Comparative Assessment of Gasifier Cookstove Performance on Smallholder Farms in Three Regions in Kenya

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Design

2.2. Study Area

2.3. Selection of Households and Development of Cooking Schedule

2.4. Cookstoves

2.5. Cooking Test

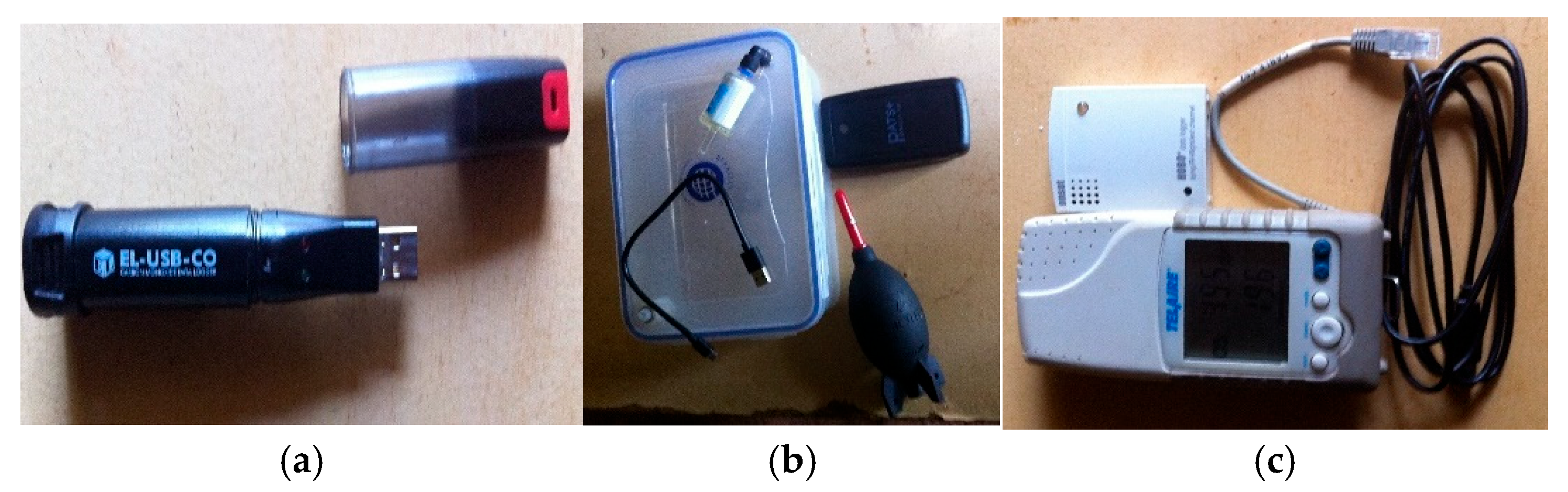

2.6. Measurement of Gases and Particulate Concentrations

2.7. Description of the Kitchen/Cooking Area

2.8. Combustion Properties

2.9. Fuel Consumption

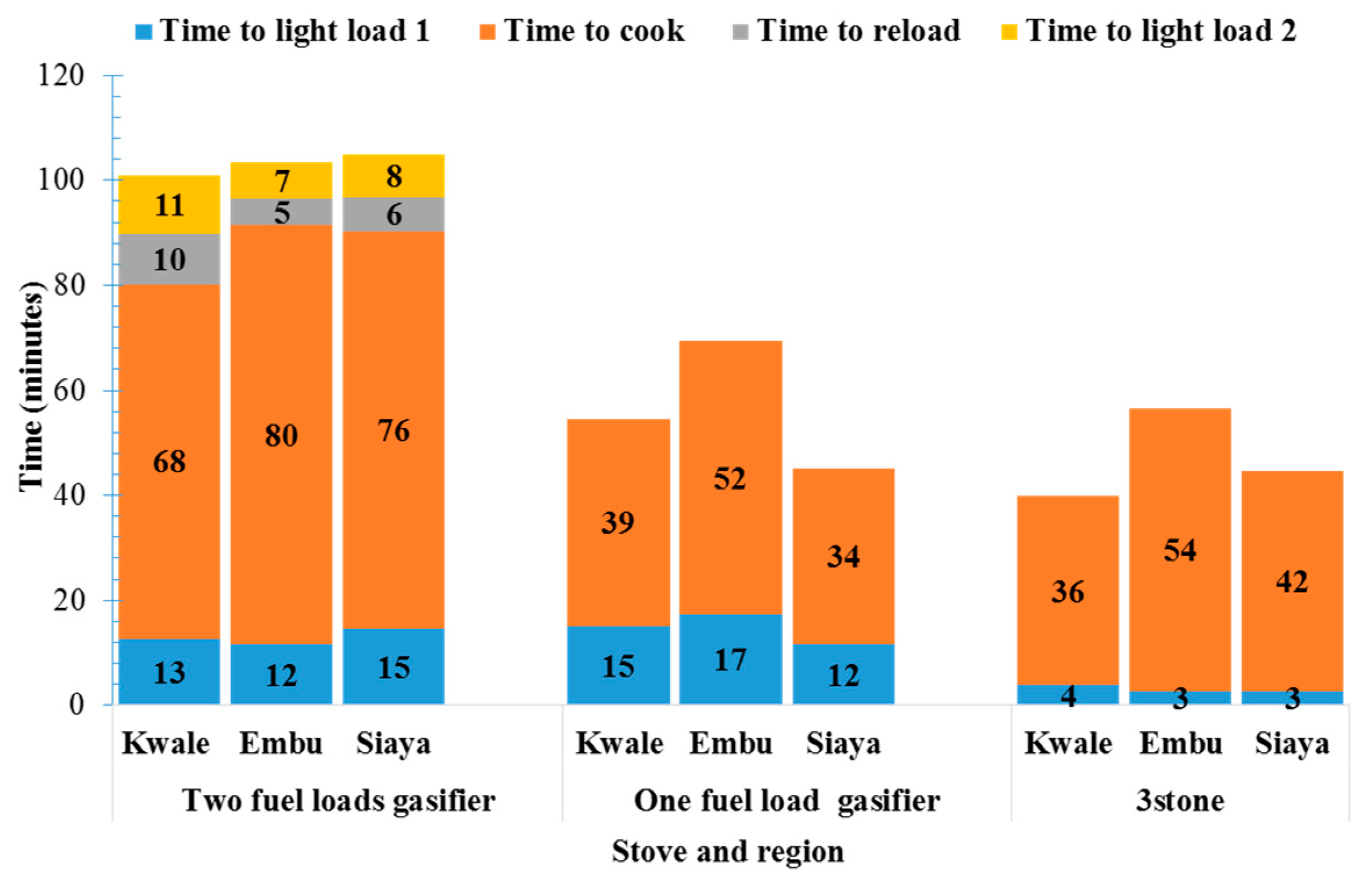

2.10. Time Spent in Cooking

2.11. Limitations of the Study

2.12. Data Management and Analysis

3. Results

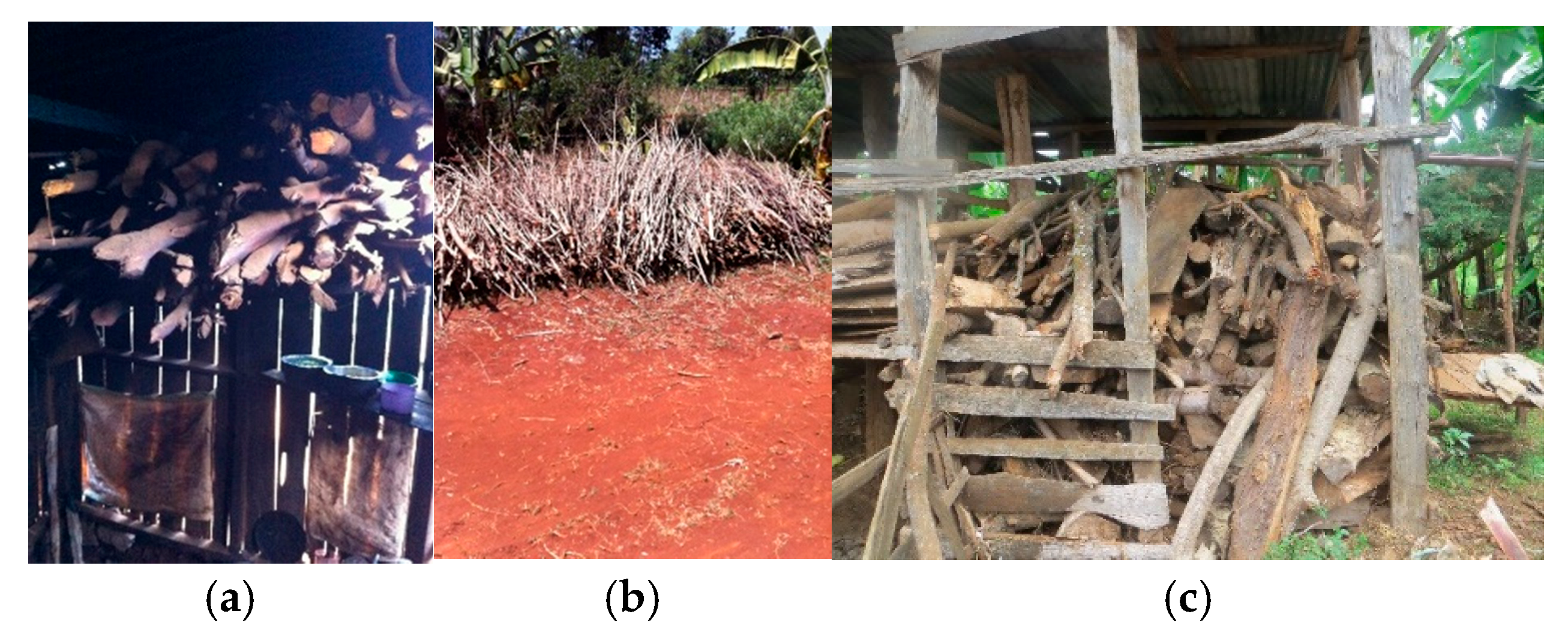

3.1. Fuel Types Used

3.2. Adoption of the Gasifier Cookstove

3.3. Combustion Properties of Firewood Used and Produced Char

3.4. Description of the Respondents’ Kitchens

3.5. Time Used While Cooking with Gasifier and Three-Stone Open Fire

3.6. Firewood Preparation and Cooking Responsibilities

3.7. Firewood Usage and Char Production in Gasifier

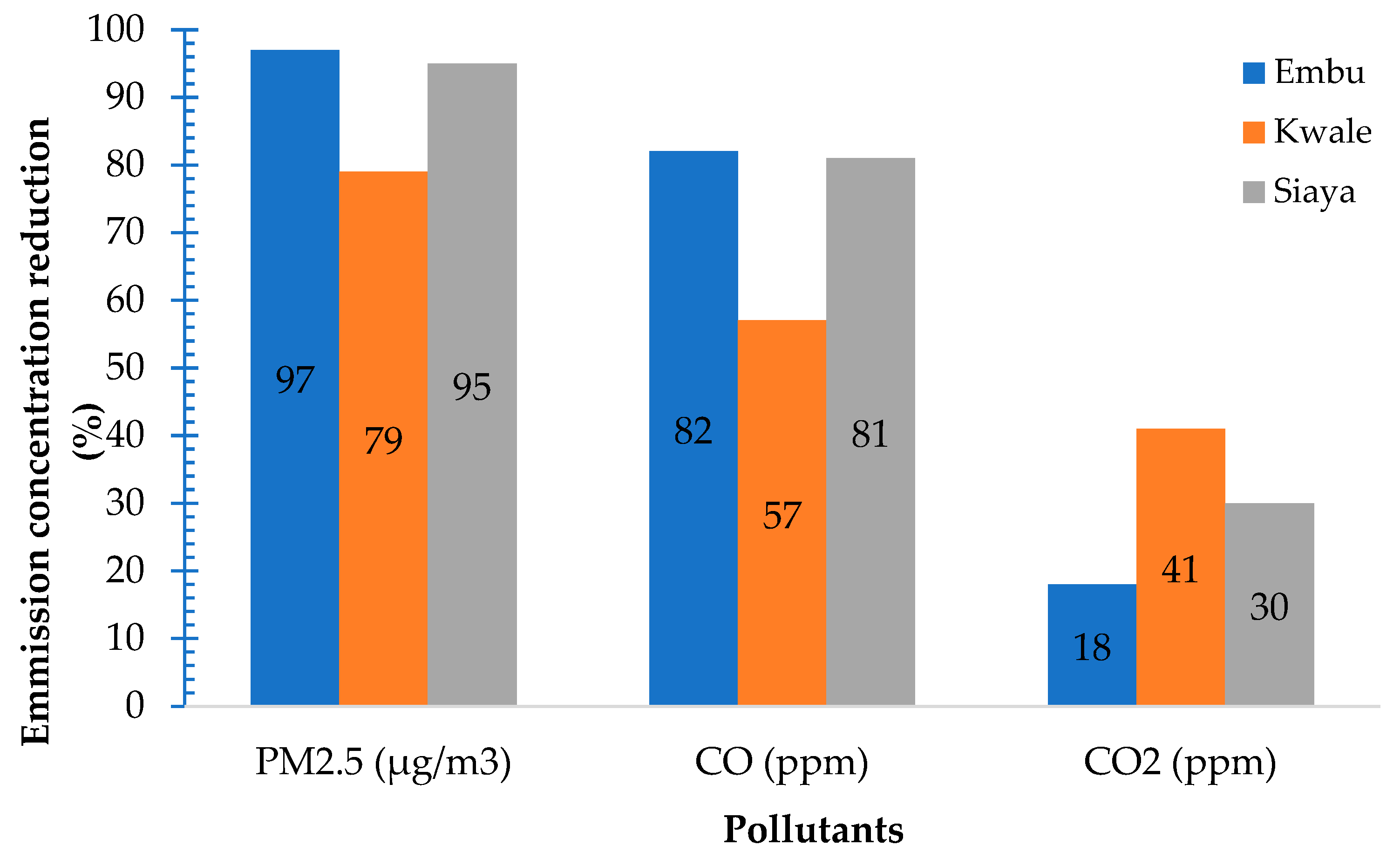

3.8. Concentrations of CO, CO2 and PM2.5

3.9. Summary Comparison Among the Three Sites

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CRA | Commission on Revenue Allocation |

| FAO | Food and Agricultural Organization |

| GHG | Green House Gases |

| HH | Household |

| IEA | International Energy Agency |

| IRENA | International Renewable Energy Agency |

| KIRDI | Kenya Institute of Research and Development Institute |

| LHV | Low heating value |

| MoE | Ministry of Energy |

| OSHA | Occupational Safety and Health Administration |

| PEL | Permissible Exposure Limit |

| PM2.5 | Fine particulate matter |

| PPM | Parts per million |

| TLUD | Top Lit-Updraft |

| Ts | Total solids |

| UNSD | United Nation Statistics Division |

| WHO | World Health Organization |

References

- Clancy, J.S.; Skutsch, M.M.; Batchelor, S. The Gender-Energy-Poverty Nexus: Finding the Energy to Address Gender Concerns in Development; Prepared under DFID Project, CNTR99852; Gamos Ltd.: Reading, UK, 2003. [Google Scholar]

- International Energy Agency; International Renewable Energy Agency; United Nations Statistics Division; World Bank; World Health Organization. Tracking SDG 7: The Energy Progress Report 2022. © World Bank. License: CC BY 3.0 IGO. 2022. Available online: http://hdl.handle.net/10986/38017 (accessed on 17 February 2024).

- Food and Agriculture Organization of the United Nations (FAO). The Charcoal Transition: Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods; van Dam, J., Ed.; FAO: Rome, Italy, 2017. [Google Scholar]

- Bonjour, S.; Adair-Rohani, H.; Wolf, J.; Bruce, N.G.; Mehta, S.; APrüss-Ustün MLahiff EARehfuess VMishra Smith, K.R. Solid fuel use for household cooking: Country and regional estimates for 1980–2010. Environ. Health Perspect. 2013, 121, 784–790. [Google Scholar] [CrossRef]

- Edwards, R.D.; Smith, K.R.; Zhang, J.; Ma, Y. Models to predict emissions of health-damaging pollutants and global warming contributions of residential fuel/stove combinations in China. Chemosphere 2003, 50, 201–215. [Google Scholar] [CrossRef]

- Ministry of Energy (MoE). Kenya Household Cooking Sector Study; Assessment of the Supply and Demand of Cooking Solutions at the Household Level. 2019. Available online: https://www.eedadvisory.com/wp-content/uploads/2019/11/moe-2019-cooking-sector-study-.pdf (accessed on 15 March 2025).

- Zomer, R.J.; Trabucco, A.; Coe, R.; Place, F.; van Noordwijk, M.; Xu, J.C. Trees on Farms: An Update and Reanalysis of Agroforestry’s Global Extent and Socio-Ecological Characteristics; Working Paper; World Agroforestry Centre (ICRAF) Southeast Asia Regional Program: Bogor, Indonesia, 2014; p. 179. [Google Scholar] [CrossRef]

- Githiomi, J.K.; Mugendi, D.N.; Kung’u, J.B. Analysis of household energy sources and wood fuel utilisation technologies in Kiambu, Thika and Maragwa districts of Central Kenya. J. Hortic. For. 2012, 4, 43–48. [Google Scholar] [CrossRef]

- Carvalho, R.L.; Yadav, P.; Garcia-Lopez, N.; Lindgren, R.; Nyberg, G.; Diaz-Chavez, R.; Upadhyayula, V.K.K.; Boman, C.; Athanassiadis, D. Environmental Sustainability of Bioenergy Strategies in Western Kenya to Address Household Air Pollution. Energies 2020, 13, 719. [Google Scholar] [CrossRef]

- Guta, D.; Baumgartner, J.; Jack, D.; Carter, E.; Shen, G.; Orgill-Meyer, J.; Rosenthal, J.; Dickinson, K.; Bailis, R.; Masuda, Y.; et al. A systematic review of household energy transition in low and middle income countries. Energy Res. Soc. Sci. 2022, 86, 102463. [Google Scholar] [CrossRef]

- Gill-Wiehl, A.; Price, T.; Kammen, D.M. What’s in a stove? A review of the user preferences in improved stove designs. Energy Res. Soc. Sci. 2021, 81, 102281. [Google Scholar] [CrossRef]

- Pakravan, M.H.; MacCarty, N. What Motivates Behavior Change? Analyzing User Intentions to Adopt Clean Technologies in Low-Resource Settings Using the Theory of Planned Behavior. Energies 2020, 13, 3021. [Google Scholar] [CrossRef]

- Gill-Wiehl, A.; Sievers, S.; Kammen, D.M. The value of community technology workers for LPG use: A pilot in Shirati, Tanzania. Energy Sustain. Soc. 2022, 12, 5. [Google Scholar] [CrossRef]

- Williams, N.B.; Quilliam, R.S.; Campbell, B.; Ghatani, R.; Dickie, J. Taboos, toilets and biogas: Socio-technical pathways to acceptance of a sustainable household technology. Energy Res. Soc. Sci. 2022, 86, 102448. [Google Scholar] [CrossRef]

- Wahlund, M.; Palm, J. The role of energy democracy and energy citizenship for participatory energy transitions: A comprehensive review. Energy Res. Soc. Sci. 2022, 87, 102482. [Google Scholar] [CrossRef]

- Martin II, W.J.; Glass, R.I.; Balbus, J.M.; Collins, F.S. A major environmental cause of death. Science 2011, 334, 180–181. [Google Scholar] [CrossRef]

- Torres-Rojas, D.; Lehmann, J.; Hobbs, P.; Joseph, S.; Neufeldt, H. Biomass availability, energy consumption and biochar production in rural households of Western Kenya. Biomass Bioenergy 2011, 35, 3537–3546. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; CAyuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Kätterer, T.; Roobroeck, D.; Kimutai, G.; Karltun, E.; Nyberg, G.; Sundberg, C.; Roing de Nowina, K. Maize grain yield responses to realistic biochar application rates on smallholder farms in Kenya. Agron. Sustain. Dev. 2022, 42, 63. [Google Scholar] [CrossRef]

- Jeffery, S.; Abalos, D.; Prodana, M.; Bastos, A.C.; van Groenigen, J.W.; Hungate, B.A.; Verheijen, F. Biochar boosts tropical but not temperate crop yields. Environ. Res. Lett. 2017, 12, 053001. [Google Scholar] [CrossRef]

- Uwingabire, S.; Chamshama, S.A.O.; Nyberg, G.; Nduwamungu, J. Gasifier use for cooking and biochar production by smallholder farmers in Rwanda. Biofuels 2024, 16, 77–84. [Google Scholar] [CrossRef]

- Gitau, J.K.; Sundberg, C.; Mutune, J.; Mendum, R.; Njenga, M. Use of biochar-producing gasifier cookstove improves energy use efficiency and indoor air quality in rural households. Energies 2019, 12, 4285. [Google Scholar] [CrossRef]

- CRA Kenya. Commission on Revenue Allocation. 2014. Available online: www.crakenya.org (accessed on 14 March 2022).

- Mkuzi, H.; Mwaguni, S.; Danda, K. Re-settling displaced people in a coastal zone mining project: Evaluating the agricultural and land use potential of the proposed resettlement site–a case of titanium mining in Kenya. J. Environ. Earth Sci. 2013, 3, 152–165. [Google Scholar]

- World Health Organization. Health Effects of Particulate Matter—Policy Implications for Countries in Eastern Europe, Caucasus and Central Asia; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2013. Available online: http://www.euro.who.int/__data/assets/pdf_file/0006/189051/Health-effects-of-particulate-matter-final-Eng.pdf (accessed on 7 March 2022).

- World Health Organization. WHO Guidelines for Indoor Air Quality: Selected Pollutants; World Health Organization, Regional Office for Europe: Copenhagen, Denmark, 2010. Available online: http://www.who.int/iris/handle/10665/260127 (accessed on 7 March 2023).

- Occupational Safety and Health Administration (OSHA). Permissible Exposure Limits, OSHA Annotated Table Z-1 ACGIH® Threshold Limit Values (TLVs®) (ACGIH® 2019). Available online: https://www.osha.gov/dsg/annotated-pels/tablez-1.html (accessed on 12 July 2022).

- SS-EN14918:2010; Solid Biofuels—Determination of Calorific Value. SIS: Stockholm, Sweden, 2010.

- SS-EN ISO 18122:2015; Solid Biofuels—Determination of Ash Content. SIS: Stockholm, Sweden, 2015.

- SS-EN ISO 20134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. SIS: Stockholm, Sweden, 2015.

- Kar, A.; Zerriffi, H. From cookstove acquisition to cooking transition: Framing the behavioural aspects of cookstove interventions. Energy Res. Soc. Sci. 2018, 42, 23–33. [Google Scholar] [CrossRef]

- Malakar, Y.; Greig, C.; van de Fliert, E. Resistance in rejecting solid fuels: Beyond availability and adoption in the structural dominations of cooking practices in rural India. Energy Res. Soc. Sci. 2018, 46, 225–235. [Google Scholar] [CrossRef]

- Ado, A.; Darazo, I.R.; Babayo, M.A. Determinants of fuels stacking behavior among households in Bauchi metropolis. Bus. Manag. Rev. 2016, 7, 84. [Google Scholar]

- Jürisoo, M.; Lambe, F.; Osborne, M. Beyond buying: The application of service design methodology to understand adoption of clean cookstoves in Kenya and Zambia. Energy Res. Soc. Sci. 2018, 39, 164–176. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Lambe, F.; Roe, J.; Matin, N.; Makuch, K.E.; Osborne, M. Do we need better behaved cooks? Reviewing behavioural change strategies for improving the sustainability and effectiveness of cookstove programs. Energy Res. Soc. Sci. 2020, 70, 101788. [Google Scholar] [CrossRef]

- Lambe, F.; Rana, Y.; Kwambokaa, E.; Holmlidb, S.; Lyckec, K.; Ringstromc, S.; Annebackc, J.; Ghosha, E.; O’Connerd, M.; Bailis, R. Opening the black pot: A service design-driven approach to understanding the use of cleaner cookstoves in peri urban Kenya. Energy Res. Soc. Sci. 2020, 70, 101754. [Google Scholar] [CrossRef]

- Lindgren, S.A. Clean cooking for all? A critical review of behavior, stakeholder engagement, and adoption for the global diffusion of improved cookstoves. Energy Res. Soc. Sci. 2020, 68, 101539. [Google Scholar] [CrossRef]

- Njenga, M.; Gitau, J.K.; Mendum, R. Women’s work is never done: Lifting the gendered burden of firewood collection and household energy use in Kenya. Energy Res. Soc. Sci. 2021, 7, 102071. [Google Scholar] [CrossRef]

- Taylor, A. W179 Wood Products Information Moisture Content of ‘Seasoned’ Firewood; The University of Tennessee Agricultural Extension Service: Tennessee, TN, USA, 2010; Available online: http://trace.tennessee.edu/utk_agexfores/101 (accessed on 19 July 2024).

- Sepp, S. Multiple-Household Fuel Use—A Balanced Choice Between Firewood, Charcoal and LPG; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Addis Ababa, Ethiopia, 2014. [Google Scholar]

- Fuwape, J.A.; Akindele, S.O. Biomass yield and energy value of some fast growing multipurpose trees in Nigeria. Biomass Bioenergy 1997, 12, 101–106. [Google Scholar] [CrossRef]

- Nirmal, J.I.; Patel, K.; Kumar, R.N.; Kumar, B.R. An evaluation of fuelwood properties of some Aravally mountain tree and shrub species of Western India. Biomass Bioenergy 2011, 35, 411–414. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Industrial Charcoal Making Mechanical Wood Products Branch, Forest Industries Division Forestry; FAO: Rome, Italy, 1985; p. 63. [Google Scholar]

- Chanchani, D.; Oskarsson, P. ‘If the gas runs out, we are not going to sleep hungry’: Exploring household energy choices in India’s critically polluted coal belt. Energy Res. Soc. Sci. 2021, 80, 102181. [Google Scholar] [CrossRef]

- Palit, D.; Bhattacharyya, S.C. Adoption of cleaner cookstoves: Barriers and way forward. Boil. Point 2014, 64, 6–9. [Google Scholar]

- Jagoe, K.; Rossanese, M.; Charron, D.; Rouse, J.; Waweru, F.; Waruguru, M.; Delapena, S.; Piedrahita, R.; Livingston, K.; Ipe, J. Sharing the burden: Shifts in family time use, agency and gender dynamics after introduction of new cookstoves in rural Kenya. Energy Res. Soc. Sci. 2020, 64, 101413. [Google Scholar] [CrossRef]

- Sundberg, C.; Karltun, E.; Gitau, J.K.; Kätterer, T.; Kimutai, G.; Mahmoud, Y.; Njenga, M.; Nyberg, G.; Roing de Nowina, K.; Roobroeck, D.; et al. Biochar from cookstoves reduces greenhouse gas emissions from smallholder farms in Africa. Mitig. Adapt. Strateg. Glob. Change 2020, 25, 953–967. [Google Scholar] [CrossRef]

- Eltigani, A.; Olsson, A.; Krause, A.; Ernest, B.; Fridahl, M.; Yanda, P.; Hansson, A. Exploring lessons from five years of biochar-producing cookstoves in the Kagera region, Tanzania. Energy Sustain. Dev. 2022, 71, 141–150. [Google Scholar] [CrossRef]

- World Health Organisation. World Health Statistics 2018: Monitoring Health for the Sustainable Development Goals (SDGs). 2018. Available online: https://www.who.int/en/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 27 August 2024).

- Qiu, Y.; Yang, F.A.; Lai, W. The impact of indoor air pollution on health outcomes and cognitive abilities: Empirical evidence from China. Popul. Environ. 2019, 40, 388–410. [Google Scholar] [CrossRef]

- Li, S.; Meng, J.; Zheng, H.; Zhang, N.; Huo, J.; Li, Y.; Guan, D. The driving forces behind the change in energy consumption in developing countries. Environ. Res. Lett. 2021, 16, 054002. [Google Scholar] [CrossRef]

| Moisture, 105 °C (%) | Ash, 550 °C (% ts) | Volatile Matter (% ts) | C-Fix (% ts) | LHVfw db (MJ/kg) | |

|---|---|---|---|---|---|

| Kwale # | |||||

| Average neem a | 9 ± 0.2 | 2.2 ± 0.3 | 79.4 ± 0.6 | 18.4 ± 0.4 | 18.4 ± 0.1 |

| Average casuarina b | 8.7 ± 0.1 | 1.4 ± 0.1 | 81.4 ± 0.3 | 17.2 ± 0.3 | 18.4 ± 0.1 |

| Embu | |||||

| Grevillea c | 8.7 | 0.8 | 81.7 | 17.5 | 18.6 |

| Macadamia c | 9.3 | 1.1 | 81.1 | 17.8 | 18.3 |

| Siaya | |||||

| Markhamia d | 6.1 | 3.6 | 80.0 | 16.4 | 18.3 |

| Eucalyptus c | 6.0 | 1.0 | 80.0 | 19.0 | 18.7 |

| Moisture, 105 °C (%) | Ash, 550 °C (% ts) | Volatile Matter (% ts) | C-Fix (% ts) | LHVch db (MJ/kg) | |

|---|---|---|---|---|---|

| Kwale # | |||||

| Average Neem a | 8 ± 0.2 | 4.8 ± 0.3 | 10.4 ± 0.5 | 84.8 ± 0.6 | 32 ± 0.1 |

| Average Casuarina b | 7.5 ± 0.3 | 3.4 | 10.9 ± 0.7 | 85.3 | 32.4 ± 0.2 |

| Embu | |||||

| Grevillea c | 8.7 | 3.1 | 8.7 | 88.2 | 32.7 |

| Macadamia c | 7.5 | 3.1 | 10.3 | 86.6 | 32.7 |

| Siaya | |||||

| Markhamia d | 4.1 | 10.8 | 15.6 | 73.7 | 30.1 |

| Eucalyptus c | 3.8 | 3.4 | 10.1 | 86.5 | 31.7 |

| Site | Cooking Area | Door/Door Space | Window/Window Space | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Separate Structure | Inside Main House | Has Windows | Does Not Have Windows | Has Physical Door | Has Door Space | Open | Closed | Open | Closed | |

| Embu | 25 | 0 | 18 | 7 | 24 | 1 | 25 | 0 | 3 | 13 |

| Siaya | 20 | 5 | 9 | 16 | 22 | 3 | 25 | 0 | 8 | 1 |

| Kwale | 15 | 10 | 8 | 17 | 7 | 14 | 21 | 0 | 8 | 0 |

| Activity | Person Responsible in Relation to Household Head | Embu | Kwale | Siaya |

|---|---|---|---|---|

| Firewood preparation | Male head | 5 | 11 | 8 |

| Female head | 1 | 1 | 4 | |

| Wife | 9 | 9 | 10 | |

| Son | 5 | 1 | 2 | |

| Daughter | 2 | 2 | ||

| Hired labor | 2 | |||

| Brother-in-law | 1 | |||

| Grandson | 1 | 1 | ||

| Cooking | Male head | 3 | ||

| Female head | 4 | 2 | 6 | |

| Wife | 18 | 17 | 18 | |

| Daughter | 3 | 3 | ||

| Daughter-in-law | 1 |

| Site | No. HHs | Average Fuel (g) | Average Char (g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 Firewood Load | 2 Firewood Load | 1 Load | 1 + 2 Load | Total Fuel Use * | 1 Load | 1 + 2 Load | Total | ||

| Gross | Net | ||||||||

| Embu | 20 | 5 | 1054 ± 31 | 1745 ± 76 | 1192 ± 63 | 841 ± 46 | 181 ± 8 | 286 ± 36 | 202 ± 12 |

| Siaya | 20 | 5 | 831 ± 26 | 1534 ± 77 | 972 ± 63 | 677 ± 45 | 153 ± 7 | 266 ± 21 | 176 ± 11 |

| Kwale # | 19 | 6 | 1009 ± 34 | 1748 ± 146 | 1208 ± 74 | 863 ± 53 | 173 ± 6 | 284 ± 33 | 200 ± 13 |

| Site | Fuel Used (g) | Char Produced (g) | % Char | Fuel Used 3-Stone (g) | % Fuel Saving (Char as Fuel) | % Fuel Saving (Char Not Fuel) | |

|---|---|---|---|---|---|---|---|

| Gross | Net | ||||||

| Embu | 1361 ± 206.5 | 955 ± 149.5 | 232.6 ± 33.9 | 17.1 | 1784 ± 203.8 | 46.5 | 24 |

| Kwale # | 1205 ± 207.9 | 859 ± 155.4 | 198 ± 32.2 | 16.8 | 1475 ± 159.9 | 41.8 | 18 |

| Siaya | 1028 ± 125.9 | 624.3 ± 10.3 | 188.2 ± 25.3 | 18.3 | 1792 ± 248.7 | 65.2 | 43 |

| Site | 25 Cooking with Gasifier | 5 HHs Cooking with Both Stoves | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CO (ppm) | CO2 (ppm) | PM2.5 (μg/m3) | CO (ppm) | PM2.5 (μg/m3) | CO2 (ppm) | ||||

| Gasifier | 3stone | Gasifier | 3stone | Gasifier | 3stone | ||||

| Embu | 10 ± 2 | 590 ± 13 | 317 ± 82 | 5 ± 3 | 28 ± 12 | 150 ± 78 | 4843 ± 3719 | 570 ± 26 | 695 ± 56 |

| Kwale # | 8 ± 2 | 701 ± 51 | 291 ± 193 | 6 ± 3 | 14 ± 5 | 187 ± 75 | 874 ± 411 | 647 ± 25 | 1091 ± 353 |

| Siaya | 8 ± 2 | 619 ± 14 | 164 ± 36 | 6 ± 2 | 31 ± 17 | 136 ± 52 | 2761 ± 1690 | 588 ± 17 | 840 ± 169 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gitau, J.K.; Sundberg, C.; Mendum, R.; Njenga, M. Comparative Assessment of Gasifier Cookstove Performance on Smallholder Farms in Three Regions in Kenya. Sustainability 2025, 17, 5872. https://doi.org/10.3390/su17135872

Gitau JK, Sundberg C, Mendum R, Njenga M. Comparative Assessment of Gasifier Cookstove Performance on Smallholder Farms in Three Regions in Kenya. Sustainability. 2025; 17(13):5872. https://doi.org/10.3390/su17135872

Chicago/Turabian StyleGitau, James Kinyua, Cecilia Sundberg, Ruth Mendum, and Mary Njenga. 2025. "Comparative Assessment of Gasifier Cookstove Performance on Smallholder Farms in Three Regions in Kenya" Sustainability 17, no. 13: 5872. https://doi.org/10.3390/su17135872

APA StyleGitau, J. K., Sundberg, C., Mendum, R., & Njenga, M. (2025). Comparative Assessment of Gasifier Cookstove Performance on Smallholder Farms in Three Regions in Kenya. Sustainability, 17(13), 5872. https://doi.org/10.3390/su17135872