Abstract

The convergence of intelligent computational innovations—exemplified by cognitive intelligence—into the real economy is fundamentally transforming traditional industries and driving high-quality development. As a cornerstone of national economic growth, the energy sector faces mounting pressure to meet demands for green, low-carbon, and sustainable development, particularly under “dual carbon” targets and tightening regulatory frameworks. This study examines how digital transformation in this sector facilitates or impedes carbon emission reduction and green growth. Focusing on five key energy subsectors, including coal mining and processing, a coupling coordination model assesses the interaction between digitalization and greening. Utilizing panel data spanning from 2014 to 2023, the study systematically evaluates the level of digital–green coordination across the sector. The results indicate notable inter-sectoral variation, alongside a consistent upward trend in the overall coupling coordination, reaching moderate to high levels. These findings offer critical strategic insights for policymakers and energy enterprises seeking to harmonize digital innovation with green transition goals. The empirical evidence underscores the potential of next-generation technologies to expedite intelligent system upgrades, embed green development practices, and enhance enterprise-level carbon reduction and sustainability performance.

1. Introduction

Amid the Fourth Industrial Revolution, integrating next-generation information technologies—such as artificial intelligence, big data, and the industrial Internet—with enterprise-level green technologies and sustainable practices has become a key driver of high-quality economic development []. The United States has designated green manufacturing as a strategic priority to enhance the global competitiveness of its manufacturing sector, emphasizing the development of sustainable technologies aimed at minimizing energy consumption, reducing greenhouse emissions, and decreasing dependence on non-renewable resources throughout production processes []. Over a decade ago, the European Union introduced the “Digitising European Industry” initiative, which advocated for the application of the Internet of Things, big data and AI across industrial sectors to improve energy efficiency and accelerate the transition from traditional manufacturing to digital green production models []. In 2017, the United Kingdom published the Green Paper on the Modern Industrial Strategy, underscoring the need to increase investment in research and innovation, enhance energy supply efficiency, promote green development, and advance industrial digitalization []. Similarly, Japan has prioritized the dual transformation of its industrial base by using digital technologies to connect equipment, personnel, departments, and enterprises, thereby strengthening the digital and green foundations of its industrial system []. Since 2012, China has systematically advanced “Digital China” through a series of national policies and strategic deployments. The Opinions on Accelerating the Comprehensive Green Transformation of Economic and Social Development highlight five key areas—including industrial structure and energy systems—as priorities for achieving comprehensive green transformation []. The deep integration of industrial digitalization, intelligentization, and greening now sustains China’s long-term economic growth as a pivotal force. Research and practical exploration into the synergistic development of digitalization and greening within industrial systems are essential for simultaneously advancing economic performance and ecological sustainability. These efforts also provide valuable frameworks and strategic references for global enterprises pursuing digital, intelligent, green, and low-carbon development pathways [].

Energy constitutes the cornerstone of a nation’s economic and social development, underpinning industrial production, transportation, residential consumption, and a broad spectrum of economic activities []. As a strategic sector, the energy industry is instrumental in supporting national development priorities and strengthening security across critical domains. The convergence of energy systems with artificial intelligence (AI) technologies represents an irreversible trajectory with the potential to reshape the energy landscape profoundly. AI applications span the entire energy value chain—from production and transmission to consumption—offering opportunities to optimize operations, improve energy efficiency, and elevate system-wide management capabilities []. In the consumption domain, AI facilitates intelligent control and energy-saving strategies, fostering more sustainable and innovative patterns of energy use []. Against the backdrop of the “carbon peaking” targets, it is essential to accelerate low-carbon transformation in the energy sector, significantly enhance energy system efficiency, and bolster innovation capacity to support green development. Achieving these objectives requires a strategic emphasis on technological innovation, the systematic upgrading of the energy industry’s foundational capabilities, the modernization of supply chains, and the rapid advancement of digital and intelligent energy infrastructure. Ultimately, fostering deep integration and coordinated progress in digitalization greening within the energy sector is vital to ensure long-term sustainable and high-quality development.

Currently, an increasing number of scholars have explored the digital transformation of the energy industry. Ref. [] examined digital transformation’s influence on energy efficiency, concluding that it significantly enhances energy efficiency at the firm level. Ref. [] quantitatively assessed digital transformation’s link to energy security, arguing that the digitalization and carbon neutrality efforts of energy enterprises positively contribute to energy security. They advocate for the establishment of digital intelligent innovation platforms and the digital upgrading of energy enterprises. Ref. [] underscored the pivotal role of risk management and control within clean energy projects, asserting that digital applications can substantially advance and facilitate the greening of the industry. Ref. [] proposed enhancing total factor energy efficiency through accelerating digital infrastructure construction, promoting industrial energy digitalization, and advancing low-carbon-technology R&D. Ref. [] emphasized that digital transformation serves as a key to modernizing the energy industry system. Overall, despite the diversity in research perspectives and analytical dimensions, a consensus emerges among scholars that digital transformation not only significantly improves production and energy efficiency within enterprises but actively drives clean energy sector development, thereby supporting green and sustainable energy industry transformation.

In green innovation within the energy industry, Ref. [] examined the driving mechanisms behind green innovation in energy enterprises. Their findings indicate that internal factors—such as enterprise digitalization, dynamic capabilities, and resource redundancy—and external conditions, including environmental drivers, market vitality, and regulatory pressure, jointly shape it. They proposed that for new energy enterprises, the core driving model is a dual-drive mechanism based on digitalization and dynamic capabilities. Ref. [] argued that green and low-carbon energy enterprise transformation underpins high-quality development in the energy sector and is a key strategy for mitigating global climate change. Ref. [] identified a nonlinear link between enterprise-level energy efficiency and green technological innovation, revealing that low levels of green innovation may inhibit energy efficiency while high levels of innovation substantially improve it. Ref. [] emphasized that China’s green transformation in the energy sector holds global significance. They asserted that technological advancement is the primary engine driving the green transition. At the same time, a well-functioning market environment serves as the fundamental safeguard for promoting green development among energy enterprises. Overall, the extant literature suggests that green energy industry transformation now represents a strategic response to climate change. To meet these goals, enterprises necessitate an accelerated push toward digital transformation.

A growing body of research has examined digital–green integration within the energy industry. Ref. [] investigated the spatiotemporal distribution, dynamic evolution, regional disparities, and carbon reduction effects of coupling coordination in the energy sector’s digital–green development. The study recommended tailored regional policies and advancing initiatives like “Eastern Data, Western Computing” to enhance sector synergy, thereby facilitating carbon emission reduction. Ref. [] found that digital transformation significantly enhances enterprise energy efficiency, primarily by strengthening green innovation capabilities and optimizing energy structures. Ref. [] argued that energy sector digitalization effectively enhances total factor productivity in energy enterprises. Ref. [] emphasized that amid new technological and industrial revolutions, digital–green coordinated development now represents an inevitable trend, serving as a key driver of global economic growth and a core component of national competitiveness. Ref. [] noted that digital–green integration is vital for building modern industrial systems. Green energy industry development lays the foundation for digital progress, while digital technologies empower green transformation and data elements catalyze cross-sectoral innovation. Ref. [] demonstrated that digital finance significantly boosts green innovation in energy enterprises, enhancing green innovation scale and quality. Synthesizing these findings, broad consensus confirms that Industry 4.0 drives irreversible digital–green coordinated development in the energy sector. Digital transformation improves energy efficiency and production management while supporting enterprise carbon reduction. Meanwhile, pursuing green and low-carbon sustainability compels continuous optimization of digital infrastructure and comprehensive integration of technologies like AI and big data into all operational stages, thereby advancing traditional energy industry transformation.

Judging from the existing literature of scholars at home and abroad, most scholars’ research results mainly focus on the digital transformation of energy industry or the green development of energy enterprises and study one aspect or dimension of digitalization and greening. A few scholars have studied the integration and development of digitalization and greening of industrial enterprises and manufacturing industries and measured the coordinated development level of digitalization and greening in different regions according to the situation in China, and achieved certain research results. It has formed a consensus that industrial digitalization can empower green development and traction in green digital transformation and realize the integration of enterprise digitalization and green development, which provides a theoretical basis for the study of this article. However, did energy enterprises promote green development in the process of digital transformation, and to what extent? To what extent is the green development of energy enterprises the result of digital transformation? That is, what is the level of coordinated development of digital and green energy industry? At present, there are few studies about the mechanism and measurement of the energy industry’s digital and green coupling coordinated development, but measuring this is of great guiding value for enterprises to promote the digital construction process and realize the green development of energy enterprises. The marginal contributions of this paper are as follows: Firstly, it measures the level of digital green coupling and collaborative development of the energy industry, which further enriches and makes up the theory of digital transformation and green integration and collaborative development of energy enterprises, and fills the research gap of digital green coupling and collaborative development level measurement of the energy industry. Second, the research results have important practical guiding significance for guiding the investment and development process of digital transformation of energy enterprises and realizing the development path of accelerating the integration of digitalization and greening.

2. Mechanisms of Coupled and Coordinated Development Between Digitalization and Greening in the Energy Industry

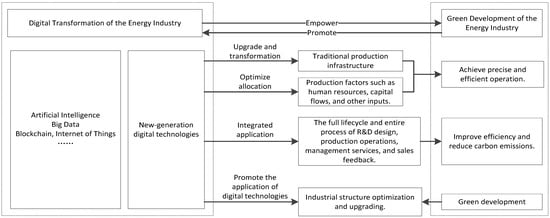

The concept originated in the 1950s, initially referring to analog-to-digital conversion. Since the 1990s, with rapidly advancing Internet and information technologies, digitalization has evolved to encompass organizational optimization, automation, and intelligent upgrading through new-generation digital technologies []. In parallel, greening represents a critical dimension of industrial transformation. Against intensifying greenhouse effects and global warming, carbon reduction has emerged as a central objective for global industrial green transformation. China’s government proposed “dual carbon” targets—peaking emissions by 2030 and carbon neutrality by 2060—establishing a strategic roadmap for energy sector green/low-carbon development []. As a foundational pillar of modern industrial systems, pursuing green/low-carbon energy development has become a shared global goal []. The theoretical mechanism for digital–green coupling coordination in the energy sector is illustrated in Figure 1.

Figure 1.

Mechanism of coupled and coordinated development between digitalization and greening in the energy industry.

First, energy industry digitalization serves as a key enabler for green development. Accelerated advancement and deep integration of technologies like big data, IoT, and AI within energy enterprises provide powerful impetus and expanded pathways for green transformation initiatives []. Refs. [,] examined how digitalization drives green innovation in energy enterprises, finding it promotes such innovation by reducing operational costs, alleviating financing constraints, and enhancing external supervision effectiveness. Refs. [,] argued that energy digitalization reconfigures the entire energy value chain systemically and intelligently—not merely upgrading production and consumption processes. This enhances energy utilization efficiency, reduces carbon emissions, and drives green/low-carbon enterprise development. Drawing on existing research and field investigations, this study contends that digital technologies—by transforming productive system components—enable optimal resource allocation, reduce waste, and enhance precision efficiency in green transition. These applications facilitate intelligent upgrades of fragmented infrastructures across temporal–spatial dimensions, strengthening lifecycle capabilities from R&D to sales through real-time monitoring. Consequently, digitalization improves enterprise productivity and management efficiency, reduces energy consumption emissions, and achieves low-carbon green development objectives [].

Second, green energy development drives digital transformation. The growing demand for greening within energy enterprises actively accelerates the adoption and application of digital technologies across their operational and management processes. Refs. [,,] pointed out that existing research often uses improvements in enterprise-level green technological innovation as the key metric for evaluating firms undergoing green energy transition. Refs. [,] emphasized that the imperative to transform the energy sector and meet environmental protection requirements is increasingly propelling the advancement of digitalization. In synthesizing the findings of these studies, it is evident that achieving the “dual carbon” goals necessitates that enterprises significantly cut emissions during this context; corporate pursuit for green growth requires implementing sophisticated tech that monitors the entire production and management lifecycle in energy firms. Through precision control of inputs, scientific production planning, resource conservation, and efficiency enhancement, digitalization enables green, low-carbon operations and supports the broader transition toward sustainability []. The green imperative thus compels energy enterprises to adopt digital technologies not only to upgrade their industrial structures and optimize energy use but also to enhance the resilience and long-term viability of the digital economy.

Third, intertwined digital and green progress within the energy industry represents a core engine driving the evolution of new productive forces in energy enterprises. As previously discussed, digitalization acts as both a catalyst and enabler of green development, while greening simultaneously motivates and reinforces digital transformation. The absence of digital transformation impedes green development from achieving reductions in production and operational costs or improving transformation efficiency; conversely, digital transformation lacking green integration risks losing strategic direction and failing to realize its ultimate objectives within the energy sector. The synergistic integration of these two dimensions ushers in a new era of digital governance aligned with the “dual carbon” goals, fostering the reconstruction of digitally intelligent, low-carbon modes of production and consumption. This process promotes the emergence of novel green–digital energy industrial ecosystems and establishes a collaborative development paradigm characterized by the triadic interplay of green, digital, and energy sectors. Through qualitative and efficiency-driven transformations, this coordinated synergy serves as a central catalyst for premium growth in the energy industry [].

3. Measurement of the Level of Coupled and Coordinated Development

The synergistic interplay between digitalization and greening within the energy sector manifests considerable complexity and interactivity. Existing literature reveals a substantial body of research that independently measures digital maturity alongside green performance among enterprises. While the specific indicator systems employed across these studies vary, their core metrics generally exhibit convergence. Building upon a comprehensive synthesis and critical analysis of prior research, this study develops measurement indicator systems for both the digitalization and greening levels of the energy industry. The construction of these systems adheres to principles of objectivity, scientific rigor, feasibility, and data accessibility, drawing extensively from authoritative sources, including the China Statistical Yearbook and the China Environmental Statistical Yearbook.

3.1. Construction of the Digitalization Level Measurement Indicator System for the Energy Industry

With the swift progress and broad integration of Internet tech, this concept of digitalization has expanded from isolated, single-point applications to encompass the entire industrial value chain. This expansion effectively dismantles data silos and information barriers, thereby substantially enhancing production efficiency []. The 14th Five-Year Plan for Digital Economy Growth underscores the imperative to accelerate the digital upgrading of traditional industries while fostering novel sectors and commercial formats with innovative paradigms. Consequently, digital transformation and industrial upgrading have become a shared consensus among both academia and industry practitioners. In constructing indicators to measure enterprise digital development levels, methodologies such as literature reviews, surveys, and interviews are predominantly employed. Ref. [] developed a measurement system for enterprise digital transformation grounded in dual aspects: digital technology maturity and the breadth of digital technology commercialization. Their system incorporates multiple indicators, including new product R&D, R&D investment, and revenue from new product sales. Ref. [] applied entropy-weighted TOPSIS and factor analysis to assess enterprise digital transformation levels, selecting indicators such as digitalization of R&D processes, production processes, and collaborative innovation development. Ref. [] utilized metrics including FTE research staff, research spending, novel product development costs, and new product sales revenue to quantify enterprise digital development. Ref. [], in their analysis of the synergy between digitalization and greening, employed indicators like technological innovation, R&D intensity, digital benefits, and energy consumption levels to measure enterprise digital maturity. Synthesizing the extant literature, it is evident that indicator selection for measuring enterprise digital transformation predominantly emphasizes dimensions such as the number of novel product development initiatives, novel product sales income, research personnel FTEs, research funding, patent application counts, and the number of innovative enterprises.

Drawing from a comprehensive analysis of existing studies regarding digital development measurement indicators and taking into account the data availability in the China Statistical Yearbook, a preliminary indicator system for assessing the digital development level was initially constructed. Ensuring scientific validity and practicality for the system, expert interviews were conducted with eight scholars specializing in digital economy research from five high-level universities, including Laurel University, Northwest University of China, and Xi’an University of Architecture and Technology. Through this consultation process, specific qualitative indicators that were difficult to quantify—such as R&D intensity and entrepreneurial innovation orientation—were excluded. At the same time, relevant, measurable indicators, such as total innovation expenditures, were added to enhance the comprehensiveness of the system. Ultimately, the finalized measurement indicator system for assessing the energy sector’s digital maturity was established, as detailed in Table 1.

Table 1.

Indicator system for measuring digitalization level in the energy industry.

3.2. Construction of the Indicator System for Measuring the Green Development Level of the Energy Industry

Green development in the industry primarily refers to the incorporation of environmental values and sustainable principles throughout the industry’s growth process. This is achieved by optimizing resource allocation, enhancing environmental protection efforts, and minimizing pollutant emissions, thereby fostering a harmonious relationship between human activity and the natural environment. It encompasses both green production practices and institutional mechanisms supporting environmental sustainability. As a strategic pillar of national economic development, promoting green development in the energy industry not only serves as a vital pathway to achieving high-quality economic growth but also represents an essential response to dual-carbon targets. In constructing indicator systems to assess the energy sector’s environmental performance, existing research generally adopts comprehensive frameworks that include dimensions such as resource efficiency and pollutant emissions. Ref. [] emphasized that enterprise greening is primarily reflected in reductions in carbon emissions, environmental pollution control, and lower consumption of production inputs.

Ref. [] evaluated enterprise-level green development using indicators such as energy consumption per GDP unit, water usage per GDP unit, industrial solid waste recycling rate, effluent discharge, industrial refuse emissions, and releases of production-related smoke and dust. Ref. [] employed metrics such as the industrial solid waste recycling rate, industrial wastewater emissions, and industrial gaseous emissions to assess the greening level of energy enterprises. Synthesizing the indicator frameworks employed by various scholars, it is evident that the energy sector’s environmental performance is typically reflected in metrics related to effluent, gaseous emissions, refuse discharge, and resource use efficiency. Following a systematic examination of existing studies on green development measurement indicators and taking into consideration the availability of data from the China Statistical Yearbook, China Environmental Statistical Yearbook, and China Energy Statistical Yearbook, a preliminary indicator system for measuring green development was established. Furthermore, after conducting interviews with 10 experts in ecology, environmental protection, and industrial economics from five top-tier institutions—including Laurier University (Canada), Kunming University of Science and Technology, Northwest University, and Anhui University of Finance and Economics—the preliminary index system was affirmed. The experts also recommended incorporating the critical indicator of energy consumption. As a result, the finalized measurement index system for evaluating the sector’s environmental sustainability energy sector was determined, as displayed in Table 2.

Table 2.

Measurement indicator system for the green development level of the energy industry.

3.3. Construction of the Research Model

The energy industry comprises a range of subindustries, including coal extraction and preparation; oil and gas production; petroleum, coal, and fuel refining; electricity and heat generation and distribution; and gas manufacturing and distribution. Ensuring scientific validity, reproducibility, and practicality for gathering collection within this study, the analysis concentrates on evaluating the coupling and synergistic advancement of digital and environmental transition within these five core subsectors in the energy sector.

In research procedures, information entropy weighting and system synergy modeling are primarily adopted. This entropy-based weighting approach serves to impartially assign weights for the digitalization and green development indicators. On this basis, system synergy analysis between digital and environmental transformation is constructed, quantifying the alignment level across these dual systems within the energy sector. Drawing on the measurement results, targeted policy recommendations and strategic suggestions are subsequently proposed, facilitating synergistic progress in digital evolution and sustainable development in this sector.

3.3.1. Entropy Weighting Method for Calculating Indicator Weights

Entropy weighting is a widely used and effective technique for determining indicator weights in comprehensive evaluations. As an objective weighting approach, it relies on entropy theory to quantify variation dispersion among evaluation indicators, thereby reflecting their relative importance in the overall assessment [,,]. Specifically, the lower the entropy value for an indicator, the higher its variability and discriminative power, signifying a more substantial influence on the comprehensive evaluation and thus warranting a higher weight. In contrast, a larger entropy value implies lower dispersion and weaker differentiation, resulting in a lower assigned weight. The detailed procedure for applying entropy weighting to measure digitalization alongside green development in the energy industry is designed and implemented as follows:

(1) Normalize the evaluation indicators for the digitalization and green development of the energy industry to eliminate the impact of differing dimensions. Dimensionless processing prior to the calculation of information entropy and indicator weights ensures comparability among indicators with varying measurement units. This step enables a unified scale for analysis, thereby enhancing the objectivity and accuracy of subsequent weight assignments.

When the indicator is positive,

When the indicator is negative,

where represents the year in which data for measuring the digitalization or greening of the energy industry was collected, and ; represents the specific indicators used to measure digitalization and greening, and ; refers to the original value of the j-th indicator in the i-th year. refers to the standardized value of the j-th indicator in the i-th year; and represent the maximum and minimum values of the j-th indicator during the evaluation and measurement stage, respectively.

(2) Based on the normalized indicators, compute the proportional distribution of each measurement indicator regarding the digitalization and green development of the energy industry. Ensure that all values undergo non-negative transformation to maintain validity for subsequent entropy calculations.

(3) Calculate the entropy value of the evaluation indicators.

(4) Calculate the entropy weight of the evaluation indicators.

where is the coefficient of variation g.

3.3.2. Construction and Analysis of the Coupling Coordination Degree Model

System synergy analysis is widely employed to examine the interrelationships amongst complex systems, investigate their interaction mechanisms, and quantify the degree of coordination between distinct yet interconnected subsystems [,]. To assess the system alignment degree across digital and sustainable transformation within the energy sector, a mathematical model is constructed to examine the interaction and mutual influence of the digital evolution process and the sustainability process. This framework also evaluates the independent development level of each subsystem, thereby enabling a comprehensive understanding of the internal structure and operational dynamics of the coupled digital–green development system in the energy sector. It serves as a scientific basis for guiding the continuous optimization of system integration. The specific calculation formulas are presented in Equations (6) and (7).

Formula-wise, C denotes coupling intensity across the digital system and the environmental process within energy sector, quantitatively reflecting the overall coordination effect between these two subsystems. The variables U1 and U2 correspond to the performance scores for energy sector’s digital and environmental subsystems, respectively. Coefficient D represents the coordination degree, while T signifies the overall coordination index combining both digital and environmental processes. Additionally, parameters α and β denote respective weights assigned to digitalization and greening, respectively, capturing their relative importance and contribution; these coefficients are subject to determination.

Based on a review of existing literature, Ref. [] in their analysis of the spatiotemporal patterns and differentiation mechanisms for system synergy across digital economy and environmental progress, assigned equal weights of 0.5 to both α and β. Similarly, Ref. [] when examining the evolutionary traits of system alignment between digital and environmental transition in China, also set α and β to 0.5, reflecting the current phase in China’s economic–social progress. The consensus among most scholars [] is that the relative importance and contribution of the two subsystems—energy industry digitalization and greenization—are approximately equal; hence, the equal weighting α = β = 0.5 is commonly adopted. Under this weighting scheme, system alignment intensity D across the digital and environmental processes in the energy industry effectively mitigates or eliminates the distortions caused by dynamic data imbalances in the coupling degree, thereby providing a comprehensive reflection of the synergistic interaction between energy industry digital and sustainable advancement.

The numerical value for system synergy level D corresponds to distinct categories of coordinated interaction. Drawing on the findings of the majority of scholars [], synergy intensity across digital and environmental transition within the energy sector falls into multiple divisions according to the magnitude of D. Table 3 presents a broad classification of digitalization and greening coupling coordination types, providing an overall framework to distinguish between maladjusted and coordinated states. In contrast, Table 4 offers a more granular and detailed subdivision than Table 3, featuring narrower intervals between coupling coordination levels. This finer categorization enables a more precise assessment of the digital–green coupling coordination degree within the energy industry, particularly in cases of maladjustment or poor coordination, thereby furnishing a more robust and practical foundation for devising targeted strategies to advance synergistic progress in digital and environmental initiatives in this sector.

Table 3.

Classification standard of coupling and coordination types of industrial digitalization and greening.

Table 4.

Classification standard of coupling coordination degree of industrial digitalization and greening.

The coupling coordination degree D varies in magnitude, corresponding to distinct types of coupling coordination. Synthesizing the findings of extant scholarly research [], synergy level across digital and environmental transition within the energy sector falls into specific types based on the value of D. Table 3 classifies these types into broad intervals, enabling a general understanding of whether the system is maladjusted or coordinated according to the coupling coordination measurement outcomes. In contrast, Table 4 provides a more refined and detailed classification than Table 3, with narrower intervals between coupling coordination levels. This finer stratification allows for a more precise determination of the digital–green coupling coordination degree in the energy industry, which is particularly useful for identifying maladjustment or poor coordination. Consequently, it offers a more reliable and practical foundation for formulating targeted strategies to advance synergistic progress in digitalization and greening within this sector.

3.4. Data Sources and Statistical Analysis

The data collection for assessing the digitalization and environmental performance levels in the energy sector covers ten years from 2014 to 2023, focusing on five major subindustries: coal extraction and preparation; oil and gas production; refining of petroleum, coal, and other fuels; electricity and heat generation and distribution; and gas manufacturing and distribution. Data related to digital transformation primarily derive from the China Statistical Yearbook. Specifically, the 20th section (“Science and Technology”) in each annual edition provides statistical information for nine indicators reflecting the digital transformation and development of the aforementioned energy subsectors. Key data tables include China Statistical Yearbook No. 20-6 (innovation activities and patents for large-scale industrial firms), No.20-9 (new product development and production), and No. 20-11 (relevant technological innovation metrics). Metrics employed to assess environmental performance originate in the China Environment Statistical Yearbook alongside the China Energy Statistical Yearbook. From the China Environment Statistical Yearbook, No. 2-12 (industrial wastewater discharge and treatment), No. 4-3 (industrial waste gas emissions and control), and No. 5-1 (generation, discharge, and utilization of industrial solid waste) provide key metrics. From the Energy Statistical Yearbook, supporting data are obtained from No. 1-1 (energy production, consumption, and GDP growth), No. 1-10 (primary pollutant releases per area), and No. 4-1 (total energy usage plus structure). To address occasional data gaps, the trend interpolation method is employed for imputation. Ensuring that sample information aligns closely with study objectives, reliability and validity analyses are performed post-collection, and descriptive statistical analyses are conducted to summarize and characterize the sample’s key features.

3.4.1. Reliability Test Analysis of Data

Using SPSS 16.0, a reliability assessment of the statistical data regarding digitalization and greening in the energy industry over the period from 2014 to 2023 was conducted. The analysis encompassed the overall energy sector as well as five key subindustries: coal extraction and preparation; oil and gas production; petroleum, coal, and other fuel processing; electricity and heat generation and distribution; and gas manufacturing and distribution. Cronbach’s alpha evaluated internal consistency for indicator systems. Prior to analysis, all raw data were standardized, and factor analysis was performed to calculate Cronbach’s alpha coefficients of the sample datasets. The results of reliability assessments are displayed in Table 5 and Table 6.

Table 5.

Reliability test results of digitalization measurement data for the energy industry.

Table 6.

Reliability test results of green development measurement data for the energy industry.

The reliability test results for the digitalization measurement data of the five energy subsectors—coal extraction, oil/gas production, petroleum, coal and other fuel refining, power/heat generation and supply, and gas manufacturing—are 0.894, 0.986, 0.987, 0.863, and 0.986, respectively. For the green development measurement data, α values for the corresponding sectors were 0.815, 0.798, 0.853, 0.892, and 0.788, respectively. According to standard reliability thresholds, a Cronbach’s alpha value ≥0.7 indicates acceptable reliability, while values ≥0.8 reflect high reliability. These results suggest that both the digitalization and green development indicator systems across the overall energy industry and its five subsectors possess strong internal consistency and reliability, thereby laying robust groundwork for further empirical study and modeling work.

3.4.2. Validity Test Analysis of the Data

Exploratory factor analysis evaluated the validity of the statistical information on digitalization and green development in the energy sector from 2014 to 2023. This analysis encompassed five key subindustries: coal extraction, oil/gas production, petroleum, coal and other fuel refining, power/heat generation and supply, and gas manufacturing. The detailed outcomes of the validity tests are presented in Table 7 and Table 8.

Table 7.

Validity test results of digitalization measurement data in the energy industry.

Table 8.

Validity test results of green development measurement data in the energy industry.

Kaiser–Meyer–Olkin (KMO) values for validity assessment of digitalization measurement data across five primary energy segments—coal extraction, oil/gas production, petroleum, coal and other fuel refining, power/heat generation, and gas manufacturing—are 0.718, 0.831, 0.784, 0.826, and 0.763, respectively. Correspondingly, the KMO values for the green development measurement data in these sectors are 0.769, 0.851, 0.788, 0.801, and 0.776, respectively. According to the standard interpretative criteria of the KMO measure, values in the range of 0.7–0.8 indicate acceptable validity suitable for further analytical procedures. In contrast, values exceeding 0.8 signify a high level of structural validity and suitability for factor analysis. Based on these findings, all KMO values surpass the threshold of 0.7, confirming that the datasets on both digital and environmental progress within the energy industry—alongside its five key subsectors—demonstrate robust validity and provide a sound empirical basis for subsequent research stages.

4. Empirical Analysis of the Coupled and Coordinated Development of Digitalization and Green Development in the Energy Industry

4.1. Entropy Weight Measurement of the Development Levels of Digitalization and Green Development

Entropy weighting determines and examines indicator importance across the measurement systems for digital development and green development across five key sectors of the energy industry: coal extraction, oil/gas production, petroleum, coal and other fuel refining, power/heat generation, and gas manufacturing. This method enables the assessment of various relative contributions of various indicators pertaining to digitalization and greening, thereby laying a quantitative foundation for evaluating system synergy between both developmental dimensions across the energy sector.

4.1.1. Entropy Weight Measurement of the Digitalization Level in the Energy Industry

The evaluation framework for the energy sector’s digital maturity comprises nine core indicators: the count of novel product initiatives, investment in innovative product development, income from new product sales, FTE research staff, total research spending, patent application count, number of enterprises undertaking innovation, the proportion of such enterprises among all large-scale industrial enterprises, and total innovation expenditure. These indicators encompass five primary subsectors of the energy sector: coal extraction, oil and gas production, petroleum, coal and other fuel refining, thermal power generation and supply, and gas production and supply. By utilizing entropy weighting for measuring digitalization level, equal importance was applied to data from the five subsectors to obtain an aggregated evaluation. The specific results of this measurement, including the relative weight ranking of each indicator, are presented in Table 9. This table provides a comprehensive overview of the selected indicators for assessing the digital development level across the entire energy industry and displays their respective weightings derived through the entropy weight method.

Table 9.

Entropy weight measurement results of digitalization development level in the energy industry.

Based on the entropy weight measurement results of digitalization level across the energy sector, the weights assigned to nine evaluation indicators exhibit relatively minor differences. Among them, the indicator with the highest weight is R&D expenditure for new product development, at 0.1272. In contrast, the lowest weight corresponds to the proportion of enterprises engaged in product or process innovation among all the above-designated industrial enterprises, at 0.0958, yielding a weight difference of only 0.0314. These findings suggest that the digitalization process within the energy industry is progressing in a balanced and comprehensive manner across all indicators. This outcome is particularly noteworthy as it reflects the absence of significant deficiencies in China’s digitalization efforts within the energy sector, thereby establishing a robust foundation for further advancements in digital and intelligent infrastructure.

Table 10 presents the weights of the digitalization development level measurement indicators for five specific sectors within the energy industry—coal extraction, oil/gas production, petroleum, coal and other fuel refining, power/heat generation, and gas manufacturing—calculated using the entropy weight method. This table primarily summarizes the weighting outcomes of various indicators employed to assess the digital development levels across these distinct energy subsectors.

Table 10.

Weights of digitalization level measurement indicators for five specific sectors of the energy industry.

According to Table 10, the weights assigned to digitalization metrics differ notably among the five energy industry segments: coal extraction, oil/gas production, petroleum, coal, and other fuel refining, power/heat generation, and gas manufacturing. This variation reflects sector-specific emphases on distinct dimensions of digital advancement. Within coal extraction, although the number of new product development projects is relatively high, the expenditures on new product R&D and innovation-related costs remain comparatively low, indicating greater R&D efficiency characterized by higher output with lower input. Conversely, the oil and natural gas extraction sector exhibits a relatively high proportion of enterprises engaged in product or process innovation, underscoring both the willingness and capability for innovation within the sector. Additionally, this sector benefits from more substantial funding support for new product R&D and a higher volume of patent applications. Nevertheless, the comparatively low number of new product development projects suggests limitations in the industry’s ability to effectively translate scientific and technological achievements into practical outputs, highlighting an area for improvement in innovation transformation capacity.

A considerable number of enterprises in the petroleum, coal, and other fuel processing industries engage in product or process innovation activities. Most of these enterprises demonstrate a strong willingness to invest in new product research and development, resulting in substantial economic returns. The newly developed products contribute significantly to enterprise revenue. In contrast, while the electric power and thermal generation sectors also feature extensive participation in enterprises involved in innovation activities, the sales revenue generated from newly developed products remains relatively low. Within the gas sector, although the absolute count of enterprises undertaking product or process innovation is relatively high, these innovative enterprises constitute only a small fraction of large-scale industrial enterprises. This disparity indicates a relatively low level of digital adoption among traditional large firms across the gas sector, underscoring the urgent need to accelerate their transformation and upgrading processes.

4.1.2. Entropy Weight Measurement of Green Development Level in the Energy Industry

Environmental performance across the energy sector was evaluated using eight measurement indicators: energy consumption, ind. effluent discharge, ind. effluent treatment, ind. SO2 emissions, ind. NOx emissions, ind. particulate matter emissions, municipal solid waste generation, and comprehensive utilization of general solid waste. These indicators encompass five distinct energy segments: coal extraction, oil/gas production, petroleum, coal and other fuel refining, electricity and heat generation and distribution, and gas manufacturing. In applying EWM to assess environmental progress level, data from these five sectors are aggregated using an equal-weighted summation approach. The detailed measurement outcomes and corresponding indicator weight rankings are presented in Table 11, which primarily reflects the green development evaluation of the energy sector and the relative importance for each indicator as derived from the entropy weight analysis.

Table 11.

Entropy weight measurement results of green development level in the energy industry.

The entropy weight analysis of the energy industry’s green development level indicates that industrial wastewater discharge, industrial nitrogen oxide emissions, and energy consumption remain the top three weighted indicators. This highlights that traditional patterns of pollution and resource consumption within the energy sector have yet to be effectively mitigated during the green transition. Consequently, there is an urgent need to accelerate the transformation and upgrading of conventional manufacturing via integrating next-generation digital tools. The relatively high weight assigned to industrial wastewater treatment, ranked fourth, suggests an increasing emphasis on ecological and environmental protection within the industry, signaling progress in advancing green development. Despite technological advancements and the implementation of targeted measures yielding preliminary successes, the comparatively low weight of the solid waste recycling rate reveals that the sustainability transition of the energy sector remains incomplete. To foster more rapid and effective green development, it is imperative to empower traditional energy enterprises with digital technologies that enhance waste reuse efficiency.

EWM determined weights for environmental performance metrics across five specific energy industry segments: coal processing, oil/gas extraction, petroleum, coal and other fuel refining, electric power/heat supply, and gas operations. The resulting weights are presented in Table 12, which primarily illustrates the entropy weight-derived indicator weights for green development assessment within these five distinct industry sectors.

Table 12.

Weights of green development level measurement indicators for five specific sectors in the energy industry.

Based on the weights of five specific indicators measuring the green development level across energy industry sectors—including coal processing, oil/gas extraction, petroleum, coal and other fuel refining, power/heat supply, and gas operations—the coal mining and washing sector exhibits high levels of energy consumption, PM emissions, and industrial SO2 discharges. This suggests that traditional pollution patterns within this sector have not been substantially mitigated. Conversely, industrial wastewater discharge is relatively low, while the capacity for industrial wastewater treatment is increasing, indicating progress in environmental management within the coal processing industry.

Measurement outcomes for the oil/gas exploration sector indicate elevated levels of NOx discharges, energy usage, and municipal refuse generation, underscoring the urgent need to accelerate pollutant emission reduction through digital–green synergy, thereby enhancing sustainability efficiency via carbon and emission reductions. In the fuel refining sector, despite substantial industrial wastewater discharge, the volume of treated wastewater is also significant, reflecting notable achievements in wastewater management by enterprises. Although industrial wastewater discharge remains relatively high in power/heat generation, energy consumption in these industries is lower compared to other energy sectors, indicating considerable progress in energy consumption modernization for conventional sectors. While production-related particulate emissions and general solid waste generation remain elevated, improvements in recycling rate for general waste further attest to advancements in the sector’s green development, primarily driven by digital empowerment. Conversely, across the gas sector, high levels of production-linked wastewater discharge, nitrogen oxide emissions, energy consumption, and sulfur dioxide emissions persist, coupled with low capacities for wastewater treatment and comprehensive solid waste utilization. These findings reveal that the gas sector remains a representative traditional industry with relatively low levels of digitalization and greening, necessitating accelerated transformation and upgrading through the adoption of next-generation digital technologies.

EWM quantified the importance of digital and environmental metrics within the energy industry, as well as across five specific segments: coal processing, oil/gas extraction, petroleum, coal and other fuel refining, power heat generation and distribution, and gas operations. These weighting results serve as the empirical foundation for subsequent calculation system alignment degree across digital and sustainable progress within the overall energy sector and its constituent sectors.

4.2. Measurement of the Coupling Coordination Degree of Digitalization and Greening in the Energy Industry

4.2.1. Measurement and Analysis of the Overall Coupling Coordination Degree of Digitalization and Greening in the Energy Industry

Based on the system synergy model, the coupling intensity, comprehensive concordance index, and alignment level for digital and environmental transition within the energy sector from 2013 to 2022 were calculated using Equations (6) and (7). These calculations integrated the weighting results of digitalization and greening across five specific energy sectors, namely the overall energy sector, coal processing, natural gas production, petroleum, coal and other fuel refining, electricity and thermal energy generation, and gas operations, respectively. Results are presented in Table 13.

Table 13.

Coupling coordination degree of digital greening in energy industry from 2014 to 2023.

The calculation results of system synergy level across digital and environmental transition within the energy sector reveal a consistent upward trend. Specifically, synergy intensity across these dual dimensions improves over time, indicating a complementary relationship whereby their synergistic and integrated development has surpassed previous limitations, achieving a state of integrated system evolution. This finding aligns with Ref. [] assessment of synergy progress industrial digitalization and environmental transition in China, which similarly demonstrates a year-on-year increase. During digital upgrading for the energy sector, firms face potential risks and increased costs associated with investments in new technologies, R&D and design of new products, intelligent production line upgrades, and pollutant treatment. Such factors may temporarily elevate energy consumption; however, these effects are transient. Over the past decade, coordinated measurements reveal that digital transition and environmental progress across the energy industry proceed in harmony. Following digital upgrading, energy enterprises can achieve cost reduction, efficiency enhancement, and effective carbon and emission abatement within a relatively short timeframe, with these benefits becoming increasingly pronounced over time. This conclusion corroborates Ref. [] findings that digitalization and the application of digital technologies promote carbon mitigation, pollution control, quality enhancement, and efficiency gains during the pursuit of green development.

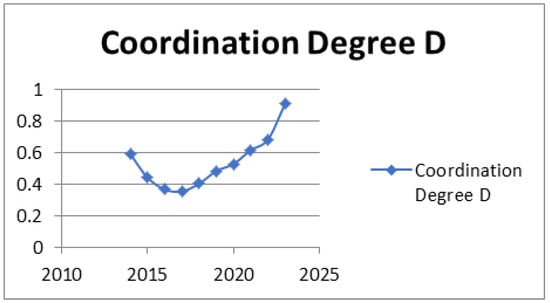

By converting the data presented in Table 13 into Figure 2, the status and temporal trend of synergistic progress between digitalization and environmental transition across the energy sector over the past decade are depicted more intuitively and clearly.

Figure 2.

Coordinated development status and trend of digital greening of energy industry in recent 10 years.

With respect to the progression in coupling synergy across the digital and environmental transition, the energy industry exhibited a moderate coordination stage in 2014 and 2015. During 2016 and 2017, the system entered a transitional coordination phase characterized by a slight decline in the coupling coordination degree between digital and green systems. From 2018 onward, the coupling coordination degree demonstrated a steady upward trend, evolving from moderate coordination to high-quality coordination. Notably, the coordination level surged from initial coordination in 2022 to premium coordination, a shift closely attributable to extensive implementation of next-generation digital technologies—such as big data, artificial intelligence, and the Internet—alongside the emergence of novel, productive forces alongside robust governmental support. Achieving high-quality coordination between digitalization and greening represents an optimal objective for both academic research and practical economic development. Nevertheless, with the coordination degree currently at 0.9071, there remains potential for further sustainable advancement. Moreover, the pronounced increase from 0.6818 in 2022 to 0.9071 raises concerns regarding possible fluctuations or volatility in 2024 and beyond, underscoring the need for continued monitoring and strategic reinforcement.

Analysis of the coordinated development trend between digitalization and greening in the energy industry over the past decade, as depicted in Figure 2, identifies 2017 as a critical inflection point. Specifically, 2017 marks the lowest level of coordination, followed by a sustained year-on-year increase from 2018 through 2023. Examination of the curve’s slope further elucidates the evolutionary trajectory of the industry’s digital–green coordination. Between 2017 and 2022, the slope remains positive and exhibits continuous growth; however, the annual rate of increase diminishes progressively, indicating ongoing improvement in coordination degree but at a decelerating pace. Notably, from 2022 to 2023, the slope of the coupling degree curve experiences a sharp rise, reflecting significant achievements enabled by digital technologies in cost reduction, efficiency enhancement, carbon and emission abatement, and the reciprocal promotion of digital transformation through green development within energy enterprises. Projecting from the observed coupling coordination trend, it is anticipated that the digital–green coordination level in the energy industry will continue to improve, advancing steadily toward a stage of high-quality coordination.

4.2.2. Calculation and Analysis of the Coupling Coordination Degree of Digitalization and Greening in Specific Energy Industry Sectors

The coupling coordination degree of digital greening across five specific energy sectors—including coal processing, oil/gas production, petroleum, coal and other fuel refining, power and heat generation and distribution, and gas operations—was calculated for the period from 2014 to 2023. The results for the coupling degree, comprehensive concordance index, and coordination degree are presented in Table 14.

Table 14.

Coupling coordination degree of digital greening in five specific sectors of energy industry from 2014 to 2023.

According to the coupling coordination degree measurements for digitalization and greening across the five specific energy sectors, all sectors have exhibited a clear upward trend in coordination in recent years. In 2023, the coupling coordination degree for the coal mining and washing sector reached 0.68, corresponding to a primary coordination stage; the oil and natural gas extraction sector reached 0.75, indicating a moderate coordination stage; the petroleum, coal, and other fuel processing sector reached 0.72, also reflecting moderate coordination; the electricity and heat production and supply sector achieved 0.81, indicative of good coordination; and the gas production and supply sector reached 0.76, corresponding to a moderate coordination stage. When classified by coordination type, all five sectors fall within the category of high coordination. This suggests that the digitalization and greening systems within these energy sectors are complementary and have undergone synergistic integration, resulting in development that has transcended previous boundaries and formed a spiral trajectory of mutual reinforcement and advancement. The increasing coordination between digitalization and greening in these sectors can be attributed to several key drivers. These include the national “carbon peaking and carbon neutrality” policy, which imposes strict requirements on energy enterprises for carbon and emission reduction; the catalytic role of deep integration between next-generation digital technologies—such as artificial intelligence—and energy enterprises in driving transformation; market pressures related to growing demand for green products; and internal imperatives for cost reduction and efficiency enhancement. The convergence of these internal and external forces has rendered the coordinated development of digital–green integration within the energy industry an inevitable and strategic trend.

Based on the coupling coordination degree measurements of digitalization and greening over the past decade, the coal mining and washing industry has demonstrated relatively stable performance, with coordination degree values fluctuating between 0.47 and 0.71. This range reflects a status of moderate to high coordination, indicating that a synergistic development pattern between digitalization and greening has been established, wherein both systems reinforce and propel one another. As a critical component of the national energy framework, the coal industry assumes an indispensable role in safeguarding energy security and supporting macroeconomic stability. In light of this, the state has placed significant emphasis on enhancing safety in coal mining operations and promoting the extensive deployment of next-generation digital technologies—such as artificial intelligence—alongside advancing the industry’s transition toward green, low-carbon, and sustainable development. By integrating intelligent digital technologies, coal enterprises are now capable of conducting real-time monitoring and data analytics of production processes, enabling timely identification and mitigation of potential safety hazards and resource inefficiencies. This shift fosters the intelligent transformation of the coal sector, enhances automation levels, and reduces risks associated with manual operations. Under the guidance of technological innovation, the coal industry is better positioned to address environmental constraints and respond to evolving market demands, thereby advancing toward a more sustainable, secure, and efficient developmental trajectory. Consequently, the coal mining and washing industry has consistently maintained a coordinated level of digital–green coupling development.

The coupling coordination degree of digital greening within the power and thermal production and supply industries has exhibited significant volatility over the past decade. In particular, the coordination degree reached a low of 0.36 in 2016, reflecting a state of mild imbalance. As major contributors to carbon emissions within the energy sector—accounting for over 50% of total emissions—these industries historically relied heavily on conventional thermal power generation and coal-based heating, thereby presenting substantial challenges to achieving green and sustainable development goals. Prior to the formal introduction of the “carbon peaking and carbon neutrality” (dual carbon) targets, limited progress had been made in reducing emissions. Following the establishment of dual carbon objectives, the power and thermal sectors intensified their efforts in technological innovation, increasingly incorporating renewable energy sources such as wind, solar, and nuclear power into electricity and heat generation systems. Concurrently, digital technologies began to be deployed across production and supply chains, generating initial results in reducing carbon emissions. However, due to the relatively short timeframe since the adoption of digital solutions, their synergistic integration with green development objectives has yet to yield substantial or consistent coordination outcomes. Consequently, although the digital–green coupling coordination level reached 0.81 in 2023—indicating a state of good coordination—the values in preceding years hovered near the thresholds of maladjustment or marginal coordination; this pattern suggests that the early stages of digital transformation in traditional energy industries often prioritize technological modernization while insufficiently integrating environmental considerations. As a result, the digital and green subsystems have not yet achieved robust mutual reinforcement. To fully realize the potential of coordinated digital–green development, it remains essential to strengthen the integration between digital innovation and green transition strategies within these sectors.

In contrast to the electric power and thermal production and supply sectors, the gas production and supply industry exhibits a relatively low level of digital–green coupling coordination. Although there has been a gradual annual improvement—indicating a progressive, albeit slow, integration of digital and green systems—the overall pace of development remains sluggish. Over the past decade, the coordination status between the digital and green subsystems in this industry has remained mainly within the categories of slight imbalance, near imbalance, or marginal coordination. As a traditionally structured sector, the gas production and supply industry has relatively modest requirements for automation and intelligence. Moreover, given that natural gas combustion results in comparatively low levels of environmental pollution, national-level investment and policy focus on its digital and green transformation have been limited. This has resulted in persistent challenges, including outdated production equipment with low levels of automation, inadequate information integration capabilities, suboptimal customer service quality, and weaknesses in data security management. However, evolving energy consumption patterns, increasing diversification of customer demands, intensified market competition, and broader energy structure adjustments underscore the urgent need for digital transformation and green upgrading in this sector. To advance the high-quality development of the gas production and supply industry, it is imperative to accelerate the integration of intelligent technologies and green innovations. This will enhance system coordination, improve operational efficiency, and elevate the overall level of digital–green coupling coordination within the industry.

Over the past decade, the coupling coordination degree of the petroleum and natural gas extraction industry, as well as the petroleum, coal, and other fuel processing industries, has exhibited broadly similar patterns. Both sectors have predominantly remained within the stages of moderate to high coordination, indicating that the digital and green subsystems have established a relationship characterized by coordinated development and mutual reinforcement. As a pillar of the national economy, the petrochemical industry possesses substantial economic weight, extensive industrial linkages, and a complex, vertically integrated value chain. It plays a critical role in economic development, public welfare, and national defense while simultaneously bearing the strategic responsibility of safeguarding national energy security. This sector is further distinguished by characteristics such as diversified product structures, high technological intensity, significant environmental burdens, and intense international competition. In the context of the digital economy, enterprises within these industries have increasingly embraced the deep integration of next-generation digital technologies—including artificial intelligence, big data, and cloud computing—into their production, management, and operational frameworks. The transition toward digital intelligence has emerged as a necessary pathway to achieving green, low-carbon, sustainable, and high-quality development objectives. Throughout the past decade, both the oil and gas extraction sector and the fuel processing industry have prioritized technological innovation and digital adoption, thereby realizing improvements in cost efficiency, operational performance, emissions reduction, and long-term sustainability. Nevertheless, the current levels of digital–green coupling coordination in both industries remain suboptimal. There is still considerable potential to enhance systemic synergy and fully unlock the benefits of integrated digital and green transformation.

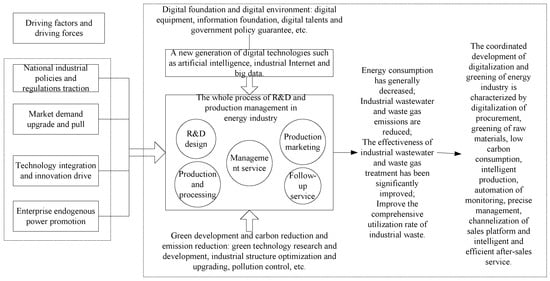

4.3. Driving Mechanism of Energy Industry’s Digital–Green Coupling Coordinated Development

The aforementioned measurement results indicate that although the overall trend of digital–green coupling coordination in the energy industry—as well as in its five major subsectors—has shown steady improvement over the past decade, fluctuations and occasional declines have also occurred in certain years. This underscores that the integration process between digitalization and green development in the energy sector remains dynamic and uneven. Looking ahead to the next decade and beyond, it becomes crucial to investigate the underlying driving factors and mechanisms that shape and sustain the coordinated development of digital–green coupling in the energy industry. Drawing upon an extensive review of domestic and international literature, expert interviews with 13 scholars from six universities—including Laurel University, Northwest University of China, Xi’an University of Architecture and Technology, and Hefei University of Technology—and field investigations of representative enterprises in the energy sector, combined with the author’s long-term empirical research, this study identifies four key dimensions of drivers promoting the coordinated development of digital and green transformation in the energy industry. First, national industrial policies and regulatory frameworks serve as strategic levers, offering directional guidance and policy traction that facilitate the alignment of digital and green agendas. Second, the structural upgrading of market demand within the energy industry functions as a catalytic force, stimulating enterprises to adopt integrated digital and green practices to meet emerging consumer and societal expectations. Third, the synergistic convergence of digital empowerment and green technological innovation not only represents a hallmark of the Fourth Industrial Revolution but also reflects a historical imperative for the deep integration of next-generation digital technologies with the energy sector and other foundational real-economy industries. Fourth, the endogenous motivations of energy enterprises—centered on improving operational efficiency, reducing costs, and enhancing product and corporate competitiveness—compel firms to adopt a dual digital–green transformation strategy as a pathway to sustainable development. The conceptual framework illustrating the driving mechanisms underpinning the coordinated coupling of digitalization and greening in the energy industry is presented in Figure 3.

Figure 3.

Driving mechanism of coordinated digital–green development of energy industry.

1. Traction of national industrial policies and regulations:

Policies and regulations serve as a critical and irreplaceable driving force in steering synergistic transformation across the energy sector toward digitalization alongside environmental transition. Strategic directives issued at the national level not only provide a clear trajectory but also establish robust institutional guarantees for advancing the transformation agenda. In 2025, the “Government Work Report” explicitly underscored “advancing decarbonization, pollution control, alongside sustainable expansion, and accelerating the holistic eco-shift of socioeconomic progress,” thereby elevating the green transition as a national strategic priority. Furthermore, the CPC Central Committee Decision on Deepening Reform Holistically and Advancing China’s Modernization, from the Third Plenum of the 20th CPC Central Committee, reiterated criticality for “promoting advanced, smart, and eco-friendly evolution within the industrial sector,” thereby charting a clear course for industrial transformation and upgrading. Collectively, these high-level policy frameworks provide robust groundwork for the dual revolution across the energy sector, simultaneously advancing digitalization and green development.

2. The market demand of the energy industry is upgraded and driven.

Market demand has emerged as a pivotal force in propelling the coordinated transformation of the energy industry toward digitalization and greening, primarily reflected in two dimensions: the evolution of consumer preferences and the tightening of international green trade regulations. As societal environmental awareness continues to deepen, consumers increasingly prioritize the environmental attributes of products, signaling a marked shift in consumption patterns. Empirical research indicates a growing consumer inclination toward low-carbon, recyclable, and environmentally friendly products, accompanied by heightened expectations for environmental performance throughout the entire product lifecycle. Modern consumers not only evaluate products based on their quality and functionality but also emphasize the environmental narratives and ethical standards underlying production processes. This transformation in consumption behavior provides market-driven impetus for energy enterprises to integrate digitalization with greening strategies, leveraging digital technologies to achieve comprehensive lifecycle environmental management. Concurrently, the escalation of global green trade barriers—such as the implementation of carbon border adjustment mechanisms—has exerted considerable external pressure on China’s industrial development while simultaneously presenting new opportunities for transformation. Notably, the European Union’s Carbon Border Adjustment Mechanism (CBAM) directly internalizes the carbon emission costs of export-oriented enterprises, thereby reshaping the competitive landscape. In response, export-driven enterprises in key regions such as Shanghai have proactively undertaken low-carbon transitions through the procurement of green certificates and green electricity. Since 2021, cumulative purchases of green certificates have surpassed 27 million, with green electricity usage exceeding 15 billion kilowatt-hours, significantly bolstering international competitiveness. In this context, international green trade regulations have become an exogenous catalyst accelerating the dual digital and green transformation of China’s energy and industrial sectors.

3. Technology integration and innovation drive, digital empowerment and the coordinated development of green technologies:

Technology integration serves as the fundamental driving force behind the coordinated advancement of digital greening within industries. This dynamic is evidenced by the enabling role of digital technologies in promoting green transformation and the reciprocal influence of green technologies on the evolution of digital industries. Digital innovations—exemplified by artificial intelligence, the Internet of Things, and big data analytics—offer robust technical tools and methodologies that facilitate the sustainable transformation of traditional industrial sectors. Specifically, the industrial Internet reshapes the industrial and energy knowledge frameworks through the integration of data, computational power, and algorithms, enabling precise monitoring and optimal allocation of resource consumption. In energy sector production, the deployment of digital technologies supports intelligent assembly line operations that effectively reduce energy usage while enhancing production efficiency. Furthermore, energy management systems provide real-time monitoring and evaluation of critical production indicators, such as energy consumption and emissions, ensuring adherence to environmental and sustainability standards throughout the manufacturing process.

4. The endogenous driving force of the enterprise, the dual driver of cost saving and efficiency improvement:

At the enterprise level within the energy industry, optimizing economic benefits and enhancing competitiveness constitute the primary internal drivers of digital green transformation. Empirical evidence increasingly demonstrates that digital–green collaborative transformation has evolved from a passive, compliance-driven activity characterized by “high investment and low return” into a strategic initiative that delivers tangible financial gains. The advantages of this transformation are principally manifested across three dimensions: reductions in operational costs, improvement of resource utilization efficiency, and strengthening of market competitiveness. By implementing digital control systems for precise management of production processes, enterprises can rapidly adapt to fluctuations in product pricing, dynamically adjust production schedules, effectively lower operational expenses, enhance resource efficiency, and achieve reductions in carbon emissions.

The driving mechanism underlying the coupled and coordinated development of digitalization and greening in the energy industry not only elucidates the key priorities for enterprises in advancing digital and green transformation but also establishes a theoretical foundation and practical framework for identifying effective pathways to promote their integrated and synergistic progress.

5. Pathways to Enhance the Coupled Development of Digitalization and Greening in the Energy Industry

The coordinated development of digitalization and greening within the energy industry constitutes not only an essential prerequisite for enterprise transformation and upgrading, enhancing product and service quality, and achieving carbon reduction and emission control but also a critical strategic choice to drive high-quality economic growth and serve as a new catalyst for rapid economic expansion amid the Fourth Industrial Revolution []. Several perspectives and findings presented in this study align with existing literature, including evidence that digital transformation in the energy sector significantly enhances both production efficiency and energy utilization while actively promoting the green and low-carbon sustainable development of energy enterprises. Consistent with scholarly consensus, this research confirms that the level of coordinated digital–green development among Chinese industrial enterprises is progressively improving annually. Moreover, this study diverges from prior research by addressing a critical gap: it develops a theoretical framework and empirical measures for assessing the coupling and coordination level of digitalization and greening in the energy industry. These contributions provide valuable theoretical and practical insights, offering important guidance for energy enterprises to accelerate the integration and advancement of digital and green initiatives.