Antimicrobial Action of Ginger and Ornamental Rock Wastes for Cement Mortar

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

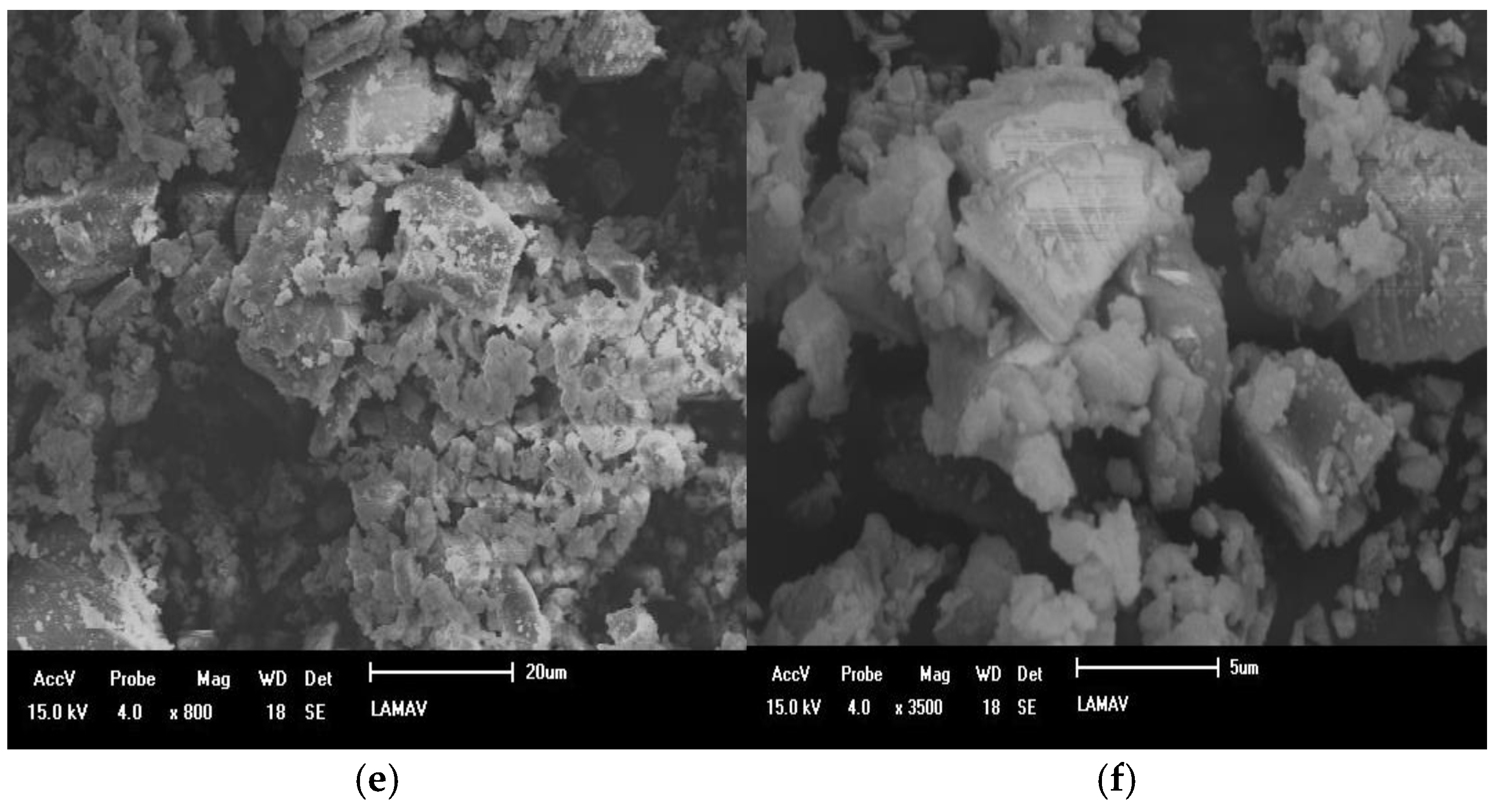

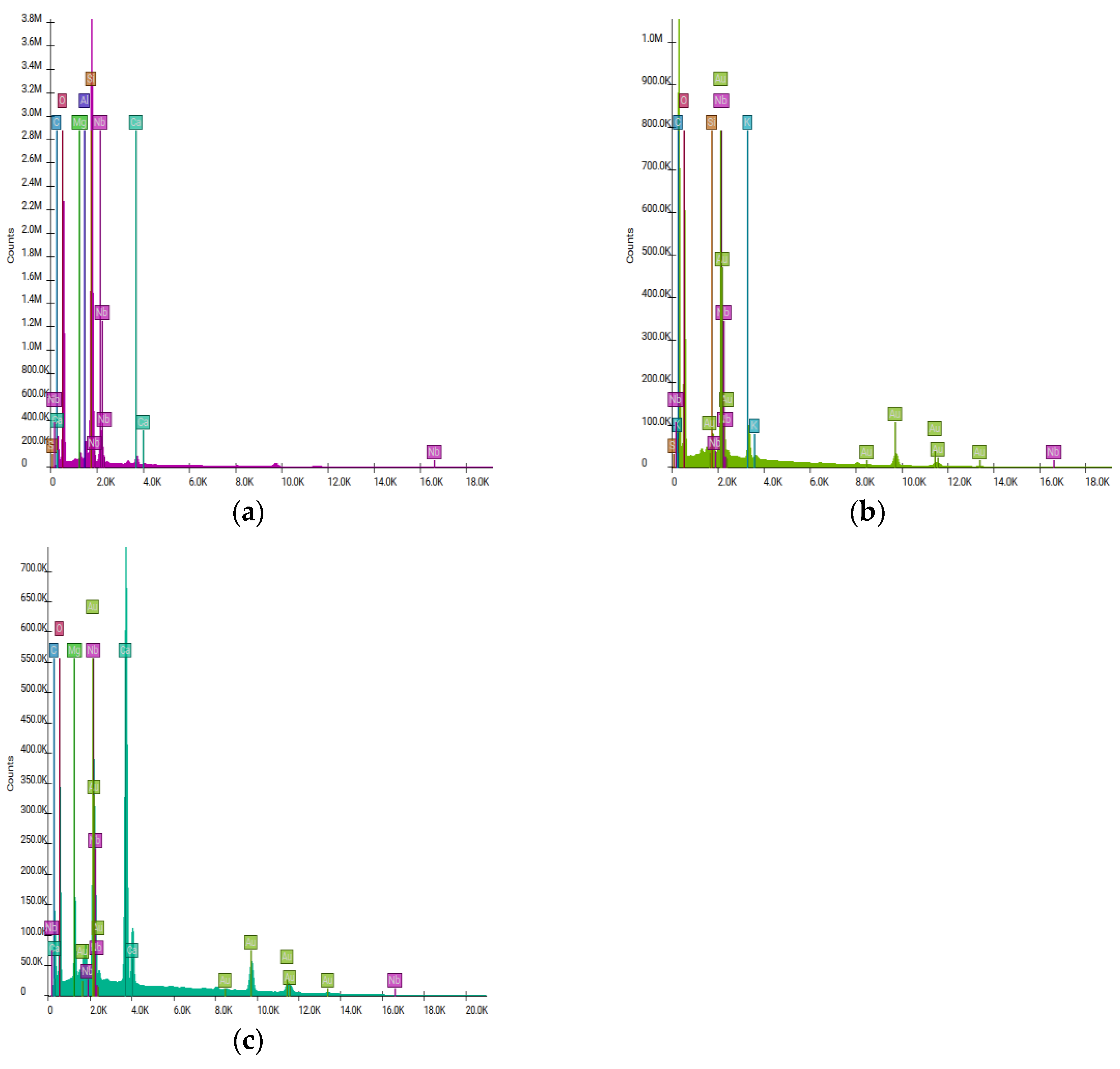

2.2. Morphological Characterization

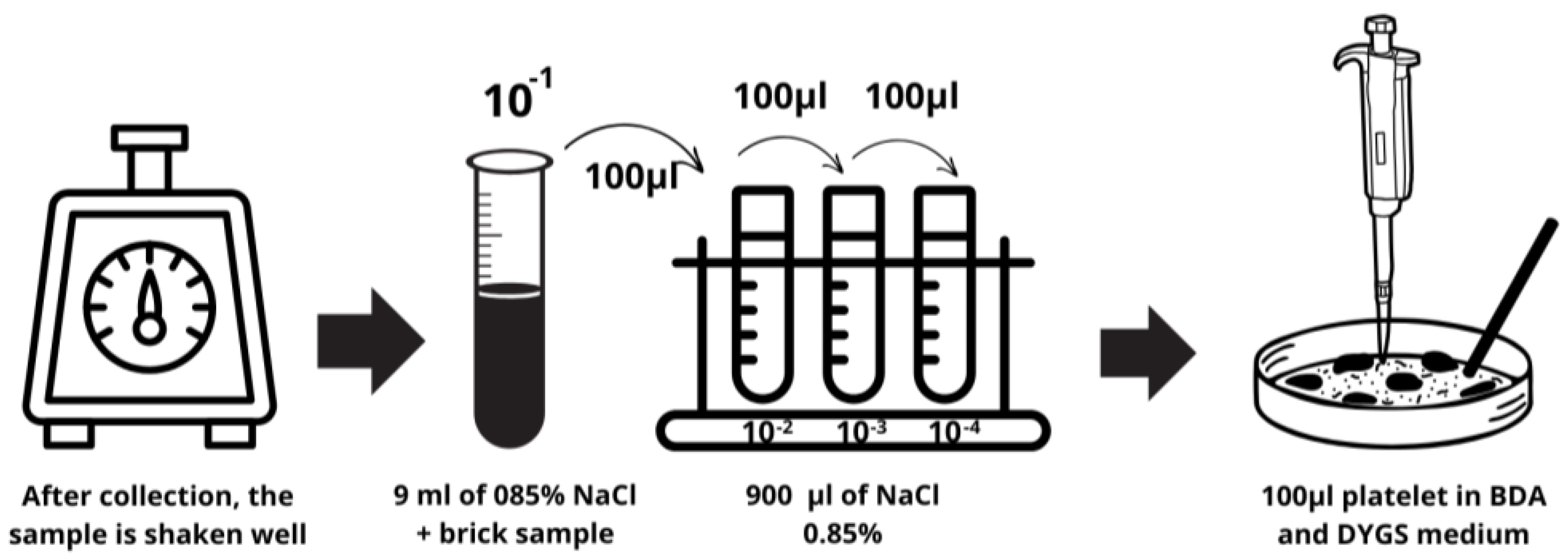

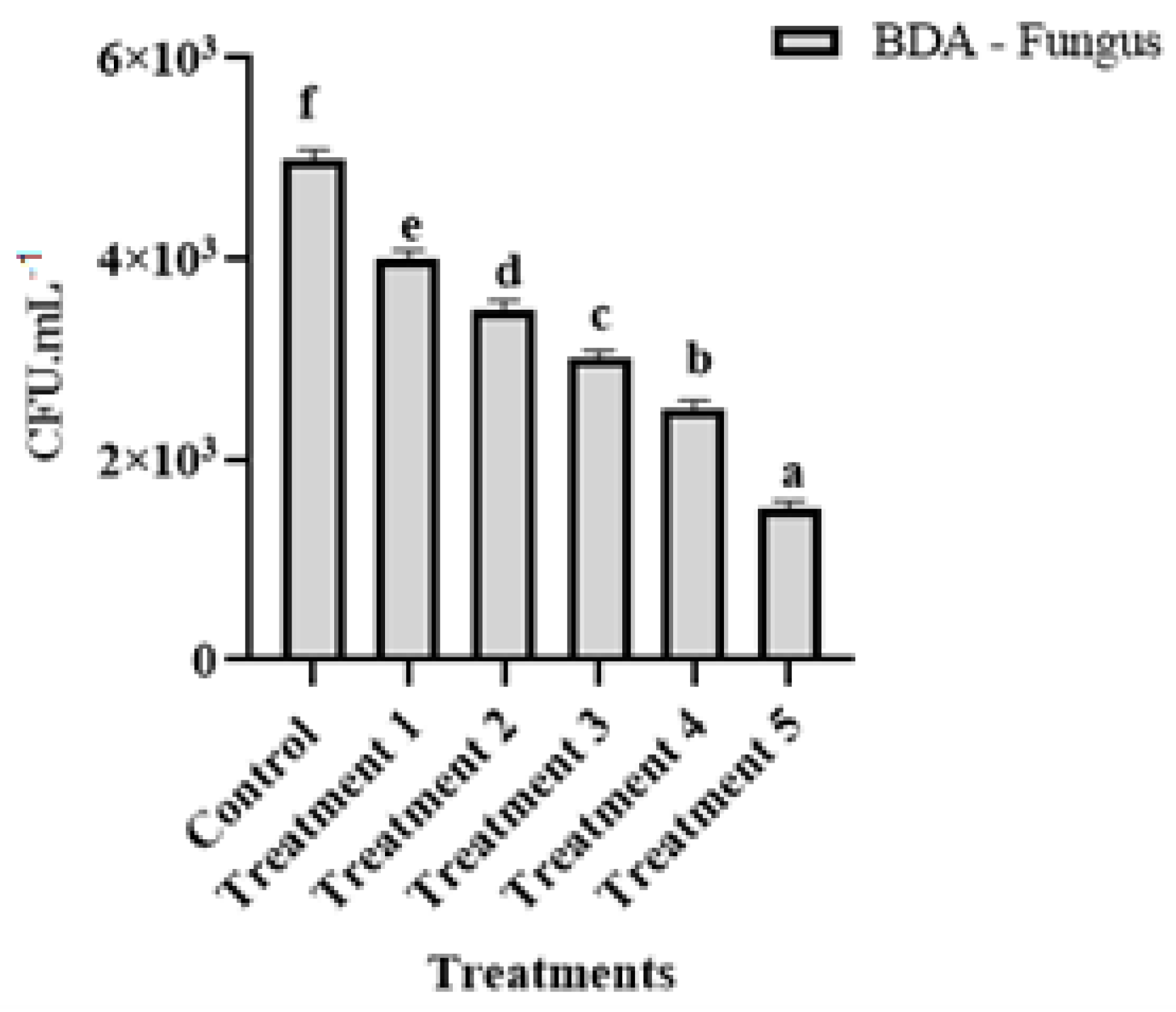

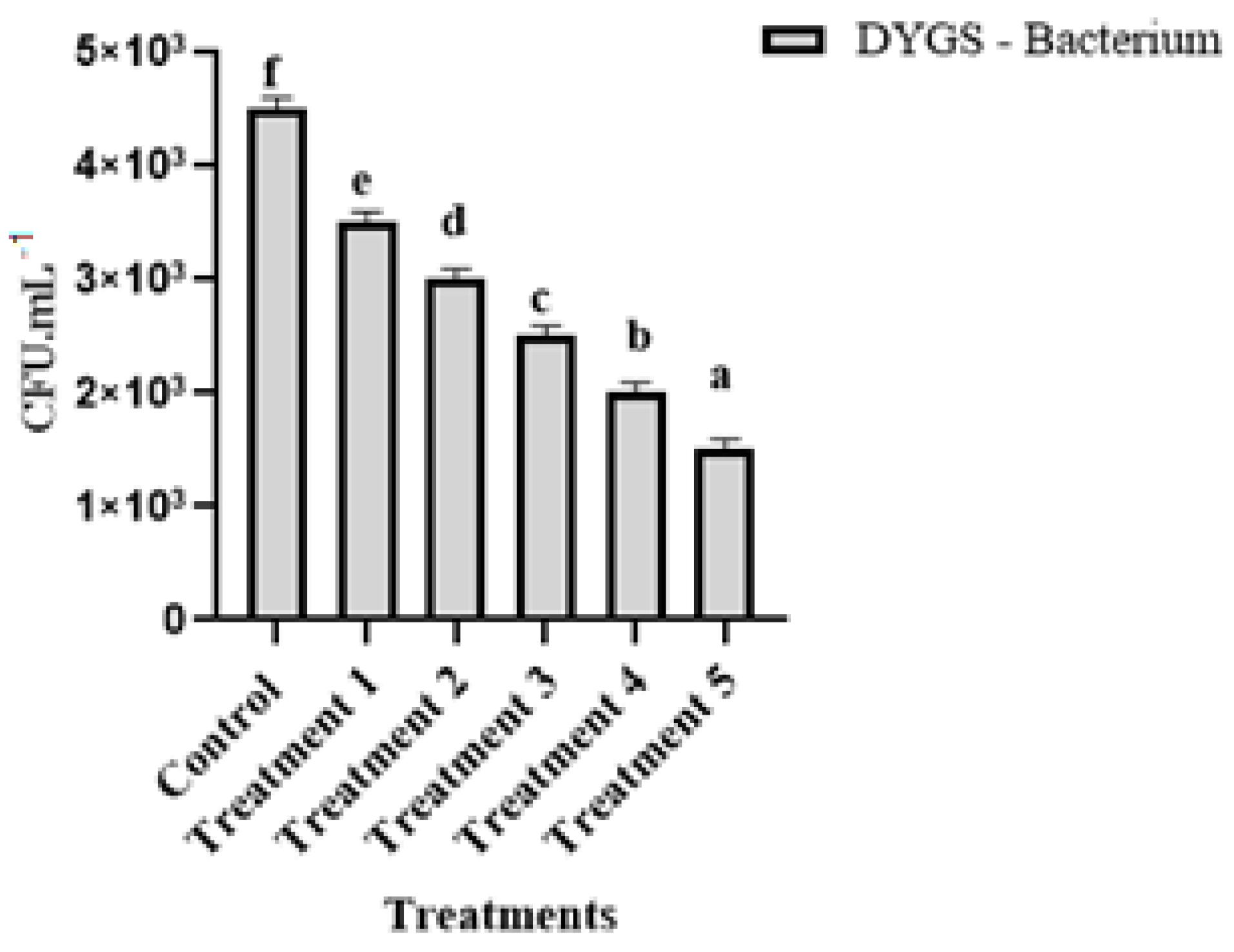

2.3. Microorganism Isolation

2.4. Mortar Fabrication

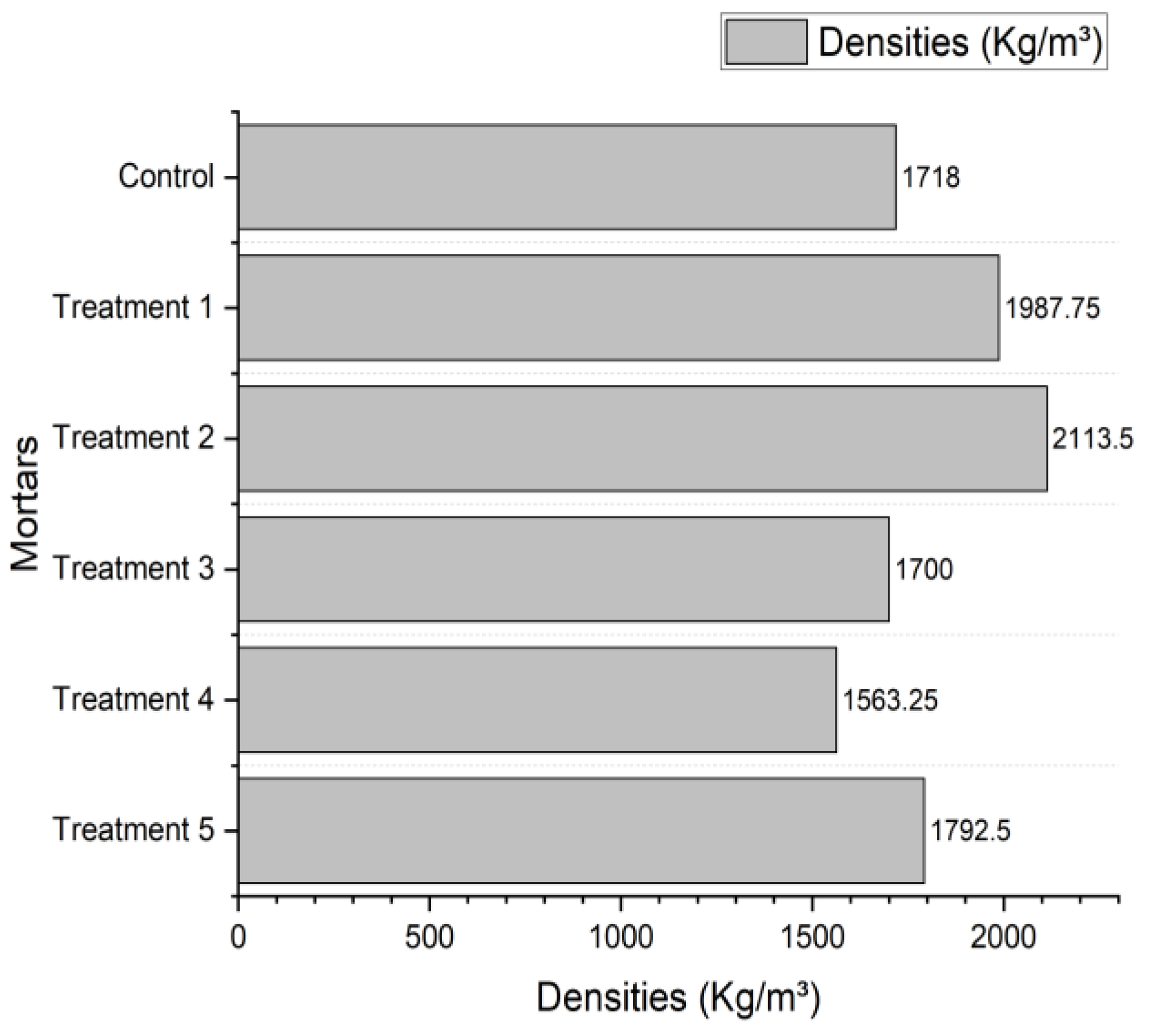

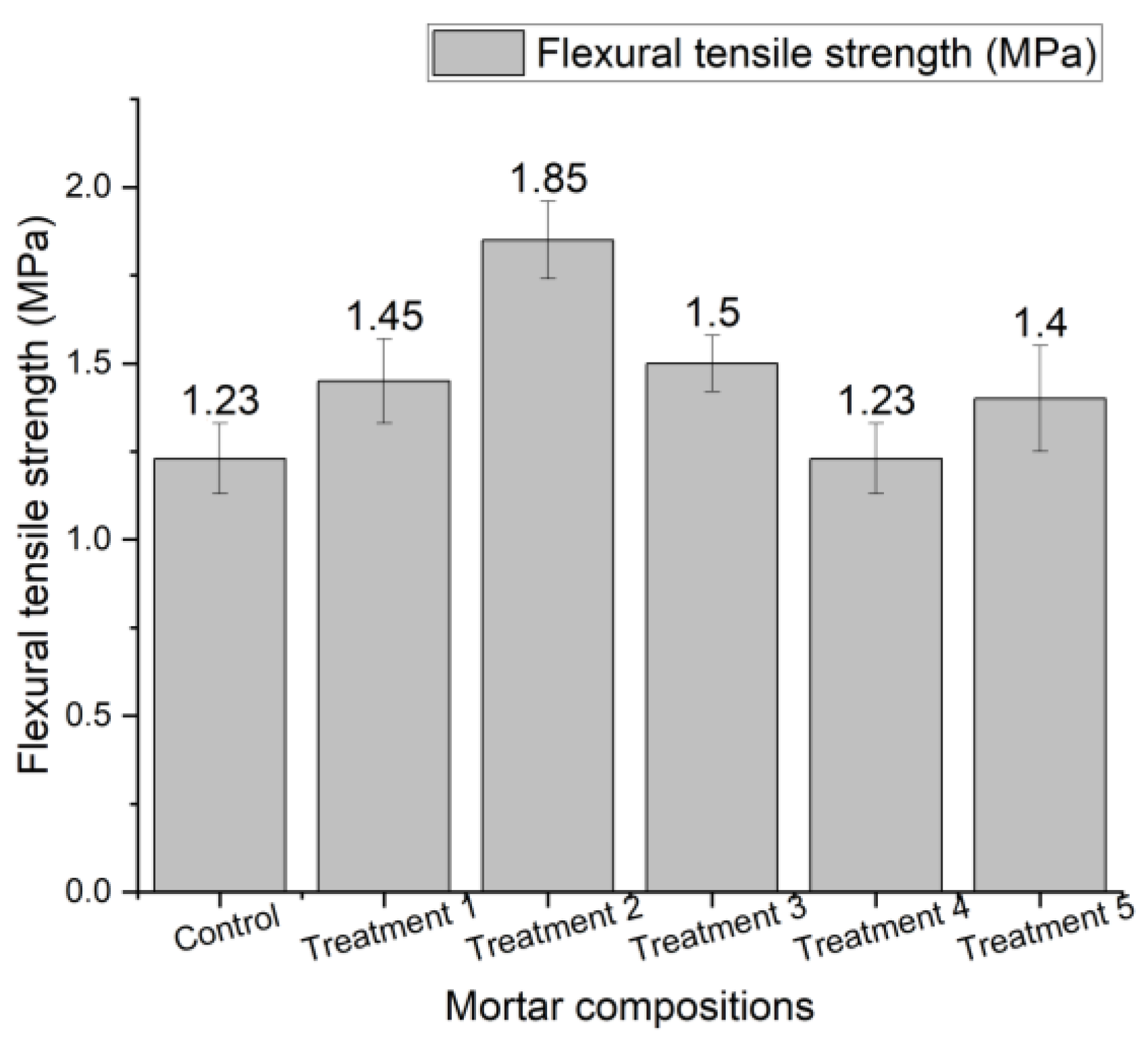

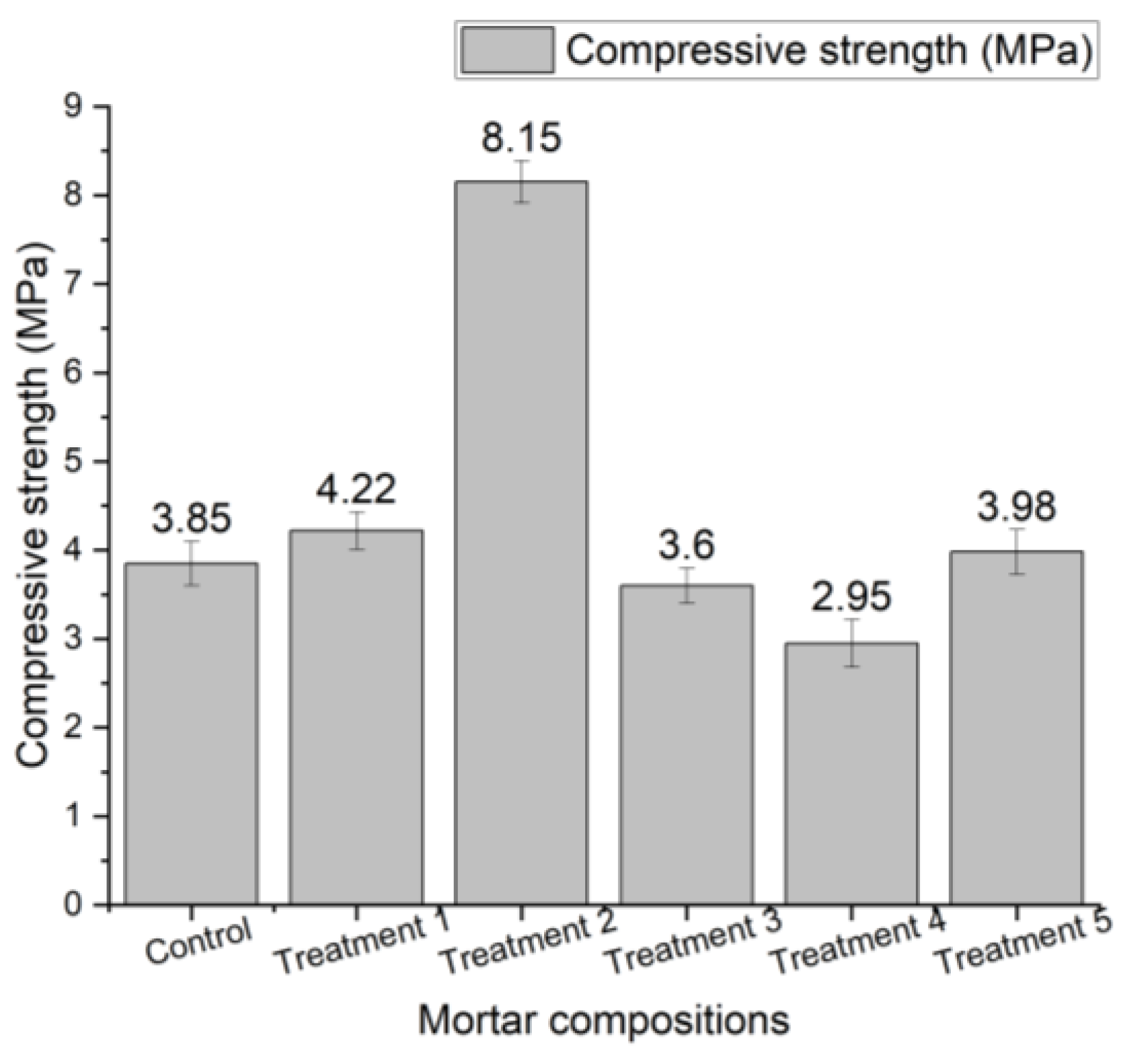

2.5. Physical and Technological Tests

2.6. Weathering Performance

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UENF | State University of Northern Rio de Janeiro Darcy Ribeiro |

| LAMAV | Advanced Materials Laboratory |

| CFU | Colony-forming units |

| SEM | Scanning electron microscope |

| EDS | Energy-dispersive detector |

| BDA | Batata dextrose agar |

| DYGS | Dextrose yeast glucose sucrose |

References

- Lopes, L.d.F. Civil Construction Materials I; Editora e Distribuidora Educacional S.A: Sao Paulo, Brazil, 2017; p. 192. Available online: https://cm-kls-con-tent.s3.amazonaws.com/201702/INTERATIVAS_2_0/MATERIAIS_DE_CONSTRUCAO_CIVIL_I/U1/LIVRO_UNICO.pdf (accessed on 26 January 2025).

- Rosello, M.T.V. Cement Mortars for Albanileria; Instituto Eduardo Torroja: Madrid, Spain, 1976. [Google Scholar]

- Ribeiro, R.P.; Sichieri, E.P.; Alves, D.T.; De Castro Xavier, G.; De Azevedo, A.R.G.; Monteiro, S.N. Adherence of Brazilian dimension stones by mortar adhesion: Influence of temperature. J. Mater. Res. Technol. 2023, 24, 8547–8557. [Google Scholar] [CrossRef]

- Botelho, L.C.G.; Xavier, G.C.; Paes, A.L.C.; Azevedo, A.R.G. Lime replacement by finely ground clay from the north fluminense region of RJ in mortar for coating walls and ceilings. J. Mater. Res. Technol. 2023, 23, 5105–5114. [Google Scholar] [CrossRef]

- Bonfim, W.B.; De Paula, H.M. Characterization of different biomass ashes as supplementary cementitious material to produce coating mortar. J. Clean. Prod. 2021, 291, 125869. [Google Scholar] [CrossRef]

- De Aquino, L.A.S.; Silva, T.R.C.; Teixeira Marvila, M.; De Azevedo, A.R.G. Agro-industrial waste from corn straw fiber: Perspectives of application in mortars for coating and laying blocks based on Ordinary Portland cement and hydrated lime. Constr. Build. Mater. 2022, 353, 129111. [Google Scholar] [CrossRef]

- Pulido-Arcas, J.A.; Flores-Alés, V.; Pérez-Fargallo, A. Coating mortars with improved physical properties, economic cost, and carbon footprint. Case Stud. Constr. Mater. 2022, 16, e01095. [Google Scholar] [CrossRef]

- Wang, D.; Guan, F.; Feng, C.; Mathivanan, K.; Zhang, R.; Sand, W. Review on Microbially Influenced Concrete Corrosion. Microorganisms 2023, 11, 2076. [Google Scholar] [CrossRef]

- Farooq, S.B.; Sikandar, M.A.; Khan, M.H.; Zhao, Q.; Zhu, H.; Ullah, N.; Noman, M.; Khan, I.U.H. Effect of Sodium Paraben-based Anti-fungal Agents in Controlling the Aspergillus niger Growth in Cement Mortars. J. Adv. Concr. Technol. 2023, 21, 680–694. [Google Scholar] [CrossRef]

- Lekshmi, M.S.; Vishnudas, S.; Anil, K.R. Lignocellulosic materials as reinforcement and replacement for binders in masonry mortar. Constr. Build. Mater. 2021, 282, 122607. [Google Scholar]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef]

- Silva, A.; Gaspar, P.L.; De Brito, J. Durability of current renderings: A probabilistic analysis. Autom. Constr. 2014, 44, 92–102. [Google Scholar] [CrossRef]

- Guessous, S.; Laraki, M.; Sekhara, Y. Advanced expansion joints monitoring system based on IoT and intelligent development. Mater. Today Proc. 3rd Int. Congr. Mater. Struct. Stab. 2022, 58, 1272–1276. [Google Scholar] [CrossRef]

- Junior, G.B.; Nascimento, L.C.; de Castro Xavier, G.; Monteiro, S.N.; Vieira, C.M.; Marvila, M.T.; Alledi, C.T. Durability for coating mortars: Review of methodologies. J. Mater. Res. Technol. 2024, 30, 657–671. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Szelag, M. Advanced interactions of cement-based materials with microorganisms: A review and future perspective. J. Build. Eng. 2022, 45, 103458. [Google Scholar] [CrossRef]

- Fatima, A.; Verma, A.; Ahmad, D.; Khan, F.; Tripathi, K.; Meenakshi, D.R.V. Current Updates on Isolation, Maintenance, Improvement and Preservation of Industrial Strains. In Futuristic Trends in Biotechnology; Book 21, IIP Series; Selfypage Developers Pvt Ltd.: Chikmagalur, India, 2024; Volume 3, pp. 124–136, e-ISBN: 978-93-6252-519-2. [Google Scholar]

- Nogueira, A.V.; Filho, G.N.S. Microbiology. Florianópolis, Brazil. Biology-Ead-Ufsc. 2015, p. 211. Available online: https://antigo.uab.ufsc.br/biologia//files/2020/08/Microbiologia.pdf (accessed on 15 May 2025).

- Yamanaka, T.; Helgeland, L.; Farstad, I.N.; Fukushima, H.; Midtvedt, T.; Brandtzaeg, P. Microbial colonization drives lymphocyte accumulation and differentiation in the follicle-associated epithelium of Peyer’s patches. J. Immunol. 2003, 170, 816–822. [Google Scholar] [CrossRef]

- Wiktor, V.; De Leo, F.; Urzì, C.; Guyonnet, R.; Grosseau, P.H.; Garcia-Diaz, E. Accelerated laboratory test to study fungal biodeterioration of cementitious matrix. Int. Biodeterior. Biodegrad. 2009, 63, 1061–1065. [Google Scholar] [CrossRef]

- Stanaszek-Tomal, E. Microorganisms in Red Ceramic Building Materials—A Review. Coatings 2024, 14, 985. [Google Scholar] [CrossRef]

- Elfaky, M.A.; Okairy, H.M.; Abdallah, H.M.; Koshak, A.E.; Mohamed, G.A.; Ibrahim, S.R.M.; Alzain, A.A.; Hegazy, W.A.H.; Khafagy, E.-S.; Seleem, N.M. Assessing the antibacterial potential of 6-gingerol: Combined experimental and computational approaches. Saudi Pharm. J. 2024, 32, 102041. [Google Scholar] [CrossRef]

- Singh, G.; Kapoor, I.P.S.; Pandey, S.K.; Singh, U.K.; Singh, R.K. Studies on essential oils: Part 10. Antibacterial activity of volatile oils of some spices. Phytother. Res. 2008, 22, 695–700. [Google Scholar] [CrossRef]

- Ghasemzadeh, A.; Jaafar, H.Z.E.; Rahmat, A. Identification and concentration of some flavonoids and the antioxidant activity of Malaysian young ginger (Zingiber officinale Roscoe) varieties. Molecules 2010, 15, 4324–4333. [Google Scholar] [CrossRef]

- De Leo, F.; Urzì, C. Fungal Colonization on Treated and Untreated Stone Surfaces; Swets & Zeitlinger BV: Lisse, The Netherlands, 2003; pp. 213–218. [Google Scholar]

- ABNT NBR16697; Ciment Portland—Requisitos. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2018. Available online: https://www.target.com.br/produtos/normas-tecnicas/44630/nbr16697-cimento-portland-requisitos (accessed on 26 January 2025).

- ABNT NBR7214; Normal Sand for Cement Testing. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2015. Available online: https://www.target.com.br/produtos/normas-tecnicas/36277/nbr7214-areia-normal-para-ensaio-de-cimento-especificacao (accessed on 26 January 2025).

- ABNT NBR7215; Portland Cement—Determination of Resistance. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 1996. Available online: https://www.target.com.br/produtos/normas-tecnicas/36304/nbr7215-cimento-portland-determinacao-da-resistencia-a-compressao-de-corpos-de-prova-cilindricos (accessed on 26 January 2025).

- Instituto Federal do Espírito Santo (IFES). Primeira Cultivar de Gengibre no Brasil é Registrada no Espírito Santo. 2024. Available online: https://www.ifes.edu.br/noticias/21437-primeira-cultivar-de-gengibre-no-brasil-e-registrada-no-espirito-santo (accessed on 16 April 2025).

- Vaňatka, M.; Wandrol, P.; Klusacek, J.; Vaverka, O.; Šembera, O.; Tůma, T.; Stephens, C. What Can You Do with a Million X-rays? Microsc. Microanal. 2022, 28, 500–502. [Google Scholar] [CrossRef]

- Li, L.; Mao, L.; Yang, J. A Review of Principles, Analytical Methods, and Applications of SEM-EDS in Cementitious Materials Characterization. Adv. Mater. Technol. 2024, 10, 2401175. [Google Scholar] [CrossRef]

- Barreto, M.D.; Figueiredo, M.D.; da Silva, M.V.; de Andrade, A.G.; de Oliveira, J.D.; Almeida, C.M.; de Araújo, L.C.; dos Reis Junior, O.V.; Junior, M.U.; da Costa, A.F.; et al. Biotechnological Potential of Endophytic Bacteria to Improve the Micropropagated Seedling of Variety RB92579 Sugarcane (Saccharum officinarum L.). Adv. Microbiol. 2018, 8, 859–873. [Google Scholar] [CrossRef]

- Aoki, S.; Yahara, H.; Nakao, R.; Tsuzukibashi, O.; Yahara, K. Development of selective isolation media for detecting the genera Actinomyces and Schaalia from oral specimens containing indigenous bacteria. Access Microbiol. 2024, 6, 000768.v3. [Google Scholar] [CrossRef]

- Martini, K.M.; Boddu, S.S.; Nemenman, I.; Vega, N.M. Maximum likelihood estimators for colony-forming units. Microbiol. Spectr. 2024, 12, e03946-23. [Google Scholar] [CrossRef]

- ABNT NBR16541; Mortar for Laying and Covering. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2016. Available online: https://www.target.com.br/produtos/normas-tecnicas/44109/nbr16541-argamassa-para-assentamento-e-revestimento-de-paredes-e-tetos-preparo-da-mistura-for-carrying-out-of-tests (accessed on 26 January 2025).

- EN 998-1:2017-02; Specification for Mortar for Masonry—Part 1: R. German Institute for Standardization: Berlin, Germany, 2017. Available online: https://www.intertekinform.com/en-gb/standards/din-en-998-1-2017-02-414796_saig_din_din_2839402/?srsltid=AfmBOoomVx7Br6JyEEvkUiIhmfsJ8YsyTS2qmxNmYk-J3JetMg8uA1L5 (accessed on 26 January 2025).

- ABNT NBR13276; Mortar for Laying. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2016. Available online: https://www.normas.com.br/visualizar/abnt-nbr-nm/5141/abnt-nbr13276-argamassa-para-assentamento-e-revestimento-de-paredes-e-tetos-determinacao-do-consistency-index (accessed on 26 January 2025).

- Xiao, M.; Xi, J.; Qiu, P.; Deng, C.; Li, F.; Wei, J.; Gao, P.; Yu, Q. Evaluation of tensile properties and cracking potential evolution of fly ash-cement mortar at early age based on digital image correlation method. Constr. Build. Mater. 2024, 412, 134855. [Google Scholar] [CrossRef]

- ABNT NBR13278; Mortar for Laying and Covering. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2005. Available online: https://www.target.com.br/produtos/normas-tecnicas/36207/nbr13278-argamassa-para-assentamento-e-revestimento-de-paredes-e-tetos-determinacao-da-densidade-mass-and-incorporated-air-content (accessed on 26 January 2025).

- ABNT NBR13279; Mortar for Laying and Covering. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2005. Available online: https://www.target.com.br/produtos/normas-tecnicas/36208/nbr13279-argamassa-para-assentamento-e-revestimento-de-paredes-e-tetos-determinacao-da-resistencia-the-traction-in-flexion-and-compression (accessed on 28 January 2025).

- ABNT NBR16605; Portland Cement and Other Powdered Materials. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2017. Available online: https://www.target.com.br/produtos/normas-tecnicas/44314/nbr16605-cimento-portland-e-outros-materiais-em-po-determinacao-da-massa-especifica (accessed on 5 March 2025).

- Burgmann, S.; Breit, W. Impact of Particle Shape of Crushed Natural and Recycled Fine Aggregate on Fresh and Hardened Mortar Properties. Research Square. 2023. Available online: https://www.researchsquare.com/article/rs-3062446/v1 (accessed on 5 January 2025).

- Li, T.; Nogueira, R.; De Brito, J.; Liu, J. Influence of fine aggregate’s morphology on mortars’ rheology. J. Build. Eng. 2023, 63, 105450. [Google Scholar] [CrossRef]

- Estephane, P.; Garboczi, E.J.; Bullard, J.W.; Wallevik, Ó.H. Using fine sand shape metrics determined from X-ray microcomputed tomography to illustrate the influence of particle shape on the properties of dispersed mortars. Cem. Concr. Compos. 2021, 123, 104176. [Google Scholar] [CrossRef]

- Abhishek Ranka, A.R. Lime as Construction Material: Process and Application. In Futuristic Trends in Construction Materials and Civil Engineering; Book 11, IIP Series; Selfypage Developers Pvt Ltd.: Chikmagalur, India, 2023; Volume 2, pp. 260–268. ISBN 978-93-5747-754-3. [Google Scholar]

- Autef, A.; Joussein, E.; Gasgnier, G.; Rossignol, S. Feasibility of aluminosilicate compounds from various raw materials: Chemical reactivity and mechanical properties. Powder Technol. 2016, 301, 169–178. [Google Scholar] [CrossRef]

- Moreira, P.I.; De Oliveira Dias, J.; De Castro Xavier, G.; Vieira, C.M.; Alexandre, J.; Monteiro, S.N.; Ribeiro, R.P.; De Azevedo, A.R.G. Ornamental Stone Processing Waste Incorporated in the Production of Mortars: Technological Influence and Environmental Performance Analysis. Sustainability 2022, 14, 5904. [Google Scholar] [CrossRef]

- De Pádua, P.G.L.; Cordeiro, G.C. Effect of K2O content on properties of sugar cane bagasse ash-cement-based systems. Adv. Cem. Res. 2022, 34, 57–66. [Google Scholar] [CrossRef]

- Li, K.F.; Yang, C.Q.; Zeng, L.; Xu, F.; Pan, Y. Effects of nano-SiO2 on interfacial bonding performance between normal strength concrete and high strength concrete. J. Build. Eng. 2023, 68, 106052. [Google Scholar] [CrossRef]

- Bacarji, E.; Toledo Filho, R.D.; Koenders, E.A.B.; Figueiredo, E.P.; Lopes, J.L.M.P. Sustainability perspective of marble and granite residues as concrete fillers. Constr. Build. Mater. 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Martinelli, E.; Gatto, G. Enhancing Sustainability in Construction: Water Effect on Jute Fiber Composite Mortar. Period. Polytech. Civ. Eng. 2024, 68, 974–986. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Lima, T.E.S.; Reis, R.H.M.; Oliveira, M.S.; Candido, V.S.; Monteiro, S.N. Guaruman fiber: A promising reinforcement for cement-based mortars. Case Stud. Constr. Mater. 2022, 16, e01029. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Rocha, H.A.; Marvila, M.T.; Cecchin, D.; Xavier, G.C.; Da Silva, R.C.; Ferraz, P.F.P.; Conti, L.; Rossi, G. Application of pineapple fiber in the development of sustainable mortars. Agron. Res. 2021, 13, 1387–1395. [Google Scholar]

- Chen, X.; Wu, S.; Zhou, J. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. Spec. Sect. Recycl. Wastes Use Constr. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Pereira, M.M.L.; Capuzzo, V.M.S.; de Melo Lameiras, R. Evaluation of use of marble and granite cutting waste to the production of self-compacting concrete. Constr. Build. Mater. 2022, 345, 128261. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, X.; Wu, Z.; Zhang, Q. The Effect of Initial Defects on Overall Mechanical Properties of Concrete Material. Comput. Mater. Contin. 2020, 62, 413–442. [Google Scholar] [CrossRef]

- Mohamed, M.S.; El-Sayed, M.S. Antimicrobial activity of cement pastes incorporating natural plant powders. Constr. Build. Mater. 2021, 271, 121567. [Google Scholar] [CrossRef]

- Kordestani, G.K.; Yekta, B.E. Durability and antimicrobial properties of mortars containing plant-based additives. Mater. Sci. Eng. C 2019, 104, 109885. [Google Scholar] [CrossRef]

- Bellik, Y. Total antioxidant activity and antimicrobial potency of the essential oil and oleoresin of Zingiber officinale Roscoe. Asian Pac. J. Trop. Dis. 2014, 4, 40–44. [Google Scholar] [CrossRef]

- Teles, A.M.; dos Santos, B.A.; Ferreira, C.G.; Mouchreck, A.N.; da Silva Calabrese, K.; Abreu-Silva, A.L.; Almeida-Souza, F. Ginger (Zingiber officinale) Antimicrobial Potential: A Review; IntechOpen: London, UK, 2019. [Google Scholar]

| Mixtures | Sand (g) | Cement (%) | Lime (%) | Ornamental Rock Waste (%) | Ginger (%) | Water (%) |

|---|---|---|---|---|---|---|

| Control | 1200 | 16.67 | - | - | - | 23.75 |

| Treatment 1 | 1200 | 16.67 | 16.67 | - | - | 21.67 |

| Treatment 2 | 1200 | 16.67 | - | 10.00 | - | 20.00 |

| Treatment 3 | 1200 | 16.67 | 16.67 | - | 0.42 | 21.67 |

| Treatment 4 | 1200 | 16.67 | 16.67 | - | 0.83 | 21.67 |

| Treatment 5 | 1200 | 16.67 | 16.67 | 5.00 | 1.25 | 19.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siqueira, R.M.; Souza, B.S.P.d.; Alexandre, J.; Intorne, A.C.; Maria, E.J.; Monteiro, S.N.; Azevedo, A.R.G.d. Antimicrobial Action of Ginger and Ornamental Rock Wastes for Cement Mortar. Sustainability 2025, 17, 4698. https://doi.org/10.3390/su17104698

Siqueira RM, Souza BSPd, Alexandre J, Intorne AC, Maria EJ, Monteiro SN, Azevedo ARGd. Antimicrobial Action of Ginger and Ornamental Rock Wastes for Cement Mortar. Sustainability. 2025; 17(10):4698. https://doi.org/10.3390/su17104698

Chicago/Turabian StyleSiqueira, Romário Moreira, Bruna Sthefanie Paz de Souza, Jonas Alexandre, Aline Chaves Intorne, Edmilson José Maria, Sergio Neves Monteiro, and Afonso Rangel Garcez de Azevedo. 2025. "Antimicrobial Action of Ginger and Ornamental Rock Wastes for Cement Mortar" Sustainability 17, no. 10: 4698. https://doi.org/10.3390/su17104698

APA StyleSiqueira, R. M., Souza, B. S. P. d., Alexandre, J., Intorne, A. C., Maria, E. J., Monteiro, S. N., & Azevedo, A. R. G. d. (2025). Antimicrobial Action of Ginger and Ornamental Rock Wastes for Cement Mortar. Sustainability, 17(10), 4698. https://doi.org/10.3390/su17104698