1. Introduction

With the growing global population, the volume of urban wastewater and sewage sludge (SS) is constantly increasing, intensifying challenges related to their efficient, economical, and environmentally safe disposal [

1,

2]. The issue of processing, dewatering, and disposing of sewage sludge, which accumulates in large quantities in urban and rural areas, is particularly acute for many countries, including Kazakhstan [

3,

4].

Sewage sludge presents a significant disposal challenge due to its high content of heavy metal salts, pesticides, and other destructive groups of organic compounds [

5]. Reducing sludge generation and transforming it into a harmless product are the primary objectives of modern technologies.

In 2005, 52% of sewage sludge in the European Union was used in agriculture, 38% was incinerated, and 10% was disposed of in landfills [

6]. Due to the high concentrations of phosphorus and nitrogen, SS can serve as an effective fertilizer [

7]. However, its use in agriculture is limited by the presence of heavy metals, harmful impurities, and the need to eliminate pathogenic microorganisms and helminth eggs.

The analysis of international practices [

8] indicates that incineration is a promising method for sewage sludge treatment and disposal in large cities. The most rational approach involves incineration followed by the use of the resulting ash as a raw material for producing building materials [

9].

Alternative disposal methods, such as landfilling, have their disadvantages [

10], including challenges related to groundwater contamination and biogas emissions during sludge decomposition. Currently, in Kazakhstan, the most common sewage sludge disposal method is burial in sludge beds, which occupy large land areas.

One of the most promising approaches for sludge utilization, leveraging its beneficial properties while minimizing its negative impacts, involves using it in construction industry. According to Cieślik [

11], the main applications include the cementing of ashes, high temperature vitrification with silica addition, and roof tile, brick, lightweight aggregate, cement, concrete, and geopolymer materials. However, most of those applications use ashes remaining after the incineration of sewage sludge. Some research also indicate that the direct use of sewage sludge in the construction industry is possible through high-temperature vitrification, as SS pyrolysis residues are characterized by a solid stabilization of contaminants, such as heavy metals [

12], and toxic organics are oxidized to inorganic compounds and pose no threat to the environment.

High-temperature vitrification is an expensive process, so further research is needed toward the use of raw sewage sludge in building materials. For instance, Christodoulou and Stamatelatou [

13] investigated methods and technologies for using raw sludge and excess activated sludge mixtures as additives in cement production. The high content of organic matter and calcium oxides in the sludge suggests its potential use in asphalt concrete production, as bitumen interacts well with carbonates and is compatible with organic substances of natural origin and petroleum products [

14].

Using sewage sludge in the production of ceramic building materials is among the most promising directions. Ceramic manufacturers are increasingly looking to expand their product ranges and volumes by reducing dependence on the properties of clays from specific regions. It is also important to mention that extensive clay extraction may have a negative environmental impact, especially on aquatic ecosystems [

15]; therefore, there is a need for the development of sustainable and eco-friendly alternatives to conventional clay brick production. This can be achieved by modifying raw material compositions with additional components [

16]. Several studies have focused on the properties of ceramic building materials produced using sewage sludge as an additive [

17,

18]. These studies highlight multiple benefits, including increased plasticity, strength, frost resistance, and reduced density. It also needs to be emphasized that the sludge used for brick production does not pose a threat to the environment, and, in particular, the heavy metals contained in the sewage sludge are not leached from the product. Accordingly, the sludge embedded in the structure of the brick can be considered inert. In this way, the use of SS for brick production can be viewed as a more sustainable alternative, for example, to agricultural use of the sludge [

19].

The main motivation to this study was the fact that in many developing countries, including Kazakhstan, environmentally unfavorable methods of sewage sludge disposal predominate (e.g., landfilling). An additional threat to the environment is the fact that most of the waste sludge in these countries is so-called raw sludge, which is not subjected to stabilization processes (aerobic or anaerobic). Producing ceramic bricks requires balancing two conflicting objectives: improving sinterability, which increases strength, and enhancing porosity, which reduces density and strength. To produce high-quality products, it is essential to determine the optimal ratio of clay and sewage sludge in the mixture. Although the effect of different doses of SS added to clay used in brick production has been studied by many researchers, relatively few works concern raw sludge, and the research we conducted is the first of its kind in Kazakhstan. Considering the possibility of the practical application of the obtained results as soon as possible, in the current phase of research, we focused on the physical, mechanical, and structural properties of clay bricks with addition of raw, unstabilized SS; these properties determine the bricks’ suitability as a construction material. The next stage of research should include planning additional tests, including the potential ecological risk associated with the use of such construction material. Another motivation was assumption that the raw SS from Almaty’s wastewater treatment plant, when included in ceramic brick mixtures, would perform the following functions: (a) Burning additive—the significant organic content in the sludge allows its use as a substitute for traditional burning additives, such as sawdust; furthermore, the rounded shape of sludge particles, compared to the elongated form of sawdust, should improve the structure of the ceramic matrix. (b) Diluting additive—the mineral content suggests that the sludge could replace traditional chamotte and ash. (c) Crystallization additive—the presence of heavy metals could accelerate the crystallization of the melt. In this regard, the main objective of our study was to assess the feasibility of producing ceramic bricks using clay from the Almaty region, Kazakhstan, with added sewage sludge, the disposal of which is a significant issue in the region.

2. Materials and Methods

The wastewater treatment plant (WWTP) in Almaty includes three units: mechanical treatment, biological treatment, and wastewater discharge. The design capacity of the treatment facilities is 640,000 m3 per day, with an average inflow of 380,000 m3/day.

Suspended solids in the wastewater, capable of settling or floating under gravity, are removed in primary radial sedimentation tanks. Excess activated sludge from secondary clarifiers is also pumped to the distribution chamber of primary radial sedimentation tanks. Sediment collected in each tank is moved to a sump by scraper bridges and then pumped to sludge drying beds. The sludge is removed 1–3 times daily according to a pumping schedule prepared for a specific period. On average, 3700 m3 of sludge is sent daily to sludge drying beds.

Currently, only sludge drying beds are used for sludge treatment. These drying beds are designed for natural dewatering. The dewatered sludge is then transported to disposal sites. The sludge treatment process at Almaty Aeration Station is shown in

Figure 1.

For the laboratory experimental studies, samples of sewage sludge were taken from the primary radial sedimentation tanks of Aeration Station before being transferred to the sludge drying beds. Samples were collected manually in accordance with general guidelines [

20]. Before conducting laboratory experiments, SS was dewatered and sterilized through thermal treatment at 120 °C, resulting in a moisture content of 2.45%. To achieve relatively uniform fractions, the sludge was crushed to a size smaller than 1 mm and sieved. Thus, sludge particles used in the experiments were up to 1 mm in size.

The chemical composition of the sludge from Almaty’s WWTP was analyzed using established methodologies [

21,

22] in the laboratories of LLP “Institute of Hydrogeology and Geoecology named after U.M. Akhmedsafin” and the State Enterprise “Astana Su Arnasy”. Generalized value s for the oxides SiO

2, Al

2O

3, Fe

2O

3, K

2O, MgO, and CaO were determined according to the method FR. 1.31.2016.25423 [

21].

The granulometric composition of the processed sludge was determined using the methodology described in GOST 12536-2014 “Interstate Standard for Soils: Methods for Laboratory Determination of Granulometric (Grain) and Microaggregate Composition” [

23].

The main technological processes in brick production are as follows [

24]:

In laboratory conditions, clay from the Dolan deposit in the Almaty region was used to produce ceramic bricks. The deposit is located on the eastern slope of the Dolan River’s left bank, 2 km northwest of the Dolan settlement and 20 km west of Almaty City, in the foothills of the Zailiyskiy Alatau. The terrain is hilly with a gentle slope to the north, at altitudes ranging from 800 to 820 m above sea level. The approved geological resources of this deposit for a period of at least 24 years amount to 201,600 m3, and the existing brick production plant in this region has a permit for the extraction of 3260 m3 of clay per year.

The primary properties of the clay raw material were determined using standard methods in accordance with the requirements of GOST 21216-2014 “Clay Raw Materials: Testing Methods” [

25]. The chemical composition of the clay was analyzed using X-ray fluorescence spectroscopy on an X-ray spectrometer. In addition, SEM analysis of sewage sludge and clay was performed to examine samples surface’s topography and composition.

To evaluate the potential use of sewage sludge as an additive in ceramic bricks, an experiment was conducted based on standard ceramic brick manufacturing technology. Four compositions of mixtures were prepared, designated as 100:0 (pure clay), 95:5 (95%—clay, 5%—sludge), 90:10 (90%—clay, 10%—sludge), and 85:15 (85%—clay, 15%—sludge), and used for bricks manufacturing.

In Kazakhstan, the quality of the bricks is regulated by GOST 530-2012 “Bricks and Ceramic Stones” [

26], which includes a number of indicators, the most important of which are the shape and dimensions of the product. The total shrinkage during drying and firing is typically about 8%. With this shrinkage, the freshly molded raw brick should have the following dimensions: length—271 mm, width—130 mm, and thickness—70 mm.

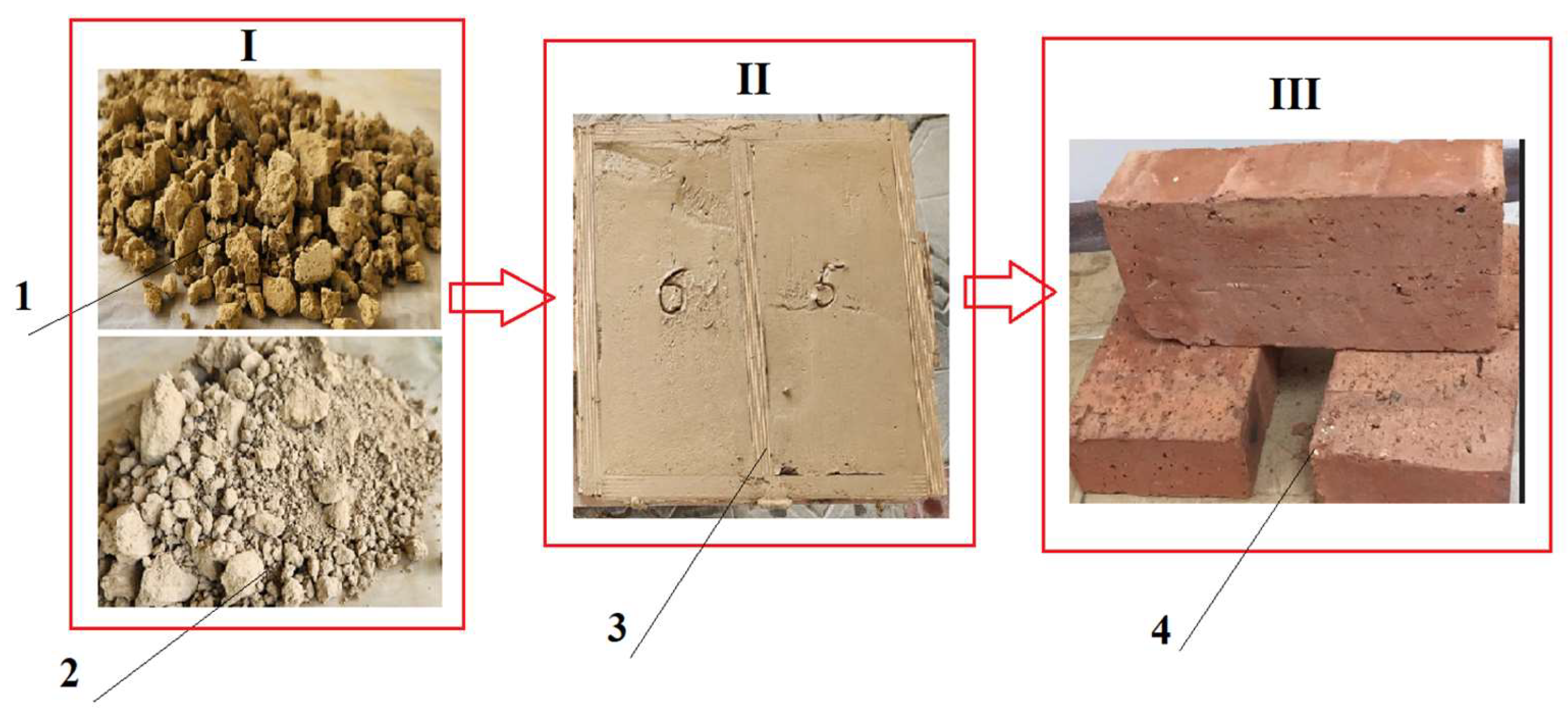

The brick production process consisted of three main stages: clay extraction; sewage sludge and clay mixture preparation; brick forming, drying, and firing. The brick production process diagram is shown in

Figure 2.

During the preparation of the mixture, clay lumps were crushed into particles of 1 mm. Simultaneously, stone inclusions and other impurities were removed from the batch. Brick drying was carried out in summer, outdoors, under a canopy on a concrete platform at an average air temperature of 25–38 °C for 10–16 days until the moisture content was reduced to 5–6%. Firing was performed in muffle furnaces under the following conditions: a temperature increase rate of 300 °C/hour, a slower increase in the temperature range of 500–600 °C, a hold time of 3 h at the maximum temperature (950 °C), and cooling inside the furnace.

The analysis of the obtained brick samples was conducted using standard methods in the laboratories of Satbayev University, Almaty. The key criteria for determining effectiveness included the main technical characteristics of ceramic bricks: strength, density, water absorption, and frost resistance.

Brick strength tests for compression and bending were conducted according to the requirements of GOST 8462–85 “Wall Materials. Methods for Determining the Limits of Strength in Compression and Bending” [

27].

The compressive strength Rc of a sample was calculated using the following formula:

where P is the maximum load recorded during sample testing (MN), (kgf); and F is the cross-sectional area of the sample, calculated as the arithmetic mean of the areas of its upper and lower surfaces, m

2 (cm

2).

The flexural strength Rb of a sample was determined using the following formula:

where P is the maximum load recorded during sample testing, MN (kgf); l is the distance between the axes of the supports, m (cm); b is the width of the sample, m (cm); and h is the height of the sample in the middle of the span without the leveling layer, m (cm).

Brick density is the physical quantity defined as the mass of the material per unit volume. The average density is determined from at least three brick samples. The sample volume is calculated based on its geometric dimensions, measured with an error of no more than 1 mm. The average density of a sample is calculated as the ratio of the sample volume to the mass of the sample, dried to a constant mass [

27].

Water absorption is an important quality indicator of ceramic bricks and is a function of their porosity, which depends on the grain composition of the mixture, its molding moisture, and the specific pressure during compaction. The water absorption of ceramic bricks should be at least 6%. To determine water absorption, five bricks were selected from the batch. Before testing, the ceramic bricks were dried to a constant mass. The brick samples were placed in a container with water at a temperature of 20 °C on a rack so that the water level was 2 cm above the bricks, and they were kept for 48 h. After saturation, the samples were removed from the water, wiped, and weighed. Water absorption was determined as the difference in the mass of water-saturated and dried samples divided by the mass of dried sample and expressed in percents [

28].

The average value of water absorption for all samples, calculated to 1% accuracy, is taken as the water absorption value.

Porosity is determined as the ratio of the volume of sand filling the voids to the brick volume. Bricks can be solid (without voids), solid with technological voids (porosity not exceeding 13%), or hollow (porosity greater than 13%).

The voids in the brick placed on a sheet of paper on a flat surface with openings facing upwards are filled with dry quartz sand with a fraction of 0.5–1.0 mm. The brick is removed, the sand is poured into a glass measuring cylinder, and its volume is recorded [

25].

The result of the measurement is taken as the average value of three parallel measurements, rounded to 1%.

Frost resistance is the ability of the material, in a water-saturated state, to withstand repeated freezing and thawing cycles without signs of destruction. Frost resistance is characterized by the number of freeze (at temperatures not higher than −18 °C) and thaw cycles (in water) that the material can withstand without strength reduction, mass loss, or external damage as specified in the relevant GOST standard [

26]. Materials are classified by frost resistance grades: F15, F25, F35, F50, F100, etc. For example, a frost resistance grade of F15 for bricks means that the samples from the batch withstand at least 15 freeze–thaw cycles without external damage (chipping, surface peeling, etc.).

3. Results and Discussion

3.1. Chemical and Granulometric Composition of Clay and Sewage Sludge

After drying, the sludge is a loose, low-strength, primarily fine-grained material. Determining the chemical composition of sewage sludge is crucial when selecting a method for its utilization. Therefore, the chemical composition of SS from the WWTP in Almaty was analyzed. The data on the chemical composition of SS are presented in

Table 1.

The data in

Table 1 indicate that the primary chemical compounds in sewage sludge are silicon dioxide (35.7%), aluminum oxide (7.3%), iron oxide (11.2%), and calcium oxide (10.6%). The presence of calcium oxide is a positive factor in ceramic brick production, as it plants the formation of calcium-containing phases, such as anorthite, during firing. The iron oxide in the sludge indicates the presence of quartz and feldspar minerals. The concentration of heavy metals, including the most toxic ones, such as As, Pb, Cd and Cr, is relatively small. Nevertheless, the potential risk of releasing heavy metals into the environment from products containing sewage sludge should be taken into account. Other studies, however, show that ceramic bricks containing SS appear to be an environmentally safe product. Leaching tests conducted by Cusido and Cremades [

29] proved that the addition of SS to ceramic products does not increase the content of heavy metals in the leachate, regardless of the sludge dose used, while Weng et al. [

30] showed that leachate for ceramic bricks prepared with of up to 30% of SS added contains significantly less heavy metals, including Zn and Cd, than leachate for dried sludge. This can be attributed to the fact that at a firing temperature of 950 °C, heavy metals pass into stable non-leachable forms, often binding in a crystalline or glassy matrix. This significantly reduces their mobility and prevents environmental pollution.

As previously noted, clay from the Dolan deposit in the Almaty region was used to produce ceramic bricks. The chemical composition of the clay is shown in

Table 2.

Based on the content of Al2O3 and colored metal oxides in the calcined state, the raw material is acidic, with a high Fe2O3 content and low TiO2 content.

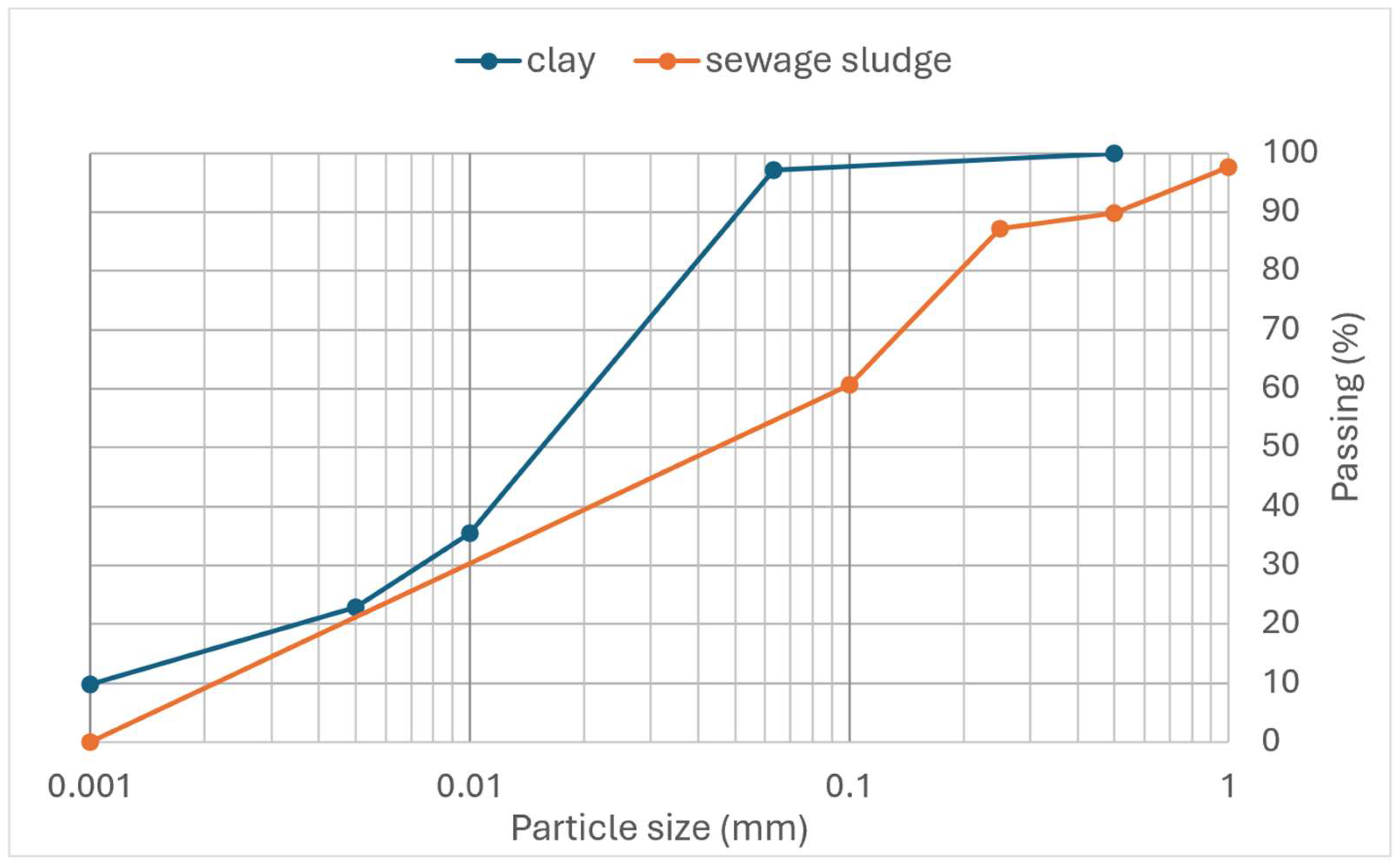

Granulometric composition is a key indicator of the physical properties and structure of the material. The granulometric composition of processed sewage sludge and clay from Dolan deposit was determined, and the results are presented in

Figure 3.

The analysis revealed that the dried sludge contains a significant amount of fine sand, as well as coarse, medium, and fine dust particles. For the clay, considering the fine-grained fraction content of 0.005 mm, the sample belongs to the group of medium-dispersed raw materials.

In addition, the plastic limit (PL), defined as moisture content of the sample that can no longer be rolled into a 3 mm diameter thread without crumbling, and the liquid limit (LL), defined as the water content at which the sample changes from plastic state to a liquid state, were determined. For the raw clay, the PL and LL values were 15.49% and 26.5% respectively, which allowed estimating the plasticity index (PI = LL − PL) as 11.01%. In turn, the PI was determined for the tested clay and sewage sludge mixtures of three compositions: 95:5 (5%wt of sewage sludge added to clay)—10.84%, 90:10—10.18%, and 85:15—9.66%. In our opinion, the decrease in plasticity is related to the presence of organic matter and mineral admixtures in the sludge, which disrupt the structure of the clay matrix and reduce its ability to retain water. The pure clay, as well as all examined compositions, can be classified as moderately plastic (PI > 7), which meets formal requirements for raw materials used for brick production [

26].

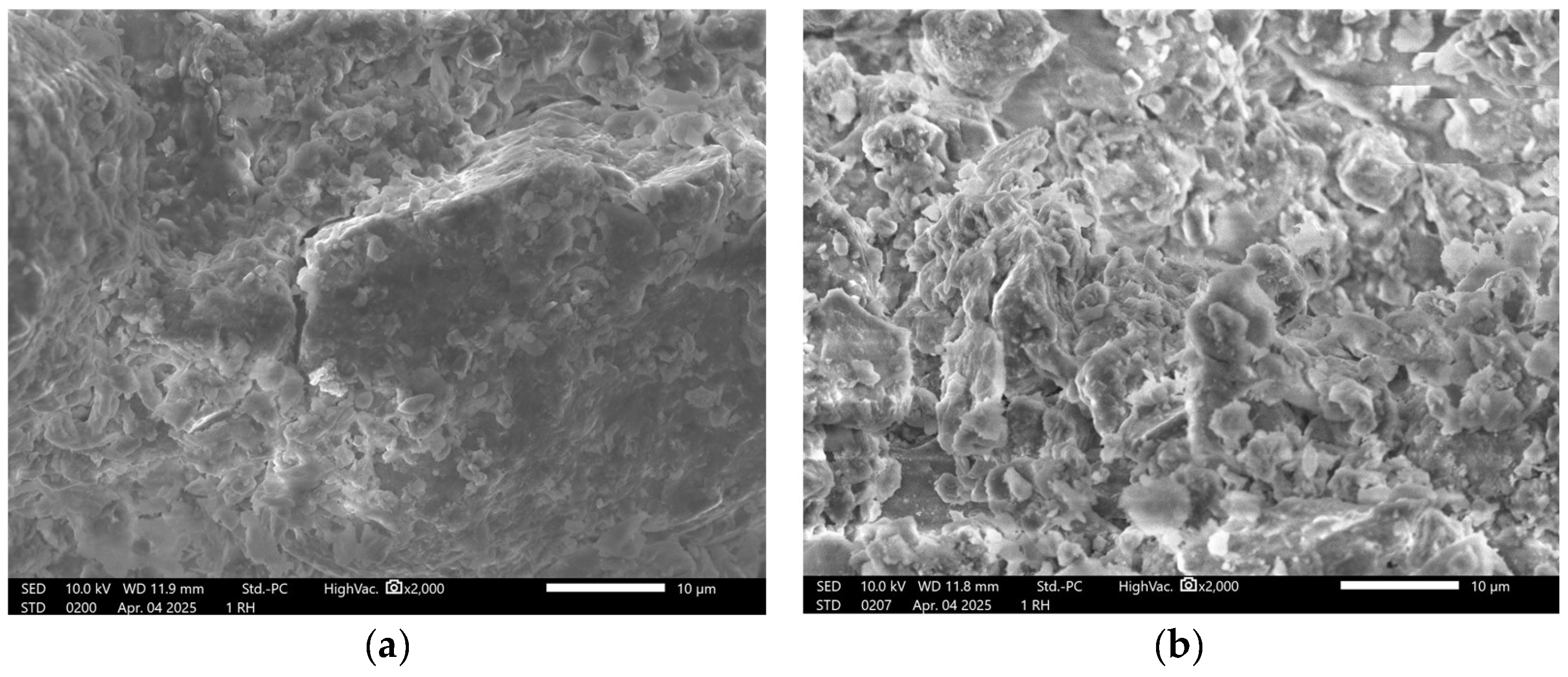

3.2. Scanning Electron Microscopy (SEM) Analysis

To compare the microstructure of raw clay and sewage sludge, SEM analysis was performed. Samples were examined using NeoScope benchtop scanning electron microscope JCM-7000 under magnitudes of 500, 1000, 2000, and 3500.

Figure 4 presents example micrographs obtained with magnitude 2000.

It can be observed that particles of various shapes and sizes, from submicron to several micrometers, are present in the sewage sludge, forming larger aggregates with irregular shapes. The observed aggregates may be the result of flocculation, aided by biological material present in the sludge. There is also considerable porosity between the particles. The presence of particles of different sizes and irregular shapes may indicate that there are components of different origin in the sludge: mineral, organic and inorganic, as well as biological. In the case of clay, a more homogeneous structure is apparent, containing mainly particles of small size, which is confirmed by the results of the granulometric composition of sewage sludge and clay (

Figure 3).

3.3. Results of Laboratory Experimental Studies

In laboratory experiments, the following characteristics were selected as criteria for determining the effectiveness of ceramic bricks: strength, density, water absorption, and frost resistance.

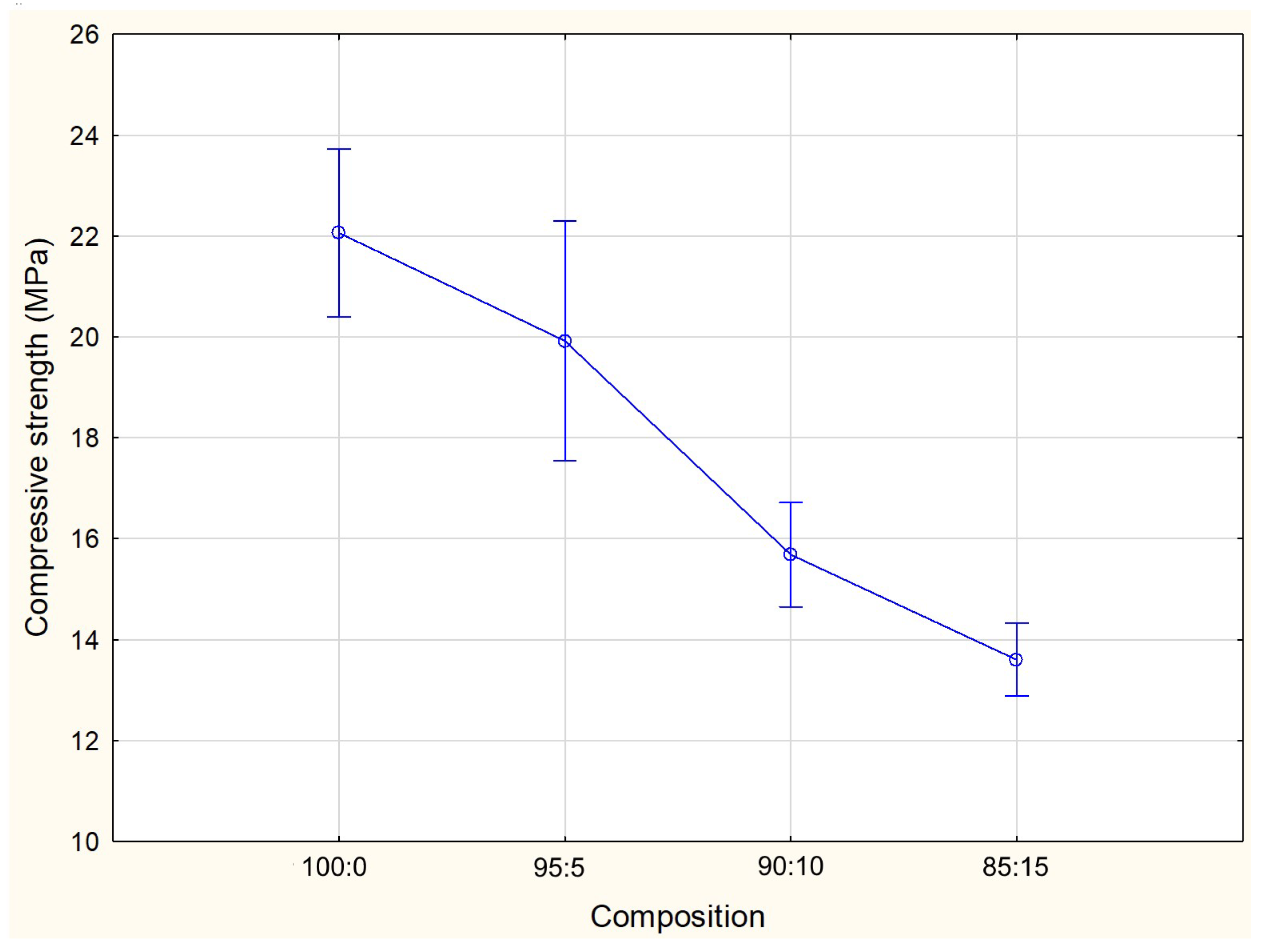

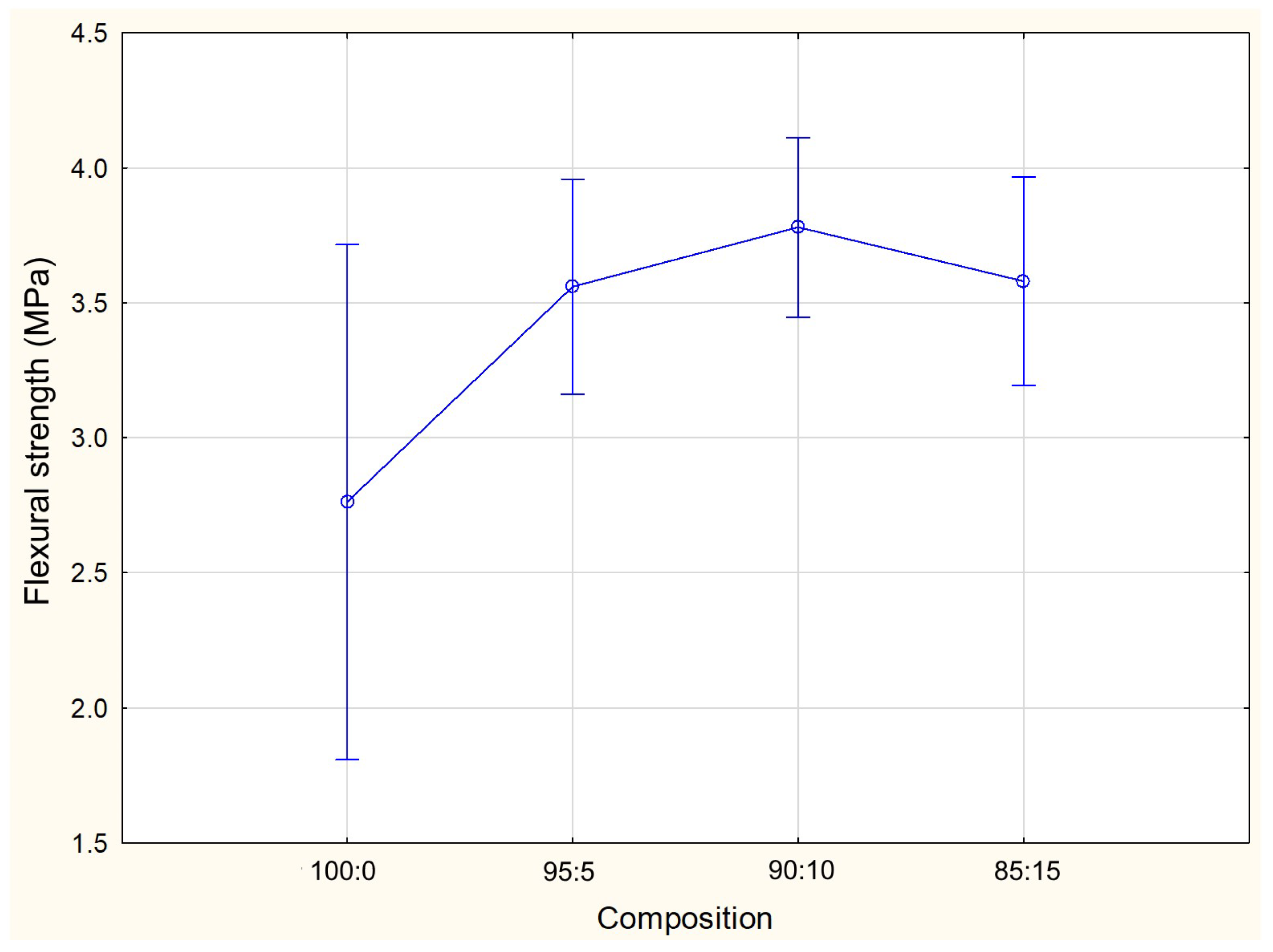

The compressive and flexural strength limits of the bricks were determined using samples consisting of five whole bricks for each composition. The variations in the obtained results are presented as graphs of mean values and 95% confidence limits in

Figure 5 and

Figure 6, respectively. Graphs were prepared used TIBCO Statistica ver.13 software.

The experiment revealed that the addition of sewage sludge significantly reduces compressive strength. A decrease in compressive strength may be attributed to the bulk density decrease and the increase in water absorption with the increase in the amount of added SS (

Figure 7 and

Figure 8). In addition, deterioration in the cohesion of the structure may occur with the addition of a loose and weakly bound component (dry sludge), in contrast to homogeneous and plastic clay. The obtained results are mostly consistent with data from other studies. For example, Martinez-Garcia et al. [

31] found a significant reduction in the compressive strength of bricks from 38 MPa for pure clay bricks to 18 MPa (addition of 15%wt SS), i.e., by 52%, while in the review work by Munoz Velasco et al. [

32], an average estimate of the reduction in the compressive strength of bricks manufactured with the addition of SS was presented from 25 MPa (pure clay bricks) to 18 MPa (addition of 15%wt SS).

On the other hand, a slight increase in flexural strength was observed. This increase may be attributed to the presence of mineral fractions (Fe

2O

3 and SiO

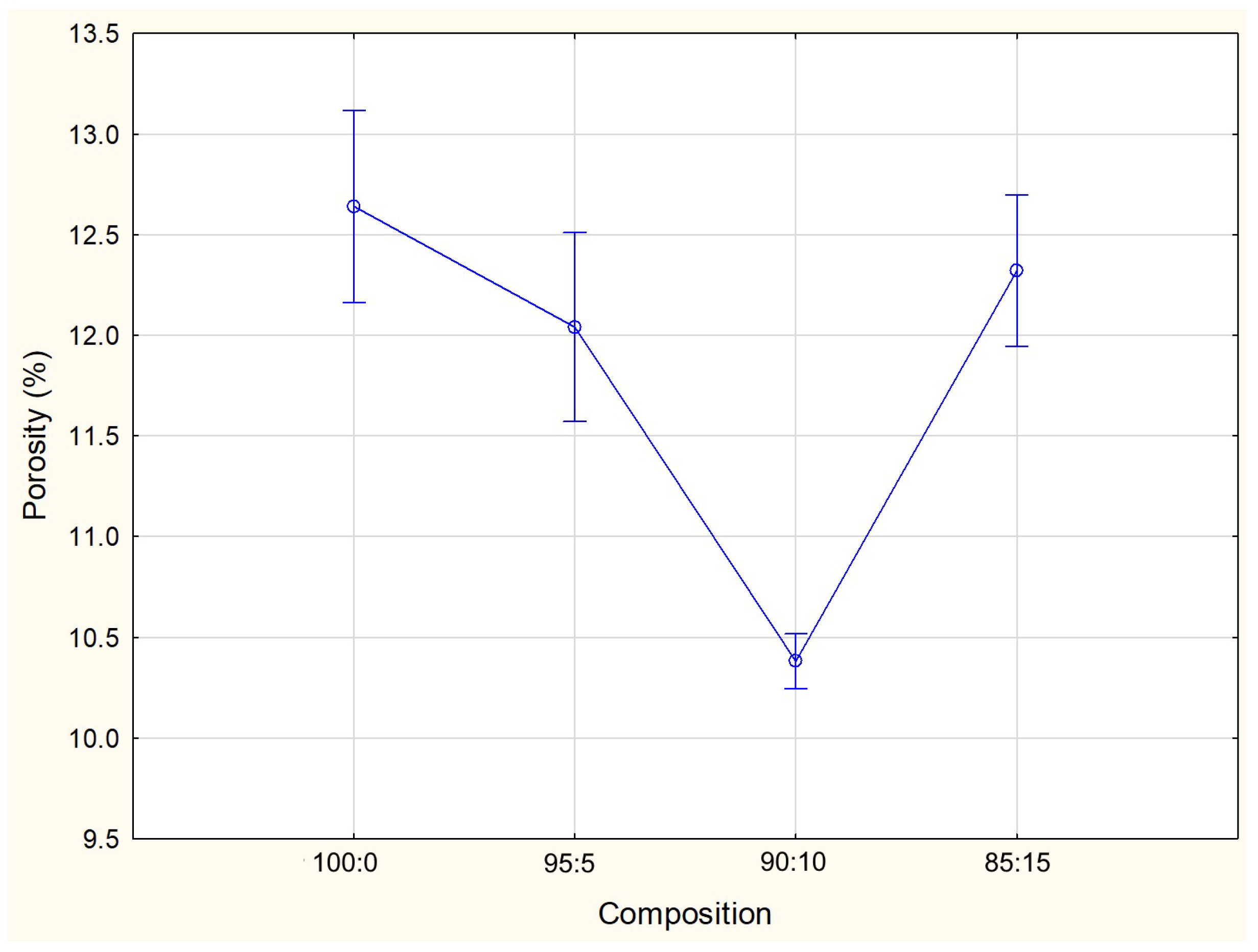

2) and fine-sand grains in SS, which help stabilize the structure during bending. The maximum value of flexural strength for the composition with 10%wt SS can be related to the decrease in porosity observed for this dose of SS (

Figure 9). The average density, water absorption, and porosity of the bricks was determined similar to the strength analyses, using samples of five whole bricks for each composition. The mean values with 95% confidence limits are presented in

Figure 7,

Figure 8 and

Figure 9, respectively.

As anticipated, the average density of the tested samples decreased proportionally to the increase in the amount of sludge in the mixture, reaching about 80% of the reference value (composition 100:00) for the 85:15 composition containing 15%wt sewage sludge. One of the reasons for the decrease in the density of the bricks may be the firing of the organic fraction present in the sludge [

31,

33]. As the result, additional pores are formed, increasing porosity and decreasing density. Similar results were obtained by Martinez-Garcia et al. [

31], who observed a decrease in the bulk density of the bricks from 11% (for the mixture with 5% of SS added) to 17% (15% of SS added).

Analysis of the data shows that the 90:10 composition, with sludge content of 10% by weight, demonstrated the best physico-mechanical properties. This composition showed increased flexural strength and a simultaneous reduction in average density by 15.4%, indicating the improved structural quality of the resulting ceramics.

Water absorption is crucial for the durability of bricks. With smaller amounts of absorbed water, the expected resistance to external conditions is greater. An increase in the amount of added SS to the clay can cause a decrease in the binding capacity of the mixture, which, in turn, leads to an increase in the size of internal pores in the brick. Consequently, the amount of water absorbed by the brick increases [

30]. This phenomenon is also confirmed by SEM micrographs (

Figure 4b), where flocculated and loose sludge structures are visible, promoting the formation of capillaries.

The obtained results follow a similar trend and are consistent with observations from other studies. However, the values obtained in different studies may vary, depending on the properties of clay and SS used. For example, Areias et al. [

17] noted an increase in water absorption of 9%, from 20.6% (pure clay) to 22.6% (15%wt SS), while Zat et al. [

5] noted an increase of 41%, from 9.55% (pure clay) to 16.31% (15%wt SS) for bricks sintered in a temperature of 950 °C. It is worth noting that in our study, for the 95:5 and 90:10 compositions, the increase in water absorption was insignificant (by 4% and 5.7% respectively, compared to the composition 100:0), whereas in the 85:15 composition, it was significant (by 27.4% compared to the 100:0 composition).

Porosity tests showed a significant decrease for the 90:10 composition, which can be related to the structure and composition of the sewage sludge. At this concentration, the sludge can perform a compacting function due to the fine-grained fraction particles and high organic compounds content, which, when mixed and dried, contribute to a denser arrangement of particles in the molding mass. This leads to a decrease in the total pore volume in the brick body after sintering. In addition, at this concentration, partial melting of organic residues may occur, which contributes to the baking of small pores, especially at a firing temperature of 950 °C. With a further increase in the sludge content (over 10%), the effect changes, since excess organic matter and uneven distribution of phases can again increase porosity.

Pore geometry analysis showed that the diameter of vertical cylindrical pores and the side dimensions of square pores did not exceed 20 mm, while the width of slit-like pores did not exceed 16 mm. The porosity of the ceramic bricks did not exceed 13%.

Frost resistance tests of ceramic brick samples with different compositions showed no external damage (chips, surface peeling, etc.) after 20 freeze–thaw cycles, so each examined composition can be classified as grade F15 according to GOST 530-2012 [

26].

It is worth emphasizing that the results of our research are largely consistent with the findings of the other researchers discussed above. With an increasing proportion of sludge in the mixture of clay and sewage sludge, the compressive strength of the bricks decreases, and their density also decreases, while water absorption increases. However, when the proportion of sludge in the mixture with clay does not exceed 15%wt, both the compressive strength and the level of water absorption still meet the requirements set for construction products in various countries, including Kazakhstan.