Assessing the Impact of Residual Municipal Solid Waste Characteristics on Screw Press Performance in a Mechanical Biological Treatment Plant Optimized with Anaerobic Digestion

Abstract

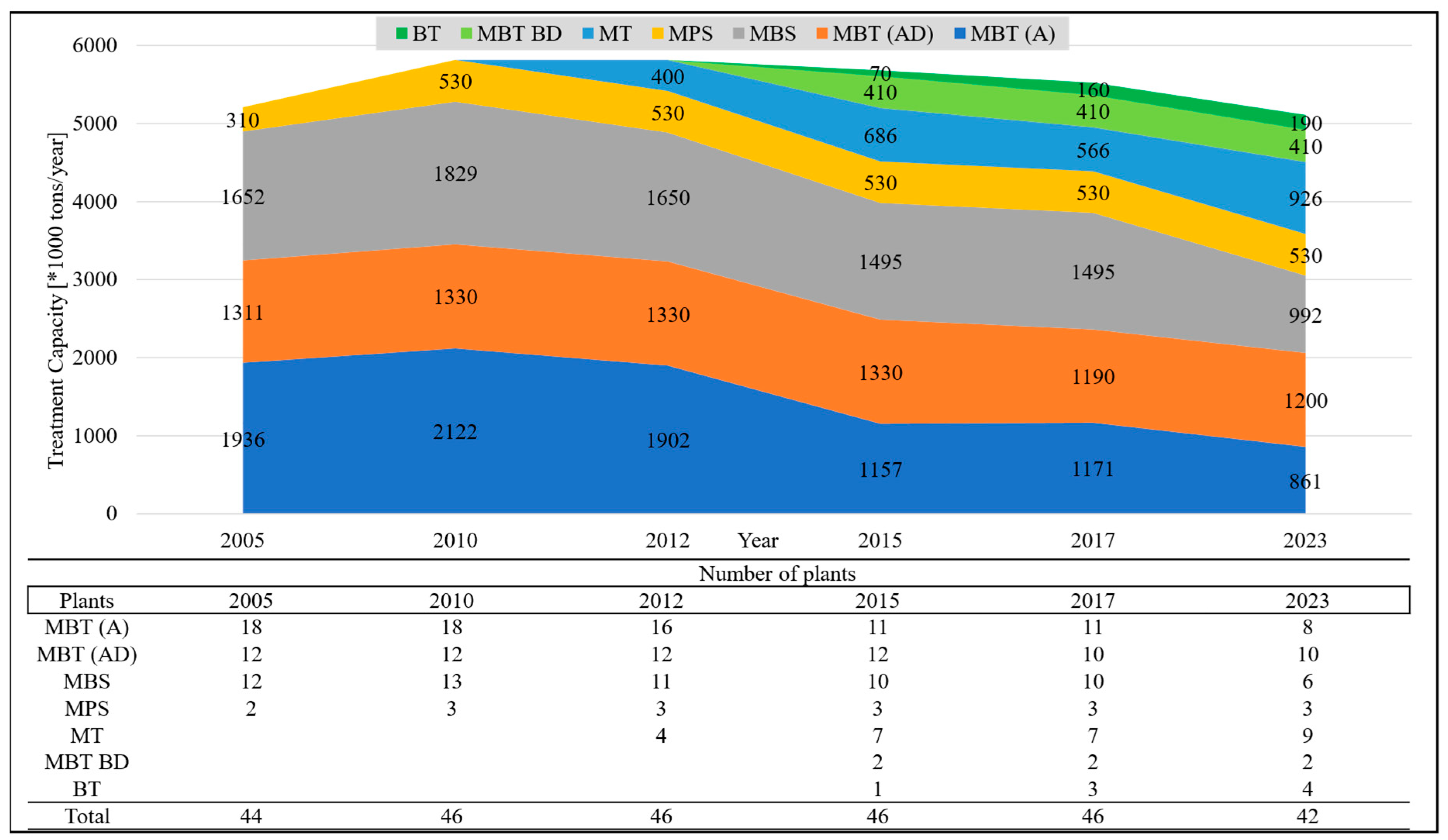

1. Introduction

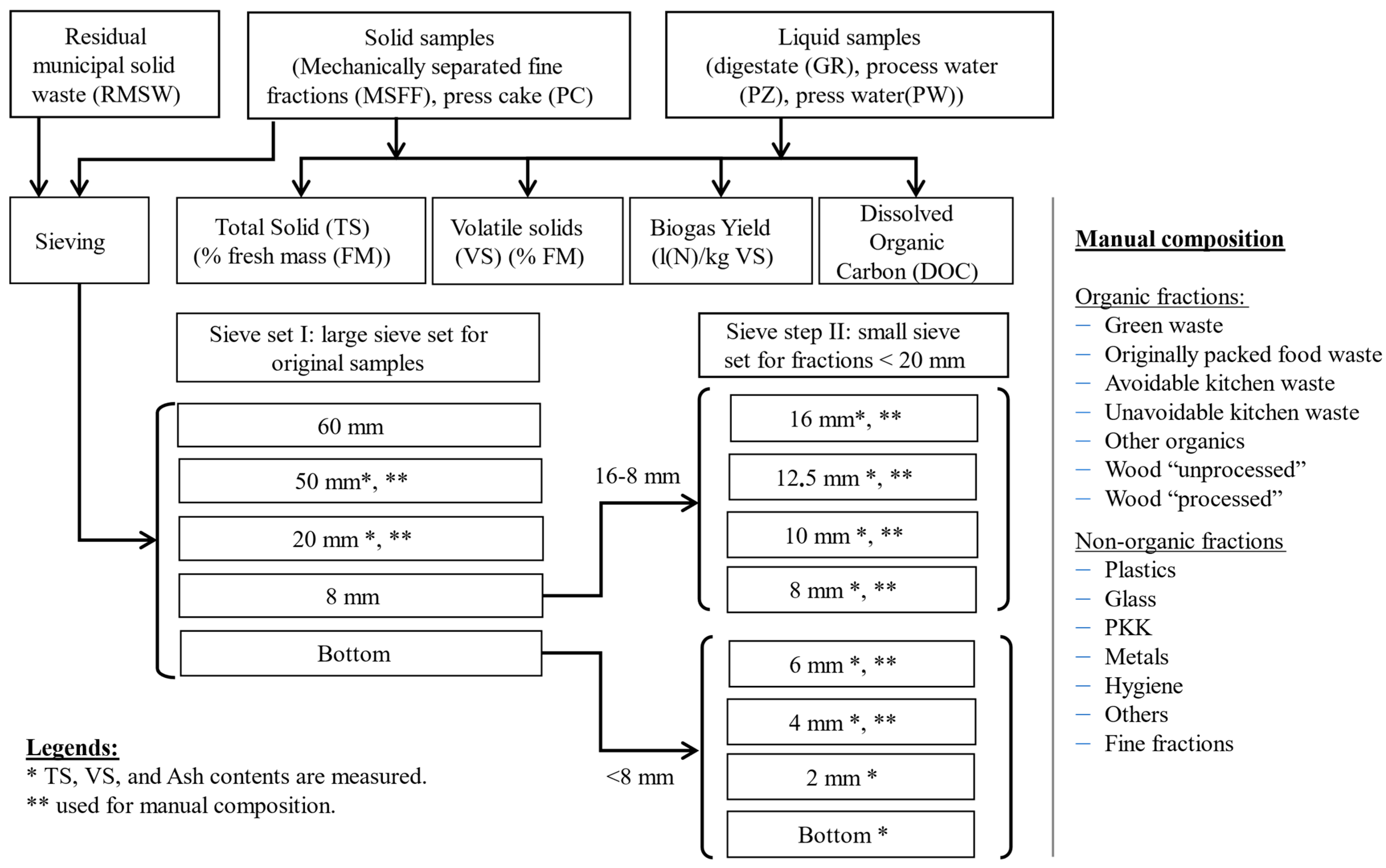

2. Materials and Methods

2.1. The MBT Plant of This Study

- (1)

- The Screw Press (SP) (type AS 625 from Bellmer-Kufferath);

- (2)

- Five small reactors (45 m3) and one large stirred tank reactor (435 m3)

- (3)

- Biogas treatment and utilization units.

2.2. Sampling Methods

2.3. Analytical Methods

2.4. Experimental Model with Screw Press at the EVA MBT Plant

2.5. Setup of the Operating Parameters of the Screw Press

3. Results

3.1. Characteristics of the Residual Municipal Solid Waste (RMSW)

3.2. Characteristics of Mechanically Separated Fine Fractions

3.3. Quality of the Digestate (GR) and Process Water (PZ) Added to MSFF

3.4. Quality of the Press Water Generated from Pressing Experiments

3.5. Quality of the Press Cake Generated from Pressing Experiments

4. Discussion

4.1. Efficiency of Shredding and Screening to Separate Organics from Input RMSW to MSFF

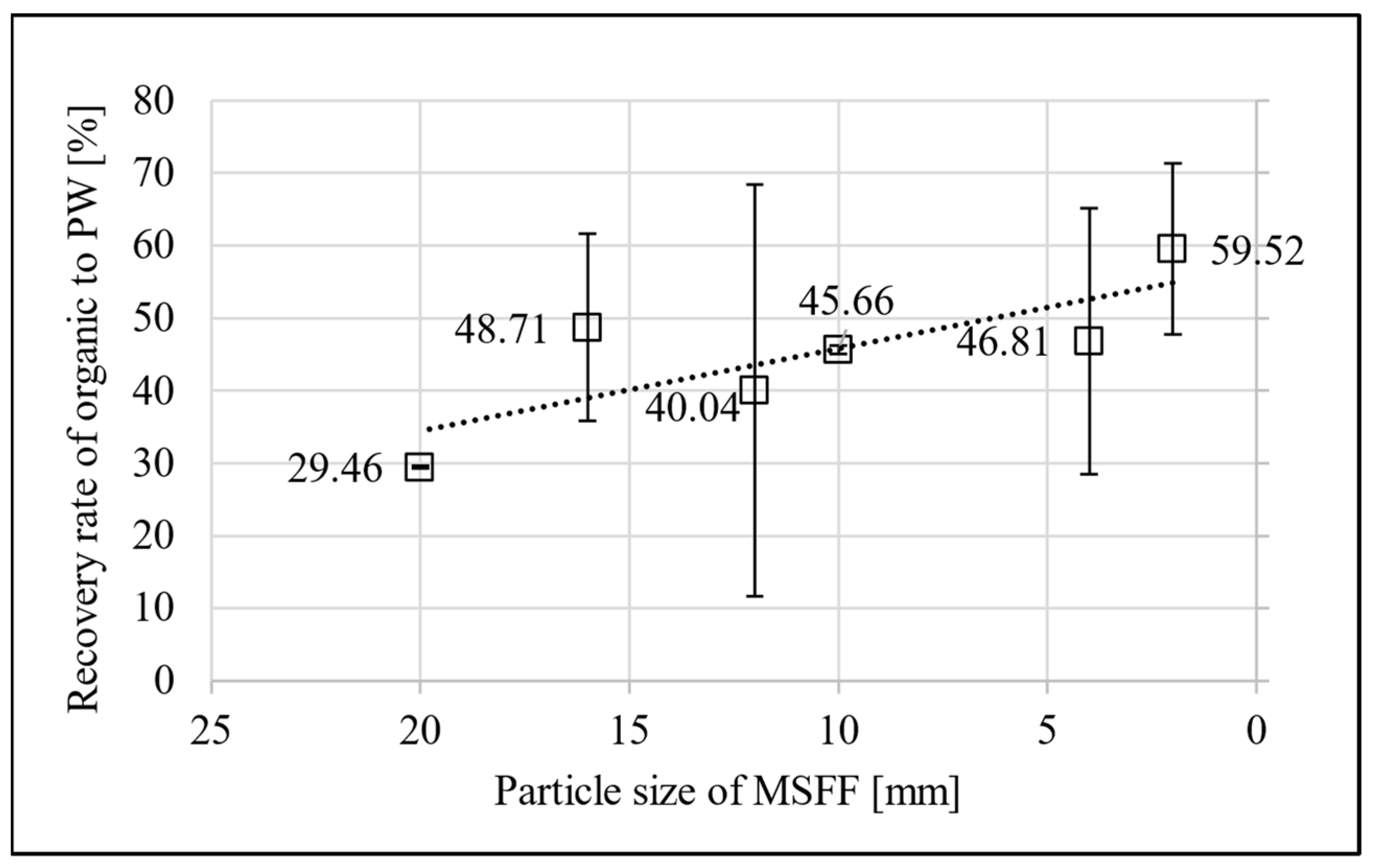

4.2. Impact of Particle Size of MSFF on the Screw Press Performance to Recover Organic Matter from MSFF to Press Water

4.3. Performance of Screw Press Based on Recovery Rate from MSFF to Press Water

5. Conclusions

- (1)

- Mechanical treatment: The combination of shredding and rotary drum screening significantly increased the organic content from 29% in RMSW to 46% in MSFF, achieving a 92% recovery of biodegradable material.

- (2)

- PW quality: The subsequent pressing process produced press water with minimal inert content, resulting in a 50% improvement in biogas yield compared to the input mix, reaching 416 m3/ton of VS.

- (3)

- VS and biogas recovery: The screw press setup in this study successfully recovered 24% of the VS and 38% of the biogas from the input mix to the PW, with higher recovery from finer fractions.

- (4)

- Recommendations: For future studies, it is recommended to optimize the operation of the screw press by investigating key parameters such as pressure (bar), liquid-to-MSFF ratio (L/ton), screw press basket opening size (mm), feed rate to the screw press (ton/h), and the mixing time of liquid and MSFF prior to pressing (minutes).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dödens, H.; Gallenkemper, B.; Ketelsen, K.; Kranert, M.; Klaus, F. Status MBA in Deutschland: MBP—State oft the Art in Germany. Müll Abfall 2007, 39, 576–579. [Google Scholar]

- Pfaff-Simoneit, W. Entwicklung eines sektoralen Ansatzes zum Aufbau von nachhaltigen Abfallwirtschaftssystemen in Entwicklungsländern vor dem Hintergrund von Klimawandel und Ressourcenverknappung. Ph.D. Thesis, Universität Rostock, Rostock, Germany, 2012. [Google Scholar]

- Lornage, R.; Redon, E.; Lagier, T.; Hébé, I.; Carré, J. Performance of a low cost MBT prior to landfilling: Study of the biological treatment of size reduced MSW without mechanical sorting. Waste Manag. 2007, 27, 1755–1764. [Google Scholar] [CrossRef] [PubMed]

- Statistisches Bundesamt. Neue Rekordmenge an Haushaltsabfällen im Jahr. 2021. Available online: https://www.destatis.de/DE/Presse/Pressemitteilungen/2022/12/PD22_546_321.html (accessed on 19 August 2024).

- Dornbusch, H.-J.; Hannes, L.; Santjer, M.; Böhm, C.; Wüst, S.; Zwisele, B.; Kern, M.; Siepenkothen, H.-J.; Kanthak, M. Vergleichende Analyse von Siedlungsrestabfällen aus repräsentativen Regionen in Deutschland zur Bestimmung des Anteils an Problemstoffen und verwertbaren Materialien: Abschlussbericht; Herausgegeben vom Umweltbundesamt: Dessau-Roßlau, Germany, 2020. [Google Scholar]

- Lenkiewicz, Z.; Tenald, D.; Filho, C.S.; Ramola, A. Beyond an Age of Waste; Turning Rubbish into a Resource: Global Waste Management Outlook 2024. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/44939/global_waste_management_outlook_2024.pdf?sequence=3 (accessed on 15 August 2024).

- World Bank Group. What a Waste 2.0: Aglobal Snapshot of Solid Waste Managment to 2050: Urban Development Series; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- European Compost Network ECN e.V. Guidance Seperate Collection; European Compost Network ECN e.V.: Bochum, Germany, 2022. [Google Scholar]

- Favoino, E.; Giavini, M.; Di Parco Monz, S.A. Bio-Waste Generation in the EU—Current Capture and Future Potential; Bio-Based Industries Consortium (BIC): Brussels, Belgium, 2020. [Google Scholar]

- Wirtschaftsbetriebe Duisburg. Abfallentsorgungsgebührensatzung Gültig ab 01.01.2025 (Lesefassung); Wirtschaftsbetriebe Duisburg: Duisburg, Germany, 2025. [Google Scholar]

- EUWID Recycling und Entsorgung. Pro und Contra Sortiergebot für gemischte Abfälle in Abfallrahmenrichtlinie. Available online: https://www.euwid-recycling.de/news/international/pro-und-contra-sortiergebot-fuer-gemischte-abfaelle-in-abfallrahmenrichtlinie/ (accessed on 17 August 2024).

- The Federal Government of Germany. National Bioeconomy Strategy; The Federal Government of Germany: Berlin, Germany, 2020. [Google Scholar]

- European Environment Agency. Reaching 2030’s Residual Municipal Waste Target—Why Recycling Is Not Enough—European Environment Agency. Available online: https://www.eea.europa.eu/publications/reaching-2030s-residual-municipal-waste?utm_source=chatgpt.com (accessed on 5 March 2025).

- European Environment Agency. Many EU Member States Not on Track to Meet Recycling Targets for Municipal Waste and Packaging Waste. Available online: https://www.eea.europa.eu/publications/many-eu-member-states (accessed on 17 August 2024).

- Blasenbauer, D.; Lipp, A.-M.; Fellner, J.; Lederer, J. Rückgewinnungspotential von Kunststoffverpackungen durch automatisierte Sortierung von gemischtem Siedlungsabfall–eine Fallstudie aus Österreich. In Proceedings of the 13 WISSENSCHAFTSKONGRESS Kreislauf—und Ressourcenwirtschaft; Zusammenarbeit mit der Fakultät für Bau—und Umweltingenieurwesen der Technischen Universität Wien, Technischen Universität Wien, Vienna, Austria, 15–16 February 2024; DGAW, Ed.; Volume 13, pp. 189–192. [Google Scholar]

- Bardos, P. Composting of Mechanically Segregated Fractions of Municipal Solid Waste—A Review; SITA Environmental Trust: Truro, UK, 2004. [Google Scholar]

- Baere, L.D.; Mattheeuws, B. Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste in Europe:—Status, Experience and Prospects. Munic. Solid Wastes 2017, 38, 517–526. [Google Scholar]

- Ketelsen, K.; Becker, G. Weiterentwicklung der mechanisch-biologischen Abfallbehandlung (MBA) mit den Zielen der OptImierung der Ressourceneffizienz und Minimierung von Treibhausgasemissionen; Umweltbundesamt: Dessau-Roßlau, Germany, 2023. [Google Scholar]

- Bewani, R.; Böning, T.; Nassour, A.; Nelles, M. Increasing the Efficiency of Mechanical-Biological Residual Waste Treatment through the Fermentation of the Liquid after Pressing the Organic Fractions. In Proceedings of the 13 WISSENSCHAFTSKONGRESS Kreislauf—und Ressourcenwirtschaft; Zusammenarbeit mit der Fakultät für Bau—und Umweltingenieurwesen der Technischen Universität Wien, Technischen Universität Wien, Vienna, Austria, 15–16 February 2024; DGAW, Ed.; Volume 13, pp. 145–150. [Google Scholar]

- Merten, M.; Person, G.; Schreiber, M. Moderne Abfallbehandlung—Die MBA Kahlenberg. 2006, pp. 65–103. Available online: https://www.abfallwirtschaft-ortenaukreis.de/fileadmin/user_upload/11-MBA/MBA_Artikel_und_ZAK_Verfahren.pdf (accessed on 7 July 2025).

- de Baere, L. Will anaerobic digestion of solid waste survive in the future? Water Sci. Technol. 2006, 53, 187–194. [Google Scholar] [CrossRef]

- Thanos Bourtsalas, A.C.; Themelis, N.J. Materials and energy recovery at six European MBT plants. Waste Manag. 2022, 141, 79–91. [Google Scholar] [CrossRef] [PubMed]

- Bewani, R. Comparison of Biowaste and Compost Composition, Management, and Quality Analysis in Stuttgart and Kurdistan Region of Iraq (KRI). Master’s Thesis, Universität Stuttgart, Stuttgart, Germany, 2018. [Google Scholar]

- Ketelsen, K. Umrüstung von Mechsnisch-Biologischen Abfallbehandlungsanlagen- Unter Kosten-, Klima- und Energieeffizienzaspekten. In Proceedings of the Conference Presentation “Berliner Energiekonferenz Erneuerbare Energien”, Berlin, Germany, 6 September 2010. [Google Scholar]

- Ketelsen, K.; Kanning, K.; Cuhls, C. Optimisation of MBT Considering Energy Efficiency and Protection of Resources and Climate (Presentaion). In Proceedings of the Conference Presentation “Waste-to-Resource”, Hannover, Germany, 24 May 2011. [Google Scholar]

- Bolzonella, D.; Pavan, P.; Mace, S.; Cecchi, F. Dry anaerobic digestion of differently sorted organic municipal solid waste: A full-scale experience. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2006, 53, 23–32. [Google Scholar] [CrossRef]

- Bernstad, A.; Malmquist, L.; Truedsson, C.; La Cour Jansen, J. Need for improvements in physical pretreatment of source-separated household food waste. Waste Manag. 2013, 33, 746–754. [Google Scholar] [CrossRef]

- Campuzano, R.; González-Martínez, S. Characteristics of the organic fraction of municipal solid waste and methane production: A review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

- de Baere, L. Anaerobic digestion of solid waste: State-of-the-art. Water Sci. Technol. 2000, 41, 283–290. [Google Scholar] [CrossRef]

- Lamolinara, B.; Pérez-Martínez, A.; Guardado-Yordi, E.; Guillén Fiallos, C.; Diéguez-Santana, K.; Ruiz-Mercado, G.J. Anaerobic digestate management, environmental impacts, and techno-economic challenges. Waste Manag. 2022, 140, 14–30. [Google Scholar] [CrossRef]

- Chuda, A.; Ziemiński, K. Challenges in Treatment of Digestate Liquid Fraction from Biogas Plant. Performance of Nitrogen Removal and Microbial Activity in Activated Sludge Process. Energies 2021, 14, 7321. [Google Scholar] [CrossRef]

- Hansen, T.L.; La Jansen, J.C.; Davidsson, A.; Christensen, T.H. Effects of pre-treatment technologies on quantity and quality of source-sorted municipal organic waste for biogas recovery. Waste Manag. 2007, 27, 398–405. [Google Scholar] [CrossRef] [PubMed]

- Meirer, M.; Müller, W.; Bockreis, A. Waste Management and The Environment VIII. In Proceedings of the Waste Management, Valencia, Spain, 7–9 June 2016; Brebbia, C.A., Itoh, H., Eds.; WIT Press Southampton: Torquay, UK, 2016; pp. 277–288. [Google Scholar]

- Meirer, M.; Müller, W.; Bockreis, A. Mechanische Abtrennung biogener Reststoffe aus Restabfall für die Co-Vergärung in Faultürmen kommunaler Kläranlagen. Österr Wasser Abfallw 2017, 69, 397–404. [Google Scholar] [CrossRef]

- Arina, D.; Orupe, A. Comparison of municipal solid waste characteristics after separation by star and drum screen systems. In Proceedings of the 4th International Conference Civil Engineering’13 Proceedings Part I Environment and Environmental Effects, Jelgava, Latvia, 16–17 May 2013; pp. 318–322. [Google Scholar]

- Arina, D.; Kalnacs, J.; Bendere, R.; Murasovs, A. Engineering for Rural Development. In Proceedings of the 18th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 22 May 2019; pp. 1599–1604. [Google Scholar]

- Bayard, R.; Morais, J.d.A.; Ducom, G.; Achour, F.; Rouez, M.; Gourdon, R. Assessment of the effectiveness of an industrial unit of mechanical-biological treatment of municipal solid waste. J. Hazard. Mater. 2010, 175, 23–32. [Google Scholar] [CrossRef]

- Bolzonella, D.; Battistoni, P.; Susinii, C.; Cecchi, F. Anaerobic codigestion of waste activated sludge and OFMSW: The experiences of viareggio and treviso plants (Italy). Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2006, 53, 203–211. [Google Scholar] [CrossRef]

- BTA International GmbH. BTA—Biotechnical Recycling. Available online: https://bta-international.de/ (accessed on 11 November 2024).

- Jank, A.; Müller, W.; Waldhuber, S.; Gerke, F.; Ebner, C.; Bockreis, A. Hydrocyclones for the separation of impurities in pretreated biowaste. Waste Manag. 2017, 64, 12–19. [Google Scholar] [CrossRef]

- Effenberger, J.; Jahn, L.; Kuehn, V. Co-digestion of press liquids of source-sorted municipal organic waste in anaerobic sludge treatment of municipal wastewater treatment plants. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2016, 73, 3080–3086. [Google Scholar] [CrossRef]

- Romero-Güiza, M.S.; Peces, M.; Astals, S.; Benavent, J.; Valls, J.; Mata-Alvarez, J. Implementation of a prototypal optical sorter as core of the new pre-treatment configuration of a mechanical–biological treatment plant treating OFMSW through anaerobic digestion. Appl. Energy 2014, 135, 63–70. [Google Scholar] [CrossRef]

- Meirer, M. Physikalische Aufbereitung von Restabfällen zur Co-Vergärung in Abwasserreinigungsanlagen. Ph.D. Thesis, Leopold-Franzens-Universität Innsbruck, Innsbruck, Austria, 2018. [Google Scholar]

- Osei, K.; Andoh, R. Optimal Grit Removal and Control in Collection Systems and at Treatment Plants. In Proceedings of the World Environmental and Water Resources Congress 2008, Honolulu, HI, USA, 12–16 May 2008; Babcock, Roger, W., Eds.; ASCE: Reston, VA, USA, 2008; pp. 1–7. [Google Scholar]

- Abfallzweckverband Südniedersachsen. MBA—Verfahrensbeschreibung: Phase I: Mechanische Aufbereitung (MA) der Abfälle Phase II: Biologische Behandlung (BA) in der Trockenvergärung. Available online: https://www.as-nds.de/mba/verfahren/index.html (accessed on 5 October 2024).

- Xu, S.; Kong, X.; Liu, J.; Zhao, K.; Zhao, G.; Bahdolla, A. Effects of high-pressure extruding pretreatment on MSW upgrading and hydrolysis enhancement. Waste Manag. 2016, 58, 81–89. [Google Scholar] [CrossRef]

- Meirer, M.; Müller, W.; Bockreis, A. Innovative Abfallaufbereitung: Erzeugung hochwertiger Substrate für Biogas- & Kläranlagen: Poster. In Proceedings of the Österreichische Abfallwirtschaftstagung 2017, Graz, Austria, 10–11 May 2017. [Google Scholar]

- Nowak, O.; Ebner, C. Verwertung organischer Reststoffe in Faulbehältern kommunaler Kläranlagen. Österr Wasser Abfallw 2016, 68, 108–117. [Google Scholar] [CrossRef]

- Nayono, S.E. Foodwaste as a Co-Substrate in a Fed-Batch Anaerobic Biowaste Digester for Constant Biogas Supply. Ph.D. Thesis, Universität Fridericiana zu Karlsruhe (TH), Karlsruhe, Germany, 2009. [Google Scholar]

- Lopes, A.C.P. Mechanical Pretreatment of Residual Waste for Codigestion in Wastewater Treatment Plants. Ph.D. Thesis, Leopold-Franzens-Universität Innsbruck, Innsbruck, Austria, 2021. [Google Scholar]

- Cesaro, A.; Cieri, V.; Belgiorno, V. Press-extrusion pretreatment of the organic fraction of municipal solid waste for enhanced methane production. J. Mater. Cycles Waste Manag. 2020, 23, 130–138. [Google Scholar] [CrossRef]

- Sutco Recyclingtechnik GmbH; Entsorgungsgesellschaft Westmünsterland mbH; Universität Duisburg-Essen. Forschungs- und Entwicklungs-Vorhaben Energieeffiziente Bioabfallverwertung = EnBV: Abschlussbericht Anschlussvorhaben; Sutco Recyclingtechnik GmbH: Bergisch Gladbach, Germany, 2015. [Google Scholar]

- Erbenschwanger Verwertungs- und g g Abfallentsorgungs-Gesellschaft mbH; Universität Rostock. FuE-Vorhaben “Presswasservergärung Restabfall = PV-R”: An die Deutsche Bundesstiftung Umwelt (DBU); Deutsche Bundesstiftung Umwelt (DBU): Osnabrück, Germany, 2017. [Google Scholar]

- Anaergia Technologies GmbH. Separator FSP—Anaergia Technologies—Komponenten für eine nachhaltige Zukunft (EN). Available online: https://www.anaergia-technologies.com/en/products/separation/separator/ (accessed on 19 October 2024).

- Jank, A.; Müller, W.; Schneider, I.; Gerke, F.; Bockreis, A. Waste Separation Press (WSP): A mechanical pretreatment option for organic waste from source separation. Waste Manag. 2015, 39, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.R.; Ng, W.J. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): Progress and challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Huang, X. The Promotion of Anaerobic Digestion Technology Upgrades in Waste Stream Treatment Plants for Circular Economy in the Context of “Dual Carbon”: Global Status, Development Trend, and Future Challenges. Water 2024, 16, 3718. [Google Scholar] [CrossRef]

- Córdoba, V.E.; Santalla, E.M. Estimation of long-term methane emissions from Mechanical-Biological Treatment waste through biomethane potential test. Environ. Technol. 2021, 43, 3835–3847. [Google Scholar] [CrossRef]

- Gesetz zur Förderung der Kreislaufwirtschaft und Sicherung der umweltverträglichen Bewirtschaftung von Abfällen (Kreislaufwirtschaftsgesetz KrWG): Bundesgesetz. 2012. Available online: https://datenbank.nwb.de/Dokument/434480/ (accessed on 15 January 2024).

- Nelles, M.; Böning, T.; Bewani, R.; Nassour, A. FuE-Vorhaben “Presswasservergärung Restabfall” DBU-Förderkennzeichen: 33791/01; Endbericht (vom 15.2.2022); Universität Rostock—Agrar-und Umweltwissenschaftliche Fakultät: Rostock, Germany, 2022. [Google Scholar]

- Wagner, J.; Kuegler, T.; Baumann, J.; Günther, M.; Finke, E. Bericht zur Fortschreibung der Sortierrichtlinie 1998: Bericht zur Fortschreibung der Richtlinie zur einheitlichen Abfallanalytik in Sachsen: Freistaat Sachsen; Landesamt für Umwelt, Landwirtschaft und Geologie: Dresden, Germany, 2014. [Google Scholar]

- Vergärung organischer Stoffe Substratcharakterisierung, Probenahme, Stoffdatenerhebung, Gärversuche. English “Fermentation of organic materials Characterisation of the substrate, sampling, collection of material data, fermentation tests”: VDI 4630, November 2016. Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-4630-fermentation-of-organic-materials-characterization-of-the-substrate-sampling-collection-of-material-data-fermentation-tests (accessed on 7 July 2025).

- Deutsches Institut für Normung. Characterization of Waste—Calculation of Dry Matter by Determination of Dry Residue or Water Content; German Version EN 14346:2006, 03/2007. Available online: https://www.dinmedia.de/en/standard/din-en-14346/92061940 (accessed on 7 March 2025).

- Deutsches Institut für Normung. Charakterisierung von Abfall—Bestimmung des Glühverlustes in Abfall, Schlamm und Sedimenten, Deutsche Fassung EN 15169:2007 (Characterization of Waste—Determination of Loss on Ignition in Waste, Sludge and Sediments; German Version EN 15169:2007), 05/2007. Available online: https://www.dinmedia.de/de/norm/din-en-15169/93016789 (accessed on 7 March 2025).

- Deutsches Institut für Normung. Untersuchung von Feststoffen—Probenvorbehandlung, -Vorbereitung und -Aufarbeitung für Chemische, Biologische und Physikalische Untersuchungen (Investigation of Solids—Pre-Treatment, Preparation and Processing of Samples for Chemical, Biological and Physical Investigations), 07.2009. Available online: https://www.dinmedia.de/de/norm/din-19747/118510306 (accessed on 5 March 2025).

- Deutsches Institut für Normung. Wasseranalytik—Anleitungen zur Bestimmung des Gesamten Organischen Kohlenstoffs (TOC) und des Gelösten Organischen Kohlenstoffs (DOC); Deutsche Fassung EN 1484:1997 (Water Analysis—Guidelines for the Determination of Total Organic Carbon (TOC) and Dissolved Organic Carbon (DOC); German Version EN 1484:1997). Available online: https://www.din.de/de/mitwirken/normenausschuesse/naw/wdc-beuth:din21:301999219 (accessed on 5 March 2025).

- INFA GmbH; Wirtschaftsbetriebe Duisburg AöR. Zusammensetzung des Restabfalls in der Stadt Duisburg: Ergebnistabellen (intern). 2019. [Google Scholar]

- Ministry of Environmental Protection and Regional Development of the Republic of Latvia. Assessment of Content of Municipal Solid, Hazardous and Producing Waste in Waste Management Regions; Ministry of Environmental Protection and Regional Development of the Republic of Latvia: Rīga, Latvia, 2018; Online. (In Latvian)

- Lombardi, F.; Zingaretti, D.; Verginelli, I.; Costa, G. Optimization of the Biostabilization Process of an Italian Mechanical–Biological Treatment Plant to Account for Changes in Waste Composition. Waste Biomass Valor. 2022, 13, 3787–3800. [Google Scholar] [CrossRef]

- Meirhofer, M.; Pieber, S.; Ragossnig, A.; Brooks, L.; Fercher, E. Behandlungsoptionen für eine MBA-Schwerfraktion—Am Beispiel der MBA Oberpullendorf. In Proceedings of the 10th DepoTech-Conference 2010, Leoben, Austria, 3–5 November 2010; Volume 2010, pp. 271–276. [Google Scholar]

- de Araújo Morais, J.; Ducom, G.; Achour, F.; Rouez, M.; Bayard, R. Mass balance to assess the efficiency of a mechanical-biological treatment. Waste Manag. 2008, 28, 1791–1800. [Google Scholar] [CrossRef]

- Di Maria, F.; Micale, C.; Sordi, A.; Cirulli, G.; Marionni, M. Urban mining: Quality and quantity of recyclable and recoverable material mechanically and physically extractable from residual waste. Waste Manag. 2013, 33, 2594–2599. [Google Scholar] [CrossRef] [PubMed]

- Burnley, S.J.; Ellis, J.C.; Flowerdew, R.; Poll, A.J.; Prosser, H. Assessing the composition of municipal solid waste in Wales. Resour. Conserv. Recycl. 2007, 49, 264–283. [Google Scholar] [CrossRef]

- Matveev, Y.; Geletukha, G. Prospects of Energy Utilisation of Municipal Solid Waste in Ukraine: Uabio Position Paper № 22; Bioenergy Association of Ukraine: Kyiv, Ukraine, 2019. [Google Scholar]

- Ministry of Environment. Waste Management Program of the Republic of Serbia for the Period 2022–2031; Official Gazette of the Republic of Serbia: Belgrade, Serbia, 2022.

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Anaerobic digestion of mechanically treated OFMSW: Experimental data on biogas/methane production and residues characterization. Bioresour. Technol. 2011, 102, 8885–8892. [Google Scholar] [CrossRef] [PubMed]

- Stiftung Zentrale Stelle Verpackungsregister. Verwertungsmengen Verpackungen Privater Endverbrauch 2018–2021: Presentation. Available online: https://www.verpackungsregister.org/fileadmin/files/Presse/ZSVR_Auswertung_Recyclingquoten_2018-2021.pdf (accessed on 7 July 2025).

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Biodrying for mechanical-biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 2009, 100, 2747–2761. [Google Scholar] [CrossRef] [PubMed]

- Cook, E.; Wagland, S.; Coulon, F. Investigation into the non-biological outputs of mechanical-biological treatment facilities. Waste Manag. 2015, 46, 212–226. [Google Scholar] [CrossRef] [PubMed]

- Department for Environment Food and Rural Affairs. Mechanical Biological Treatment of Municipal Solid Waste; Department for Environment Food and Rural Affairs: London, UK, 2013.

- Nayono, S.E.; Winter, J.; Gallert, C. Anaerobic digestion of pressed off leachate from the organic fraction of municipal solid waste. Waste Manag. 2010, 30, 1828–1833. [Google Scholar] [CrossRef]

- Farneti, A.; Cozzolino, C.; Bolzonella, D.; Innocenti, L.; Cecchi, F. Semi-dry anaerobic digestion of OFMSW: The new full scale plant of Verona (Italy). In Proceedings of the II International Symposium on Anaerobic Digestion of Solid Waste—II-ISAD-SW, Barcelona, Spain, 15–17 June 1999; Volume 2, p. 330. [Google Scholar]

- Lissens, G.; Vandevivere, P.; de Baere, L.; Biey, E.M.; Verstraete, W. Solid waste digestors: Process performance and practice for municipal solid waste digestion. Water Sci. Technol. 2001, 44, 91–102. [Google Scholar] [CrossRef]

| Quality of Waste | Pressure (bar) | (GR + PZ)/MSFF (L/ton) | Press Basket (mm) | Feeding to SP (ton/h) |

|---|---|---|---|---|

| 4.5 | 1000 GR:PZ 4:1 | 5 | 18

|

| Investigated in this study | Constant | |||

| MSFF (This Study) | FR (1) | LAT (2) | LAT (3) | IT (4) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fractions | 60–50 mm | 50–20 mm | 20–8 mm | <8 mm | Average | <70 mm | <60 mm | 25–60 mm | 0–25 mm | <20 mm |

| Organic | 2.81 | 17.03 | 23.03 | 22.5 | 26 ± 5.46 | 11 | 28 | 20.3 | 14.7 | 36 |

| Glass | 0.00 | 8.31 | 26.76 | 33.7 | 22.79 ± 2.64 | 10.5 | 6.2 | 11.10 | 21.50 | 22.2 |

| Stone | 0.00 | 4.67 | 21.80 | 30.3 | 18.43 ± 3.40 | - | 5.6 | - | - | - |

| 3D plastic | 27.56 | 5.21 | 6.33 | 1.8 | 5.14 ± 2.65 | 4 | 6 | 9.90 | 4.30 | 3.18 |

| Plastic foil | 15.13 | 3.89 | 1.97 | 0.34 | 2.29 ± 1.33 | 4 | - | |||

| PPK | 5.84 | 22.33 | 1.98 | 3.19 | 8.88 ± 3.57 | 2.4 | 36 | 18.50 | 6.20 | - |

| Hygiene | 31.89 | 30.98 | 10.70 | 13.19 ± 0.97 | 3.6 | 5.6 | 10.30 | 1.80 | - | |

| Textile | 12.76 | 1.06 | 0.70 | 0.47 | 1.08 ± 0.15 | 0.5 | 1.8 | 5.40 | 1.40 | - |

| Metals | 0.94 | 1.88 | 0.09 | 2.50 | 1.47 ± 0.60 | 1.7 | 1.7 | 2.2 | 2.10 | 0.69 |

| Others | 3.06 | 3.70 | 6.64 | 4.56 | 5.18 ± 0.17 | 9.7 | 0.4 | 6.6 | 7.10 | 28.9 |

| Fine | - | - | - | - | - | 55.9 | 8.4 | 15.6 | 40.10 | - |

| Particle Size [mm] | MSFF (This Study) | PC (This Study) | ||||

|---|---|---|---|---|---|---|

| MC [% fm] | VS [% fm] | Ash [% fm] | MC [% fm] | VS [% fm] | Ash [% fm] | |

| >50 | 1.00 ± 0.61 | 1.71 ± 1.03 | 0.78 ± 0.47 | 3.04 ± 0.41 | 2.14 ± 1.01 | 0.52 ± 0.38 |

| 50–20 | 13.31 ± 4.86 | 8.50 ± 5.27 | 6.84 ± 5.49 | 24.80 ± 2.95 | 12.19 ± 3.47 | 13.88 ± 2.65 |

| 20–16 | 1.16 ± 0.40 | 0.95 ± 0.56 | 0.48 ± 0.33 | 1.44 ± 3.37 | 0.65 ± 0.39 | 0.76 ± 0.09 |

| 16–12.5 | 1.95 ± 0.49 | 1.61 ± 0.43 | 0.79 ± 0.85 | 3.21 ± 3.21 | 1.20 ± 0.43 | 1.95 ± 2.58 |

| 12.5–10 | 2.25 ± 0.19 | 1.25 ± 0.35 | 1.52 ± 0.20 | 2.30 ± 0.51 | 0.77 ± 0.25 | 1.48 ± 0.35 |

| 10–8 | 3.17 ± 1.59 | 1.78 ± 0.45 | 2.04 ± 1.17 | 1.96 ± 0.01 | 0.87 ± 0.23 | 0.97 ± 0.22 |

| 8–6 | 1.31 ± 0.07 | 0.51 ± 0.23 | 0.86 ± 0.14 | 1.53 ± 0.21 | 0.40 ± 0.23 | 1.12 ± 0.09 |

| 6–4 | 4.20 ± 0.18 | 1.59 ± 0.01 | 1.71 ± 1.72 | 2.91 ± 0.53 | 1.29 ± 0.29 | 1.90 ± 0.04 |

| 4–2 | 5.64 ± 1.37 | 2.39 ± 0.78 | 2.94 ± 1.73 | 2.73 ± 0.01 | 1.21 ± 0.03 | 1.72 ± 0.10 |

| <2 | 14.57 ± 6.39 | 5.75 ± 1.59 | 6.89 ± 1.98 | 5.15 ± 3.19 | 2.46 ± 1.33 | 3.02 ± 1.60 |

| Materials | TS [% fm] | VS [% fm] | DOC [mg/L] | Biogas [l(N)/kg VS] |

|---|---|---|---|---|

| MSFF | 58 ± 1.52 | 25.5 ± 2.81 | 4238 | 280 ± 80.84 |

| GR | 2.72 ± 0.75 | 1.01 ± 0.85 | 2709 | 146 ± 20.67 |

| PZ | 1.50 ± 0.16 | 0.80 ± 0.07 | 4680 | 289 ± 0.03 |

| PW | 16 ± 1.53 | 8.00 ± 2.32 | 9050 | 416 ± 56.16 |

| PC | 51 ± 3.46 | 22.5 ± 2.21 | 4027 | 211 ± 31.54 |

| Type of Waste | Type of Pressing | TS [% fm] | VS [% fm] | DOC [mg/L] | Biogas [L(N)/kg VS |

|---|---|---|---|---|---|

| SP (4.5 bar) | 16 ± 1.53 | 8.00 ± 2.32 | 9050 ± 2752.59 | 416 ± 56.16 |

| SP (4–5.5 bar) | 20–24 | 13–16 | - | 570–760 |

| Piston press (40 bar) | 9 | 6 | - | 450 |

| Range | - | 9–24 | 6–16 | - | 450–760 |

| SP (4 bar) | 10–21 | 8–11 | 10,000–12,000 | 250–450 |

| SP | 12–19 | 7–12 | - | - |

| SP | 17 | 12 | - | - |

| Range | - | 10–28 | 7–25 | - | 50–458 |

| Fractions | 60–50 mm | 50–20 mm | 20–8 mm | <8 mm | Average |

|---|---|---|---|---|---|

| Organic | 2.81 | 17.03 | 23.03 | 22.5 | 22.5 ± 1.99 |

| Glass | 0.00 | 8.31 | 26.76 | 33.7 | 22.79 ± 2.27 |

| Stone | 0.00 | 4.67 | 21.80 | 30.3 | 18.43 ± 0.34 |

| 3D plastic | 27.56 | 5.21 | 6.33 | 1.8 | 5.14 ± 0.39 |

| Plastic foil | 15.13 | 3.89 | 1.97 | 0.34 | 2.29 ± 0.14 |

| PPK | 5.84 | 22.33 | 1.98 | 3.19 | 8.88 ± 1.33 |

| Hygiene | 31.89 | 30.98 | 10.70 | 13.19 ± 2.24 | |

| Textile | 12.76 | 1.06 | 0.70 | 0.47 | 1.08 ± 0.05 |

| Metals | 0.94 | 1.88 | 0.09 | 2.50 | 1.47 ± 2.07 |

| Others | 3.06 | 3.70 | 6.64 | 4.56 | 5.18 ± 1.53 |

| Experiments | Materials | Fresh Mass | Total Solid (TS) | Volatile Solid (VS) | Biogas | |||

|---|---|---|---|---|---|---|---|---|

| Recovery Rate [% Input fm] | Concentration [% fm] | Recovery Rate [% Input TS] | Concentration [% fm] | Recovery Rate [% Input VS] | Biogas Potential [m3/Mg VS] | Recovery Rate [% Input Biogas] | ||

| Press Experiment 1 (PE1): This study Pressure: 4.5 bars GR + PZ/MSFF: 1000 L/ton Mixing time before pressing: No Mesh size: 5 mm | MSFF < 60 mm | 58 | 25.50 | 280 | ||||

| GR | 2.7 | 1.01 | 147 | |||||

| PZ | 1.5 | 0.80 | 289 | |||||

| Input mix to SP | 100 | 30 | 100 | 13 | 100 | 276 | 100 | |

| PW | 47 | 16 | 22 | 8.00 | 24 | 416 | 38 | |

| PC | 53 | 51 | 78 | 22.50 | 76 | 211 | 62 | |

| PE2: Piston press Pressure: 50 bars Water (10 °C)/MSFF: 330 L/ton Mixing time before pressing: 2 h Mesh size: 5 mm | MSFF < 80 mm | 72 | 46.10 | 470 | ||||

| Tap water | - | |||||||

| Input mix | 100 | 48 | 100 | 30.72 | 100 | 100 | ||

| PW | 49 | 35 | 35 | 21.70 | 34 | 320 | 23 | |

| PC | 51 | 61 | 65 | 39.65 | 66 | - | ||

| PE3: Piston press Pressure: 40 bars Water (70 °C)/MSFF: 1560 L/ton Mixing time before pressing: 1.5 h Mesh size: 5 mm | MSFF < 40 mm | 74 | 47 | 360 | ||||

| Tap water | - | |||||||

| Input mix | 100 | 29 | 100 | 18.27 | 100 | 100 | ||

| PW1 | 67 | 9 | 22 | 69 | 24 | 450 | 30 | |

| PW2 | 5 | 19 | 3 | 64 | 3 | - | 4 | |

| PC | 28 | 77 | 75 | 62 | 72 | - | 66 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bewani, R.; Nassour, A.; Böning, T.; Sprafke, J.; Nelles, M. Assessing the Impact of Residual Municipal Solid Waste Characteristics on Screw Press Performance in a Mechanical Biological Treatment Plant Optimized with Anaerobic Digestion. Sustainability 2025, 17, 6365. https://doi.org/10.3390/su17146365

Bewani R, Nassour A, Böning T, Sprafke J, Nelles M. Assessing the Impact of Residual Municipal Solid Waste Characteristics on Screw Press Performance in a Mechanical Biological Treatment Plant Optimized with Anaerobic Digestion. Sustainability. 2025; 17(14):6365. https://doi.org/10.3390/su17146365

Chicago/Turabian StyleBewani, Rzgar, Abdallah Nassour, Thomas Böning, Jan Sprafke, and Michael Nelles. 2025. "Assessing the Impact of Residual Municipal Solid Waste Characteristics on Screw Press Performance in a Mechanical Biological Treatment Plant Optimized with Anaerobic Digestion" Sustainability 17, no. 14: 6365. https://doi.org/10.3390/su17146365

APA StyleBewani, R., Nassour, A., Böning, T., Sprafke, J., & Nelles, M. (2025). Assessing the Impact of Residual Municipal Solid Waste Characteristics on Screw Press Performance in a Mechanical Biological Treatment Plant Optimized with Anaerobic Digestion. Sustainability, 17(14), 6365. https://doi.org/10.3390/su17146365