1. Introduction

The ultimate goal of a country’s development is the well-being of its people. Economic development plays a special role here. It is aimed at making it stable and rapid. On the other hand, focusing solely on economic results means that it can occur at the expense of people’s social well-being and environmental protection. In order to harmonize all three essential components of development, economic, social, and ecological, the concept of sustainable development was developed, the essence of which can be described as follows: none of the three components mentioned above can develop at the expense of the others [

1,

2,

3,

4]. On the other hand, literature sources note that of these three components, the most important role is, nevertheless, played by economic development, since both the social and ecological situation of the country depend on it [

3,

5,

6,

7].

Economic development is a very complex phenomenon. Its essential parts are industry, construction, transport, agriculture, and services [

8]. Therefore, the economic condition of the country is the result of the development of these sectors. Transport plays a special role here. Its importance can be reflected in the following three aspects: First, as a percentage of the country’s annual gross domestic product. In the countries of the European Union in 2023, it ranged from 2 to 11 percent [

9].

Secondly, the transport sector is special in that it is closely linked to almost all other sectors, since the price of every good or service includes transport costs. Thirdly, the transport sector accounts for almost 30 percent of all energy consumption [

8]. Transport is also significant due to growing production volumes, economic ties between countries caused by globalization processes, regional development, and thus the increasing scale of international transportation. Therefore, there is a need to look for ways to improve the transport systems of countries and increase the efficiency of their activities [

10]. When searching for them, it is necessary to evaluate today’s requirements for cargo transportation: reducing CO

2 emissions, increasing transportation safety, reducing road loading, reducing time losses at transshipment points, faster cargo delivery, reducing the time for preparing and processing transportation documentation, reducing overall transportation costs, etc. [

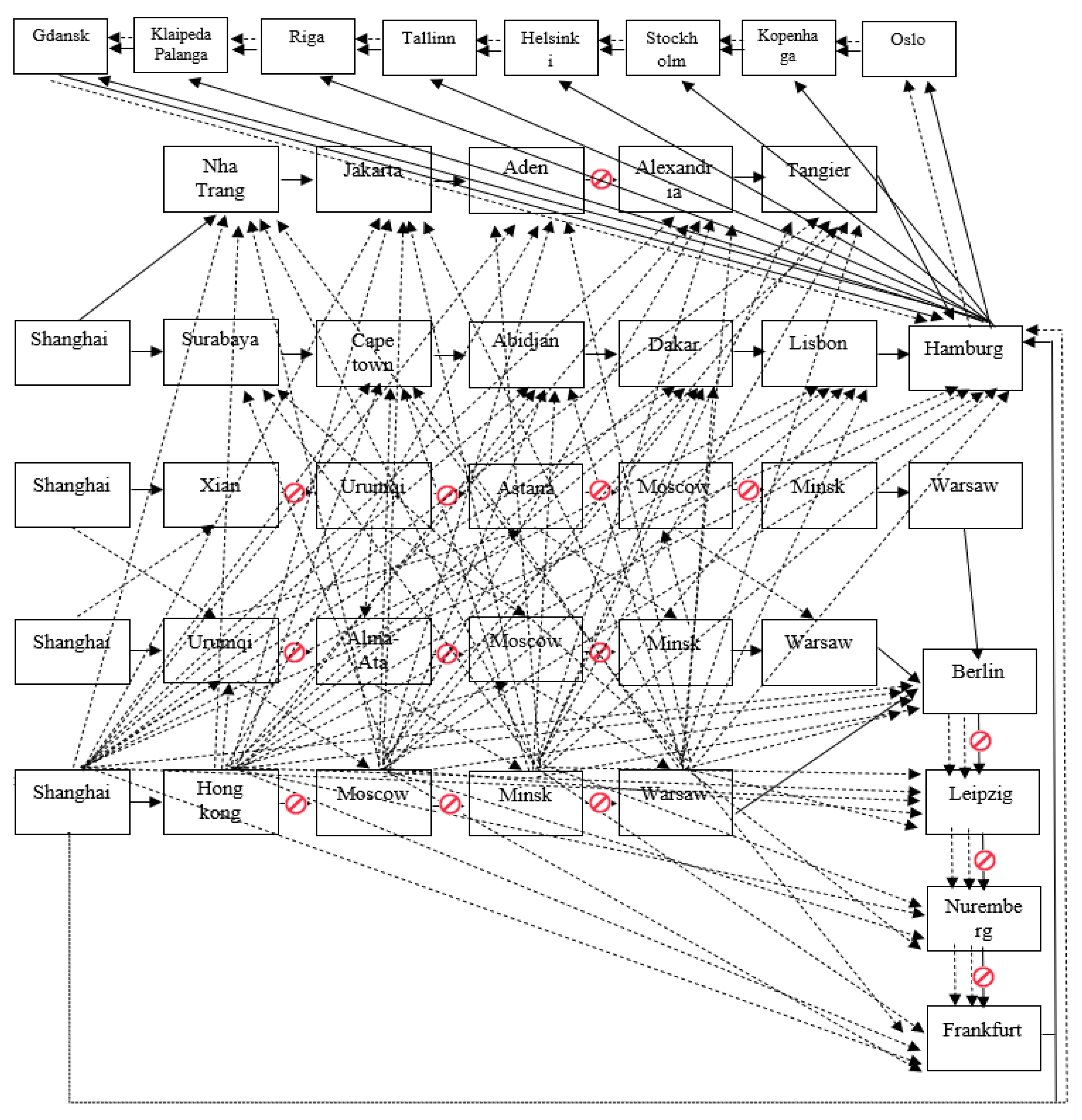

11]. It is clear that it is impossible to meet these requirements by transporting goods by one mode of transport. A transport system must be formed that would ensure the effective planning, organization, and management of the delivery of finished products from their production to the place of consumption. In essence, it is a transport logistics system that combines different modes of transport—air, rail, road, and water—as well as all elements of the supply chain (cargo storage, loading, unloading, transportation, etc.). In an organizational sense, all these elements are combined by a logistics center. The principal model of the cargo supply chain by transport is presented in

Figure 1.

Figure 1 shows that the logistics center plays a crucial role in the supply chain. It solves such important issues as creating optimal routes for transporting goods, determining the size of cargo lots, efficiently distributing vehicles and resources, and responding to unexpected changes in the transportation process (traffic conditions, orders, technical equipment failures, etc.) [

12,

13,

14,

15,

16,

17]. A logistics center must plan, organize, and manage its activities in such a way as to ensure both the quality of customer service and the achievement of the best possible commercial results [

18,

19,

20,

21]. This cannot be achieved using a single mode of transport, so a combined method of freight transport has been introduced. It is called multimodal transport (MT). Today, it is generally accepted that this is an essential method of increasing the efficiency of the transport system. Its essence can be briefly described as the carriage of goods by at least two different modes of transport (ECE, European Commission). One of the results of the globalization processes taking place in the world is the constantly increasing volumes of international transport, which is why the importance of international MT has increased. The United Nations Convention in 1980 provided the following definition: it is the carriage of goods by at least two different modes of transport under a contract of carriage, when the goods are coordinated and controlled by the modal transport operator and the consignor in one country, and the place of delivery of the goods is in another country. This shows that the carriage of goods by multimodal transport implies a large, complex system. In order to achieve its effective functioning, it must be seen and analyzed from two aspects—static and dynamic. The first is its structure, i.e., its constituent elements and their mutual relationships, and the second, the circumstances of the system’s functioning. The structure of the freight transport MT system must be formed in such a way that it includes all the elements necessary for effective functioning—all necessary vehicles, warehouse facilities, and infrastructure facilities (service, repair, etc.). The methodology is based on multi-criteria model calculations on total cost to be minimized, total carbon dioxide emission to be minimized, and the weighted average of product delivery time from factories to the logistics center to be minimized. On the other hand, a fundamental role in this system is played by the circumstances of its functioning, the essence of which is the solution of strategic and current tasks. This would be demand research and forecasting, and the resulting search for market development opportunities; selection of optimal routes for transporting goods; determination of the size of goods stocks; and vehicle loading, supplier management, effective distribution of transport resources, etc. The degree of utilization of the opportunities provided by multimodal transport for freight transport, i.e., delivery times and costs, largely depends on the solution of these issues. In this way, a complex optimization problem is formed, the solution of which would allow achieving the above-mentioned goals. Operating under such conditions, transport needs to meet both state and commercial operational requirements—to reduce CO

2 emissions, increase transportation safety, reduce road congestion, and also increase operational efficiency, i.e., to deliver cargo in the shortest time and at the lowest cost. All this implies the need to improve the performance of all links in the cargo transportation chain.

The aim of the article is to propose a methodology for multimodal cargo transportation that would allow cargo to be delivered in the shortest time and at minimal cost. The adequacy of the methodology is verified based on specific international shipments.

The structure of the paper is as follows.

Section 2 presents a literature review. In

Section 3, the multi-criteria model is presented. The procedure for solving the problem is proposed in

Section 4.

Section 5 presents the study analysis, and

Section 6—a discussion of the research results. The last part of the article is the Conclusions Section, in which we present, among other things, the prospects for further development of the model.

2. Literature Review

The importance of the transport sector for economic development is analyzed in many literature sources [

11,

22,

23,

24,

25,

26]. Its impact is examined both at the national and regional levels. Two main directions of such research can be conditionally distinguished. The first is aimed at analyzing the impact of the transport sector on the overall economic development of the country, and the second is aimed at analyzing its individual aspects. Other types of research can also be seen, for example, those aimed at the role of transport in the overall logistics chain. The first group of research can be attributed to the analysis of the impact of road freight transport development on regional economic development [

27]. It is examined in the context of the regulation of the transport of goods. The aim is to determine the impact of such regulation on the economic development of the region. Another study also examines the impact of the transport sector on regional development. It emphasizes that the transport system is an essential component of the development of any country [

22,

28]. As transportation distances increase, the role of transport connections grows [

29]. The transport sector promotes the overall development of the country, primarily economic and social; increases its competitiveness; improves international relations, etc. [

23]. The transport sector stands out from the rest due to its close links with almost all other sectors, since the price of every good or service includes transport costs. Therefore, its insufficient development can become an obstacle to the further development of these sectors [

30]. The second direction of the impact of the transport sector on the development of countries is the analysis of this impact on individual aspects of economic development. The main ones are CO

2 emissions, the link between transport structure and economic performance, transport and energy consumption, and others. The impact of the transport sector on CO

2 emissions is analyzed using the example of four countries: France, Italy, Germany, and England [

11]. It has been found that this impact can be regulated primarily through political measures. A significant portion of this type of research is devoted to examining the transport sector and its infrastructure [

22,

24,

25,

26]. An analysis of the links between transport infrastructure and the economic development results of 28 EU countries in 2000–2014 was carried out. A positive overall impact of infrastructure components on the economic growth of the countries was identified [

22].

The environmental impact of transport has increasingly been taken into account in decision-making processes. Some studies aim to present methodologies and computer programs that address these issues [

31,

32,

33].

Transport is an essential activity for the socio-economic development of countries. However, it is one of the most energy-intensive and polluting sectors, and its environmental impact is expected to increase in the future. As a result, there is a growing need for more efficient and sustainable management of this sector. Therefore, advanced decision-support tools are being developed to design balanced transportation systems [

34,

35,

36].

An integrated approach to modeling balanced sustainability risks in freight transport systems is presented in [

37].

The studies offer multi-criteria models for evaluating balanced freight transport systems [

31,

38].

Currently, the transport sector is facing increasing demands to reduce both environmental impact and freight transportation costs. Another emerging requirement, driven by end consumers, is environmental accountability—referred to as the ecological footprint—which implies that the emissions from each freight movement are allocated to the cargo itself [

39,

40].

A considerable number of studies have been dedicated to optimization in multimodal freight transport problems. Reviews of such studies are presented in [

41,

42].

Information requirements and the legal framework for coordinating multimodal transport systems are discussed in [

43]. The study [

44] applies multi-objective optimization for route selection in multimodal freight transport.

Dynamic multimodal freight routing using an optimization approach is presented in [

45]. A systematic literature review on the use of metaheuristics for optimizing multimodal transport is provided in [

46].

The modeling and planning of multimodal transport paths with regard to risk and energy efficiency using AND/OR graphs and discrete ant colony optimization is presented in [

47].

Another study analyzes the impact of investments in transport infrastructure on economic growth in developed countries at the city and regional levels. The authors of the article state that the issue is very complex, and therefore, limit themselves to summarizing the most important problems and the formulation of related policies, and presenting further directions for research [

23]. The results of a systematic analysis of empirical studies on the impact of transport infrastructure on productivity and economic growth are presented in another study [

24]. It is concluded that these results are contradictory for a variety of reasons. The author divides them all into three categories:

Different research contexts: The research period, geographical location, and the countries’ abilities to promote economic development;

Different research objects: Different economic sectors, types of transport infrastructure, and their quality level;

Different methods of quantitative assessment of the state of the phenomenon under study: In one case, correlation–regression analysis is used, but different econometric model evaluation methods are applied in the other functional specifications.

In addition to the above, there are literature sources that analyze the impact of the transport infrastructure of individual countries on economic growth. In one of them, the impact of transport infrastructure of 28 regions of the country on economic growth is analyzed at two levels (general and regional). The study was conducted in the period 1990–2017. A significant but different impact was determined depending on various factors that, in general, form the specific situation of the object under study [

25]. Another study of its kind analyzes the impact of India’s transport infrastructure on economic growth [

26]. The literature also examines the impact of transport sector development on energy consumption [

48]. This is an important research area, as it is characterized by high demand for it. The transport sector generates significant revenue from customs duties and is, therefore, an important source of increasing the country’s GDP. On the other hand, it is related to global energy security issues. The study is designed to examine the impact of air, rail, and maritime container transportation on energy demand, customs duties, and the country’s economic growth. The literature also examines the relationship between transport logistics, foreign direct investment, and the country’s economic growth [

49].

It has been established that transport and its logistics structure increase the attractiveness for foreign direct investment and contribute to the sustainable economic growth of the country. The reviewed studies were mostly based on correlation–regression analysis. Other analysis methods were also applied—time series, functional specifications, etc. The goal of logistics centers is to deliver cargo in the shortest time and at minimal cost.

3. Methodology of the Supply Optimization Problem

In this paper, the problem of constructing a schedule of transport operations from factories to a logistics center is considered. Thus, the model takes into account only the first phase of the process shown in

Figure 1—the transportation of goods from producers to the logistics center. The omission of the second phase—from the logistics center through clients to consumers—is due to the fact that the transportation of goods along these routes is strictly determined by client orders. It is, therefore, assumed that the distributor has no way of determining it other than that determined by these orders. Various modes of transportation can be used to carry out transport operations between manufacturers and the logistics center. The problem is analyzed for a finite time horizon consisting of

T weeks.

The analyzed problem can be presented as a dynamic multi-criteria decision model. It is assumed that the decision-maker—the manager responsible for planning transportation operations—is interested in achieving three basic goals:

Financial goal: Minimizing total delivery costs from factories to the logistics center.

Environmental goal: Minimizing the negative impact of supply chain operations on the environment.

High level of customer service goal: minimizing delivery times from factories to the logistics center.

Delivery costs include not only the cost of transportation itself, but also the cost of loading and unloading operations, as well as the cost of storing the product, both in factories and in the logistics center. To assess the environmental impact of transportation operations, the carbon dioxide emission is calculated, which depends on both the amount of product transported and the transportation modes used. Finally, the level of customer service is measured by the average delivery time.

In previous work [

50], an interactive procedure for solving the problem was used. This is a convenient tool when the decision-maker is unable to define his or her preferences precisely enough at the initial stage of the procedure, e.g., by defining weighting factors reflecting the importance he or she assigns to individual criteria. However, interactive procedures require the involvement of the decision-maker throughout the entire process of the final solution identification. He or she must analyze the proposed solutions one by one and determine whether they are satisfactory, and if not, indicate how they should be improved. This approach is typically used to address unique, strategic decisions. However, the problem considered in this paper is of a different nature. It is solved recurrently, and thus requires proposing a procedure that will automatically identify the solution that best fits the decision-maker’s preferences. Therefore, in this study, an alternative approach is presented, in which a solution is sought that is as close as possible to the ideal solution (defined by the best values of each criterion obtained in single-criterion optimization problems).

Limitations of studies based on the results presented in this paper illustrate that freight transportation in the context of the economic development system has influenced scholarly publication patterns considerably, while in China and European countries, the variations are manifested only slightly. The authors conclude that generalizations of freight transportation from China to European countries, reflecting issues of CO2 emissions, reduction in road load, and increase in transportation safety, are flawed. Research evaluation systems need to take logistics, supply chain management, and load transportation into account because of the crucial epistemic and social roles in the Chinese transport system.

In addition, the model presented here takes into account the possibility of delays in the delivery of the product to the logistics center, assuming that such delays trigger a contractual penalty. The cost of delayed deliveries is included in the total cost. It is also assumed that all deliveries must be finalized within the analyzed planning horizon. Thus, the delayed deliveries at the end of the last week must be zero.

It is assumed that for each week, the following data are available:

The number of units of product that can be produced in each factory;

Throughput of each transportation mode—The considerations for determining the number of units that can be shipped by every mode;

The number of units of the product that should be available in the logistics center.

Additionally, for each transportation mode and for each route between a particular factory and the logistics center, the following parameters are estimated:

Unit transportation costs;

Carbon dioxide emission key considerations for determining the number of units that can be shipped by each mode;

Transportation time, expressed by the number of weeks that elapse between shipping the product out of the factory and receiving it at the logistics center.

The inventory holding costs in factories and in logistics centers, as well as the delayed delivery cost, are assumed to be the same during the whole planning horizon.

The following notation is applied (subscripts t, i, and j throughout the paper stand for the quantities defined below):

t—week number (t = 0, 1, …, T);

i—factory number (i = 1, …, I);

j—transportation mode number (j = 1, …, J);

pi,t—the number of units that can be produced in factory i in week t;

Dt—demand in logistics unit by week t;

ei,j—unit carbon dioxide emission—emissions resulting from transporting one unit of product from factory i to the logistics center using the j-th mode of transport;

τi,j—the number of weeks it takes to transport the product from factory i to the logistics center using the j-th mode of transport;

hi—the cost of storing a unit of product in the warehouse of the i-th factory for a week;

H—the cost of storing a unit of product in the warehouse of the logistics center for a week;

P—delayed delivery cost—the cost incurred when the delivery of a unit of product is delayed by a week;

ci,j—unit transportation cost for factory i and transportation mode j;

Bj—throughput of transportation mode j—the maximal number of units that can be shipped in each week from all factories to the logistics center;

yi,t—production volume at factory i in week t;

xi,j,t—the volume of shipments from factory i to the logistics center in week t using the j-th mode of transport;

zi,t—the amount of product held in stock at factory i at the end of week t;

zi,0—the amount of product held in stock at factory i at the beginning of the first week;

Zt—amount of product held in stock in the logistics center at the end of week t;

Z0—the amount of product held in stock at the logistics center at the beginning of the first week;

St—the shortage of product units at the logistic center last week t.

Multi-criteria model is as follows:

Criteria:

- 2.

Total carbon dioxide emission (to be minimized):

- 3.

Weighted average of product delivery time from factories to the logistics center (to be minimized):

The denominator of the above formula represents the sum of demand for all periods, and as a result, is always positive. Thus, there is no danger that ATT could not be calculated due to the zero value of the denominator.

Constraints:

- 2.

Relations between the number of units of product stored in inventory at factories at the end of each week, the number of units stored in inventory at the end of the previous week, the production volume, and the number of units shipped:

- 3.

Relations between the number of units of product stored in inventory at the logistics center at the end of week t − 1, the amount of product delivered in week t, the demand, and the shortage of product in weeks t and t − 1:

- 4.

Constraints determining that the number of units of product stored in inventory at factories and in the logistics center should be zero at the end of the last week:

- 5.

Constraints determining the throughput of each transportation mode in each week:

- 6.

Constraints specifying the latest week in which the product can be shipped from factories, taking into account the time for transporting the product to the delivery center using the j-th transportation mode:

- 7.

Non-negativity constraints:

5. Study Analysis

To establish the applicability of the suggested approach, the problem of a European logistics company importing a product from two factories located in China to a logistics center located in Germany is considered. Deliveries can be made via four modes of transport: air (j = 1), sea (j = 2), rail (j = 3), and road (j = 4). A 40 ft container is used as the unit of transport. The delivery schedule is constructed for 10 weeks.

Based on the data obtained at the company, the following parameters of the model were assessed:

The specific calculation of a product should be produced in every factory for the next 10 weeks.

Demand for the product at the logistics center in each of the weeks in the analyzed time horizon.

Throughput of each transportation mode.

Unit transportation cost for each transportation mode.

The carbon dioxide emission resulting from transporting a unit of product between different locations in the context of a transportation model factory and logistics center (for each transportation mode).

Transportation time: the number of weeks needed to transport the product from each factory logistics unit (for each transportation mode).

Unit inventory holding cost in each factory.

Logistics center refers to the cost incurred for storing inventory.

Delayed delivery cost.

Multimodal transport is usually used to complete shipments from Asia to Europe. Parameters of our model were estimated considering the simultaneous use of different modes of transport, while taking into account the mode that plays a leading role in moving products in a logistics system, for the shipments from Asia to Europe.

The parameters of the model are as follows:

B1 = 50, B2 = 200, B3 = 200, and B4 = 100.

h1 = 12, h2 = 10, H = 30, P = 50.

First, the weights of the criteria were estimated. The decision-maker was asked to judge the criteria in pairs for their relative importance. Using the AHP method, the weights of the criteria were estimated (consistency ratio

CR = 0.062):

The problem was solved and the results were presented to the decision-maker: the identified solution and additionally the best (min) and the worst (max) values of the criteria determined in single-criterion problems (

Table 4). The row “Proposed solution” presents the solution of the linear programming problem with objective function (17), whereas the rows “min” and “max” present the best and the worst values of the criteria determined in single-objective problems.

As the decision-maker found the value of

TCF unsatisfactory, the relationship between the criteria was re-examined. As before, the AHP method was used, obtaining the following criteria weights (consistency ratio

CR = 0.007):

Analyzing the new solution (

Table 5), the decision-maker found it unsatisfactory because of the extreme increase in the value of the

total cost.

The relationship between the criteria was re-examined once more, and new values of weights were determined (consistency ratio

CR = 0.028):

The third solution (

Table 6) was finally accepted by the decision-maker.

Transportation schedule related to a specific solution in

Table 7.

The example shown above is relatively small (80 variables and 52 constraints). Our motivation was to show a simple example that would allow us to demonstrate in detail how the proposed procedure works. The small size means that the calculations could easily be performed in a spreadsheet. Using the proposed approach for a larger-size problem would, of course, require the use of professional optimization software.

6. Discussion of the Research Results

In the approach presented above, problem-solving begins with acquiring information from the decision-maker about the relationship between the criteria. Using it, the weights of the criteria are determined, which then makes it possible to determine the solution lying closest to the ideal solution, defined by the best values of each criterion obtained in single-criterion linear programming problems. However, after the results were presented, the decision-maker felt that the proposed solution did not fully meet his preferences. After adjusting the criteria weights, a new solution was obtained, which again was not accepted by the decision-maker due to the extreme increase in total cost. Finally, the third solution was accepted. It differs slightly from the first proposal: the total cost increased by 1.25%, while the total carbon dioxide emission decreased by 1.1% and the average transportation time decreased by 1.47%. At the same time, the analysis made the decision-maker realize that a significant reduction in carbon dioxide emissions or average transportation time requires a significant increase in cost.

According to the determined transportation schedule, 1000 units of product should be produced at each factory. Transportation from factory no. 1 should be shipped by sea. In turn, the product produced at factory no. 2 should be shipped by rail (300 units) and road transport (700 units).

The search for a solution even better suited to the decision-maker’s preferences would require his or her more intensive involvement, which is usually not possible in the case of decisions of an operational nature, such as those considered in the paper. Decisions of this type usually have to be made fairly quickly, making it impossible to analyze the relationship between the criteria for a long time. Nevertheless, if a decision-maker is willing to spend more time on this type of analysis, he or she can use methods based on an interactive approach, such as the one presented in [

33].

There are important to conclude this scientific article research based on the supply chain load transportation from Shanghai to Hamburg. Additional load transportation is organized from Hamburg to Gdansk by different transport modes. The loads from the origin city to the final destination are transported by multimodal transport: road, railroad, sea, and air. As demonstrated in open and closed ways, closed ways are not useful for transportation of loads due to different issues such as accidents, reparations, risks, weather conditions, piracy, geopolitics, natural disasters, sabotage, terrorist acts, and crimes (

Figure 2).

Suppose in the researched model we can provide a multimodal transport chain transporting loads from China to Europe, mainly having logistics distribution centers in Germany. To provide on-time loads and consume less fuel, and save money, it is important to provide a supply chain logistics model and put mathematical calculations based on the objective functions. While planning for transporting loads from far countries to Europe, the main objectives are to load the maximum possible loads, to consume minimum fuel and time, and save financial resources.

7. Conclusions

The importance of the transport sector of countries has increased significantly in recent years due to the fact that it accounts for a significant share of the annual gross domestic product (in some EU countries it reaches up to 11 percent); it serves almost all sectors of economic activity, since part of the price of each good or service is made up of transport costs; and it accounts for almost 30 percent of all energy consumed. The economic development of countries is accompanied by constantly growing production volumes, the development of economic relations between countries and regions caused by globalization processes, and the related growing scale of both domestic and international cargo transportation. Operating under such conditions, transport needs to meet both state and commercial operational requirements—to reduce CO2 emissions, increase transportation safety, reduce road congestion, and also increase operational efficiency, i.e., to deliver cargo in the shortest time and at the lowest cost. All this implies the need to improve the performance of all links in the cargo transportation chain. A key role in it is played by logistics centers, which are responsible for planning, organizing, and managing cargo transportation. These tasks are especially important for the first stage of the transportation chain-from the manufacturer to the logistics center. Meanwhile, their transportation from the center to the consumer is determined in orders, i.e., it is quite strictly regulated. In the first stage, on the contrary, it is possible to combine various modes of transport and routes.

Future research directions based on China’s high-speed economic, logistics, and supply chain growth in the near future have been challenged in the past decades. Transportation is the main area to promote sustainable development systems to expand domestic demand and supply. In the future, the growth of China will mainly focus on the multimodal load transportation indicator, which is freight turnover. The stability of logistics systems due to challenges in the transport market remains under globalization issues, affecting supply chain networks through the optimization of CO2 emissions, reduction in road load, increase in transport safety, and cargo transportation in the shortest time and at the lowest cost. For future research, this study can be extended by considering, along with transport infrastructure, multiplier factors in load transportation from China to Europe. Research implications studies should also be considered to assess the effectiveness of the sustainability of currently available tools, models, and methods to deeply understand the distributional impact in national and international transport logistics chains. To evaluate the performance of supply chain systems in China, it is important to analyze human, cultural, and social factors related to load transportation.

In this complex situation, multimodal transport takes on special importance, the essence of which is the transportation of cargo by at least two different modes of transport. By combining air, sea, rail, and road transport, logistics centers have the opportunity to create optimal transportation routes, effectively use vehicles and resources, promptly respond to unexpected changes in the transportation process, etc. This would allow achieving the main goal—to transport cargo in the shortest possible time and at the lowest cost.

The proposed methodology allows for a reduction of the total carbon dioxide emission by 1.1 percent, and the average duration of cargo transportation by 1.47 percent. On the other hand, the total cost of their delivery increases by 1.25 percent. This is inevitable if one wants to significantly reduce both carbon dioxide emissions into the air and the average transportation time.

The procedure presented here is flexible and allows other criteria to be taken into account as well. Unlike the methods previously presented in the literature, our procedure takes into account that the decision-maker is not quite sure what he or she would like to achieve. Therefore, we propose that after the criteria weights are determined using the AHP method and the solution is determined, he or she should have the opportunity to correct his or her assessments and see how this affects the determined solution. In the example presented, it turned out that the solution determined as the third was very close to the first. Thus, the decision-maker became convinced that reducing carbon emissions entails an extreme increase in transportation costs. Although the differences in the values of the criteria obtained for solutions no. 1 and no. 3 are small, in the long run, they can bring significant benefits to the company.

For models similar to the one presented in the paper, sensitivity analysis is often performed. Since in the proposed procedure the criteria weights are determined using the AHP method, the authors chose not to conduct such an analysis in a traditional way. Instead, a partially interactive approach was used, allowing the decision-maker to redefine the relationship between the criteria and then showing the consequences that such a change leads to. Thus, the decision-maker has the opportunity to observe how a change in his or her preferences affects the designated solution.

The example presented in the paper is relatively small in size (ten periods, two factories, and four types of transportation), which is a limitation of the study. In future research, the authors intend to analyze the possibility of using multi-criteria dynamic programming, which is an effective tool for solving more complex problems. This allows the logistics center employee—decision-maker to achieve all three essential cargo transportation goals—financial, ecological, and customer service quality. On the other hand, considering the fact that to achieve them, the logistics center must solve logistics operations planning and management tasks on a daily basis, continuing research should seek the simplest possible solutions, which would at the same time allow for reducing the subjectivity of the final decisions to a minimum. This would significantly increase the efficiency of cargo transportation.