Abstract

As China enters a high-quality development stage, balancing economic growth and environmental sustainability is essential. Can industrial intelligence reconcile these goals? Using theoretical modeling, this paper integrates production decisions, pollution emissions, and environmental regulations to construct a micro-level analytical framework incorporating technology choice and emission reduction investment. It theoretically explores how robot adoption affects firms’ emission reduction behaviors and empirically tests the model using data from Chinese listed companies (2011–2022). Results indicate that industrial robots significantly reduce firms’ pollution emission intensity through productivity boost, technological progress, and emission reduction effects. Additionally, heterogeneity analyses show that robots have stronger pollution-reducing impacts in heavily polluting industries, state-owned enterprises, and regions with stringent environmental regulations. Therefore, policymakers should encourage robot adoption based on local contexts, formulate differentiated environmental regulations, and implement targeted strategies to maximize robots’ emission reduction potential. Accelerating green and intelligent transformation of enterprises will further align ecological protection with sustainable economic and social development.

1. Introduction

China’s pursuit of high-quality development necessitates reconciling economic growth with ecological sustainability, particularly amid tightening resource constraints and escalating environmental pressures [1]. The imperative to mitigate industrial pollution has emerged as a strategic priority for achieving green transformation, as emphasized in national policy frameworks such as the 14th Five-Year Plan for Green Industrial Development and the 2035 Beautiful China Initiative [2,3]. Recent advancements in industrial robotics present a transformative opportunity to address these challenges [4,5,6]. Empirical studies suggest that robotic adoption enhances production efficiency while concurrently reducing energy intensity and emissions through technological innovation [7,8,9]. This dual capacity aligns with China’s carbon peaking and carbon neutrality goals, offering pathways to decouple economic expansion from environmental degradation. Consequently, deciphering the mechanistic pathways through which robotic integration governs eco-production efficiency constitutes a strategic imperative for Chinese enterprises.

Scholarly investigations have increasingly examined the environmental implications of industrial robot deployment across multi-dimensional analyses spanning macroeconomic, sectoral, and firm-level perspectives. At the macroeconomic scale, studies emphasize industrial robots’ capacity to drive persistent carbon mitigation through systemic productivity gains and technological spillovers, potentially accelerating low-carbon economic transitions [10,11,12]. Sectoral analyses particularly highlight manufacturing industries’ pollution abatement achievements through robotic automation in production processes and supply chain optimization [13]. Firm-level evidence reveals dual mechanisms where robotic adoption not only reduces focal enterprises’ emissions but also generates spillover effects across industrial networks through cleaner production paradigms [14]. However, divergent perspectives challenge this technological optimism. The productivity rebound hypothesis posits that efficiency improvements from automation may paradoxically elevate aggregate pollution through output expansion and energy consumption escalation [15]. Contrarily, nonlinear analyses propose an equilibrium threshold effect, suggesting initial emission increases during early-stage robot adoption followed by gradual mitigation as intelligent manufacturing systems mature [16]. This theoretical pluralism underscores ongoing academic debates regarding the environmental efficacy of robotics, reflecting complex interactions between technological advancement, production scaling effects, and institutional contexts in shaping sustainability outcomes. The unresolved discourse necessitates further empirical validation to reconcile these competing frameworks.

This study develops a micro-analytical framework integrating production strategies, environmental governance, and regulatory dynamics to explore how industrial robot adoption influences corporate emission reduction mechanisms. Leveraging micro-level datasets from Chinese listed firms, the research employs empirical validation to assess robotic applications’ environmental impacts. The findings demonstrate that robotic integration significantly mitigates pollutant emission intensity through three pathways: technological advancement in production processes, workforce skill enhancement, and innovation in emission control systems. Heterogeneity analysis reveals differential impacts across enterprise ownership structures, industrial pollution categories, and regional regulatory stringency. These insights highlight the dual role of industrial automation in advancing economic efficiency and ecological sustainability, providing critical implications for policymakers to formulate targeted strategies that balance technological modernization with environmental stewardship in industrial transformation initiatives.

This study makes three key contributions to the emerging discourse on intelligent manufacturing and environmental sustainability. First, it advances a comprehensive theoretical framework integrating robotic automation with production decision-making and environmental governance mechanisms, addressing the theoretical fragmentation in existing literature that predominantly relies on empirical correlations. By modeling the interplay between industrial robot adoption, energy consumption patterns, and emission control strategies, this research establishes a foundation for understanding the green transformation mechanisms in industrial automation. Second, it innovates measurement methodology by employing textual analysis techniques to quantify enterprise-level robotic adoption intensity from corporate disclosures, overcoming the limitations of conventional industry-aggregated robot stock metrics that obscure firm-specific operational dynamics [17]. The proposed approach enables precise tracking of automation evolution across diverse market entities beyond manufacturing sectors. Third, the investigation bridges critical data gaps through constructing original emission intensity indicators for Chinese listed companies, circumventing the temporal and sectoral constraints inherent in outdated industrial databases. This methodological advancement facilitates contemporary micro-level analysis of intelligent technologies’ environmental impacts, offering policymakers actionable insights for balancing technological advancement with ecological preservation in developing economies.

2. Related Work

Research closely related to this article mainly focuses on two areas: first, literature on robot applications and green performance; second, research on robot applications and pollution emissions.

2.1. Robot Applications and Green Performance

Contemporary scholarship increasingly interrogates the nexus between industrial robotic integration and environmental performance, yielding multidimensional yet fragmented insights. Macroeconomic investigations, exemplified by Qian et al. (2023), establish robotics’ capacity to enhance green development via productivity optimization and human capital advancement [18]. This perspective is reinforced by Rong et al. (2023), whose econometric analyses confirm positive automation-energy efficiency linkages within sustainable production systems [19]. Provincial-scale longitudinal studies, typified by Yin and Zeng (2023), further validate robotics’ role in reducing regional industrial energy intensity [20]. However, Zhao et al. (2022) challenge linear progress assumptions by identifying U-shaped automation-productivity relationships, suggesting complex technological assimilation thresholds [21]. Micro-enterprise studies provide complementary granular insights. Gan et al. (2022) demonstrate how robotic applications stimulate corporate green innovation through labor restructuring and cost-reduction pathways [22], while Liu et al. (2022) utilize enterprise surveys to establish technological progress as the primary mechanism for efficiency gains [23]. These investigations collectively reveal significant outcome heterogeneity across ownership structures and industrial contexts. Methodologically, prevailing approaches exhibit notable constraints. While econometric modeling dominates the field [19,21], the underutilization of mixed-methods designs—particularly process-tracing and comparative case studies—limits exploration of contextual mediating variables. This methodological gap impedes comprehensive understanding of implementation variances across state-owned versus private enterprises.

However, theoretical gaps persist in three domains: insufficient integration of circular economy principles into automation frameworks, inadequate attention to spatial spillover effects in robot diffusion models, and limited examination of rebound effects in material throughput. Crucially, few studies reconcile the employment-ecology tradeoffs inherent in developing economies’ automation transitions. Critical scholarship cautions against technological determinism, emphasizing how institutional ecosystems fundamentally condition environmental outcomes. This contingent perspective, while acknowledged in synthesis studies, remains inadequately operationalized in empirical research designs. This study focuses specifically on robot adoption—defined as the physical deployment of automated machinery for production tasks—distinct from broader artificial intelligence (AI) systems that encompass algorithmic decision-making without mechanical actuators. While robots may incorporate AI for operational optimization, they constitute a physical subset of smart manufacturing ecosystems. Smart manufacturing represents the comprehensive digitization of production systems, where robotic automation serves as one implementation layer alongside IoT connectivity and data analytics.

2.2. Robot Applications and Pollution Emissions

Existing scholarship predominantly examines robotic applications’ environmental impacts through multiscale analytical frameworks. Macroeconomic research utilizing International Federation of Robotics (IFR) datasets reveals substantial regional heterogeneity in pollution outcomes. Luan et al. (2022) demonstrated automation’s potential to inadvertently exacerbate atmospheric pollutants through production-scale expansion effects [15], while Yu et al. (2022) identified countervailing mitigation mechanisms via municipal-level energy efficiency improvements and green technological advancement [24]. This empirical dichotomy highlights fundamental tensions between productivity gains and ecological externalities. Cross-national comparative approaches—exemplified by Yang et al.’s (2023) spatial econometric modeling—further challenge linear assumptions by establishing U-shaped automation-emission relationships governed by technological absorption thresholds [16]. The academic discourse remains divided, with some scholars emphasizing the rebound effects of productivity-driven energy consumption, while others highlight automation’s potential in optimizing production processes and enabling cleaner technologies. These contrasting viewpoints necessitate deeper investigation into contextual factors mediating robotics’ environmental impacts, particularly concerning enterprise-level operational dynamics and regional policy frameworks.

Emerging scholarship has progressively shifted focus toward micro-level analyses of industrial robot adoption’s environmental implications. Pioneering studies in this domain frequently employ enterprise-level datasets derived from China’s industrial enterprises, integrating pollution emission records to construct comprehensive firm-specific environmental profiles. Drawing upon Acemoglu & Restrepo’s (2020) analytical framework [17], researchers have developed innovative methodologies to disaggregate industry-wide robotic penetration metrics into enterprise-level indicators, enabling precise evaluation of automation’s ecological impacts. Empirical investigations by Lee et al. (2022) reveal significant emission intensity reductions through robotic implementation, particularly emphasizing the mediating roles of human capital optimization and technological innovation [13]. Subsequent analyses by Xu et al. (2023) further identify efficiency-driven pathways, demonstrating how robotic integration alleviates financial constraints while enhancing production sustainability [25]. Notably, Zi et al. (2025) expand this discourse through longitudinal analysis of listed manufacturing firms, establishing robust correlations between robotic deployment and emission intensity reduction via synergistic technological and organizational innovations [26]. Alternative methodological approaches employing import-based robotic metrics corroborate these findings, revealing multifaceted benefits including energy efficiency improvements and proactive environmental investment strategies [27,28,29]. The collective evidence underscores industrial automation’s dual capacity to enhance economic productivity while addressing ecological externalities. These micro-level insights complement existing macroeconomic perspectives, offering nuanced understanding of enterprise-level transformation mechanisms. The convergence of findings across methodological approaches substantiates robotic adoption as a viable strategy for achieving sustainable manufacturing transitions, informing policy formulation for technology-driven ecological modernization. Future research directions might explore sector-specific implementation thresholds and regional regulatory synergies to optimize environmental outcomes.

Contemporary scholarship examining robotic technologies’ ecological impacts remains predominantly constrained to macroeconomic frameworks. Micro-level investigations utilizing outdated industrial databases fail to capture automation’s evolving emission reduction effects, limiting practical relevance. Conventional robot penetration metrics further inadequately reflect enterprise-scale implementation heterogeneity. Addressing these methodological constraints, this research pioneers a novel analytical approach through two substantive innovations: First, we construct an original dataset integrating multidimensional robotic stock indicators with granular pollution emission records for China’s manufacturing listed enterprises. Second, we develop refined quantification protocols employing computational textual analysis of corporate disclosures to precisely measure operational integration beyond nominal adoption. These advancements establish an empirical foundation for reevaluating how robotic integration mitigates ecological footprints across heterogeneous production contexts. Our methodology enables unprecedented assessment of context-specific sustainability outcomes, accounting for enterprise-level governance capabilities and resource configurations. The framework significantly advances understanding of contingent implementation pathways, informing strategic resource deployment aligned with ecological modernization objectives under varying contextual contingencies.

3. Theoretical Hypothesis

3.1. Consumer and Producer Decision-Making

Drawing on Shapiro and Walker [30], this study assumes a market with heterogeneous products and representative consumers exhibiting constant elasticity of substitution preferences. The consumer utility function is modeled using a CES specification, expressed as the following:

Equation (1) is the utility of the representative consumer, where ) represents the consumer’s consumption of commodity i, and represents the commodity set of various products in the market. > 1) represents the elasticity of substitution between two products. According to the principle of maximizing the consumer effect, the consumer demand function for commodity i is as follows:

where is the price of commodity i and is the total income of consumers. Assume that the consumer has no savings and spends all of their income on consumption. P is the market price index, which can be expressed as follows:

Referring to the practice of Huang et al. [28], it is assumed that enterprises use labor, robots, and energy as production factors and have heterogeneous productivity. At this point, the production function of the enterprise is the following:

where is the productivity of the enterprise, represents the energy input in the enterprise’s production, and and are the use of labor and robots, respectively. As can be seen from formula (4), robots and labor can be substituted for each other, and b is used to measure the relative productivity of robots and labor. According to the research of Acemoglu and Restrepo (2020) [17], robots can bring about technological advancements in production, so b > 1.

3.2. Equilibrium Analysis

To simplify the model, this paper assumes that there is a complete substitution between labor and robots. When firms use labor for production, the output is given by ,where represents the productivity of firms choosing labor-based production. When firms use robots for production, the output becomes , with denoting the productivity of robot-based production.

According to Equation (4), in accordance with the principle of maximizing the producer’s profit, when the enterprise uses labor and energy for production, the usage of energy and labor is, respectively, as follows:

Similarly, when an enterprise uses robots and energy for production, its energy and labor usage are, respectively, as follows:

3.3. Research Hypotheses

3.3.1. Productivity Boost Effect

Based on Equations (5) and (7), the energy consumption intensity of the enterprise when using the labor-energy combination for production and robot-energy for production can be calculated respectively:

When the enterprise uses labor for production, the energy consumption intensity is as follows:

When enterprises use labor for production, the intensity of energy consumption is as follows:

where, , and denote the prices of labor, robots, and energy, respectively, which are assumed to be exogenous variables in this paper. From Equations (9) and (10), it can be seen that enterprises can reduce the intensity of energy consumption by increasing labor productivity and thereby reduce the intensity of pollutant emissions. Given the advancements in production technology brought about by the application of robots [17,27,31], therefore, Thus, Hypothesis 1 can be derived:

Hypothesis 1:

The application of robots reduces the intensity of pollution emissions in enterprises through productivity improvements.

3.3.2. Technological Progress Effect

By comparing Equations (9) and (10) simultaneously, we can obtain . According to the study by Huang et al. (2022) [28], the marginal cost of using robots is lower than the marginal cost of hiring labor in the production process. Therefore, . So, it can be concluded that > 1: that is, when enterprises use robots instead of labor for production, due to the increase in productivity resulting from the replacement of humans by machines, the energy consumption intensity of enterprises decreases. At the same time, the intensity of pollutant emissions is closely related to the intensity of energy consumption. Therefore, as the energy consumption of enterprises decreases, the pollution emission intensity of enterprises will also decrease accordingly. Thus, this paper proposes the hypothesis:

Hypothesis 2:

The application of industrial robots reduces the intensity of pollutant emissions of enterprises through the effect of technological progress.

3.3.3. Emission Reduction Effect

Enterprises emit pollutants when they use energy for production. Referring to the practice of Lin et al. [32], it is assumed that the emissions per unit of energy consumption produced by the enterprise is . Therefore, when the enterprise uses labor and robots for production, the pollution emissions are, respectively, as follows:

Here, denotes the emission level per unit of energy consumption, which is used to reflect the firm’s emission reduction technology. According to the research of Forslid et al. (2018) [33], an enterprise will introduce emission reduction equipment based on their production conditions. The higher the productivity of a firm, the higher its marginal output. Therefore, the unit cost of introducing emission reduction equipment is lower, and it has a greater incentive to invest in such equipment. Thus, in this paper, the enterprise emission reduction technology is reconfigured as follows: , where is the emission reduction effect of the investment in emission reduction equipment. Due to the existence of environmental regulations, enterprises need to pay a cost per unit of pollutant . Therefore, when the enterprise uses labor for production, its total cost function is as follows:

Among them, When enterprises use robots instead of labor for production, the total cost function is as follows:

Among them, additional installation and maintenance costs are required for enterprises to use robots for production.

According to the enterprise marginal cost pricing method, the product pricing for enterprises using labor and robots for production is as follows:

Among them, . Combining Equations (4), (13) and (14), the profits of the enterprise when using labor and robots for production can be obtained as follows:

Among them, = . According to the first-order condition for maximizing corporate profits, the optimal emission reduction investments of the enterprise can be obtained as follows:

Among them, and are, respectively, the investment in emission reduction equipment when enterprises use labor and robots for production. Because , That is to say, when companies use robots instead of labor for production, they increase investment in emission reduction equipment.

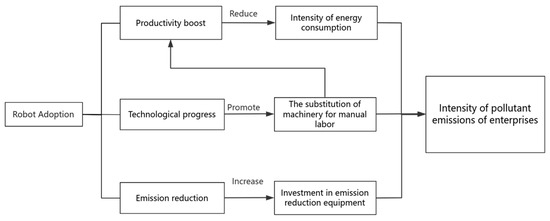

Furthermore, from the equation we can deduce that after firms use robots, . This means that by substituting robots for labor, firms will further enhance their emission reduction technology, thereby reducing the emissions per unit of energy consumption. Therefore, Hypothesis 3 is proposed in this paper, and the theoretical framework is shown in Figure 1.

Figure 1.

The key pathways enterprise robot adoption influences the intensity of pollution emission.

Hypothesis 3:

The application of robots will reduce the intensity of corporate pollution emissions through the effect of emission reduction technology.

4. Research Methods and Data

4.1. Model Design

Based on the aforementioned theoretical analysis, this paper designs a benchmark regression model to explore the pollution reduction effect of industrial robot applications:

Among them, the subscripts f, i, p, and t stand for enterprise, industry, province, and year, respectively. indicates the annual pollutant emission intensity at the enterprise level, measured by dividing the enterprise’s pollutant emissions of that year by its total output value; is the core explanatory variable, representing the logarithm of industrial robot stock at the enterprise level; is a control variable at the enterprise level; is the enterprise fixed effect, used to control individual heterogeneous information that does not change over time. We also introduced industry-year and provincial-year fixed effects to eliminate the influence of all other unobserved time-varying characteristics in the provinces where the industry and the enterprise are located; is the error term, which covers all other unobserved time-varying factors that may affect the intensity of pollution emissions from the enterprise.

4.2. Variable Description

Explained Variable: Enterprise Pollutant Emission Intensity. Given the absence of publicly disclosed pollutant emission data by listed companies, this study employs the methodology outlined by Duodu and Mpuure (2023) to quantify emission intensity [34]. Python-based text mining techniques are applied to extract pollutant emission metrics—including chemical oxygen demand (COD), ammonia nitrogen (NH), sulfur dioxide (SO2), and nitrogen oxides (NOX)—from corporate disclosures such as sustainability reports and environmental disclosures. To account for firm-scale heterogeneity, emissions are normalized by total corporate assets, yielding a standardized measure of pollutant emission intensity per unit of asset value. This approach aligns with established practices in environmental economics, ensuring comparability across firms while addressing data availability constraints.

The core explanatory variable in this study is the logarithm of firm-level industrial robot adoption. While existing research predominantly relies on industry-aggregated robot stock data from the International Federation of Robotics (IFR), such macro-level metrics inadequately capture enterprise-specific automation patterns. Drawing upon Zhu et al.’s text-mining methodology [35], this paper constructs listed firms’ robotic adoption indicators through semantic analysis of annual reports. Specifically, Python 3.8.20-based keyword extraction quantifies robotic technology references in corporate disclosures, followed by manual verification to ensure conceptual relevance and measurement accuracy. This approach enables precise micro-level operationalization of industrial automation intensity while addressing data granularity limitations inherent in conventional robotics statistics.

4.3. Data Description

Drawing on Wang and Dong’s (2016) historical analysis of China’s robotic adoption trajectory [36], this study examines listed firms from 2011 to 2022, a period marking accelerated industrial automation. The 2011–2022 timeframe captures China’s critical industrial automation acceleration phase, initiated by the “Smart Manufacturing Development Plan (2011–2015)” and maturing during the “Made in China 2025” implementation. This period encompasses the full automation lifecycle—from initial robot deployment to measurable environmental outcomes—while controlling for exogenous structural disruptions through our fixed-effects design. Firm-level data are sourced from the CSMAR database, supplemented by annual reports extracted from Shanghai/Shenzhen stock exchanges and patent records from the China Patent Database. To ensure robustness, continuous variables undergo winsorization to mitigate outlier distortions. The methodological framework integrates multi-source datasets to capture technological diffusion patterns critical for assessing automation’s ecological impacts. This temporal and spatial alignment enables precise evaluation of industrial robots’ role in sustainable technological transitions, addressing data limitations in prior macro-level studies. Variable definitions and descriptive statistics are systematically detailed in Table 1 and Table 2.

Table 1.

Enterprise variables description.

Table 2.

Descriptive statistics of the main variables.

5. Analysis of Empirical Results

5.1. Baseline Regression Results

Table 3 presents the results of the baseline regression. Among them, columns (1) and (2) are for the regression of gas pollutant emission intensity, and columns (3) and (4) are for the regression of water pollutant emission intensity. The regression results showed that the Robot coefficient was significantly negative, indicating that the application of industrial robots significantly reduced the emission intensity of air and water pollutants in enterprises, that is, the higher the degree of robot application in enterprises, the better the pollution reduction effect of enterprises. The reason for this is that robots have replaced inefficient manual operations through precise production process control and data-driven decision optimization, achieving technological leaps and reducing energy consumption. Secondly, smart manufacturing systems have significantly improved energy efficiency, with observations showing a decrease in energy consumption per unit of output value for companies applying robots. Finally, the intelligent production system driven by robots has forced enterprises to increase investment in environmental protection equipment, such as the increase in the purchase of sulfur dioxide purification devices by enterprises, and the strengthening of end-of-pipe treatment capabilities has formed the effect of emission reduction technology. As a result, the regression results in Table 3 demonstrate that the application of robots can significantly reduce the intensity of pollution emissions from enterprises. These results confirm H1: Robot adoption significantly reduces emission intensity.

Table 3.

Effects of robot application on enterprise pollution emission intensity.

5.2. Endogeneity Test

To address potential endogeneity concerns arising from omitted variables and bidirectional causality between robot adoption and emission reduction effects, this study employs instrumental variable (IV) approaches following established methodologies. Drawing upon Acemoglu & Restrepo’s framework [37], we construct a Bartik-type instrumental variable (IV1) by leveraging regional-industry variations in robot stock accumulation, specifically utilizing the lagged average robot stock among peer enterprises within the same industry-region cluster. Furthermore, adopting Fang & Liu’s identification strategy [38], we develop a second instrumental variable (IV2) based on the cubic deviation between firm-level robot stock and the industry-city average, excluding the focal enterprise. These IV specifications effectively mitigate measurement errors and simultaneity bias while satisfying relevance and exclusion restrictions. The two-stage least squares (2SLS) estimations are presented in Table 4.

Table 4.

Instrumental variable regression.

The instrumental variables regression results are presented in Table 4. Panel A employs the first instrumental variable (IV1), while Panel B utilizes the second instrumental variable (IV2). Both panels consistently demonstrate that the coefficient for industrial robot adoption remains statistically negative and significant after addressing potential endogeneity concerns, confirming the robustness of the pollution-reduction effect. To validate the instrumental variable approach, comprehensive diagnostic tests were conducted. The first-stage F-statistics substantially exceeded the conventional threshold, satisfying the relevance criterion. Additionally, the Lagrange Multiplier (LM) tests rejected the under-identification hypothesis at the 1% significance level, ensuring the exclusion restriction holds. These results collectively reinforce the conclusion that industrial robot implementation effectively reduces corporate pollution emission intensity. The empirical framework passed the necessary diagnostic checks, affirming the reliability of the causal inference drawn from the instrumental variables analysis.

5.3. Robustness Test

5.3.1. Change the Measurement Method for Industrial Robots

To ensure robustness, we re-examined our model by replacing the primary explanatory variable (enterprise robot stock) with annual robot installations, given China’s exponential adoption of automation technologies. As presented in Table 5, the coefficient for robot deployment remains statistically negative at the 1% level, confirming the stability of our baseline findings regarding industrial robots’ pollution mitigation effects.

Table 5.

Robustness test: Change the measurement method of industrial robots.

5.3.2. Change the Measurement Method of Pollutant Emissions

To validate the robustness of our findings, we re-examined the model using environmental levies as alternative proxies for corporate pollution emissions. Specifically, we substituted the dependent variable with total emission charges (EFF), air pollutant fees (EFF_Air), water pollutant fees (EFF_Water), and solid waste fees (EFF_Solid), which reflect regulatory compliance costs tied to emission volumes. As shown in Table 6, all robot adoption coefficients remain statistically negative, corroborating the baseline conclusion that automation reduces pollution externalities. This consistency across multiple fee-based metrics confirms that industrial robots systematically lower firms’ environmental liabilities, irrespective of pollutant type.

Table 6.

Robustness test: Replacing the core variable.

5.3.3. Replace the Sample

To address potential sample heterogeneity, we conduct robustness analyses by refining the sample composition and extending the temporal scope (Table 7). Panel A restricts the sample to manufacturing firms, as this sector dominates China’s industrial pollution emissions. The results reveal significantly larger negative coefficients for robot adoption compared to the baseline estimates, underscoring manufacturing’s central role in pollution generation and the amplified environmental benefits of automation in this sector. Panel B extends the sample period to 2007–2020 to account for China’s post-2007 industrial output surge and the lagged diffusion of robotics. While the robot coefficients remain statistically negative, their magnitude slightly decreases relative to the baseline (2011–2020). This attenuation likely reflects the early-stage, limited adoption of industrial robots prior to 2010, when automation technologies were less mature and their pollution-mitigating effects were less pronounced. Post-2010, the accelerated deployment of robots aligns with enhanced emission reduction efficiency, as smart manufacturing systems achieved greater operational and energy optimization. These robustness checks affirm the reliability of our core findings across heterogeneous samples and temporal contexts.

Table 7.

Robustness test: Sample replacement regression.

6. Heterogeneity Analysis

6.1. Quality of Regional Environmental Regulation Intensity

The pollution reduction effects of industrial robot adoption may exhibit regional heterogeneity due to variations in environmental regulation stringency. To examine this, we construct an environmental regulation intensity index at the provincial level and categorize enterprises into high-regulation (regulation = 1) and low-regulation (regulation = 0) groups based on the median value. An interaction term (Robot × Reg) is introduced by multiplying robot stock with the regulation dummy variable. Regression results (Table 8 Panel A) reveal a statistically significant negative coefficient for Robot × Reg, indicating that robot adoption in high-regulation regions achieves more pronounced emission reductions compared to low-regulation areas. This aligns with the hypothesis that stringent environmental policies amplify the pollution-mitigation potential of robots. Mechanistically, elevated regulatory pressure raises pollution costs, incentivizing firms to adopt robots for cleaner production. Such adoption leverages robots’ dual advantages: technological upgrading (e.g., precision manufacturing and energy efficiency optimization) and green innovation (e.g., process redesign to align with sustainability goals). These effects collectively enhance compliance with environmental standards while reducing emission intensity, particularly in regions prioritizing ecological governance.

Table 8.

Heterogeneity of enterprise property rights.

6.2. Heterogeneity in Pollution Levels

To assess industry-specific variations in pollution mitigation effects, we categorize enterprises into high-pollution (heavy = 1) and low-pollution (heavy = 0) groups based on emission profiles. An interaction term (Robot × Heavy) is constructed by combining robot stock with the pollution-intensity dummy variable. Regression results (Panel B, Table 8) demonstrate significantly positive coefficients for Robot × Heavy, revealing that robot adoption in high-pollution industries achieves greater emission reductions than in low-pollution sectors. This disparity likely stems from dual institutional and technological drivers. Under China’s “dual carbon” policy framework, high-pollution enterprises face intensified regulatory pressures, compelling them to adopt robots to replace energy-intensive processes and optimize production efficiency. Simultaneously, robots enable precision control over manufacturing workflows, reducing energy waste and enhancing end-of-pipe treatment capacity. The integration of automation fosters economies of scale in pollution control infrastructure, amplifying emission-abatement returns. These findings highlight the dual role of industrial robots: as a compliance tool for meeting stringent environmental mandates and as a catalyst for green technological transitions, particularly in pollution-intensive sectors where marginal gains from automation are magnified.

6.3. Heterogeneity of Property Rights

To examine ownership-driven disparities in pollution mitigation, we classify enterprises into state-owned (SOE) and private entities, constructing an interaction term (Robot × SOE) by combining robot stock with ownership dummies. Regression results (Panel C, Table 8) show significantly negative coefficients for Robot × SOE, indicating stronger emission-abatement effects in SOEs compared to private firms. This divergence stems from institutional and operational distinctions. SOEs exhibit higher compliance with administrative mandates, systematically phasing out obsolete technologies and prioritizing investments in pollution-control infrastructure. Under China’s “dual carbon” policy framework, SOEs face amplified pressure to align with national sustainability agendas, driving proactive adoption of robots for energy-efficient production retrofits and end-of-pipe treatment optimization. Additionally, SOEs benefit from preferential access to policy incentives (e.g., subsidies for green technology adoption), enabling deeper integration of automation into environmental governance systems. In contrast, private firms, constrained by capital and regulatory flexibility gaps, exhibit slower adoption rates and fragmented implementation. These findings underscore how ownership structures mediate the environmental efficacy of automation, with SOEs leveraging institutional advantages to amplify robots’ role in achieving pollution-intensity reduction targets. The results align with the documented synergy between state-led governance and technological adoption in advancing industrial sustainability.

7. Impact Mechanism Testing

To investigate the pollution mitigation mechanisms of industrial robot adoption, this study employs a three-channel analytical framework encompassing technological advancement, energy efficiency optimization, and emission control innovation. First, robotic automation drives production process modernization through labor substitution, generating technological spillovers that enhance total factor productivity. As evidenced in Columns (1)–(2) of Table 9, the positive coefficients for productivity metrics (TFP_LP and TFP_OP) confirm that robot implementation significantly improves operational efficiency, thereby reducing emission intensity per unit output. The productivity boost effect manifests through automotive welding implementations exemplified by FAW-Volkswagen’s standardized robotic cells, where accelerated production cycles reduce energy intensity per unit—a pattern aligning with our total factor productivity findings. This validates Hypothesis 1 regarding productivity-driven pollution abatement.

Table 9.

Mechanism analysis.

Second, the energy transition mechanism is examined through inverse energy intensity indicators. Robotic systems optimize energy utilization patterns by minimizing coal and gas consumption per production unit, as demonstrated by negative coefficients for Energy_Coal and Energy_Gas in Columns (3)–(4). The reduced energy intensity directly correlates with lower emission outputs, substantiating Hypothesis 2 about energy conservation effects. The technological progress pathway materializes in precision textile applications, notably Youngor Group’s automated dyeing systems, where minimized chemical surplus achieves dual emission and resource efficiency gains—consistent with our demonstrated energy intensity reductions.

Third, the analysis evaluates emission control innovations using environmental equipment investments (Env_inv) and SO2 removal efficiency (SO2_remove). Columns (5)–(6) reveal that robot-adopting firms exhibit significantly higher pollution control expenditures and treatment effectiveness, aligning with Forslid et al.’s (2018) proposition about productivity-driven environmental investments [33]. Dedicated emission control operations emerge through hermetic chemical handling systems, as implemented by Wanhua Chemical, where sealed robotic transfer mechanisms substantially contain volatile organic compounds—corroborating our environmental investment metrics, while reinforcing the integrated nature of these sustainable production mechanisms. This demonstrates how automation enables technological leapfrogging in end-of-pipe treatment systems, confirming Hypothesis 3′s emission reduction technology effect.

These interconnected pathways illustrate how robotic integration facilitates sustainable production practices through synergistic operational upgrades, energy system optimization, and proactive environmental governance. The findings underscore intelligent manufacturing’s dual capacity to enhance economic efficiency while addressing ecological externalities.

8. Result and Discussion

This study investigates the environmental implications of industrial robot adoption in China’s manufacturing sector through a dual analytical framework integrating theoretical modeling and empirical validation. By constructing a heterogeneous enterprise model incorporating robotic automation, labor, and energy inputs, the research systematically examines how intelligent manufacturing technologies influence corporate pollution emission intensity. Utilizing textual analysis of listed firms’ disclosures from 2011–2022 to quantify robotic adoption, the empirical analysis reveals three critical pathways through which robotic adoption reduces emission intensity: operational efficiency gains, energy-saving technological upgrades, and innovation in pollution control systems. The findings demonstrate statistically significant emission reductions across air and water pollutants, with robustness confirmed through instrumental variable approaches and multiple sensitivity tests. Heterogeneity analysis highlights enhanced mitigation outcomes in state-owned enterprises, pollution-intensive industries, and regions with stringent environmental governance, suggesting that regulatory frameworks and organizational characteristics mediate automation’s ecological impacts. These results underscore industrial robots’ dual capacity to drive both economic modernization and environmental stewardship, providing policymakers with empirical evidence to design sector-specific strategies aligning technological advancement with China’s carbon neutrality objectives.

Diverging from prior macroeconomic analyses exemplified by Shapiro & Walker (2018) [30], our firm-level textual methodology uniquely validates industrial robots’ tripartite emission-reduction pathway: productivity enhancement, precision-driven technological optimization, and pollution-abatement innovation. Crucially, we establish how state-owned enterprises’ institutional compliance capabilities amplify these effects—resolving critical gaps in ownership-heterogeneity literature while advancing beyond theoretical debates on technological optimism. This positions robotic integration as a structural catalyst for sustainable transitions in emerging economies. Our findings generate implementable policy frameworks: sector-specific automation roadmaps calibrated to regional governance contexts, thereby transforming academic insights into actionable carbon-neutrality strategies. These contributions collectively redefine automation’s role from mere efficiency enhancement to an institutionalized ecological modernization driver, offering empirically grounded solutions for reconciling economic growth with environmental stewardship under China’s unique developmental paradigm.

Author Contributions

F.C. (writing—original draft, software, visualization), W.L. (methodology, visualization, writing—review and editing, supervision). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ali, K.; Jianguo, D.; Kirikkaleli, D. How do energy resources and financial development cause environmental sustainability? Energy Rep. 2023, 9, 4036–4048. [Google Scholar] [CrossRef]

- Guenat, S.; Purnell, P.; Davies, Z.G.; Nawrath, M.; Stringer, L.C.; Babu, G.R.; Balasubramanian, M.; Ballantyne, E.E.F.; Bylappa, B.K.; Chen, B.; et al. Meeting sustainable development goals via robotics and autonomous systems. Nat. Commun. 2022, 13, 3559. [Google Scholar] [CrossRef]

- Zhang, Y.; Lan, M.; Zhao, Y.; Su, Z.; Hao, Y.; Du, H. Regional carbon emission pressure and corporate green innovation. Appl. Energy 2024, 360, 122625. [Google Scholar] [CrossRef]

- Lockhart, A.; Marvin, S.; While, A. Towards new ecologies of automation: Robotics and the re-engineering of nature. Geoforum 2023, 145, 103825. [Google Scholar] [CrossRef]

- Dixon, J.; Hong, B.; Wu, L. The robot revolution: Managerial and employment consequences for firms. Manag. Sci. 2021, 67, 5586–5605. [Google Scholar] [CrossRef]

- Mai, V.; Vanderborght, B.; Haidegger, T.; Khamis, A.; Bhargava, N.; Boesl, D.B.O.; Gabriels, K.; Jacobs, A.; Moon, A.J.; Nakauchi, R.; et al. The role of robotics in achieving the United Nations sustainable development goals—The experts’ meeting at the 2021 IEEE/RSJ IROS workshop. IEEE Robot. Autom. Mag. 2022, 29, 92–107. [Google Scholar] [CrossRef]

- Lakshmi, V.; Bahli, B. Understanding the robotization landscape transformation: A centering resonance analysis. J. Innov. Knowl. 2020, 5, 59–67. [Google Scholar] [CrossRef]

- Song, J.; Chen, Y.; Luan, F. Air pollution, water pollution, and robots: Is technology the panacea. J. Environ. Manag. 2023, 330, 117170. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, F.; Mai, Q. Robot adoption and green productivity: Curse or Boon. Sustain. Prod. Consum. 2022, 34, 1–11. [Google Scholar] [CrossRef]

- Yu, L.; Wang, Y.; Wei, X.; Zeng, C. Towards low-carbon development: The role of industrial robots in decarbonization in Chinese cities. J. Environ. Manag. 2023, 330, 117216. [Google Scholar] [CrossRef]

- Zhou, W.; Zhuang, Y.; Chen, Y. How does artificial intelligence affect pollutant emissions by improving energy efficiency and developing green technology. Energy Econ. 2024, 131, 107355. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Pan, A.; Han, M.; Veglianti, E. Carbon emission reduction effects of industrial robot applications: Heterogeneity characteristics and influencing mechanisms. Technol. Soc. 2022, 70, 102034. [Google Scholar] [CrossRef]

- Lee, C.C.; Qin, S.; Li, Y. Does industrial robot application promote green technology innovation in the manufacturing industry? Technol. Forecast. Soc. Change 2022, 183, 121893. [Google Scholar] [CrossRef]

- Cheng, K.; Jin, Z.; Wu, G. Unveiling the role of artificial intelligence in influencing enterprise environmental performance: Evidence from China. J. Clean. Prod. 2024, 440, 140934. [Google Scholar] [CrossRef]

- Luan, F.; Yang, X.; Chen, Y.; Regis, P.J. Industrial robots and air environment: A moderated mediation model of population density and energy consumption. Sustain. Prod. Consum. 2022, 30, 870–888. [Google Scholar] [CrossRef]

- Yang, X.; Luan, F.; Zhang, J.; Zhang, Z. Testing for quadratic impact of industrial robots on environmental performance and reaction to green technology and environmental cost. Environ. Sci. Pollut. Res. 2023, 30, 92782–92800. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Robots and jobs: Evidence from US labor markets. J. Political Econ. 2020, 128, 2188–2244. [Google Scholar] [CrossRef]

- Qian, Y.; Liu, J.; Shi, L.; Forrest, J.Y.L.; Yang, Z. Can artificial intelligence improve green economic growth? Evidence from China. Environ. Sci. Pollut. Res. 2023, 30, 16418–16437. [Google Scholar] [CrossRef]

- Rong, J.; Wang, W.; Zhang, H. Does artificial intelligence improve energy productivity in China’s industrial sector? Empirical evidence based on the spatial moderation model. Energy Environ. 2024, 35, 4026–4048. [Google Scholar] [CrossRef]

- Yin, Z.H.; Zeng, W.P. The effects of industrial intelligence on China’s energy intensity: The role of technology absorptive capacity. Technol. Forecast. Soc. Change 2023, 191, 122506. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, Y.; Sun, X. How does artificial intelligence affect green economic growth?—Evidence from China. Sci. Total Environ. 2022, 834, 155306. [Google Scholar] [CrossRef]

- Gan, J.; Liu, L.; Qiao, G.; Zhang, Q. The role of robot adoption in green innovation: Evidence from China. Econ. Model. 2023, 119, 106128. [Google Scholar] [CrossRef]

- Liu, J.; Qian, Y.; Yang, Y.; Yang, Z. Can artificial intelligence improve the energy efficiency of manufacturing companies? Evidence from China. Int. J. Environ. Res. Public Health 2022, 19, 2091. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Zeng, C.; Wei, X. The impact of industrial robots’ application on air pollution in China: Mechanisms of energy use efficiency and green technological innovation. Sci. Prog. 2022, 105, 00368504221144093. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Zhang, H.; Han, M.; Yang, L.Y. Robot adoption and corporate pollution emissions: Evidence from China. Pac. -Basin Financ. J. 2025, 90, 102647. [Google Scholar] [CrossRef]

- Zi, S.; Pan, Z.; Chen, Y.; Liu, X.; Ban, Q. Intelligent Manufacturing and Pollution Emissions from Chinese Manufacturing Firms: Theories and Mechanisms. Sustainability 2025, 17, 773. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. The race between man and machine: Implications of technology for growth, factor shares, and employment. Am. Econ. Rev. 2018, 108, 1488–1542. [Google Scholar] [CrossRef]

- Huang, G.; He, L.Y.; Lin, X. Robot adoption and energy performance: Evidence from Chinese industrial firms. Energy Econ. 2022, 107, 105837. [Google Scholar] [CrossRef]

- Zhu, H.; Sang, B.; Zhang, C.; Guo, L. Have industrial robots improved pollution reduction? A theoretical approach and empirical analysis. China World Econ. 2023, 31, 153–172. [Google Scholar] [CrossRef]

- Shapiro, J.S.; Walker, R. Why is pollution from US manufacturing declining? The roles of environmental regulation, productivity, and trade. Am. Econ. Rev. 2018, 108, 3814–3854. [Google Scholar] [CrossRef]

- Fan, H.; Hu, Y.; Tang, L. Labor costs and the adoption of robots in China. J. Econ. Behav. Organ. 2021, 186, 608–631. [Google Scholar] [CrossRef]

- Lin, X.; Liu, Q.; Feng, G. Smart Manufacturing and Green Development: From the Perspective of Industrial Robot Imports. World Econ. 2023, 46, 3–31. [Google Scholar]

- Forslid, R.; Okubo, T.; Ulltveit-Moe, K.H. Why are firms that export cleaner? International trade, abatement and environmental emissions. J. Environ. Econ. Manag. 2018, 91, 166–183. [Google Scholar] [CrossRef]

- Ma, S.; Wei, W.; Li, J. Has the digital economy improved the ecological environment? Empirical evidence from China. Environ. Sci. Pollut. 2023, 30, 91887–91901. [Google Scholar] [CrossRef]

- Zhu, Z.; Song, T.; Huang, J. Executive Cognitive Structure, Digital Policy, and Firms’ Digital Transformation. IEEE Trans. Eng. Manag. 2022, 71, 2579–2592. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, W. How is the rise of robots affecting China’s labor market?—Evidence from listed manufacturing companies. Econ. Res. 2020, 55, 159–175. [Google Scholar]

- Acemoglu, D.; Restrepo, P. Automation and new tasks: How technology displaces and reinstates labor. J. Econ. Perspect. 2019, 33, 3–30. [Google Scholar] [CrossRef]

- Fang, X.; Liu, M. How does the digital transformation drive digital technology innovation of enterprises? Evidence from enterprise’s digital patents. Technol. Forecast. Soc. Change 2024, 204, 123428. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).