Configuring Supply Chain Resilience Under Natural Disaster Risk

Abstract

1. Introduction

2. Literature Review

2.1. Supply Chain Resilience

2.2. Influencing Factors of Supply Chain Resilience

3. Theoretical Analysis and Research Hypotheses

3.1. Theoretical Foundation

3.2. Analysis of Internal Influencing Factors of Supply Chain Resilience in the Context of Disasters

3.3. Analysis of External Influencing Factors on Supply Chain Resilience in Disaster Contexts

3.4. Analysis of Influencing Factors on Supply Chain Resilience Based on fsQCA

4. Structural Equation Modeling Analysis

4.1. Research Design and Data Processing

4.2. Measurement Model Assessment

4.3. Structural Path Analysis and Hypothesis Testing

4.4. Discussion of Findings and Theoretical Implications

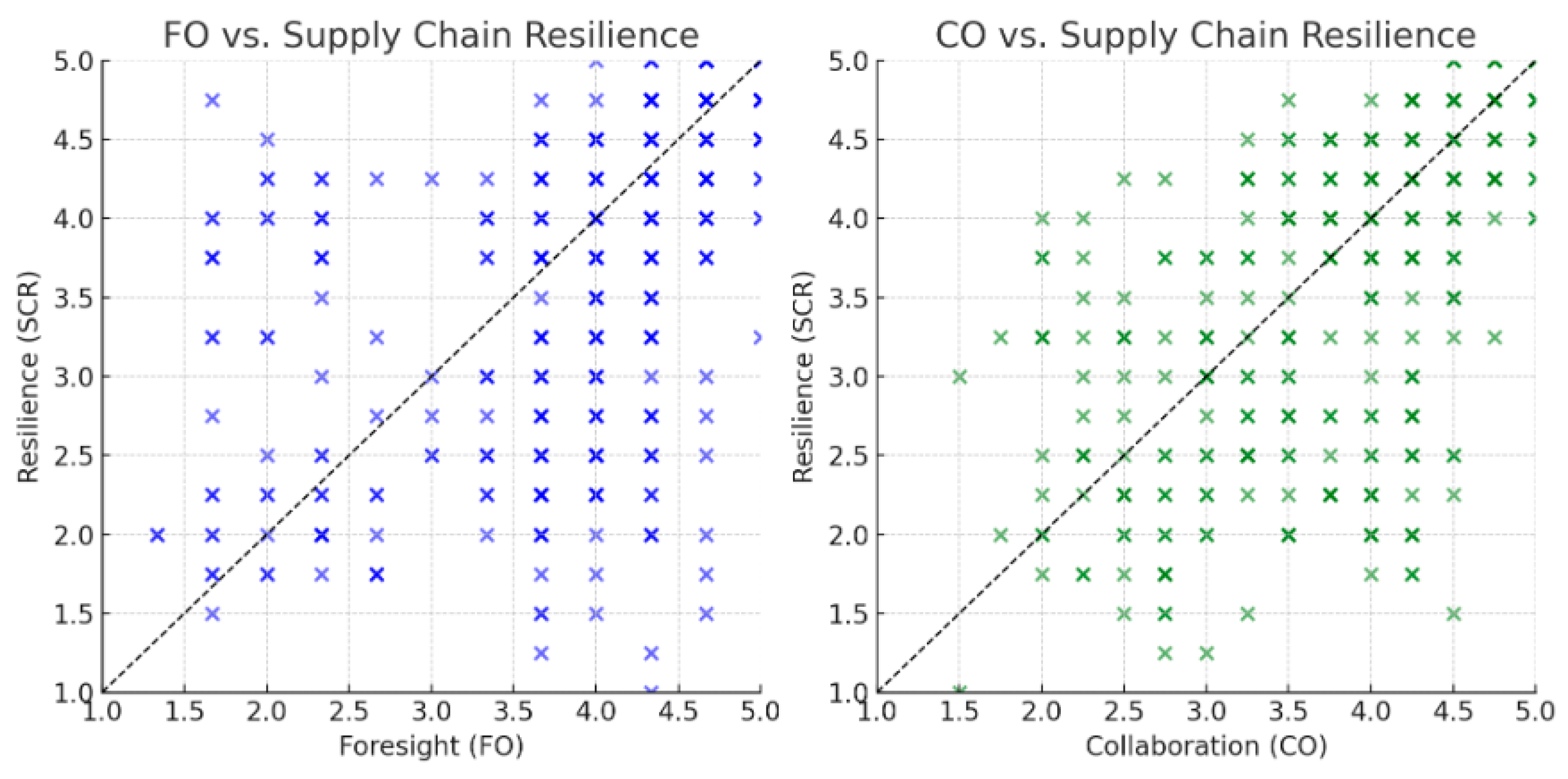

5. Analysis of Influencing Factors of Supply Chain Resilience Based on fsQCA

5.1. Selection and Calibration of Variables

5.2. Necessity Analysis

5.3. Configuration Adequacy Analysis

5.3.1. Configuration Path Analysis for High Supply Chain Resilience Under Disaster Background

5.3.2. Configuration Path Analysis for Low Supply Chain Resilience Under Disaster Background

5.4. Robustness-Oriented Sensitivity Analysis

5.5. Integration of SEM and fsQCA Results

6. Conclusions

6.1. Research Conclusions

6.2. Theoretical Contributions

6.3. Managerial Implications

6.4. Research Limitations and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SR | Supply Chain Resilience |

| FO | Forward-looking |

| FL | Flexibility |

| VI | Visibility |

| SU | Supportiveness |

| CO | Supply Chain Collaboration |

References

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Parast, M. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int. J. Prod. Econ. 2016, 171, 116–133. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. Eur. J. Inf. Syst. 2015, 33, 111–122. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Liu, Q. Enhancing supply chain resilience through multi-agent coordination under compound disaster scenarios. J. Environ. Manag. 2025, 344, 125532. [Google Scholar] [CrossRef]

- Ma, S. How to Prevent Supply Chain Risks? China Econ. Informatiz. 2003, 21. [Google Scholar]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Pei, Y. Review and Future Prospect of Supply Chain Resilience Research at Home and Abroad. Bus. Econ. Res. 2024, 13, 33–36. [Google Scholar]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Li, S.; Xu, M.; Cui, L. Research on Sustainable Resilient Supply Chain Network: Review and Prospect In the management science. Zhongguoguanlikexue 2025, 1–25. [Google Scholar] [CrossRef]

- Pfeffer, J.; Salancik, G.R. The external control of organizations: A resource dependence perspective. Soc. Sci. Electron. Publ. 2003, 23, 123–133. [Google Scholar]

- Fan, X.; Lu, M. Influencing Factors and Evaluation of Automotive Enterprise Supply Chain Resilience Under COVID-19. J. Ind. Technol. Econ. 2020, 39, 21–28. [Google Scholar]

- Zhu, L.; Chen, J.; Yuan, J. Research on Key Influencing Factors of Prefabricated Building Supply Chain Resilience Based on ISM. J. Civ. Eng. Manag. 2020, 37, 108–114. [Google Scholar]

- Mehreen, K.A.; Syed, M.H.; Sheheryar, M.Q. Exploring the critical success factors of a resilient supply chain. Eng. Manag. Prod. Serv. 2023, 15, 41–56. [Google Scholar]

- Osaro, A.; Zulkipli, G.; Radzuan, R.A. Framework to Enhance Supply Chain Resilience the Case of Malaysian Pharmaceutical Industry. Glob. Bus. Manag. Res. 2014, 6, 219–225. [Google Scholar]

- Wang, Y.; Gao, Y.; Teng, C. A Review and Expansion of Supply Chain Resilience Under Disturbances. Manag. Rev. 2017, 29, 204–216. [Google Scholar]

- Wan, Y.; Dai, X.; Guo, Y. A Review of Foreign Research on Supply Chain Response. Commer. Times 2011, 25, 23–24. [Google Scholar]

- Jabbarzadeh, A.; Haughton, M.; Khosrojerdi, A. Closed-loop Supply Chain Network Design under Disruption Risks: A Robust Approach with Real World Application. Comput. Ind. Eng. 2018, 116, 178–191. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, X.; Sun, J.; Zhang, Y.; Wang, Y. What Does Not Kill You Makes You Stronger: Supply Chain Resilience and Corporate Sustainability Through Emerging IT Capability. IEEE Trans. Eng. Manag. 2024, 71, 10507–10521. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Queiroz, M.M.; Priyadarshinee, P. Digital Supply Chain Capabilities: Mitigating Disruptions and Leveraging Competitive Advantage Under COVID-19. IEEE Trans. Eng. Manag. 2024, 71, 14105–14109. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Sridharan, R. Design for Supply Chain Collaboration. Bus. Process Manag. J. 2008, 14, 401–418. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The Role of Collaboration in Supply Chain Resilience. Supply Chain. Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Imran, A.; Sev, N.; Bruce, G. Building resilience in SMEs of perishable product supply chains: Enablers, barriers and risks. Prod. Plan. Control 2017, 28, 1236–1250. [Google Scholar]

- He, M.; Wang, W. International Insights and Chinese Strategies for Modern Supply Chain Development. Reform 2018, 22–35. [Google Scholar]

- Liu, X. Enhancing Supply Chain Resilience: The Formulation and Direction of Japanese Policies. Mod. Jpn. Econ. 2021, 240, 1–14. [Google Scholar]

- Zheng, X.; Zheng, Z.; Xu, X. A Review of Supply Chain Risk Management—Risk Control. Technol. Econ. 2013, 32, 118–124. [Google Scholar]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain readiness, response and recovery for resilience. Supply Chain. Manag. Int. J. 2016, 21, 709–731. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply chain capabilities, risks, and resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Rahman, S. Supply chain resilience: Role of complexities and strategies. Int. J. Prod. Res. 2015, 53, 6809–6819. [Google Scholar] [CrossRef]

- Bo, Y.; Ping, S.; Delong, D. Risk Assessment and Control of Agricultural Product Supply Chains in the Internet of Things Environment. J. Ind. Eng. Eng. Manag. 2014, 28, 196–202. [Google Scholar]

- Haiwen, H.; Shihua, M. An Empirical Study on the Impact of Market Sensing, Coordination, and Innovation on Supply Chain Adaptability. Chin. J. Manag. 2020, 17, 131–138. [Google Scholar]

- Melnyk, S.A.; Closs, D.J.; Griffis, S.E.; Zobel, C.W.; Macdonald, J.R.; Stank, T.P.; Calantone, R.J.; Vaidyanathan, R.; Smith, C.D.; Jones, E. Understanding Supply Chain Resilience; Peerless Media, LLC: Framington, NM, USA, 2014. [Google Scholar]

- ELBaz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef] [PubMed]

- Williams, B.D.; Roh, J.; Tokar, T.; Swink, M. Leveraging supply chain visibility for responsiveness: The moderating role of internal integration. J. Oper. Manag. 2013, 31, 543–554. [Google Scholar] [CrossRef]

- Kang, Y. Research on Supply Chain Network Risk Management Based on Complex Network Theory. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2014. [Google Scholar]

- Grant, R.M. Toward A Knowledge-based theory of the firm. Strateg. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

- Blackhurst, J.; Dunn, K.S.; Craighead, C.W. An Empirically Derived Framework of Global Supply Resiliency. J. Bus. Logist. 2011, 32, 374–391. [Google Scholar] [CrossRef]

- Uta, J.; Stan, M. Supply chain resilience in the global financial crisis: Nan empirical study. Supply Chain. Manag. Int. J. 2011, 16, 246–259. [Google Scholar]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain. Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Chen, J.; Huang, S.; Liu, Y. From Empowerment to Enablement—Enterprise Operations Management in the Digital Environment. Manag. World 2020, 36, 117–128. [Google Scholar]

- Zhu, Q.; Zhou, S. Competitive Analysis of Automotive Parts Manufacturers and Remanufacturers Based on Government Price Subsidies. J. Syst. Manag. 2014, 23, 367–373. [Google Scholar]

- Yang, Y.; Xu, X. Post-disaster grain supply chain resilience with government aid. Transp. Res. Part E Logist. Transp. Rev. 2015, 76, 139–159. [Google Scholar] [CrossRef]

- Philip, L.; Cesar, R. Risk and Resilience in Agri-Food Supply Chains: The Case of the ASDA Pork Link Supply Chain in Scotland. Supply Chain. Manag. Int. J. 2013, 18, 219–231. [Google Scholar]

- Mandal, S. The influence of organizational culture on healthcare supply chain resilience: Moderating role of technology orientation. J. Bus. Ind. Mark. 2017, 32, 1021–1037. [Google Scholar] [CrossRef]

- Cheng, J.; Lu, K. Enhancing effects of supply chain resilience: Insights from trajectory and resource-based perspectives. Supply Chain. Manag. 2017, 22, 329–340. [Google Scholar] [CrossRef]

- Du, Y.; Jia, L. Configuration Perspective and Qualitative Comparative Analysis (QCA): A New Path for Management Research. Manag. World 2017, 6, 155–167. [Google Scholar]

- Wieland, A.; Marcus, W.C. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Zhu, Q.; Krikke, H.; Caniells, M. Collaborate or not? A system dynamics study on disruption recovery. Ind. Manag. Data Syst. 2016, 116, 271–290. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Soni, U.; Chandra, C. Supply chain resilience: Model development and empirical analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar] [CrossRef]

- Ma, X.; Huang, M.; Yang, M. Research on Influencing Factors of Supply Chain Resilience: Based on SEM and fsQCA Methods. Syst. Eng. Theory Pract. 2023, 43, 2484–2501. [Google Scholar]

- Sheng, Z.; Wang, H.; Hu, Z. Supply Chain Resilience: Adapting to Complexity—A Perspective from Complex System Management. Chin. J. Manag. Sci. 2022, 30, 1–7. [Google Scholar]

- Ragin, C.C.; Fiss, P.C. Net effects analysis versus configurational analysis: An empirical demonstration. Redesigning Soc. Inq. Fuzzy Sets Beyond 2008, 240, 190–212. [Google Scholar]

- Muckstadt, D.H.; Murray, J.A.; Rappold, D.E. Collins Guidelines for Collaborative Supply Chain System Design and Operation. Inf. Syst. Front. 2001, 13, 424–453. [Google Scholar]

- Schneider, C.Q.; Wagemann, C. Set-Theoretic Methods for The Social Sciences: A Guide to Qualitative Comparative Analysis; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Pappas, I.O.; Woodside, A.G. Fuzzy-set Qualitative Comparative Analysis (fsQCA): Guidelines for research practice in Information Systems and marketing. Int. J. Inf. Manag. 2021, 58, 102310. [Google Scholar] [CrossRef]

- Rihoux, B.; Ragin, C.C. Configurational Comparative Methods: Qualitative Comparative Analysis (QCA) and Related Techniques; AGE Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Greckhamer, T.; Furnari, S.; Fiss, P.C.; Aguilera, R.V. Studying configurations with qualitative comparative analysis: Best practices in strategy and organization research. Strateg. Organ. 2018, 16, 482–495. [Google Scholar] [CrossRef]

- Zhang, M.; Du, Y. The Application of QCA Method in Organization and Management Research: Positioning, Strategy and Direction. J. Sci. 2019, 16, 1312–1323. [Google Scholar]

- Huang, M.; Zhang, M.; Pi, S.; Chen, Z.; Li, Y.; Wu, H.; Xu, T.; Zhao, L.; Wang, Q.; Liu, J.; et al. Reverse cross-border M&A Integration configuration and M&A integration Performance of Chinese enterprises Relationship Research. J. Manag. 2019, 16, 656–664. [Google Scholar]

| Variable | Items | Source |

|---|---|---|

| Forward-looking | FO1: The company regularly identifies and assesses potential natural disaster risks. FO2: The company has a dedicated team or system to identify and assess natural disaster risks and respond to possible disasters. FO3: Your company has established a risk early warning system. FO4: Your company has detailed emergency plans to deal with natural disasters. FO5: Your company has implemented risk management strategies in supply chain management. FO6: Your company has a continuous supply chain optimization and re-evaluation mechanism after disasters. | Jain V, Kumar S, Soni U [50] |

| Flexibility | FL1: Your company can quickly reconfigure the supply chain in response to market changes. FL2: When disasters occur, your company can promptly identify the affected links in the supply chain. FL3: Your company can dynamically adjust inventory levels based on market demand and supply conditions. FL4: After a disaster, your company can relatively easily adjust its operation mode (production scale, production process, product switching) in the event of natural disasters. | Williams B D, Roh J, Tokar T [35] |

| Visibility | VI1: Your company achieves information transparency throughout the entire process from order processing, inventory management, transportation to distribution. VI2: In the event of natural disasters, your company uses real-time digital technology to integrate the flow of goods, capital, information, and logistics. VI3: When natural disasters occur, your company can quickly identify and respond to breakpoints in the supply chain through supply chain visibility, reducing the losses caused by disasters. | Ma Xiaoyu et al. [51]; Zhou H [49] |

| Supportiveness | SU1: In terms of early warning and information sharing for natural disasters, our company believes that the support provided by the government has effectively helped us respond in a timely manner. SU2: After the disaster occurred, our company felt that the government’s resource allocation and assistance were very timely. SU3: The financial aid, tax reduction, and technical support provided by the government during the post-disaster reconstruction and recovery process have greatly helped our company resume normal operations. SU4: After natural disasters, the government’s market regulation and consumer confidence restoration plans have made significant contributions to the stability of our company’s market. | Yuefeng Yang [43] |

| Supply Chain Collaboration | CO1: In your enterprise’s supply chain collaboration, resource sharing can enhance supply chain resilience. CO2: Your enterprise’s supply chain collaboration helps to deal with uncertainties brought about by natural disasters and other emergencies. CO3: Your enterprise collaborates with other enterprises in the supply chain to optimize supply adjustment and resource allocation to enhance supply chain resilience. CO4: After a disaster occurs, your enterprise can rely on supply chain partners to quickly restore the disrupted supply chain. | ZHU Quan [49], Wieland A [48] |

| Supply Chain Resilience | SR1: Our enterprise has the ability to cope with the changes brought about by supply chain shocks. SR2: Our enterprise has the ability to adapt to supply chain shocks. SR3: Our enterprise can respond quickly to supply chain shocks. SR4: Our enterprise can maintain a high level of situational awareness at all times regarding supply chain shocks. | Ambulkar [3]; ELBaz J et al. [34] |

| Statistical Variable | Category | Percentage | Statistical Variable | Category | Percentage |

|---|---|---|---|---|---|

| Gender | Male | 52.6% | Occupation Category | Front-line Manager | 57% |

| Middle Manager | 18.7% | ||||

| Senior Manager | 6.1% | ||||

| Consultant | 14.7% | ||||

| Female | 47.4% | Other Positions | 3.4% | ||

| Age | Under 30 | 45% | Enterprise Type | Raw Material Supplier | 14% |

| 31~40 | 26.5% | Commodity Producer | 23.6% | ||

| 41~50 | 16.5% | Logistics Servicer | 20.9% | ||

| Retailer | 30.5% | ||||

| Over 50 | 12% | Consumer | 11.1% |

| Item | Outer Loading | VIF | Cronbach’s Alpha | CR | AVE |

|---|---|---|---|---|---|

| FO | 0.847 | 0.887 | 0.566 | ||

| FO1 | 0.759 | 1.678 | |||

| FO2 | 0.756 | 1.772 | |||

| FO3 | 0.769 | 1.781 | |||

| FO4 | 0.746 | 1.638 | |||

| FO5 | 0.743 | 1.685 | |||

| FO6 | 0.742 | 1.573 | |||

| FL | 0.839 | 0.892 | 0.675 | ||

| FL1 | 0.836 | 1.892 | |||

| FL2 | 0.792 | 1.730 | |||

| FL3 | 0.831 | 1.918 | |||

| FL4 | 0.827 | 1.864 | |||

| VI | 0.791 | 0.877 | 0.703 | ||

| VI1 | 0.829 | 1.659 | |||

| VI2 | 0.825 | 1.720 | |||

| VI3 | 0.861 | 1.623 | |||

| SU | 0.820 | 0.881 | 0.650 | ||

| SU1 | 0.821 | 1.714 | |||

| SU2 | 0.808 | 1.799 | |||

| SU3 | 0.806 | 1.733 | |||

| SU4 | 0.788 | 1.661 | |||

| CO | 0.784 | 0.861 | 0.607 | ||

| CO1 | 0.790 | 1.575 | |||

| CO2 | 0.812 | 1.611 | |||

| CO3 | 0.728 | 1.418 | |||

| CO4 | 0.784 | 1.587 | |||

| SCR | 0.851 | 0.900 | 0.691 | ||

| SCR1 | 0.844 | 1.963 | |||

| SCR2 | 0.837 | 1.966 | |||

| SCR3 | 0.838 | 2.004 | |||

| SCR4 | 0.806 | 1.795 |

| KMO Measure of Sampling Adequacy | 0.924 | |

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 4457.418 |

| Degrees of Freedom (df) | 300 | |

| Significance (p-value) | 0.000 | |

| Model | x2/df | NFI | CFI | TLI | RMR | RMSEA |

|---|---|---|---|---|---|---|

| Reference Threshold | <3 | >0.9 | >0.9 | >0.9 | <0.05 | <0.08 |

| Actual Value | 1.360 | 0.923 | 0.978 | 0.975 | 0.034 | 0.030 |

| Construct | CO | FL | FO | SCR | SU | VI |

|---|---|---|---|---|---|---|

| CO | 0.779 | 0.440 | 0.477 | 0.527 | 0.415 | 0.443 |

| FL | 0.440 | 0.822 | 0.392 | 0.478 | 0.429 | 0.487 |

| FO | 0.477 | 0.392 | 0.753 | 0.479 | 0.409 | 0.426 |

| SCR | 0.527 | 0.478 | 0.479 | 0.832 | 0.463 | 0.485 |

| SU | 0.415 | 0.429 | 0.409 | 0.463 | 0.806 | 0.383 |

| VI | 0.443 | 0.487 | 0.426 | 0.485 | 0.383 | 0.838 |

| Construct Pair | HTMT Value | Construct Pair | HTMT Value |

|---|---|---|---|

| FL <-> CO | 0.537 | SU <-> FO | 0.487 |

| FO <-> CO | 0.584 | SU <-> SCR | 0.552 |

| FO <-> FL | 0.465 | VI <-> CO | 0.560 |

| SCR <-> CO | 0.641 | VI <-> FL | 0.591 |

| SCR <-> FL | 0.562 | VI <-> FO | 0.519 |

| SCR <-> FO | 0.560 | VI <-> SCR | 0.582 |

| SU <-> CO | 0.511 | VI <-> SU | 0.478 |

| SU <-> FL | 0.514 |

| Hypothesis | Hypothesis Item | Path Coefficient | T Value | p Value | Significance |

|---|---|---|---|---|---|

| H1 | FO -> SCR | 0.167 | 2.67 | 0.008 | Yes |

| H2 | FL -> SCR | 0.156 | 2.75 | 0.006 | Yes |

| H3 | VI -> SCR | 0.171 | 3.11 | 0.002 | Yes |

| H4 | SU -> SCR | 0.167 | 3.14 | 0.002 | Yes |

| H5 | CO -> SCR | 0.235 | 3.73 | 0.000 | Yes |

| Variable | High Supply Chain Resilience | |

|---|---|---|

| Consistency | Coverage | |

| Forward-looking | 0.909059 | 0.774445 |

| ~Forward-looking | 0.137514 | 0.526323 |

| Flexibility | 0.873378 | 0.803902 |

| ~Flexibility | 0.177712 | 0.509686 |

| Visibility | 0.883447 | 0.772046 |

| ~Visibility | 0.164482 | 0.565623 |

| Supportiveness | 0.893815 | 0.786746 |

| ~Supportiveness | 0.158473 | 0.530005 |

| Supply Chain Collaboration | 0.912587 | 0.780862 |

| ~Supply Chain Collaboration | 0.137153 | 0.514836 |

| Conditional Configurations | SR | ~SR | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| FO | ● | V | ● | V | V | ||

| FL | ● | V | V | V | V | V | |

| VI | ● | V | V | ● | ● | V | |

| SU | ● | V | ● | ● | V | ||

| CO | ● | ● | V | V | ● | V | |

| Original Coverage | 0.66 | 0.26 | 0.14 | 0.15 | 0.23 | 0.16 | 0.21 |

| Unique Coverage | 0.66 | 0.01 | 0.01 | 0.03 | 0.00 | 0.02 | 0.06 |

| Overall Consistency | 0.88 | 0.85 | 0.97 | 0.97 | 0.85 | 0.91 | 0.95 |

| Solution Coverage | 0.66 | 0.394 | |||||

| Solution Consistency Level | 0.88 | 0.841 |

| Conditional Configurations | SR | ~SR | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| FO | ● | V | ● | V | V | ||

| FL | ● | V | V | V | V | V | |

| VI | ● | V | V | ● | ● | V | |

| SU | ● | V | ● | ● | V | ||

| CO | ● | ● | V | V | ● | V | |

| Original Coverage | 0.66 | 0.26 | 0.14 | 0.15 | 0.23 | 0.16 | 0.21 |

| Unique Coverage | 0.66 | 0.01 | 0.01 | 0.03 | 0.00 | 0.02 | 0.06 |

| Overall Consistency | 0.88 | 0.85 | 0.97 | 0.97 | 0.85 | 0.91 | 0.95 |

| Solution Coverage | 0.66 | 0.394 | |||||

| Solution Consistency Level | 0.88 | 0.841 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Shan, P. Configuring Supply Chain Resilience Under Natural Disaster Risk. Sustainability 2025, 17, 6346. https://doi.org/10.3390/su17146346

Cheng J, Shan P. Configuring Supply Chain Resilience Under Natural Disaster Risk. Sustainability. 2025; 17(14):6346. https://doi.org/10.3390/su17146346

Chicago/Turabian StyleCheng, Jiaqi, and Peng Shan. 2025. "Configuring Supply Chain Resilience Under Natural Disaster Risk" Sustainability 17, no. 14: 6346. https://doi.org/10.3390/su17146346

APA StyleCheng, J., & Shan, P. (2025). Configuring Supply Chain Resilience Under Natural Disaster Risk. Sustainability, 17(14), 6346. https://doi.org/10.3390/su17146346