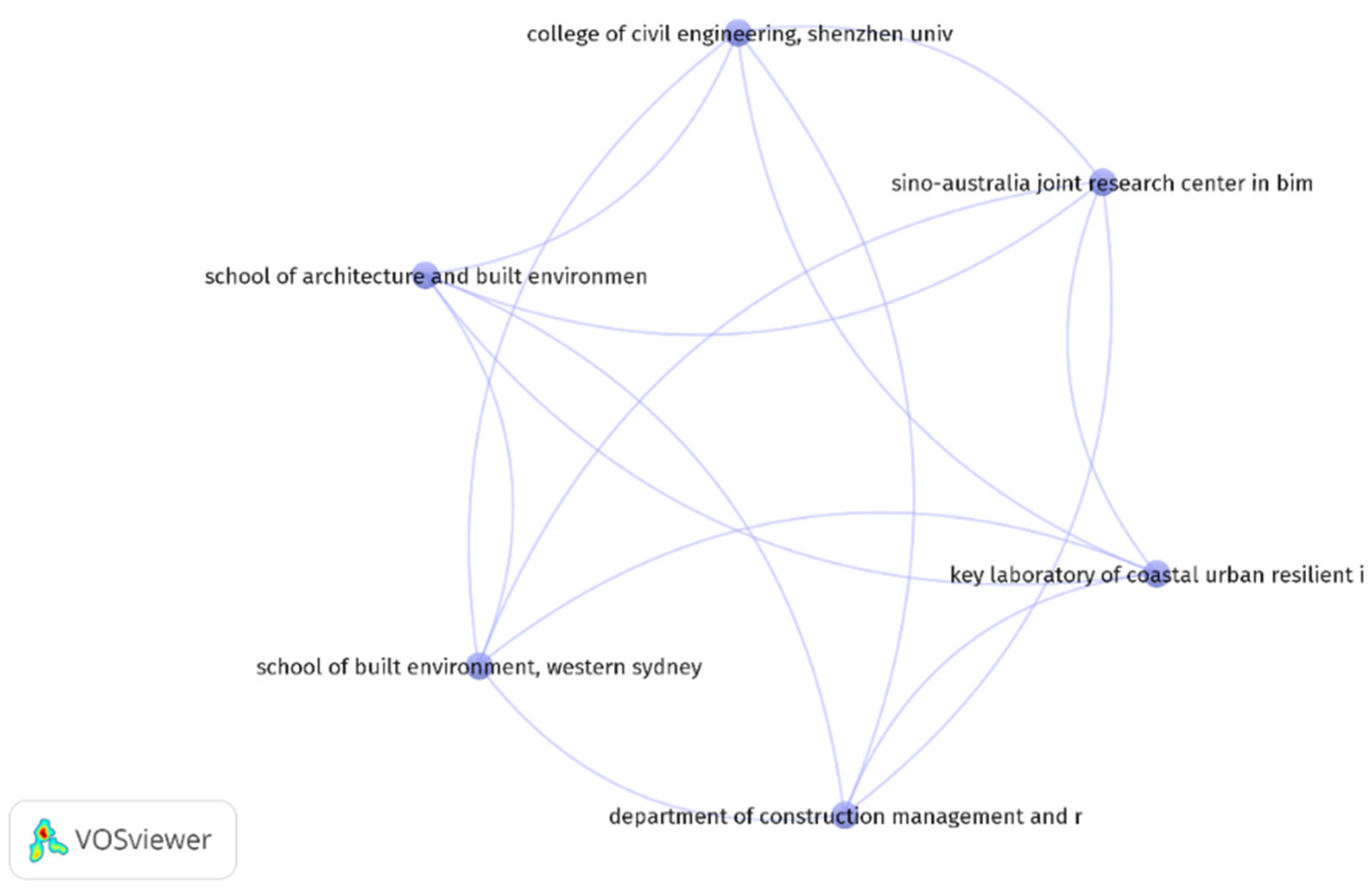

- Leading Institutions:

- ○

- Khalifa University (United Arab Emirates) stands out as a regional leader in the development of integrative frameworks that combine the Lean Project Delivery System (LPDS), circular strategies, and digital technologies such as BIM and blockchain [15]. The institution consistently delivers systematic reviews and bibliometric analyses supported by conceptual models tailored to rapidly transitioning contexts.

- ○

- École de Technologie Supérieure (ÉTS Montréal) (Canada) emerges as a North American hub for applied research in Lean deconstruction. Through empirical case studies grounded in real-world projects, ÉTS promotes material reuse, reverse logistics, and circular flows. Its collaboration with industry and public authorities underscores a high-impact model of territorial knowledge transfer [25].

- ○

- University of Johannesburg (South Africa) develops a research agenda focused on sustainable industrialization in emerging economies. Its contributions emphasize the adaptation of Lean and CE strategies to local contexts, with particular attention to Industry 4.0 technologies and socio-economic constraints [30,40].

- ○

- University of Warith Alanbiyaa (United Kingdom) specializes in sustainable off-site construction. Its work applies LC strategies to prefabrication systems within a CE framework, using scientometric methods to identify structural gaps and emerging research directions [32].

- ○

- University of Messina (Italy) and University of Szczecin (Poland) offer strong theoretical contributions at the intersection of Lean, CE, and reverse logistics. Their interdisciplinary lens addresses the managerial, systemic, and business model implications of integrated practices in the construction sector.

- Geographic Distribution of Contributions:

- ○

- Australia stands out as a global leader in this field. The country’s contributions, particularly those by Minunno (172 citations) and Siriwardhana (66 citations), demonstrate both methodological rigor and conceptual innovation. Australian research frequently explores the integration of Lean philosophy, CE principles, and Industry 4.0 technologies within prefabrication systems and digital modeling frameworks tailored to circular construction contexts [26].

- ○

- Brazil occupies a central position in the theoretical modeling of LC-CE interactions. Work by Benachio and Freitas provides foundational analytical frameworks, including interaction matrices and conceptual models with strong value for both academic research and education [14]. This theoretical emphasis positions Brazil as a key contributor to methodological formalization in the field.

- ○

- Canadian contributions, notably from ÉTS Montréal, adopt a practice-based approach grounded in local contexts. These studies focus on deconstruction and material reuse, mobilizing Lean tools to support territorially embedded circular strategies. Field-based experimentation in regions such as Gaspésie reflects a strong alignment with place-based CE logic.

- ○

- The United Arab Emirates, through Khalifa University, illustrates a dynamic model of CE transition in dense urban settings. Research emphasizes integrated frameworks combining Lean Project Delivery, BIM modeling, circular flow management, and digital governance. These models are designed to address the rapid urban development and sustainability imperatives of the region [15].

- ○

- China and the United States: A Sino-American axis is visible through significant contributions focused on industrial prefabrication, logistics optimization, and simulation-based waste flow modeling. Scholars such as Du, Zhang, and Hu use scientometric and quantitative tools to map Lean practices within off-site construction systems, offering scalable solutions for industrialized environments [34].

- ○

- Other Contributors: Additional contributions come from the United Kingdom, Italy, Indonesia, South Africa, and Poland. These studies frequently adopt interdisciplinary, critical, or cross-institutional approaches. Collectively, they enrich the field through diverse lenses, including reverse logistics, sustainable business models, and technological adaptation in developing contexts.

- Distribution by Scientific Journals:

- ○

- The Journal of Cleaner Production (Elsevier): This journal emerges as the most represented and most cited source in the corpus-hosting several foundational articles, including one with up to 178 citations. Its editorial focus on systemic sustainability, industrial transitions, and resource optimization makes it a strategic platform for promoting integrative LC-CE frameworks. It provides a rigorous outlet for works addressing flow efficiency, waste minimization, and circular resource management.

- ○

- Sustainability (MDPI): A major contributor to the field’s empirical grounding, Sustainability features case-based studies exploring pilot deconstruction projects, local reuse strategies, and contextualized prefabrication initiatives. Its thematic openness supports pluralistic and regionally diverse contributions, including perspectives from non-Western or developing contexts. It plays a crucial role in scaling local innovations to global discourse.

- ○

- Automation in Construction: Recognized for its technological orientation, this journal concentrates on digitalization in construction, off-site manufacturing, and Lean prefabrication. It provides a bridge between LC principles and advanced technologies such as BIM, digital twins, and Industry 4.0. It is a primary venue for exploring the technological enablers of circular and Lean convergence.

- ○

- The Journal of Construction Engineering and Management (ASCE): This outlet contributes to reinforcing the managerial and operational dimensions of the LC-CE nexus. It hosts studies focusing on project performance, risk mitigation, scheduling reliability, and the structuring of collaborative delivery models, including IPD. Its methodological rigor and managerial emphasis complement the technological and environmental focus of other outlets.

- ○

- The Lean Construction Journal: Although less frequent in volume, this specialized journal provides deep theoretical insights into Lean implementation in the AEC sector. Its niche focus enables the detailed analysis of Lean integration with complementary paradigms, including CE, BIM, and collaborative governance mechanisms. It serves as a key venue for advancing conceptual clarity and methodological precision in the LC community.

- ○

- Additional Outlets and Conferences: Complementary platforms such as Smart and Sustainable Built Environment, Business Strategy and the Environment, and international conferences (e.g., ARCOM 2023 and ASCE Structures Congress) also support dissemination. These venues underscore the field’s expansion into professional, strategic, and crossdisciplinary domains, bridging academic research with practical applications.

- Greater terminological consistency.

- Shared methodological standards.

- Stronger cross-platform integration in future research initiatives.

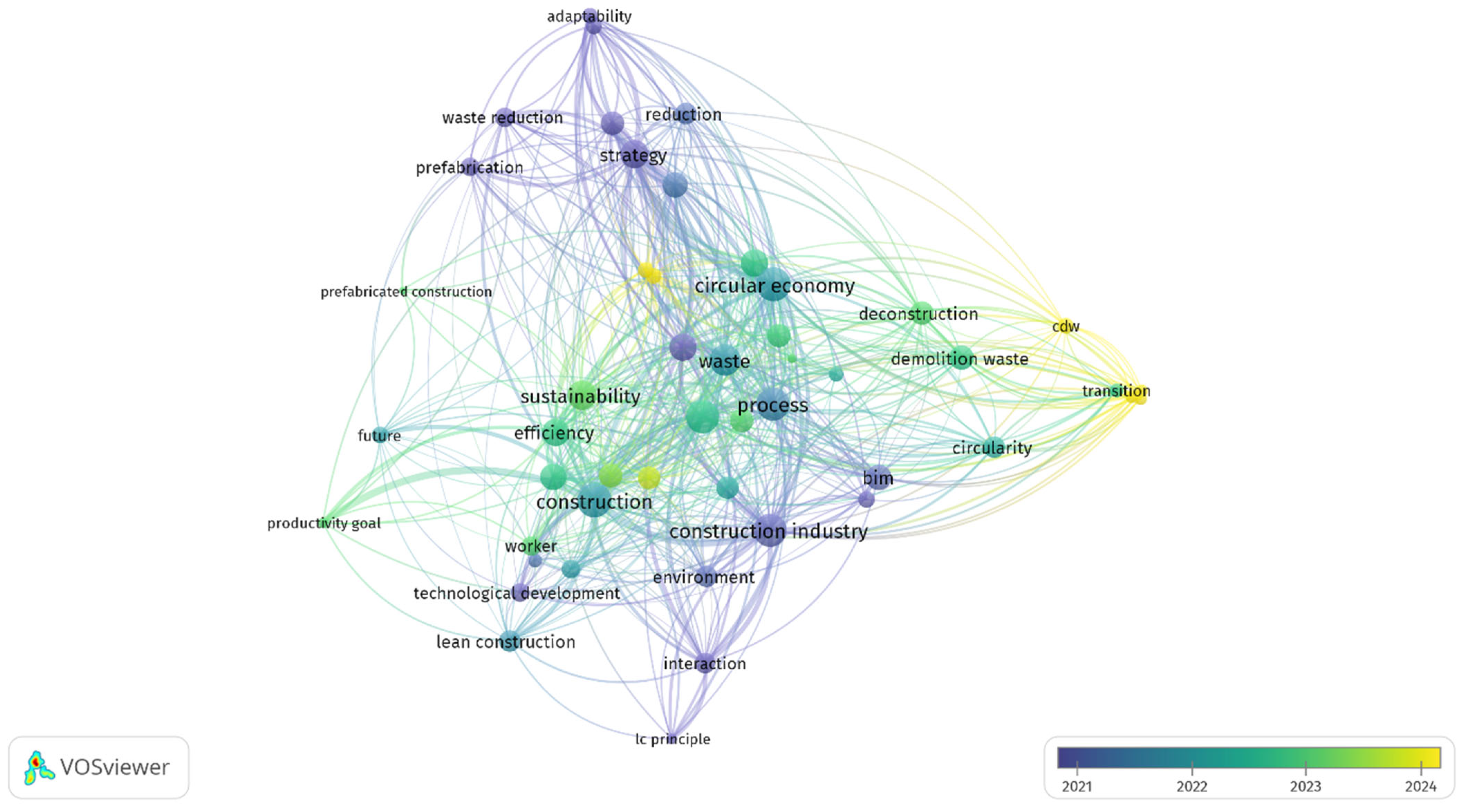

4.1.3. QR1-3: Intellectual Structure:

- Thematic Clusters (Keyword Co-Occurrence Analysis)

- ○

- Blue cluster—Foundational Lean Focus: This historical core centers on keywords such as “construction”, “process”, and “sustainability”. It reflects the early focus of the field on productivity enhancement, process reliability, and waste reduction—key tenets of LC. These themes frequently appear alongside well-established tools such as the LPS, JIT, and visual management.

- ○

- Green cluster—Transitional Strategies: This cluster highlights an evolving research direction characterized by terms like “prefabrication”, “adaptability”, and “waste minimization”. It captures the growing interest in modular and flexible design strategies, linking Lean’s process-driven logic to circular objectives such as resource recovery and lifecycle extension.

- ○

- Yellow cluster—Circular Expansion and Systemic Integration: Keywords such as “circular economy”, “deconstruction”, “transition”, and “construction and demolition waste” (CDW) define this cluster. It signals the field’s recent expansion into systemic sustainability, including policy instruments, design-for-disassembly, and the role of public regulation in enabling circularity.

- ○

- Purple cluster—Technological and Operational Infrastructure: Located at the base of the map, this cluster groups terms like “lean construction”, “technology”, “worker,” and “productivity goal”. It anchors the operational core of the field, reflecting its grounding in production theory and its progressive digitalization. This includes the integration of BIM, digital twins, and Industry 4.0 tools.

- ○

- Thematic Poles and Co-Citation Structure:

- ○

- Regional Dynamics and Case Study from Indonesia

- ○

- Toward a More Integrated Research Community

4.1.4. QR1-4: Lexical Evolution of Keywords

4.2. Qualitative Findings

4.2.1. QR2-1-Foundational Principles Shared by LC and the CE

- ○

- Waste elimination across material, time, energy, and labor dimensions.

- ○

- Continuous improvement (Kaizen) and the pursuit of standardized, reliable processes.

- ○

- Customer-defined value creation, guiding flow optimization, and decision-making.

- ○

- Pull-based production logic, aligning workflows with real-time demand to reduce inventories and overproduction.

- ○

- DfD and modularity.

- ○

- Component adaptability and reuse-oriented specifications.

- ○

- Lifecycle extension through robust reverse logistics systems.

4.2.2. QR2-2-Synergies Identified with a View to Sustainability

4.2.3. QR2-3-Tools, Methods, and Joint Practices

4.2.4. QR2-4-Observed Performances in LC-CE Projects

- Environmental Performance:

- Economic Performance:

- Operational Performance:

- Social performance:

4.2.5. QR2-5-Barriers, Challenges, and Conditions for Success

- Environmental Barriers:

- Economic Barriers:

- Technical challenges:

- Organizational Barriers:

- Regulatory Constraints:

- Cultural Barriers and Behavioral Levers:

4.2.6. QR2-6-Recommendations and Strategic Outlook

- Strengthening Crossdisciplinary Skills and Fostering an Integrated LC-CE Mindset

- Standardization of Flows, Data, and Performance Indicators

- Collaborative Governance and Integrated Contracting

- Incentive-Based Regulation and Economic Instruments

- Advanced digitization and intelligent tools for circularity

- Cultural Transformation and Behavioral Levers

5. Conclusions

- -

- Growing conceptual convergence: LC and CE increasingly align around shared goals such as waste minimization and resource efficiency. However, their differing operational logics generate both synergies and tensions, which require adaptive governance and collaborative models to be effectively resolved.

- -

- Operational enablers: The implementation of closed-loop construction practices relies on a coherent combination of Lean tools (e.g., Last Planner System or VSM) and digital platforms (e.g., BIM or digital twins) to monitor material flows, sequence tasks, and enable reuse.

- -

- Empirical gains: Documented outcomes include significant environmental gains (e.g., up to 90% waste diversion), economic savings through reuse, improved scheduling performance via prefabrication, and emerging evidence of social value creation in deconstruction-based projects.

- -

- Persistent barriers: Implementation remains hindered by fragmented supply chains, low digital interoperability, high entry costs, and regulatory gaps. These obstacles are particularly pronounced in emerging economies, where informal markets and limited infrastructure constrain circular practices.

- -

- Strategic levers: Six mutually reinforcing drivers—crossdisciplinary competencies, collaborative governance, interoperable digital systems, standardized KPIs, incentive-based regulation, and demonstrator projects—emerge as critical conditions for systemic LC-CE integration.

6. Limitations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3R | Reduce, Reuse, Recycle |

| 6R | Refuse, Reduce, Reuse, Repair, Recycle, Recover |

| 10R | Refuse, Rethink, Reduce, Reuse, Repair, Refurbish, Remanufacture, Repurpose, Recycle, Recover |

| ABM | Agent-Based Modeling |

| BIM | Building Information Modelling |

| BAMB | Buildings as Material Banks |

| CE | Circular Economy |

| CDW | Construction and Demolition Waste |

| C2C | Cradle-to-Cradle |

| DfD | Design for Disassembly |

| DfMA | Design for Manufacture and Assembly |

| DES | Discrete Event Simulation |

| EAST | Easy, Attractive, Social, Timely (framework de changeset compartmental) |

| ESG | Environmental, Social, and Governance |

| IFC4 | Industry Foundation Classes (version 4)—format standard exchange BIM |

| IPD | Integrated Project Delivery |

| IoT | Internet of Things |

| JIT | Just-in-Time |

| KPI | Key Performance Indicator |

| LCA | Life Cycle Assessment |

| LC | Lean Construction |

| LEED | Leadership in Energy and Environmental Design |

| LPDS | Lean Project Delivery System |

| LPS | Last Planner System |

| MDPI | Multidisciplinary Digital Publishing Institute |

| PFEP | Plan for Every Part |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| RFID | Radio Frequency Identification |

| SD | System Dynamics |

| SME | Small and Medium-sized Enterprises |

| SLR | Systematic literature review |

| TFV | Transformation–Flow–Value (Lean theory) |

| TPS | Toyota Production System |

| VDC | Virtual Design and Construction |

| VOSviewer | Visualization of Similarities viewer |

| VSM | Value Stream Mapping |

Appendix A

| Ref. | Type of Publication | Fundamental LC-CE Principles (QR2-1) | Synergies Between LC and CE (QR2-2) | Tools/Methods (QR2-3) |

|---|---|---|---|---|

| [15] | Conceptual study combining a systematic review (175 articles) with the development of an integrative theoretical framework based on bibliometric and thematic analysis. | LC: Waste minimization (time, materials, and overproduction), pull flow, Kaizen, and interdisciplinary collaboration. CE: Reduce, reuse, recycle, DfD, durability, and resource loop closure. | The LC-CE combination enables the joint reduction in inefficiencies and the circularization of resource flows. It enhances environmental resilience, lowers carbon footprints, and improves project quality and durability. | VSM to map circular flows; LPS for collaborative planning; JIT for synchronizing circular logistics. BIM for modeling and traceability; DfD for disassembly-oriented design; LCA to assess environmental impacts. |

| [39] | Professional communication presented at an ASCE conference, focused on behavior-driven approaches to low-carbon engineering design. | LC (implicit): Design simplification, efficiency-driven decision-making, and reduction in cognitive biases. CE: Lifecycle thinking, DFD, reuse of timber and steel components, and extension of service life. | Implicit alignment with the “first-time-right” philosophy. Promotes minimalist, behaviorally informed design targeting low-carbon outcomes, disassemblability, and long-term adaptability. | Carbon cheat sheets; simplified Excel-based LCA; EAST Framework for behavioral nudging; internal benchmarking tools and durability indicators integrated into early-stage design processes. |

| [33] | Conceptual review integrating scientific and policy literature on Construction 4.0, with a focus on required competencies and their alignment with Lean and CE logics. | LC: Waste reduction, standardization, Kaizen, and collaborative planning. CE: Building life extension, modularity, and reduction in environmental footprint. | Construction 4.0 acts as a catalyst: digitalization, modularity, and advanced technologies synchronize Lean process flows with circularity objectives. Both approaches converge to enhance overall project performance. | BIM for coordination and modeling; LPS for participatory scheduling; Digital Twins for asset maintenance; IoT systems for real-time control; off-site construction to reduce waste and shorten schedules. |

| [17] | Theoretical study integrating Lean, CE, and Industry 4.0, proposing a unified transformation model for sustainable production chains. | LC: Kaizen, standardization, pull-based flows, and customer-oriented quality. CE: Resource loops, proactive maintenance, product–service systems, and regeneration. | LC provides operational structuring, while CE offers strategic environmental direction. Their complementarity serves as a lever for transitioning to zero-waste, resource-efficient production systems. | VSM, 5S, JIT, Kaizen, Heijunka; circular tools including DfD and remanufacturing; IoT and blockchain for traceability; digital simulation to anticipate closed-loop flows. |

| [32] | Mixed-method systematic review (bibliometric and qualitative) on Lean off-site construction, exploring links with circularity through modular prefabrication. | LC: Kaizen, pull-based flows (JIT), standardization, and Last Planner System (LPS). CE: Not formally framed, but present through modular design, component optimization, and adaptability. | Synergies are implicitly suggested via prefabrication: industrialization supports waste reduction, enhanced traceability, and reuse opportunities. However, the study lacks a formal theoretical integration of the two approaches. | Classical Lean tools (LPS, VSM, 5S, JIT) applied in off-site environments using Industry 4.0 technologies: BIM, IoT, augmented reality, robotics, and cyber-physical systems, enabling dynamic traceability and adaptability. |

| [36] | Qualitative case study based on three construction projects in the UAE, focusing on the application of circular principles during the pre-construction phase. | LC: Referenced indirectly through normative practices such as pre-planning, waste reduction, and process industrialization. CE: Application of the 3R principles (Reduce, Reuse, Recycle), prefabrication, design for waste prevention, and BIM-supported circular flow management. | Technologies such as DfMA, BIM, and 3D printing simultaneously reduce waste (in line with Lean logic) and reinforce material circularity. Pre-construction planning serves as a strategic interface, aligning Lean efficiency with circular waste prevention goals. | BIM, 3D Printed Concrete (3DPC), DfMA, construction and demolition waste (CDW) management plans, LEED, and local sustainability guidelines. On-site technologies for sorting, storage, and monitoring of material flows. |

| [37] | Exploratory scientific communication based on case studies and a descriptive–critical assessment of circularity levels in the construction sector. | LC: Operational application through Lean delivery models and early-stage planning practices. CE: Structured around the ReSOLVE framework (Regenerate, Share, Optimize, Loop, Virtualize, Exchange), with an emphasis on modular and disassemblability design. | Prefabrication and digital modeling act as dual enablers of Lean–CE integration. Modular logistics are coordinated according to a closed-loop logic enabled by BIM and digital twins. | ReSOLVE framework, BIM, digital twins, DfMA, modular Lean design frameworks, reverse logistics, and integrated energy and infrastructure sharing systems. |

| [38] | Applied case study on green demolition of an urban building, combining BIM modeling and JIT planning. | LC: JIT planning, streamlined coordination, reduction in waiting times, and process waste. CE: 10R framework, buildings as material banks, design for deconstruction and reuse. | Operational synergy between BIM and JIT enables waste reduction, flow synchronization, and maximized material reuse. The approach integrates green principles to minimize the project’s carbon footprint. | 3D/4D BIM modeling, JIT scheduling, Sankey diagrams, and reverse-flow demolition simulation. |

| [14] | Qualitative study based on content analysis and the construction of an interaction matrix between Lean principles and CE practices. | LC: Elimination of non-value-adding activities, Kaizen, process transparency, and integrated control. CE: Waste as a resource, systemic design, material diversification, and use of renewable energy. | The study identifies 70 positive interactions between LC and CE. Lean provides an operational framework; CE brings long-term circular goals. Off-site construction and material passports are cited as areas of strong convergence. | Circularity assessment tools (e.g., BAMB), LCA, material passports, design simulations, off-site construction techniques, and preventive maintenance. |

| [35] | Exploratory qualitative research focused on building deconstruction, using BIM to model Lean and Circular processes. | LC: Sixteen adapted principles for deconstruction; strategic and operational planning (pull systems and standardization). CE: Material reuse, secondary market creation, and closed-loop systems. | Pull-based planning is aligned with the demand for recoverable components. Lean enhances operational efficiency, while CE maximizes resource valorization. BIM acts as a digital enabler that bridges both paradigms. | 3D scanning, as-built modeling, 4D simulation, deconstruction-oriented VSM, connected resale platforms, and real-time coordination through BIM-enabled tablets. |

| [34] | Systematic and scientometric review applied to the context of Lean prefabrication. | LC: Kaizen, JIT, standardization, pull-based workflows, and waste minimization. CE: DfD, modularity, and material reuse. | Shared objectives include waste reduction and modular standardization. Prefabrication acts as a key convergence point between LC and CE by combining quality with disassembly potential. | VSM, JIT, Kanban, 5S, Kaizen, and Takt Time Planning. BIM, RFID, and IoT for traceability and digital production. DfMA applied to modular components. |

| [30] | Descriptive empirical study exploring the intersection of LC, CE, and digitalization within the Construction 4.0 framework. | LC: Waste elimination (muda), Kaizen, standardization, and pull system logic. CE: Recycling, DFD, lifecycle extension, and regenerative processes. | LC optimizes immediate process flows, while CE supports long-term value preservation. DFD emerges as a practical bridge between Lean workflows and circular objectives. | LPS, BIM, JIT, 5S, and visual management. IoT and sensors for real-time performance monitoring. Integrated digital approach linking LC and CE strategies. |

| [40] | Book chapter synthesizing demolition waste management practices through a circular lens with implicit Lean logic. | LC (implicit): Source reduction, process efficiency, and structured planning. CE: 3R hierarchy (Reduce, Reuse, and Recycle), eco-design, energy recovery, and prevention. | Lean streamlines production workflows, while CE frames the systemic management of demolition waste. The waste hierarchy acts as a conceptual bridge aligning both approaches. | 3R principles, modularity, and substitution of toxic materials with bio-based alternatives. Waste management plans, BIM, selective demolition, closed-loop material systems. |

| [31] | Systematic review proposing a conceptual framework for integrating LC and CE within the construction supply chain. | LC: Standardization, Kaizen, streamlined logistics, and client value creation. CE: Resource preservation, DFD, and closed-loop systems. | LC offers procedural rigor, while CE introduces long-term systemic sustainability. Integration enhances supply chain performance through circular logistics and value retention. | VSM, LPS, DfD, BIM, Lean supply chain management. Combined focus on traceability, circularity, and operational efficiency. |

| [12] | Empirical study employing a hybrid modeling approach (Agent-Based Modeling, System Dynamics, DES) applied to urban waste management under LC-CE integration. | LC: Reduction in waiting time, process optimization, Kaizen. CE: Waste valorization, closed-loop material flows, planned sorting, and reuse. | The hybrid simulation illustrates that Lean supports efficient sorting and logistics, while CE maximizes reuse and reduces environmental impact. | Hybrid modeling combining ABM + SD + DES; comparative analysis between LC-based and conventional construction; time–cost–impact assessment; dynamic visualization. |

| [26] | Qualitative critical review on CE in prefabricated buildings, with references to Lean principles. | LC: Lean production, pull systems, and process standardization. CE: Seven circular strategies, including DfD, adaptability, recyclability, traceability, and modularity. | Modular prefabrication serves as a key enabler of LC-CE integration. Industrialized processes support both standardization and circular disassembly. | Lean production systems, BIM modeling, DfD strategies, material passports, detachable modules, RFID/barcodes, and circular supply chain logistics. |

| [41] | Scientific communication based on text mining analysis of 89 publications on LC, CE, and sustainable innovation. | LC: Kaizen, PDCA, reduction in both physical and cognitive waste. CE: Closed-loop systems, regeneration, DfD, and material reuse. | Lean provides an operational framework, while CE defines the strategic direction. Their integration enhances sustainable consumption and production (SCP) practices and strengthens sectoral resilience. | Text mining, DfD, modular design, eco-materials, LCA, Cradle-to-Cradle principles, BIM integration, and industrial symbiosis frameworks. |

| [25] | In-depth field-based case study conducted in Quebec (five deconstructed buildings), focused on maximizing material reuse. | LC: Kaizen, planned flows, 5S methodology, standardization, and operational efficiency. CE: Optimal material reuse, waste minimization, and DFD. | Lean accelerates the achievement of circular goals through standardized and collaborative practices. The integration optimizes outbound flows and reduces resource losses. | 5S, VSM, standardized sorting and storage processes, IPD, BIM, materials databases, and Lean-based checklists. |

References

- Kim, T.-Y. The Role of Critical Minerals in Clean Energy Transitions; International Energy Agency: Washington, DC, USA, 2023. [Google Scholar]

- UNEP. Partnership and United Nations Environment Programme. In Reducing Consumer Food Waste Using Green and Digital Technologies; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- Menegaki, M.; Damigos, D. A Review on Current Situation and Challenges of Construction and Demolition Waste Management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Teh, S.H.; Wiedmann, T.; Moore, S. Mixed-Unit Hybrid Life Cycle Assessment Applied to the Recycling of Construction Materials. J. Econ. Struct. 2018, 7, 13. [Google Scholar] [CrossRef]

- Circularity Gap Report. Available online: https://global.circularity-gap.world/ (accessed on 10 July 2025).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Illankoon, C.; Vithanage, S.C. Closing the Loop in the Construction Industry: A Systematic Literature Review on the Development of Circular Economy. J. Build. Eng. 2023, 76, 107362. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G.A. Lean Project Management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- Cho, S.; Ballard, G. Last Planner and Integrated Project Delivery. Lean Constr. J. 2011, 2011, 67–78. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ding, Z.; Cao, X.; Shi, M.; Tam, V.W.Y.; Illankoon, I.M.C.S. New Hybrid Simulation Model for Urban Construction Waste Management: An Empirical Study. Proc. Inst. Civ. Eng. Eng. Sustain. 2021, 174, 275–288. [Google Scholar] [CrossRef]

- Swarnakar, V.; Khalfan, M. Circular Economy in Construction and Demolition Waste Management: An in-Depth Review and Future Perspectives in the Construction Sector. Smart Sustain. Built Environ. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Interactions between Lean Construction Principles and Circular Economy Practices for the Construction Industry. J. Constr. Eng. Manag. 2021, 147, 04021068. [Google Scholar] [CrossRef]

- Saradara, S.M.; Khalfan, M.M.A.; Jaya, S.V.; Swarnakar, V.; Rauf, A.; El Fadel, M. Advancing Building Construction: A Novel Conceptual Framework Integrating Circularity with Modified Lean Project Delivery Systems. Dev. Built Environ. 2024, 20, 100531. [Google Scholar] [CrossRef]

- Chen, Q.; Reichard, G.; Beliveau, Y. Interface Management—A Facilitator of Lean Construction and Agile Project Management. Int. Group Lean Constr. 2007, 1, 57–66. [Google Scholar]

- Ciliberto, C.; Szopik-Depczynska, K.; Tarczynska-Luniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy Transition: A Sustainable Lean Manufacturing Recipe for Industry 4.0. Bus. Strategy Environ. 2021, 30, 3255–3272. [Google Scholar] [CrossRef]

- Ossio, F.; Salinas, C.; Hernández, H. Circular Economy in the Built Environment: A Systematic Literature Review and Definition of the Circular Construction Concept. J. Clean. Prod. 2023, 414, 137738. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the Circular Economy to the UN Sustainable Development Goals through Sustainable Construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, CA, USA, 1992; Volume 72. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking; Simon and Schuster: New York, NY, USA, 1996. [Google Scholar]

- Sacks, R.; Radosavljevic, M.; Barak, R. Requirements for Building Information Modeling Based Lean Production Management Systems for Construction. Autom. Constr. 2010, 19, 641–655. [Google Scholar] [CrossRef]

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A. Lean Construction Implementation in the Saudi Arabian Construction Industry. Constr. Econ. Build. 2017, 17, 46–69. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Lean Construction Implementation in the Moroccan Construction Industry: Awareness, Benefits and Barriers. J. Eng. Des. Technol. 2018, 16, 533–556. [Google Scholar] [CrossRef]

- Boukherroub, T.; Nganmi Tchakoutio, A.; Drapeau, N. Using Lean in Deconstruction Projects for Maximising the Reuse of Materials: A Canadian Case Study. Sustainability 2024, 16, 1816. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Chen, Y.; Qiu, D.; Chen, X. Integrating Lean Construction with Sustainable Construction: Drivers, Dilemmas and Countermeasures. Sustainability 2024, 16, 9387. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.K.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P. The Journal Coverage of Web of Science, Scopus and Dimensions: A Comparative Analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Lekan, A.; Clinton, A.; Fayomi, O.; James, O. Lean Thinking and Industrial 4.0 Approach to Achieving Construction 4.0 for Industrialization and Technological Development. Buildings 2020, 10, 221. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping Construction Supply Chain Processes with Circular Economy Strategies: A Systematic Literature Review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Hadi, A.; Cheung, F.; Adjei, S.; Dulaimi, A. Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0. J. Constr. Eng. Manag. 2023, 149, 03123007. [Google Scholar] [CrossRef]

- Siriwardhana, S.; Moehler, R.C. Enabling Productivity Goals through Construction 4.0 Skills: Theories, Debates, Definitions. J. Clean. Prod. 2023, 425, 139011. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. Lean Manufacturing Applications in Prefabricated Construction Projects. Autom. Constr. 2023, 150, 104790. [Google Scholar] [CrossRef]

- Marzouk, M.; Elmaraghy, A.; Voordijk, H. Lean Deconstruction Approach for Buildings Demolition Processes Using BIM. Lean Constr. J. 2019, 2019, 147–173. [Google Scholar]

- Nie, P.; Dahanayake, K.C.; Sumanarathna, N. Exploring UAE’s Transition towards Circular Economy through Construction and Demolition Waste Management in the Pre-Construction Stage–A Case Study Approach. Smart Sustain. Built Environ. 2024, 13, 246–266. [Google Scholar] [CrossRef]

- Nazareth, A.P. How Close Is the Built Environment to Achieving Circularity? IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012070. [Google Scholar] [CrossRef]

- Andriyani, N.; Suprobo, P.; Adi, T.J.W.; Aspar, W.A.N.; Jatmiko, A.D.; Santoso, A.D. Integrating Urban Building Information Modeling and Circular Economy Framework for Green Sustainability. Glob. J. Environ. Sci. Manag. 2024, 10, 1313–1332. [Google Scholar] [CrossRef]

- Bergsagel, D. Design Behavior: How to Save Our Planet and Influence People. In Proceedings of the Structures Congress 2022, Atlanta, Georgia, 20–23 April 2022; American Society of Civil Engineers: Atlanta, Georgia, 2022; pp. 271–282. [Google Scholar]

- Nyika, J.; Dinka, M.O.; Mbao, E.O. Measures to Divert Construction and Demotion Waste from Landfill Disposal. In Technical Landfills and Waste Management; Souabi, S., Anouzla, A., Eds.; Springer Water; Springer Nature: Cham, Switzerland, 2024; pp. 189–205. ISBN 978-3-031-55664-7. [Google Scholar]

- Omotayo, T.S.; Awuzie, B.; Lovelin, O. Synergising Continuous Improvement with Circular Economy for Advancing Innovation in the Construction Sector: A Text Mining Approach. 2023. Available online: https://researchportal.northumbria.ac.uk/ws/portalfiles/portal/130706407/Arcom_conference.pdf (accessed on 20 July 2025).

- Pomponi, F.; Moncaster, A. Circular Economy for the Built Environment: A Research Framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular Economy in the Construction Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ji, X.; Liu, G.; Ulgiati, S. Evaluating the Transition towards Cleaner Production in the Construction and Demolition Sector of China: A Review. J. Clean. Prod. 2018, 195, 418–434. [Google Scholar] [CrossRef]

- Jain, M.S.; Sudarsan, J.S.; Parija, P.P. Managing Construction and Demolition Waste Using Lean Tools to Achieve Environmental Sustainability: An Indian Perspective. Environ. Sci. Pollut. Res. 2023, 30, 57188–57200. [Google Scholar] [CrossRef] [PubMed]

- Keskiniva, K.; Saari, A.; Junnonen, J. Takt Planning in Apartment Building Renovation Projects. Buildings 2020, 10, 226. [Google Scholar] [CrossRef]

- Tommelein, I. Work Density Method for Takt Planning of Construction Processes with Nonrepetitive Work. J. Constr. Eng. Manag. 2022, 148, 0002398. [Google Scholar] [CrossRef]

- Power, W.; Sinnott, D.; Lynch, P. Takt Complementing Last Planner® System on Residential Construction Projects. Constr. Econ. Build. 2024, 24, 58–80. [Google Scholar] [CrossRef]

- Talla, A.; McIlwaine, S. Industry 4.0 and the Circular Economy: Using Design-Stage Digital Technology to Reduce Construction Waste. Smart Sustain. Built Environ. 2024, 13, 179–198. [Google Scholar] [CrossRef]

- Többen, J.; Opdenakker, R. Developing a Framework to Integrate Circularity into Construction Projects. Sustainability 2022, 14, 5136. [Google Scholar] [CrossRef]

- Fu, F.; Sun, J.; Pasquire, C. Carbon Emission Assessment for Steel Structure Based on Lean Construction Process. J. Intell. Robot. Syst. Theory Appl. 2015, 79, 401–416. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring Environmental and Economic Costs and Benefits of a Circular Economy Approach to the Construction and Demolition Sector. A Literature Review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular Economy Practices in the Built Environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Kazmi, R.; Chakraborty, M. Identification of Parameters and Indicators for Implementing Circularity in the Construction Industry. J. Eng. Appl. Sci. 2023, 70, 77. [Google Scholar] [CrossRef]

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M.; Usher, C.; O’Reilly, K. Technology Adoption in the BIM Implementation for Lean Architectural Practice. Autom. Constr. 2011, 20, 189–195. [Google Scholar] [CrossRef]

- Hei, S.; Zhang, H.; Luo, S.; Zhang, R.; Zhou, C.; Cong, M.; Ye, H. Implementing BIM and Lean Construction Methods for the Improved Performance of a Construction Project at the Disassembly and Reuse Stage: A Case Study in Dezhou, China. Sustainability 2024, 16, 656. [Google Scholar] [CrossRef]

- Heigermoser, D.; García de Soto, B.; Abbott, E.L.S.; Chua, D.K.H. BIM-Based Last Planner System Tool for Improving Construction Project Management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Karatas, I.; Budak, A. Investigation of Influence on Construction Waste of the Lean-BIM Interaction in Construction Phase Using Multiple Correspondence Analysis. Proc. Inst. Civ. Eng. Eng. Sustain. 2023, 177, 242–255. [Google Scholar] [CrossRef]

- Nguyen, T.; Nguyen, T.; Van Tran, T. Building Information Modeling (BIM) for Construction Project Schedule Management: A Review. Eng. Technol. Appl. Sci. Res. 2024, 14, 13133–13142. [Google Scholar] [CrossRef]

- Schery, C.; Vignon, Y.; Caiado, R.; Santos, R.; Congro, M.; Corseuil, E.; Roehl, D. BIM Critical Factors and Benefits for Public Sector: From a Systematic Review to an Empirical Fuzzy Multicriteria Approach. Braz. J. Oper. Prod. Manag. 2023, 20, 1837. [Google Scholar] [CrossRef]

- Zhan, Z.; Tang, Y.; Wang, C.; Yap, J.; Lim, Y. System Dynamics Outlook on BIM and LEAN Interaction in Construction Quantity Surveying. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2022, 46, 3947–3962. [Google Scholar] [CrossRef]

- Altan, E.; Işık, Z. Digital Twins in Lean Construction: A Neutrosophic AHP—BOCR Analysis Approach. Eng. Constr. Archit. Manag. 2023, 31, 5029–5056. [Google Scholar] [CrossRef]

- Martinez, E.; Pfister, L. Benefits and Limitations of Using Low-Code Development to Support Digitalization in the Construction Industry. Autom. Constr. 2023, 152, 104909. [Google Scholar] [CrossRef]

- Ugural, M.N.; Aghili, S.; Burgan, H.I. Adoption of Lean Construction and AI/IoT Technologies in Iran’s Public Construction Sector: A Mixed-Methods Approach Using Fuzzy Logic. Buildings 2024, 14, 3317. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Ahmad, R.; Li, X. Integrating Lean Production Strategies, Virtual Reality Technique and Building Information Modeling Method for Mass Customization in Cabinet Manufacturing. Eng. Constr. Archit. Manag. 2022, 29, 3970–3996. [Google Scholar] [CrossRef]

- Ahmed, S.; Majava, J.; Aaltonen, K. Implementation of Circular Economy in Construction Projects: A Procurement Strategy Approach. Constr. Innov. 2024, 24, 204–222. [Google Scholar] [CrossRef]

- Mahmoud, Z.; Angelé-Halgand, N.; Churruca, K.; Ellis, L.A.; Braithwaite, J. The Impact of Lean Management on Frontline Healthcare Professionals: A Scoping Review of the Literature. BMC Health Serv. Res. 2021, 21, 383. [Google Scholar] [CrossRef] [PubMed]

- Adisorn, T.; Tholen, L.; Götz, T. Towards a Digital Product Passport Fit for Contributing to a Circular Economy. Energies 2021, 14, 2289. [Google Scholar] [CrossRef]

- Ibrahim, A.; Zayed, T.; Lafhaj, Z. Trends and Gaps in Lean Construction Practices for Construction of Megaprojects: A Critical Review. Alex. Eng. J. 2025, 118, 174–193. [Google Scholar] [CrossRef]

- Khanna, M.; Elghaish, F.; McIlwaine, S.; Brooks, T. Feasibility of Implementing Ipd Approach for Infrastructure Projects in Developing Countries. J. Inf. Technol. Constr. 2021, 26, 902–921. [Google Scholar] [CrossRef]

| Dimensions | Code | Research Questions |

|---|---|---|

| (i) Quantitative | QR1-1 | What are the chronological developments and publication trends in the LC-CE research domain? |

| QR1-2 | Who are the main contributors in this field (journals, countries, authors, institutions)? | |

| QR1-3 | What is the intellectual structure of this research area (co-citation networks, co-authorship, thematic clusters)? | |

| QR1-4 | What are the most frequent keywords, and how have they evolved over time? | |

| (ii) Qualitative | QR2-1 | According to the literature, what are the core principles of LC and CE when applied jointly in the construction sector? |

| QR2-2 | What synergies between these two approaches have been identified in the literature from an environmental, economic, or systemic sustainability perspective? | |

| QR2-3 | What tools, methods, or practices are simultaneously mobilized in construction projects to implement both Lean and CE strategies? | |

| QR2-4 | What types of performance outcomes are reported (environmental, economic, social, or operational), and what specific results are observed? | |

| QR2-5 | What barriers, challenges, or enabling conditions are documented in the literature regarding the integration of these approaches? | |

| QR2-6 | What recommendations or future directions are proposed by the authors to support and enhance the effective integration of LC and CE principles? |

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Studies addressing the joint integration of LC and CE | Studies dealing exclusively with either LC or CE in isolation |

| Explicit integration of Lean methodologies and CE principles | Studies not related to the construction sector |

| Literature reviews, as well as quantitative, qualitative, or mixed-method studies reporting on LC-CE integration outcomes | Publications not available in full text |

| Publications published in peer-reviewed scientific journals or conference proceedings | Theses, dissertations, reports, or non-peer-reviewed publications |

| No language restrictions applied | |

| Reference | Type | Authors | Institution | Country | Year | Journals | Cited by |

|---|---|---|---|---|---|---|---|

| [17] | Article | Ciliberto, C.; Szopik-Depczynska, K.; Tarczynska-Luniewska, M.; Ruggieri, A.; Ioppolo, G. |

| Italie | 2021 | Business Strategy and the Environment | 178 |

| [26] | Article | Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. |

| Australia | 2018 | Buildings | 172 |

| [30] | Article | Lekan, A.; Clinton, A.; Fayomi, O.S.I.; James, O. | University of Johannesburg; | South Africa | 2020 | Buildings | 144 |

| [31] | Review | Chen, Q.; Feng, H.; Garcia de Soto, B. |

| United Arab Emirates/ United Kingdom | 2022 | Journal of Cleaner Production | 102 |

| [32] | Review | Hadi, A.; Cheung, F.; Adjei, S.; Dulaimi, A. |

| United Kingdom | 2023 | Journal of Construction Engineering and Management | 83 |

| [33] | Article | Siriwardhana, S.; Moehler, R.C. |

| Australie | 2023 | Journal of Cleaner Production | 66 |

| [34] | Review | Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. |

| China/United States | 2023 | Automation in Construction | 52 |

| [14] | Article | Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. | Civil Construction Engineering, Federal Univ; | Brazil | 2021 | Journal of Construction Engineering and Management | 33 |

| [35] | Article | Marzouk, M.; Elmaraghy, A.; Voordijk, H. |

| Egypt/Netherlands | 2019 | Lean Construction Journal | 28 |

| [36] | Article | Nie, P.; Dahanayake, K.C.; Sumanarathna, N. |

| United Arab Emirates | 2024 | Smart and Sustainable Built Environment | 15 |

| [37] | Conference paper | Nazareth, A.P. |

| United Kingdom | 2019 | IOP Conference Series: Earth and Environmental Science | 10 |

| [25] | Article | Boukherroub, T.; Nganmi, Tchakoutio, A.; Drapeau, N. |

| Canada | 2024 | Sustainability | 3 |

| [15] | Review | Saradara, S.M.; Khalfan, M.M.A.; Jaya, S.V.; Swarnakar, V.; Rauf, A.; El Fadel, M. |

| United Arab Emirates | 2024 | Developments in the Built Environment | 3 |

| [38] | Article | Andriyani, N.; Suprobo, P.; Adi, T.J.W.; Aspar, W.A.N.; Jatmiko, A.D.; Santoso, A.D. |

| Indonesia | 2024 | Global Journal of Environmental Science and Management | 3 |

| [12] | Article | Ding, Z.; Cao, X.; Shi, M.; Tam, V.W.Y.; Illankoon, I.M.C.S. |

| China/Australia | 2021 | Proceedings of the Institution of Civil Engineers: Engineering Sustainability | 2 |

| [39] | Conference paper | Bergsagel, D. |

| United States | 2022 | Structures Congress 2022 | 0 |

| [40] | Book chapter | Nyika, J.; Dinka, M.O.; Mbao, E.O. |

| South Africa/Kenya | 2024 | Springer Water | 0 |

| [41] | Conference paper | Omotayo, T.S.; Awuzie B.; Lovelin, O. |

| South Africa/United Kingdom | 2023 | Proceedings of the 39th Annual ARCOM Conference: Constructing for the Future, ARCOM 2023 | 0 |

| Performance Dimension | Key Outcome | Source | Context and Method | Quantitative Evidence |

|---|---|---|---|---|

| Environmental | High waste diversion | [36] | Off-site modular pods; shift from on-site finishing to modular | Up to 90% waste reduction |

| Material preservation at end-of-life | [26] | DfD, comparative Life Cycle Assessment | 62% of building mass is reusable | |

| Environmental cost saving via simulation | [12] | Hybrid ABM/SD/DES + BIM model for urban CDW flows | 10.65% reduction in environmental costs | |

| Digital enabler effect | [25,35] | BIM + Material Passports for deconstruction planning | Qualitative: improved separation and reuse accuracy | |

| Economic | Cost avoidance via reuse | [35] | Real deconstruction case with BIM tracking | Salvaged structural components recovered |

| Lower demolition cost | [25] | Reuse centers with Lean workflows | Confirmed demolition cost saving | |

| Urban reuse saving | [17] | Controlled site-level planning in urban context | ~USD 56,000 saving | |

| Modeled project saving | [12] | Simulation: CDW management | 1.36% total cost reduction | |

| Operational | Shorter cycle times, fewer reworks | [32] | Off-site standard modules, controlled weather risk | Time and error reduction (qualitative) |

| JIT + BIM synergy | [35] | Pull planning + sequencing of tasks | Reduced delays, smoother workflows | |

| Simulation of flow optimization | [12] | Forecasting bottlenecks; proactive allocation | >10% cycle time saving (modeled) | |

| Social | Better working conditions and upskilling | [32,36] | Controlled factory work vs. on-site tasks | Improved safety, technical skill requirements |

| Local job creation potential | [25,40] | On-site sorting, reuse centers | Informal to semi-formal local jobs | |

| Governance and trust building | [41] | Integrated supply chains and Kaizen cycles | Enhanced collaboration, knowledge sharing |

| Dimension | Barriers Identified | Key Enabling Conditions |

|---|---|---|

| Environmental | Limited stakeholder awareness of lifecycle impacts and poor integration of environmental KPIs within Lean dashboards remain widespread. Moreover, many project teams still lack training in LCA methods essential for eco-design decisions [2,11,36,40,65,66]. | To overcome this, visual CO2 indicators embedded in BIM, combined with systematic training in lifecycle thinking and the standardization of on-site sorting protocols, are identified as priority levers [34,36]. |

| Economic | High upfront costs for adopting BIM, DfMA, or 3D printing discourage SMEs, while the lack of visibility on the profitability of reused materials and insufficient local resale channels maintain uncertainty [32,35,36]. | Solutions include public support for local recycling value chains, targeted subsidies for circular prefabrication, and integration of lifecycle costing into public procurement to valorize long-term savings [32,35,36]. |

| Technical | The heterogeneity of digital tools, absence of open interoperability standards, and limited capacity of BIM for tracking second-life materials hinder data flow and traceability [2,8,32]. | Deploying LC-CE digital twins, adopting open standards such as IFC4, and using PFEP for structuring reverse logistics can mitigate these technical silos [10,18,37]. |

| Organizational | Fragmented workflows between design, production, and logistics phases, a lack of shared vision for circularity among stakeholders, and Lean leadership limited to site operations reduce system-wide coherence [10,32,36]. | Cross-functional training, formation of integrated teams early in design, and collaborative governance based on shared BIM platforms are recommended enablers [10,32,36]. |

| Regulatory | The absence of clear legal frameworks for waste sorting and traceability, lack of certification for reused materials, and fragmented regulations across governance levels all obstruct scale-up [30,36,41]. | Aligning CE–BIM with existing regulatory frameworks, enforcing mandatory circular management plans in contracts, and creating dedicated circularity labels or certifications are strategic priorities [30,36,41]. |

| Cultural /Behavioral | Deeply rooted “new build” culture, psychological resistance to deconstruction practices, and a limited circular mindset in Lean teams all hinder adoption [10,18]. | Demonstrator projects, a strong collective narrative, and media promotion of flagship circular pilots can help shift mindsets and normalize reuse [10,18]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Hafiane, A.; En-nadi, A.; Ramadany, M. Towards Sustainable Construction: Systematic Review of Lean and Circular Economy Integration. Sustainability 2025, 17, 6735. https://doi.org/10.3390/su17156735

El Hafiane A, En-nadi A, Ramadany M. Towards Sustainable Construction: Systematic Review of Lean and Circular Economy Integration. Sustainability. 2025; 17(15):6735. https://doi.org/10.3390/su17156735

Chicago/Turabian StyleEl Hafiane, Abderrazzak, Abdelali En-nadi, and Mohamed Ramadany. 2025. "Towards Sustainable Construction: Systematic Review of Lean and Circular Economy Integration" Sustainability 17, no. 15: 6735. https://doi.org/10.3390/su17156735

APA StyleEl Hafiane, A., En-nadi, A., & Ramadany, M. (2025). Towards Sustainable Construction: Systematic Review of Lean and Circular Economy Integration. Sustainability, 17(15), 6735. https://doi.org/10.3390/su17156735