Advances in Biotechnology in the Circular Economy: A Path to the Sustainable Use of Resources

Abstract

1. Introduction

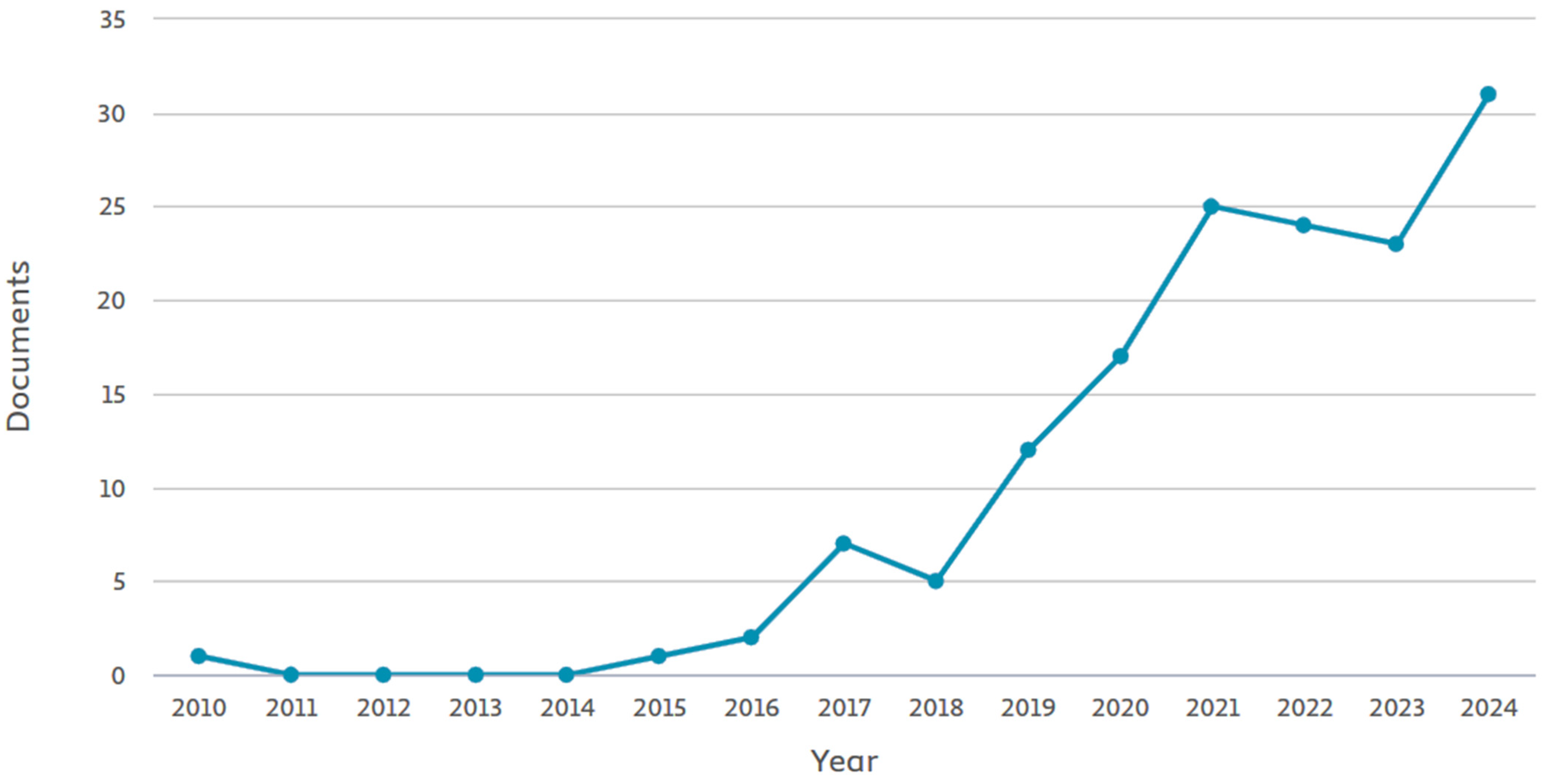

2. Review and Contextualization

2.1. Bioplastics: Sustainable Alternatives to Conventional Plastics

2.2. Anaerobic Digestion: Closing Nutrient and Energy Cycles

2.3. Industrial Biotechnology and Biorefineries

2.4. Bioremediation: Restoring Degraded Environments

2.5. Microalgae: Carbon Capture and Sustainable Production

2.6. The Food Industry: Waste Valorization and Sustainable Production

2.7. Advances in Biotechnology for the CE: Converting Waste into Valuable Resources

3. Methodology

3.1. Search Strategy and Information Source

3.2. Inclusion and Exclusion Criteria

- Inclusion criteria:

- o

- Articles written in English;

- o

- Published in 2023 or 2024;

- o

- Peer-reviewed original research;

- o

- Indexed under Environmental Sciences; Chemical Engineering; or Biochemistry, Genetics and Molecular Biology.

- Exclusion criteria:

- o

- Review articles, conference papers, book chapters, or non-peer-reviewed content;

- o

- Studies outside the defined timeframe;

- o

- Articles in other languages;

- o

- Irrelevant thematic focus (unrelated to the CE or biotechnology);

- o

- Duplicate records.

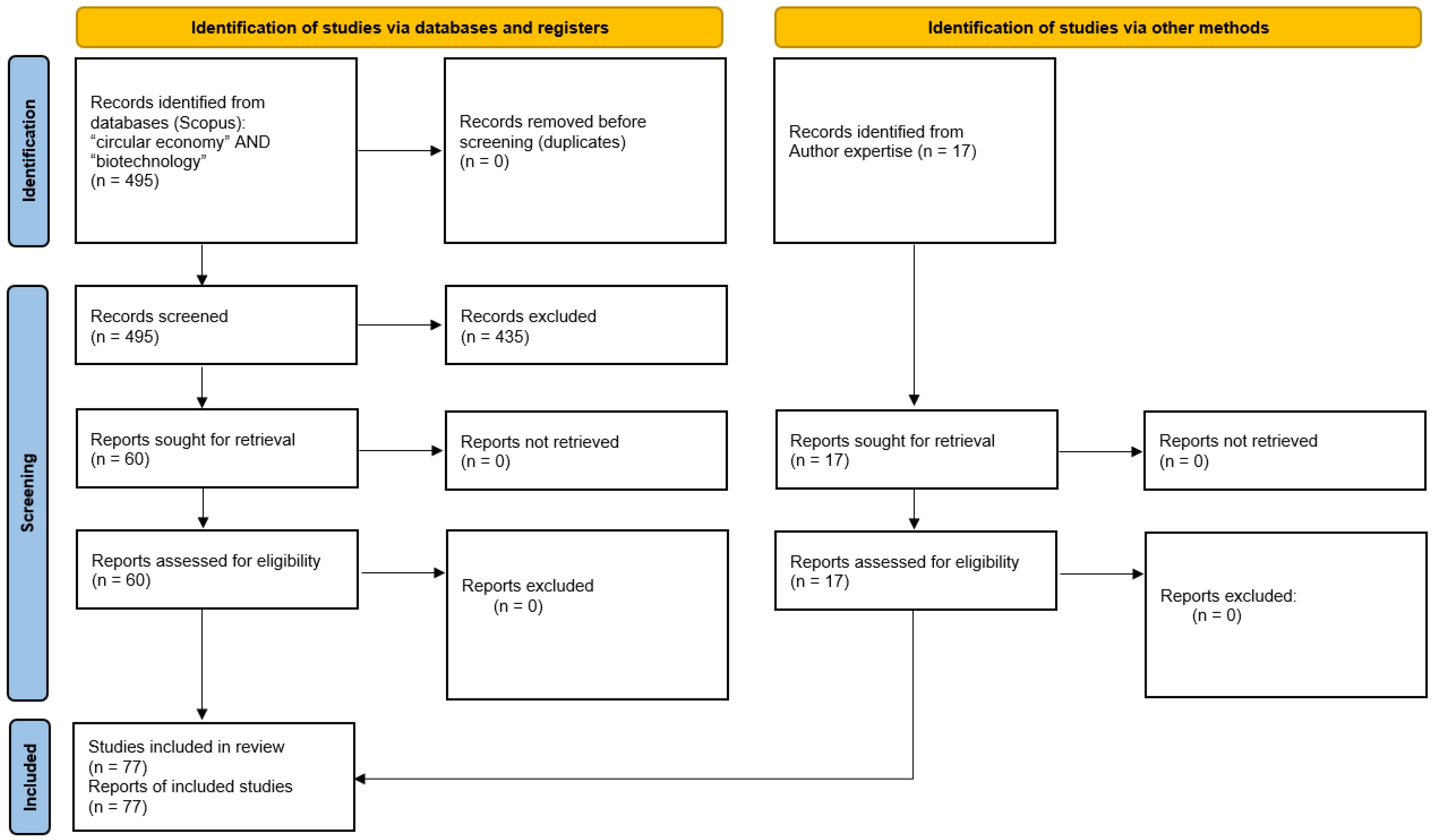

3.3. Additional Sources

3.4. Selection and Screening Process

- Title and abstract screening based on CE–biotechnology relevance.

- Full-text assessment for methodological and thematic adequacy.

- Expert validation and complementary search for literature not fully indexed.

3.5. Screening and Eligibility Summary

- Title and abstract review: 60 studies passed the initial filters.

- Full-text analysis: These 60 were evaluated in detail.

- Manual additions: 17 studies were added based on references and expert monitoring of the emerging literature. This process followed predefined criteria, ensuring objectivity.

3.6. Thematic Categorization Classification of Studies by Thematic Area

- Wastewater Treatment and Water Management—Biotechnological solutions for wastewater treatment and water recovery.

- Biopolymer and Bioplastic Production—Development of biodegradable plastics and polymers from renewable sources.

- Biofuel and Bioenergy Production—Conversion of biomass and organic waste into clean energy.

- Bioremediation and Environmental Recovery—Use of microorganisms to decontaminate and rehabilitate polluted environments.

- Circular Economy and Waste Valorization—Strategies for converting waste into high-value products.

- Enzymatic and Microbial Biotechnology—Application of enzymes and microorganisms to optimize industrial processes.

- Applications in the Food Industry and Agriculture—Use of biotechnology to promote sustainability in food production and agriculture.

- Nanotechnology and Advanced Materials—Development of nanomaterials derived from biomass for environmental and industrial applications.

- Industrial Biotechnology and Biorefineries—Integration of industrial bioprocesses for resource optimization.

4. Results

4.1. Characterization of the Results by Thematic Areas

4.1.1. Wastewater Treatment and Water Management

4.1.2. Biopolymer and Bioplastic Production

4.1.3. Production of Biofuels and Bioenergy

4.1.4. Bioremediation and Environmental Cleanup

4.1.5. Circular Economy and Waste Recovery

4.1.6. Enzymatic and Microbial Biotechnology

4.1.7. Applications in Food and Agriculture

4.1.8. Nanotechnology and Advanced Materials

4.1.9. Industrial Biotechnology and Biorefineries

4.1.10. General Summary

5. Discussion

5.1. Integration of Biotechnological Solutions

5.2. Sustainability and Innovation

5.3. Emerging Technologies and Their Potential

5.4. Challenges and Barriers

5.5. Implications for the Future

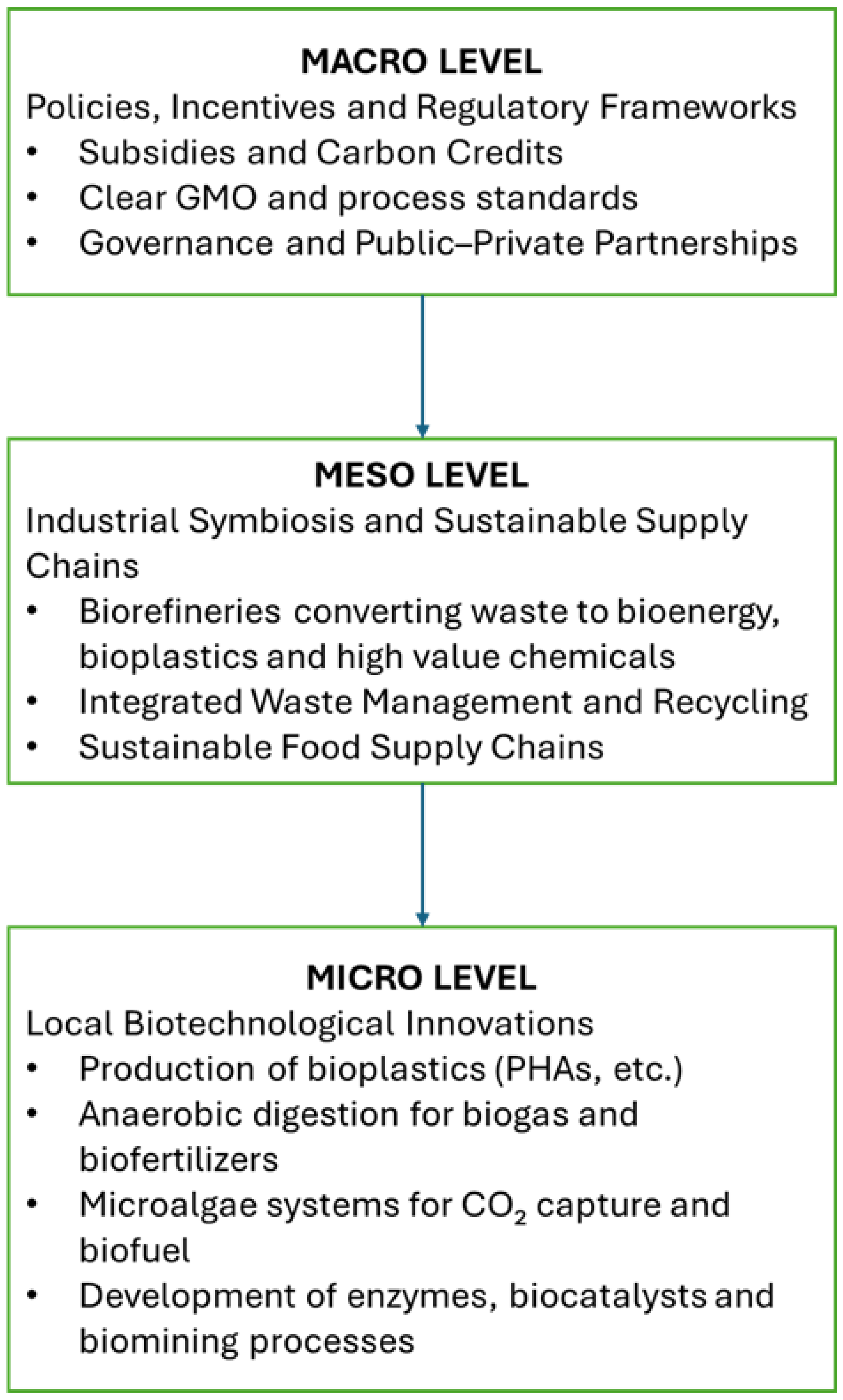

5.6. Conceptual Framework for a Biotechnology-Based Circular Economy

- Micro Level: Encompasses individual innovations, such as the production of PHAs from agricultural byproducts, which offer alternatives to conventional plastics, and AD, which converts organic waste into biogas and biofertilizers, promoting energy and nutrient recovery [5,8,11,47]. In addition, multifunctional microalgal systems that capture CO2 and generate bioenergy reinforce this level of innovation.

- Meso Level: Facilitates industrial symbiosis, allowing waste from one sector to be used as raw material in another. Biorefineries, for example, can fractionate residual biomass to produce bioenergy, chemicals, and biomaterials, ensuring the maximum use of available resources [2,10]. In the food sector, the use of biosurfactants and enzymes derived from agro-industrial byproducts can replace synthetic ingredients, reducing waste and increasing process efficiency [21,86].

- Macro Level: Establishes a structural basis for the adoption of biotechnology, incorporating economic guidelines and regulatory policies that encourage sustainable practices. Renewable energy solutions such as microbial biodiesel and carbon-neutral wastewater treatment systems exemplify the connection between biotechnology and climate policies [48,103]. Integration with nanotechnology improves pollutant detection and resource recovery, while mechanisms such as carbon pricing and incentives for waste recovery promote large-scale implementation [123,128].

6. Conclusions

Limitations and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Manganda, A.S.; Sehnem, S.; Lara, A.C. Transition to the Circular Economy: Innovative and Disruptive Production Technologies Adopted by Agribusiness Startups. Environ. Qual. Manag. 2024, 34, e22293. [Google Scholar] [CrossRef]

- Maroldi, W.V.; de Andrade Arruda Fernandes, I.; Junior, B.D.; Pedro, A.C.; Maciel, G.M.; Haminiuk, C.W.I. Waste from the Food Industry: Innovations in Biorefineries for Sustainable Use of Resources and Generation of Value. Bioresour. Technol. 2024, 413, 131447. [Google Scholar] [CrossRef]

- Becci, A.; Amato, A.; D’Arcangelo, M.; Merli, G.; Beolchini, F. Optimization of Sustainable Processes for the Extraction of Precious Metals from End-Of-Life Printed Circuit Boards. Chem. Eng. Trans. 2024, 111, 607–612. [Google Scholar] [CrossRef]

- Herrmann, L.W.; Letti, L.A.J.; Penha, R.D.O.; Soccol, V.T.; Rodrigues, C.; Soccol, C.R. Bacillus Genus Industrial Applications and Innovation: First Steps towards a Circular Bioeconomy. Biotechnol. Adv. 2024, 70, 108300. [Google Scholar] [CrossRef] [PubMed]

- Tello-Cruzado, B.K.; Azañedo-Vargas, M.; Quiñones-Cerna, C.E.; Fuentes-Olivera, A.; Rodríguez-Soto, J.C.; Quezada-Alvarez, M.A.; Cruz-Monzon, J.A. Use of Enzymatic Hydrolysate from Agroindustrial Asparagus Waste as Substrate for the Production of Polyhydroxyalkanoate by Bacillus Thuringiensis. Environ. Res. Eng. Manag. 2024, 80, 8–16. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, S.-G.; Xia, P.-F. Blue Valorization of Lignin-Derived Monomers via Reprogramming Marine Bacterium Roseovarius Nubinhibens. Appl. Environ. Microbiol. 2024, 90, e0089024. [Google Scholar] [CrossRef]

- Muigano, M.N.; Mauti, G.O.; Anami, S.E.; Onguso, J.M. Advances and Challenges in Polyhydroxyalkanoates (PHA) Production Using Halomonas Species: A Review. Int. J. Biol. Macromol. 2025, 309, 142850. [Google Scholar] [CrossRef]

- Park, H.; He, H.; Yan, X.; Liu, X.; Scrutton, N.S.; Chen, G.-Q. PHA Is Not Just a Bioplastic! Biotechnol. Adv. 2024, 71, 108320. [Google Scholar] [CrossRef]

- Wongsirichot, P. Pilot Scale Polyhydroxyalkanoates Biopolymer Production Using Pure Cultures: Current Status and Future Opportunities. Crit. Rev. Biotechnol. 2024, 45, 887–903. [Google Scholar] [CrossRef]

- Zhang, F.; Ren, S.; Liang, H.; Wang, Z.; Yan, Y.; Wang, J.; Peng, Y. Organics Recovery from Waste Activated Sludge In-Situ Driving Efficient Nitrogen Removal from Mature Landfill Leachate: An Innovative Biotechnology with Energy Superiority. Engineering 2024, 34, 120–132. [Google Scholar] [CrossRef]

- Timm, T.G.; Schipmann, D.B.D.; Costa, T.M.; Tavares, L.B.B. Remediation of Brewery Wastewater and Reuse for β-Glucans Production by Basidiomycete Fungi. Waste Biomass Valorization 2024, 15, 4629–4645. [Google Scholar] [CrossRef]

- Chandekar, B.; Rohit, M.V.; Patel, S.K.S. Efficient Dark-Fermentation Biohydrogen Production by Shigella Flexneri SPD1 from Biowaste-Derived Sugars through Green Solvents Approach. Bioresour. Technol. 2024, 410, 131276. [Google Scholar] [CrossRef]

- Checa-Fernández, A.; Santos, A.; Chicaiza, K.Y.; Martin-Sanz, J.P.; Valverde-Asenjo, I.; Quintana, J.R.; Fernández, J.; Domínguez, C.M. Exploring the Potential of Horse Amendment for the Remediation of HCHs-Polluted Soils. J. Environ. Manag. 2024, 364, 121436. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, C.; Zhang, K.; Zhang, L.; Bi, R.; Zhang, Y.; Hu, Z. One-Step Bioremediation of Hypersaline and Nutrient-Rich Food Industry Process Water with a Domestic Microbial Community Containing Diatom Halamphora Coffeaeformis. Water Res. 2024, 254, 121430. [Google Scholar] [CrossRef] [PubMed]

- Najar-Almanzor, C.E.; Velasco-Iglesias, K.D.; Solis-Bañuelos, M.; González-Díaz, R.L.; Guerrero-Higareda, S.; Fuentes-Carrasco, O.J.; García-Cayuela, T.; Carrillo-Nieves, D. Chlorella Vulgaris-Mediated Bioremediation of Food and Beverage Wastewater from Industries in Mexico: Results and Perspectives towards Sustainability and Circular Economy. Sci. Total Environ. 2024, 940, 173753. [Google Scholar] [CrossRef] [PubMed]

- Oliva, G.; Buonerba, A.; Grassi, A.; Hasan, S.W.; Korshin, G.V.; Zorpas, A.A.; Belgiorno, V.; Naddeo, V.; Zarra, T. Microalgae to Biodiesel: A Novel Green Conversion Method for High-Quality Lipids Recovery and in-Situ Transesterification to Fatty Acid Methyl Esters. J. Environ. Manag. 2024, 357, 120830. [Google Scholar] [CrossRef] [PubMed]

- Policastro, G.; Ebrahimi, S.; Weissbrodt, D.G.; Fabbricino, M.; van Loosdrecht, M.C.M. Selecting for a High Lipid Accumulating Microalgae Culture by Dual Growth Limitation in a Continuous Bioreactor. Sci. Total Environ. 2024, 912, 169213. [Google Scholar] [CrossRef]

- Stirk, W.A.; Bálint, P.; Široká, J.; Novák, O.; Rétfalvi, T.; Berzsenyi, Z.; Notterpek, J.; Varga, Z.; Maróti, G.; van Staden, J.; et al. Comparison of Plant Biostimulating Properties of Chlorella Sorokiniana Biomass Produced in Batch and Semi-Continuous Systems Supplemented with Pig Manure or Acetate. J. Biotechnol. 2024, 381, 27–35. [Google Scholar] [CrossRef]

- Buller, R.; Lutz, S.; Kazlauskas, R.J.; Snajdrova, R.; Moore, J.C.; Bornscheuer, U.T. From Nature to Industry: Harnessing Enzymes for Biocatalysis. Science 2023, 382, eadh8615. [Google Scholar] [CrossRef]

- Gonçalves, M.S.; Tavares, I.M.D.C.; Sampaio, I.C.F.; dos Santos, M.M.O.; Ambrósio, H.L.B.S.; Araújo, S.C.; Veloso, C.M.; Neta, J.L.V.; Mendes, A.A.; dos Anjos, P.N.M.; et al. New Biocatalyst Produced from Fermented Biomass: Improvement of Adsorptive Characteristics and Application in Aroma Synthesis. 3 Biotech 2024, 14, 189. [Google Scholar] [CrossRef]

- Joshi, N.; Grewal, J.; Drewniak, L.; Pranaw, K. Bioprospecting CAZymes Repertoire of Aspergillus Fumigatus for Eco-Friendly Value-Added Transformations of Agro-Forest Biomass. Biotechnol. Biofuels Bioprod. 2024, 17, 3. [Google Scholar] [CrossRef] [PubMed]

- Thapa, S.; Mishra, J.; Arora, N.; Mishra, P.; Li, H.; O′Hair, J.; Bhatti, S.; Zhou, S. Microbial Cellulolytic Enzymes: Diversity and Biotechnology with Reference to Lignocellulosic Biomass Degradation. Rev. Environ. Sci. Biotechnol. 2020, 19, 621–648. [Google Scholar] [CrossRef]

- Maghraby, Y.R.; El-Shabasy, R.M.; Ibrahim, A.H.; Azzazy, H.M.E.-S. Enzyme Immobilization Technologies and Industrial Applications. ACS Omega 2023, 8, 5184–5196. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, S.; Chakravarty, A.; Ikram, S. A Comprehensive Review on Incredible Renewable Carriers as Promising Platforms for Enzyme Immobilization & Thereof Strategies. Int. J. Biol. Macromol. 2021, 167, 962–986. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Naturally-Derived Biopolymers: Potential Platforms for Enzyme Immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482. [Google Scholar] [CrossRef]

- Qi, L.; Qiao, J. Design of Switchable Enzyme Carriers Based on Stimuli-Responsive Porous Polymer Membranes for Bioapplications. ACS Appl. Bio Mater. 2021, 4, 4706–4719. [Google Scholar] [CrossRef]

- Serbent, M.P.; Magario, I.; Saux, C. Immobilizing White-Rot Fungi Laccase: Toward Bio-Derived Supports as a Circular Economy Approach in Organochlorine Removal. Biotechnol. Bioeng. 2024, 121, 434–455. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Keith, M.; Koller, M.; Lackner, M. Carbon Recycling of High Value Bioplastics: A Route to a Zero-Waste Future. Polymers 2024, 16, 1621. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, Y.; Chen, X.; Yu, X.; Li, W.; Zhang, S.; Meng, X.; Zhao, Z.-M.; Dong, T.; Anderson, A.; et al. Sustainable Bioplastics Derived from Renewable Natural Resources for Food Packaging. Matter 2023, 6, 97–127. [Google Scholar] [CrossRef]

- Grgurević, K.; Bramberger, D.; Miloloža, M.; Stublić, K.; Ocelić Bulatović, V.; Ranilović, J.; Ukić, Š.; Bolanča, T.; Cvetnić, M.; Markić, M.; et al. Producing and Characterizing Polyhydroxyalkanoates from Starch and Chickpea Waste Using Mixed Microbial Cultures in Solid-State Fermentation. Polymers 2024, 16, 3407. [Google Scholar] [CrossRef]

- Kusuma, H.S.; Sabita, A.; Putri, N.A.; Azliza, N.; Illiyanasafa, N.; Darmokoesoemo, H.; Amenaghawon, A.N.; Kurniawan, T.A. Waste to Wealth: Polyhydroxyalkanoates (PHA) Production from Food Waste for a Sustainable Packaging Paradigm. Food Chem. Mol. Sci. 2024, 9, 100225. [Google Scholar] [CrossRef]

- Mulders, M.; Tamis, J.; Abbas, B.; Sousa, J.; Dijkman, H.; Rozendal, R.; Kleerebezem, R. Pilot-Scale Polyhydroxyalkanoate Production from Organic Waste: Process Characteristics at High pH and High Ammonium Concentration. J. Environ. Eng. 2020, 146, 04020049. [Google Scholar] [CrossRef]

- Tu, W.-L.; Hsiung, Y.-C.; Liang, C.-H.; Huang, J.-M.; Ou, C.-M.; Guo, G.-L. Polyhydroxyalkanoate Production from Food Packaging Wastepaper. BioResources 2023, 19, 539–551. [Google Scholar] [CrossRef]

- Ahuja, V.; Singh, P.K.; Mahata, C.; Jeon, J.-M.; Kumar, G.; Yang, Y.-H.; Bhatia, S.K. A Review on Microbes Mediated Resource Recovery and Bioplastic (Polyhydroxyalkanoates) Production from Wastewater. Microb. Cell Fact. 2024, 23, 187. [Google Scholar] [CrossRef] [PubMed]

- Martín-González, D.; de la Fuente Tagarro, C.; De Lucas, A.; Bordel, S.; Santos-Beneit, F. Genetic Modifications in Bacteria for the Degradation of Synthetic Polymers: A Review. Int. J. Mol. Sci. 2024, 25, 5536. [Google Scholar] [CrossRef] [PubMed]

- Schneier, A.; Melaugh, G.; Sadler, J.C. Engineered Plastic-Associated Bacteria for Biodegradation and Bioremediation. Biotechnol. Environ. 2024, 1, 7. [Google Scholar] [CrossRef] [PubMed]

- Gautam, S.; Gautam, A.; Pawaday, J.; Kanzariya, R.K.; Yao, Z. Current Status and Challenges in the Commercial Production of Polyhydroxyalkanoate-Based Bioplastic: A Review. Processes 2024, 12, 1720. [Google Scholar] [CrossRef]

- Thamarai, P.; Vickram, A.S.; Saravanan, A.; Deivayanai, V.C.; Evangeline, S. Recent Advancements in Biosynthesis, Industrial Production, and Environmental Applications of Polyhydroxyalkanoates (PHAs): A Review. Bioresour. Technol. Rep. 2024, 27, 101957. [Google Scholar] [CrossRef]

- Gundlapalli, M.; Ganesan, S. Polyhydroxyalkanoates (PHAs): Key Challenges in Production and Sustainable Strategies for Cost Reduction within a Circular Economy Framework. Results Eng. 2025, 26, 105345. [Google Scholar] [CrossRef]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and Opportunities of Biodegradable Plastics: A Mini Review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Van Roijen, E.C.; Miller, S.A. A Review of Bioplastics at End-of-Life: Linking Experimental Biodegradation Studies and Life Cycle Impact Assessments. Resour. Conserv. Recycl. 2022, 181, 106236. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public Attitudes towards Bioplastics—Knowledge, Perception and End-of-Life Management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Antunes, E.C.; Temmink, H.; Schuur, B. Polymer and Alcohol-Based Three-Phase Partitioning Systems for Separation of Polysaccharide and Protein. J. Chem. Technol. Biotechnol. 2024, 99, 259–269. [Google Scholar] [CrossRef]

- Cazier, E.A.; Pham, T.-N.; Cossus, L.; Abla, M.; Ilc, T.; Lawrence, P. Exploring Industrial Lignocellulosic Waste: Sources, Types, and Potential as High-Value Molecules. Waste Manag. 2024, 188, 11–38. [Google Scholar] [CrossRef]

- Papa, G.; Cucina, M.; Echchouki, K.; De Nisi, P.; Adani, F. Anaerobic Digestion of Organic Waste Allows Recovering Energy and Enhancing the Subsequent Bioplastic Degradation in Soil. Resour. Conserv. Recycl. 2023, 188, 106694. [Google Scholar] [CrossRef]

- Souza, M.F.D.; Akyol, Ç.; Willems, B.; Huizinga, A.; van Calker, S.; Van Dael, M.; De Meyer, A.; Guisson, R.; Michels, E.; Meers, E. From Grass to Gas and beyond: Anaerobic Digestion as a Key Enabling Technology for a Residual Grass Biorefinery. Waste Manag. 2024, 182, 1–10. [Google Scholar] [CrossRef]

- Pasquarelli, F.; Oliva, G.; Mariniello, A.; Buonerba, A.; Li, C.-W.; Belgiorno, V.; Naddeo, V.; Zarra, T. Carbon Neutrality in Wastewater Treatment Plants: An Integrated Biotechnological-Based Solution for Nutrients Recovery, Odour Abatement and CO2 Conversion in Alternative Energy Drivers. Chemosphere 2024, 354, 141700. [Google Scholar] [CrossRef]

- Adekunle, A.; Ukaigwe, S.; Bezerra dos Santos, A.; Iorhemen, O.T. Potential for Curdlan Recovery from Aerobic Granular Sludge Wastewater Treatment Systems—A Review. Chemosphere 2024, 362, 142504. [Google Scholar] [CrossRef]

- Lad, B.C.; Coleman, S.M.; Alper, H.S. Microbial Valorization of Underutilized and Nonconventional Waste Streams. J. Ind. Microbiol. Biotechnol. 2022, 49, kuab056. [Google Scholar] [CrossRef]

- Kandasamy, S.; Senthilkumar, B.; Pandiselvam, H.; Chitra, M.; Abinesh, B.S.; Jayanthi, B.D.S.; Manickam, N.; Kalaiselvi, T.; Arun, B.S. Microbial Valorization of Industrial Waste Biomass Using Mixed Culture Medium of Microbes and Its Economic Importance. AIP Conf. Proc. 2024, 3161, 020070. [Google Scholar]

- Uddin, M.M.; Wright, M.M. Anaerobic Digestion Fundamentals, Challenges, and Technological Advances. Phys. Sci. Rev. 2023, 8, 2819–2837. [Google Scholar] [CrossRef]

- Preethi, M.G.; Banu, J.R. Indexing Energy and Cost of the Pretreatment for Economically Efficient Bioenergy Generation. Front. Energy Res. 2023, 10, 1060599. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K. Anaerobic Digestate Management for Carbon Neutrality and Fertilizer Use: A Review of Current Practices and Future Opportunities. Biomass Bioenergy 2024, 180, 106991. [Google Scholar] [CrossRef]

- Cozma, P.; Bețianu, C.; Hlihor, R.-M.; Simion, I.M.; Gavrilescu, M. Bio-Recovery of Metals through Biomining within Circularity-Based Solutions. Processes 2024, 12, 1793. [Google Scholar] [CrossRef]

- Vo, P.H.N.; Danaee, S.; Hai, H.T.N.; Huy, L.N.; Nguyen, T.A.H.; Nguyen, H.T.M.; Kuzhiumparambil, U.; Kim, M.; Nghiem, L.D.; Ralph, P.J. Biomining for Sustainable Recovery of Rare Earth Elements from Mining Waste: A Comprehensive Review. Sci. Total Environ. 2024, 908, 168210. [Google Scholar] [CrossRef]

- Jaiswal, M.; Srivastava, S. A Review on Sustainable Approach of Bioleaching of Precious Metals from Electronic Wastes. J. Hazard. Mater. Adv. 2024, 14, 100435. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, H.S.; Şengör, S.; Sani, R.K.; Kumar, S. Bioleaching of Metals from Waste Printed Circuit Boards Using Bacterial Isolates Native to Abandoned Gold Mine. Biometals 2021, 34, 1043–1058. [Google Scholar] [CrossRef]

- Aminian-Dehkordi, J.; Mousavi, S.M.; Marashi, S.-A.; Jafari, A.; Mijakovic, I. A Systems-Based Approach for Cyanide Overproduction by Bacillus Megaterium for Gold Bioleaching Enhancement. Front. Bioeng. Biotechnol. 2020, 8, 528. [Google Scholar] [CrossRef]

- Abbasi, B.; Harper, J.; Ahmadvand, S. A Short Critique on Biomining Technology for Critical Materials. World J. Microbiol. Biotechnol. 2021, 37, 87. [Google Scholar] [CrossRef]

- Vera, M.; Schippers, A.; Hedrich, S.; Sand, W. Progress in Bioleaching: Fundamentals and Mechanisms of Microbial Metal Sulfide Oxidation—Part A. Appl. Microbiol. Biotechnol. 2022, 106, 6933–6952. [Google Scholar] [CrossRef]

- Anekwe, I.M.S.; Isa, Y.M. Bioremediation of Acid Mine Drainage—Review. Alex. Eng. J. 2023, 65, 1047–1075. [Google Scholar] [CrossRef]

- Kondakindi, V.R.; Pabbati, R.; Erukulla, P.; Maddela, N.R.; Prasad, R. Bioremediation of Heavy Metals-Contaminated Sites by Microbial Extracellular Polymeric Substances—A Critical View. Environ. Chem. Ecotoxicol. 2024, 6, 408–421. [Google Scholar] [CrossRef]

- Kuppan, N.; Padman, M.; Mahadeva, M.; Srinivasan, S.; Devarajan, R. A Comprehensive Review of Sustainable Bioremediation Techniques: Eco Friendly Solutions for Waste and Pollution Management. Waste Manag. Bull. 2024, 2, 154–171. [Google Scholar] [CrossRef]

- Martínez-Espinosa, R.M. Halophilic Archaea as Tools for Bioremediation Technologies. Appl. Microbiol. Biotechnol. 2024, 108, 401. [Google Scholar] [CrossRef] [PubMed]

- Navina, B.K.; Velmurugan, N.K.; Kumar, P.S.; Rangasamy, G.; Palanivelu, J.; Thamarai, P.; Vickram, A.S.; Saravanan, A.; Shakoor, A. Fungal Bioremediation Approaches for the Removal of Toxic Pollutants: Mechanistic Understanding for Biorefinery Applications. Chemosphere 2024, 350, 141123. [Google Scholar] [CrossRef] [PubMed]

- Maqsood, Q.; Sumrin, A.; Waseem, R.; Hussain, M.; Imtiaz, M.; Hussain, N. Bioengineered Microbial Strains for Detoxification of Toxic Environmental Pollutants. Environ. Res. 2023, 227, 115665. [Google Scholar] [CrossRef]

- Perera, I.C.; Hemamali, E.H. Genetically Modified Organisms for Bioremediation: Current Research and Advancements. In Bioremediation of Environmental Pollutants; Suyal, D.C., Soni, R., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 163–186. ISBN 978-3-030-86168-1. [Google Scholar]

- Sharma, S.; Pathania, S.; Bhagta, S.; Kaushal, N.; Bhardwaj, S.; Bhatia, R.K.; Walia, A. Microbial Remediation of Polluted Environment by Using Recombinant E. Coli: A Review. Biotechnol. Environ. 2024, 1, 8. [Google Scholar] [CrossRef]

- Kumar, N.M.; Muthukumaran, C.; Sharmila, G.; Gurunathan, B. Genetically Modified Organisms and Its Impact on the Enhancement of Bioremediation. In Bioremediation: Applications for Environmental Protection and Management; Varjani, S.J., Agarwal, A.K., Gnansounou, E., Gurunathan, B., Eds.; Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 53–76. ISBN 978-981-10-7484-4. [Google Scholar]

- Liu, X.; Sathishkumar, K.; Zhang, H.; Saxena, K.K.; Zhang, F.; Naraginti, S.; K, A.; Rajendiran, R.; Rajasekar, A.; Guo, X. Frontiers in Environmental Cleanup: Recent Advances in Remediation of Emerging Pollutants from Soil and Water. J. Hazard. Mater. Adv. 2024, 16, 100461. [Google Scholar] [CrossRef]

- Vishwakarma, G.S.; Bhattacharjee, G.; Gohil, N.; Singh, V. Current Status, Challenges and Future of Bioremediation. In Bioremediation of Pollutants; Elsevier: Amsterdam, The Nertherlands, 2020; pp. 403–415. ISBN 978-0-12-819025-8. [Google Scholar]

- Rafeeq, H.; Afsheen, N.; Rafique, S.; Arshad, A.; Intisar, M.; Hussain, A.; Bilal, M.; Iqbal, H.M.N. Genetically Engineered Microorganisms for Environmental Remediation. Chemosphere 2023, 310, 136751. [Google Scholar] [CrossRef]

- Wesseler, J.; Kleter, G.; Meulenbroek, M.; Purnhagen, K.P. EU Regulation of Genetically Modified Microorganisms in Light of New Policy Developments: Possible Implications for EU Bioeconomy Investments. Appl. Eco. Perspect. Pol. 2023, 45, 839–859. [Google Scholar] [CrossRef]

- Ali, S.S.; Hassan, L.H.S.; El-Sheekh, M. Microalgae-Mediated Bioremediation: Current Trends and Opportunities—A Review. Arch. Microbiol. 2024, 206, 343. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, K.K.; Dutta, S.; Banerjee, I.; Pohrmen, C.B.; Kumar, V. Photosynthetic Microalgae–Based Carbon Sequestration and Generation of Biomass in Biorefinery Approach for Renewable Biofuels for a Cleaner Environment. Biomass Conv. Bioref. 2023, 13, 7403–7421. [Google Scholar] [CrossRef]

- Geremia, E.; Ripa, M.; Catone, C.M.; Ulgiati, S. A Review about Microalgae Wastewater Treatment for Bioremediation and Biomass Production—A New Challenge for Europe. Environments 2021, 8, 136. [Google Scholar] [CrossRef]

- Kumar, R.; Ghosh, A.K.; Pal, P. Synergy of Biofuel Production with Waste Remediation along with Value-Added Co-Products Recovery through Microalgae Cultivation: A Review of Membrane-Integrated Green Approach. Sci. Total Environ. 2020, 698, 134169. [Google Scholar] [CrossRef]

- Amenorfenyo, D.K.; Huang, X.; Zhang, Y.; Zeng, Q.; Zhang, N.; Ren, J.; Huang, Q. Microalgae Wastewater Treatment: Potentials, Benefits and the Challenges. IJERPH 2019, 16, 1910. [Google Scholar] [CrossRef]

- Kamyab, H.; Chelliapan, S.; Lee, C.T.; Rezania, S.; Talaiekhozani, A.; Khademi, T.; Kumar, A. Microalgae Cultivation Using Various Sources of Organic Substrate for High Lipid Content. In New Trends in Urban Drainage Modelling; Mannina, G., Ed.; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2019; pp. 893–898. ISBN 978-3-319-99866-4. [Google Scholar]

- Osorio-Reyes, J.G.; Valenzuela-Amaro, H.M.; Pizaña-Aranda, J.J.P.; Ramírez-Gamboa, D.; Meléndez-Sánchez, E.R.; López-Arellanes, M.E.; Castañeda-Antonio, M.D.; Coronado-Apodaca, K.G.; Gomes Araújo, R.; Sosa-Hernández, J.E.; et al. Microalgae-Based Biotechnology as Alternative Biofertilizers for Soil Enhancement and Carbon Footprint Reduction: Advantages and Implications. Mar. Drugs 2023, 21, 93. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Ponnusamy, V.K.; Jeyakumar, R.B.; Sirohi, R.; Piechota, G.; Shobana, S.; Dharmaraja, J.; Lay, C.; Saratale, G.D.; Shin, H.S.; et al. Microalgae Cultivation Strategies Using Cost–Effective Nutrient Sources: Recent Updates and Progress towards Biofuel Production. Bioresour. Technol. 2022, 361, 127691. [Google Scholar] [CrossRef]

- Yu, B.S.; Pyo, S.; Lee, J.; Han, K. Microalgae: A Multifaceted Catalyst for Sustainable Solutions in Renewable Energy, Food Security, and Environmental Management. Microb. Cell Fact. 2024, 23, 308. [Google Scholar] [CrossRef]

- Muñoz-Seijas, N.; Fernandes, H.; Outeiriño, D.; Morán-Aguilar, M.G.; Domínguez, J.M.; Salgado, J.M. Potential Use of Frass from Edible Insect Tenebrio Molitor for Proteases Production by Solid-State Fermentation. Food Bioprod. Process. 2024, 144, 146–155. [Google Scholar] [CrossRef]

- Urrutia, R.I.; Jesser, E.N.; Gutierrez, V.S.; Rodriguez, S.; Gumilar, F.; Murray, A.P.; Volpe, M.A.; Werdin-González, J.O. From Waste to Food and Bioinsecticides: An Innovative System Integrating Tenebrio Molitor Bioconversion and Pyrolysis Bio-Oil Production. Chemosphere 2023, 340, 139847. [Google Scholar] [CrossRef] [PubMed]

- Eras-Muñoz, E.; Wongsirichot, P.; Ingham, B.; Winterburn, J.; Gea, T.; Font, X. Screening of Alternative Nitrogen Sources for Sophorolipid Production through Submerged Fermentation Using Starmerella Bombicola. Waste Manag. 2024, 186, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Qazanfarzadeh, Z.; Ganesan, A.R.; Mariniello, L.; Conterno, L.; Kumaravel, V. Valorization of Brewer’s Spent Grain for Sustainable Food Packaging. J. Clean. Prod. 2023, 385, 135726. [Google Scholar] [CrossRef]

- Rachwał, K.; Waśko, A.; Gustaw, K.; Polak-Berecka, M. Utilization of Brewery Wastes in Food Industry. PeerJ 2020, 8, e9427. [Google Scholar] [CrossRef]

- Galanakis, C.M. The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis. Foods 2020, 9, 523. [Google Scholar] [CrossRef]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global Food Demand and the Sustainable Intensification of Agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Xu, Y.-S.; Li, Z.-J.; Xu, L.-W.; Ma, W.; Li, Y.-F.; Guo, D.-S.; Sun, X.-M.; Huang, H. Turning Waste into Treasure: A New Direction for Low-Cost Production of Lipid Chemicals from Thraustochytrids. Biotechnol. Adv. 2024, 73, 108354. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Lin, H.; Sui, J.; Wang, K.; Wang, H.; Cao, L. Seafood Waste Derived Carbon Nanomaterials for Removal and Detection of Food Safety Hazards. Sci. Total Environ. 2024, 929, 172332. [Google Scholar] [CrossRef]

- Zheng, C.; Gao, L.; Sun, H.; Zhao, X.-Y.; Gao, Z.; Liu, J.; Guo, W. Advancements in Enzymatic Reaction-Mediated Microbial Transformation. Heliyon 2024, 10, e38187. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Jakhar, S.K.; Mangla, S.K.; Gangwani, K.K. Critical Factors to Environment Management in a Closed Loop Supply Chain. J. Clean. Prod. 2020, 255, 120239. [Google Scholar] [CrossRef]

- Yadav, A.; Sharma, V.; Tsai, M.-L.; Sharma, D.; Nargotra, P.; Chen, C.-W.; Sun, P.-P.; Dong, C.-D. Synergistic Microwave and Acidic Deep Eutectic Solvent-Based Pretreatment of Theobroma Cacao Pod Husk Biomass for Xylooligosaccharides Production. Bioresour. Technol. 2024, 400, 130702. [Google Scholar] [CrossRef] [PubMed]

- Sayago, U.F.C.; Ballesteros, V.B. Development of a Wastewater Treatment System Contaminated with Cr (VI) through Vegetable Biomass Modified with TIO2. Int. J. Environ. Sci. Technol. 2024, 22, 6521–6534. [Google Scholar] [CrossRef]

- Chen, S.; Hu, Y.H. Advancements and Future Directions in Waste Plastics Recycling: From Mechanical Methods to Innovative Chemical Processes. Chem. Eng. J. 2024, 493, 152727. [Google Scholar] [CrossRef]

- Rahman, M.; Tabassum, Z. Biotechnological Approach to Treat Textile Dyeing Effluents: A Critical Review Analysing the Practical Applications. Text. Leather Rev. 2024, 7, 124–152. [Google Scholar] [CrossRef]

- Caldas, M.; Neves, M.; Franco, A.R.; Bhattacharya, M.; Reis, R.L.; Correlo, V.M. Silane Grafted Biosourced Melanin: A Sustainable Approach for Nanobiosensing Applications. ACS Sustain. Chem. Eng. 2024, 12, 2149–2161. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Olusanya, M.O. Biotechnological Trends and Optimization of Arachis Hypogaea Residues Valorization: A Bibliometric Analysis and Comprehensive Review. Bioresour. Technol. 2024, 414, 131585. [Google Scholar] [CrossRef]

- Elser, J.J.; Call, D.F.; Deaver, J.A.; Duckworth, O.W.; Mayer, B.K.; McLamore, E.; Rittmann, B.; Mahmood, M.; Westerhoff, P. The Phosphorus Challenge: Biotechnology Approaches for a Sustainable Phosphorus System. Curr. Opin. Biotechnol. 2024, 90, 103197. [Google Scholar] [CrossRef]

- Danya, U.; Kamaraj, M.; Babu, P.S.; Aravind, J. Bibliometric Analysis and Review of Food Waste Management via Sustainable Approaches. Glob. J. Environ. Sci. Manag. 2024, 10, 2127–2144. [Google Scholar] [CrossRef]

- Bencresciuto, G.F.; Mandalà, C.; Migliori, C.A.; Giansante, L.; Di Giacinto, L.; Bardi, L. Microbial Biotechnologies to Produce Biodiesel and Biolubricants from Dairy Effluents. Fermentation 2024, 10, 278. [Google Scholar] [CrossRef]

- Stankiewicz, K.; Boroń, P.; Prajsnar, J.; Żelazny, M.; Heliasz, M.; Hunter, W.; Lenart-Boroń, A. Second Life of Water and Wastewater in the Context of Circular Economy—Do the Membrane Bioreactor Technology and Storage Reservoirs Make the Recycled Water Safe for Further Use? Sci. Total Environ. 2024, 921, 170995. [Google Scholar] [CrossRef]

- Kousar, A.; Khan, H.A.; Farid, S.; Zhao, Q.; Zeb, I. Recent Advances on Environmentally Sustainable Valorization of Spent Mushroom Substrate: A Review. Biofuels Bioprod. Biorefin. 2024, 18, 639–651. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and Weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef] [PubMed]

- Chadegani, A.A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ebrahim, N.A. A Comparison between Two Main Academic Literature Collections: Web of Science and Scopus Databases. ASS 2013, 9, p18. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, W. A Tale of Two Databases: The Use of Web of Science and Scopus in Academic Papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef]

- Macke, J.; Genari, D. Systematic Literature Review on Sustainable Human Resource Management. J. Clean. Prod. 2019, 208, 806–815. [Google Scholar] [CrossRef]

- Bramer, W.M.; Rethlefsen, M.L.; Kleijnen, J.; Franco, O.H. Optimal Database Combinations for Literature Searches in Systematic Reviews: A Prospective Exploratory Study. Syst. Rev. 2017, 6, 245. [Google Scholar] [CrossRef]

- Mugion, R.G.; Elmo, G.C.; Ungaro, V.; Di Pietro, L.; Martucci, O. A Systematic Literature Review of Selected Aspects of Life Cycle Assessment of Rare Earth Elements: Integration of Digital Technologies for Sustainable Production and Recycling. Sustainability 2025, 17, 5825. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, M.; Park, G.; Kim, E.; Song, H.; Jung, S.; Park, Y.-K.; Tsang, Y.F.; Lee, J.; Kwon, E.E. Chemicals and Fuels from Lipid-Containing Biomass: A Comprehensive Exploration. Biotechnol. Adv. 2024, 75, 108418. [Google Scholar] [CrossRef]

- Liu, J.-L.; Yao, J.; Tang, C.; Ma, B.; Liu, X.; Bashir, S.; Sunahara, G.; Duran, R. A Critical Review on Bioremediation Technologies of Metal(Loid) Tailings: Practice and Policy. J. Environ. Manag. 2024, 359, 121003. [Google Scholar] [CrossRef]

- Bari, E.; Far, M.G.; Daniel, G.; Bozorgzadeh, Y.; Ribera, J.; Aghajani, H.; Hosseinpourpia, R. Fungal Behavior and Recent Developments in Biopulping Technology. World J. Microbiol. Biotechnol. 2024, 40, 207. [Google Scholar] [CrossRef]

- da Silva, T.H.H.; Sehnem, S. The Utilization of Industry 4.0 Technologies to Enhance the Circular Economy through the Engagement of Stakeholders in Brazilian Food Technology Companies. Bus. Strategy Environ. 2024, 34, 129–161. [Google Scholar] [CrossRef]

- Yusoff, M.A.; Mohammadi, P.; Ahmad, F.; Sanusi, N.A.; Hosseinzadeh-Bandbafha, H.; Vatanparast, H.; Aghbashlo, M.; Tabatabaei, M. Valorization of Seafood Waste: A Review of Life Cycle Assessment Studies in Biorefinery Applications. Sci. Total Environ. 2024, 952, 175810. [Google Scholar] [CrossRef]

- Zoppi, M.; Falasco, E.; Schoefs, B.; Bona, F. Turning Waste into Resources: A Comprehensive Review on the Valorisation of Elodea Nuttallii Biomass. J. Environ. Manag. 2024, 369, 122258. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, T.; Bose, D.; Sharma, D.; Patel, D. A Review on Cellulose Degrading Microbes and Its Applications. Ind. Biotechnol. 2024, 20, 26–39. [Google Scholar] [CrossRef]

- Jofre, F.M.; Queiroz, S.D.S.; Sanchez, D.A.; Arruda, P.V.; Santos, J.C.D.; Felipe, M.D.G.D.A. Biotechnological Potential of Yeast Cell Wall: An Overview. Biotechnol. Prog. 2024, 40, e3491. [Google Scholar] [CrossRef] [PubMed]

- Lima, P.C.; Karimian, P.; Johnston, E.; Hartley, C.J. The Use of Trichoderma Spp. for the Bioconversion of Agro-Industrial Waste Biomass via Fermentation: A Review. Fermentation 2024, 10, 442. [Google Scholar] [CrossRef]

- Bueno-Mancebo, J.; Artola, A.; Barrena, R.; Rivero-Pino, F. Potential Role of Sophorolipids in Sustainable Food Systems. Trends Food Sci. Technol. 2024, 143, 104265. [Google Scholar] [CrossRef]

- Kumar, N.; Zaidi, S.; Endlay, N.; Janbade, A.V.; Gupta, M.K. Significance & role of biotechnologic alapplications in environmental & energy sustainability in pulp & paper industry—An overview. IPPTA Q. J. Indian Pulp Pap. Tech. Assoc. 2024, 36, 149–154. [Google Scholar]

- Mühl, D.D.; da Silva, M.V.B.; de Oliveira, L. How to Build a Bioeconomic Food System: A Thematic Review. Circ. Econ. Sustain. 2024, 4, 1697–1727. [Google Scholar] [CrossRef]

- Gavrilescu, M. From Pollutants to Products: Microbial Cell Factories Driving Sustainable Biomanufacturing and Environmental Conservation. Chem. Eng. J. 2024, 500, 157152. [Google Scholar] [CrossRef]

- Jaffari, Z.H.; Hong, J.; Park, K.Y. A Systematic Review of Innovations in Tannery Solid Waste Treatment: A Viable Solution for the Circular Economy. Sci. Total Environ. 2024, 948, 174848. [Google Scholar] [CrossRef]

- Kumar Srivastava, R.; Sarangi, P.K.; Sahoo, U.K.; Thakur, T.K.; Singh, H.B.; Subudhi, S. Biocatalysts for Biomethanol Production: Advancements and Future Prospects. Appl. Chem. Eng. 2024, 7, 2646. [Google Scholar] [CrossRef]

- Najar, I.N.; Sharma, P.; Das, R.; Tamang, S.; Mondal, K.; Thakur, N.; Gandhi, S.G.; Kumar, V. From Waste Management to Circular Economy: Leveraging Thermophiles for Sustainable Growth and Global Resource Optimization. J. Environ. Manag. 2024, 360, 121136. [Google Scholar] [CrossRef]

- Nifatova, O.; Danko, Y.; Petrychuk, S.; Romanenko, V. Modern Bioeconomy Measurement in the Green Economy Paradigm: Four Pillars of Alternative Bioeconomy. Sustainability 2024, 16, 9612. [Google Scholar] [CrossRef]

- Aryal, M. Phytoremediation Strategies for Mitigating Environmental Toxicants. Heliyon 2024, 10, e38683. [Google Scholar] [CrossRef] [PubMed]

- Javanmardi, E.; Maresova, P.; Xie, N.; Mierzwiak, R. Exploring Business Models for Managing Uncertainty in Healthcare, Medical Devices, and Biotechnology Industries. Heliyon 2024, 10, e25962. [Google Scholar] [CrossRef] [PubMed]

- Naruetharadhol, P.; ConwayLenihan, A.; McGuirk, H. Assessing the Role of Public Policy in Fostering Global Eco-Innovation. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100294. [Google Scholar] [CrossRef]

- Rashid, A.B.; Kausik, M.A.K. AI Revolutionizing Industries Worldwide: A Comprehensive Overview of Its Diverse Applications. Hybrid Adv. 2024, 7, 100277. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Fajardo, O.; Dorado, F.; Lora, A. The Potential for Bioeconomy and Biotechnology Transfer and Collaboration Between Colombia and China. Sustainability 2025, 17, 5083. [Google Scholar] [CrossRef]

- Gawel, E.; Pannicke, N.; Hagemann, N. A Path Transition Towards a Bioeconomy—The Crucial Role of Sustainability. Sustainability 2019, 11, 3005. [Google Scholar] [CrossRef]

| Area | Reference | Title | Research Focus/Main Contributions |

|---|---|---|---|

| 1. Wastewater treatment and water management | [49] | Potential for curdlan recovery from aerobic granular sludge | Overview of resource recovery from aerobic granular sludge (AGS) systems, focusing on curdlan biosynthesis. |

| [15] | Bioremediation of food and beverage wastewater | Bioremediation of food and beverage wastewater using C. vulgaris. | |

| [48] | Carbon neutrality in wastewater treatment plants | Integrated biotechnological solution for carbon-neutral wastewater treatment. | |

| [96] | Development of a wastewater treatment system contaminated with Cr (VI) through vegetable biomass modified with TiO2 | Development of a wastewater treatment system for chromium removal using TiO2-modified biomass. | |

| [104] | Second life of water and wastewater in the context of circular economy | Assessment of recycled water safety using membrane bioreactor technology and storage reservoirs. | |

| [14] | One-step bioremediation of hypersaline and nutrient-rich food industry process water | Bioremediation of hypersaline food industry process water using a microbial community. | |

| [10] | Organics recovery from waste activated sludge in-situ driving efficient nitrogen removal | Innovative biotechnology for organics recovery from sludge and nitrogen removal from landfill leachate. | |

| 2. Biopolymer and bioplastic production | [44] | Polymer- and alcohol-based three-phase partitioning systems | Development of three-phase partitioning systems for biopolymer separation and recyclability assessment. |

| [8] | PHA is not just a bioplastic! | Review of PHA applications beyond bioplastics in various industries. | |

| [5] | Use of enzymatic hydrolysate from agro-industrial asparagus waste | Production of PHA from asparagus waste using B. thuringiensis. | |

| [9] | Pilot scale polyhydroxyalkanoates biopolymer production | Review of pilot-scale PHA production using pure cultures and future opportunities. | |

| 3. Biofuel and bioenergy production | [103] | Microbial biotechnologies to produce biodiesel and biolubricants | Production of biodiesel and biolubricants from dairy effluents using microbial fermentation. |

| [12] | Efficient dark fermentation biohydrogen production | Biohydrogen production from biowaste-derived sugars using Shigella flexneri. | |

| [112] | Chemicals and fuels from lipid-containing biomass | Review of lipid valorization processes for producing chemicals and fuels from biomass. | |

| [16] | Microalgae to biodiesel: A novel green conversion method | Novel method for biodiesel production from microalgae using in situ transesterification. | |

| [47] | From grass to gas and beyond: Anaerobic digestion | Use of anaerobic digestion for biogas production from residual grass. | |

| 4. Bioremediation and environmental cleanup | [13] | Exploring the potential of horse amendment for the remediation of HCHs-polluted soils | Use of organic amendments for bioremediation of HCH-polluted soils. |

| [113] | A critical review on bioremediation technologies of metal(loid) tailings | Review of bioremediation technologies for metal(loid) tailings and policy implications. | |

| [65] | Halophilic archaea as tools for bioremediation technologies | Use of halophilic archaea for the bioremediation of saline environments. | |

| [66] | Fungal bioremediation approaches for the removal of toxic pollutants | Review of fungal bioremediation for toxic pollutant removal and biorefinery applications. | |

| [27] | Immobilizing white-rot fungi laccase | Immobilization of laccase on bio-derived supports for organochlorine removal. | |

| [11] | Remediation of brewery wastewater and reuse for β-glucans production | Bioremediation of brewery wastewater and production of β-glucans using basidiomycete fungi. | |

| 5. Circular economy and waste valorization | [114] | Fungal behavior and recent developments in bio pulping technology | Advances in bio-pulping technology using fungi for sustainable pulp production. |

| [45] | Exploring industrial lignocellulosic waste | Review of lignocellulosic waste sources and their potential for producing high-value molecules. | |

| [115] | The utilization of Industry 4.0 technologies to enhance the circular economy | Integration of Industry 4.0 technologies in Brazilian FoodTec startups to promote the circular economy. | |

| [102] | Bibliometric analysis and review of food waste management | Review of sustainable approaches for food waste management and valorization. | |

| [105] | Recent advances on environmentally sustainable valorization of spent mushroom substrate | Review of sustainable applications for spent mushroom substrate (SMS) in various industries. | |

| [100] | Biotechnological trends and optimization of Arachis hypogaea residues | Review of groundnut residue valorization for bioproducts and optimization techniques. | |

| [2] | Waste from the food industry: Innovations in biorefineries | Review of biorefinery innovations for valorizing food industry waste. | |

| [116] | Valorization of seafood waste: A review of life cycle assessment studies | Review of life cycle assessment studies for seafood waste valorization in biorefineries. | |

| [117] | Turning waste into resources: A comprehensive review on the valorization of Elodea nuttallii biomass | Review of valorization methods for Elodea nuttallii biomass in various applications. | |

| 6. Enzyme and microbial biotechnology | [118] | A review on cellulose degrading microbes and their applications | Review of cellulose-degrading microbes and their applications in biofuel production and bioremediation. |

| [86] | Screening of alternative nitrogen sources for sophorolipid production | Optimization of sophorolipid production using agricultural byproducts as nitrogen sources. | |

| [20] | New biocatalyst produced from fermented biomass | Development of biocatalysts from fermented biomass for enzyme immobilization and aroma synthesis. | |

| [119] | Biotechnological potential of yeast cell wall | Overview of yeast cell wall components and their biotechnological applications. | |

| [21] | Bioprospecting CAZymes repertoire of Aspergillus fumigatus | Optimization of hydrolytic enzyme production from lignocellulosic waste using Aspergillus fumigatus. | |

| [120] | The use of Trichoderma spp. for the bioconversion of agro-industrial waste biomass | Review of Trichoderma spp. for bioconversion of agro-industrial waste via fermentation. | |

| [36] | Genetic modifications in bacteria for the degradation of synthetic polymers | Review of genetic modifications in bacteria for synthetic polymer degradation. | |

| [84] | Potential use of frass from edible insect Tenebrio molitor for proteases production | Production of proteases from frass of Tenebrio molitor using solid-state fermentation. | |

| 7. Food and agriculture applications | [121] | Potential role of sophorolipids in sustainable food systems | Exploration of sophorolipids as biosurfactants and bioactive agents in the food industry. |

| [4] | Bacillus genus industrial applications and innovation | Review of Bacillus applications in various industries and their role in the circular bioeconomy. | |

| [122] | Significance and role of biotechnological applications in environmental and energy sustainability | Overview of biotechnological applications in the pulp and paper industry for sustainability. | |

| [1] | Transition to the circular economy: innovative and disruptive production technologies | Analysis of innovative technologies adopted by agribusiness startups for the circular economy transition. | |

| [123] | How to build a bioeconomic food system | Thematic review on building a bioeconomic food system for sustainability. | |

| [18] | Comparison of plant biostimulating properties of Chlorella sorokiniana biomass | Comparison of Chlorella sorokiniana biomass for plant biostimulant production. | |

| 8. Nanotechnology and advanced materials | [99] | Silane grafted biosourced melanin: a sustainable approach for nanobiosensing applications | Development of sustainable nanobiosensors using biosourced melanin for biomedical applications. |

| [92] | Seafood waste derived carbon nanomaterials for removal and detection of food safety hazards | Use of seafood waste-derived carbon nanomaterials for food safety applications. | |

| 9. Industrial biotechnology and biorefineries | [3] | Optimization of sustainable processes for the extraction of precious metals from end-of-life printed circuit boards | Sustainable methods for recovering precious metals from electronic waste using biotechnology. |

| [97] | Advancements and future directions in waste plastics recycling | Review of innovative chemical processes for plastic recycling and future directions. | |

| [101] | The phosphorus challenge: Biotechnology approaches for a sustainable phosphorus system | Biotechnological approaches for sustainable phosphorus recovery and management. | |

| [124] | From pollutants to products: Microbial cell factories driving sustainable biomanufacturing | Role of microbial cell factories in sustainable biomanufacturing and environmental conservation. | |

| [125] | A systematic review of innovations in tannery solid waste treatment | Review of thermochemical and biological methods for tannery waste treatment. | |

| [126] | Biocatalysts for biomethanol production | Review of biocatalytic pathways for biomethanol production and future prospects. | |

| [127] | From waste management to circular economy: Leveraging thermophiles for sustainable growth | Use of thermophilic microbes for waste management and resource optimization. | |

| [128] | Modern bioeconomy measurement in the green economy paradigm | Analysis of bioeconomy measurement and its integration with green economy principles. | |

| [17] | Selecting for a high lipid accumulating microalgae culture by dual growth limitation | Optimization of lipid accumulation in microalgae using dual-growth limitation in bioreactors. | |

| [98] | Biotechnological approach to treat textile dyeing effluents | Review of biotechnological methods for treating textile dyeing effluents. | |

| [6] | Blue valorization of lignin-derived monomers via reprogramming marine bacterium Roseovarius nubinhibens | Valorization of lignin-derived monomers using the marine bacterium Roseovarius nubinhibens. | |

| [95] | Synergistic microwave and acidic deep eutectic solvent (DES)-based pretreatment of Theobroma cacao pod husk biomass | Production of xylooligosaccharides from cocoa pod husks using microwave-assisted DES pretreatment. | |

| [91] | Turning waste into treasure: A new direction for low-cost production of lipid chemicals from Thraustochytrids | Low-cost production of lipid chemicals from Thraustochytrids using waste materials. |

| Area | Reference | Title | Research Focus/Main Contributions |

|---|---|---|---|

| Enzymatic and microbial biotechnology | [19] | From nature to industry: Harnessing enzymes for biocatalysis | Reviews the use of natural and engineered enzymes for industrial biocatalysis in sustainable applications. |

| [23] | Enzyme Immobilization Technologies and Industrial Applications | Presents innovative methods and materials for enzyme immobilization in industrial environments. | |

| [37] | Engineered plastic-associated bacteria for biodegradation and bioremediation | Explores engineered bacteria associated with plastics to enhance biodegradation and bioremediation processes. | |

| Wastewater treatment and water management | [75] | Microalgae-mediated bioremediation: Current trends and opportunities—A review | Describes genetically modified microalgae for the removal of industrial pollutants, including heavy metals and nitrates. |

| Bioremediation and environmental recovery | [129] | Phytoremediation strategies for mitigating environmental toxicants | Compares vermiremediation (earthworms) and phytoremediation (plants) for the degradation of toxic organic pollutants. |

| [57] | A review on sustainable approach of bioleaching of precious metals from electronic wastes | Explores bioleaching techniques using microorganisms to extract valuable metals from electronic waste (e-waste) sustainably. | |

| [67] | Bioengineered microbial strains for detoxification of toxic environmental pollutants | Explores genetically modified microbial strains for the detoxification of various pollutants. | |

| [69] | Microbial remediation of polluted environment by using recombinant E. coli: a review | Evaluates the use of recombinant E. coli in the bioremediation of industrial contaminants. | |

| Industrial biotechnology and biorefineries | [55] | Bio-Recovery of Metals through Biomining within Circularity-Based Solutions | Integrates biomining and circular economy strategies using GMMs for metal recovery from mining waste. |

| [70] | Genetically Modified Organisms and Its Impact on the Enhancement of Bioremediation | Highlights the potential of GMMs to accelerate bioremediation processes. | |

| Biopolymer and bioplastic production | [7] | Advances and challenges in polyhydroxyalkanoates (PHA) production using Halomonas species | Reviews the state of the art in PHA production using Halomonas species, emphasizing sustainable bioplastic alternatives. |

| [32] | Waste to wealth: Polyhydroxyalkanoates (PHA) production from food waste for a sustainable packaging paradigm | Demonstrates fermentation routes to convert household food waste into PHAs, promoting the circular bioeconomy. | |

| [38] | Pilot-scale production of PHAs using pure cultures | Validates the technical and environmental viability of producing PHAs at a pilot scale using pure microbial cultures, thereby contributing to sustainable bioplastic production. | |

| [39] | Validates the technical and environmental viability of producing PHAs at a pilot scale using pure microbial cultures, thereby contributing to sustainable bioplastic production. | Analyzes industrial capacities and identifies strategic sectors such as agriculture, medicine, and sustainable packaging for the application of bioplastics in the global market. | |

| [31] | Utilization of chickpea starch waste for PHA production | Demonstrates fermentation routes to convert chickpea starch waste into polyhydroxyalkanoates (PHAs), offering a sustainable alternative to petroleum-based plastics. | |

| Circular bioeconomy and waste valorization | [85] | From waste to food and bioinsecticides: An innovative system integrating Tenebrio molitor bioconversion | Presents an integrated system converting organic waste into food and bioinsecticides through insect bioconversion. |

| [87] | Valorization of brewer’s spent grain for sustainable food packaging | Explores the use of spent grain from brewing as a sustainable raw material for food packaging. |

| Biotechnological Strategy | Applications | Advantages | Limitations |

|---|---|---|---|

| Wastewater treatment and water management | Wastewater treatment, nutrient and water recovery | Pollution reduction, resource recovery, synergy with other biotechnologies | Requires proper infrastructure; sensitive to organic load variations |

| Biopolymer and bioplastic production | Packaging, agriculture, medical applications | Biodegradable fossil plastic alternative | High production cost, scalability challenges |

| Biofuel and bioenergy production | Biomass and waste conversion into biogas, bioethanol, biodiesel | Renewable energy and waste reduction; can integrate with AD | Variable efficiency, need for pretreatment |

| Bioremediation and environmental recovery | Soil and water decontamination, pollutant removal | Eco-friendly, low-cost, adaptable | Slow process, affected by environmental factors, scalability limitations |

| Circular economy and waste valorization | Conversion of waste into high-value products (e.g., bioactives) | Waste reduction, added economic value | Variable technical and economic feasibility |

| Enzymatic and microbial biotechnology | Pollutant degradation, bioproduct synthesis, food industry | High specificity, mild operational conditions | Cost and stability of enzymes, limited reuse |

| Applications in food industry and agriculture | Biofertilizers, biopesticides, crop enhancement | Sustainable agriculture, reduced agrochemical use | Market acceptance, complex regulatory pathways |

| Nanotechnology and advanced materials | Smart packaging, controlled release systems, remediation | High reactivity, technological innovation, cross-sector use | High cost, environmental risks not fully understood |

| Industrial biotechnology and biorefineries | Integrated processes for biomass utilization | Resource efficiency, reduced environmental impact | High technical complexity, investment needs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carmona Marques, P.; Fernandes, P.C.B.; Sampaio, P.; Silva, J. Advances in Biotechnology in the Circular Economy: A Path to the Sustainable Use of Resources. Sustainability 2025, 17, 6391. https://doi.org/10.3390/su17146391

Carmona Marques P, Fernandes PCB, Sampaio P, Silva J. Advances in Biotechnology in the Circular Economy: A Path to the Sustainable Use of Resources. Sustainability. 2025; 17(14):6391. https://doi.org/10.3390/su17146391

Chicago/Turabian StyleCarmona Marques, Pedro, Pedro C. B. Fernandes, Pedro Sampaio, and Joaquim Silva. 2025. "Advances in Biotechnology in the Circular Economy: A Path to the Sustainable Use of Resources" Sustainability 17, no. 14: 6391. https://doi.org/10.3390/su17146391

APA StyleCarmona Marques, P., Fernandes, P. C. B., Sampaio, P., & Silva, J. (2025). Advances in Biotechnology in the Circular Economy: A Path to the Sustainable Use of Resources. Sustainability, 17(14), 6391. https://doi.org/10.3390/su17146391