Sustainability-Oriented Assessment of Passenger Car Emissions in Relation to Euro Standards Using the ECE-15 Driving Cycle

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Equipment

- The engine was warmed up to its normal operating temperature to ensure proper functioning of the exhaust gas after-treatment systems;

- The vehicle’s technical condition was faultless: no diagnostic trouble codes were present in the control units, the exhaust system was undamaged, and all manufacturer-specified components were intact;

- The tests were conducted under simulated driving conditions based on the ECE-15 cycle.

2.2. Calculation Methodology

or QCO = CCO × 9.669 × Gexh/3600 = CCO × 2.686 × 10−4 × Gexh (g/s).

or QCO2 = CCO2 × 15.19 × Gexh/3600 = CCO2 × 42.2 × 10−4 × Gexh (g/s).

or QNO = Cp_NO × 1.036 × 10−3 × Gexh/3600 = Cp_NO × 0.2877 × 10−6 × Gexh (g/s).

or QHC = Cp_HC × 0.4784 × Gexh/3600 = Cp_HC × 0.1329 × 10−6 × Gexh (g/s).

2.3. Study Limitations

3. Results and Discussions

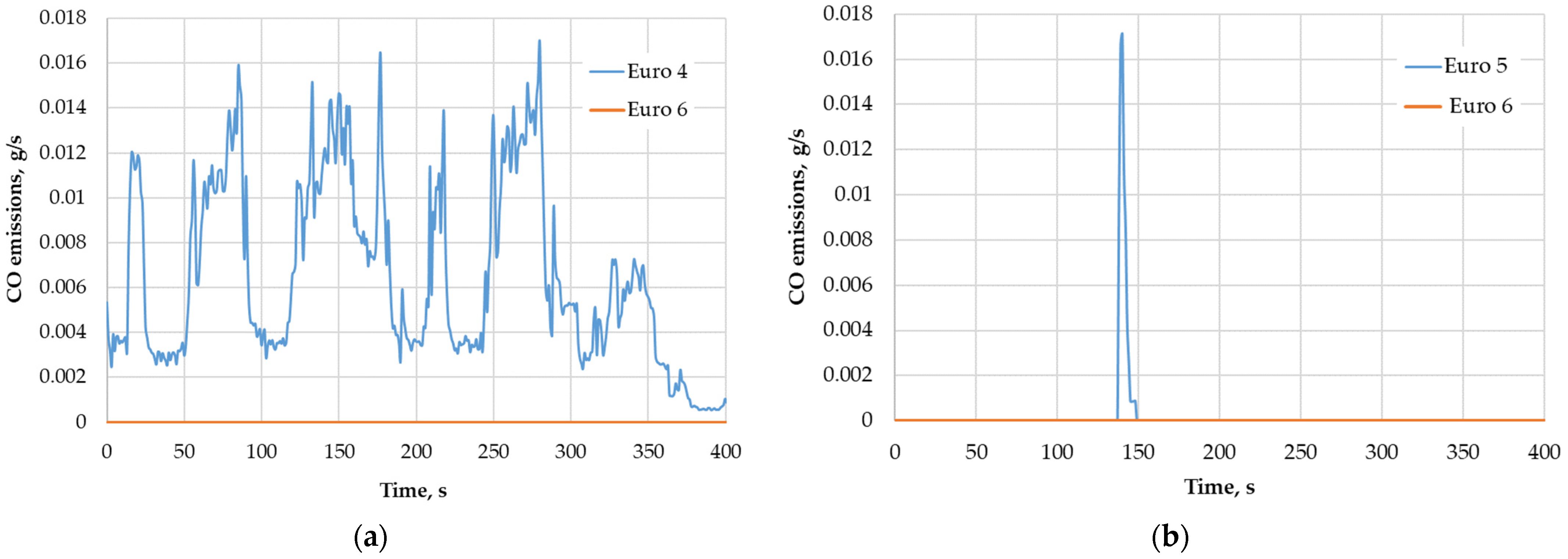

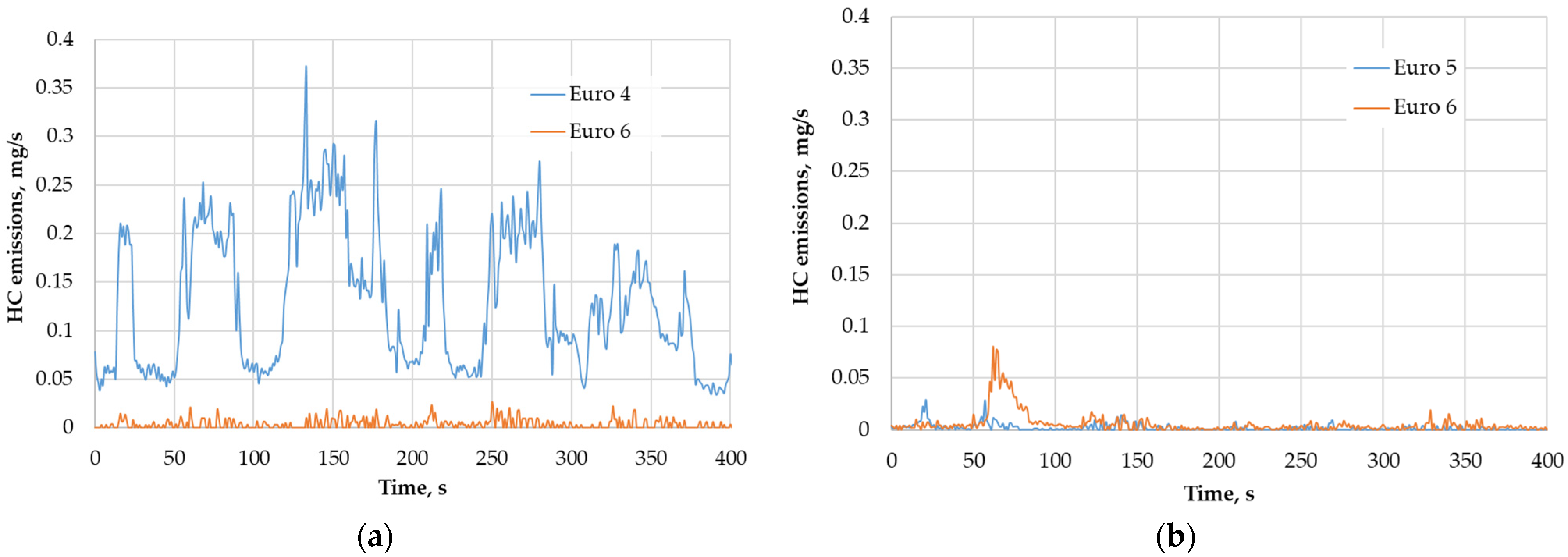

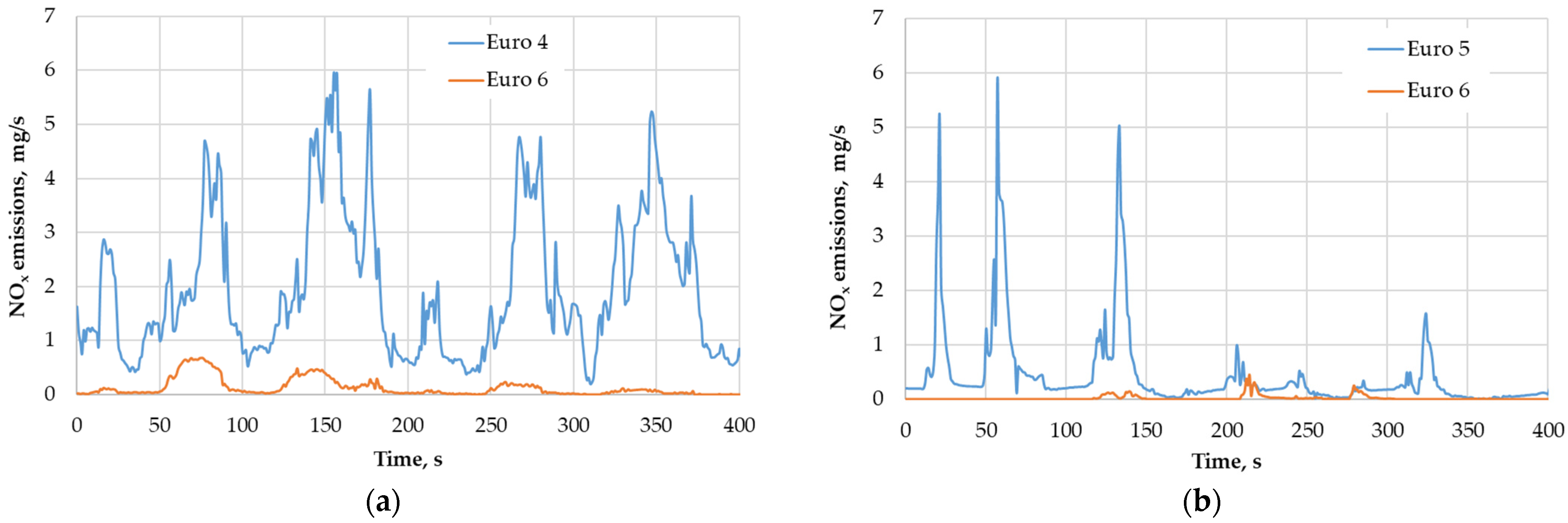

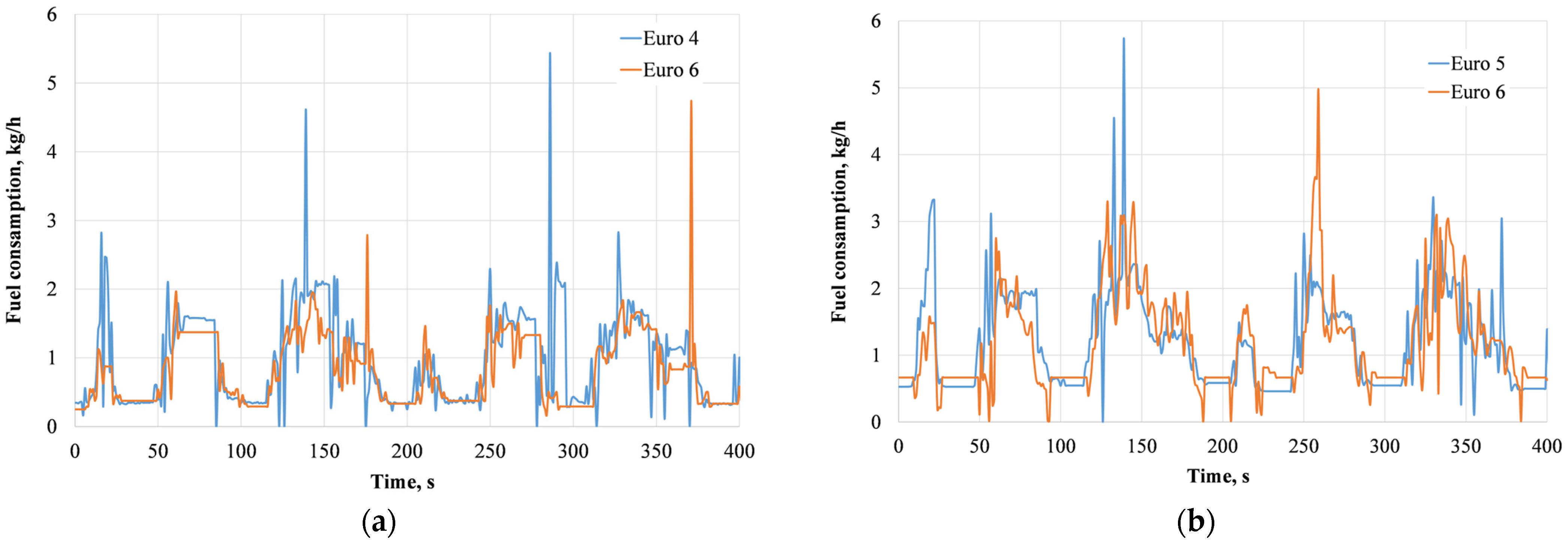

3.1. Experimental Research

3.2. Calculation Results

4. Conclusions

- The Nissan Qashqai+2 J10 (Euro 4) exceeded the CO limit by 2.07 times, while NOx was 1.46 times lower, and HC emissions were 2 times below the allowed value. CO2 emissions exceeded the limit by only 1.06 times, which can be considered a marginal deviation.

- The VW Passat B8 (Euro 6) demonstrated very low emissions: CO was undetectable, HC amounted to only 1.6% of the limit, and NOx was 3.81 times lower. CO2 emissions exceeded the limit by only 2.9%.

- The Nissan Qashqai J11 (Euro 5) emitted 33 times less CO and 333 times less HC, but NOx exceeded the limit by 1.32 times. CO2 emissions were 62.8% higher than the Euro 5 threshold.

- The VW Passat B8 (Euro 6) had no detectable CO emissions, HC amounted to just 1% of the allowed limit, NOx was 15 times lower, and CO2 emissions were 51.4% above the regulated value.

- While most tested vehicles complied with regulated pollutant limits (CO, HC, and NOx), all exceeded their respective CO2 standards. This finding highlights a key challenge in current emission reduction strategies: without major changes to combustion engine architecture or the adoption of low-carbon fuels, significant CO2 reductions remain unattainable.

- The developed emission calculation methodology is universal and applicable to any driving cycle, making it suitable for evaluating results obtained under various testing conditions. In addition to its scientific role, the methodology developed in this study has practical implications for the certification of retrofitted vehicles equipped with combined conventional fuel and hydrogen supply systems. The methodology could be further improved by incorporating automated data acquisition solutions and real-time flow analysis, thereby increasing the accuracy of the results.

- In further research, the methodology developed in this study will be applied to an expanded vehicle sample to enhance the reliability, statistical robustness, and practical relevance of the findings. The focus will shift toward retrofitted internal combustion engine vehicles powered by alternative fuels—such as hydrogen, liquefied petroleum gas, or compressed natural gas—with the aim of evaluating not only their emissions, fuel consumption, and operating parameters but also their compliance with environmental regulations. The ultimate objective is to support the type-approval and certification of modified vehicles, using the validated methodology as a standard emissions evaluation tool under controlled driving cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DOC | Diesel oxidation catalyst |

| DPF | Diesel particulate filter |

| EGR | Exhaust gas recirculation |

| ICE | Internal combustion engine |

| HC | Hydrocarbon |

| NEDC | New European Driving Cycle |

| NO | Nitrogen monoxide |

| NO2 | Nitrogen dioxide |

| NOx | Nitrogen oxides |

| NSC | NOx storage catalyst |

| OBD | On-board diagnostics |

| RDE | Real driving emissions |

| SCR | Selective catalytic reduction |

| TWC | Three-way catalysts |

| ULSD | Ultra-low sulfur diesel |

| WLTP | Worldwide Harmonized Light-Duty Vehicles Test Procedure |

References

- Jing, Q.-L.; Liu, H.-Z.; Yu, W.-Q.; He, X. The Impact of Public Transportation on Carbon Emissions—From the Perspective of Energy Consumption. Sustainability 2022, 14, 6248. [Google Scholar] [CrossRef]

- Rimpas, D.; Barkas, D.E.; Orfanos, V.A.; Christakis, I. Decarbonizing the Transportation Sector: A Review on the Role of Electric Vehicles Towards the European Green Deal for the New Emission Standards. Air 2025, 3, 10. [Google Scholar] [CrossRef]

- Ferrer, A.L.C.; Thomé, A.M.T. Carbon Emissions in Transportation: A Synthesis Framework. Sustainability 2023, 15, 8475. [Google Scholar] [CrossRef]

- Liang, J.; Wang, F.; Feng, J.; Zhao, M.; Fang, R.; Pi, D.; Yin, G. A Hierarchical Control of Independently Driven Electric Vehicles Considering Handling Stability and Energy Conservation. IEEE Trans. Intell. Veh. 2024, 9, 738–751. [Google Scholar] [CrossRef]

- Liu, H.; Yu, S.; Wang, T.; Li, J.; Wang, Y. A Systematic Review on Sustainability Assessment of Internal Combustion Engines. J. Clean. Prod. 2024, 451, 141996. [Google Scholar] [CrossRef]

- Emissions Distributions by Vehicle Age and Policy Implications; TRUE—The Real Urban Emissions Initiative: London, UK, 2020; p. 8. Available online: https://theicct.org/wp-content/uploads/2021/06/US-TRUE-emissions-distribution-oct2020.pdf?utm_source=chatgpt.com (accessed on 23 May 2025).

- Pilusa, T.J.; Mollagee, M.M.; Muzenda, E. Reduction of Vehicle Exhaust Emissions from Diesel Engines Using the Whale Concept Filter. Aerosol Air Qual. Res. 2012, 12, 994–1006. [Google Scholar] [CrossRef]

- Liu, B.; Shi, Q.; He, L.; Qiu, D. A Study on the Construction of Hefei Urban Driving Cycle for Passenger Vehicle. IFAC-PapersOnLine 2018, 51, 854–858. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Li, J.; Li, J.; Xu, F.; Han, F.; He, J.; Chen, Q.; Chen, X. RDE & Dynamometer Analysis of Light-Duty Vehicle Emissions across Altitudes, Temperatures, and Driving Styles. PLoS ONE 2025, 20, e0318298. [Google Scholar] [CrossRef]

- Alkama, R.; Ait-Idir, F.; Slimani, Z. Estimation and Measurement of the Automobile Pollution: Application to Bejaia Case. Glob. NEST J. 2006, 8, 277–281. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, C.; Ge, Y.; Hao, L.; Tan, J.; Wang, X.; Zhang, P.; Wang, Y.; Tian, W.; Lin, Z.; et al. Fuel Consumption and Emission Performance from Light-Duty Conventional/Hybrid-Electric Vehicles over Different Cycles and Real Driving Tests. Fuel 2020, 278, 118340. [Google Scholar] [CrossRef]

- Sofwan, N.M.; Latif, M.T. Characteristics of the Real-Driving Emissions from Gasoline Passenger Vehicles in the Kuala Lumpur Urban Environment. Atmos. Pollut. Res. 2021, 12, 306–315. [Google Scholar] [CrossRef]

- Chong, H.S.; Park, Y.; Kwon, S.; Hong, Y. Analysis of Real Driving Gaseous Emissions from Light-Duty Diesel Vehicles. Transp. Res. Part Transp. Environ. 2018, 65, 485–499. [Google Scholar] [CrossRef]

- Bagheri, E.; Tehrani, M.M.; Azadi, M.; Moosavian, A. Impact of Driving Characteristic Parameters and Vehicle Type on Fuel Consumption and Emissions Performance over Real Driving Cycles. PLoS ONE 2025, 20, e0317098. [Google Scholar] [CrossRef]

- Pöhler, D.; Schmidt, C.; Horbanski, M.; Schmitt, S.; Lampel, J. Identification of Manipulated & Defective Truck NOx Emission Reduction Systems with Plume Chasing for Authority Inspections. Transp. Res. Procedia 2023, 72, 1661–1668. [Google Scholar] [CrossRef]

- Jong, W.; Van Der Linde, V. Clean Diesel and Dirty Scandal: The Echo of Volkswagen’s Dieselgate in an Intra-Industry Setting. Public Relat. Rev. 2022, 48, 102146. [Google Scholar] [CrossRef]

- Alé-Chilet, J.; Chen, C.; Li, J.; Reynaert, M. Colluding Against Environmental Regulation. Rev. Econ. Stud. 2025, 37, rdaf024. [Google Scholar] [CrossRef]

- Reynaert, M.; Sallee, J.M. Who Benefits When Firms Game Corrective Policies? Am. Econ. J. Econ. Policy 2021, 13, 372–412. [Google Scholar] [CrossRef]

- Reynaert, M. Abatement Strategies and the Cost of Environmental Regulation: Emission Standards on the European Car Market. Rev. Econ. Stud. 2021, 88, 454–488. [Google Scholar] [CrossRef]

- Alexander, D.; Schwandt, H. The Impact of Car Pollution on Infant and Child Health: Evidence from Emissions Cheating. Rev. Econ. Stud. 2022, 89, 2872–2910. [Google Scholar] [CrossRef]

- Bachmann, R.; Ehrlich, G.; Fan, Y.; Ruzic, D.; Leard, B. Firms and Collective Reputation: A Study of the Volkswagen Emissions Scandal. J. Eur. Econ. Assoc. 2023, 21, 484–525. [Google Scholar] [CrossRef]

- Ater, I.; Yoseph, N.S. The Impact of Environmental Fraud on the Used Car Market: Evidence from Dieselgate. J. Ind. Econ. 2022, 70, 463–491. [Google Scholar] [CrossRef]

- Holland, S.P.; Mansur, E.T.; Muller, N.Z.; Yates, A.J. Damages and Expected Deaths Due to Excess NOx Emissions from 2009 to 2015 Volkswagen Diesel Vehicles. Environ. Sci. Technol. 2016, 50, 1111–1117. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Fattah, I.M.R.; Ong, H.C.; Ashik, F.R.; Hassan, M.M.; Murshed, M.T.; Imran, M.A.; Rahman, M.H.; Rahman, M.A.; Hasan, M.A.M.; et al. State-of-the-Art of Establishing Test Procedures for Real Driving Gaseous Emissions from Light- and Heavy-Duty Vehicles. Energies 2021, 14, 4195. [Google Scholar] [CrossRef]

- Triantafyllopoulos, G.; Dimaratos, A.; Ntziachristos, L.; Bernard, Y.; Dornoff, J.; Samaras, Z. A Study on the CO2 and NOx Emissions Performance of Euro 6 Diesel Vehicles under Various Chassis Dynamometer and On-Road Conditions Including Latest Regulatory Provisions. Sci. Total Environ. 2019, 666, 337–346. [Google Scholar] [CrossRef]

- Bodisco, T.; Zare, A. Practicalities and Driving Dynamics of a Real Driving Emissions (RDE) Euro 6 Regulation Homologation Test. Energies 2019, 12, 2306. [Google Scholar] [CrossRef]

- Zachiotis, A.T.; Giakoumis, E.G. Non-Regulatory Parameters Effect on Consumption and Emissions from a Diesel-Powered van over the WLTC. Transp. Res. Part Transp. Environ. 2019, 74, 104–123. [Google Scholar] [CrossRef]

- Claßen, J.; Krysmon, S.; Dorscheidt, F.; Sterlepper, S.; Pischinger, S. Real Driving Emission Calibration—Review of Current Validation Methods against the Background of Future Emission Legislation. Appl. Sci. 2021, 11, 5429. [Google Scholar] [CrossRef]

- Pelkmans, L.; Debal, P. Comparison of On-Road Emissions with Emissions Measured on Chassis Dynamometer Test Cycles. Transp. Res. Part Transp. Environ. 2006, 11, 233–241. [Google Scholar] [CrossRef]

- DIN 70200:2012-06; Technical Product Documentation—System of Documentation—General Principles. Beuth Verlag (DIN Media): Berlin, Germany, 2012.

- EN ISO 9001:2015; Quality Management Systems—Requirements. CEN/ISO: Brussels, Belgium, 2015.

- ISO 3930/OIML R 99; Instruments for Measuring Vehicle Exhaust Emissions. ISO: Geneva, Switzerland, 2000.

- UNECE. Uniform Provisions Concerning the Approval of Engines with Regard to the Emission of Visible Pollutants and the Measurement of Engine Power; Regulation No. 24; United Nations Economic Commission for Europe: Geneva, Switzerland, 2006. [Google Scholar]

- Boguski, T.K. Understanding Units of Measurement. Available online: https://cfpub.epa.gov/ncer_abstracts/index.cfm/fuseaction/display.files/fileid/14285 (accessed on 23 May 2025).

- Makarevičienė, V.; Pukalskas, S.; Janulis, P. Comparative Investigation of Rapeseed Oil Ethyl and Methyl Ester Emissions = Lyginamieji Rapsų Aliejaus Etil- Ir Metilesterių Deginių Emisijos Tyrimai. Aplink. Inž. 2001, 9, 158–163. [Google Scholar]

- Council Directive 70/220/EEC of 20 March 1970 on the Approximation of the Laws of the Member States Relating to Measures to Be Taken Against Air Pollution by Gases from Positive-Ignition Engines of Motor Vehicles; Council of the European Communities: Brussels, Belgium, 1970; Volume TOC.

- Al-Esawi, N.; Al Qubeissi, M.; Whitaker, R.; Sazhin, S.S. Blended E85–Diesel Fuel Droplet Heating and Evaporation. Energy Fuels 2019, 33, 2477–2488. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, S.; Min, K. Prediction of NOx Considering NO and NO2 for a CI Engine. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2022, 236, 1058–1068. [Google Scholar] [CrossRef]

- Brimblecombe, P.; Chu, M.; Liu, C.-H.; Fu, Y.; Wei, P.; Ning, Z. Roadside NO2/NOx and Primary NO2 from Individual Vehicles. Atmos. Environ. 2023, 295, 119562. [Google Scholar] [CrossRef]

- Wang, X.; Huang, K.; Yuan, L.; Xi, S.; Yan, W.; Geng, Z.; Cong, Y.; Sun, Y.; Tan, H.; Wu, X.; et al. Activation of Surface Oxygen Sites in a Cobalt-Based Perovskite Model Catalyst for CO Oxidation. J. Phys. Chem. Lett. 2018, 9, 4146–4154. [Google Scholar] [CrossRef]

- He, C.B.; Pan, K.L.; Chang, M.B. Catalytic Oxidation of Trichloroethylene from Gas Streams by Perovskite-Type Catalysts. Environ. Sci. Pollut. Res. 2018, 25, 11584–11594. [Google Scholar] [CrossRef]

- Tang, W.; Lu, X.; Liu, F.; Du, S.; Weng, J.; Hoang, S.; Wang, S.; Nam, C.-Y.; Gao, P.-X. Ceria-Based Nanoflake Arrays Integrated on 3D Cordierite Honeycombs for Efficient Low-Temperature Diesel Oxidation Catalyst. Appl. Catal. B Environ. 2019, 245, 623–634. [Google Scholar] [CrossRef]

- Nose, H.; Inoue, T.; Katagiri, S.; Sakai, A.; Kawasaki, T.; Okamura, M. Fuel Enrichment Control System by Catalyst Temperature Estimation to Enable Frequent Stoichiometric Operation at High Engine Speed/Load Condition; SAE Technical Paper: Warrendale, PA, USA, 2013. [Google Scholar]

- Fuel Trim Info—Ross-Tech Wiki. Available online: https://wiki.ross-tech.com/wiki/index.php/Fuel_Trim_Info?utm_source=chatgpt.com (accessed on 12 May 2025).

- Gogola, R.; Kósa, A. Electronic Control of Fuel Mixture Preparation and Injection in Internal Combustion Engines. Am. J. Mech. Eng. 2014, 2, 231–238. [Google Scholar] [CrossRef][Green Version]

- Martínez-Munuera, J.C.; Giménez-Mañogil, J.A.; Matarrese, R.; Castoldi, L.; García-García, A. NOx Reduction Pathways during LNT Operation over Ceria Containing Catalysts: Effect of Copper Presence and Barium Content. Appl. Sci. 2021, 11, 5700. [Google Scholar] [CrossRef]

- Schöneborn, M.; Harmening, T.; Giménez-Mañogil, J.; Martínez-Munuera, J.C.; García-García, A. Improved NOx Storage/Release Properties of Ceria-Based Lean NOx Trap Compositions with MnOx Modification. Materials 2019, 12, 2127. [Google Scholar] [CrossRef]

- Getsoian, A.B.; Theis, J.R.; Lambert, C.K. Sensitivity of Three-Way Catalyst Light-Off Temperature to Air-Fuel Ratio. Emiss. Control Sci. Technol. 2018, 4, 136–142. [Google Scholar] [CrossRef]

- Mc Grane, L.; Douglas, R.; Irwin, K.; Stewart, J.; Woods, A.; Muehlstaedt, F. A Study of the Effect of Light-Off Temperatures and Light-Off Curve Shape on the Cumulative Emissions Performance of 3-Way Catalytic Converters; SAE Technical Paper: Warrendale, PA, USA, 2021. [Google Scholar]

- E, J.; Zuo, W.; Gao, J.; Peng, Q.; Zhang, Z.; Hieu, P.M. Effect Analysis on Pressure Drop of the Continuous Regeneration-Diesel Particulate Filter Based on NO2 Assisted Regeneration. Appl. Therm. Eng. 2016, 100, 356–366. [Google Scholar] [CrossRef]

- Herreros, J.M.; Gill, S.S.; Lefort, I.; Tsolakis, A.; Millington, P.; Moss, E. Enhancing the Low Temperature Oxidation Performance over a Pt and a Pt–Pd Diesel Oxidation Catalyst. Appl. Catal. B Environ. 2014, 147, 835–841. [Google Scholar] [CrossRef]

- Geng, Y.; Shan, W.; Liu, F.; Yang, S. Adjustment of Operation Temperature Window of Mn-Ce Oxide Catalyst for the Selective Catalytic Reduction of NO with NH3. J. Hazard. Mater. 2021, 405, 124223. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Tian, J.; Li, J.; Cao, C.; Wang, S.; Lv, J.; Zheng, W.; Tan, D. The Development of Diesel Oxidation Catalysts and the Effect of Sulfur Dioxide on Catalysts of Metal-Based Diesel Oxidation Catalysts: A Review. Fuel Process. Technol. 2022, 233, 107317. [Google Scholar] [CrossRef]

- Xie, L.; Jiang, G.; Qian, F. Research on Aftertreatment Inlet_Outlet Insulation for A Nonroad Middle Range Diesel Engine. Catalysts 2020, 10, 454. [Google Scholar] [CrossRef]

- Tsuchiya, A.; Masaoka, S.; Ohyama, J.; Sawabe, K.; Satsuma, A. Effects of Carbon Number and Bond Saturation on Hydrocarbon Combustion over a Diesel Oxidation Catalyst. Catal. Sci. Technol. 2020, 10, 3868–3874. [Google Scholar] [CrossRef]

- Cho, C.P.; Kwon, O.S.; Lee, Y.J. Effects of the Sulfur Content of Liquefied Petroleum Gas on Regulated and Unregulated Emissions from Liquefied Petroleum Gas Vehicle. Fuel 2014, 137, 328–334. [Google Scholar] [CrossRef]

- Han, D.; E, J.; Deng, Y.; Chen, J.; Leng, E.; Liao, G.; Zhao, X.; Feng, C.; Zhang, F. A Review of Studies Using Hydrocarbon Adsorption Material for Reducing Hydrocarbon Emissions from Cold Start of Gasoline Engine. Renew. Sustain. Energy Rev. 2021, 135, 110079. [Google Scholar] [CrossRef]

- Li, J.; Kumar, A.; Chen, X.; Currier, N.; Yezerets, A. Impact of Different Forms of Sulfur Poisoning on Diesel Oxidation Catalyst Performance; SAE Technical Paper: Warrendale, PA, USA, 2013; p. 2013-01-0514. [Google Scholar]

- Weiss, M.; Bonnel, P.; Kühlwein, J.; Provenza, A.; Lambrecht, U.; Alessandrini, S.; Carriero, M.; Colombo, R.; Forni, F.; Lanappe, G.; et al. Will Euro 6 Reduce the NOx Emissions of New Diesel Cars?—Insights from on-Road Tests with Portable Emissions Measurement Systems (PEMS). Atmos. Environ. 2012, 62, 657–665. [Google Scholar] [CrossRef]

- AECC—Catalysts—From Oxidation Catalysts to Three-Way Catalysts; AECC: Wakefield, MA, USA, 2024.

- Dimaratos, A.; Giechaskiel, B.; Clairotte, M.; Fontaras, G. Impact of Active Diesel Particulate Filter Regeneration on Carbon Dioxide, Nitrogen Oxides and Particle Number Emissions from Euro 5 and 6 Vehicles under Laboratory Testing and Real-World Driving. Energies 2022, 15, 5070. [Google Scholar] [CrossRef]

- SMMT. New Car CO2 Report 2015; The Society of Motor Manufacturers and Traders: London, UK, 2015; p. 19. [Google Scholar]

- Romero, C.A.; Correa, P.; Ariza Echeverri, E.A.; Vergara, D. Strategies for Reducing Automobile Fuel Consumption. Appl. Sci. 2024, 14, 910. [Google Scholar] [CrossRef]

- Koszalka, G.; Hunicz, J. Comparative Study of Energy Losses Related to the Ring Pack Operation in Homogeneous Charge Compression Ignition and Spark Ignition Combustion. Energy 2021, 235, 121388. [Google Scholar] [CrossRef]

- Pacura, W.; Szramowiat-Sala, K.; Gołaś, J. Emissions from Light-Duty Vehicles—From Statistics to Emission Regulations and Vehicle Testing in the European Union. Energies 2023, 17, 209. [Google Scholar] [CrossRef]

| Parameter | Test Vehicles | |||

|---|---|---|---|---|

| Nissan Qashqai+2, J10 | VW Passat, B8 | Nissan Qashqai, J11 | VW Passat, B8 | |

| Fuel | Diesel | Diesel | Gasoline | Gasoline |

| Euro emission standard | Euro 4 | Euro 6 | Euro 5 | Euro 6 |

| Year of manufacture | 2010 | 2019 | 2014 | 2019 |

| Engine displacement, cm3 | 1461 | 1968 | 1197 | 1984 |

| Number of cylinders | 4 | 4 | 4 | 4 |

| Number of valves | 2 | 4 | 2 | 4 |

| Fuel supply system | Common rail, direct injection | Common rail, direct injection | Direct injection | Direct injection |

| Engine power, kW (rpm) | 78 (4000) | 110 (3750) | 85 (4500) | 140 (4750) |

| Torque, Nm (rpm) | 240 (1750) | 360 (1750 … 3000) | 190 (2000) | 320 (1500 … 4100) |

| CO2 emissions (combined) *, g/km | 145 | 140 | 129 | 175 |

| Unladen weight, kg | 1604 | 1600 | 1399 | 1530 |

| Parameter | Value |

|---|---|

| Type | R100/1 |

| Power of eddy current brake, kW | 260 |

| Maximum test speed, km/h | 260 |

| Maximum traction power, kW | 260 |

| Maximum traction force, kN | 6 |

| Measurement error, % | ±2 |

| Parameter | Measurement Limits | Resolution |

|---|---|---|

| Opacity, % | 0 … 100 | 0.1 |

| Absorption (K-Value), m−1 | 0 … 99.99 | 0.01 |

| CO, %vol. | 0 … 10 | 0.01 |

| CO2, %vol. | 0 … 20 | 0.1 |

| HC, ppm vol. | 0 … 20,000 | 1 |

| O2, %vol. | 0 … 25 | 0.01 |

| NOx, ppm vol. | 0 … 5000 | 1 |

| λ-calculation | 0 … 9.999 | 0.001 |

| Vehicle | Emitted Pollutant | Measured and Calculated Emissions | Value of Euro Standard |

|---|---|---|---|

| Nissan Qashqai+2, J10 Diesel Euro 4 | NOx | 0.365 | 0.25 |

| CO | 1.161 | 0.50 | |

| HC | 0.025 | 0.05 | |

| CO2 | 154 | 145 | |

| VW Passat, B8 Diesel Euro 6 | NOx | 0.021 | 0.08 |

| CO | 0 | 0.50 | |

| HC | 0.0008 | 0.05 | |

| CO2 | 144 | 140 | |

| Nissan Qashqai, J11 Gasoline Euro 5 | NOx | 0.079 | 0.06 |

| CO | 0.030 | 1.0 | |

| HC | 0.0003 | 0.10 | |

| CO2 | 210 | 129 | |

| VW Passat, B8 Gasoline Euro 6 | NOx | 0.004 | 0.06 |

| CO | 0 | 1.0 | |

| HC | 0.001 | 0.10 | |

| CO2 | 265 | 175 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pukalskas, S.; Adamaitis, D.; Paliulis, D.; Mikaliūnas, Š. Sustainability-Oriented Assessment of Passenger Car Emissions in Relation to Euro Standards Using the ECE-15 Driving Cycle. Sustainability 2025, 17, 6000. https://doi.org/10.3390/su17136000

Pukalskas S, Adamaitis D, Paliulis D, Mikaliūnas Š. Sustainability-Oriented Assessment of Passenger Car Emissions in Relation to Euro Standards Using the ECE-15 Driving Cycle. Sustainability. 2025; 17(13):6000. https://doi.org/10.3390/su17136000

Chicago/Turabian StylePukalskas, Saugirdas, Dominik Adamaitis, Dainius Paliulis, and Šarūnas Mikaliūnas. 2025. "Sustainability-Oriented Assessment of Passenger Car Emissions in Relation to Euro Standards Using the ECE-15 Driving Cycle" Sustainability 17, no. 13: 6000. https://doi.org/10.3390/su17136000

APA StylePukalskas, S., Adamaitis, D., Paliulis, D., & Mikaliūnas, Š. (2025). Sustainability-Oriented Assessment of Passenger Car Emissions in Relation to Euro Standards Using the ECE-15 Driving Cycle. Sustainability, 17(13), 6000. https://doi.org/10.3390/su17136000