Effects of Circumferential and Interaction Angles of Hydrogen Jets and Diesel Sprays on Combustion Characteristics in a Hydrogen–Diesel Dual-Fuel CI Engine

Abstract

1. Introduction

2. Mathematical Models and Characterization Parameters of Combustion Process

2.1. Mathematical Models

2.2. Characterization Parameters of Combustion Process

- (1)

- Combustion characterization parameters

- (2)

- Mixing characterization parameters

3. Results and Discussion

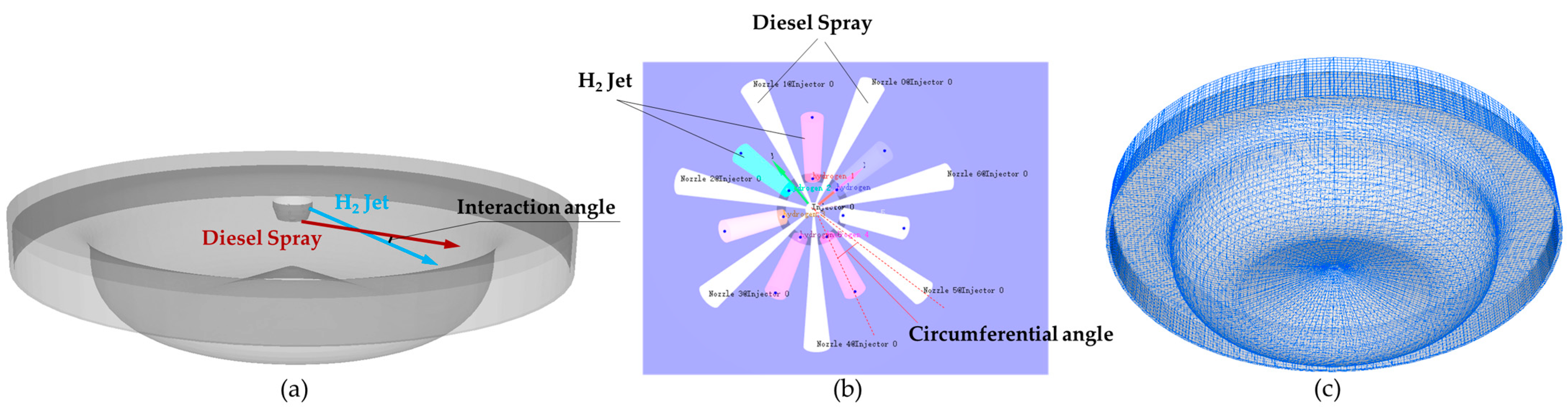

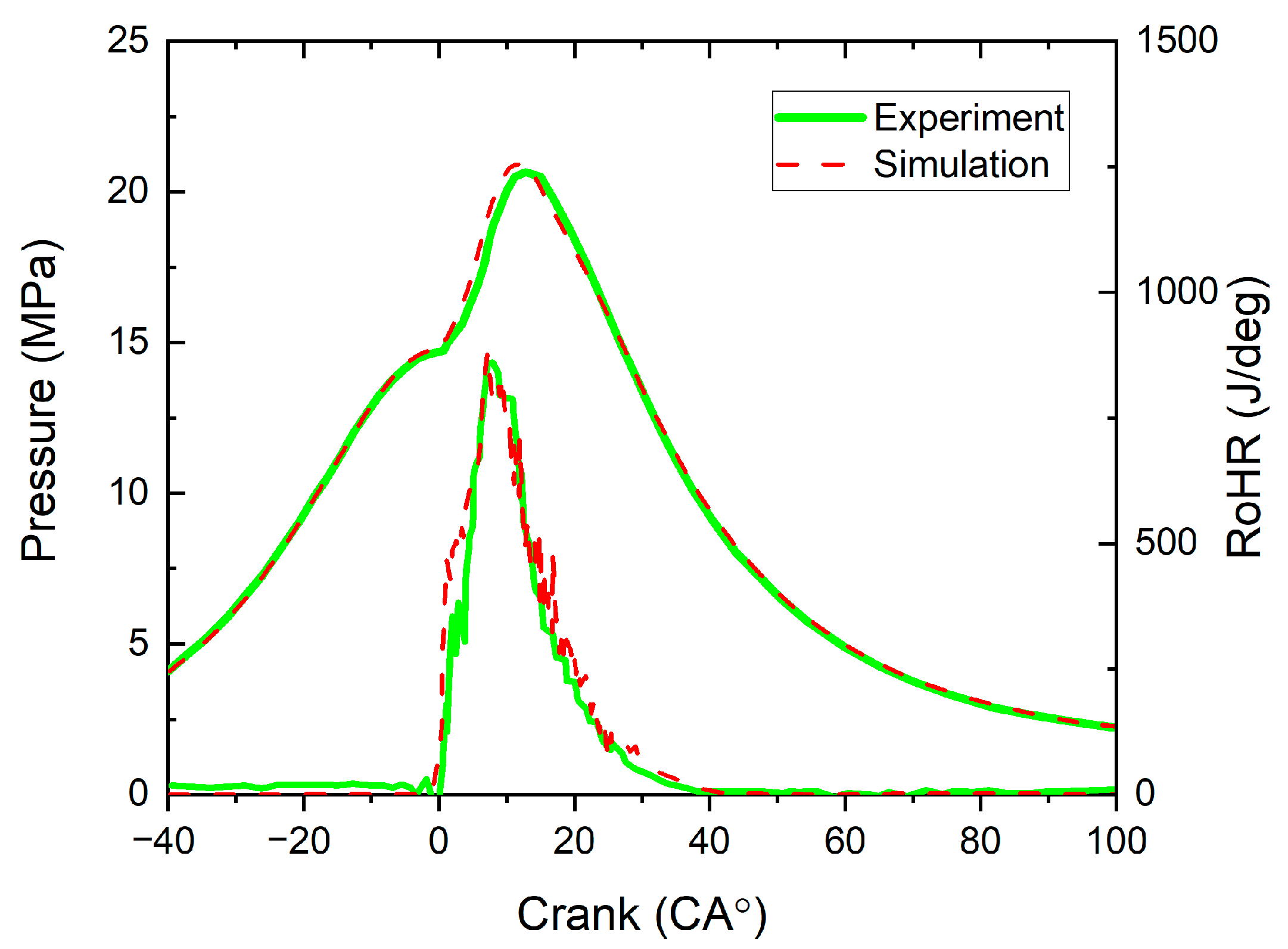

3.1. Grid Independence Analysis and Model Validation

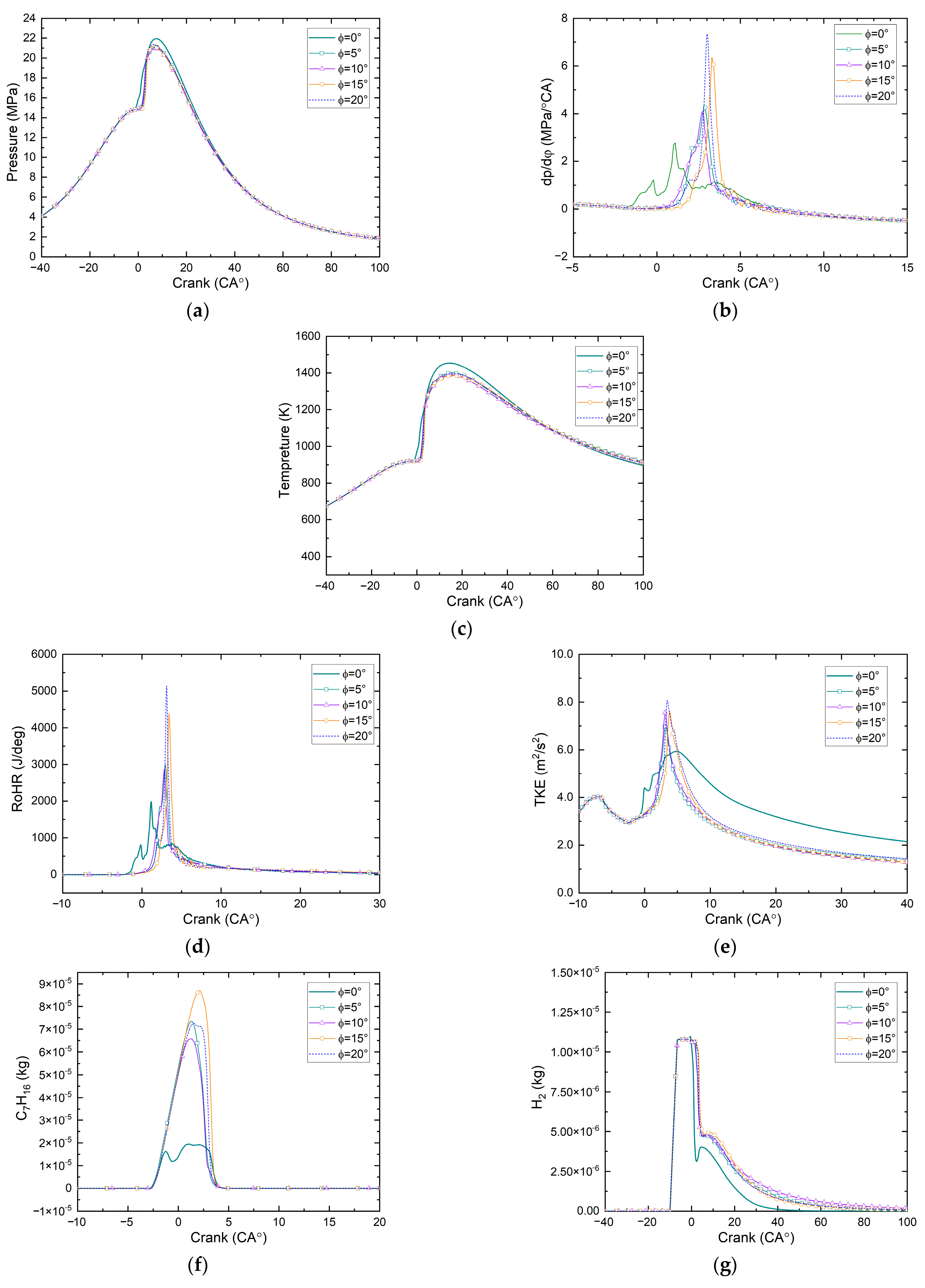

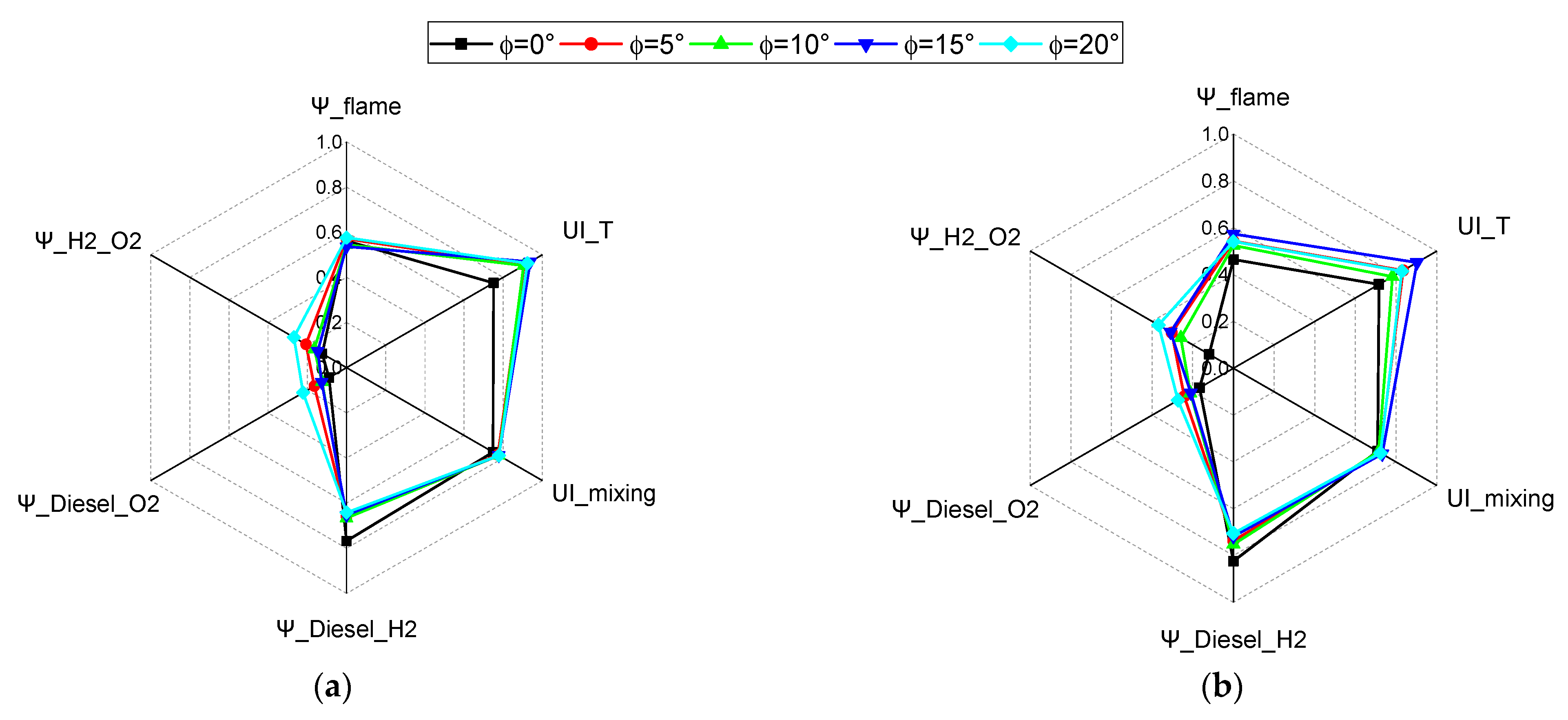

3.2. Effect of Circumferential Angle Between Hydrogen Jets and Diesel Sprays

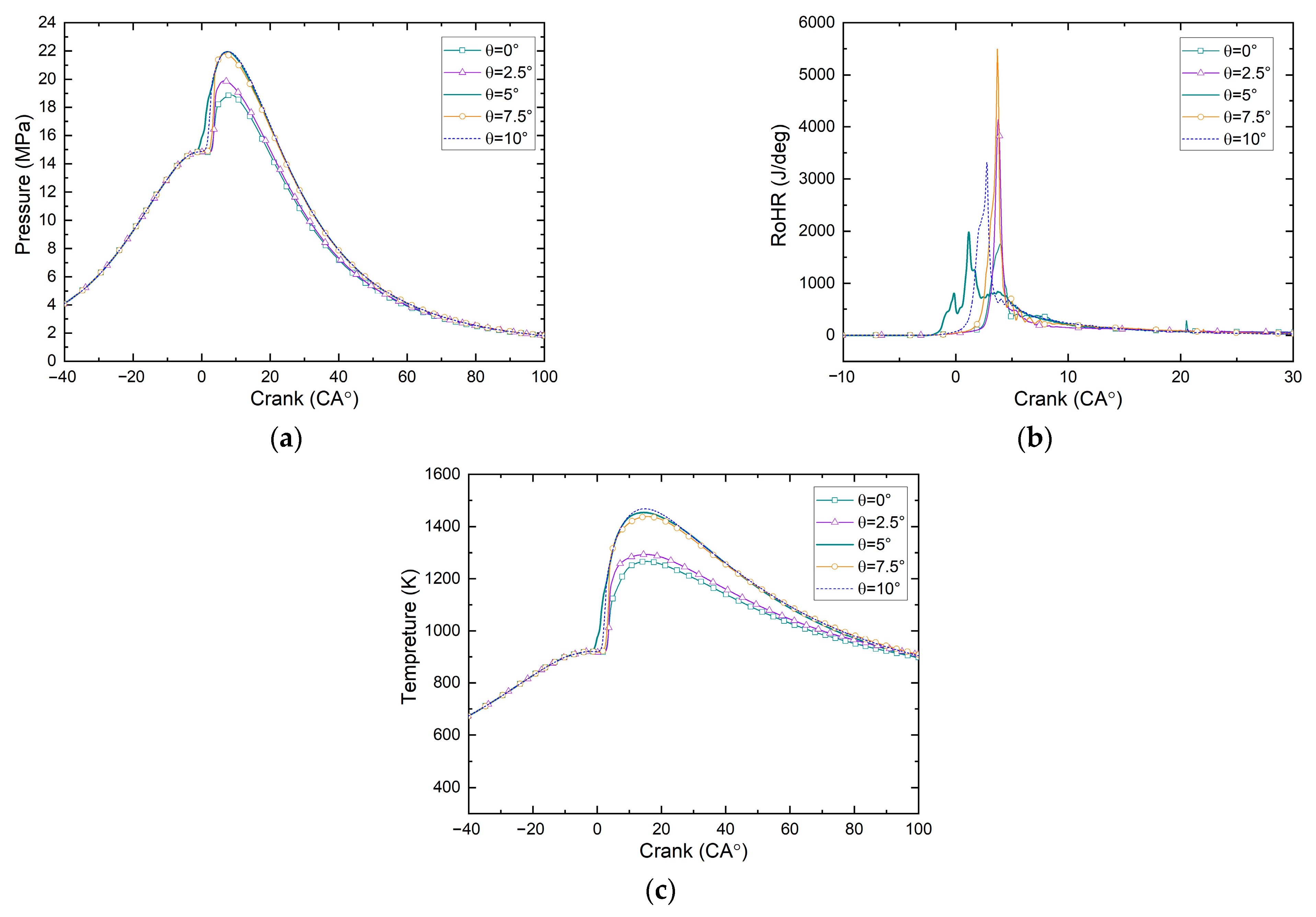

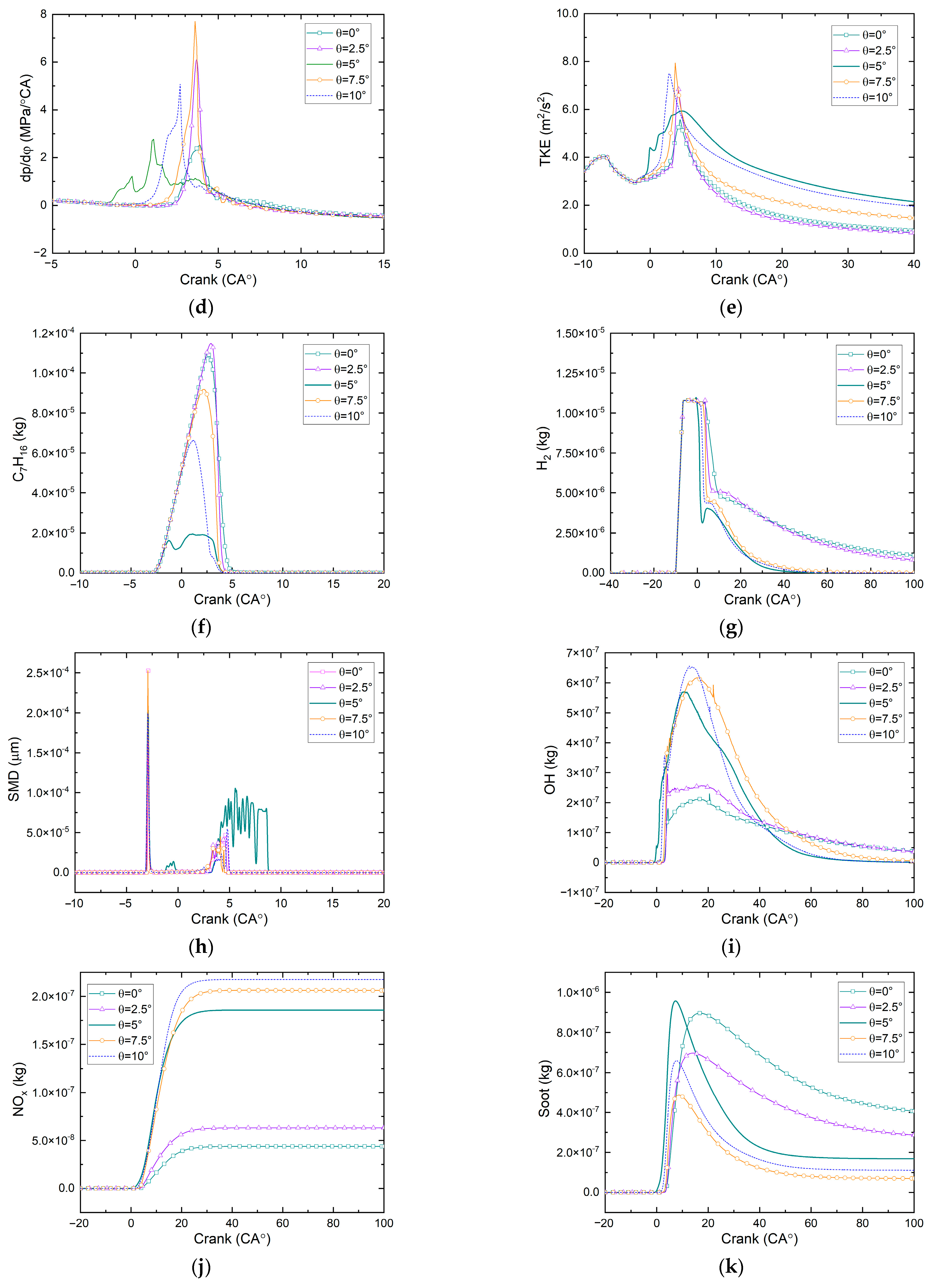

3.3. Effect of Interaction Angle Between Hydrogen Jets and Diesel Sprays

4. Conclusions

- (1)

- A circumferential angle of φ = 0° yielded the highest in-cylinder pressure (20.92 MPa) and temperature (1267 K), along with the earliest ignition timing (−0.3° CA ATDC) and shortest combustion duration (18.11° CA). This configuration maximized turbulence kinetic energy and fuel–air mixing, leading to 47.26 kW indicated power—the highest among tested cases. However, φ = 0° also produced 29.6% higher NOx and 34.5% higher soot emissions compared to φ = 15°, where emissions were minimized due to reduced flame interference and oxygen competition.

- (2)

- An interaction angle of θ = 7.5° achieved the best balance between combustion efficiency and work output, with 47.69 kW indicated power and 15.28° CA combustion duration. Vertical interference at θ ≥ 5° enhanced flame propagation and reduced residual fuel mass, but NOx emissions increased by ~35% relative to θ = 0°. At θ = 0° weak coupling between hydrogen and diesel sprays resulted in poor mixing (ψ_Diesel_H2 ≈ 0.5) and 40.76 kW indicated power—the lowest performance.

- (3)

- Configurations with higher combustion temperatures (e.g., φ = 0°, θ ≥ 5°) increased thermal NOx via the Zeldovich mechanism but reduced soot by ~30% due to improved oxidation. For example, φ = 15° reduced soot by 34.5% but sacrificed 12% indicated power compared to φ = 0°. The equivalence ratio uniformity index (UI_mix) exceeded 0.85 for φ = 10–20°, but combustion efficiency was compromised by fuel-rich zones. Co-axial alignment (φ = 0°) improved local mixing (ψ_Diesel_O2 > 0.6) but intensified oxygen competition near spray regions.

- (4)

- With the φ = 0° and θ = 7.5° combination, the high-pressure loop indicated that the work reaches its maximum value, accompanied by NOx and soot emissions of 2.06 × 10−7 kg and 6.88 × 10−8 kg, respectively. In contrast, the φ = 0° and θ = 5° configuration achieves a 9.7% reduction in NOx while maintaining a minimal 0.9% drop in indicated work, albeit at the expense of a 144.2% increase in soot production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and emission characteristics of a hydrogen-diesel dual-fuel engine. Int. J. Hydrogen Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Akal, D.; Öztuna, S.; Büyükakın, M.K. A review of hydrogen usage in internal combustion engines (gasoline-Lpg-diesel) from combustion performance aspect. Int. J. Hydrogen Energy 2020, 45, 35257–35268. [Google Scholar] [CrossRef]

- Wright, M.L.; Lewis, A.C. Decarbonisation of heavy-duty diesel engines using hydrogen fuel: A review of the potential impact on NO x emissions. Environ. Sci. Atmos. 2022, 2, 852–866. [Google Scholar] [CrossRef]

- Gnanamoorthi, V.; Vimalananth, V.T. Effect of hydrogen fuel at higher flow rate under dual fuel mode in CRDI diesel engine. Int. J. Hydrogen Energy 2020, 45, 16874–16889. [Google Scholar] [CrossRef]

- Jamrozik, A.; Grab-Rogaliński, K.; Tutak, W. Hydrogen effects on combustion stability, performance and emission of diesel engine. Int. J. Hydrogen Energy 2020, 45, 19936–19947. [Google Scholar] [CrossRef]

- Vargün, M.; Yapmaz, A.; Kalender, V.; Yılmaz, I.T. Investigation of the effects of using hydrogen enriched fuel blends in a diesel engine on engine performance, combustion and exhaust emissions. Int. J. Hydrogen Energy 2025, 97, 1399–1410. [Google Scholar] [CrossRef]

- Estrada, L.; Moreno, E.; Gonzalez-Quiroga, A.; Bula, A.; Duarte-Forero, J. Experimental assessment of performance and emissions for hydrogen-diesel dual fuel operation in a low displacement compression ignition engine. Heliyon 2022, 8, e09285. [Google Scholar] [CrossRef]

- Grab-Rogalinski, K.A.; Tutak, W.; Jamrozik, A. Comparative Analysis of Combustion Process of Dual Fuel Diesel Engine Fueled by Diesel/Hydrogen and Biodiesel/Hydrogen; SAE Technical Paper; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

- Ahmed, S.A.; Zhou, S.; Tsegay, S.; Ahmad, N.; Zhu, Y. Effects of hydrogen-enriched biogas on combustion and emission of a dual-fuel diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 5644–5659. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Effect of natural gas enrichment with hydrogen on combustion process and emission characteristic of a dual fuel diesel engine. Int. J. Hydrogen Energy 2020, 45, 9088–9097. [Google Scholar] [CrossRef]

- Subramanian, B.; Thangavel, V. Experimental investigations on performance, emission and combustion characteristics of Diesel-Hydrogen and Diesel-HHO gas in a Dual fuel CI engine. Int. J. Hydrogen Energy 2020, 45, 25479–25492. [Google Scholar] [CrossRef]

- Karagöz, Y.; Sandalcı, T.; Yüksek, L.; Dalkılıç, A. Engine performance and emission effects of diesel burns enriched by hydrogen on different engine loads. Int. J. Hydrogen Energy 2015, 40, 6702–6713. [Google Scholar] [CrossRef]

- Akhtar, M.U.S.; Asfand, F.; Khan, M.I.; Mishra, R.; Ball, A.D. Performance and emissions characteristics of hydrogen-diesel dual-fuel combustion for heavy-duty engines. Int. J. Hydrogen Energy 2025, in press. [CrossRef]

- Li, Z.; Liu, J.; Ji, Q.; Sun, P.; Wang, X.; Xiang, P. Influence of hydrogen fraction and injection timing on in-cylinder combustion and emission characteristics of hydrogen-diesel dual-fuel engine. Fuel Process. Technol. 2023, 252, 107990. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, X.; Guo, Z.; Li, D.; Wang, T.; Gong, T.; You, T. Effect of Exhaust Gas Recirculation and Spark Timing on Combustion and Emission Performance of an Oxygen-Enriched Gasoline Engine. ACS Omega 2022, 7, 42208–42220. [Google Scholar] [CrossRef] [PubMed]

- Rorimpandey, P.; Zhai, G.; Kook, S.; Hawkes, E.R.; Chan, Q.N. Effects of energy-share and ambient oxygen concentration on hydrogen-diesel dual-fuel direct-injection (H2DDI) combustion in compression-ignition conditions. Int. J. Hydrogen Energy 2024, 49, 1346–1361. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, H.; Li, M.; Yao, M. Study on the double injection strategy of gasoline partially premixed combustion under a light-duty optical engine. SAE Int. J. Engines 2016, 9, 2185–2193. [Google Scholar] [CrossRef]

- Bayramoğlu, K.; Yılmaz, S. Emission and performance estimation in hydrogen injection strategies on diesel engines. Int. J. Hydrogen Energy 2021, 46, 29732–29744. [Google Scholar] [CrossRef]

- Babayev, R.; Andersson, A.; Dalmau, A.S.; Im, H.G.; Johansson, B. Computational comparison of the conventional diesel and hydrogen direct-injection compression-ignition combustion engines. Fuel 2022, 307, 121909. [Google Scholar] [CrossRef]

- Wang, Y.; Evans, A.; Srna, A.; Wehrfritz, A.; Hawkes, E.; Liu, X.; Kook, S.; Chan, Q.N. A Numerical Investigation of Mixture Formation and Combustion Characteristics of a Hydrogen-Diesel Dual Direct Injection Engine; SAE Technical Paper; SAE: Warrendale, PA, USA, 2021. [Google Scholar]

- Mancaruso, E.; Rossetti, S.; Vaglieco, B.M. Analysis of Dual Fuel Hydrogen/Diesel Combustion Varying Diesel and Hydrogen Injection Parameters in a Single Cylinder Research Engine; SAE Technical Paper; SAE: Warrendale, PA, USA, 2024. [Google Scholar]

- Das, S.; Das, B. Effect of injection parameters on the hydrogen enriched dual-fuel CRDI diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 10176–10199. [Google Scholar] [CrossRef]

- Fink, G.; Jud, M.; Sattelmayer, T. Fundamental study of diesel-piloted natural gas direct injection under different operating conditions. J. Eng. Gas Turbines Power 2019, 141, 091006. [Google Scholar] [CrossRef]

- Rorimpandey, P.; Yip, H.L.; Srna, A.; Zhai, G.; Wehrfritz, A.; Kook, S.; Hawkes, E.R.; Chan, Q.N. Hydrogen-diesel dual-fuel direct-injection (H2DDI) combustion under compression-ignition engine conditions. Int. J. Hydrogen Energy 2023, 48, 766–783. [Google Scholar] [CrossRef]

- Versteeg, H.K. An Introduction to Computational Fluid Dynamics the Finite Volume Method, 2/E; Pearson Education India: Delhi, India, 2007. [Google Scholar]

- Steve Karman, L., Jr. SPLITFLOW-A 3D unstructured Cartesian/prismatic grid CFD code for complex geometries. In Proceedings of the 33rd Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 1995; p. 343. [Google Scholar]

- Widiawaty, C.D.; Siswantara, A.I.; Gunadi, G.G.R.; Andira, M.A.; Budiarso; Budiyanto, M.A.; Syafei, M.H.G.; Adanta, D. Optimization of inverse-Prandtl of Dissipation in standard k-ε Turbulence Model for Predicting Flow Field of Crossflow Turbine. CFD Lett. 2022, 14, 112–127. [Google Scholar] [CrossRef]

- Jia, M.; Pan, H.; Bian, Y.; Zhang, Z.; Chang, Y.; Liu, H. Calibration of the constants in the kelvin-helmholtz rayleigh-taylor (KH-RT) breakup model for diesel spray under wide conditions based on advanced data analysis techniques. At. Sprays 2022, 32, 1–27. [Google Scholar] [CrossRef]

- Hiroyasu, H.; Kadota, T.; Arai, M. Development and use of a spray combustion modeling to predict diesel engine efficiency and pollutant emissions: Part 1 combustion modeling. Bull. JSME 1983, 26, 569–575. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Guo, H. A numerical investigation on NO2 formation reaction pathway in a natural gas–diesel dual fuel engine. Combust. Flame 2018, 190, 337–348. [Google Scholar] [CrossRef]

- Ra, Y.; Reitz, R.D. A reduced chemical kinetic model for IC engine combustion simulations with primary reference fuels. Combust. Flame 2008, 155, 713–738. [Google Scholar] [CrossRef]

- Anetor, L.; Odetunde, C.; Osakue, E.E. Computational analysis of the extended Zeldovich mechanism. Arab. J. Sci. Eng. 2014, 39, 8287–8305. [Google Scholar] [CrossRef]

- Lam, N.; Tunestal, P.; Andersson, A. Simulation of System Brake Efficiency in a Double Compression-Expansion Engine-Concept (DCEE) Based on Experimental Combustion Data; SAE Technical Paper; SAE: Warrendale, PA, USA, 2019. [Google Scholar]

- Li, H.; Liu, S.; Liew, C.; Li, Y.; Wayne, S.; Clark, N. An investigation on the mechanism of the increased NO2 emissions from H2-diesel dual fuel engine. Int. J. Hydrogen Energy 2018, 43, 3837–3844. [Google Scholar] [CrossRef]

- Lopatin, O.P. Chemistry of the process of formation of nitrogen oxides in the combustion chamber of gas-diesel. J. Phys. Conf. Ser. 2020, 1515, 052004. [Google Scholar] [CrossRef]

- Moussa, S.G.; Leithead, A.; Li, S.M.; Chan, T.W.; Wentzell, J.J.; Stroud, C.; Zhang, J.; Lee, P.; Lu, G.; Brook, J.R.; et al. Emissions of hydrogen cyanide from on-road gasoline and diesel vehicles. Atmos. Environ. 2016, 131, 185–195. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, M.; Zhu, Y.; Cao, L.; Zhu, B.; Wu, J.; Lin, Y.; Huang, X. A review of the effects of hydrogen, carbon dioxide, and water vapor addition on soot formation in hydrocarbon flames. Int. J. Hydrogen Energy 2021, 46, 31400–31427. [Google Scholar] [CrossRef]

| CDC [33] | HDDF | |

|---|---|---|

| Cylinder bore/mm | 131 | |

| Stroke/mm | 158 | |

| Connecting rod length/mm | 267.5 | |

| Compression ratio | 11.5:1 | |

| Engine speed/RPM | 1200 | |

| Piston temperature/K | 800 | |

| Cylinder liner temperature/K | 610 | |

| Cylinder head temperature/K | 740 | |

| Number of diesel and H2 nozzle orifices | 7 | |

| Diesel orifice diameter/mm | 0.265 | |

| Diesel spray umbrella angle/° | 135, 140, 145, 150, 155 | |

| Diesel injection timing/° CA ATDC | −3 | |

| H2 energy share, HES/% | 0 | 40 |

| H2 injection mass/mg | 0 | 41.3 |

| H2 orifice diameter/mm | 0 | 1 |

| H2 spray umbrella angle/° | 0 | 135 |

| H2 injection timing/° CA ATDC | −10 | |

| In-cylinder gas pressure at IVC/bar | 6.8 | 6.8 |

| In-cylinder gas temperature at IVC/K | 446 | 446 |

| Diesel injection mass/mg | 275.6 | 165.4 |

| Case | Mean Grid Size, μm | Cell Number |

|---|---|---|

| A | 400 | 0.82 × 106 |

| B | 300 | 1.31 × 106 |

| C | 200 | 1.85 × 106 |

| D | 150 | 2.37 × 106 |

| E | 100 | 2.85 × 106 |

| φ = 0° | φ = 5° | φ = 10° | φ = 15° | φ = 20° | |

|---|---|---|---|---|---|

| Ignition time (° CA ATDC) | −0.3 | 1.9 | 1.6 | 2.3 | 1.9 |

| Center of combustion (° CA ATDC) | 4.11 | 4.57 | 4.74 | 4.45 | 4.12 |

| Combustion duration (° CA) | 18.11 | 25.84 | 28.91 | 24.10 | 23.38 |

| Mean effective pressure of high-pressure cycle (MPa) | 6.39 | 6.27 | 6.21 | 6.22 | 6.23 |

| Indicated power of high-pressure cycle (kW) | 47.26 | 46.48 | 45.92 | 46.37 | 46.34 |

| Circumferential Angles (φ) | fMEP | fNOx | fSoot |

|---|---|---|---|

| 0° | 1 | 0 | 0.092 |

| 5° | 0.333 | 0.166 | 0.200 |

| 10° | 0 | 0.252 | 0 |

| 15° | 0.056 | 0.292 | 0.404 |

| 20° | 0.111 | 0.294 | 0.272 |

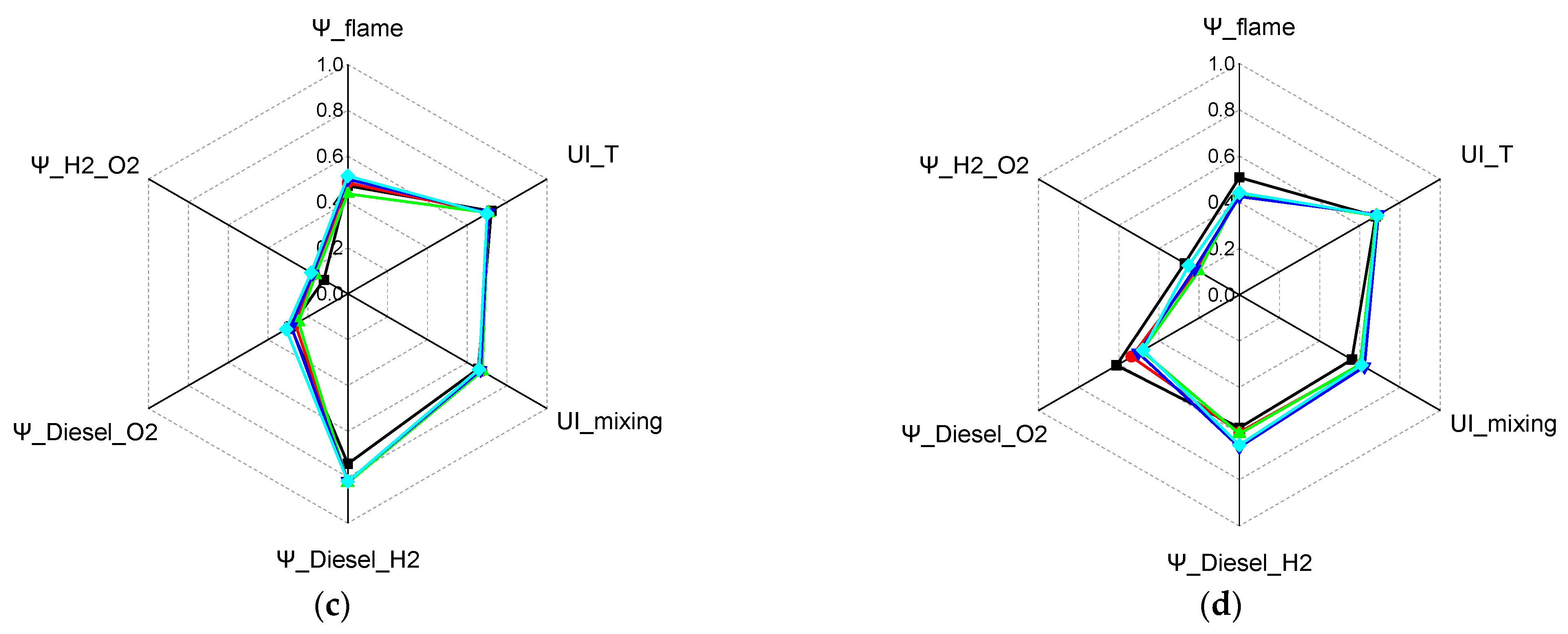

| Crank Angle (° CA ATDC) | Circumferential Angles (°) | Ψ_Flame | UI_T | UI_Mixing | Ψ_Diesel_H2 | Ψ_Diesel_O2 | Ψ_H2_O2 |

|---|---|---|---|---|---|---|---|

| −2 | 0 | 0.561 | 0.750 | 0.748 | 0.768 | 0.089 | 0.124 |

| 5 | 0.570 | 0.907 | 0.772 | 0.659 | 0.164 | 0.207 | |

| 10 | 0.545 | 0.904 | 0.778 | 0.667 | 0.125 | 0.164 | |

| 15 | 0.536 | 0.938 | 0.778 | 0.653 | 0.127 | 0.147 | |

| 20 | 0.576 | 0.923 | 0.778 | 0.642 | 0.222 | 0.269 | |

| 0 | 0 | 0.464 | 0.716 | 0.709 | 0.824 | 0.167 | 0.119 |

| 5 | 0.543 | 0.835 | 0.722 | 0.737 | 0.242 | 0.303 | |

| 10 | 0.524 | 0.783 | 0.714 | 0.752 | 0.212 | 0.259 | |

| 15 | 0.573 | 0.903 | 0.732 | 0.718 | 0.210 | 0.309 | |

| 20 | 0.541 | 0.829 | 0.724 | 0.705 | 0.273 | 0.369 | |

| 5 | 0 | 0.470 | 0.721 | 0.655 | 0.742 | 0.286 | 0.120 |

| 5 | 0.483 | 0.705 | 0.672 | 0.818 | 0.264 | 0.168 | |

| 10 | 0.436 | 0.706 | 0.674 | 0.823 | 0.247 | 0.163 | |

| 15 | 0.499 | 0.706 | 0.667 | 0.817 | 0.284 | 0.175 | |

| 20 | 0.514 | 0.699 | 0.659 | 0.818 | 0.309 | 0.184 | |

| 10 | 0 | 0.507 | 0.679 | 0.560 | 0.576 | 0.611 | 0.272 |

| 5 | 0.437 | 0.686 | 0.605 | 0.595 | 0.536 | 0.214 | |

| 10 | 0.438 | 0.682 | 0.602 | 0.601 | 0.485 | 0.203 | |

| 15 | 0.424 | 0.692 | 0.622 | 0.659 | 0.503 | 0.223 | |

| 20 | 0.442 | 0.686 | 0.607 | 0.649 | 0.479 | 0.253 |

| θ = 0° | θ = 2.5° | θ = 5° | θ = 7.5° | θ = 10° | |

|---|---|---|---|---|---|

| Ignition time (° CA ATDC) | 2.9 | 3.1 | −0.3 | 1.6 | 2.5 |

| Center of combustion (° CA ATDC) | 8.68 | 6.27 | 4.11 | 4.03 | 4.01 |

| Combustion duration (° CA) | 25.02 | 20.27 | 18.11 | 15.28 | 16.97 |

| Mean effective pressure of high-pressure cycle (MPa) | 5.92 | 6.02 | 6.39 | 6.36 | 6.30 |

| Indicated power of high-pressure cycle (kW) | 40.76 | 42.29 | 47.26 | 47.69 | 47.33 |

| Interaction Angle (θ) | fMEP | fNOx | fSoot |

|---|---|---|---|

| 0° | 0 | 0.799 | 0 |

| 2.5° | 0.213 | 0.71 | 0.289 |

| 5° | 1 | 0.146 | 0.547 |

| 7.5° | 0.936 | 0.052 | 0.814 |

| 10° | 0.809 | 0 | 0.702 |

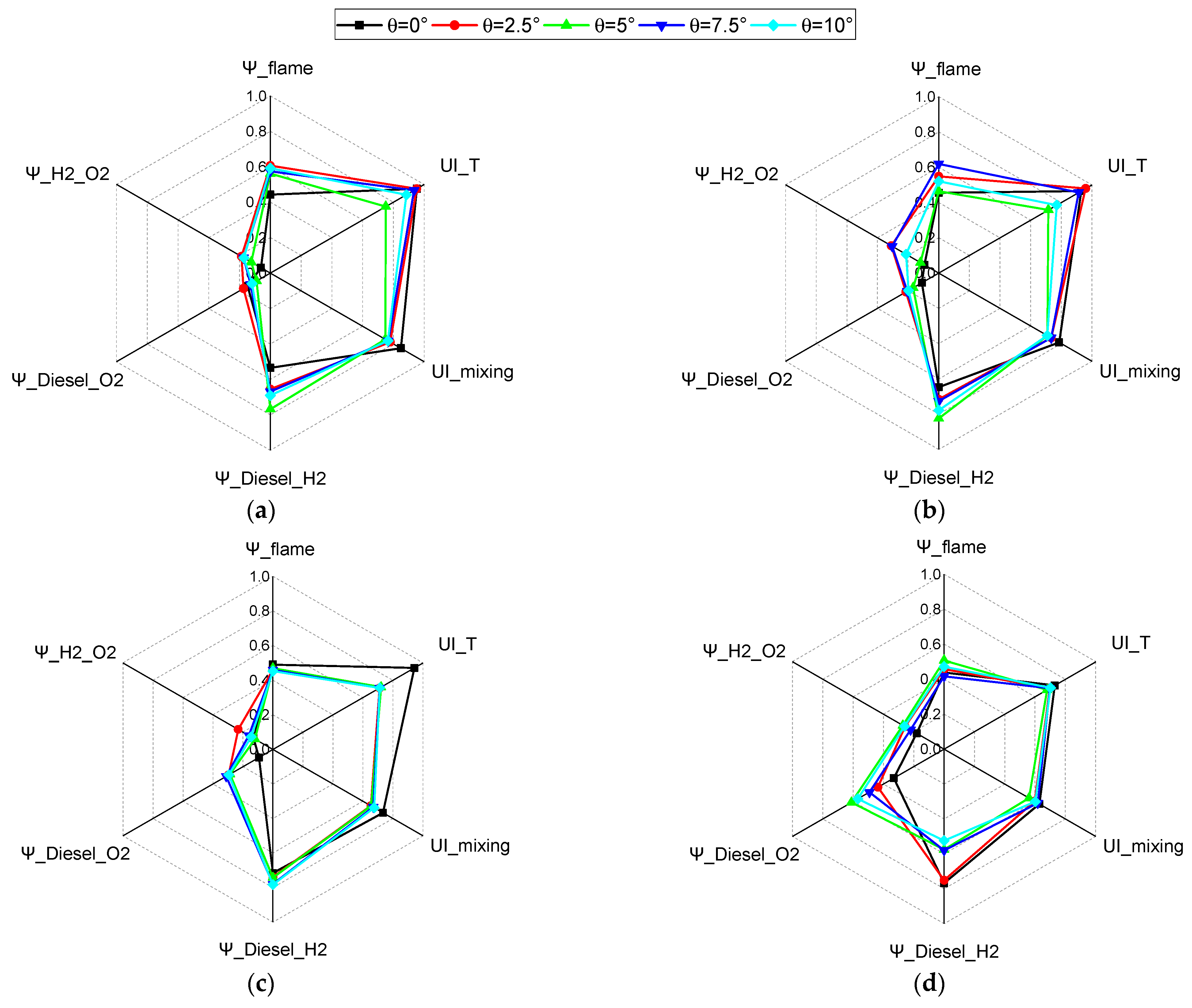

| Crank Angle (° CA ATDC) | Interaction Angles (°) | Ψ_Flame | UI_T | UI_Mixing | Ψ_Diesel_H2 | Ψ_Diesel_O2 | Ψ_H2_O2 |

|---|---|---|---|---|---|---|---|

| −2 | 0 | 0.443 | 0.952 | 0.848 | 0.535 | 0.148 | 0.061 |

| 5 | 0.606 | 0.951 | 0.779 | 0.655 | 0.174 | 0.188 | |

| 10 | 0.561 | 0.750 | 0.748 | 0.768 | 0.089 | 0.124 | |

| 15 | 0.574 | 0.934 | 0.766 | 0.669 | 0.128 | 0.173 | |

| 20 | 0.591 | 0.884 | 0.764 | 0.691 | 0.119 | 0.172 | |

| 0 | 0 | 0.455 | 0.93 | 0.786 | 0.647 | 0.110 | 0.093 |

| 5 | 0.548 | 0.959 | 0.734 | 0.716 | 0.214 | 0.309 | |

| 10 | 0.464 | 0.716 | 0.709 | 0.824 | 0.167 | 0.119 | |

| 15 | 0.619 | 0.914 | 0.734 | 0.726 | 0.205 | 0.304 | |

| 20 | 0.520 | 0.770 | 0.708 | 0.778 | 0.197 | 0.213 | |

| 5 | 0 | 0.490 | 0.943 | 0.733 | 0.716 | 0.093 | 0.129 |

| 5 | 0.461 | 0.711 | 0.653 | 0.739 | 0.296 | 0.232 | |

| 10 | 0.470 | 0.721 | 0.655 | 0.742 | 0.286 | 0.120 | |

| 15 | 0.460 | 0.711 | 0.669 | 0.780 | 0.312 | 0.161 | |

| 20 | 0.453 | 0.712 | 0.675 | 0.783 | 0.295 | 0.146 | |

| 10 | 0 | 0.439 | 0.730 | 0.628 | 0.768 | 0.332 | 0.181 |

| 5 | 0.458 | 0.697 | 0.597 | 0.751 | 0.437 | 0.258 | |

| 10 | 0.507 | 0.679 | 0.560 | 0.576 | 0.611 | 0.272 | |

| 15 | 0.417 | 0.697 | 0.618 | 0.580 | 0.493 | 0.221 | |

| 20 | 0.472 | 0.702 | 0.601 | 0.525 | 0.570 | 0.261 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Li, Z.; Xu, Y.; Li, X. Effects of Circumferential and Interaction Angles of Hydrogen Jets and Diesel Sprays on Combustion Characteristics in a Hydrogen–Diesel Dual-Fuel CI Engine. Sustainability 2025, 17, 6059. https://doi.org/10.3390/su17136059

Zhang Q, Li Z, Xu Y, Li X. Effects of Circumferential and Interaction Angles of Hydrogen Jets and Diesel Sprays on Combustion Characteristics in a Hydrogen–Diesel Dual-Fuel CI Engine. Sustainability. 2025; 17(13):6059. https://doi.org/10.3390/su17136059

Chicago/Turabian StyleZhang, Qiang, Zhipeng Li, Yang Xu, and Xiangrong Li. 2025. "Effects of Circumferential and Interaction Angles of Hydrogen Jets and Diesel Sprays on Combustion Characteristics in a Hydrogen–Diesel Dual-Fuel CI Engine" Sustainability 17, no. 13: 6059. https://doi.org/10.3390/su17136059

APA StyleZhang, Q., Li, Z., Xu, Y., & Li, X. (2025). Effects of Circumferential and Interaction Angles of Hydrogen Jets and Diesel Sprays on Combustion Characteristics in a Hydrogen–Diesel Dual-Fuel CI Engine. Sustainability, 17(13), 6059. https://doi.org/10.3390/su17136059