Biofuels, E-Fuels, and Waste-Derived Fuels: Advances, Challenges, and Future Directions

Abstract

1. Introduction

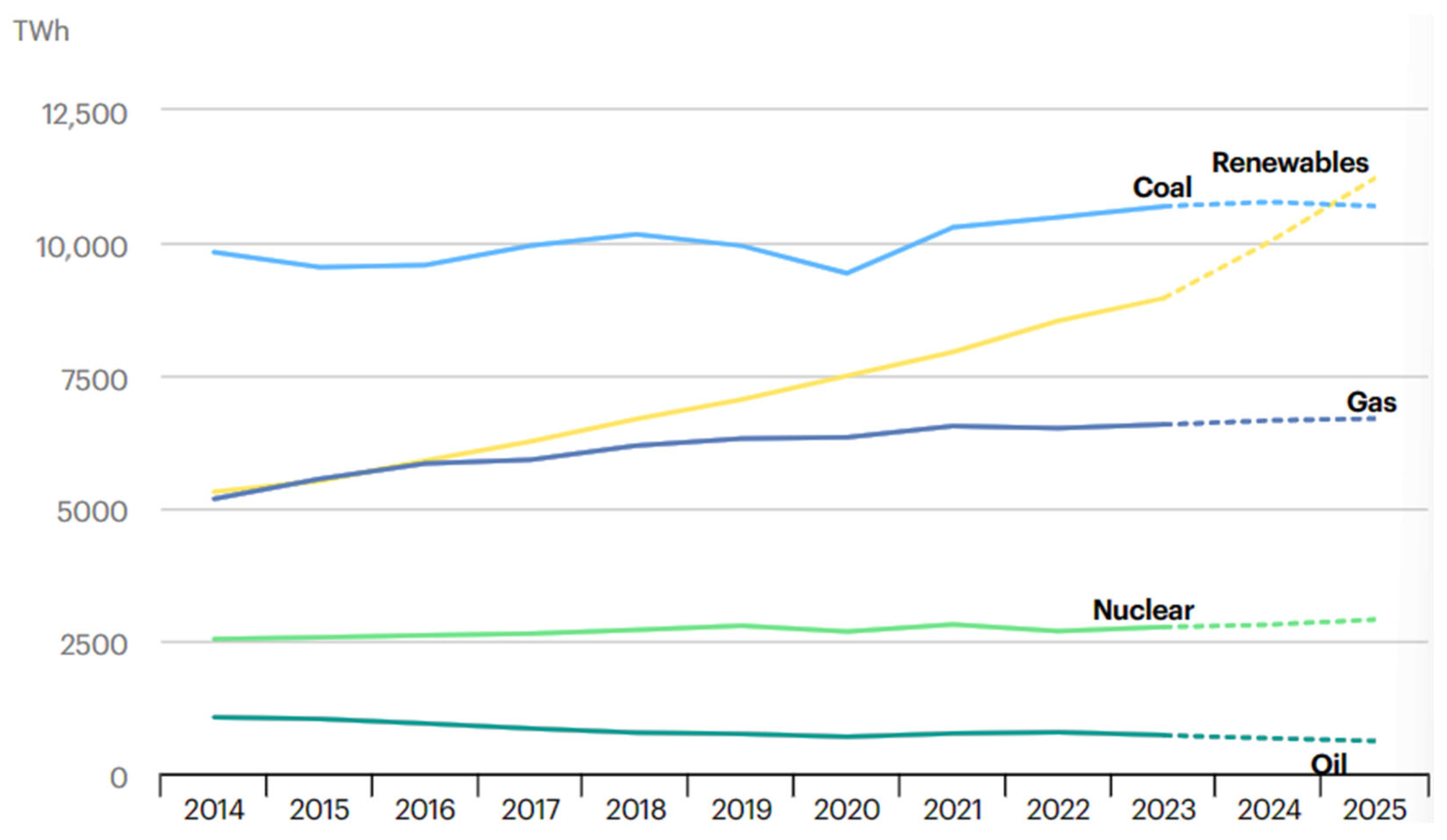

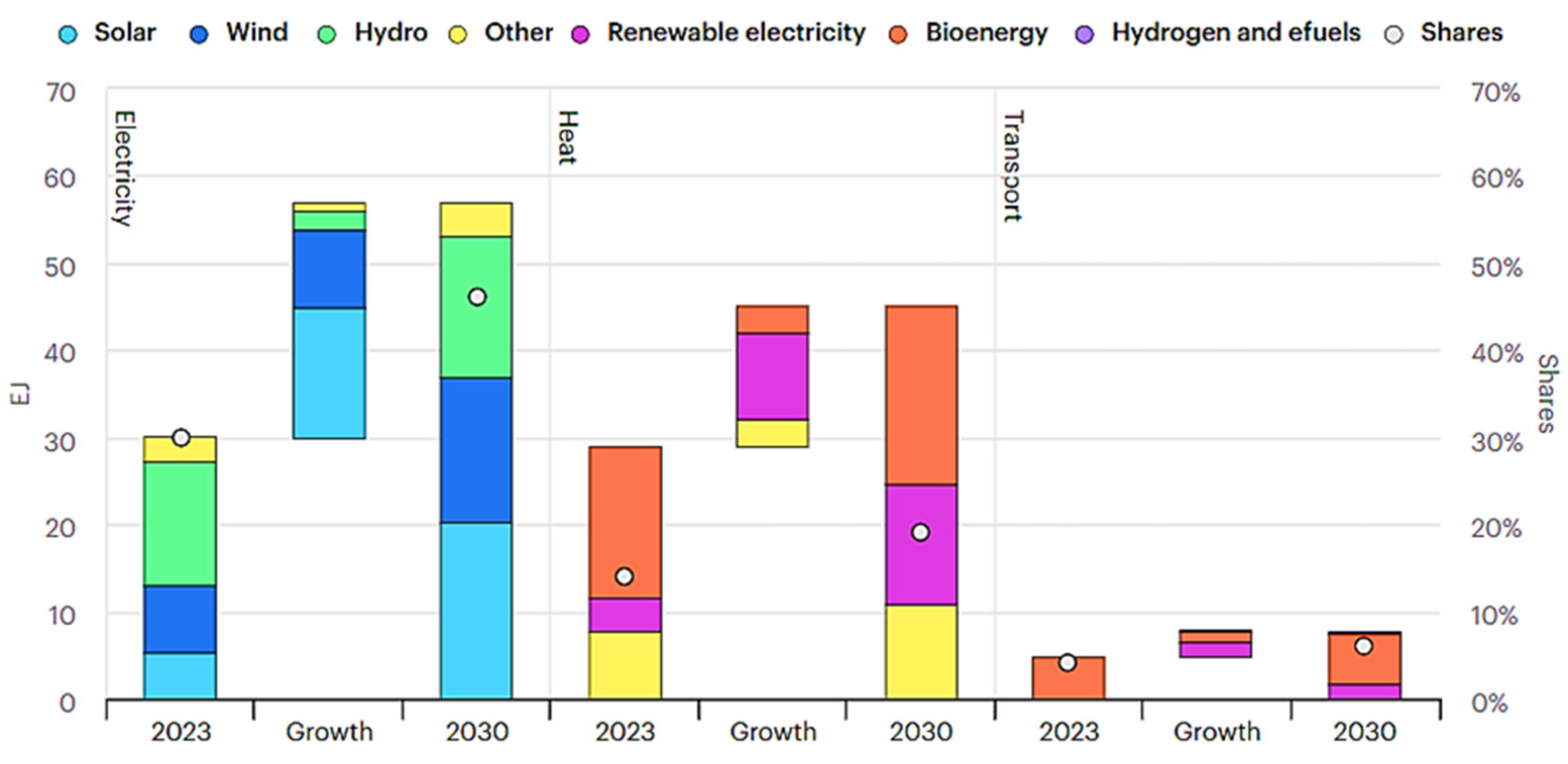

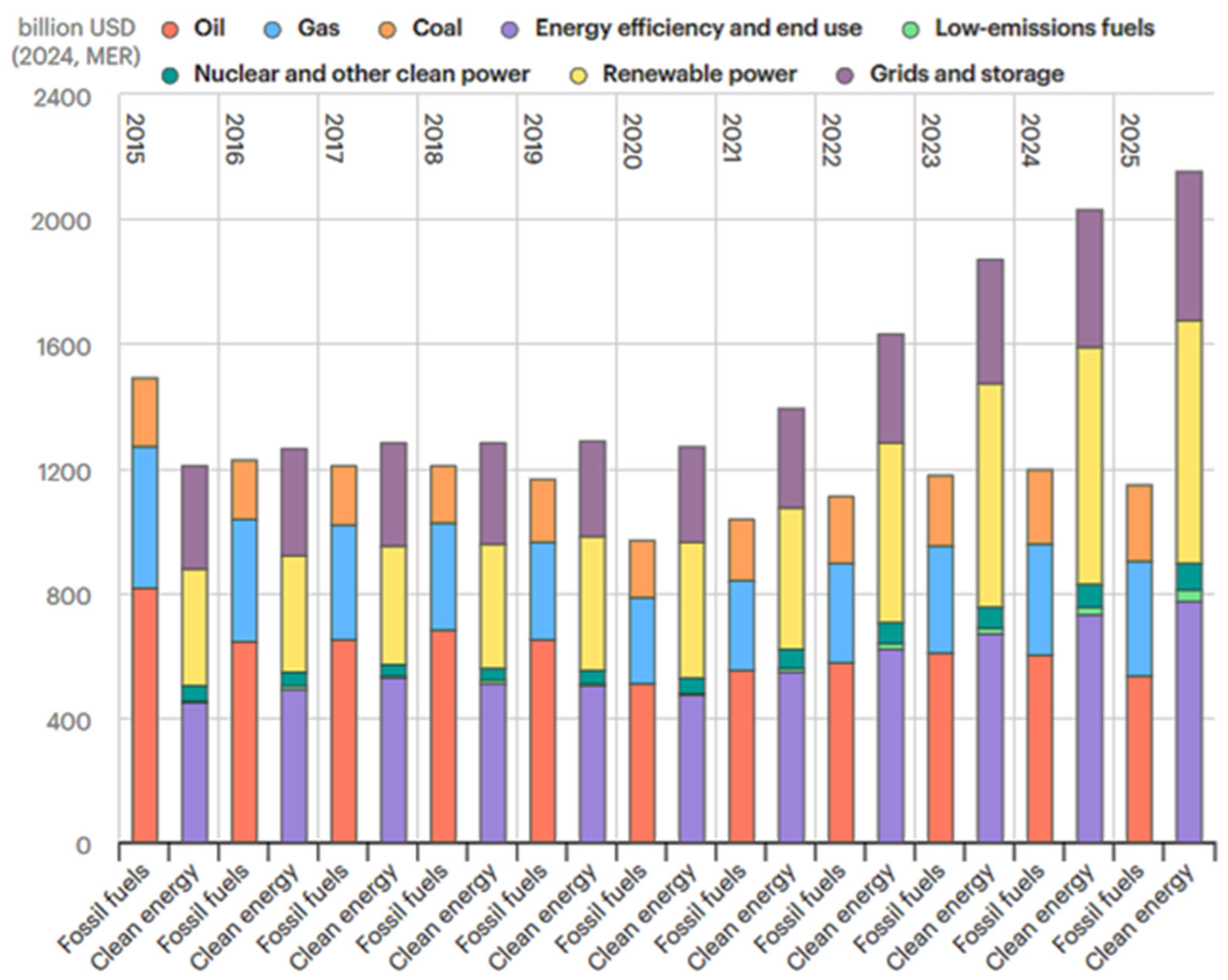

1.1. The Imperative for an Energy Transition

1.2. The Role of Ecofuels and the Objectives of This Review

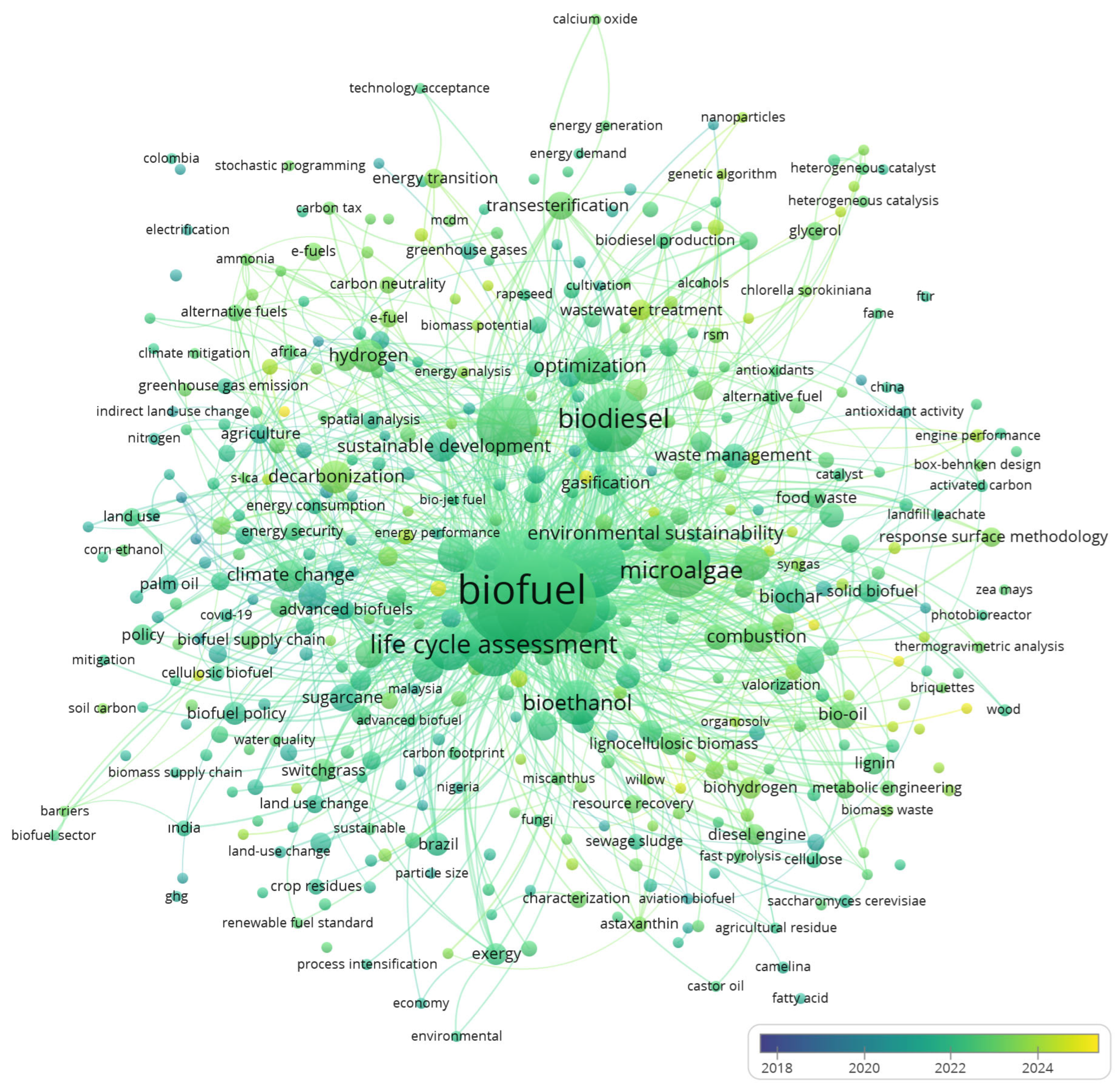

2. Methodology

3. Biofuels

3.1. First-Generation Biofuels

3.2. Second-Generation Biofuels

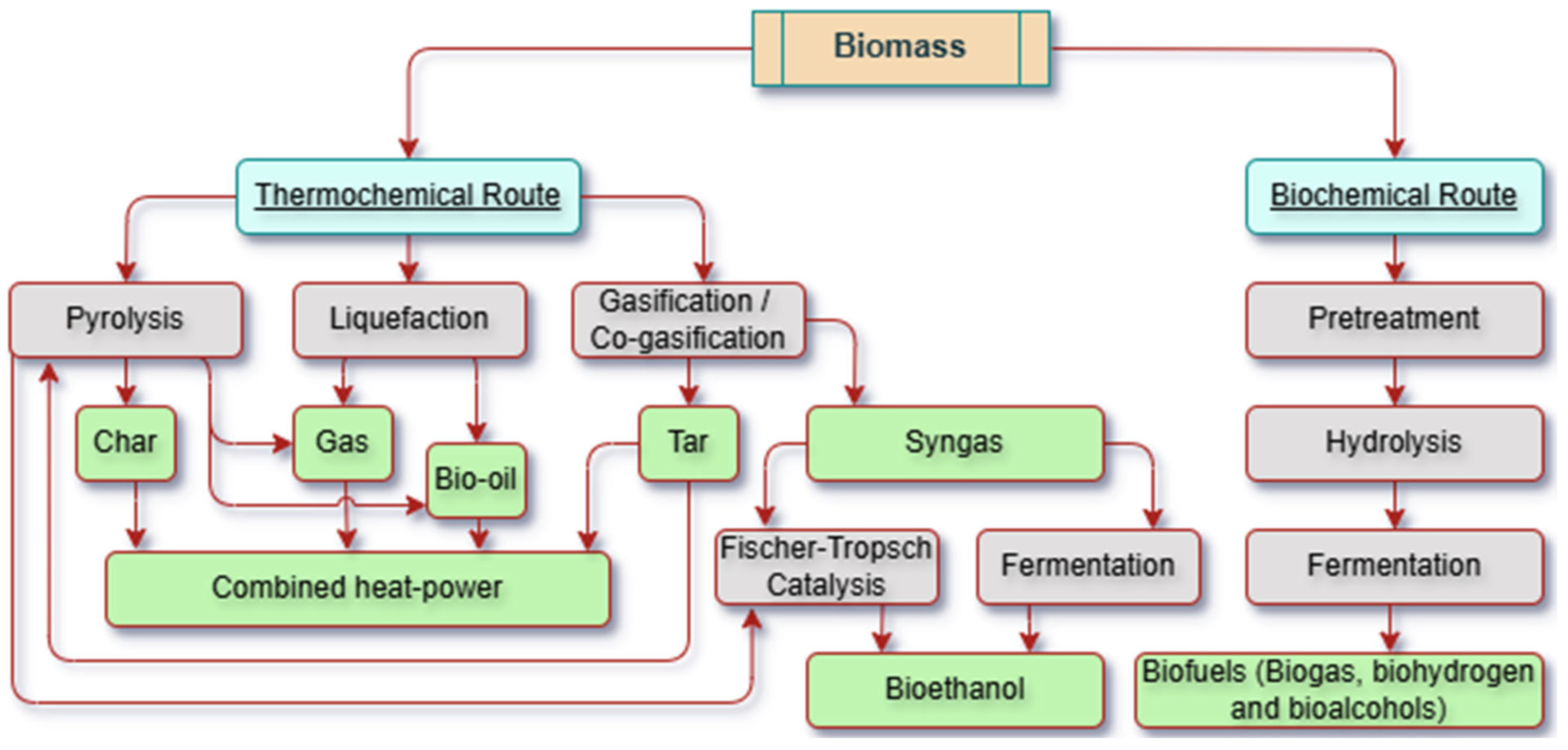

3.2.1. Biochemical Route

3.2.2. Thermochemical Route

3.3. Third-Generation Biofuels

3.4. Fourth-Generation Biofuels

3.5. Fifth-Generation Biofuels

3.6. Biofuel Types by Physical Condition

3.6.1. Liquid Biofuels

3.6.2. Gaseous Biofuels

3.6.3. Solid Biofuels

3.7. Challenges of Biofuel

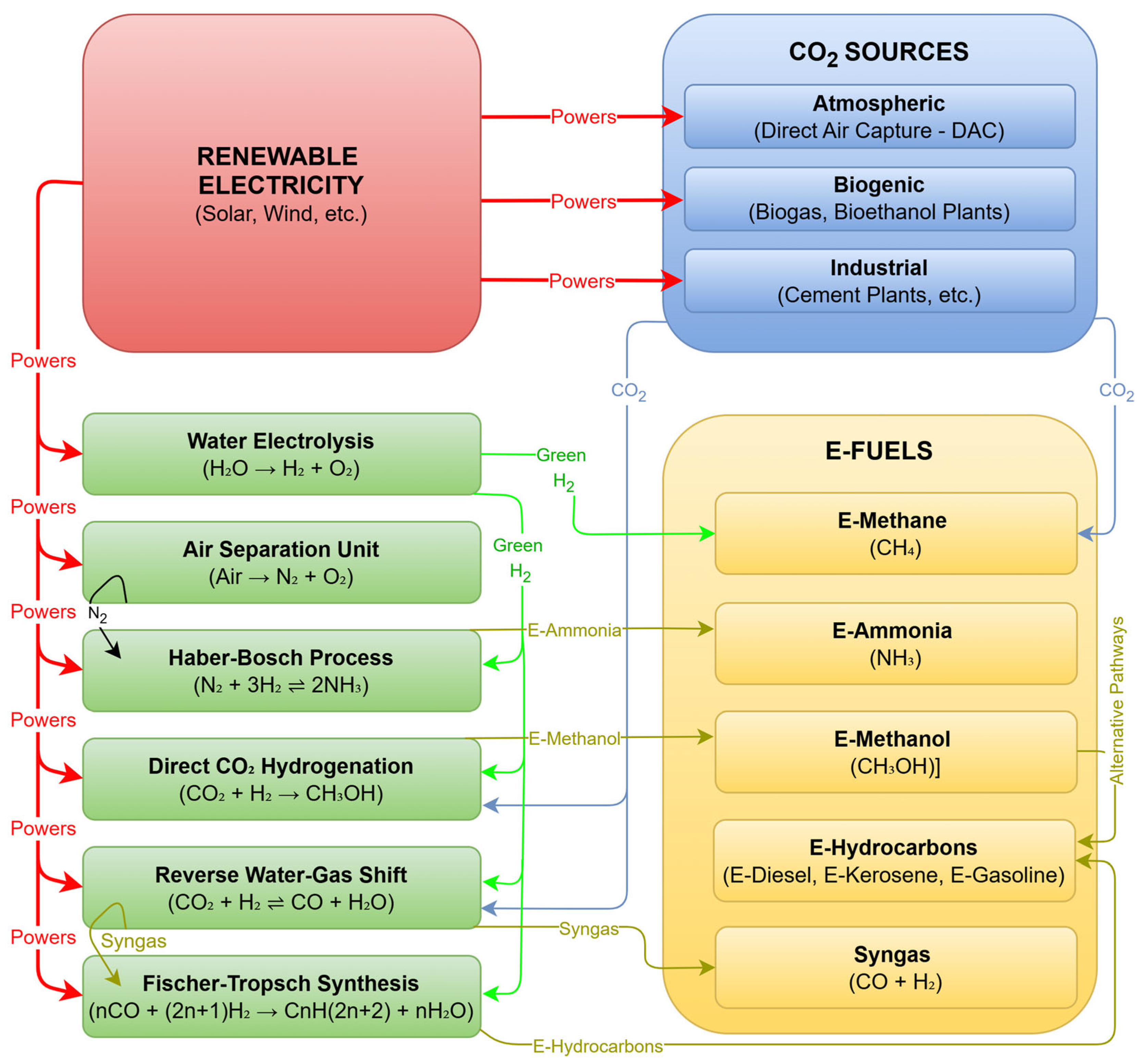

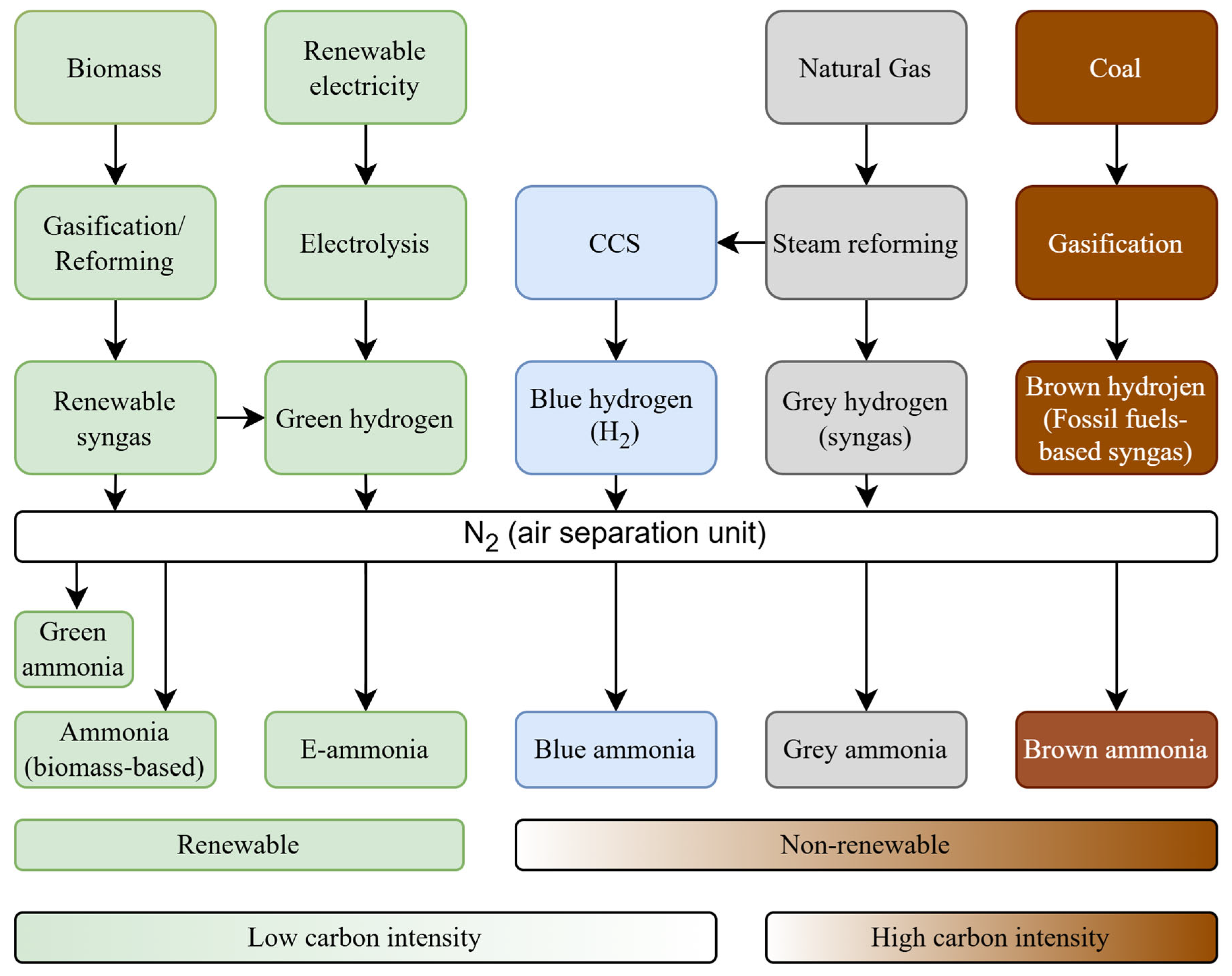

4. Electrofuels (E-Fuels)

Challenges of E-Fuels

5. Waste-Derived Fuels

5.1. Thermochemical Conversion of Plastic and Tire Waste

5.2. Waste Tire Pyrolysis

5.3. Tire Gasification

5.4. Hydrothermal Liquefaction of Tires

5.5. Valorization of Char

6. Discussion

6.1. Resource and Feedstock Constraints: The Sustainability Test

6.2. Techno-Economic Viability, Scalability, and Policy Levers

6.3. Infrastructural Challenges and Systemic Integration

6.4. Sustainability Beyond Renewability: LCA, Policy Coherence, and the Role of Ecofuels

7. Future Perspectives

7.1. Strategic Deployment for Hard-to-Abate Sectors

7.2. The Future of Sustainable Feedstocks

7.3. Critical Pathways for E-Fuel Scalability

7.4. Long-Term Vision: Emerging Carbon-Free Fuel Technologies

8. Conclusions

- Implementing a multifaceted strategy that champions technological neutrality while directing advanced biofuels and e-Fuels towards hard-to-abate sectors like aviation and maritime transport. These sectors are critical as direct electrification faces substantial energy density limitations.

- Moving beyond simple renewability to ensure holistic, long-term environmental, social, and economic viability across the entire value chain. This involves accelerating the research, development, and deployment of second-generation biofuels from lignocellulosic wastes and third-generation options like algae (with potential oil yields up to 136,900 L/ha/yr) alongside waste-to-fuel technologies to minimize resource conflicts and the ILUC impacts associated with some 1-G biofuels. Ensuring traceability for feedstocks like UCO, where EU consumption has significantly outpaced domestic collection (estimated at 1.5–1.7 Mt/yr versus ~2.85 Mt UCOME in 2019), is also key.

- Significantly boosting investment in R&D to reduce costs and improve efficiencies in e-fuel production pathways. This includes green hydrogen, where announced large-scale projects reached a potential investment value of USD 680 billion by 2024 against confirmed FIDs of USD 75 billion, and aiming for outputs like 50 Mt from electrolysis and 15 Mt from CCUS-equipped facilities by 2030 to meet net-zero targets. Sustainable CO2 sourcing, moving beyond current reliance on DAC, which is still maturing despite pilot plants, is paramount. Exploring and supporting emerging carbon-free fuel options, such as ammonia, which shows promise for sectors like maritime shipping with new engines becoming available, will also be vital.

- Focusing concerted global efforts on securing sustainable and diverse feedstock availability, which has been identified as the most significant limiting factor across all ecofuel pathways. Simultaneously, strategic planning and investment are required for the massive scale-up of supporting infrastructure. This includes vastly expanded renewable electricity generation, considering the global installed offshore wind capacity was approximately 81 GW by the end of 2024, dwarfed by projected needs, grid reinforcement, and networks for CO2 capture (with 90–95% effectiveness at point sources), transport, and utilization or storage.

- Developing and maintaining clear, stable, and internationally harmonized policy environments that provide long-term investment security beyond current targets like the EU’s 2035 phase-out of new fossil-fueled car sales. These policies must support innovation and create a level playing field for all genuinely sustainable ecofuel solutions.

Funding

Data Availability Statement

Conflicts of Interest

References

- IPCC. Climate Change. 2021: The Physical Science Basis. Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 6 April 2025).

- Lazarus, M.; van Asselt, H. Fossil fuel supply and climate policy: Exploring the road less taken. Clim Change 2018, 150, 1–13. [Google Scholar] [CrossRef]

- UNEP. Emissions Gap Report. 2022. United Nations Environment Programme. Available online: https://www.unep.org/resources/emissions-gap-report-2022 (accessed on 6 April 2025).

- Gitelman, L.; Magaril, E.; Kozhevnikov, M. Energy Security: New Threats and Solutions. Energies 2023, 16, 2869. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 6 April 2025).

- DOE. Inflation Reduction Act of 2022. U.S. Department of Energy. Available online: https://www.energy.gov/lpo/inflation-reduction-act-2022?nrg_redirect=374451 (accessed on 6 April 2025).

- IEA. Renewables 2024. International Energy Agency. 2024. Available online: https://www.iea.org/reports/renewables-2024/global-overview (accessed on 6 April 2025).

- Statista. Global Fossil Fuel Share in Energy Consumption 1965–2023. Statista Research Department. Available online: https://www.statista.com/statistics/1302762/fossil-fuel-share-in-energy-consumption-worldwide/ (accessed on 6 April 2025).

- EEA. Trends and Projections in Europe 2024; European Environment Agency: Copenhagen, Denmark, 2024; pp. 1–68. [Google Scholar] [CrossRef]

- Distefano, T.; Lodi, L.; Biggeri, M. Material footprint and import dependency in EU27: Past trends and future challenges. J. Clean. Prod. 2024, 472, 143384. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions REPowerEU Plan (COM/2022/230 final). Office of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52022DC0230 (accessed on 6 April 2025).

- IEA. Energy Technology Perspectives 2023. International Energy Agency. January 2023. pp. 1–464. Available online: https://www.iea.org/reports/energy-technology-perspectives-2023 (accessed on 6 April 2025).

- IPCC. Climate Change 2022: Mitigation of Climate Change. In Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change IPCC; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- European Parliament and Council. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance). Official Journal of the European Union, December 2018. Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj/eng (accessed on 6 April 2025).

- Al-Breiki, M.; Bicer, Y. Comparative life cycle assessment of sustainable energy carriers including production, storage, overseas transport and utilization. J. Clean. Prod. 2021, 279, 123481. [Google Scholar] [CrossRef]

- Kolb, S.; Plankenbühler, T.; Hofmann, K.; Bergerson, J.; Karl, J. Life cycle greenhouse gas emissions of renewable gas technologies: A comparative review. Renew. Sustain. Energy Rev. 2021, 146, 111147. [Google Scholar] [CrossRef]

- Huang, J.; Fan, H.; Xu, X.; Liu, Z. Life Cycle Greenhouse Gas Emission Assessment for Using Alternative Marine Fuels: A Very Large Crude Carrier (VLCC) Case Study. J. Mar. Sci. Eng. 2022, 10, 1969. [Google Scholar] [CrossRef]

- Gan, Y.; Ng, C.; Elgowainy, A.; Marcinkoski, J. Considering Embodied Greenhouse Emissions of Nuclear and Renewable Power Plants for Electrolytic Hydrogen and Its Use for Synthetic Ammonia, Methanol, Fischer-Tropsch Fuel Production. Environ. Sci. Technol. 2024, 58, 18654–18662. [Google Scholar] [CrossRef]

- Cappello, V.; Sun, P.; Elgowainy, A. Blending low-carbon hydrogen with natural gas: Impact on energy and life cycle emissions in natural gas pipelines. Gas Sci. Eng. 2024, 128, 205389. [Google Scholar] [CrossRef]

- IEA. World Energy Investment 2025; International Energy Agency: Paris, France, 2025; pp. 1–255. Available online: https://www.iea.org/reports/world-energy-investment-2025 (accessed on 6 April 2025).

- Degen, F.; Research, F. Lithium-ion battery cell production in Europe: Scenarios for reducing energy consumption and greenhouse gas emissions until 2030. J. Ind. Ecol. 2023, 27, 964–976. [Google Scholar] [CrossRef]

- Duffner, F.; Kronemeyer, N.; Tübke, J.; Leker, J.; Winter, M.; Schmuch, R. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nat. Energy 2021, 6, 123–134. [Google Scholar] [CrossRef]

- Vinayak, A.K.; Li, M.; Huang, X.; Dong, P.; Amine, K.; Lu, J.; Wang, X. Circular economies for lithium-ion batteries and challenges to their implementation. Next Mater. 2024, 5, 100231. [Google Scholar] [CrossRef]

- Yu, M.; Bai, B.; Xiong, S.; Liao, X. Evaluating environmental impacts and economic performance of remanufacturing electric vehicle lithium-ion batteries. J. Clean. Prod. 2021, 321, 128935. [Google Scholar] [CrossRef]

- Pellow, M.A.; Ambrose, H.; Mulvaney, D.; Betita, R.; Shaw, S. Research gaps in environmental life cycle assessments of lithium ion batteries for grid-scale stationary energy storage systems: End-of-life options and other issues. Sustain. Mater. Technol. 2020, 23, e00120. [Google Scholar] [CrossRef]

- Dudić, B. Global Development and Sustainability of Lithium-Ion Batteries in Electric Vehicles. Adv. Eng. Lett. 2024, 3, 83–90. [Google Scholar] [CrossRef]

- Shojaeddini, E.; Alonso, E.; Nassar, N.T. Estimating price elasticity of demand for mineral commodities used in Lithium-ion batteries in the face of surging demand. Resour. Conserv. Recycl. 2024, 207, 107664. [Google Scholar] [CrossRef]

- Shannak, S.; Cochrane, L.; Bobarykina, D. Strategic analysis of metal dependency in the transition to low-carbon energy: A critical examination of nickel, cobalt, lithium, graphite, and copper scarcity using IEA future scenarios. Energy Res. Soc. Sci. 2024, 118, 103773. [Google Scholar] [CrossRef]

- Cui, Z.; Xie, Q.; Manthiram, A. A Cobalt- and Manganese-Free High-Nickel Layered Oxide Cathode for Long-Life, Safer Lithium-Ion Batteries. Adv. Energy Mater. 2021, 11, 2102421. [Google Scholar] [CrossRef]

- Biswal, B.K.; Zhang, B.; Thi, P.; Tran, M.; Zhang, J.; Balasubramanian, R. Recycling of spent lithium-ion batteries for a sustainable future: Recent advancements. Chem. Soc. Rev. 2024, 53, 5552–5592. [Google Scholar] [CrossRef]

- Jiang, S.-Q.; Nie, C.-C.; Li, X.-G.; Shi, S.-X.; Gao, Q.; Wang, Y.-S.; Zhu, X.-N.; Wang, Z. Review on comprehensive recycling of spent lithium-ion batteries: A full component utilization process for green and sustainable production. Sep. Purif. Technol. 2023, 315, 123684. [Google Scholar] [CrossRef]

- Xu, P.; Tan, D.H.S.; Jiao, B.; Gao, H.; Yu, X.; Chen, Z. A Materials Perspective on Direct Recycling of Lithium-Ion Batteries: Principles, Challenges and Opportunities. Adv. Funct. Mater. 2023, 33, 2213168. [Google Scholar] [CrossRef]

- Yokoi, R.; Kataoka, R.; Masese, T.; Bach, V.; Finkbeiner, M.; Weil, M.; Baumann, M.; Motoshita, M. Potentials and hotspots of post-lithium-ion batteries: Environmental impacts and supply risks for sodium- and potassium-ion batteries. Resour. Conserv. Recycl. 2024, 204, 107526. [Google Scholar] [CrossRef]

- Łukasz, B.; Rybakowska, I.; Krakowiak, A.; Gregorczyk, M.; Waldman, W. Lithium batteries safety, wider perspective. Int. J. Occup. Med. Environ. Health 2022, 36, 3–20. [Google Scholar] [CrossRef]

- Costa, C.M.; Barbosa, J.C.; Gonçalves, R.; Castro, H.; Campo, F.J.D.; Lanceros-Méndez, S. Recycling and environmental issues of lithium-ion batteries: Advances, challenges and opportunities. Energy Storage Mater. 2021, 37, 433–465. [Google Scholar] [CrossRef]

- Oldknow, K.; Mulligan, K.; McTaggart-Cowan, G. The trajectory of hybrid and hydrogen technologies in North American heavy haul operations. Railw. Eng. Sci. 2021, 29, 233–247. [Google Scholar] [CrossRef]

- Rolo, I.; Costa, V.A.F.; Brito, F.P. Hydrogen-Based Energy Systems: Current Technology Development Status, Opportunities and Challenges. Energies 2023, 17, 180. [Google Scholar] [CrossRef]

- Krause, J.; Yugo, M.; Samaras, Z.; Edwards, S.; Fontaras, G.; Dauphin, R.; Prenninger, P.; Neugebauer, S. Well-to-wheels scenarios for 2050 carbon-neutral road transport in the EU. J. Clean. Prod. 2024, 443, 141084. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Swic, A.; Mitoraj-Wojtanek, M. The Development of Electromobility in Poland and EU States as a Tool for Management of CO2 Emissions. Energies 2019, 12, 2942. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2024. 2024, pp. 1–398. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 6 April 2025).

- International Energy Agency (IEA). Electricity Mid-Year Update. 2024, pp. 1–52. Available online: https://www.iea.org/reports/electricity-mid-year-update-july-2024 (accessed on 6 April 2025).

- Liu, X.; Elgowainy, A.; Vijayagopal, R.; Wang, M. Well-to-Wheels Analysis of Zero-Emission Plug-In Battery Electric Vehicle Technology for Medium- And Heavy-Duty Trucks. Environ. Sci. Technol. 2021, 55, 538–546. [Google Scholar] [CrossRef] [PubMed]

- Demuynck, J.; Dauphin, R.; Yugo, M.; Villafuerte, P.M.; Bosteels, D. Advanced Emission Controls and Sustainable Renewable Fuels for Low Pollutant and CO2 Emissions on a Diesel Passenger Car. Sustainability 2021, 13, 12711. [Google Scholar] [CrossRef]

- Manna, J.; Jha, P.; Sarkhel, R.; Banerjee, C.; Tripathi, A.K.; Nouni, M.R. Opportunities for green hydrogen production in petroleum refining and ammonia synthesis industries in India. Int. J. Hydrogen Energy 2021, 46, 38212–38231. [Google Scholar] [CrossRef]

- Amin, M.; Shah, H.H.; Bashir, B.; Iqbal, M.A.; Shah, U.H.; Ali, M.U. Environmental Assessment of Hydrogen Utilization in Various Applications and Alternative Renewable Sources for Hydrogen Production: A Review. Energies 2023, 16, 4348. [Google Scholar] [CrossRef]

- Dickson, R.; Akhtar, M.S.; Abbas, A.; Park, E.D.; Liu, J. Global transportation of green hydrogen via liquid carriers: Economic and environmental sustainability analysis, policy implications, and future directions. Green Chem. 2022, 24, 8484–8493. [Google Scholar] [CrossRef]

- Bhuiyan, M.M.H.; Siddique, Z. Hydrogen as an alternative fuel: A comprehensive review of challenges and opportunities in production, storage, and transportation. Int. J. Hydrogen Energy 2025, 102, 1026–1044. [Google Scholar] [CrossRef]

- Raeesi, R.; Searle, C.; Balta-Ozkan, N.; Marsiliani, L.; Tian, M.; Greening, P. Hydrogen supply chain and refuelling network design: Assessment of alternative scenarios for the long-haul road freight in the UK. Int. J. Hydrogen Energy 2024, 52, 667–687. [Google Scholar] [CrossRef]

- Gan, G.; Hong, G.; Zhang, W. Active Hydrogen for Electrochemical Ammonia Synthesis. Adv. Funct. Mater. 2024, 35, 2401472. [Google Scholar] [CrossRef]

- Ramli, R.M.; Hasnain, S.M.W.U.; Farooqi, A.S.; Addin, A.H.S.; Abdullah, B.; Arslan, M.T.; Farooqi, S.A. A comprehensive review on hydrogen production via catalytic ammonia decomposition over Ni-based catalysts. Int. J. Hydrogen Energy 2025, 97, 593–613. [Google Scholar] [CrossRef]

- Maslova, V.; Cordier, N.; Fourré, E.; Grishin, A.; Veryasov, G.; Batiot-Dupeyrat, C. Hydrogen production from ammonia decomposition in electric field over La-based materials. Int. J. Hydrogen Energy 2024, 85, 694–704. [Google Scholar] [CrossRef]

- Chen, W.; Yang, X.; Chen, Z.; Ou, Z.; Hu, J.; Xu, Y.; Li, Y.; Ren, X.; Ye, S.; Qiu, J.; et al. Emerging Applications, Developments, Prospects, and Challenges of Electrochemical Nitrate-to-Ammonia Conversion. Adv. Funct. Mater. 2023, 33, 2300512. [Google Scholar] [CrossRef]

- Scarfiello, C.; Soulantica, K.; Cayez, S.; Durupt, A.; Viau, G.; Le Breton, N.; Boudalis, A.K.; Meunier, F.; Clet, G.; Barreau, M.; et al. Modified Co/TiO2 catalysts for CO2 hydrogenation to fuels. J. Catal. 2023, 428, 115202. [Google Scholar] [CrossRef]

- Wei, J.; Ge, Q.; Yao, R.; Wen, Z.; Fang, C.; Guo, L.; Xu, H.; Sun, J. Directly converting CO2 into a gasoline fuel. Nat. Commun. 2017, 8, 15174. [Google Scholar] [CrossRef]

- Nnabuife, S.G.; Ugbeh-Johnson, J.; Okeke, N.E.; Ogbonnaya, C. Present and Projected Developments in Hydrogen Production: A Technological Review. Carbon Capture Sci. Technol. 2022, 3, 100042. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Hydrogen Demand—Global Hydrogen Review 2024. Available online: https://www.iea.org/reports/global-hydrogen-review-2024/hydrogen-demand (accessed on 12 April 2025).

- Yao, D.; Liu, C.; Zhang, Y.; Wang, S.; Nie, Y.; Qiao, M.; Zhu, D. Modulating selectivity and stability of the direct seawater electrolysis for sustainable green hydrogen production. Mater. Today Catal. 2025, 8, 100089. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Hydrogen. Available online: https://www.iea.org/energy-system/low-emission-fuels/hydrogen (accessed on 12 April 2025).

- Stori, V. Offshore Wind to Green Hydrogen: Insights from Europe. Clean Energy States Alliance. 2021. Available online: https://www.cesa.org/wp-content/uploads/Offshore-Wind-to-Green-Hydrogen-Insights-from-Europe.pdf (accessed on 12 April 2025).

- Hydrogen Council; McKinsey & Company. Hydrogen Insights 2024. 2024. Available online: https://hydrogencouncil.com/wp-content/uploads/2024/09/Hydrogen-Insights-2024.pdf (accessed on 12 April 2025).

- Clean Hydrogen Observatory. The European Hydrogen Market Landscape. 2024. Available online: https://observatory.clean-hydrogen.europa.eu/sites/default/files/2024-11/The%20European%20hydrogen%20market%20landscape_November%202024.pdf (accessed on 12 April 2025).

- Blackridge; Blackridge Research & Consulting. Top 7 Green Hydrogen Projects in the World. 2024. Available online: https://www.blackridgeresearch.com/blog/latest-list-of-largest-biggest-green-hydrogen-h2-projects-plants-in-the-world (accessed on 12 April 2025).

- Martin, P.; World’s Largest Green Hydrogen Project Begins Production in China. Hydrogen Insight. Available online: https://www.hydrogeninsight.com/production/worlds-largest-green-hydrogen-project-begins-production-in-china/2-1-1478233?zephr_sso_ott=NhXllj (accessed on 12 April 2025).

- Wouters, F. Green hydrogen in Saudi Arabia’s NEOM. In The Clean Hydrogen Economy and Saudi Arabia: Domestic Developments and International Opportunities, 1st ed.; Taylor and Francis: Oxfordshire, UK, 2024; pp. 98–111. [Google Scholar]

- Choe, C.; Lim, H. Life Cycle-Based Strategy and Feasibility of Surplus-to-X-to-Electricity on Domestic Surplus Utilization in the Republic of Korea. Korean J. Chem. Eng. 2025, 42, 1669–1682. [Google Scholar] [CrossRef]

- Wang, C.; Walsh, S.D.C.; Longden, T.; Palmer, G.; Lutalo, I.; Dargaville, R. Optimising renewable generation configurations of off-grid green ammonia production systems considering Haber-Bosch flexibility. Energy Convers. Manag. 2023, 280, 116790. [Google Scholar] [CrossRef]

- Sutherland, D.; Bradbury, M. UK Wind and Global Offshore Wind: 2024 in Review. Renewable UK. Available online: https://www.renewableuk.com/energypulse/blog/uk-wind-and-global-offshore-wind-2024-in-review/ (accessed on 12 April 2025).

- Carlot, F.; Klossa, A.; Pluchet, J.; Clauwaert, S.; Viel, P.; Blondeau, L.; Van Houdt, Y. Offshore Wind & Hydrogen Integration. Arthur Little. Available online: https://www.adlittle.com/it-en/insights/report/offshore-wind-hydrogen-integration (accessed on 12 April 2025).

- Morton, E.M.; Deetjen, T.A.; Goodarzi, S. Optimizing hydrogen production capacity and day ahead market bidding for a wind farm in Texas. Int. J. Hydrogen Energy 2023, 48, 17420–17433. [Google Scholar] [CrossRef]

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M. Assessment of industrial-scale green hydrogen production using renewable energy. Proc. Inst. Mech. Eng. Part A J. Power Energy 2024, 238, 569–587. [Google Scholar] [CrossRef]

- Kakoulaki, G.; Kougias, I.; Taylor, N.; Dolci, F.; Moya, J.; Jäger-Waldau, A. Green hydrogen in Europe—A regional assessment: Substituting existing production with electrolysis powered by renewables. Energy Convers. Manag. 2021, 228, 113649. [Google Scholar] [CrossRef]

- ECA. Special Report 29/2023: The EU’s Support for Sustainable Biofuels in Transport—An Unclear Route Ahead; Royal Society Publishing: London, UK, 2023; Available online: https://www.eca.europa.eu/en/publications?ref=sr-2023-29 (accessed on 19 April 2025).

- European Council. Fit for 55—Consilium. Available online: https://www.consilium.europa.eu/en/policies/fit-for-55/ (accessed on 28 May 2025).

- Mohammadi, H.; Saddler, J. Implementation Agendas: Compare-and-Contrast Transport Biofuels Policies; IEA Bioenergy (Technology Collaboration Programme): Paris, France, 2023; Available online: https://www.ieabioenergy.com/wp-content/uploads/2024/01/Implementation-Agendas-Compare-and-Contrast-Transport-Biofuels-Policies.pdf (accessed on 20 May 2025).

- Dwivedi, P.; Mishra, P.K.; Mondal, M.K.; Srivastava, N. Non-biodegradable polymeric waste pyrolysis for energy recovery. Heliyon 2019, 5, e02198. [Google Scholar] [CrossRef]

- Elkhalifa, S.; Mariyam, S.; Mackey, H.R.; Al-Ansari, T.; McKay, G.; Parthasarathy, P. Pyrolysis Valorization of Vegetable Wastes: Thermal, Kinetic, Thermodynamics, and Pyrogas Analyses. Energies 2022, 15, 6277. [Google Scholar] [CrossRef]

- Wang, Z.; Burra, K.G.; Lei, T.; Gupta, A.K. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review. Prog. Energy Combust. Sci. 2021, 84, 100899. [Google Scholar] [CrossRef]

- Dyer, A.C.; Nahil, M.A.; Williams, P.T. Catalytic co-pyrolysis of biomass and waste plastics as a route to upgraded bio-oil. J. Energy Inst. 2021, 97, 27–36. [Google Scholar] [CrossRef]

- Ansari, K.B.; Hassan, S.Z.; Bhoi, R.; Ahmad, E. Co-pyrolysis of biomass and plastic wastes: A review on reactants synergy, catalyst impact, process parameter, hydrocarbon fuel potential, COVID-19. J. Environ. Chem. Eng. 2021, 9, 106436. [Google Scholar] [CrossRef]

- Ryu, H.W.; Kim, D.H.; Jae, J.; Lam, S.S.; Park, E.D.; Park, Y.K. Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons. Bioresour. Technol. 2020, 310, 123473. [Google Scholar] [CrossRef]

- Dornoff, J.; ICCT20-International Council on Clean Transportation. CO2 Emission Standards for New Passenger Cars and Vans in the European Union. Available online: https://theicct.org/publication/eu-co2-standards-cars-vans-may23/ (accessed on 13 April 2025).

- Boretti, A. Advancements in E-Fuel combustion systems for a sustainable energy future. Int. J. Hydrogen Energy 2024, 79, 258–266. [Google Scholar] [CrossRef]

- European Commission. Renewable Hydrogen. Available online: https://energy.ec.europa.eu/topics/eus-energy-system/hydrogen/renewable-hydrogen_en (accessed on 13 April 2025).

- Maranduba, H.L.; Robra, S.; Nascimento, I.A.; da Cruz, R.S.; Rodrigues, L.B.; de Almeida Neto, J.A. Improving the energy balance of microalgae biodiesel: Synergy with an autonomous sugarcane ethanol distillery. Energy 2016, 115, 888–895. [Google Scholar] [CrossRef]

- Edwin, M.; Nila, J.N.; Nair, M.S. Biofuel production: An initiative of environmentally sound technologies (EST’s) or Green technologies. In Environmental Sustainability of Biofuels: Prospects and Challenges; Elsevier: Amsterdam, The Netherlands, 2022; pp. 99–136. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Khanna, V. Life cycle sustainability aspects of microalgal biofuels. In Assessing and Measuring Environmental Impact and Sustainability; Butterworth-Heinema, J., Klemeš, J., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 255–276. [Google Scholar] [CrossRef]

- Mayer, F.D.; Brondani, M.; Carrillo, M.C.V.; Hoffmann, R.; Lora, E.E.S. Revisiting energy efficiency, renewability, and sustainability indicators in biofuels life cycle: Analysis and standardization proposal. J. Clean. Prod. 2020, 252, 119850. [Google Scholar] [CrossRef]

- Castiñeiras-Filho, S.L.P.; Pradelle, F. Modeling of microalgal biodiesel production integrated to a sugarcane ethanol plant: Energy and exergy efficiencies and environmental impacts due to trade-offs in the usage of bagasse in the Brazilian context. J. Clean. Prod. 2023, 395, 136461. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Klitgaard, K. Energy and the Wealth of Nations: An Introduction to Biophysical Economics; Springer: Cham, Switzerland, 2018; pp. 1–511. [Google Scholar] [CrossRef]

- WOS. Search the Web of Science Core Collection. Web of Science. Available online: https://www.webofscience.com/wos/woscc/summary/dbc0a7a0-6adb-441d-9c0e-899071c0674d-0142adf09a/relevance/1 (accessed on 5 February 2025).

- Eck, N.J.V.; Waltman, L. VOSviewer 1.6.20; Centre for Science and Technology Studies, Leiden University: Leiden, The Netherlands, 2025; Available online: https://www.vosviewer.com/ (accessed on 11 January 2025).

- IEA. Factsheet: What Is Bioenergy?—Bioenergy. Technology Collaboration Programme by IEA. Available online: https://www.ieabioenergy.com/blog/publications/what-is-bioenergy/ (accessed on 16 April 2025).

- ECA. Review 01/2022: Energy Taxation, Carbon Pricing and Energy Subsidies; European Court of Auditors: Luxembourg, 2022; Available online: https://www.eca.europa.eu/en/publications/RW22_01 (accessed on 19 April 2025).

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86 (Suppl. S1), S108–S117. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Household Air Pollution. Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 16 April 2025).

- Romero, M.J.A.; Duca, D.; Maceratesi, V.; Di Stefano, S.; De Francesco, C.; Toscano, G. Preliminary Study on the Thermal Behavior and Chemical-Physical Characteristics of Woody Biomass as Solid Biofuels. Processes 2023, 11, 154. [Google Scholar] [CrossRef]

- Ahmad, K.A.; Ahmad, E.; Al Mesfer, M.K.; Nigam, K.D.P. Bio-coal and bio-coke production from agro residues. Chem. Eng. J. 2023, 473, 145340. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Onuh, E.I.; Aigbodion, V.S. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies 2021, 14, 5687. [Google Scholar] [CrossRef]

- Sadaqat, B.; Dar, M.A.; Xie, R.; Sun, J. Drawbacks of first-generation biofuels: Challenges and paradigm shifts in technology for second- and third-generation biofuels. In Biofuels and Sustainability: Life Cycle Assessments, System Biology, Policies, and Emerging Technologies; Zhu, D., Dar, M.A., Shahnawaz, M., Eds.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2024; pp. 33–47. [Google Scholar] [CrossRef]

- Sharma, T.; Chauhan, P.S.; Patel, M.; Singh, A.; Kaur, M.; Chauhan, G.; Rana, B.B.; Kumar, N.; Walia, A. Carbon negative biofuels: A step ahead of carbon neutrality. Biofuels 2025, 1–21. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.-H. Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef]

- Ghosh, N.; Rhithuparna, D.; Rokhum, S.L.; Halder, G. Ethical issues pertaining to sustainable biodiesel synthesis over trans/esterification process. Sustain. Chem. Pharm. 2023, 33, 101123. [Google Scholar] [CrossRef]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 11206–11210. [Google Scholar] [CrossRef] [PubMed]

- Sandford, C.; Malins, C.; Vourliotakis, G.; Panoutsou, C. ‘Low ILUC-Risk’ as a Sustainability Standard for Biofuels in the EU. Energies 2024, 17, 2365. [Google Scholar] [CrossRef]

- Løkke, S.; Aramendia, E.; Malskær, J. A review of public opinion on liquid biofuels in the EU: Current knowledge and future challenges. Biomass Bioenergy 2021, 150, 106094. [Google Scholar] [CrossRef]

- Vackeová, S. The role of bioethanol in achieving EU targets Simona Vackeová ePURE Government Affairs Director. In Proceedings of the 14th ISCC Global Sustainability Conference, Brussels, Belgium, 22 February 2024; Available online: https://www.iscc-system.org/wp-content/uploads/2024/02/1.8_The-Role-of-Bioethanol-in-Achieving-EU-Targets-%E2%80%93-Simona-Vackeova-Director-of-Government-Affairs-ePURE-Belgium.pdf (accessed on 20 April 2025).

- Albaladejo, M.; Elgueta, A.M.; Amador, G. Sustainable Fuels: A Key Player in Decarbonizing Hard-to-Abate Sectors; Royal Society Publishing: London, UK, 2024. [Google Scholar] [CrossRef]

- Filho, A.Z.; Woiciechowski, A.L.; Letti, L.A.J.; Torres, L.A.Z.; Valladares-Diestra, K.K.; Soccol, C.R. Feedstocks for First-Generation Bioethanol Production. In Liquid Biofuels: Bioethanol; Soccol, C.R., Pereira, G.A.G., Dussap, C.-G., Vandenberghe, L.P.d.S., Eds.; Springer: Cham, Switzerland, 2022; Volume 12, pp. 13–27. [Google Scholar] [CrossRef]

- Mićić, V.; Jotanović, M. Bioethanol as fuel for internal combustion engines. Zast. Mater. 2015, 56, 403–408. [Google Scholar] [CrossRef]

- Mizik, T. European Union guidelines for the production of different generations of biofuels. In Biofuels and Sustainability: Life Cycle Assessments, System Biology, Policies, and Emerging Technologies; Zhu, D., Dar, M.A., Shahnawaz, M., Eds.; Woodhead Publishing: Cambridge, UK, Elsevier Science Ltd.: Amsterdam, The Netherlands; 2024; pp. 205–219. [Google Scholar] [CrossRef]

- Jurić, F.; Krajcar, M.; Duić, N.; Vujanović, M. Investigating the pollutant formation and combustion characteristics of biofuels in compression ignition engines: A numerical study. Therm. Sci. Eng. Prog. 2023, 43, 101939. [Google Scholar] [CrossRef]

- Topaloğlu, A.; Esen, Ö.; Turanlı-Yıldız, B.; Arslan, M.; Çakar, Z.P. From Saccharomyces cerevisiae to Ethanol: Unlocking the Power of Evolutionary Engineering in Metabolic Engineering Applications. J. Fungi 2023, 9, 984. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A Comprehensive Review on 1st-Generation Biodiesel Feedstock Palm Oil: Production, Engine Performance, and Exhaust Emissions. BioEnergy Res. 2020, 14, 1–22. [Google Scholar] [CrossRef]

- Yilbaşi, Z.; Yesilyurt, M.K.; Yaman, H.; Arslan, M. The industrial-grade hemp (Cannabis sativa L.) seed oil biodiesel application in a diesel engine: Combustion, harmful pollutants, and performance characteristics. Sci. Technol. Energy Transit. 2022, 77, 1–36. [Google Scholar] [CrossRef]

- Prasad, S.; Yadav, K.K.; Kumar, S.; Pandita, P.; Bhutto, J.K.; Alreshidi, M.A.; Ravindran, B.; Yaseen, Z.M.; Osman, S.M.; Cabral-Pinto, M.M. Review on biofuel production: Sustainable development scenario, environment, and climate change perspectives —A sustainable approach. J. Environ. Chem. Eng. 2024, 12, 111996. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: A review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Adewuyi, A. Underutilized Lignocellulosic Waste as Sources of Feedstock for Biofuel Production in Developing Countries. Front. Energy Res. 2022, 10, 741570. [Google Scholar] [CrossRef]

- Lin, C.-Y. The Influences of Promising Feedstock Variability on Advanced Biofuel Production: A Review. J. Mar. Sci. Technol. 2022, 29, 714–730. [Google Scholar] [CrossRef]

- Foteinis, S.; Chatzisymeon, E.; Litinas, A.; Tsoutsos, T. Used-cooking-oil biodiesel: Life cycle assessment and comparison with first- and third-generation biofuel. Renew. Energy 2020, 153, 588–600. [Google Scholar] [CrossRef]

- Tsegaye, B.; Jaiswal, S.; Jaiswal, A.K. Food Waste Biorefinery: Pathway towards Circular Bioeconomy. Foods 2021, 10, 1174. [Google Scholar] [CrossRef]

- Ghosh, P.R.; Fawcett, D.; Sharma, S.B.; Poinern, G.E.J. Progress towards Sustainable Utilisation and Management of Food Wastes in the Global Economy. Int. J. Food Sci. 2016, 2016, 3563478. [Google Scholar] [CrossRef]

- Pancaldi, F.; Trindade, L.M. Marginal Lands to Grow Novel Bio-Based Crops: A Plant Breeding Perspective. Front. Plant Sci. 2020, 11, 227. [Google Scholar] [CrossRef]

- Panda, A.K.; Manyapu, V.; Mandpe, A.; Paliya, S. Plant-Based Biofuels: A Sustainable Solution for Energy Production. In Emerging Sustainable Technologies for Biofuel Production; Environmental Science; Shah, M., Deka, D., Eds.; Springer: Cham, Switzerland, 2024; pp. 247–273. [Google Scholar] [CrossRef]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Awad, F.N.; Qi, X.; Sahu, J. Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew. Sustain. Energy Rev. 2019, 105, 105–128. [Google Scholar] [CrossRef]

- Aslam, M. Transformation of 1-G and 2-G liquid biomass to green fuels using hydroprocessing technology: A promising technology for biorefinery development. Biomass Bioenergy 2022, 163, 106510. [Google Scholar] [CrossRef]

- Lindorfer, J.; Lettner, M.; Fazeni, K.; Rosenfeld, D.; Annevelink, B.; Mandl, M. Technical, Economic and Environmental Assessment of Biorefinery Concepts Developing a Practical Approach for Characterisation; IEA Bioenergy: Paris, France, 2019; Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/07/TEE_assessment_report_final_20190704-1.pdf (accessed on 22 April 2025).

- Garver, M.P.; Liu, S. Development of Thermochemical and Biochemical Technologies for Biorefineries. In Bioenergy Research: Advances and Applications, 27th ed.; Gupta, V.K., Tuohy, M.G., Kubicek, C.P., Saddler, J., Xu, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 457–488. [Google Scholar] [CrossRef]

- Nishshanka, G.K.S.H.; Anthonio, R.A.D.P.; Nimarshana, P.; Ariyadasa, T.U.; Chang, J.-S. Marine microalgae as sustainable feedstock for multi-product biorefineries. Biochem. Eng. J. 2022, 187, 108593. [Google Scholar] [CrossRef]

- Zhao, Z.-T.; Ding, J.; Pang, J.-W.; Bao, M.-Y.; Luo, J.; Wang, B.-Y.; Liu, B.-F.; Zhang, L.-Y.; Ren, N.-Q.; Yang, S.-S. Pretreatments of lignocellulosic biomass for biohydrogen biorefinery: Recent progress, techno-economic feasibility and prospectives. Crit. Rev. Environ. Sci. Technol. 2025, 55, 1070–1096. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front. Energy Res. 2018, 6, 419973. [Google Scholar] [CrossRef]

- Calvo-Flores, F.G.; Martin-Martinez, F.J. Biorefineries: Achievements and challenges for a bio-based economy. Front. Chem. 2022, 10, 973417. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Verhé, R.; Desender, L.; De Clercq, G.; Makara, A.; Generowicz, N.; Harazin, P. Second-generation biofuel production from the organic fraction of municipal solid waste. Front. Energy Res. 2022, 10, 919415. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Funke, A.; Dahmen, N. Direct Thermochemical Liquefaction Characteristics, Processes and Technologies. IEA Bioenergy Technology Collaboration Programme. 2020. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/07/Direct-Thermochemical-Liquefaction-Brochure-final.pdf (accessed on 24 April 2025).

- Teh, J.S.; Teoh, Y.H.; How, H.G.; Sher, F. Thermal Analysis Technologies for Biomass Feedstocks: A State-of-the-Art Review. Processes 2021, 9, 1610. [Google Scholar] [CrossRef]

- Yadav, N.; Yadav, G.; Bakthavachalam, V.; Potturaja, L.; Roy, J.K.; Elumalai, S. Agro-industrial residue torrefaction to bio-coal: Its physico-chemical characterization and potential applications in energy and environmental protection. Bioresour. Technol. 2025, 418, 131948. [Google Scholar] [CrossRef]

- Rashwan, S.S.; Adelusi, O.; Boulet, M.; Moreau, S. Turning trash into treasure: A comprehensive review on torrefaction of refuse-derived fuel from an industrial perspective. Energy Convers. Manag. 2025, 326, 119516. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Obada, D.O.; Kekung, M.O.; Levonyan, T.; Norval, G.W. Palm oil mill derived empty palm fruit bunches as a feed stock for renewable energy applications in Nigeria: A review. Bioresour. Technol. Rep. 2023, 24, 101666. [Google Scholar] [CrossRef]

- Kumar, R.N.; Aarthi, V. From biomass to syngas, fuels and chemicals-A review. In Proceedings of the National Conference on Energy and Chemicals from Biomass (NCECB), Puducherry, Hindistan: AIP Conference Proceedings, Puducherry, India, 10–11 October 2019. [Google Scholar] [CrossRef]

- He, Y.; Liu, R.; Yellezuome, D.; Peng, W.; Tabatabaei, M. Upgrading of biomass-derived bio-oil via catalytic hydrogenation with Rh and Pd catalysts. Renew. Energy 2022, 184, 487–497. [Google Scholar] [CrossRef]

- Chen, G.; Liang, L.; Li, N.; Lu, X.; Yan, B.; Cheng, Z. Upgrading of Bio-Oil Model Compounds and Bio-Crude into Biofuel by Electrocatalysis: A Review. ChemSusChem 2020, 14, 1037–1052. [Google Scholar] [CrossRef]

- Mercader, F.d.M.; Groeneveld, M.J.; Kersten, S.R.A.; Geantet, C.; Toussaint, G.; Way, N.W.J.; Schaverien, C.J.; Hogendoorn, K.J.A. Hydrodeoxygenation of pyrolysis oil fractions: Process understanding and quality assessment through co-processing in refinery units. Energy Environ. Sci. 2011, 4, 985–997. [Google Scholar] [CrossRef]

- Bharath, G.; Rambabu, K.; Hai, A.; Banat, F.; Taher, H.; Schmidt, J.E.; Show, P.L. Catalytic hydrodeoxygenation of biomass-derived pyrolysis oil over alloyed bimetallic Ni3Fe nanocatalyst for high-grade biofuel production. Energy Convers. Manag. 2020, 213, 112859. [Google Scholar] [CrossRef]

- Ata, B.; Jamil, A.A. Performance Investigation of Integrated Gasification Combined Cycle Power Plant for Polygeneration—TUprints; Technische Universität Darmstadt: Darmstadt, Germany, 2022. [Google Scholar] [CrossRef]

- Booz, J.; Höhner, D.; Burmester, S. Production of Synthesis Gas. In CO2 and CO as Feedstock Sustainable Carbon Sources for the Circular Economy; Kircher, M., Schwarz, T., Eds.; Springer: Cham, Switzerland, 2023; pp. 63–81. [Google Scholar] [CrossRef]

- Mazurova, K.; Miyassarova, A.; Eliseev, O.; Stytsenko, V.; Glotov, A.; Stavitskaya, A. Fischer–Tropsch Synthesis Catalysts for Selective Production of Diesel Fraction. Catalysts 2023, 13, 1215. [Google Scholar] [CrossRef]

- Amin, M.; Usman, M.; Kella, T.; Khan, W.U.; Khan, I.A.; Lee, K.H. Issues and challenges of Fischer–Tropsch synthesis catalysts. Front. Chem. 2024, 12, 1462503. [Google Scholar] [CrossRef]

- Adil, A.; Prasad, B.; Rao, L. Methanol generation from bio-syngas: Experimental analysis and modeling studies. Environ. Dev. Sustain. 2023, 26, 21503–21527. [Google Scholar] [CrossRef]

- Caballero, J.J.B.; Zaini, I.N.; Yang, W. Reforming processes for syngas production: A mini-review on the current status, challenges, and prospects for biomass conversion to fuels. Appl. Energy Combust. Sci. 2022, 10, 100064. [Google Scholar] [CrossRef]

- Chmielarz, L. Dehydration of Methanol to Dimethyl Ether—Current State and Perspectives. Catalysts 2024, 14, 308. [Google Scholar] [CrossRef]

- Anto, S.; Mukherjee, S.S.; Muthappa, R.; Mathimani, T.; Deviram, G.; Kumar, S.S.; Verma, T.N.; Pugazhendhi, A. Algae as green energy reserve: Technological outlook on biofuel production. Chemosphere 2020, 242, 125079. [Google Scholar] [CrossRef]

- Occhipinti, P.S.; Russo, N.; Foti, P.; Zingale, I.M.; Pino, A.; Romeo, F.V.; Randazzo, C.L.; Caggia, C. Current challenges of microalgae applications: Exploiting the potential of non-conventional microalgae species. J. Sci. Food Agric. 2023, 104, 3823–3833. [Google Scholar] [CrossRef]

- Ribeiro, R.L.L.; Vargas, J.V.C.; Mariano, A.B.; Ordonez, J.C. The experimental validation of a large-scale compact tubular microalgae photobioreactor model. Int. J. Energy Res. 2017, 41, 2221–2235. [Google Scholar] [CrossRef]

- Cornell University; Greene, C.; Huntley, M.; Archibald, I.; Gerber, L.; Sills, D.; Granados, J.; Tester, J.; Beal, C.; Walsh, M.; et al. Marine Microalgae: Climate, Energy, and Food Security from the Sea. Oceanography 2016, 29, 10–15. [Google Scholar] [CrossRef]

- Tahir, F.; Ashfaq, H.; Khan, A.Z.; Amin, M.; Akbar, I.; Malik, H.A.; Abdullah, M.; Alessa, A.H.; Alsaigh, A.A.; Ralph, P.J.; et al. Emerging trends in algae farming on non-arable lands for resource reclamation, recycling, and mitigation of climate change-driven food security challenges. Rev. Environ. Sci. Bio Technol. 2024, 23, 869–896. [Google Scholar] [CrossRef]

- Ashitha, A.; Rakhimol, K.R.; Jyothis, M. Fate of the conventional fertilizers in environment. In Controlled Release Fertilizers for Sustainable Agriculture; Lewu, F.B., Volova, T., Thomas, S., Eds.; Academic Press: New York, NY, USA, 2021; pp. 25–39. [Google Scholar] [CrossRef]

- Epa.gov. United States Environmental Protection Agency. Available online: https://www.epa.gov/nutrientpollution/sources-and-solutions-agriculture (accessed on 26 April 2025).

- Li, G.; Yao, J. A Review of Algae-Based Carbon Capture, Utilization, and Storage (Algae-Based CCUS). Gases 2024, 4, 468–503. [Google Scholar] [CrossRef]

- Fernández, L.A.G.; Castillo, N.A.M.; Polo, M.S.; Frómeta, A.E.N.; Cadre, J.E.V. Algal-Based Carbonaceous Materials for Environmental Remediation: Advances in Wastewater Treatment, Carbon Sequestration, and Biofuel Applications. Processes 2025, 13, 556. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, J.; Abdullah, R.; Cheah, W.Y.; Zhao, D.; Ling, T.C. Comprehensive Advancements in Hydrogel, and Its Application in Microalgae Cultivation and Wastewater Treatment. J. Microbiol. Biotechnol. 2024, 35, e2407038. [Google Scholar] [CrossRef]

- DOE. Algae Cultivation for Carbon Capture and Utilization Workshop Summary Report; DOE: Orlando, FL, USA, 2017. Available online: https://www.energy.gov/eere/bioenergy/articles/algae-cultivation-carbon-capture-and-utilization-workshop-summary-report-0 (accessed on 26 April 2025).

- Ghesti, G.F.; Silveira, E.A.; Guimarães, M.G.; Evaristo, R.B.; Costa, M. Towards a sustainable waste-to-energy pathway to pequi biomass residues: Biochar, syngas, and biodiesel analysis. Waste Manag. 2022, 143, 144–156. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Ge, Y.; Liang, R.; Sun, Y.; Cheng, Z.; Yan, B.; Chen, G. Technologies integration towards bio-fuels production: A state-of-the-art review. Appl. Energy Combust. Sci. 2022, 10, 100070. [Google Scholar] [CrossRef]

- Ma, X.-N.; Chen, T.-P.; Yang, B.; Liu, J.; Chen, F. Lipid Production from Nannochloropsis. Mar. Drugs 2016, 14, 61. [Google Scholar] [CrossRef]

- Shokravi, H.; Heidarrezaei, M.; Shokravi, Z.; Ong, H.C.; Lau, W.J.; Din, M.F.M.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass for bioeconomic development. J. Biotechnol. 2022, 360, 23–36. [Google Scholar] [CrossRef]

- Ren, M.; Ogden, K.; Lian, B. Effect of culture conditions on the growth rate and lipid production of microalgae Nannochloropsis gaditana. J. Renew. Sustain. Energy 2013, 5, 063138. [Google Scholar] [CrossRef]

- Moravvej, Z.; Makarem, M.A.; Rahimpour, M.R. The fourth generation of biofuel. In Second and Third Generation of Feedstocks: The Evolution of Biofuels; Basile, A., Dalena, F., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 557–597. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.; Nguyen, T.H.P. Sustainability of the four generations of biofuels–A review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Cavelius, P.; Engelhart-Straub, S.; Mehlmer, N.; Lercher, J.; Awad, D.; Brück, T. The potential of biofuels from first to fourth generation. PLoS Biol. 2023, 21, e3002063. [Google Scholar] [CrossRef]

- Raman, R.; Sreenivasan, A.; Kulkarni, N.V.; Suresh, M.; Nedungadi, P. Analyzing the contributions of biofuels, biomass, and bioenergy to sustainable development goals. iScience 2025, 28, 112157. [Google Scholar] [CrossRef]

- Padder, S.A.; Khan, R.; Rather, R.A. Biofuel generations: New insights into challenges and opportunities in their microbe-derived industrial production. Biomass Bioenergy 2024, 185, 107220. [Google Scholar] [CrossRef]

- Bajpai, P. Fourth Generation Biofuels. In Springer Briefs in Applied Sciences and Technology; Springer Nature Singapore: Singapore, 2022. [Google Scholar] [CrossRef]

- Kululo, W.W.; Habtu, N.G.; Abera, M.K.; Sendekie, Z.B.; Fanta, S.W.; Yemata, T.A. Recent Advances in Biochemical, Thermochemical, and Hybrid Conversion Approaches for Biofuel Production from Lignocellulosic Biomass: A Review. In Green Energy and Technology; Springer Nature: London, UK, 2025; pp. 297–330. [Google Scholar] [CrossRef]

- Mizik, T.; Igbeghe, C.B.; Deák, Z. Production Efficiency of Advanced Liquid Biofuels: Prospects and Challenges. Energies 2025, 18, 1008. [Google Scholar] [CrossRef]

- Hidalgo, D.; Urueña, A.; Martín-Marroquín, J.M.; Díez, D. Integrated Approach for Biomass Conversion Using Thermochemical Routes with Anaerobic Digestion and Syngas Fermentation. Sustainability 2025, 17, 3615. [Google Scholar] [CrossRef]

- DOE. Advancing Synergistic Waste Utilization as Biofuels Feedstocks: Preprocessing, Coproducts, and Sustainability. 2021. Available online: https://www.energy.gov/sites/default/files/2022-06/beto-waste-biofuels-wrksp-report.pdf (accessed on 26 April 2025).

- Marzban, N.; Psarianos, M.; Herrmann, C.; Schulz-Nielsen, L.; Olszewska-Widdrat, A.; Arefi, A.; Pecenka, R.; Grundmann, P.; Schlüter, O.K.; Hoffmann, T.; et al. Smart integrated biorefineries in bioeconomy: A concept toward zero-waste, emission reduction, and self-sufficient energy production. Biofuel Res. J. 2025, 12, 2319–2349. [Google Scholar] [CrossRef]

- Van Dyk, S.; Saddler, J. Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies, Potential and Challenges. IEA Bioenergy. 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/06/IEA-Bioenergy-Task-39-Progress-in-the-commercialisation-of-biojet-fuels-May-2021-1.pdf (accessed on 26 April 2025).

- Shuaibu, A.M.; Alhassan, U.H.; Shafi’i, A.M.; Kolere, M.S.; Sharma, R.; Abdurrashid, I. Biofuel: A sustainable and clean alternative to fossil fuel. GSC Adv. Res. Rev. 2024, 21, 204–222. [Google Scholar] [CrossRef]

- Aro, E.-M. From first generation biofuels to advanced solar biofuels. AMBIO 2015, 45, 24–31. [Google Scholar] [CrossRef]

- Yang, Y.; Chaffin, T.A.; Ahkami, A.H.; Blumwald, E.; Stewart, C.N. Plant synthetic biology innovations for biofuels and bioproducts. Trends Biotechnol. 2022, 40, 1454–1468. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, Z.; Maqbool, R.; Bhat, K.A. Genetic engineering and fifth-generation biofuels. In Environmental Sustainability of Biofuels: Prospects and Challenges; Hakeem, K.R., Bandh, S.A., Malla, F.A., Mehmood, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 237–251. [Google Scholar] [CrossRef]

- Aransiola, S.A.; Adeniyi, O.S.; Omoregie, I.P.; Akinhanmi, F.O.; Oniha, M.I.; Maddela, N.R. Microbial biotechnology for bioenergy: General overviews. In Microbial Biotechnology for Bioenergy; Maddela, N.R., Aransiola, S.A., Ezugwu, C.I., Eller, L.K.W., Scalvenzi, L., Meng, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 3–21. [Google Scholar] [CrossRef]

- Zohir, W.F.; Makhlof, M.E.M.; Abdallah, A.M.; El-Sheekh, M.M. Algae Cultivation Systems. In Value-added Products from Algae; Springer: Cham, Switzerland, 2024; pp. 11–41. [Google Scholar] [CrossRef]

- Burkart, M.D.; Hazari, N.; Tway, C.L.; Zeitler, E.L. Opportunities and Challenges for Catalysis in Carbon Dioxide Utilization. ACS Catal 2019, 9, 7937–7956. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, Y.; Xu, D.; Cheng, S.; Li, W.-W.; Song, H. Recent advances in synthetic biology toolkits and metabolic engineering of Ralstonia eutropha H16 for production of value-added chemicals. Biotechnol. Adv. 2025, 79, 108516. [Google Scholar] [CrossRef]

- Santolin, L.; Riedel, S.L.; Brigham, C.J. Synthetic biology toolkit of Ralstonia eutropha (Cupriavidus necator). Appl. Microbiol. Biotechnol. 2024, 108, 450. [Google Scholar] [CrossRef]

- Carbonell, P. Synthetic biology design tools for metabolic engineering. In Microbial Cell Factories Engineering for Production of Biomolecules; Singh, V., Ed.; Academic Press: New York, NY, USA, 2021; pp. 65–77. [Google Scholar] [CrossRef]

- Singh, J.; Gu, S. Commercialization potential of microalgae for biofuels production. Renew. Sustain. Energy Rev. 2010, 14, 2596–2610. [Google Scholar] [CrossRef]

- Nicoletti, G.; Arcuri, N.; Nicoletti, G.; Bruno, R. A technical and environmental comparison between hydrogen and some fossil fuels. Energy Convers. Manag. 2015, 89, 205–213. [Google Scholar] [CrossRef]

- Cherwoo, L.; Gupta, I.; Flora, G.; Verma, R.; Kapil, M.; Arya, S.K.; Ravindran, B.; Khoo, K.S.; Bhatia, S.K.; Chang, S.W.; et al. Biofuels an alternative to traditional fossil fuels: A comprehensive review. Sustain. Energy Technol. Assess. 2023, 60, 103503. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. A Math. Phys. Eng. Sci. 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Mizik, T.; Gyarmati, G. Three Pillars of Advanced Biofuels’ Sustainability. Fuels 2022, 3, 607–626. [Google Scholar] [CrossRef]

- Walls, L.E.; Rios-Solis, L. Sustainable Production of Microbial Isoprenoid Derived Advanced Biojet Fuels Using Different Generation Feedstocks: A Review. Front. Bioeng. Biotechnol. 2020, 8, 599560. [Google Scholar] [CrossRef] [PubMed]

- Lackner, M. Third-Generation Biofuels: Bacteria and Algae for Better Yield and Sustainability. In Handbook of Climate Change Mitigation and Adaptation, 3rd ed.; Lackner, M., Sajjadi, B., Chen, W.-Y., Eds.; Springer: Cham, Switzerland, 2022; Volume 3, pp. 1947–1986. [Google Scholar] [CrossRef]

- Ali, S.A.; Bangash, I.A.; Sajjad, H.; Karim, M.A.; Ahmad, F.; Ahmad, M.; Habib, K.; Shah, S.N.; Sami, A.; Laghari, Z.A.; et al. Review on the Role of Electrofuels in Decarbonizing Hard-to-Abate Transportation Sectors: Advances, Challenges, and Future Directions. Energy Fuels 2025, 39, 5051–5098. [Google Scholar] [CrossRef]

- Joshi, A.; Verma, K.K.; Rajput, V.D.; Minkina, T.; Arora, J. Recent advances in metabolic engineering of microorganisms for advancing lignocellulose-derived biofuels. Bioengineered 2022, 13, 8135–8163. [Google Scholar] [CrossRef]

- Le, A.; Guillomaitre, N. Artificial Photosynthesis: A Review of the Technology, Application, Opportunities, and Challenges. J. Stud. Res. 2022, 11, 1–11. [Google Scholar] [CrossRef]

- Fu, S.; Ma, K.; Song, X.; Sun, T.; Chen, L.; Zhang, W. Synthetic Biology Strategies and Tools to Modulate Photosynthesis in Microbes. Int. J. Mol. Sci. 2025, 26, 3116. [Google Scholar] [CrossRef]

- Yang, H.-H.; Dhital, N.B.; Wang, L.-C.; Hsieh, Y.-S.; Lee, K.-T.; Hsu, Y.-T.; Huang, S.-C. Chemical Characterization of Fine Particulate Matter in Gasoline and Diesel Vehicle Exhaust. Aerosol Air Qual. Res. 2019, 19, 1439–1449. [Google Scholar] [CrossRef]

- EPA; United States Environmental Protection Agency. Greenhouse Gas Emissions from a Typical Passenger Vehicle. US EPA. Available online: https://www.epa.gov/greenvehicles/greenhouse-gas-emissions-typical-passenger-vehicle (accessed on 25 May 2025).

- Aruga, K. Economics and Non-renewable/Renewable Resources. In Environmental and Natural Resource Economics; Aruga, K., Ed.; Springer: Cham, Switzerland, 2022; pp. 115–149. [Google Scholar] [CrossRef]

- Edo, G.I.; Itoje-Akpokiniovo, L.O.; Obasohan, P.; Ikpekoro, V.O.; Samuel, P.O.; Jikah, A.N.; Nosu, L.C.; Ekokotu, H.A.; Ugbune, U.; Oghroro, E.E.A.; et al. Impact of environmental pollution from human activities on water, air quality and climate change. Ecol. Front. 2024, 44, 874–889. [Google Scholar] [CrossRef]

- Shamoon, A.; Haleem, A.; Bahl, S.; Javaid, M.; Garg, S.B.; Sharma, R.C.; Garg, J. Environmental impact of energy production and extraction of materials—A review. Mater. Today Proc. 2022, 57, 936–941. [Google Scholar] [CrossRef]

- Wang, H.; Peng, X.; Zhang, H.; Yang, S.; Li, H. Microorganisms-promoted biodiesel production from biomass: A review. Energy Convers. Manag. X 2021, 12, 100137. [Google Scholar] [CrossRef]

- Sharif, N.; Munir, N.; Hasnain, M.; Naz, S.; Arshad, M. Environmental Impacts of Ethanol Production System. In Sustainable Ethanol and Climate Change: Sustainability Assessment for Ethanol Distilleries; Arshad, M., Ed.; Springer: Cham, Switzerland, 2021; pp. 205–223. [Google Scholar] [CrossRef]

- Tagne, R.F.T.; Santagata, R.; Tchuifon, D.R.T.; Atangana, J.A.K.; Ateba, F.R.; Vintila, T.; Ndifor-Angwagor, N.G.; Anagho, S.G.; Ulgiati, S. Environmental impact of second-generation biofuels production from agricultural residues in Cameroon: A life-cycle assessment study. J. Clean. Prod. 2022, 378, 134630. [Google Scholar] [CrossRef]

- Marques, L. Fossil Fuels. In Capitalism and Environmental Collapse; Marques, L., Ed.; Springer: Cham, Switzerland, 2020; pp. 131–155. [Google Scholar] [CrossRef]

- IEA. World Energy Employment 2023. 2023. Available online: https://www.iea.org/reports/world-energy-employment-2023/executive-summary (accessed on 26 May 2025).

- Bertrand, E.; Vandenberghe, L.P.S.; Soccol, C.R.; Sigoillot, J.-C.; Faulds, C. First Generation Bioethanol. In Green Energy and Technology; Soccol, C.R., Brar, S.K., Faulds, C., Ramos, L.P., Eds.; Springer: Cham, Switzerland, 2016; pp. 175–212. [Google Scholar] [CrossRef]

- Prade, T.; Svensson, S.-E.; Mattsson, J.E. Energy balances for biogas and solid biofuel production from industrial hemp. Biomass Bioenergy 2012, 40, 36–52. [Google Scholar] [CrossRef]

- Ordóñez, D.F.; Halfdanarson, T.; Ganzer, C.; Shah, N.; Mac Dowell, N.; Guillén-Gosálbez, G. Evaluation of the potential use of e-fuels in the European aviation sector: A comprehensive economic and environmental assessment including externalities. Sustain. Energy Fuels 2022, 6, 4749–4764. [Google Scholar] [CrossRef]

- Villarreal, J.V.; Burgués, C.; Rösch, C. Acceptability of genetically engineered algae biofuels in Europe: Opinions of experts and stakeholders. Biotechnol. Biofuels 2020, 13, 1–21. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging technologies for biofuel production: A critical review on recent progress, challenges and perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef]

- Foretich, A.; Zaimes, G.G.; Hawkins, T.R.; Newes, E. Challenges and opportunities for alternative fuels in the maritime sector. Marit. Transp. Res. 2021, 2, 100033. [Google Scholar] [CrossRef]

- Mekonnen, K.D.; Endris, Y.A.; Abdu, K.Y. Alternative Methods for Biodiesel Cetane Number Valuation: A Technical Note. ACS Omega 2024, 9, 6296–6304. [Google Scholar] [CrossRef]

- Korbag, I.; Omer, S.M.S.; Boghazala, H.; Abusasiyah, M.A.A. Biogas Production and Upgrading, Recent Advances of Biogas Production and Future Perspective. In Biogas: Recent Advances and Integrated Approaches; Abomohra, A.E.-F., Elsayed, M., Qin, Z., Ji, H., Liu, Z., Eds.; IntechOpen: London, UK, 2021; Available online: https://books.google.com/books/about/Biogas.html?hl=tr&id=TG0tEAAAQBAJ (accessed on 24 June 2025).

- Acda, M.N.; Devera, E.E. Physico-chemical properties of wood pellets from forest residues. J. Trop. For. Sci. 2013, 26, 589–595. [Google Scholar]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S. Energy Input and Quality of Pellets Made from Steam-Exploded Douglas Fir (Pseudotsuga menziesii). Energy Fuels 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Forsberg, C.; Dale, B.; Jones, D.; Hossain, T.; Morais, A.; Wendt, L. Replacing liquid fossil fuels and hydrocarbon chemical feedstocks with liquid biofuels from large-scale nuclear biorefineries. Appl. Energy 2021, 298, 117225. [Google Scholar] [CrossRef]

- Leblanc, F.; Bibas, R.; Mima, S.; Muratori, M.; Sakamoto, S.; Sano, F.; Bauer, N.; Daioglou, V.; Fujimori, S.; Gidden, M.J.; et al. The contribution of bioenergy to the decarbonization of transport: A multi-model assessment. Clim. Change 2022, 170, 1–21. [Google Scholar] [CrossRef]

- Obeid, F.; Van, T.C.; Horchler, E.J.; Guo, Y.; Verma, P.; Miljevic, B.; Brown, R.J.; Ristovski, Z.; Bodisco, T.; Rainey, T. Engine performance and emissions from fuels containing nitrogen and sulphur. Energy Convers. Manag. X 2022, 14, 100179. [Google Scholar] [CrossRef]

- Okolie, J.A.; Mukherjee, A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Next-generation biofuels and platform biochemicals from lignocellulosic biomass. Int. J. Energy Res. 2021, 45, 14145–14169. [Google Scholar] [CrossRef]

- Mendiburu, A.Z.; Lauermann, C.H.; Hayashi, T.C.; Mariños, D.J.; da Costa, R.B.R.; Coronado, C.J.; Roberts, J.J.; de Carvalho, J.A. Ethanol as a renewable biofuel: Combustion characteristics and application in engines. Energy 2022, 257, 124688. [Google Scholar] [CrossRef]

- Jayakumar, M.; Gebeyehu, K.B.; Abo, L.D.; Tadesse, A.W.; Vivekanandan, B.; Sundramurthy, V.P.; Bacha, W.; Ashokkumar, V.; Baskar, G. A comprehensive outlook on topical processing methods for biofuel production and its thermal applications: Current advances, sustainability and challenges. Fuel 2023, 349, 128690. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus climate change: Exploring potentials and challenges in the energy transition. Renew. Sustain. Energy Rev. 2024, 196, 114369. [Google Scholar] [CrossRef]

- Acharya, B.S.; Saud, P.; Sharma, S.; Perez-Verdin, G.; Grebner, D.L.; Joshi, O. Wood-Based Bioenergy in North America: An Overview of Current Knowledge. Forests 2024, 15, 1669. [Google Scholar] [CrossRef]

- El-Araby, R. Biofuel production: Exploring renewable energy solutions for a greener future. Biotechnol. Biofuels Bioprod. 2024, 17, 1–32. [Google Scholar] [CrossRef]

- Suhara, A.; Karyadi; Herawan, S.G.; Tirta, A.; Idris, M.; Roslan, M.F.; Putra, N.R.; Hananto, A.L.; Veza, I. Biodiesel Sustainability: Review of Progress and Challenges of Biodiesel as Sustainable Biofuel. Clean Technol. 2024, 6, 886–906. [Google Scholar] [CrossRef]

- Datta, P.; Bej, S.; Vasudeva, M.; Raval, K. Use of Microalgae for the Development of Carbon Neutral Bio-CNG Process. In Recent Trends and Developments in Algal Biofuels and Biorefinery; Bharadvaja, N., Kumar, L., Pandit, S., Banerjee, S., Anand, R., Eds.; Springer: Cham, Switzerland, 2024; pp. 383–399. [Google Scholar] [CrossRef]

- Lackner, M.; Fei, Q.; Guo, S.; Yang, N.; Guan, X.; Hu, P. Biomass Gasification as a Scalable, Green Route to Combined Heat and Power (CHP) and Synthesis Gas for Materials: A Review. Fuels 2024, 5, 625–649. [Google Scholar] [CrossRef]

- Li, S. Reviewing Air Pollutants Generated during the Pyrolysis of Solid Waste for Biofuel and Biochar Production: Toward Cleaner Production Practices. Sustainability 2024, 16, 1169. [Google Scholar] [CrossRef]

- Monteiro, E.; Ramos, A.; Rouboa, A. Fundamental designs of gasification plants for combined heat and power. Renew. Sustain. Energy Rev. 2024, 196, 114305. [Google Scholar] [CrossRef]

- Rey, J.; Longo, A.; Rijo, B.; Pedrero, C.; Tarelho, L.; Brito, P.; Nobre, C. A review of cleaning technologies for biomass-derived syngas. Fuel 2024, 377, 132776. [Google Scholar] [CrossRef]

- Rossin, A.R.d.S.; Cardoso, F.d.S.L.; Cordeiro, C.C.; Breitenbach, G.L.; Caetano, J.; Dragunski, D.C.; Rosenberger, A.G. Chemical Properties of Biomass. In Handbook of Biomass; Thomas, S., Hosur, M., Pasquini, D., Chirayil, C.J., Eds.; Springer: Singapore, 2024; pp. 331–347. [Google Scholar] [CrossRef]

- Seboka, A.D.; Ewunie, G.A.; Morken, J.; Feng, L.; Adaramola, M.S. Potentials and prospects of solid biowaste resources for biofuel production in Ethiopia: A systematic review of the evidence. Biomass Convers. Biorefinery 2023, 14, 30929–30960. [Google Scholar] [CrossRef]

- Vasileiadou, A. From Organic Wastes to Bioenergy, Biofuels, and Value-Added Products for Urban Sustainability and Circular Economy: A Review. Urban Sci. 2024, 8, 121. [Google Scholar] [CrossRef]

- Manandhar, A.; Mousavi-Avval, S.H.; Tatum, J.; Shrestha, E.; Nazemi, P.; Shah, A. Solid biofuels. In Biomass, Biofuels, Biochemicals: Green-Economy: Systems Analysis for Sustainability; Murthy, G.S., Gnansounou, E., Khanal, S.K., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 343–370. [Google Scholar] [CrossRef]

- Apraku, S.E.; Shen, Y. Biomass Pellet Fuel Production and Utilization in Ghana: A Review. ACS Sustain. Resour. Manag. 2024, 1, 586–603. [Google Scholar] [CrossRef]

- Cuervo, O.H.P.; Rosas, C.A.; Romanelli, G.P. Valorization of residual lignocellulosic biomass in South America: A review. Environ. Sci. Pollut. Res. 2024, 31, 44575–44607. [Google Scholar] [CrossRef]

- Ersoy, A.E.; Ugurlu, A. Bioenergy’s role in achieving a low-carbon electricity future: A case of Türkiye. Appl. Energy 2024, 372, 123799. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V. Valorization of agricultural wastes for biofuel applications. Heliyon 2022, 8, e11117. [Google Scholar] [CrossRef]

- Li, H.-Y.; Wang, B.; Wen, J.-L.; Cao, X.-F.; Sun, S.-N.; Sun, R.-C. Availability of four energy crops assessing by the enzymatic hydrolysis and structural features of lignin before and after hydrothermal treatment. Energy Convers. Manag. 2018, 155, 58–67. [Google Scholar] [CrossRef]

- Lubello, C.; Fiaschi, S.; Notari, G. Municipal solid waste composition and efficiency of separate collection: A case study in Italy. Clean. Waste Syst. 2025, 11, 100272. [Google Scholar] [CrossRef]

- Elqadhi, M.E.R.; Skrbic, S.; Mohamoud, O.A.; Asonja, A. Energy integration of corn cob in the process of drying the corn seeds. Therm. Sci. 2024, 28, 3325–3336. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Bioenergy and Biofuels. Available online: https://www.irena.org/Energy-Transition/Technology/Bioenergy-and-biofuels (accessed on 30 April 2025).

- Sarker, T.R.; Ethen, D.Z.; Asha, H.H.; Islam, S.; Ali, R. Transformation of municipal solid waste to biofuel and bio-chemicals—A review. Int. J. Environ. Sci. Technol. 2024, 22, 3811–3832. [Google Scholar] [CrossRef]

- Mignogna, D.; Szabó, M.; Ceci, P.; Avino, P. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability 2024, 16, 7036. [Google Scholar] [CrossRef]

- Searle, S.; Malins, C. A reassessment of global bioenergy potential in 2050. GCB Bioenergy 2014, 7, 328–336. [Google Scholar] [CrossRef]

- Slade, R.; Bauen, A.; Gross, R. Global bioenergy resources. Nat. Clim. Change 2014, 4, 99–105. [Google Scholar] [CrossRef]

- Thanigaivel, S.; Priya, A.; Dutta, K.; Rajendran, S.; Vasseghian, Y. Engineering strategies and opportunities of next generation biofuel from microalgae: A perspective review on the potential bioenergy feedstock. Fuel 2022, 312, 122827. [Google Scholar] [CrossRef]

- Sarwer, A.; Hussain, M.; Al-Muhtaseb, A.H.; Inayat, A.; Rafiq, S.; Khurram, M.S.; Ul-Haq, N.; Shah, N.S.; Din, A.A.; Ahmad, I.; et al. Suitability of Biofuels Production on Commercial Scale from Various Feedstocks: A Critical Review. ChemBioEng Rev. 2022, 9, 423–441. [Google Scholar] [CrossRef]

- Lundgren, J.; Vreugdenhil, B.; Ganjkhanlou, Y.; Baldwin, R. Biomass Gasification for Hydrogen Production. IEA Bioenergy Technology Collaboration Programme: Task 33. 2025. Available online: https://www.ieabioenergy.com/wp-content/uploads/2025/03/IEA-Bioenergy_T33_Bio-H2_Final_v2.pdf (accessed on 3 May 2025).

- Jafri, Y.; Ahlström, J.M.; Furusjö, E.; Harvey, S.; Pettersson, K.; Svensson, E.; Wetterlund, E. Double Yields and Negative Emissions? Resource, Climate and Cost Efficiencies in Biofuels With Carbon Capture, Storage and Utilization. Front. Energy Res. 2022, 10, 797529. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Bioenergy with Carbon Capture and Storage—Energy System—IEA. Available online: https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage/bioenergy-with-carbon-capture-and-storage (accessed on 3 May 2025).

- IEA. Bioenergy in a Net Zero Future, Summary and Conclusions from the IEA Bioenergy Workshop. IEA Bioenergy Technology Collaboration Programme. Available online: https://www.ieabioenergy.com/wp-content/uploads/2024/01/ExCo92_Workshop-Summary.pdf (accessed on 3 May 2025).

- Freer, M.; Fullonton, A.; Clery, D.; Mander, S.; Gough, C. Co-deployment of bioenergy with carbon capture and storage in the UK: Growth or gridlock? Sustain. Prod. Consum. 2024, 50, 45–68. [Google Scholar] [CrossRef]

- Pickard, C.; Pasqualino, R. Long-Term Strategies for the Compatibility of the Aviation Industry with Climate Targets: An Industrial Survey and Agenda for Systems Thinkers. Systems 2022, 10, 90. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.-H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in utilisation of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Ponnusamy, M.; Ramani, B.; Sathyamruthy, R. A Parametric Study on a Diesel Engine Fuelled Using Waste Cooking Oil Blended with Al2O3 Nanoparticle—Performance, Emission, and Combustion Characteristics. Sustainability 2021, 13, 7195. [Google Scholar] [CrossRef]

- European Commission. ‘Fit for 55’: Council Adopts Regulation on CO2 Emissions for New Cars and Vans. 2023. Available online: https://www.consilium.europa.eu/en/press/press-releases/2023/03/28/fit-for-55-council-adopts-regulation-on-co2-emissions-for-new-cars-and-vans/pdf/ (accessed on 28 May 2025).

- European Commission. Commission Delegated Regulation (EU) 2023/1184 of 10 February 2023 Supplementing Directive (EU) 2018/2001 of the European Parliament and of the Council by Establishing a Union Methodology Setting Out Detailed Rules for the Production of Renewable Liquid and Gaseous Transport Fuels of Non-Biological Origin. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32023R1184 (accessed on 28 May 2025).

- European Commission. EU Emissions Trading System (EU ETS). Available online: https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets_en (accessed on 28 May 2025).

- European Commission. Directive (EU) 2023/959 of the European Parliament and of The Council of 10 May 2023 Amending Directive 2003/87/EC Establishing A System For Greenhouse Gas Emission Allowance Trading Within the Union and Decision (EU) 2015/1814 Concerning the Establishment and Operation of A Market Stability Reserve for the Union Greenhouse Gas Emission Trading System (Text with EEA Relevance). Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32023L0959 (accessed on 28 May 2025).

- Taheripour, F.; Mueller, S.; Emery, I.; Karami, O.; Sajedinia, E.; Zhuang, Q.; Wang, M. Biofuels Induced Land Use Change Emissions: The Role of Implemented Land Use Emission Factors. Sustainability 2024, 16, 2729. [Google Scholar] [CrossRef]

- Arias, A.; Nika, C.-E.; Vasilaki, V.; Feijoo, G.; Moreira, M.T.; Katsou, E. Assessing the future prospects of emerging technologies for shipping and aviation biofuels: A critical review. Renew. Sustain. Energy Rev. 2024, 197, 114427. [Google Scholar] [CrossRef]

- van Grinsven, A.; van den Toorn, E.; van der Veen, R.; Kampman, B. Used Cooking Oil (UCO) as Biofuel Feedstock in the EU. CE Delft. Available online: https://cedelft.eu/wp-content/uploads/sites/2/2021/04/CE_Delft__200247_UCO_as_biofuel_feedstock_in_EU_FINAL-v5.pdf (accessed on 3 May 2025).

- International Energy Agency (IEA). Transport Biofuels—Renewables. 2023. Available online: https://www.iea.org/reports/renewables-2023/transport-biofuels (accessed on 3 May 2025).

- International Energy Agency (IEA). Renewable Fuels—Renewables 2024. Available online: https://www.iea.org/reports/renewables-2024/renewable-fuels (accessed on 3 May 2025).

- Hasanov, A.S.; Burkhanov, A.U.; Usmonov, B.; Khajimuratov, N.S.; Khurramova, M.M.Q. The role of sudden variance shifts in predicting volatility in bioenergy crop markets under structural breaks. Energy 2024, 293, 130535. [Google Scholar] [CrossRef]

- Uchida, N.; Lucchini, T.; Kulzer, A.C.; Agarwal, A.K.; Onorati, A.; Abdul-Manan, A.F.; Valera, H.; Payri, R.; Pesyridis, A.; Jena, A.; et al. E-fuels in IC engines: A key solution for a future decarbonized transport. Int. J. Engine Res. 2025. [Google Scholar] [CrossRef]

- Huey, C.; Metghalchi, H.; Levendis, Y. E-Fuels as Reduced Carbon Emission Options. ASME Open J. Eng. 2024, 3, 4065731. [Google Scholar] [CrossRef]

- Shi, K.; Guan, B.; Zhuang, Z.; Chen, J.; Ma, Z.; Zhu, C. Perspectives and Outlook of E-fuels: Production, Cost Effectiveness, and Applications. Energy Fuels 2024, 38, 7665–7692. [Google Scholar] [CrossRef]

- Galán-Martín, Á.; Merlich, V.T.; Díaz, I.; Pozo, C.; Pérez-Ramírez, J.; Gosálbez, G.G. Sustainability footprints of a renewable carbon transition for the petrochemical sector within planetary boundaries. One Earth 2021, 4, 565–583. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, Y.; Pan, S.; Snyder, S.W. Catalytic Processes to Accelerate Decarbonization in a Net-Zero Carbon World. ChemSusChem 2022, 15, e202201290. [Google Scholar] [CrossRef] [PubMed]

- Morch, A.; Sæle, H.; Ardanuy, J.F.; Conti, G.; Comodi, G.; Rossi, M. Current Status of Multi-carrier Energy Systems in Europe with Main Limitations and Shortcomings to the Optimal Use of Local Energy Resources. In Integrated Local Energy Communities; Di Somma, M., Papadimitriou, C., Graditi, G., Kok, K., Eds.; Wiley: Hoboken, NJ, USA, 2024; pp. 19–54. [Google Scholar] [CrossRef]

- Tsiklios, C.; Schneider, S.; Hermesmann, M.; Müller, T.E. Efficiency and optimal load capacity of E-Fuel-Based energy storage systems. Adv. Appl. Energy 2023, 10, 100140. [Google Scholar] [CrossRef]

- Dybiński, O.; Szabłowski, Ł.; Martsinchyk, A.; Szczęśniak, A.; Milewski, J.; Grzebielec, A.; Shuhayeu, P. Overview of the e-Fuels Market, Projects, and the State of the Art of Production Facilities. Energies 2025, 18, 552. [Google Scholar] [CrossRef]

- Joarder, S.A.; Islam, S.; Hasan, H.; Kutub, A.; Kabir, F.; Rashid, F.; Joarder, T.A. A comprehensive review of carbon dioxide capture, transportation, utilization, and storage: A source of future energy. Environ. Sci. Pollut. Res. 2025, 32, 9299–9332. [Google Scholar] [CrossRef] [PubMed]

- Rodin, V.; Lindorfer, J.; Böhm, H.; Vieira, L. Assessing the potential of carbon dioxide valorisation in Europe with focus on biogenic CO2. J. CO2 Util. 2020, 41, 101219. [Google Scholar] [CrossRef]

- Visconti, C.G.; Martinelli, M.; Falbo, L.; Fratalocchi, L.; Lietti, L. CO2 hydrogenation to hydrocarbons over Co and Fe-based Fischer-Tropsch catalysts. Catal. Today 2016, 277, 161–170. [Google Scholar] [CrossRef]

- Jamaati, M.; Torkashvand, M.; Tafreshi, S.S.; de Leeuw, N.H. A Review of Theoretical Studies on Carbon Monoxide Hydrogenation via Fischer–Tropsch Synthesis over Transition Metals. Molecules 2023, 28, 6525. [Google Scholar] [CrossRef]

- Apolinar-Hernández, J.E.; Bertoli, S.L.; Riella, H.G.; Soares, C.; Padoin, N. An Overview of Low-Temperature Fisch-er-Tropsch Synthesis: Market Conditions, Raw Materials, Reactors, Scale-Up, Process Intensification, Mechanisms, and Outlook. Energy Fuels 2024, 38, 1–28. [Google Scholar] [CrossRef]

- Ebrahimian, S.; Bhattacharya, S. Direct CO2 Hydrogenation over Bifunctional Catalysts to Produce Dimethyl Ether—A Review. Energies 2024, 17, 3701. [Google Scholar] [CrossRef]

- Chen, C.; Garedew, M.; Sheehan, S.W. Single-Step Production of Alcohols and Paraffins from CO2 and H2 at Metric Ton Scale. ACS Energy Lett. 2022, 7, 988–992. [Google Scholar] [CrossRef]

- Pamei, M.; Sharma, S.K.; Das, D.; Vadivel, S.; Paul, B.; Puzari, A. Challenges and advances in understanding the roadmap for direct hydrogenation of carbon dioxide to ethanol. Catal. Rev. 2024, 1–47. [Google Scholar] [CrossRef]

- Thompson, R.S.; Langlois, G.G.; Li, W.; Brann, M.R.; Sibener, S. Reverse water-gas shift chemistry inside a supersonic molecular beam nozzle. Appl. Surf. Sci. 2020, 515, 145985. [Google Scholar] [CrossRef]

- Reinikainen, M.; Braunschweiler, A.; Korpilo, S.; Simell, P.; Alopaeus, V. Two-Step Conversion of CO2 to Light Olefins: Laboratory-Scale Demonstration and Scale-Up Considerations. Chemengineering 2022, 6, 96. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Chrysikou, L.P.; Bezergianni, S. Automotive e-Fuels via Hydrocracking of FT-Wax: E-Gasoline and e-Diesel Production. Energies 2024, 17, 2756. [Google Scholar] [CrossRef]

- EIB. Methodologies for the Assessment of Project Greenhouse Gas Emissions and Emission Variations. EIB Project Carbon Footprint Methodologies. 2023. Available online: https://www.eib.org/attachments/lucalli/eib_project_carbon_footprint_methodologies_2023_en.pdf (accessed on 4 May 2025).

- Yücel, S.B.; Donar, Y.O.; Ergenekon, S.; Özoylumlu, B.; Sinağ, A. Green catalyst for clean fuel production via hydrodeoxygenation. Turk. J. Chem. 2023, 47, 968–990. [Google Scholar] [CrossRef]

- Byun, M.; Lim, D.; Lee, B.; Kim, A.; Lee, I.-B.; Brigljević, B.; Lim, H. Economically feasible decarbonization of the Haber-Bosch process through L. Collado, A. Herrero, and V. A. de la Peña O’Sheah supercritical CO2 Allam cycle integration. Appl. Energy 2022, 307, 118183. [Google Scholar] [CrossRef]

- Collado, L.; Herrero, A.; de la Peña O’Shea, V.A. From Conventional to Emerging Ammonia Production Technologies. In Powerfuels; Springer: Cham, Switzerland, 2025; pp. 713–757. [Google Scholar] [CrossRef]

- Amhamed, A.I.; Qarnain, S.S.; Hewlett, S.; Sodiq, A.; Abdellatif, Y.; Isaifan, R.J.; Alrebei, O.F. Ammonia Production Plants—A Review. Fuels 2022, 3, 408–435. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Ammonia Technology Roadmap. Available online: https://www.iea.org/reports/ammonia-technology-roadmap (accessed on 17 May 2025).

- Lin, B.; Nowrin, F.H.; Rosenthal, J.J.; Bhown, A.S.; Malmali, M. Perspective on Intensification of Haber−Bosch to Enable Ammonia Production under Milder Conditions. ACS Sustain. Chem. Eng. 2023, 11, 9880–9899. [Google Scholar] [CrossRef]

- Ojelade, O.A.; Zaman, S.F.; Ni, B.-J. Green ammonia production technologies: A review of practical progress. J. Environ. Manag. 2023, 342, 118348. [Google Scholar] [CrossRef]

- Badger, N.; Amini, S. Life cycle assessment of a novel gas switching reforming for sustainable hydrogen production with CO2 capture. Int. J. Hydrogen Energy 2025, 126, 308–318. [Google Scholar] [CrossRef]

- Geng, C.; Li, J.; Weiske, T.; Schwarz, H. Ta2+—Mediated ammonia synthesis from N2 and H2 at ambient temperature. Proc. Natl. Acad. Sci. USA 2018, 115, 11680–11687. [Google Scholar] [CrossRef] [PubMed]

- Estevez, R.; López-Tenllado, F.J.; Aguado-Deblas, L.; Bautista, F.M.; Romero, A.A.; Luna, D. Current Research on Green Ammonia (NH3) as a Potential Vector Energy for Power Storage and Engine Fuels: A Review. Energies 2023, 16, 5451. [Google Scholar] [CrossRef]

- Concepcion, J.J.; Sampaio, R.N.; Meyer, G.J. Catalytic Reduction of Carbon Monoxide to Liquid Fuels with Recyclable Hydride Donors. ACS Catal. 2024, 14, 16562–16569. [Google Scholar] [CrossRef]

- Asif, M.; Bibi, S.S.; Ahmed, S.; Irshad, M.; Hussain, M.S.; Zeb, H.; Khan, M.K.; Kim, J. Recent advances in green hydrogen production, storage and commercial-scale use via catalytic ammonia cracking. Chem. Eng. J. 2023, 473, 145381. [Google Scholar] [CrossRef]

- Tornatore, C.; Marchitto, L.; Sabia, P.; De Joannon, M. Ammonia as Green Fuel in Internal Combustion Engines: State-of-the-Art and Future Perspectives. Front. Mech. Eng. 2022, 8, 944201. [Google Scholar] [CrossRef]

- Alnajideen, M.; Shi, H.; Northrop, W.; Emberson, D.; Kane, S.; Czyzewski, P.; Alnaeli, M.; Mashruk, S.; Rouwenhorst, K.; Yu, C.; et al. Ammonia combustion and emissions in practical applications: A review. Carbon Neutrality 2024, 3, 1–45. [Google Scholar] [CrossRef]

- Inal, O.B.; Zincir, B.; Deniz, C. Investigation on the decarbonization of shipping: An approach to hydrogen and ammonia. Int. J. Hydrogen Energy 2022, 47, 19888–19900. [Google Scholar] [CrossRef]

- Samuel, M.S.; Sudhakar, M.P.; Santhappan, J.S.; Ravikumar, M.; Kalaiselvan, N.; Mathimani, T. Ammonia production from microalgal biosystem: Present scenario, cultivation systems, production technologies, and way forward. Fuel 2024, 368, 131643. [Google Scholar] [CrossRef]

- Nemmour, A.; Inayat, A.; Janajreh, I.; Ghenai, C. Green hydrogen-based E-fuels (E-methane, E-methanol, E-ammonia) to support clean energy transition: A literature review. Int. J. Hydrogen Energy 2023, 48, 29011–29033. [Google Scholar] [CrossRef]