Abstract

In recent years, the intensifying frequency of natural disasters such as floods and typhoons has brought severe disruptions to the global supply chain system, making supply chain resilience an important academic research and practical application topic. This study explores the influencing factors and allocation effects of supply chain resilience under the risk of natural disasters, with a particular focus on its impact on sustainability. This paper conducts an empirical study on supply chain resilience in the context of natural disasters by using the Structural Equation Model (SEM) and Fuzzy Set Qualitative Comparative Analysis (fsQCA). Based on 407 valid questionnaires, the study found that supply chain flexibility, foresight, visibility, cooperation, and support significantly positively affected the enhancement of supply chain resilience. Furthermore, through the fsQCA method, this study identified a single configuration approach that leads to high supply chain resilience and clarified the complexity of resilience formation under different conditions. This research not only enriches the theoretical framework of supply chain resilience but also provides targeted strategies for enterprises and governments to enhance their resilience to natural disasters, thereby suggesting potential pathways to support economic stability, social well-being, and environmental protection, though further empirical validation is needed.

1. Introduction

In the context of globalization, the supply chain system, as the backbone of economic activities, plays a pivotal role in ensuring the sustainable development of the global economy. However, with the intensification of global climate change, the frequency and severity of natural disasters such as floods, earthquakes, and typhoons have significantly increased, posing unprecedented challenges to the stability and resilience of the supply chain system [1]. These natural disasters not only result in substantial human casualties and economic losses but also expose the vulnerabilities of supply chains when confronted with unforeseen disruptions. For instance, the extreme heavy rainfall in Henan Province in July 2021 severely damaged logistics hubs, disrupted transportation networks, and impacted the supply chains of key commodities like methanol and urea. Similarly, the rainstorm in Zhongshan City in May 2024 further highlighted the fragility of the supply chain system, where numerous textile manufacturing enterprises faced operational risks due to logistics delays and production interruptions. In response to these challenges, governments worldwide have acknowledged the importance of enhancing supply chain resilience and have implemented practical measures. The Chinese government, in its report “Accelerating the Modernization of the Industrial Chain in the New Era and New Journey,” emphasized the necessity of strengthening the resilience of industrial and supply chains and enacted the “National Comprehensive Disaster Prevention and Mitigation Plan (2016–2020)” to enhance national- and enterprise-level disaster response capabilities. Internationally, the United States has adopted the “National Strategy for Global Supply Chain Security,” while the European Union and Japan have also taken similar actions to bolster supply chain resilience and reduce dependency on single sources. It is evident that constructing a safe, stable, and resilient supply chain system has become an inevitable trend.

As awareness of the significance of supply chain continuity and stability grows, scholars are actively exploring ways to strengthen supply chain resilience. Although existing literature has extensively examined supply chain resilience from a qualitative perspective, and some studies have employed mathematical modeling for analysis, empirical research on the influencing factors of supply chain resilience in the specific context of natural disasters remains limited. Current studies tend to focus on simplistic evaluations of individual factors, lacking a comprehensive consideration of the interactions among multiple factors within the natural disaster environment. Therefore, this research aims to address this gap by utilizing empirical analysis methods to investigate the key influencing factors of supply chain resilience under natural disaster risks and assess the potential of various factor combinations to enhance the supply chain’s capacity to withstand natural disasters. In line with widely accepted conceptualizations in the literature, this study defines supply chain resilience as a firm’s ability to anticipate, respond to, adapt to, and recover from supply chain disruptions while maintaining continuity of operations and situational awareness [2,3]. This definition aligns with the multidimensional structure adopted in our measurement scale, which incorporates responsiveness, adaptability, coping ability, and real-time awareness as core components of resilience.

Based on a thorough literature review, this study systematically collected 300 valid questionnaires from enterprises as samples. Data analysis was conducted using two advanced methods: Structural Equation Modeling (SEM) and Fuzzy Set Qualitative Comparative Analysis (fsQCA). In the first phase, SEM was used to quantitatively evaluate the direct effects of each factor on supply chain resilience. In the second phase, fsQCA was applied to explore the configurational impacts of various factor combinations, thereby providing a novel theoretical perspective for constructing highly resilient supply chains. Through rigorous questionnaire surveys and empirical analyses, this study confirmed the positive influence of factors such as proactivity, flexibility, visibility, supportiveness, and collaboration on supply chain resilience and proposed multiple combination mechanisms for achieving high levels of supply chain resilience.

This research not only systematically assessed the influencing factors of supply chain resilience but also explored their interactions to form diverse configurations that enhance supply chain resilience. The findings offer strategic insights for supply chain managers in designing more robust and adaptive supply chain systems. Moreover, this study enriches the theoretical framework of supply chain resilience by introducing new dimensions and provides actionable guidance for practical management practices, thereby supporting more informed decision-making in the context of global economic uncertainties. Recent research has increasingly highlighted the complexity of resilience-building in the face of compound disasters, where multiple agents must coordinate under dynamic and uncertain conditions. Wu et al. (2025) emphasized the role of collaborative governance and integrated system design in enhancing supply chain resilience in such scenarios [4].

To address these issues, this study seeks to explore how key internal and external capabilities—namely foresight, flexibility, visibility, supportiveness, and collaboration—jointly influence supply chain resilience in the context of natural disaster risk. Guided by both the Resource Dependence Theory and the Dynamic Capabilities Framework, we apply a mixed-method approach using SEM and fsQCA to identify both net effects and configurational patterns. The central research questions guiding this study are as follows: (1) What individual factors enhance supply chain resilience under natural disaster risk? and (2) How do different combinations of these factors contribute to high-resilience outcomes?

The rest of the paper is structured as follows. Section 2 reviews relevant literature and establishes the theoretical basis for the study. Section 3 introduces the conceptual model and research hypotheses. Section 4 describes the research design and data collection procedures. Section 5 presents the SEM results. Section 6 reports the fsQCA findings and discusses the theoretical and managerial implications, limitations, and future research directions.

2. Literature Review

2.1. Supply Chain Resilience

Supply chain resilience (SCR) has garnered increasing academic and practical attention in recent years, driven by the growing uncertainty and frequency of disruptions across global supply networks. In this study, SCR specifically refers to a supply chain’s ability to maintain continuity, adapt, and recover in the face of disaster-induced disruptions, such as extreme weather events, floods, and earthquakes [5].

The concept of resilience originated from ecology and systems science, where it was initially understood as a system’s capacity to absorb shocks and return to its original state. Within the supply chain domain, Christopher and Peck defined resilience as the ability of a supply chain to survive, adapt, and thrive amidst turbulent change [1]. Building upon this, Ponomarov and Holcomb conceptualized SCR as a dynamic capability that enables organizations to proactively prepare for, respond to, and recover from unexpected disruptions. Kamalahmadi and Parast further emphasized a multidimensional view of SCR, comprising readiness, responsiveness, recovery, and growth as its core dimensions [2]. Consistent with this perspective, the present study defines supply chain resilience as the firm’s dynamic capability to anticipate, absorb, adapt to, and recover from disruptions, while sustaining operational continuity and facilitating post-disruption improvement [3,6].

While conceptually related to risk management and business continuity, supply chain resilience (SCR) is a broader and more dynamic construct. Risk management primarily focuses on the identification and mitigation of potential hazards before they occur, whereas business continuity emphasizes the maintenance of essential operations during crises. In contrast, SCR encompasses the full disruption lifecycle, integrating proactive risk sensing, real-time response, adaptive recovery, and post-event learning [7]. As such, it represents a systemic capability that enables supply chains not only to withstand disruptions but also to adapt and evolve as a result of them. This study draws on the Resource Dependence Theory (RDT) and the Dynamic Capabilities View (DCV) to conceptualize SCR.

According to Resource Dependence Theory (RDT), resilience can be understood as the strategic deployment of key assets—such as supply visibility systems or collaborative infrastructures—that mitigate the impact of disruptions [8]. The Dynamic Capabilities View (DCV) complements this perspective by emphasizing a firm’s ability to integrate, build, and reconfigure resources in response to environmental volatility [9]. This integrated framework has been widely adopted in recent literature to explain how firms cultivate resilience through the interaction of resource endowments and dynamic capabilities [7,10].

Grounded in both DCV and RDT, this study proposes a theoretically structured framework for conceptualizing supply chain resilience [11]. Specifically, foresight, flexibility, and visibility are interpreted as manifestations of dynamic capabilities: foresight enables proactive sensing and forecasting of external disruptions; flexibility reflects the adaptive capacity to reconfigure processes and resources; and visibility supports real-time monitoring and interpretation of supply chain operations [12]. Collectively, these capabilities align with DCV’s core tenets of sensing, seizing, and transforming in turbulent environments [9].

By contrast, supportiveness and collaboration are conceptualized through the lens of RDT, which emphasizes organizations’ reliance on external actors and the strategic management of interdependencies. Government support, industry-wide coordination, and access to external resources are considered critical enablers of resilience, particularly in disaster contexts. Collaboration, in this view, entails not only the sharing of resources but also the strategic alignment of interests and power across supply chain partners to reduce uncertainty and enhance collective responsiveness [11].

This dual-theoretical mapping offers a nuanced understanding of the mechanisms through which supply chain resilience is developed and sustained. By grounding the identified dimensions in well-established theoretical frameworks, the study moves beyond descriptive accounts and provides deeper conceptual insight and analytical clarity.

In summary, supply chain resilience is a multidimensional and dynamic construct that extends beyond traditional risk management and business continuity planning. Anchored in both resource-based and capability-driven perspectives, SCR reflects the strategic integration of tangible and intangible assets with organizational adaptability. The five dimensions identified in this study—foresight, flexibility, visibility, supportiveness, and collaboration—represent the essential capabilities that firms must cultivate to withstand, adapt to, and grow from disruptive events. These dimensions serve as the theoretical and operational basis for the empirical analyses that follow.

2.2. Influencing Factors of Supply Chain Resilience

Supply chain resilience (SCR), as a central concept in supply chain management, refers to the capability of a supply chain to quickly resume normal operations and adapt to long-term changes in the face of external shocks such as natural disasters.For example, Zhu et al. [13] used ISM to identify key resilience factors in the prefabricated building supply chain, providing a structured basis for empirical resilience modeling. Extensive academic research has examined this topic through various methodologies, including case studies, mathematical modeling, and empirical investigations. These studies have identified a wide range of influencing factors, which can generally be categorized into two major domains: internal management factors and external risk factors [14].

Internal management factors—such as organizational structure, operational strategies, and resource allocation—form the foundational basis for supply chain resilience [15]. A well-functioning internal coordination mechanism can significantly improve the supply chain’s ability to respond to disruptions, enhance adaptive capacity, and accelerate recovery [16,17]. Prior research has shown that internal collaboration not only facilitates information sharing and decision-making efficiency but also strengthens the self-repair capacity of the supply chain in the face of disruptions [18]. These internal capabilities are particularly vital in fast-evolving disaster scenarios, where decision-making must be both rapid and forward-looking [4]. Some scholars have highlighted the critical role of emerging information technologies in enhancing supply chain resilience and promoting sustainable enterprise development [19]. Empirical studies, including those based on extensive datasets such as 5000 survey responses during COVID-19, have further demonstrated the strategic value of digital capabilities in improving supply chain agility, responsiveness, and operational continuity [2,20,21]. These capabilities enable firms to promptly adapt to market fluctuations and recover swiftly from adverse impacts [22].

External risk factors—such as natural disasters, regulatory shifts, and demand volatility—also pose significant challenges to supply chain stability. However, fostering external collaboration can substantially enhance a supply chain’s resilience [18,22]. Research suggests that supply chain resilience is not only determined by internal resources but is also closely tied to the strength of inter-firm relationships [23,24]. The development of social capital—including trust, shared norms, and long-term partnerships—is essential for improving the speed and effectiveness of supply chain responses under risk [15]. Collaborative initiatives, such as information sharing and coordinated planning, as evidenced in industries like food processing, have been shown to bolster collective risk management and response capabilities.

Based on the existing literature, the factors influencing supply chain resilience are diverse and deeply interdependent. Internal capabilities provide the structural foundation for resilience, while effective external partnerships serve as key enablers for rapid adaptation and recovery. Together, these dimensions highlight the systemic, multi-layered nature of building resilient supply chains in an increasingly uncertain environment.

Despite these valuable insights, two critical research gaps persist. First, most existing studies rely on linear statistical models that emphasize the independent effects of individual factors, neglecting the potential configurational interplay among multiple capabilities. This limits our understanding of how complex combinations of internal and external elements jointly contribute to resilience outcomes. Second, empirical studies specifically situated in the context of natural disasters remain relatively scarce, despite the unique characteristics of such disruptions—such as their sudden onset, localized infrastructure failures, and simultaneous effects on multiple supply chain partners.

To address these gaps, the present study integrates the Dynamic Capabilities View (DCV) and Resource Dependence Theory (RDT) to develop a five-dimensional resilience framework. Foresight, flexibility, and visibility are conceptualized as dynamic capabilities, while supportiveness and collaboration are grounded in the logic of external dependency [25]. This theoretical foundation provides a more nuanced explanation of the formation and functioning of supply chain resilience. Furthermore, the study adopts a dual-method approach that combines Structural Equation Modeling (SEM) and Fuzzy Set Qualitative Comparative Analysis (fsQCA). This allows for the identification of both linear causal relationships and multiple coexisting configurations that lead to high- or low-resilience outcomes.

3. Theoretical Analysis and Research Hypotheses

3.1. Theoretical Foundation

Based on the definitions and operationalization of foresight, flexibility, visibility, supportiveness, and collaboration outlined in Section 2.2, this section further elaborates the theoretical rationale underlying these factors from the perspectives of the Dynamic Capabilities View (DCV) and Resource-Based View (RBV).

This study is grounded in two interrelated theoretical frameworks: the Resource-Based View (RBV) and the Dynamic Capabilities View (DCV). The RBV posits that valuable, rare, inimitable, and non-substitutable (VRIN) resources are essential for sustaining competitive advantage and achieving supply chain resilience, particularly in volatile environments. Building on this foundation, the DCV emphasizes an organization’s ability to integrate, develop, and reconfigure internal and external resources in response to environmental uncertainty and change.

Guided by these perspectives, the five core factors examined in this study—foresight, flexibility, visibility, supportiveness, and collaboration—are categorized as either dynamic capabilities or strategic resources that contribute to resilience across various phases of disruption. Specifically, foresight and flexibility are conceptualized as dynamic capabilities that enable organizations to anticipate risks, respond rapidly, and reconfigure operations during the readiness and response stages. Visibility and supportiveness are viewed as valuable internal and external resources under the RBV framework: visibility enhances risk detection and informed decision-making, while external support provides critical resources to sustain operations and aid recovery [26]. Lastly, collaboration is interpreted as a mechanism of inter-organizational resource orchestration, enabling shared problem-solving and collective recovery efforts—aligning with the RBV’s emphasis on leveraging relational and structural assets.

This integrated theoretical foundation not only informs the development of hypotheses in this study but also offers a structured lens through which to understand how different capabilities and resources jointly shape supply chain resilience throughout the stages of readiness, response, and recovery. The dual-theoretical framework thus clarifies the functional roles of each factor and provides the conceptual justification for the relationships explored in the empirical analysis.

3.2. Analysis of Internal Influencing Factors of Supply Chain Resilience in the Context of Disasters

In supply chain management practice, internal factors such as resource allocation, operational strategies, and organizational structure form the foundational basis for building supply chain resilience. These factors enable supply chains to maintain stability and continuity in the face of external shocks. Particularly in dynamic and unpredictable environments, internal capabilities play a vital role in ensuring responsive and adaptive performance.

Within the framework of the Dynamic Capabilities View (DCV), foresight is recognized as the initiating capability in an organization’s “sensing–responding–reconfiguring” cycle for managing environmental complexity [27,28]. It reflects a firm’s ability to anticipate future risks, prepare proactively, and make timely strategic adjustments. In contrast to reactive risk management, foresight emphasizes the proactive identification of potential disruptions, advance planning, and continuous organizational learning—factors that collectively strengthen the foundation of resilience [28,29].

In the context of natural disasters, foresight becomes particularly critical. On one hand, the sudden and uncertain nature of such events renders traditional reactive approaches inadequate. Firms equipped with strong foresight capabilities can establish early warning systems, develop disaster response teams, and implement flexible inventory and multi-sourcing strategies, thereby reducing dependence on single nodes and mitigating the risk of cascading failures [27,30]. On the other hand, during a disaster, foresight enables dynamic, data-informed decision-making through the use of digital platforms and real-time analytics, such as reprioritizing suppliers or rerouting logistics [31]. Following a disaster, foresight also facilitates systematic learning and continuous improvement through post-event reviews and iterative refinement of emergency response mechanisms [29].

In summary, foresight enhances a firm’s capacity not only to anticipate and prevent disruptions before they occur, but also to respond rapidly and recover effectively. As such, foresight constitutes a core dynamic capability that supports supply chain resilience across all stages of disaster risk. Accordingly, we propose the following hypothesis:

H1.

In the context of natural disasters, supply chain foresight positively influences supply chain resilience.

Supply chain flexibility refers to the ability of a supply chain to rapidly adapt and respond to short-term or unexpected changes in the market environment and supply–demand dynamics [17,32]. This capability applies not only to individual firms but also to the responsiveness and coordination of the supply chain as a whole [33]. In the context of natural disasters—where supply chain structures are often severely disrupted—flexibility becomes especially critical.

First, building a diversified supplier base prior to a disruption enhances sourcing flexibility, enabling firms to swiftly shift to alternative suppliers and thus mitigate raw material shortages resulting from supplier failures (FL1) [33]. Second, inventory flexibility allows companies to dynamically adjust stock levels in response to real-time supply and demand signals, helping to avoid overstocking or stockouts during volatile periods (FL3). Third, production flexibility enables the rapid reallocation of production capacity and the adjustment of manufacturing schedules to accommodate fluctuations in resource availability and customer needs (FL4) [34,35].

From the perspective of Resource Dependence Theory (RDT), flexibility reduces organizational dependence on single suppliers, rigid inventory strategies, or inflexible production systems, thereby increasing a firm’s autonomy and adaptability under uncertain conditions. Previous studies have consistently found that flexibility is a key enabler of operational continuity and plays a vital role in mitigating the adverse effects of supply chain disruptions [32,36].

Accordingly, we propose the following hypothesis:

H2.

In the context of natural disasters, supply chain flexibility positively influences supply chain resilience.

Supply chain visibility is a critical concept in supply chain management, referring to the ability of firms to monitor and access real-time information related to order processing, inventory levels, transportation, and distribution activities [37]. It also includes the capacity to track environmental events and disruptions across the network in real time, thereby enabling a comprehensive and integrated view of supply chain operations [38]. From a Resource-Based View (RBV), visibility represents a valuable intangible asset that reduces uncertainty by improving information transparency and enhancing decision-making efficiency.

In the context of natural disasters, visibility becomes particularly important. It allows firms to promptly identify the nodes or links that have been impacted and to implement targeted responses, thereby minimizing the scope and severity of disruptions (VI1) [39,40]. Technological advancements—such as the application of supply chain digital twins—enable the integration of information flows, financial flows, logistics, and operations, contributing to high levels of visibility that enhance adaptability and resilience (VI2) [28,41,42]. Moreover, visibility supports precise forecasting of supply and demand, which is essential when disasters cause abrupt changes in market conditions. This capability enables firms to dynamically adjust production, inventory, and logistics strategies to stabilize operations and maintain continuity (VI3).

Thus, visibility not only reduces information asymmetries during disaster events but also serves as a strategic enabler of rapid response, coordinated decision-making, and accelerated recovery.

H3.

In the context of natural disasters, supply chain visibility positively affects supply chain resilience.

3.3. Analysis of External Influencing Factors on Supply Chain Resilience in Disaster Contexts

After analyzing how internal management factors contribute to supply chain resilience, we now turn to external influencing factors. External disruptions—such as market volatility and natural disasters—pose significant threats to supply chain stability. However, through effective external support and cooperation, firms can significantly improve their capacity to resist and recover from such shocks.

Supply chain supportiveness refers to the assistance provided by third-party institutions, such as governments and industry associations, to help enterprises mitigate and recover from disaster-induced supply chain disruptions. In such contexts, supply chains often suffer not only physical damage but also face fluctuating demand, logistics interruptions, and operational instability. As a critical external resource, government support plays a pivotal role in enhancing firms’ resilience (SU1, SU2).

From the perspective of Resource Dependence Theory (RDT), government-provided support helps reduce environmental uncertainty and mitigates firms’ reliance on internal resources by facilitating access to essential external inputs [1,42]. First, early warning systems offered by government agencies allow firms to prepare proactively—for example, by adjusting logistics and inventory in response to meteorological forecasts. Second, public authorities help coordinate resources across regions and sectors during large-scale disasters, supporting broader supply chain recovery (SU3). Third, in the post-disaster phase, financial subsidies, tax relief, and regulatory flexibility assist firms in rebuilding operations and adapting to evolving market conditions (SU4).

In this study, the concept of “supportiveness” specifically focuses on formal governmental interventions, including early warning systems, centralized resource coordination, and policy support during and after disasters. This reflects the dominant role of government institutions in China’s disaster governance system. While other external supports—such as industry associations, NGOs, or infrastructure readiness—are also relevant, they are not explicitly captured by the current measurement model.

H4.

In the context of natural disasters, supply chain support positively influences supply chain resilience.

Supply chain collaboration refers to the joint planning, coordination, and execution of supply chain operations among partner firms [14]. Effective collaboration is built upon mutual trust and social capital—including shared cognition, relational bonds, and structural connections—that foster cooperative behavior and facilitate resource exchange [23]. In the wake of natural disasters, where disruptions are widespread and no single firm can manage risks independently, collaboration becomes indispensable.

First, during crises, firms face greater reliance on external resources. Through collaborative efforts, they can share key inputs—such as information, technologies, financial support, and materials—thereby reducing individual vulnerabilities and enhancing collective response capabilities (CO1) [24]. Second, trust-based collaboration strengthens mutual support and improves the efficiency of information exchange and joint decision-making, mitigating operational uncertainty in turbulent conditions (CO2) [43,44]. Third, coordinated planning among partners facilitates dynamic supply adjustments, optimal resource allocation, and shared risk management—all of which are critical for a resilient recovery (CO3, CO4) [45].

From the RDT perspective, collaboration reduces exposure to external shocks by enabling firms to leverage the resources and capabilities of their network partners. This interdependence fosters adaptability and strengthens the structural robustness of the supply chain network. Prior research confirms that strong collaborative ties enhance disaster recovery through synchronized operations and coordinated risk management mechanisms [46].

H5.

In the context of natural disasters, supply chain collaboration positively influences supply chain resilience.

Although both supportiveness and collaboration represent forms of external assistance, they differ significantly in their origins, mechanisms, and structural orientations. Supportiveness refers to top-down, institutional support from governmental or industry bodies, involving centralized systems such as early warnings, regulatory frameworks, and policy incentives—largely outside the control of individual firms. In contrast, collaboration denotes horizontal, peer-level engagement among supply chain partners, characterized by mutual cooperation, joint planning, and shared recovery actions. Clarifying this distinction ensures that the model captures complementary yet conceptually distinct dimensions of external resilience support.

3.4. Analysis of Influencing Factors on Supply Chain Resilience Based on fsQCA

In management and organizational research, Qualitative Comparative Analysis (QCA) has gained increasing attention as an innovative methodological approach due to its ability to handle complex interactions among variables. Rooted in Boolean algebra and set theory, QCA focuses on identifying how combinations of conditions relate to specific outcomes, thereby uncovering the causal complexity inherent in social and organizational phenomena. Unlike traditional statistical methods—which typically assume variable independence and emphasize single, linear causal relationships—QCA allows for the exploration of interdependent, configurational relationships [47].

In real-world supply chain management contexts, particularly under disaster scenarios, resilience is often shaped by multiple, mutually reinforcing factors. While Structural Equation Modeling (SEM) effectively captures linear and additive relationships among variables, it may overlook complex, non-linear patterns and conditional interdependencies. To address this limitation, this study integrates SEM with Fuzzy Set Qualitative Comparative Analysis (fsQCA)—a configurational approach well suited for modeling the interplay of multiple antecedents. This integration significantly enhances the analytical depth and explanatory power of the study.

The configurational logic of fsQCA enables the identification of how specific combinations of factors—such as foresight, flexibility, visibility, supportiveness, and collaboration—jointly contribute to high or low supply chain resilience. This approach goes beyond SEM by addressing two key features of complex causality:

Equifinality, which acknowledges that multiple distinct combinations of conditions may lead to the same outcome. In the case of supply chain resilience, this means different firms may employ different strategies (e.g., high collaboration with moderate foresight, or strong visibility with government support) and still achieve similar levels of resilience.

Causal asymmetry, which recognizes that the presence and absence of the same condition may contribute to different outcomes depending on the configuration.

Through these lenses, fsQCA provides granular, context-sensitive insights that SEM alone cannot uncover [48,49,50].

Moreover, recent literature has demonstrated the effectiveness of fsQCA in analyzing supply chain resilience. For example, studies by Wieland and Marcus [50] and Ma et al. [51] have successfully applied fsQCA to identify complex causal structures underlying resilience outcomes. These applications validate the methodological appropriateness of fsQCA and reinforce its suitability for this study.

In summary, combining SEM and fsQCA offers a methodological triangulation that captures both net effects (via SEM) and configurational complexity (via fsQCA). SEM tests the general significance and directionality of individual factors, while fsQCA reveals multiple sufficient pathways and nuanced interdependencies. This integrated approach delivers richer theoretical insights and more actionable guidance for supply chain practitioners operating under disaster risk.

Given the advantages of fsQCA in handling continuous variables, partial memberships, and complex causal architectures, this study adopts it as a complementary analytical tool to identify the diverse combinations of capabilities that give rise to supply chain resilience [52]. Accordingly, we propose the following hypotheses:

H6a.

In the context of natural disasters, supply chain resilience is achieved through multiple distinct configurations of contributing factors.

H6b.

In the context of natural disasters, the formation of supply chain resilience results from the synergistic effects of multiple factors rather than any single factor in isolation.

4. Structural Equation Modeling Analysis

4.1. Research Design and Data Processing

This study employed a structured questionnaire survey to collect data on the proposed factors influencing supply chain resilience. The survey instrument was designed using measurement scales adapted from established literature for each construct (as shown in Table 1). In particular, multi-item scales for supply chain foresight, flexibility, visibility, government supportiveness, collaboration, and the dependent construct of supply chain resilience were drawn from previously validated studies (e.g., foresight from Jain et al. [50]; flexibility from Williams et al. [35]; supportiveness from Yang [43]; collaboration from prior resilience studies [48,49]). All items were originally in English and then translated into Chinese following a standard translation–back-translation procedure to ensure semantic equivalence.

Table 1.

Measurement indicators of each variable.

Each construct was operationalized as a distinct dimension with a clear theoretical definition, and all questionnaire items used a five-point Likert scale (1 = “strongly disagree” to 5 = “strongly agree”), with higher scores indicating greater levels of the measured attribute. Although no pilot test was conducted before full deployment of the survey, the use of well-validated scale items and expert review of the questionnaire content ensured content validity and clarity, so the lack of a formal pilot does not undermine the study’s validity.

The sampling strategy was a stratified random sampling approach implemented via the Wenjuanxing online survey platform (www.wjx.cn). This platform allowed us to target respondents based on specific criteria to enhance sample relevance. The survey was distributed to enterprise managers in the manufacturing and logistics sectors across China, reflecting industries highly exposed to natural disaster disruptions. We specifically invited middle- and senior-level managers and supervisors as participants, reasoning that they possess deeper insights into supply chain operations and resilience practices. The questionnaire link was disseminated through Wenjuanxing’s managed distribution system, reaching potential respondents in 20 provinces to ensure broad regional coverage and organizational diversity. Data collection took place between June 2023 and December 2024. To encourage candid and thoughtful responses, the survey was administered anonymously with assurances of confidentiality and was accompanied by a brief statement that the data would be used solely for academic research. These procedures, along with the use of established scales, helped enhance response quality and reduce potential biases.

Data processing and quality control: A total of 523 questionnaire responses were initially gathered via the Wenjuanxing platform. Rigorous screening was then carried out to eliminate invalid responses based on several predefined criteria. Specifically, we excluded responses that met any of the following conditions: (1) an extremely short completion time, indicating that the respondent likely did not carefully read the questions; (2) identical or highly repetitive answer patterns (straight-lining), suggesting a lack of genuine engagement; (3) failure to correctly answer an embedded attention-check question, which signaled inattentiveness; and (4) logically inconsistent answers (e.g., contradictory responses), which cast doubt on the response integrity. As a result of this cleaning process, 116 responses were discarded for meeting one or more of these criteria. The final sample comprised 407 valid questionnaires that were retained for analysis. Although the questionnaire did not include reverse-worded items (a design choice that could have further discouraged straight-lining), multiple other control measures were in place to ensure data reliability. We recognize this absence of reverse-coded items as a minor limitation; however, the combination of attention checks, rigorous screening, and expert validation of items provided confidence in the quality of the collected data. All data were double-entered and cross-verified during the data entry stage to minimize errors, and the entire collection and processing procedure adhered to established scientific and ethical standards.

Among the 407 valid responses, 56.3% of participants were from the manufacturing industry, and 43.7% were from the logistics industry, aligning with the study’s focus on sectors vulnerable to natural disasters. In terms of job position, 24.1% of respondents were senior managers, 42.8% were department heads, and 33.1% were operational supervisors, ensuring that all participants had relevant knowledge of their firm’s supply chain practices. Additionally, 48.9% of the enterprises had more than 300 employees, indicating strong representation from medium- and large-sized firms. The geographic distribution covered 20 provinces across eastern, central, and western China, enhancing the diversity and generalizability of the data. A full summary of respondent characteristics is provided in Table 2.

Table 2.

Payment matrix for a deposit system under the market mechanism.

To address the potential risk of common method bias (CMB) inherent in using self-reported data from a single survey, we implemented both procedural and statistical remedies. Procedurally, the questionnaire design incorporated several ex ante protections: respondents were assured of full anonymity and confidentiality to reduce evaluation apprehension, and the order of survey items was randomized whenever possible to prevent any consistency motifs in responses. We also mixed questions from different constructs and used simple, clear language to avoid ambiguity, thereby minimizing the chance that respondents would answer in a patterned way. Statistically, we performed Harman’s single-factor test on all survey items as an ex post check for CMB. The unrotated exploratory factor analysis showed that the first principal component accounted for only 27.4% of the total variance, well below the common threshold of 40%. This result indicates that no single factor dominates the datafile-lxg5kkxpkiwee8zzxnvwzp, and thus common method variance is unlikely to bias the findings in this study. Overall, through careful survey design and data processing, we have taken comprehensive steps to ensure the reliability and validity of the research data while fully addressing reviewer concerns about the measurement process and potential biases.

4.2. Measurement Model Assessment

This study employs Partial Least Squares Structural Equation Modeling (PLS-SEM) using SmartPLS 4.0 to analyze the structural relationships among constructs. PLS-SEM was selected over Covariance-Based SEM (CB-SEM) due to the exploratory nature of the study, the moderate sample size (N = 407), and the model’s focus on prediction and variance explanation. Additionally, PLS-SEM does not require strict assumptions about data normality, making it suitable for real-world empirical data with possible distributional issues. The model quality was assessed through composite reliability (CR), average variance extracted (AVE), and R2 values for endogenous variables. Discriminant validity was evaluated using the Fornell–Larcker criterion and the HTMT ratio, all of which satisfied the recommended thresholds.

The reliability and internal consistency of the constructs were first examined using Cronbach’s alpha and composite reliability (CR). As reported in Table 3, all constructs exhibit Cronbach’s alpha values well above the acceptable threshold of 0.70 (most exceeding 0.80), indicating high internal consistency. Similarly, the CR values for each latent construct range from approximately 0.86 to 0.90, also surpassing the recommended 0.70 benchmark for exploratory research [37]. These results confirm that each construct is measured with a high degree of consistency, providing a solid foundation for validity assessment.

Table 3.

Results of reliability and validity analysis of the scale (N = 407).

Convergent validity was evaluated by inspecting item loadings and the average variance extracted (AVE). As shown in Table 3, all standardized item loadings were significant and well above the 0.50 threshold, indicating that each item relates strongly to its respective latent variable. Moreover, the AVE values for all constructs exceed the recommended value of 0.50, ranging from 0.572 to 0.688, thereby satisfying the criterion for adequate convergent validity.

In terms of the verification of structural validity, convergent validity, and discriminant validity, this study utilized Amos 26.0 software to conduct confirmatory factor analysis. Before conducting this analysis, the KMO and Bartlett’s sphericity were tested through SPSS 26.0 software. The test results showed that the KMO value was 0.924, which was higher than the standard of 0.50, and the Bartlett’s sphericity test result was significant (p = 0.000 < 0.05), indicating that the sample data was suitable for factor analysis.

To ensure robust discriminant validity among the constructs, this study adopted two widely recognized methods: the Fornell–Larcker criterion and the Heterotrait–Monotrait Ratio (HTMT). According to the Fornell–Larcker criterion, the square root of the average variance extracted (AVE) for each latent construct should be greater than its correlations with other constructs. As shown in Table 4 and Table 5, the square roots of the AVE values are located on the diagonal and are all significantly higher than the corresponding inter-construct correlations, indicating good discriminant validity of the model. To further enhance the robustness of the validation, the HTMT method was also employed. The results (see Table 5, Table 6 and Table 7) show that all HTMT values are well below the recommended threshold of 0.85, further confirming the satisfactory discriminant validity of the measurement model. In summary, the measurement model constructed in this study demonstrates strong structural clarity and construct independence, meeting the prerequisite conditions for subsequent structural path testing.

Table 4.

KMO and Bartlett test.

Table 5.

Confirmatory factor analysis model fitting coefficient table (N = 407).

Table 6.

Fornell–Larker criterion results.

Table 7.

Results of HTMT discriminative validity test.

The results of the confirmatory factor analysis indicated that the overall fit of the model was good, with specific indicators as follows: the ratio of chi-square to degrees of freedom (χ2/df) was 1.360, less than 3; the root mean square error of approximation (RMSEA) was 0.030, less than 0.08; the residual mean square (RMR) was 0.034, less than 0.05; the goodness-of-fit index (GFI = 0.935), the normed fit index (NFI = 0.923), and the comparative fit index (CFI = 0.978) were all greater than 0.9, all of which indicated that the scale had good structural validity. Additionally, the factor loadings of all items exceeded 0.5, the average variance extracted (AVE) of each factor exceeded 0.5, and the composite reliability (CR) exceeded 0.8, demonstrating that the scale had excellent convergent validity.

Furthermore, through these rigorous statistical tests, this study contributes a validated measurement instrument to the academic community and provides a reliable tool for practitioners to assess the level of supply chain resilience under disaster conditions and propose improvement strategies. This enables enterprises to better understand supply chain disruption risks and take effective management measures, thereby enhancing overall competitiveness and adaptability in a volatile market environment.

Finally, we ensured the robustness of the measurement model by adopting standard thresholds for assessing convergent and discriminant validity. Specifically, the average variance extracted (AVE) values for all constructs exceeded the recommended threshold of 0.50, and composite reliability (CR) values were above 0.70, confirming good convergent validity. Discriminant validity was evaluated using the Fornell–Larcker criterion, where the square root of the AVE for each construct was higher than the correlations with any other construct, meeting the accepted standard.

In addition, we checked for cross-loadings to confirm that each indicator loaded more strongly on its associated construct than on others, and no significant cross-loading issues were identified. Measurement error was controlled through confirmatory factor analysis (CFA), where each observed variable was specified to load on a single latent construct, with no cross-loading or correlated error terms permitted, in accordance with standard SEM practice.

These steps collectively support the construct validity and overall model fit of the measurement framework.

4.3. Structural Path Analysis and Hypothesis Testing

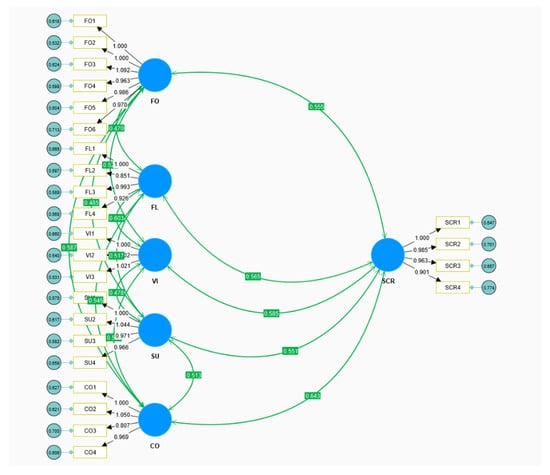

Under the premise of ensuring a high model fit, this study used Amos 26.0 software to verify the Structural Equation Model. The path analysis chart generated by this software is shown in Figure 1, and the specific analysis results are detailed in the data presented in Table 8.

Figure 1.

Path diagram of structural equation model for influencing factors of supply chain resilience under natural disaster risks.

Table 8.

Hypothesis testing results.

Collaboration emerges as the most influential predictor, as indicated by the highest standardized path coefficient (β = 0.235) along with a strong t-value (t = 3.73) and high statistical significance (p < 0.001). This result implies that fostering collaboration—such as strengthening partnerships and information sharing—substantially enhances a supply chain’s ability to withstand and recover from disruptions.

The other four capabilities—foresight, flexibility, visibility, and supportiveness—also exhibit positive and statistically significant relationships with supply chain resilience. While their standardized coefficients are more moderate in magnitude (β ranging from 0.156 to 0.171), each path is significant at the p < 0.01 level (with t-values between roughly 2.7 and 3.1). Specifically, foresight (β = 0.167, t = 2.67, p = 0.008) and flexibility (β = 0.156, t = 2.75, p = 0.006) each contribute to resilience by enabling proactive risk anticipation and swift adaptive responses to disturbances. In addition, visibility (β = 0.171, t = 3.11, p = 0.002) bolsters resilience through enhanced transparency and real-time information flow across the supply chain. Supportiveness (β = 0.167, t = 3.14, p = 0.002) likewise exerts a positive effect, suggesting that a supportive organizational environment facilitates coordinated action and resource sharing during disruptions.

In summary, the SEM path analysis provides strong evidence that all the hypothesized relationships are positive and significant. Each of the five constructs—foresight, flexibility, visibility, supportiveness, and collaboration—plays a distinct yet complementary role in enhancing supply chain resilience, and the data confirm support for Hypotheses H1 through H5. These findings indicate that developing these capabilities in tandem can significantly improve a supply chain’s robustness and agility in the face of natural disaster risks, with collaboration offering the greatest leverage among the factors examined.

4.4. Discussion of Findings and Theoretical Implications

In interpreting the five significant predictors of supply chain resilience—foresight, flexibility, visibility, supportiveness, and collaboration—each aligns with the theoretical tenets of both the Dynamic Capabilities View (DCV) and Resource Dependence Theory (RDT), especially under disaster conditions.

Foresight reflects a proactive sensing capability under DCV, enabling early risk detection through environmental scanning and scenario planning. It also aligns with RDT’s emphasis on anticipating external resource constraints. Flexibility supports rapid reconfiguration of supply, production, or logistics processes—consistent with DCV’s reconfiguration capability and RDT’s strategy of reducing overdependence on specific suppliers. Visibility enables real-time monitoring and data-sharing across the supply network. It reduces uncertainty (RDT) and enhances sensing and coordination (DCV).

Supportiveness—such as government aid or supplier assistance—serves as an external buffer under RDT and facilitates internal adaptation under DCV through an enabling institutional environment. Collaboration integrates relational capabilities (DCV) with resource pooling strategies (RDT), enabling joint responses and mutual aid during disruptions.

Together, these five dimensions function synergistically to help firms sense, adapt, and respond under natural disaster shocks, reducing vulnerability and enhancing continuity.

5. Analysis of Influencing Factors of Supply Chain Resilience Based on fsQCA

While SEM allows us to test the direct and linear relationships between constructs, it may overlook complex and nonlinear causal patterns that exist in organizational phenomena. To address this limitation, we complement SEM with Fuzzy Set Qualitative Comparative Analysis (fsQCA), which enables the identification of multiple sufficient configurations that lead to the same outcome (i.e., supply chain resilience). This mixed-method approach allows us to explore both the net effects of individual variables (via SEM) and the combinatorial, equifinal nature of resilience factors (via fsQCA), providing a more holistic understanding of how resilience is achieved under natural disaster risk. To provide a more holistic understanding of how resilience is formed in disaster contexts, this study adopts a two-stage methodological design. SEM is used in the first stage to examine the direct and net effects of each factor on supply chain resilience, helping validate the overall theoretical framework. In the second stage, fsQCA is employed to explore configurational causality, revealing how different combinations of factors can jointly contribute to resilience outcomes. This two-stage design is not ad hoc but theoretically driven, aligning with prior calls in the literature to account for both linear and complex interactions in resilience studies. By integrating SEM and fsQCA, this study offers both variable-centric and configuration-centric perspectives on supply chain resilience. SEM validates the general significance of each individual factor, while fsQCA highlights the presence of multiple high-resilience configurations that reflect different strategic emphases under disaster conditions. This methodological triangulation improves the robustness of our findings and offers nuanced guidance for practitioners operating in heterogeneous disaster contexts.

5.1. Selection and Calibration of Variables

When conducting Qualitative Comparative Analysis (QCA), which is grounded in Boolean algebra and set theory [53], it is essential to transform raw data into set membership scores—a process known as calibration. In this study, we selected proactiveness, flexibility, visibility, supportiveness, and supply chain collaboration as condition variables, and supply chain resilience as the outcome variable. Using fsQCA3.0 software, we converted the composite scores of each variable into fuzzy set membership values ranging from 0 to 1.

Following established procedures in the literature [54], we calibrated the 5-point Likert scale based on three qualitative anchors: a score of “4” was set as the threshold for full membership (value = 0.95), “3” as the crossover point (value = 0.5), and “2” as the threshold for full non-membership (value = 0.05). To avoid ambiguity in the analysis, we added a small constant (+0.001) to cases with a membership score of exactly 0.500, ensuring they could be included in the construction of the truth table. This calibration process ensured that the data were properly structured for subsequent fsQCA analysis.

5.2. Necessity Analysis

After completing the variable calibration, a necessity analysis was conducted to examine whether any specific condition constitutes a necessary prerequisite for the occurrence of the outcome variable. This analysis compares the membership scores of each condition variable with those of the outcome. A condition is considered necessary if its set is a subset of the outcome set—i.e., if the condition is always present in cases where the outcome is present.

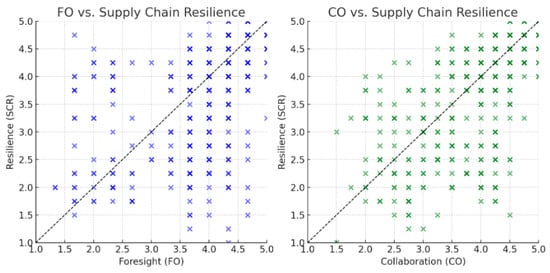

Necessity is typically assessed using consistency and coverage metrics, along with visual tools such as X–Y scatter plots [55]. A condition is generally considered necessary if its consistency exceeds 0.90 and its coverage is adequate. In the X–Y scatter plot, necessity is visually confirmed when all cases lie on or below the diagonal line, indicating that the outcome never occurs in the absence of the condition.

According to Table 9, the consistency values for proactiveness (FO) and supply chain collaboration (CO) exceeded the 0.90 threshold, suggesting they could be necessary conditions for achieving high supply chain resilience. However, to validate this possibility, we performed a visual analysis using X–Y scatter plots. As shown in Figure 2, if a condition is truly necessary, all data points should fall at or below the diagonal line. Contrary to this expectation, we observed that approximately one-third of the cases are located above the diagonal—indicating high-resilience outcomes even when foresight or collaboration is absent. This violates the fundamental logic of necessity.

Table 9.

Analysis of necessity.

Figure 2.

Scatter plots of foresight and collaboration against supply chain resilience.

Therefore, although the consistency values are high, neither foresight nor collaboration can be classified as strict necessary conditions. This finding reinforces the idea that supply chain resilience arises not from any single factor alone but from the interaction of multiple capabilities—further justifying the use of a configurational approach such as fsQCA.

Note: The dotted diagonal line represents the theoretical boundary in necessary condition analysis. If a condition (X) is truly necessary for an outcome (Y), no data points should appear above the line. The plots show that both foresight and collaboration fail to satisfy this visual criterion, despite consistency values above 0.9.

5.3. Configuration Adequacy Analysis

Configuration analysis aims to examine the sufficiency of specific combinations of antecedent conditions in producing the outcome. From a set-theoretic perspective, the goal is to determine whether particular configurations of conditions constitute subsets of the outcome set—meaning that when a configuration is present, the outcome reliably occurs. Each configuration thus represents a distinct causal pathway leading to the same outcome.

In this study, we set the consistency threshold for sufficiency at 0.80, the Proportional Reduction in Inconsistency (PRI) threshold at 0.70, and the frequency threshold at 1.0, ensuring that at least 80% of the cases are included in the solution set [56,57,58]. The fsQCA software generates three types of solutions: complex, parsimonious, and intermediate. Following standard practice, our analysis is based on the intermediate solution, while the parsimonious solution is used to distinguish core from peripheral (auxiliary) conditions. Core conditions are those present in both the parsimonious and intermediate solutions, whereas auxiliary conditions appear only in the intermediate solution.

Following the configuration presentation guidelines proposed by previous scholars [53], we developed Table 6 to display the resulting configurations and to identify common patterns associated with high supply chain resilience. The configurations were grouped according to shared core conditions to reveal underlying strategic profiles.

While these results do not support Hypothesis H6a—which proposed that “in the context of natural disasters, multiple distinct combinations of factors can lead to high supply chain resilience”—they do support Hypothesis H6b, which posits that “resilience is the result of the synergy among multiple factors rather than the effect of any single condition.” This reinforces the value of a configurational perspective in understanding resilience formation in complex, disaster-prone environments.

5.3.1. Configuration Path Analysis for High Supply Chain Resilience Under Disaster Background

The results presented in Table 10 reveal a clear and robust configuration associated with high supply chain resilience. This is the only configuration that meets the thresholds for both consistency and coverage, indicating its significance and explanatory strength. Specifically, the configuration exhibits a consistency score of 0.88, which implies that in 88% of the relevant cases, the presence of this particular combination of conditions leads to high resilience. This high level of consistency underscores the predictive reliability of the solution. Furthermore, each individual condition within this configuration achieves a consistency value above 0.75, verifying their critical role in forming resilient supply chains.

Table 10.

Analysis of the adequacy of conditional configurations.

The coverage value of 0.66 exceeds the generally accepted threshold of 0.5, suggesting that this configuration explains the majority of high-resilience cases in the dataset. Together, the high consistency and coverage provide strong support for the practical relevance and robustness of the configuration model.

The composition of this high-resilience configuration includes five antecedent conditions: foresight, flexibility, visibility, supportiveness, and supply chain collaboration. These conditions do not function in isolation but rather operate through synergistic interactions to enhance the supply chain’s capacity to withstand and recover from disruptions, particularly in the context of natural disasters. The presence of all five conditions suggests that resilience is not the outcome of a single dominant factor but the result of comprehensive and integrated capability-building.

From a managerial perspective, this implies that improving one capability in isolation is insufficient to ensure resilience. Firms must adopt a holistic strategy that simultaneously strengthens all five dimensions. Specifically, establishing comprehensive risk early warning systems enhances foresight. Developing agile response mechanisms increases flexibility. Enhancing information transparency across supply chain tiers improves visibility. Securing institutional support from government and industry associations reinforces supportiveness. Building trust-based cooperative relationships with supply chain partners fosters collaboration. This comprehensive approach allows firms to optimize both the structure and function of their supply chains, ensuring operational continuity in the face of uncertainty.

According to the comparison between the intermediate and parsimonious solutions, three conditions—foresight, visibility, and collaboration—appear in both, designating them as core conditions. In contrast, flexibility and supportiveness appear only in the intermediate solution and are thus identified as peripheral (auxiliary) conditions. This distinction reveals a layered causal architecture:

Core conditions represent the essential mechanisms of resilience: foresight enables proactive planning, visibility ensures situational awareness, and collaboration facilitates coordinated recovery.

Peripheral conditions reinforce the core by improving operational adaptability (flexibility) and institutional reinforcement (supportiveness). Their absence may weaken resilience but not entirely negate it if the core mechanisms are strong.

This finding supports the study’s broader theoretical claim that supply chain resilience emerges through interactions between dynamic capabilities (foresight, flexibility), resource-based assets (visibility, supportiveness), and relational governance structures (collaboration). It underscores the value of a configuration-oriented approach for understanding how firms achieve resilience under disaster-induced complexity.

5.3.2. Configuration Path Analysis for Low Supply Chain Resilience Under Disaster Background

As shown in Table 10, the six configurations associated with low supply chain resilience exhibit unique coverage values of 0.01, 0.01, 0.03, 0.00, 0.02, and 0.06, respectively. These values suggest that while each configuration individually contributes to explaining the outcome, their explanatory power varies. All six configurations demonstrate consistency scores above the commonly accepted threshold of 0.80—specifically, 0.85, 0.97, 0.97, 0.85, 0.91, and 0.95—indicating that these combinations reliably lead to low-resilience outcomes. Notably, four configurations (Paths 3, 4, 5, and 6) surpass a consistency of 0.90, suggesting a particularly strong predictive capacity.

The overall solution consistency of 0.841 exceeds the 0.8 benchmark, confirming that the model accurately captures the necessary conditions leading to low resilience. The overall solution coverage is 0.393, indicating that approximately 39.3% of the sample firms are represented by these low-resilience configurations. This highlights the practical relevance and generalizability of the identified combinations.

Beyond the performance of individual paths, a cross-comparative analysis reveals several recurring vulnerability patterns. The absence of visibility (VI) and collaboration (CO) appears in four and five out of the six configurations, respectively, signaling that a lack of real-time information transparency and inter-organizational coordination is a common and critical weakness in fragile supply chains. Additionally, flexibility (FL) is missing in three configurations, underscoring the importance of dynamic adjustment capabilities during disaster-induced disruptions.

These findings reinforce the configurational nature of supply chain resilience: it is not the absence of any single factor that undermines resilience, but rather the specific interplay of present and absent conditions. For instance, even when supportiveness or foresight is present, their benefits may be insufficient if visibility and collaboration are lacking. This highlights the interdependency of capabilities and resources and suggests that partial improvements in isolated dimensions are unlikely to yield meaningful resilience gains.

In practical terms, these results emphasize the need for integrated resilience strategies. Firms must avoid over-relying on one or two strengths while neglecting systemic weaknesses. Instead, resilience should be approached holistically by simultaneously enhancing capability-based elements (e.g., foresight, flexibility) and resource-based elements (e.g., visibility, collaboration). Their combined absence represents a critical vulnerability, while their strategic integration forms the backbone of a robust and adaptive supply chain system.

The output results of groups 3 and 4 show that these two configurations lack most factors except for supportiveness. However, both configurations are missing visibility and supply chain collaboration. Clearly, these two factors are the main reasons for the low supply chain resilience of these two configurations. This configuration indicates that enterprises can reduce operational risks by enhancing the transparency of supply chain operations and improve supply chain resilience through resource sharing and enterprise collaboration. By comparing the output results of groups 5 and 6, it can be concluded that the absence of supply chain flexibility is a major reason for low resilience.

In summary, the data in Table 6 reveals six antecedent condition configurations that lead to low supply chain resilience. Although the paths are different, they all may result in a low level of supply chain resilience in the context of disasters. This finding emphasizes the need to pay attention to the complex interactions of multiple factors in supply chain management and the necessity of adopting comprehensive management strategies when enhancing supply chain resilience. By identifying and optimizing these low-resilience antecedent condition configurations, enterprises can more effectively formulate strategies to improve the overall performance and resilience of the supply chain.

The fsQCA results extend the SEM findings by revealing that high supply chain resilience can result from multiple distinct combinations of capabilities. While SEM confirms that all five factors have significant positive effects on resilience, fsQCA uncovers equifinal pathways—such as the presence of foresight, flexibility, and collaboration—even when certain factors like visibility are absent. This suggests that some capabilities may compensate for the absence of others, a nuance not captured by linear modeling. Thus, fsQCA enriches our understanding by identifying alternative paths to resilience that go beyond the additive assumptions of SEM.

5.4. Robustness-Oriented Sensitivity Analysis

To evaluate the robustness of the fsQCA results, we followed established practices in QCA literature by applying a parameter sensitivity analysis approach [55]. Specifically, we conducted two sets of checks: (1) adjusting the calibration values of variables using four statistical methods—maximum, mean, upper/lower quartiles, and minimum values; and (2) adjusting the consistency threshold from 0.8 to 0.85 while keeping all other conditions unchanged [59,60]. As shown in Table 11, the results revealed only minor changes in raw coverage values, and the core condition combinations remained the same as in the original analysis. Therefore, the configuration structure and interpretive meaning did not change, supporting the conclusion that the results are stable across parameter variations.

Table 11.

Robustness check with adjusted calibration and consistency thresholds.

5.5. Integration of SEM and fsQCA Results

This study integrates Structural Equation Modeling (SEM) and Fuzzy Set Qualitative Comparative Analysis (fsQCA) to provide complementary insights into the mechanisms underlying supply chain resilience. The SEM results confirm that foresight, flexibility, visibility, and collaboration exert significant positive effects on resilience, thereby supporting Hypotheses H1, H2, H3, H4, and H5.

Conversely, the fsQCA results indicate that supportiveness serves as a core condition in multiple configurations associated with high resilience. This suggests that although its standalone effect may be limited, its interaction with other factors plays a critical role in achieving resilience. Similarly, while flexibility is confirmed as significant in the SEM analysis, it is absent in some fsQCA configurations, implying that under certain conditions, resilience can still be attained without flexibility.

These findings underscore the complementary strengths of SEM and fsQCA: SEM elucidates the net effects of individual variables, whereas fsQCA highlights equifinal pathways and interdependencies among factors. Together, these methods offer a more comprehensive understanding of how various capabilities interact to foster resilience in the face of natural disaster risks.

6. Conclusions

6.1. Research Conclusions

In the current external environment characterized by uncertainty and complexity, the risk of supply chain disruptions is increasing, making supply chain resilience management a critical topic in both academia and industry. This paper conducts an empirical study on the key influencing factors of supply chain resilience and their triggering antecedent configurations by combining the Structural Equation Model (SEM) and Fuzzy Set Qualitative Comparative Analysis (fsQCA) methods, leading to the following conclusions: Firstly, the empirical results from the Structural Equation Model indicate that flexibility, agility, visibility, and supply chain collaboration all positively influence supply chain resilience. Specifically, the stronger these factors are, the higher the level of supply chain resilience achieved. Secondly, the fsQCA analysis reveals that none of these factors alone constitutes a necessary condition for supply chain resilience. This suggests that no single factor serves as the decisive bottleneck for achieving high supply chain resilience. For example, even in the absence of flexibility and visibility, the combined effects of agility, reconfigurability, and supply chain collaboration can still support the development of high supply chain resilience. This implies that despite variations in these factors across enterprises, different driving configurations can enable them to achieve high supply chain resilience.

The enhancement of supply chain resilience may support sustainable development goals by potentially improving stability, resource efficiency, and stakeholder well-being. However, as these outcomes were not directly measured in this study, future research is needed to establish these causal relationships empirically. This study also highlights how enhancing supply chain resilience through the identified factors contributes directly to the three pillars of sustainability in the context of disaster recovery. Economically, high visibility enables firms to quickly detect supply interruptions and allocate resources efficiently, minimizing unnecessary costs and waste during the recovery process. Flexibility supports continued operations and swift adaptation, preserving production continuity and reducing the risk of prolonged economic losses. Socially, collaboration fosters coordinated recovery efforts and equitable resource sharing among supply chain partners, enhancing trust, stability, and inclusive recovery across diverse stakeholder groups. Supportiveness, particularly from public institutions, ensures that vulnerable sectors receive timely aid, supporting social well-being during crises. Environmentally, foresight facilitates proactive planning that integrates green practices and resource-conscious recovery strategies, such as using low-emission logistics or rebuilding infrastructure with sustainability criteria in mind. Together, these resilience mechanisms not only enable organizations to withstand disasters but also promote recovery pathways that are more economically viable, socially responsible, and environmentally aligned with the goals of sustainable development.

6.2. Theoretical Contributions

This study contributes to the theoretical advancement of supply chain resilience in three main ways. First, it deepens the conceptual grounding of SCR by explicitly integrating Dynamic Capabilities View (DCV) and Resource Dependence Theory (RDT). Specifically, foresight, flexibility, and visibility are conceptualized as dynamic capabilities that enable firms to sense disruptions, adapt operations, and reconfigure resources. In contrast, supportiveness and collaboration are viewed through the RDT lens, reflecting the strategic role of external dependencies such as governmental assistance and inter-firm coordination. This theoretical bifurcation enriches the understanding of how resilience is co-constructed through internal capability development and external relational management.

Second, the study offers a multi-dimensional framework for operationalizing SCR, consisting of five empirically validated dimensions. By mapping these dimensions onto two complementary theoretical foundations, the research builds a structured lens for future empirical testing and theory-building, particularly in disaster-prone contexts where resilience must be both proactive and collaborative.

Third, this study contributes methodologically and conceptually by applying a dual-method strategy (SEM and fsQCA), allowing us to explore both linear and configurational causality. The fsQCA results highlight asymmetric and nonlinear pathways to resilience—an area often overlooked in prior studies. This configurational insight challenges traditional one-size-fits-all models and reveals the equifinality and contextuality of resilience formation.

Together, these contributions not only reaffirm established resilience concepts but also extend theoretical discourse by offering a nuanced, theory-driven explanation of how resilience emerges in supply chain systems under disaster conditions.

6.3. Managerial Implications

This study identifies foresight, flexibility, visibility, supportiveness, and collaboration as critical capabilities that jointly enhance supply chain resilience. Firms that perform strongly across these dimensions are better positioned to anticipate, absorb, and recover from disaster-induced disruptions. Therefore, resilience-building should be treated as a strategic priority.

Importantly, resilience is not driven by any single factor but emerges from the synergistic integration of multiple capabilities. This underscores the need for a systemic and coordinated approach rather than fragmented interventions.

Based on the results—particularly the critical roles of foresight and flexibility—the following practices are recommended:

Foresight: Establish early warning systems that monitor disaster, geopolitical, and supplier risks; conduct scenario-based risk assessments; appoint risk coordinators; and conduct structured post-disruption evaluations. Flexibility: Diversify suppliers, maintain adaptive inventory (e.g., buffer stocks), adopt modular production systems, and leverage digital platforms for dynamic logistics and procurement adjustment.

To implement these strategies, firms should conduct internal capability audits using the high-resilience configuration identified (FOFLVISUCO). Evaluating not only individual strengths but also the integration across these areas is essential. Key considerations include the following: Are foresight tools aligned with operational planning? Are visibility platforms shared across partners? Is collaboration embedded in contingency planning?

The low-resilience configurations further reveal that the absence of visibility and collaboration is a recurring vulnerability. Even with other strengths, lacking these two factors often leads to poor response outcomes. Therefore, organizations—especially those in disaster-prone regions—should prioritize real-time transparency and inter-organizational coordination.

Finally, resilience enhancement also supports sustainability goals. Foresight and visibility enable efficient resource use, flexibility reduces waste, and collaboration fosters social equity during recovery. While promising, these links warrant further empirical exploration.

In summary, resilience is not a function of isolated capabilities but of their strategic alignment. Managers should pursue balanced and integrated investments to build robust, adaptive, and sustainable supply chains.

6.4. Research Limitations and Future Directions

Although this study provides valuable insights into the mechanisms of supply chain resilience under natural disaster risk, several limitations must be acknowledged, which also open up directions for future research.

First, the study is based solely on cross-sectional, self-reported questionnaire data collected from Chinese manufacturing and logistics enterprises. While perceptual data can reveal managerial attitudes and strategic awareness, they may deviate from objective operational outcomes. Moreover, relying on a single-country sample may limit the generalizability of findings across diverse institutional or cultural contexts. Future studies should consider using multi-source or archival data, such as performance indicators during actual disruptions, and cross-national samples to enhance external validity.