DOC Study on the Effects of Catalyst Active Component Loading and Carrier Properties on the Catalytic Conversion Efficiency of Key Gaseous Pollutants

Abstract

1. Introduction

2. Test System

3. Results and Discussion

3.1. Load Characterization

3.2. External Characterization

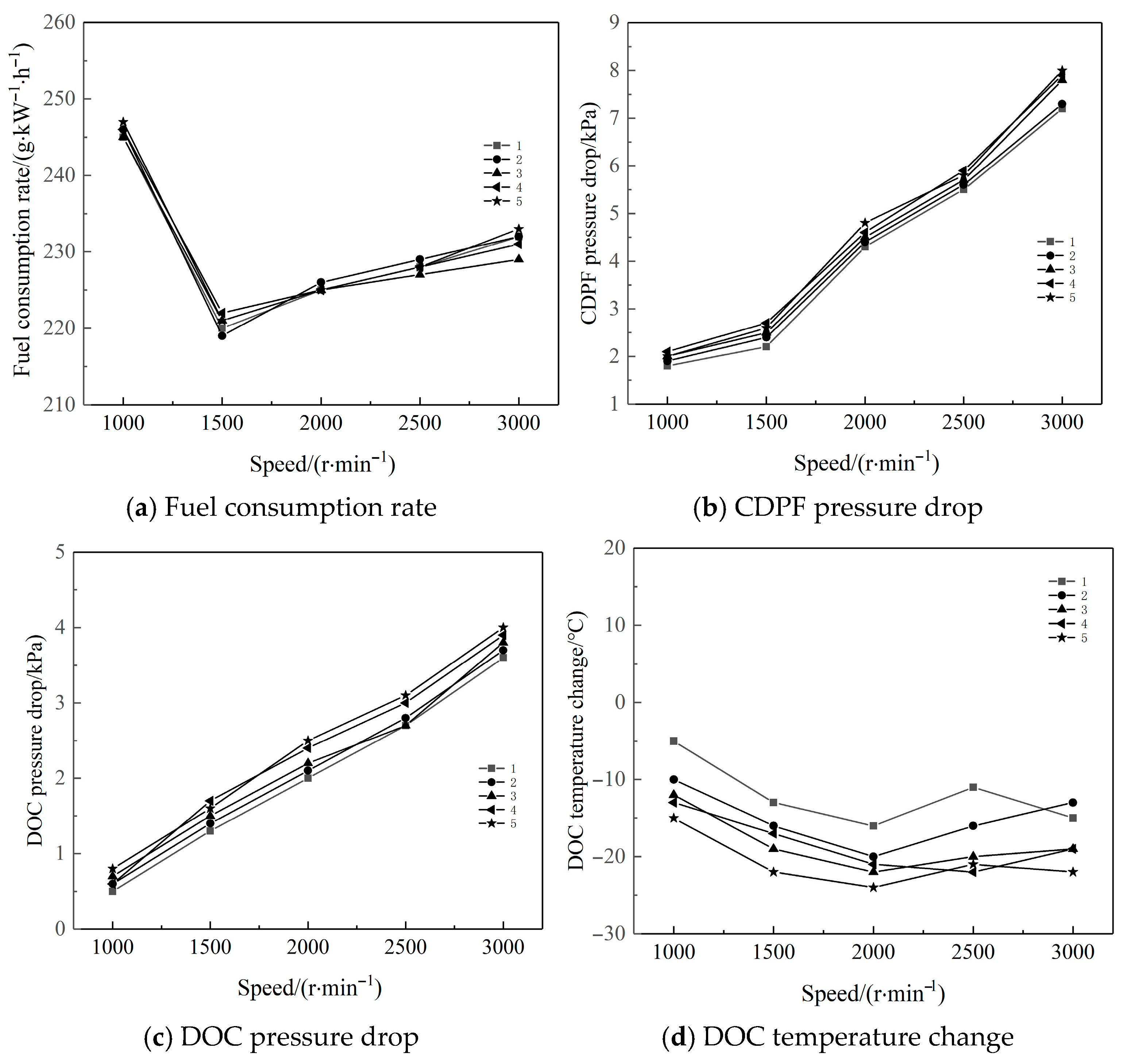

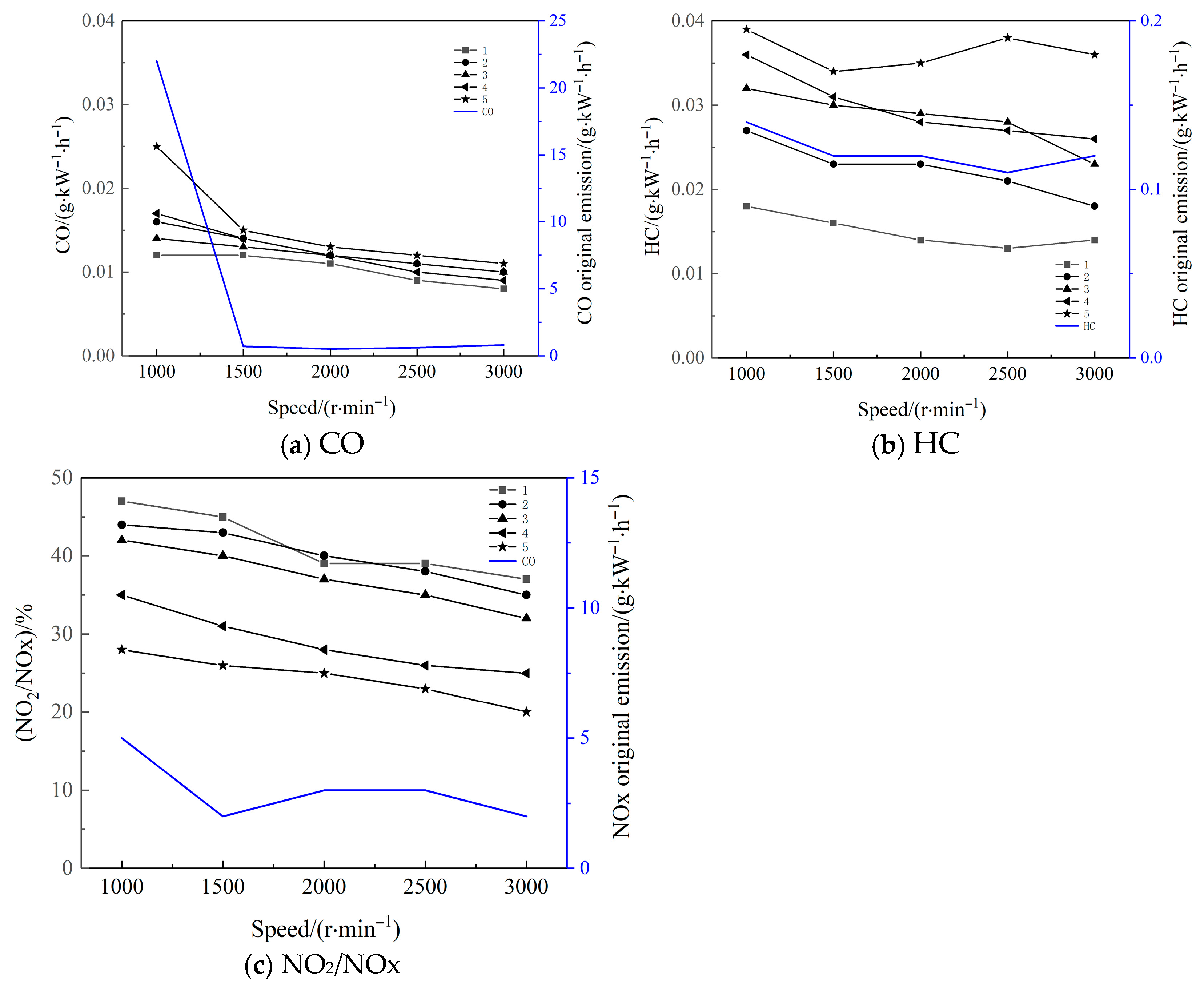

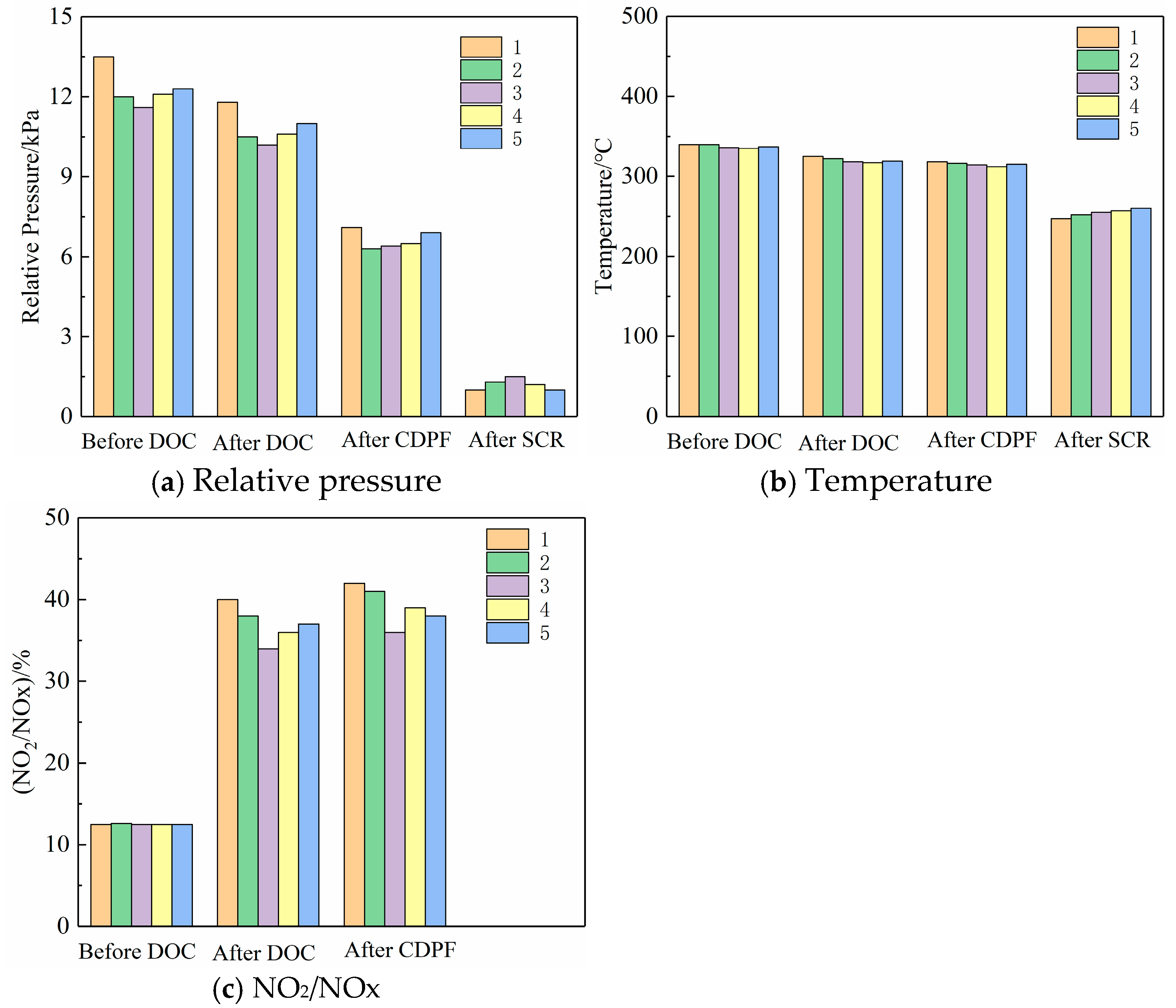

3.3. Analysis of the Impact of DOC Formulations on Downstream Post-Processors

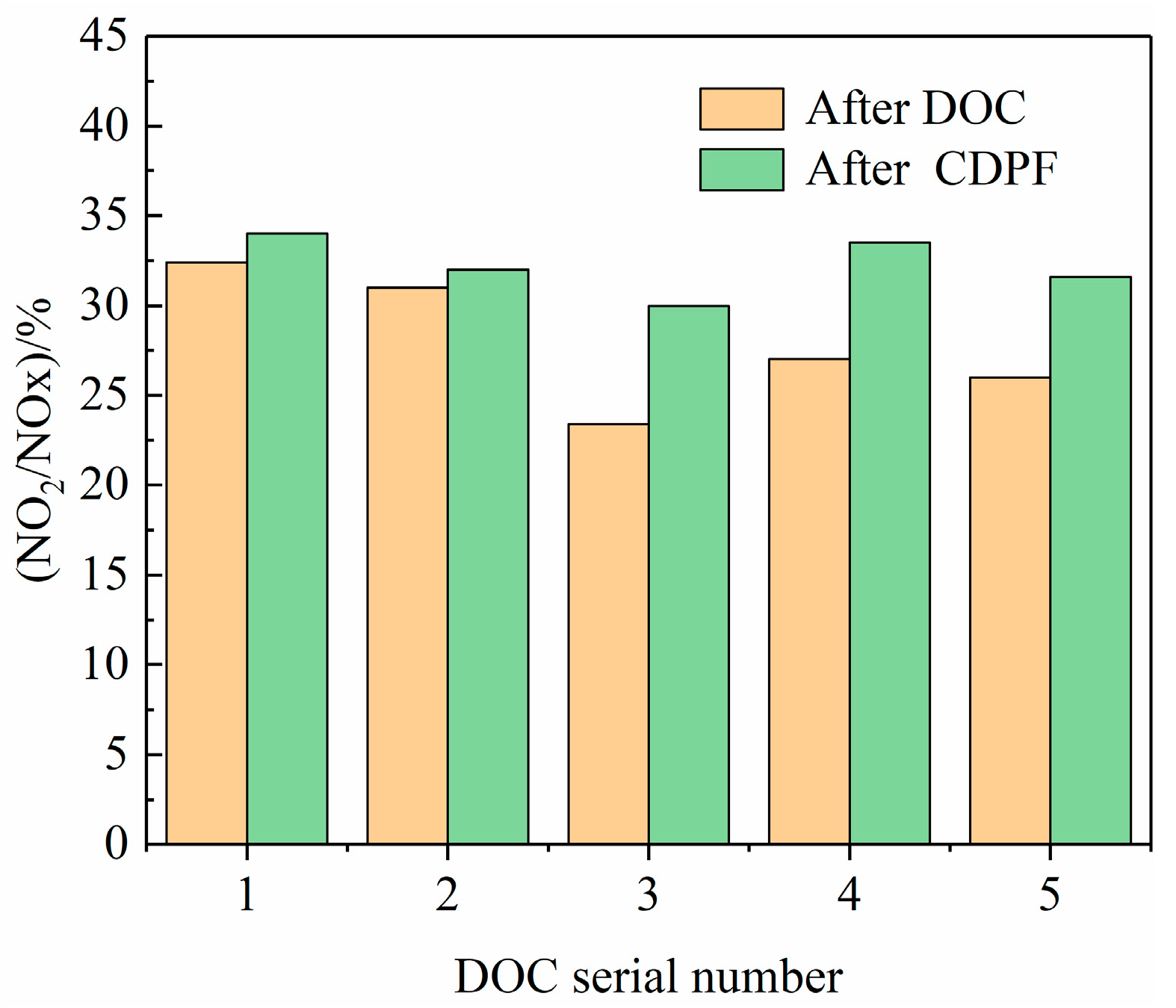

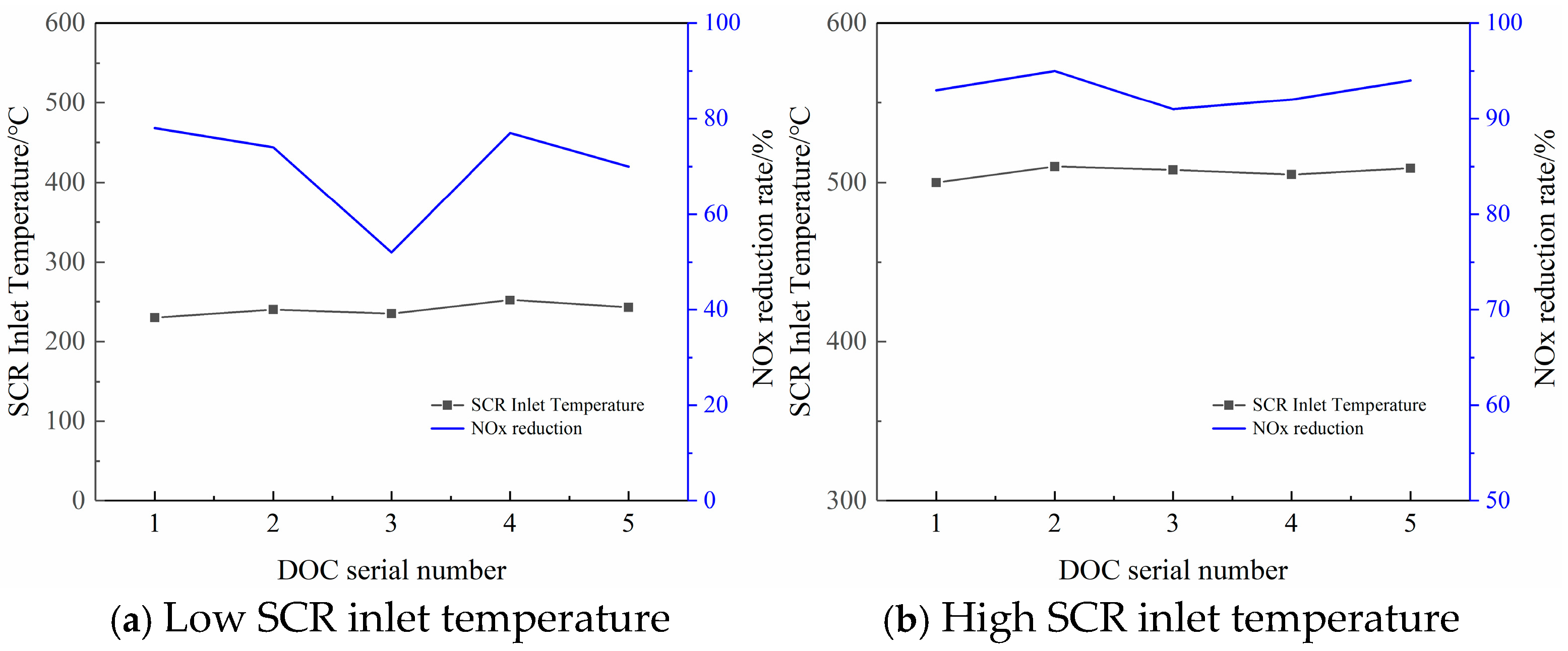

3.4. Characterization of Different Positions in the Integrated Reprocessing System

4. Conclusions

- (1)

- With the increase in precious metal loading and the decrease in the Pt/Pd ratio, the T50 of CO and HC decreases, and the conversion rates of CO and HC in the low-temperature section (<300 °C) increase; however, with the continuous increase in temperature, increasing precious metal or palladium content has a diminishing effect on CO and HC conversion, and the difference between the average conversion rates of the high-temperature section (≥300 °C) is relatively small.

- (2)

- With the increase in load, the NO conversion rate first increased and then decreased, and the NO conversion rate of all formulations reached the peak at 75% load and slightly decreased at 100% load. Before the rotational speed of 2000 r/min, the NO2/NOx ratio stayed at a high level, after which there was a decreasing trend, and it reached the lowest value at 3000 r/min. The NO conversion rate increased with the increase in the load of precious metal. The NO conversion rate increases with the increase in precious metal loading. The NO conversion rate is more sensitive to the Pt content, and the formulation with high Pt content can promote the oxidation of NO, contrary to the change rule of the CO and HC conversion rate.

- (3)

- There is no obvious difference in the fuel consumption rate between different DOC formulations. The increase in precious metal coating will slightly increase the DOC pressure drop. The change in the DOC catalyst formulation does not have much effect on the CDPF pressure drop. The temperature after the DOC is slightly lower than that before the DOC, and there are fluctuations in the temperature difference. Therefore, the change in formulation will not have a significant effect on the engine economy.

- (4)

- The average NO2/NOx ratios after the CDPF are higher than those after the DOC, and NO is further catalytically oxidized in the CDPF. When the inlet temperature of SCR is low, the high NO2 concentration is conducive to the improvement in the conversion efficiency of SCR to Nox. When the inlet temperature of SCR is high, the conversion efficiency of SCR to NOx reaches more than 90% without any obvious difference.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caliskan, H.; Ergun, Y.; Karali, I.H.; Caglayan, H.; Hong, H.; Kale, U.; Matijošius, J. Investigating the diesel engine emission performances with various novel emission filters. Energy 2025, 318, 134775. [Google Scholar] [CrossRef]

- Liu, W.; Gao, Y.; You, Y.; Jiang, C.; Hua, T.; Xia, B. Nonlinear model predictive control(NMPC) of diesel oxidation catalyst (DOC) outlet temperature for active regeneration of diesel particulate filter (DPF) in diesel engine. Energy 2024, 293, 130658. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Lin, Y.; Fang, L.; Lou, D. Particle filter performance of soot-loaded diesel particulate filter the effect of its regeneration on the particle number size distribution. J. Clean. Prod. 2024, 461, 142651. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Tang, S.; Wan, Q.; Jia, G.; Liu, B.; Li, S. Effects analysis on hydrocarbon removal performance of an adsorptive catalytic gasoline particulate filter in the gasoline engine during cold start. Energy 2023, 283, 128527. [Google Scholar] [CrossRef]

- Chen, J.Y.; Tan, Q.P.; Liu, Y.; Wang, K.; Wang, J.X.; Yang, M.X.; Lou, M.D.; Hu, Y.Z.; Yang, M.W. Interaction between NOx reduction soot oxidation for selective catalytic oxidation-selective catalytic reduction catalyst coated on diesel particulate filter: An experimental numerical study. Chem. Eng. J. 2025, 506, 160055. [Google Scholar] [CrossRef]

- Caliskan, H.; Mori, K. Environmental, enviroeconomic and enhanced thermodynamic analyses of a diesel engine with diesel oxidation catalyst (DOC) and diesel particulate filter (DPF) after treatment systems. Energy 2017, 128, 128–144. [Google Scholar] [CrossRef]

- Huang, H.; Chen, R.; Tao, S.; Wang, Y.; Zhang, L. Study of soot dynamic behavior catalytic regeneration in diesel particulate filters. Chem. Eng. J. 2024, 489, 151498. [Google Scholar] [CrossRef]

- Fan, L.; Shi, W.; Jing, J.; Dong, Z.; Yuan, J.; Qu, L. An artificial intelligence strategy for multi-objective optimization of Urea-SCR for vehicle diesel engine by RSM-VIKOR. Energy 2025, 317, 134667. [Google Scholar] [CrossRef]

- Lou, D.; Chen, Y.; Zhang, Y.; Jue, K.; Tan, P.; Hu, Z.; Fang, L. Analysis of temperature and pressure characteristics in catalyzed diesel particulate filter operation for heavy-duty diesel engine. Fuel 2022, 328, 125248. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, J.; Wu, D.; Shao, Y.; Song, X.; Guo, Z.; Liu, A.; Li, Q.; Chen, J. Contribution of Aftertreatment Technologies to Alleviating SOA and Toxicity Generation from Typical Diesel Engine-Emitted I/SVOCs. Environ. Sci. Technol. 2024, 58, 22722–22732. [Google Scholar] [CrossRef]

- Tan, P.; Yao, C.; Wang, D.; Zhu, L.; Hu, Z.; Lou, D. Design and optimization of exhaust gas aftertreatment system for a heavy-duty diesel engine. J. Cent. South. Univ. 2022, 29, 2127–2141. [Google Scholar] [CrossRef]

- Hazlett, M.J.; Epling, W.S. Mechanistic effects of Water on Carbon monoxide and propylene oxidation on platinum and palladium bimetallic catalysts. Catal. Today 2021, 360, 401–410. [Google Scholar] [CrossRef]

- He, D.; Chen, Y.; Li, S.; Liu, Y.; Zhang, H.; Jiao, Y.; Jiao, Y.; Zhao, M.; Wang, J.; Chen, Y. Unidirectional electron transfer on bismuth-doped Pt/YMn2O5 for efficient CO oxidation as diesel oxidation catalysts. ACS Catal. 2024, 14, 7353–7368. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Cao, C.; Wang, S.; Lv, J.; Zheng, W.; Tan, D. The development of diesel oxidation catalysts and the effect of sulfur dioxide on catalysts of metal-based diesel oxidation catalysts: A review. Fuel Process. Technol. 2022, 233, 107317. [Google Scholar] [CrossRef]

- Li, R.; Yang, D.; Liu, F.; Zhu, J.; Hu, Q. Study on the nano-structure characteristics of particle before and after diesel oxidation catalyst for diesel engines. Energy Sources Part A 2024, 46, 275–293. [Google Scholar] [CrossRef]

- Liang, Y.; He, D.; Ding, X.; Wang, J.; Zhao, M.; Chen, Y. Effect of MnOx phase on Pt-based catalyst for enhancing CO/C3H6/NO oxidation performance. Int. J. Hydrogen Energy 2022, 47, 30722–30731. [Google Scholar] [CrossRef]

- Lyu, X.; Wang, K.; Liang, X.; Cui, L.; Wang, Y. Analysis of the correlation between mechanical and physicochemical properties of particles based on a diesel oxidation catalytic system. Sci. Total Environ. 2024, 926, 171898. [Google Scholar] [CrossRef]

- Nie, W.; Liu, C.; Luo, C.; Hua, Y.; Yan, X.; Lian, J. Effect of pretreatment methods and doping amount of Enteromorpha on the exhaust purification performance of perovskite catalysts used in underground diesel vehicles. J. Clean. Prod. 2024, 445, 141191. [Google Scholar] [CrossRef]

- Meng, Z.; Deng, M.; Wu, D.; Ou, J.; Liu, X.; Bao, Z. The back diffusion of catalysts on the oxidation characteristics of particle layer during the CDPF active regeneration process. Fuel 2024, 365, 131155. [Google Scholar] [CrossRef]

- Shan, C.; Hou, X.; Han, R.; Jia, Q.; Hou, N.; Wang, Y.; Liu, C.; Liu, Q. Recent Advances of Gaseous Pollutant Catalytic Oxidation over Precious Metal Catalysts with SO2 Exposure. Environ. Sci. Technol. 2025, 59, 2348–2367. [Google Scholar] [CrossRef]

- Yang, Z.; Song, J.; Zhang, G.; Sun, X.; Cheng, S.; Zhang, X.; Jiang, Y. Unraveling the Promotion for SO2 and H2O Resistance of Transition Metal-doped CeO2-TiO2 Catalysts in NH3-SCR Reaction: A DFT Study. J. Hazard. Mater. 2025, 489, 137563. [Google Scholar] [CrossRef] [PubMed]

- Resitoglu, A.I.; Altinisik, K.; Keskin, A.; Ocakoglu, K. The effects of Fe2O3 based DOC and SCR catalyst on the exhaust emissions of diesel engines. Fuel 2020, 262, 116501. [Google Scholar] [CrossRef]

- Orihuela, M.P.; Miceli, P.; Ramirez-Rico, J.; Fino, D.; Chacartegui, R. Ceria-based catalytic coatings on biomorphic silicon carbide: A system for soot oxidation with enhanced properties. Chem. Eng. J. 2021, 415, 128959. [Google Scholar] [CrossRef]

- Epling, W.S.; Campbell, L.E.; Yezerets, A.; Currier, N.W.; Parks, J.E. Overview of the fundamental reactions and degradation mechanisms of NOx storage/reduction catalysts. Catal. Rev. 2004, 46, 163–245. [Google Scholar] [CrossRef]

- Promhuad, P.; Sawatmongkhon, B.; Theinnoi, K.; Wongchang, T.; Chollacoop, N.; Sukjit, E.; Tunmee, S.; Tsolakis, A. Effect of Metal Oxides (CeO2, ZnO, TiO2, and Al2O3) as the Support for Silver-Supported Catalysts on the Catalytic Oxidation of Diesel Particulate Matter. ACS Omega 2024, 9, 19282–19294. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Zhang, J.; Zhang, D.; Guo, Y.; Wu, F. Catalytic oxidation desulfurization of silica-gel-supported ionic liquid [Bmim] CoCl3 coupling oxone. Fuel 2021, 288, 119655. [Google Scholar] [CrossRef]

- Wang, P.; Jin, M.; Yu, D.; Bai, S.; Lei, L. Evolution Mechanism of N2O for the Selective Catalytic Reduction of NOx by NH3 Over Cu-SSZ-13 Assisted Fe-BEA Catalysts. Catal. Lett. 2021, 151, 3381–3395. [Google Scholar] [CrossRef]

- Papeta, O.P.; Zubkov, I.N.; Kataria, Y.V.; Saliev, A.N.; Svetogorov, R.D.; Agliullin, M.R.; Chemes, A.A.; Savost’yanov, A.P.; Yakovenko, R.E. Deactivation of Hybrid Cobalt Catalyst Based on Hierarchical Porous Zeolite in Fischer–Tropsch Synthesis. Energy Fuels 2025, 28, 134–156. [Google Scholar] [CrossRef]

- Chen, H.; Wang, H.; Chen, Z.; Zhao, H.; Geng, L.; Gao, N.; Yi, C.; Xu, H. Research progress on the spray, combustion and emission of polyoxymethylene dimethyl ethers as a diesel blend fuel: A review. Fuel 2022, 324, 124731. [Google Scholar] [CrossRef]

- Lang, Q.; Zhang, B.; Liu, Z.; Chen, Z.; Xia, Y.; Li, D.; Ma, J.; Gai, C. Cohydrothermal Carbonization of Corn Stalk and Swine Manure: Combustion Behavior of Hydrochar by Thermogravimetric Analysis. Bioresour. Technol. 2018, 271, 75–83. [Google Scholar] [CrossRef]

- Wang, J.; Ren, D.; Zhang, N.; Lang, J.; Du, Y.; He, W.; Norinaga, K.; Huo, Z. Boosting in-situ hydrodeoxygenation of fatty acids over a fine and oxygen-vacancy-rich NiAl catalyst. Renew. Energy 2023, 202, 952–960. [Google Scholar] [CrossRef]

- Zuo, Q.; Tang, Y.; Zhu, G.; Wei, K.; Guan, Q.; Zhang, B.; Shen, Z. Investigations on the soot combustion performance enhancement of a catalytic gasoline particulate filter in equilibrium state for reducing the BSFC of gasoline direct injection engine. Fuel 2021, 284, 119032. [Google Scholar] [CrossRef]

- Huang, B.; Hong, W.; Shao, K.; Wu, H. Sensitivity Analysis Study of Engine Control Parameters on Sustainable Engine Performance. Sustainability 2024, 16, 11107. [Google Scholar] [CrossRef]

- Ferreira, J.; Andrade, D.I.; Fuziki, M.E.K.; de Almeida, L.N.; Colpini, L.M.; Lenzi, G.G.; Tusset, A.M. Catalytic Systems in the Reduction of Nitrogen Oxide Emissions in Diesel-Powered Trucks. Sustainability 2022, 14, 6662. [Google Scholar] [CrossRef]

- AAtzl, B.; Pupp, M.; Rupprich, M. The Use of Photocatalysis and Titanium Dioxide on Diesel Exhaust Fumes for NOx Reduction. Sustainability 2018, 10, 4031. [Google Scholar] [CrossRef]

| Property | Numerical Value |

|---|---|

| Rating power | 77 kW |

| Rating speed | 3500 r·min−1 |

| Maximum torque speed | 2000 r·min−1 |

| Bore × Stroke | 80 × 98 mm |

| Maximum torque | 260 N·m |

| Compression ratio | 18 |

| Property | Numerical Value |

|---|---|

| Cell density | 300 cpsi |

| Carrier diameter | 145 mm |

| Carrier length | 120 mm |

| Wall thickness | 4 mm |

| Pore diameter | 1~10 um |

| Catalytic washcoat | γ-Al2O3 |

| Carrier material | Cordierite |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Xiao, L. DOC Study on the Effects of Catalyst Active Component Loading and Carrier Properties on the Catalytic Conversion Efficiency of Key Gaseous Pollutants. Sustainability 2025, 17, 6354. https://doi.org/10.3390/su17146354

Zou Y, Xiao L. DOC Study on the Effects of Catalyst Active Component Loading and Carrier Properties on the Catalytic Conversion Efficiency of Key Gaseous Pollutants. Sustainability. 2025; 17(14):6354. https://doi.org/10.3390/su17146354

Chicago/Turabian StyleZou, Yantao, and Liguang Xiao. 2025. "DOC Study on the Effects of Catalyst Active Component Loading and Carrier Properties on the Catalytic Conversion Efficiency of Key Gaseous Pollutants" Sustainability 17, no. 14: 6354. https://doi.org/10.3390/su17146354

APA StyleZou, Y., & Xiao, L. (2025). DOC Study on the Effects of Catalyst Active Component Loading and Carrier Properties on the Catalytic Conversion Efficiency of Key Gaseous Pollutants. Sustainability, 17(14), 6354. https://doi.org/10.3390/su17146354