Sustainable Prototyping: Linking Quality and Environmental Impact via QFD and LCA

Abstract

1. Introduction

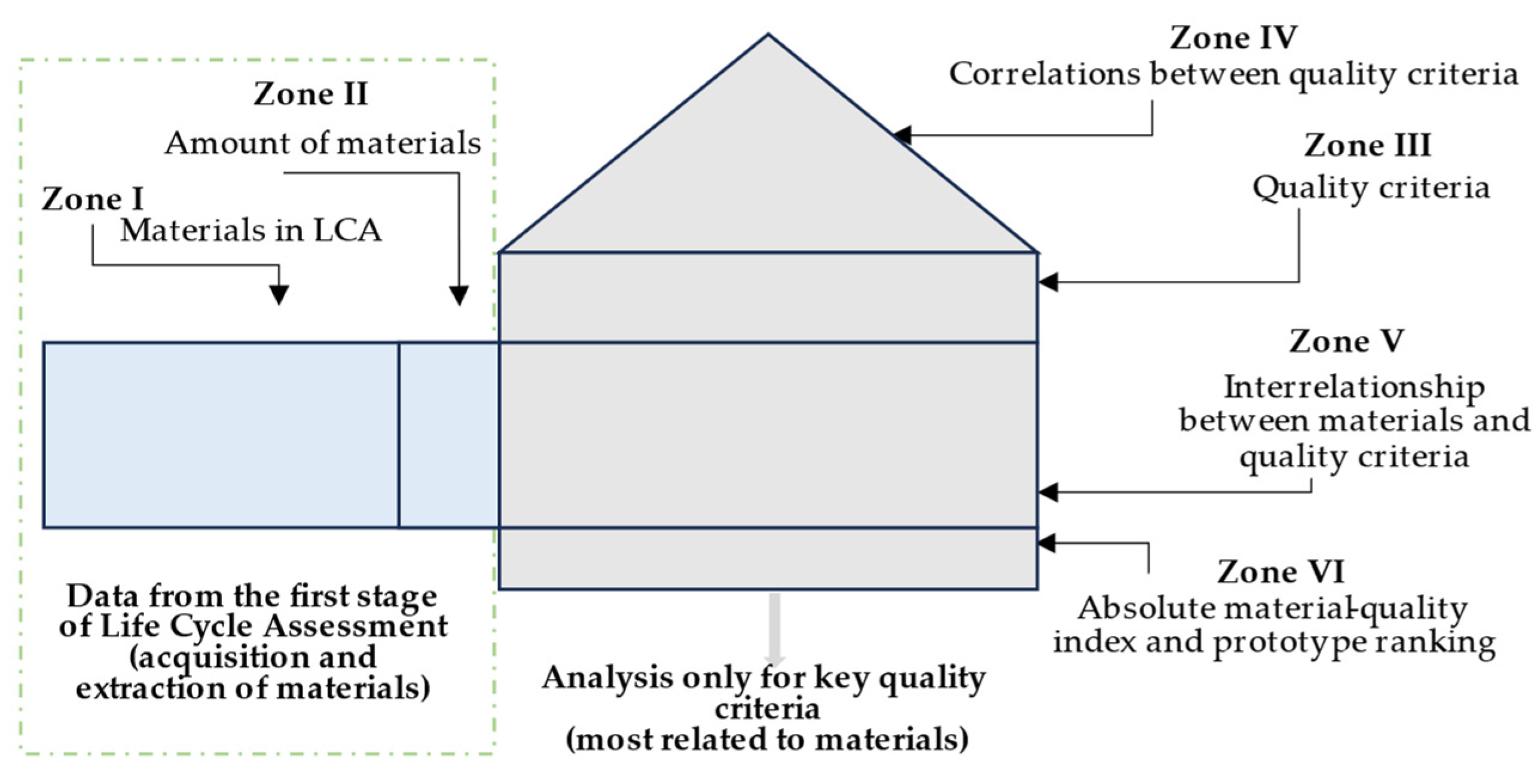

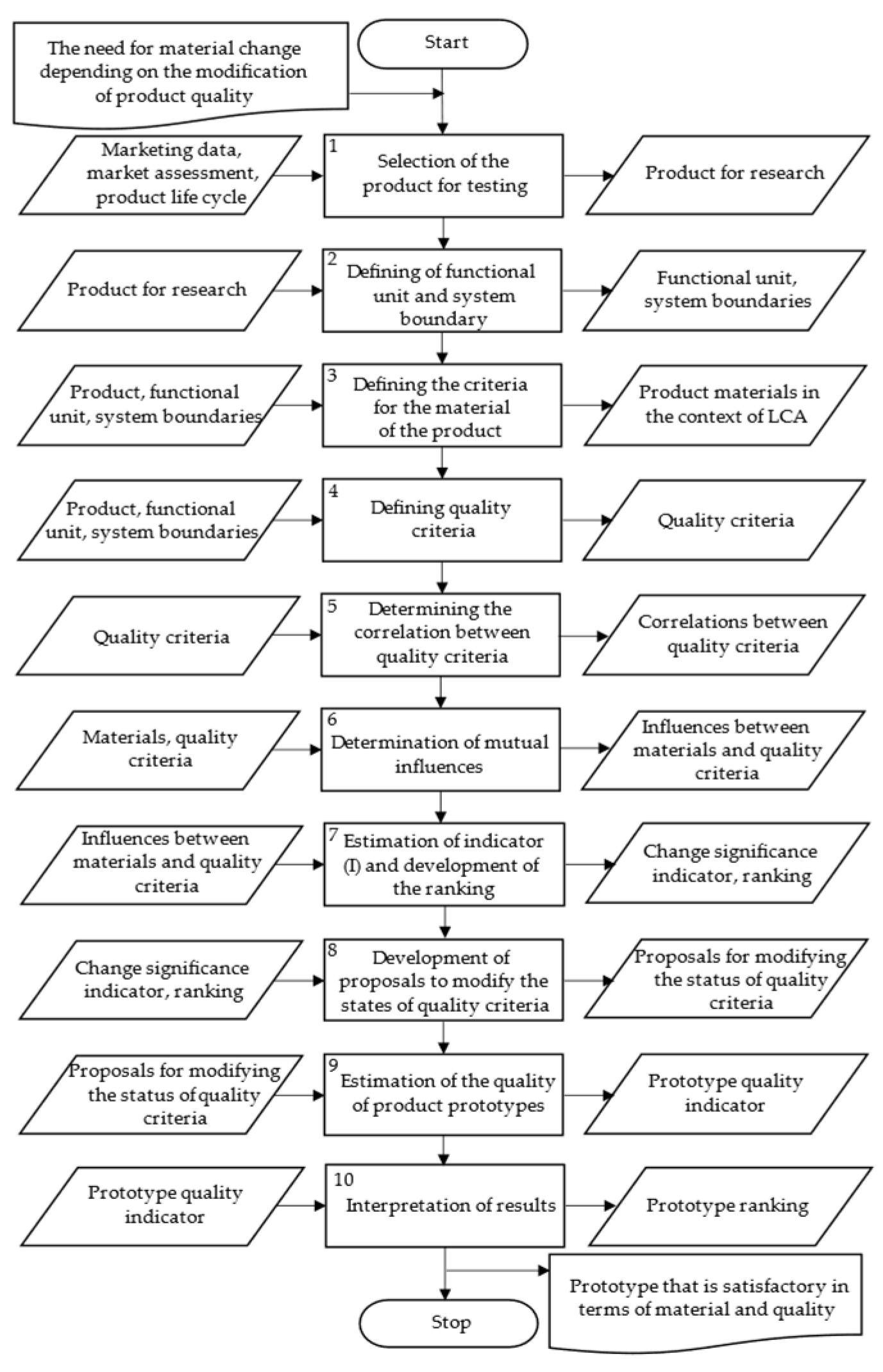

2. Development of Model: Concept and General Presentation with Description

- Selection of the product for testing. The product is optional and is selected based on the needs of the entity using the model. It may be in the development or maturity phase, newly designed, or require improvements. Market research, observations, or business development goals may guide the selection. The chosen product is treated as a reference, representing a generalisation of products with similar functions.

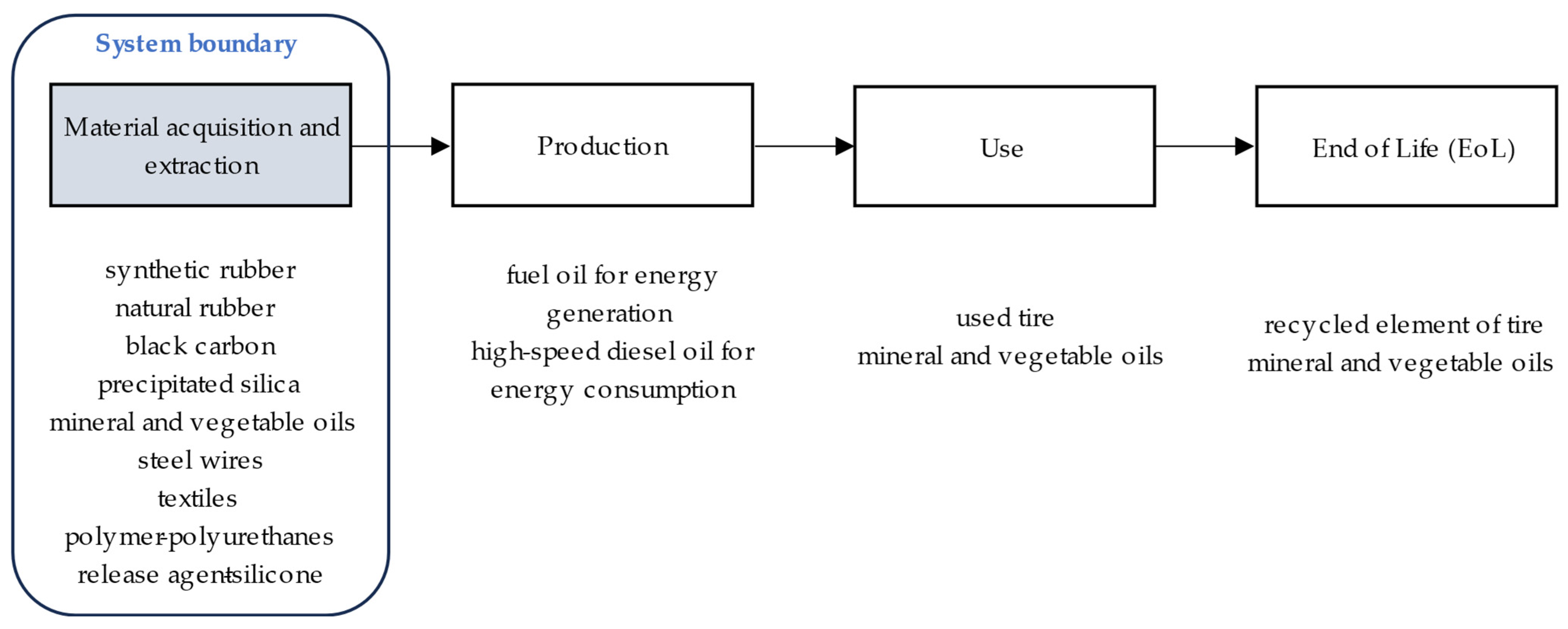

- Defining the functional unit and system boundaries. The functional unit quantifies the product’s function, allowing for data normalisation and comparison. It is defined using international metric units [39]. From example, a unit could be one product item or its weight. System boundaries refer to the analysed inputs and outputs, including environmental loads or analysis scope. A “cradle to grave” approach is assumed, covering material acquisition, production, use, and end of life. Temporal and spatial boundaries may be defined depending on data availability [39,40].

- Defining the criteria for the material of the product. According to the defined system boundaries (in the concept “from cradle to grave”), materials used in the product are identified [41,42]. The type and quantity of materials depend on the research subject. Material selection and characterisation are performed by expert teams (for example, designers or sustainability specialists) [22,43], potentially with support from LCA databases, e.g., OpenLCA. Each material should be described by a value (parameter) relative to the functional unit.

- Definition of quality criteria. The criteria that influence customer satisfaction during use are identified [44]. These criteria form the basis for evaluating product quality and are selected by expert teams, e.g., based on product catalogues. Typically, about 10 criteria are selected (or more for complex products) [45]. Quality criteria must be quantified using international metric units.

- Determining the correlation between quality criteria. Positive (+), negative (−), and neutral (no mark) correlations are identified [46]. A positive correlation means improving one criterion does not compromise another; a negative correlation implies trade-offs. No correlation indicates independence [33,34]. This supports the product development process in later model stages.

- Determination of mutual influences between material and product quality criteria. The influence of quality criteria on the environmental burdens associated with product materials is assessed [47]. For instance, achieving a certain quality may require more of a specific material, e.g., a plastic product element will have an influence on the amount of plastic used (being one of the materials). Using HoQ principles, these interactions are evaluated by experts using a rating scale: weak (—rating 1), medium (O—rating 3), strong (∎—rating 9), or no influence (no markings—rating 0) [29,33,35].

- Estimation of the material change significance index (I) and ranking development. The significance index (I) combines the normalised environmental burden (b) of materials with the interaction rating (o) between materials and quality criteria [48]. In this case, it is the values of the sum of the products of the material parameters with the assessments of their dependencies on the quality criteria (1):

- 8.

- Development of proposals to modify the states of the product quality criteria. Various modifications of current quality criteria states are proposed. A maximum of 7 ± 2 [45] modified states per criterion is recommended, including values above/below the current state or value with verbal descriptions.

- 9.

- Estimation of the quality of product prototypes. Product prototypes are initially assessed based on the current and modified states of quality criteria. Scores are assigned using a Likert scale, where 1 is low customer satisfaction with product use and 5 is high customer satisfaction with product use [49]. Scores across all states for a given criterion should sum to 1. As part of a comprehensive analysis of the quality of prototypes, it is proposed to take into account the importance of quality criteria. The quality indicator (Q) is calculated using a Weighted Sum Model (WSM) (2) [50]:

- 10.

- Interpretation of results. The results are interpreted through a normalised quality indicator, depending on environmental aspects. A prototype classification is established that is created according to the normalised Q indicator (3) [23]:

3. Results: Test and Illustration of the Model Based on a Case Study

- Wet grip;

- Cornering grip;

- Durability;

- Fuel consumption;

- Noise;

- Aquaplaning resistance in a straight line;

- Aquaplaning resistance on a curve;

- Driving stability;

- Rolling resistance coefficient;

- Tyre load capacity;

- Speed index.

4. Discussion

- Improving product quality while reducing environmental impact;

- Supporting the identification of relationships between materials with significant environmental impact and the planned product quality criteria;

- Enhancing the prototyping process to simultaneously meet customer expectations and minimise environmental impact.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Pacana, A.; Siwiec, D. Analysis of the Possibility of Used of the Quality Management Techniques with Non-Destructive Testing. Teh. Vjesn.-Technol. Gaz. 2021, 28, 45–51. [Google Scholar] [CrossRef]

- Milad, A. Recycled and Upcycled Materials in Contemporary Architecture and Civil Engineering: Their Applications, Benefits, and Challenges. Clean. Waste Syst. 2025, 10, 100203. [Google Scholar] [CrossRef]

- Smith, K.A.; Bin Mostafiz, R.; Friedland, C.; Nahmens, I. Fuzzy Logic Use Case within the Built Environment for Optimizing Sustainability versus Cost in the Material Selection Process. Front. Built Environ. 2025, 11, 1529578. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from Renewable and Sustainable Resources: Challenges and Innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Singh, A.R.; Vishnuram, P.; Alagarsamy, S.; Bajaj, M.; Blazek, V.; Damaj, I.; Rathore, R.S.; Al-Wesabi, F.N.; Othman, K.M. Electric Vehicle Charging Technologies, Infrastructure Expansion, Grid Integration Strategies, and Their Role in Promoting Sustainable e-Mobility. Alex. Eng. J. 2024, 105, 300–330. [Google Scholar] [CrossRef]

- Kumar, S.; Goel, A.; Kumar Singh, G. Intricate Analysis of Potential Materials for Sustainable Product Development. Eur. J. Sustain. Dev. 2019, 8, 114. [Google Scholar] [CrossRef]

- Sas-Boca, I.-M.; Tintelecan, M.; Pop, M.; Iluțiu-Varvara, D.-A. Severe Reduction in Section of Copper Wire Using the Technology of Wire Cold Cassette Roller Dies. Procedia Manuf. 2018, 22, 73–78. [Google Scholar] [CrossRef]

- Lei, H.; Yang, W.; Zhang, B.; Li, C.-Q. An Advanced Method for Assessing Circular Economy Performance of Built Environment. J. Clean. Prod. 2025, 486, 144561. [Google Scholar] [CrossRef]

- Usman, O.; Iorember, P.T.; Alola, A.A.; Bekun, F.V. Effect of Domestic Material Production on Environmental Sustainability in EU Countries under Changing Financial Development: A Dynamic Panel Threshold Regression Approach. Environ. Dev. Sustain. 2024, 1, 1–20. [Google Scholar] [CrossRef]

- Truong, N.; Trencher, G.; Yarime, M.; Barrett, B.; Matsubae, K. Barriers to the Adoption of Electric Cars and Electric Motorcycles in Vietnam. Transp. Res. D Transp. Environ. 2024, 131, 104204. [Google Scholar] [CrossRef]

- Kaššaj, M.; Peráček, T. Synergies and Potential of Industry 4.0 and Automated Vehicles in Smart City Infrastructure. Appl. Sci. 2024, 14, 3575. [Google Scholar] [CrossRef]

- Vadoudi, K.; Deckers, P.; Demuytere, C.; Askanian, H.; Verney, V. Comparing a Material Circularity Indicator to Life Cycle Assessment: The Case of a Three-Layer Plastic Packaging. Sustain. Prod. Consum. 2022, 33, 820–830. [Google Scholar] [CrossRef]

- Siwiec, D.; Dwornicka, R.; Pacana, A. Improving the Process of Achieving Required Microstructure and Mechanical Properties of 38mnvs6 Steel. In Proceedings of the 29th International Conference on Metallurgy and Materials, Brno, Czech Republic, 20–22 May 2020; pp. 591–596. [Google Scholar]

- Li, R.; Zhai, C. Constructing Sports Facilities Using Environment-Friendly Materials. Front. Mater. 2025, 11, 1524729. [Google Scholar] [CrossRef]

- Kravtsova, M.V.; Volkov, D.A.; Melnikova, D.A.; Kravtsov, M.V.; Bezheskaia, E.V. An Effective System for Recycling Polyethyleneterephthalate. J. Phys. Conf. Ser. 2019, 1399, 022048. [Google Scholar] [CrossRef]

- Matygulina, V.; Chistova, N.; Vititnev, A.; Chistov, R. Dry Grinding of Waste Wood Fiberboard: Theoretical and Practical Aspects Affecting the Resulting Fiber Quality. Bioresources 2021, 16, 8152–8171. [Google Scholar] [CrossRef]

- Zhang, A.; Xing, Y.; Yang, F.; Zhang, X.; Wang, H.; Yu, T. Development of a New Cold Metal Transfer Arc Additive Die Manufacturing Process. Adv. Mater. Sci. Eng. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Titone, V.; Botta, L.; Mistretta, M.C.; La Mantia, F.P. Influence of a Biodegradable Contaminant on the Mechanical Recycling of a Low-density Polyethylene Sample. Polym. Eng. Sci. 2024, 64, 845–851. [Google Scholar] [CrossRef]

- Bialy, W.; Grebski, W.; Galecki, G.; Kaniak, W. Environmental Impact of The Mechanical Coal Processing Plant. Acta Montan. Slovaca 2020, 25, 139–149. [Google Scholar] [CrossRef]

- Lotfi, S.; Deja, J.; Rem, P.; Mróz, R.; van Roekel, E.; van der Stelt, H. Mechanical Recycling of EOL Concrete into High-Grade Aggregates. Resour. Conserv. Recycl. 2014, 87, 117–125. [Google Scholar] [CrossRef]

- Vongpradubchai, S.; Rattanadecho, P. The Microwave Processing of Wood Using a Continuous Microwave Belt Drier. Chem. Eng. Process. Process Intensif. 2009, 48, 997–1003. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Materials and Products Development Based on a Novelty Approach to Quality and Life Cycle Assessment (QLCA). Materials 2024, 17, 3859. [Google Scholar] [CrossRef] [PubMed]

- Siwiec, D.; Gajdzik, B.; Gawlik, R.; Wolniak, R.; Pacana, A. Open Eco-Innovations in Sustainable Product Development: Model Framework of Design Thinking in Quality Life Cycle Assessment (DT-QLCA). J. Open Innov. Technol. Mark. Complex. 2025, 11, 100480. [Google Scholar] [CrossRef]

- Sakao, T. A QFD-Centred Design Methodology for Environmentally Conscious Product Design. Int. J. Prod. Res. 2007, 45, 4143–4162. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Kobayashi, H.; Hongu, A.; Sanehira, K. A Practical Method for Quantifying Eco-Efficiency Using Eco-Design Support Tools. J. Ind. Ecol. 2005, 9, 131–144. [Google Scholar] [CrossRef]

- Neramballi, A.; Sakao, T.; Willskytt, S.; Tillman, A.-M. A Design Navigator to Guide the Transition towards Environmentally Benign Product/Service Systems Based on LCA Results. J. Clean. Prod. 2020, 277, 124074. [Google Scholar] [CrossRef]

- Popoff, A.; Millet, D. Sustainable Life Cycle Design Using Constraint Satisfaction Problems and Quality Function Deployment. Procedia CIRP 2017, 61, 75–80. [Google Scholar] [CrossRef]

- Puglieri, F.N.; Ometto, A.R.; Salvador, R.; Barros, M.V.; Piekarski, C.M.; Rodrigues, I.M.; Diegoli Netto, O. An Environmental and Operational Analysis of Quality Function Deployment-Based Methods. Sustainability 2020, 12, 3486. [Google Scholar] [CrossRef]

- Wolniak, R. The Use of QFD Method Advantages and Limitation. Prod. Eng. Arch. 2018, 18, 14–17. [Google Scholar] [CrossRef]

- Pryshlakivsky, J.; Searcy, C. Fifteen Years of ISO 14040: A Review. J. Clean. Prod. 2013, 57, 115–123. [Google Scholar] [CrossRef]

- Wolniak, E.R.; Sȩdek, A. Using QFD Method for the Ecological Designing of Products and Services. Qual. Quant. 2009, 43, 695–701. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life Cycle Assessment. Env. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; He, Z.; He, S. Detecting and Prioritizing Product Defects Using Social Media Data and the Two-Phased QFD Method. Comput. Ind. Eng. 2023, 177, 109031. [Google Scholar] [CrossRef]

- Neira-Rodado, D.; Ortíz-Barrios, M.; De la Hoz-Escorcia, S.; Paggetti, C.; Noffrini, L.; Fratea, N. Smart Product Design Process through the Implementation of a Fuzzy Kano-AHP-DEMATEL-QFD Approach. Appl. Sci. 2020, 10, 1792. [Google Scholar] [CrossRef]

- Shi, Y.; Peng, Q. A Spectral Clustering Method to Improve Importance Rating Accuracy of Customer Requirements in QFD. Int. J. Adv. Manuf. Technol. 2020, 107, 2579–2596. [Google Scholar] [CrossRef]

- Hermann, B.G.; Kroeze, C.; Jawjit, W. Assessing Environmental Performance by Combining Life Cycle Assessment, Multi-Criteria Analysis and Environmental Performance Indicators. J. Clean. Prod. 2007, 15, 1787–1796. [Google Scholar] [CrossRef]

- Toniolo, S.; Tosato, R.C.; Gambaro, F.; Ren, J. Life Cycle Thinking Tools: Life Cycle Assessment, Life Cycle Costing and Social Life Cycle Assessment. In Life Cycle Sustainability Assessment for Decision-Making; Elsevier: Amsterdam, The Netherlands, 2020; pp. 39–56. [Google Scholar]

- Liu, Z.; Chen, X.; Liang, X. Growable Design of Passenger Vehicle Interior Space Based on FAHP and FQFD. PLoS ONE 2024, 19, e0303233. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; D’Eusanio, M.; Raggi, A.; Petti, L. Functional Unit Definition Criteria in Life Cycle Assessment and Social Life Cycle Assessment: A Discussion. In Perspectives on Social LCA; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–10. [Google Scholar]

- Zheng, X.; Easa, S.M.; Yang, Z.; Ji, T.; Jiang, Z. Life-Cycle Sustainability Assessment of Pavement Maintenance Alternatives: Methodology and Case Study. J. Clean. Prod. 2019, 213, 659–672. [Google Scholar] [CrossRef]

- Papa, I.; Panico, M.; Carandente, M.; Lopresto, V. Innovative Joining Technologies for Lightweight Material Vehicles. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2024, 238, 5674–5684. [Google Scholar] [CrossRef]

- Lustig, W.P.; Mukherjee, S.; Rudd, N.D.; Desai, A.V.; Li, J.; Ghosh, S.K. Metal–Organic Frameworks: Functional Luminescent and Photonic Materials for Sensing Applications. Chem. Soc. Rev. 2017, 46, 3242–3285. [Google Scholar] [CrossRef]

- Gajdzik, B. Digital Transformation Towards Smart Steel Manufacturing; Springer Nature: Cham, Switzerland, 2025; ISBN 978-3-031-77755-4. [Google Scholar]

- Al, S.; Abdussakir, A.; Djakfar, M.; Al, S. The Effect of Product Knowledge and Service Quality on Customer Satisfaction. J. Asian Financ. Econ. Bus. 2021, 8, 927–938. [Google Scholar]

- Mu, E.; Pereyra-Rojas, M. Practical Decision Making, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017; Volume 1, ISBN 978-3-319-33860-6. [Google Scholar]

- Kamvysi, K.; Tsironis, L.K.; Gotzamani, K. An Integrated QFD Framework for Smart City Strategy Development. TQM J. 2025, 37, 1203–1226. [Google Scholar] [CrossRef]

- Gómez, E.A.M.; Osorio, S.I.; Soriano, L.A.; Paredes, G.J.G.; Rubio, J.d.J. Exploring a Material-Focused Design Methodology: An Innovative Approach to Pressure Vessel Design. Machines 2024, 12, 81. [Google Scholar] [CrossRef]

- Pino-Servian, M.; de la Puente-Gil, Á.; Colmenar-Santos, A.; Rosales-Asensio, E. Applying QFD to the Vehicle Market Deployment Process. World Electr. Veh. J. 2025, 16, 285. [Google Scholar] [CrossRef]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D. Likert Scale: Explored and Explained. Br. J. Appl. Sci. Technol. 2015, 7, 396–403. [Google Scholar] [CrossRef]

- Yang, X.-S. Multi-Objective Optimization. In Nature-Inspired Optimization Algorithms; Elsevier: Amsterdam, The Netherlands, 2014; pp. 197–211. [Google Scholar]

- Kolman, R. Quality Engineering; PWE: Warsaw, Poland, 1992. (In Polish) [Google Scholar]

- Gajdzik, B.; Siwiec, D.; Wolniak, R.; Pacana, A. Approaching Open Innovation in Customization Frameworks for Product Prototypes with Emphasis on Quality and Life Cycle Assessment (QLCA). J. Open Innov. Technol. Mark. Complex. 2024, 10, 100268. [Google Scholar] [CrossRef]

- Kim, C.; Ludwig, C.; Park, S.; Im, C. Improvement of Tire Development Process Through Study of Tire Test Procedure and Vehicle Correlation. In Proceedings of the SAE Technical Papers; SAE: Warrendale, PA, USA, 2018; Volume 2018-April. [Google Scholar]

- Paramita Pattanaik, P.; Balu, V. Plus Size Tire: Effect on the Performance of the Vehicle. Mater. Today Proc. 2021, 81, 423–426. [Google Scholar] [CrossRef]

- Buadit, T.; Ussawarujikulchai, A.; Suchiva, K.; Papong, S.; Ma, H.-W.; Rattanapan, C. Environmental Impact of Passenger Car Tire Supply Chain in Thailand Using the Life Cycle Assessment Method. Sustain. Prod. Consum. 2023, 37, 156–168. [Google Scholar] [CrossRef]

- Dong, Y.; Zhao, Y.; Hossain, M.U.; He, Y.; Liu, P. Life Cycle Assessment of Vehicle Tires: A Systematic Review. Clean. Environ. Syst. 2021, 2, 100033. [Google Scholar] [CrossRef]

- Piotrowska, K.; Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Rudnicki, J.; Tomporowski, A.; Flizikowski, J.; Opielak, M. Assessment of the Environmental Impact of a Car Tire throughout Its Lifecycle Using the LCA Method. Materials 2019, 12, 4177. [Google Scholar] [CrossRef]

- Hennequin, T.; Huijbregts, M.A.J.; van Zelm, R. The Influence of Consumer Behavior on the Environmental Footprint of Passenger Car Tires. J. Ind. Ecol. 2023, 27, 96–109. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A.; Gazda, A. A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies. 2023, 16, 2474. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Method of Fuzzy Analysis of Qualitative-Environmental Threat in Improving Products and Processes (Fuzzy QE-FMEA). Materials 2023, 16, 1651. [Google Scholar] [CrossRef] [PubMed]

| Study | Methodology | Techniques | Case Study | Comparison and Novelty of This Study |

|---|---|---|---|---|

| [22] | Method that supports the sustainable development of materials and the products made from them based on an aggregated indicator of quality and environmental load in the life cycle (QLCA) | Weight Sum Model (WSM), Entropy, Ecoinvent with OpenLCA | Passenger car tyre | The QLCA method provides an analysis of final products in terms of quality and environment, where modifications to the states of product quality criteria and the impact of these modifications on the environment are analysed in LCA; this model focusses on a detailed analysis of the materials obtained and processed for the production of products, taking into account their burden on the environment in the context of LCA, including correlations between planned modifications of quality criteria. |

| [23] | Framework for a model integrating design thinking (DT) with the Quality Life Cycle Assessment (QLCA) model | Design thinking (DT), Ecoinvent with OpenLCA, Quality Life Cycle Assessment | Framework | The model supports the development of products according to traditional design thinking integrated with quality and product life cycle assessment (QLCA); compared with the model offered in this study, design solutions are sought depending on the materials obtained and processed in the final product and its prototypes, where this is supported by the assumptions of the QFD method (Quality Functional Development). |

| [24] | A method supporting the design process by assessing innovative product solutions that take into account customer requirements and life cycle assessment | LCA, QFD, and TRIZ (Theory of Inventive Problem Solving) | Hair dryer | Product improvement according to integrated methods based on the search for innovative design solutions and taking into account the aspect of quality and environmental impact in the life cycle, where this analysis takes place in QFD; the offered model searches for product design solutions based on QFD assumptions and takes into account the aspect of quality and environment, but in the form of identifying the increase in negative impact on the environment through unfavourable changes in the product quality criteria, which are directly related only to materials from the first phase of the life cycle and in the overall approach of the final product. |

| [25] | Eco-efficiency quantification method using Quality Function Deployment (QFD) and life cycle impact assessment (LCA) | QFD, LCA | Different case studies about eco-efficiency | Eco-efficiency analyses of products that do not consider correlation: environmental impacts resulting from changes in the environmental burdens of materials that depend on various modifications of the product quality criteria. |

| [26,27,28] | Analyses of the environmental impact of a product throughout its life cycle focussing on identifying environmentally friendly solutions that simultaneously meet customer requirements for product quality | Action design research (ADR), inflatable dinghy | Determining environmental requirements using LCA and then prioritising them, taking into account customer requirements; the offered model ensures determining the direction of product quality development by taking into account customer satisfaction with the use of the product, and thus, focussing on criteria that have a significant, direct impact on generating environmental burdens, where these burdens include materials obtained and processed for the production of the final product. |

| Materials | Unit | Average Value |

|---|---|---|

| synthetic rubber | kg | 2.330 |

| natural rubber | kg | 1.759 |

| black carbon | kg | 1.808 |

| precipitated silica | kg | 0.928 |

| mineral and vegetable oils | kg | 0.570 |

| steel wires | kg | 1.073 |

| textiles | kg | 0.445 |

| polymers–polyurethanes | kg | 0.232 |

| anti-adhesive substance (silicone) | kg | 0.242 |

| Tire Quality Criterion | Proposed Modifications to the Criteria | ||||||

|---|---|---|---|---|---|---|---|

| A0 | M1 | M2 | M3 | M4 | M5 | M6 | |

| Wet grip (class) | A | B | C | D | E | - | - |

| Corner grip (class) | A | B | C | D | E | - | - |

| Durability (years) | 5 | 6 | 7 | 8 | 9 | 10 | - |

| Fuel consumption (class) | A | B | C | D | E | - | - |

| Noise (dB) | 67–69 | 70–72 | 73–77 | - | - | - | - |

| Aquaplaning resistance | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| in a straight line (litres/second) | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| Aquaplaning resistance in a | 150 | 200 | 250 | 300 | - | - | - |

| curve (litres/second) | <6.5 | 6.6–7.7 | 7.9–9.0 | 9.1–10.5 | >10.6 | - | - |

| Driving stability (km/h) | 75 | 91–95 | 100–106 | 110–115 | - | - | - |

| Rolling resistance coefficient (RRC) | 90–110 | 120–140 | 150–180 | 190 | 210 | 200–240 | 270 |

| Tire Quality Criterion | Weight | Proposed Modifications to the Criteria | ||||||

|---|---|---|---|---|---|---|---|---|

| A0 | M1 | M2 | M3 | M4 | M5 | M6 | ||

| Wet grip (class) | 4 | 3 | 4 | 4 | 5 | 5 | - | - |

| Corner grip (class) | 4 | 3 | 4 | 4 | 5 | 5 | - | - |

| Durability (years) | 5 | 2 | 3 | 4 | 4 | 5 | 5 | - |

| Fuel consumption (class) | 2 | 3 | 4 | 4 | 5 | 5 | - | - |

| Noise (dB) | 1 | 5 | 4 | 3 | - | - | - | - |

| Aquaplaning resistance | 3 | 5 | 5 | 5 | 4 | 4 | 3 | 3 |

| in a straight line (litres/second) | 3 | 5 | 5 | 4 | 4 | 3 | 3 | 2 |

| Aquaplaning resistance in a | 3 | 3 | 4 | 5 | 5 | - | - | - |

| curve (litres/second) | 1 | 5 | 4 | 3 | 2 | 1 | - | - |

| Driving stability (km/h) | 3 | 3 | 4 | 4 | 5 | - | - | - |

| Rolling resistance coefficient (RRC) | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 |

| No. | Indicator | Verbal Description | No. | Indicator | Verbal Description |

|---|---|---|---|---|---|

| Q215 | 0.76 | beneficial | Q219 | 0.84 | distinctive |

| Q217 | 0.76 | beneficial | Q220 | 0.84 | distinctive |

| Q222 | 0.76 | beneficial | Q226 | 0.84 | distinctive |

| Q224 | 0.76 | beneficial | Q227 | 0.84 | distinctive |

| Q76 | 0.78 | beneficial | Q80 | 0.86 | distinctive |

| Q77 | 0.78 | beneficial | Q81 | 0.86 | distinctive |

| Q107 | 0.78 | beneficial | Q84 | 0.86 | distinctive |

| Q108 | 0.78 | beneficial | Q85 | 0.86 | distinctive |

| Q114 | 0.78 | beneficial | Q87 | 0.90 | distinctive |

| Q115 | 0.78 | beneficial | Q91 | 0.90 | distinctive |

| Q212 | 0.79 | beneficial | Q82 | 0.91 | excellent |

| Q213 | 0.79 | beneficial | Q86 | 0.91 | excellent |

| Q79 | 0.81 | distinctive | Q88 | 0.95 | excellent |

| Q83 | 0.81 | distinctive | Q89 | 0.95 | excellent |

| Q121 | 0.81 | distinctive | Q92 | 0.95 | excellent |

| Q122 | 0.81 | distinctive | Q93 | 0.95 | excellent |

| Q128 | 0.81 | distinctive | Q90 | 1.00 | excellent |

| Q129 | 0.81 | distinctive | Q94 | 1.00 | excellent |

| Q78 | 0.83 | distinctive |

| Aspects | Traditional QFD Method | Proposed Model Considering the Stages of QFD Method |

|---|---|---|

| Purpose | Analysis of the relationship between quality criteria (customer) and technical criteria of the product to determine the direction of product development that ensures customer satisfaction (required quality). | Analysis of the relationship between material criteria (material acquisition and extraction phase in the product life cycle) and technical product criteria (related to quality) to determine the direction of product development that ensures customer satisfaction (required quality) while simultaneously limiting the negative environmental impact throughout the life cycle. |

| Scope of analysis | Quality criteria (expressed by customers and translated into technical language), including a possible analysis of the product’s competitiveness, within the framework of the current product (excluding prototypes). | Quality criteria (expressed by customers and translated into technical language), product material criteria with their quantitative environmental impact over the life cycle, and prototyping in various states of quality criteria. |

| Input | Voice of the customer (VoC), market requirements, prior product designs. | Voice of the Customer (VoC), market requirements, prior product designs, set of materials, and the quantity sourced and processed during product production. |

| Output | Ranking of technical criteria specifying the order of criteria that need to be improved to achieve the expected quality. | Ranking of technical product criteria specifying the order of criteria that need to be improved to achieve the expected quality while simultaneously limiting the negative environmental impact. |

| Techniques | Survey, interview, brainstorming. | Survey, interview, QFD method, brainstorming, morphological analysis, elements of the LCA method. |

| Main benefits | Support for the design process, facilitating the acquisition and processing of customer requirements, and supporting designers in determining the sequence of improvement actions to achieve customer satisfaction; low-cost method. | Support for the design process, facilitating the determination of relationships between materials generating environmental burdens and quality criteria, and supporting designers in determining the sequence of improvement actions in order to achieve customer satisfaction and minimise environmental impact; low-cost model. |

| Main limitations | Complex form, need for an interdisciplinary team, difficulty in analysing a large number of criteria, time-consuming. | Complex form, modelling with simplified data, anticipated difficulties in analyses involving a large number of different criteria, time-consuming. |

| Aspects | Life Cycle Assessment Method | Proposed Model Considering the Elements of LCA Method |

|---|---|---|

| Purpose | Life cycle assessment of a product, traditionally “from cradle to grave”, where the stages of material acquisition and extraction, production, use, and end of life are analysed. The assessment is carried out according to the adopted criterion of environmental burden. | Relying on materials from the first stage of the life cycle assessment, i.e., acquisition and extraction of the materials necessary for the product. Taking into account the quantity of these materials per adopted functional unit. A full product life cycle assessment is not performed. |

| Scope of analysis | Life cycle assessment steps according to the approach adopted, e.g., “cradle to grave”. | The first stage of the life cycle assessment is limited to determining the list of main materials and their quantities (the so-called quantitative environmental burden criteria). |

| Input | System boundaries, functional unit, and product function, including inventory data (materials, energy, transportation, production, use, end of life). | System boundary, functional unit, and product function, including inventory data for materials used in the final product. |

| Output | The result of the product life cycle assessment that defines the environmental burden in relation to the analysed criterion. | List of product quality criteria most closely related to the generation of significant environmental burdens from the perspective of the materials used in the product. |

| Techniques | ISO 14040/44 | LCA method |

| Main benefits | Identification of key environmental burdens that support the process of reducing negative environmental impacts in LCA. | Identifying key relationships between material and product quality criteria to determine which quality criteria may generate the greatest environmental burden. |

| Main limitations | Problems with access to current and complete data and difficulties in interpreting complex results. | Focusses only on the first phase of LCA, involving simplified modelling of relationships between material and quality criterion. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siwiec, D.; Pacana, A. Sustainable Prototyping: Linking Quality and Environmental Impact via QFD and LCA. Sustainability 2025, 17, 5818. https://doi.org/10.3390/su17135818

Siwiec D, Pacana A. Sustainable Prototyping: Linking Quality and Environmental Impact via QFD and LCA. Sustainability. 2025; 17(13):5818. https://doi.org/10.3390/su17135818

Chicago/Turabian StyleSiwiec, Dominika, and Andrzej Pacana. 2025. "Sustainable Prototyping: Linking Quality and Environmental Impact via QFD and LCA" Sustainability 17, no. 13: 5818. https://doi.org/10.3390/su17135818

APA StyleSiwiec, D., & Pacana, A. (2025). Sustainable Prototyping: Linking Quality and Environmental Impact via QFD and LCA. Sustainability, 17(13), 5818. https://doi.org/10.3390/su17135818