Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand

Abstract

1. Introduction

2. Materials and Methods

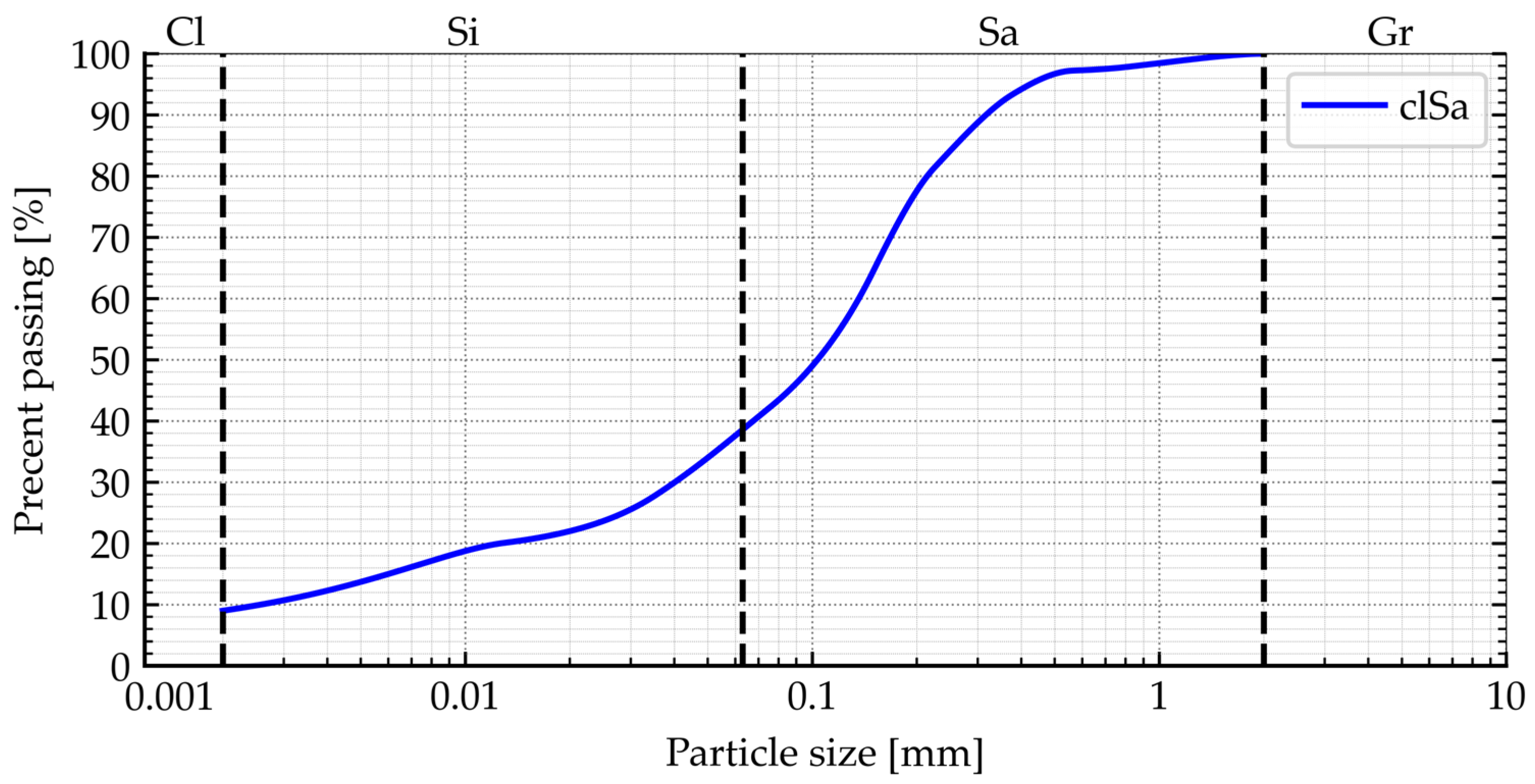

2.1. Soil

2.2. Binder

2.3. Fibers

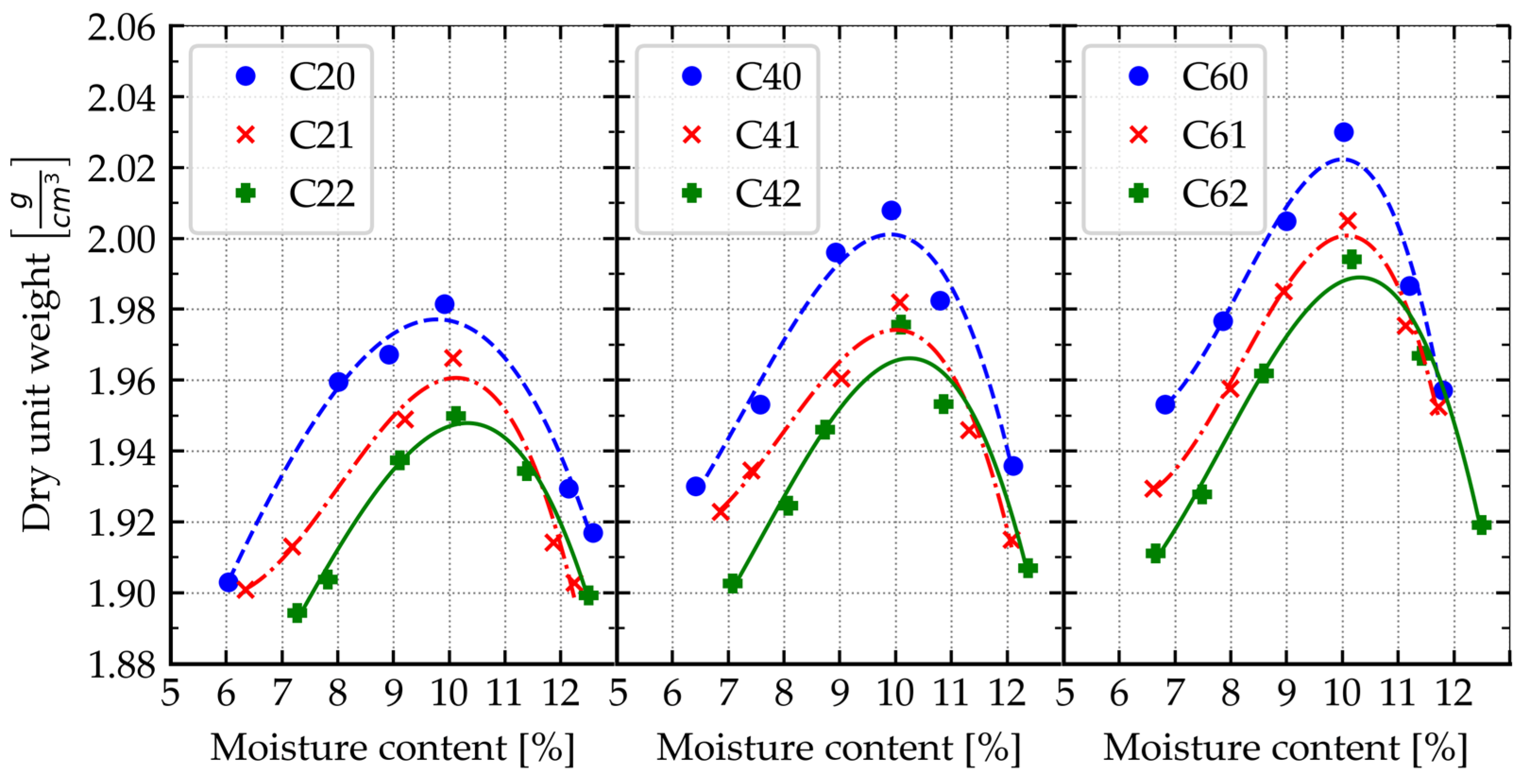

2.4. Mixtures, Sample Preparation, and Curing

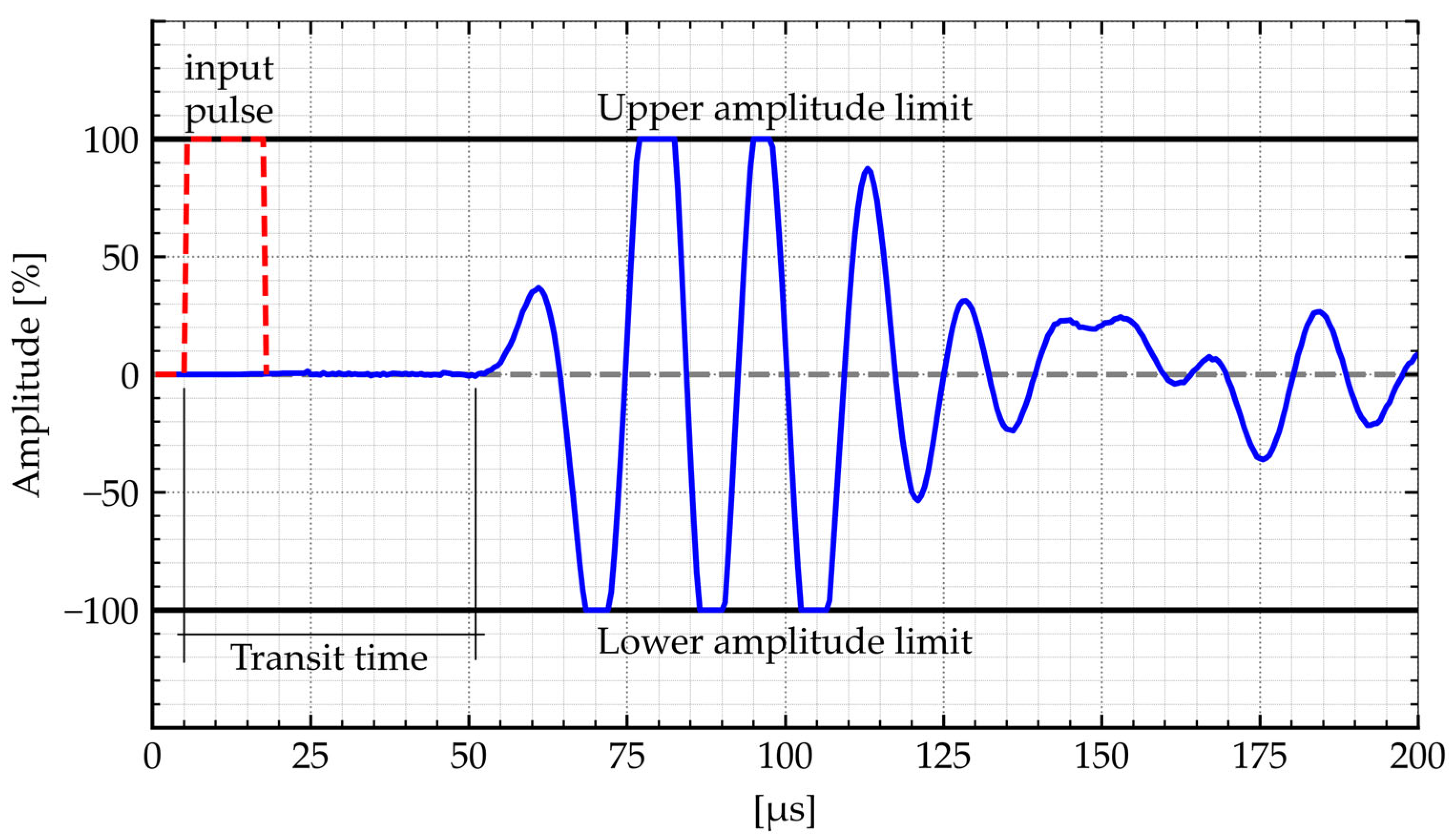

2.5. Measuring Device—Ultrasonic Pulse Velocity

2.6. Measuring Device—Unconfined Compressive Strength

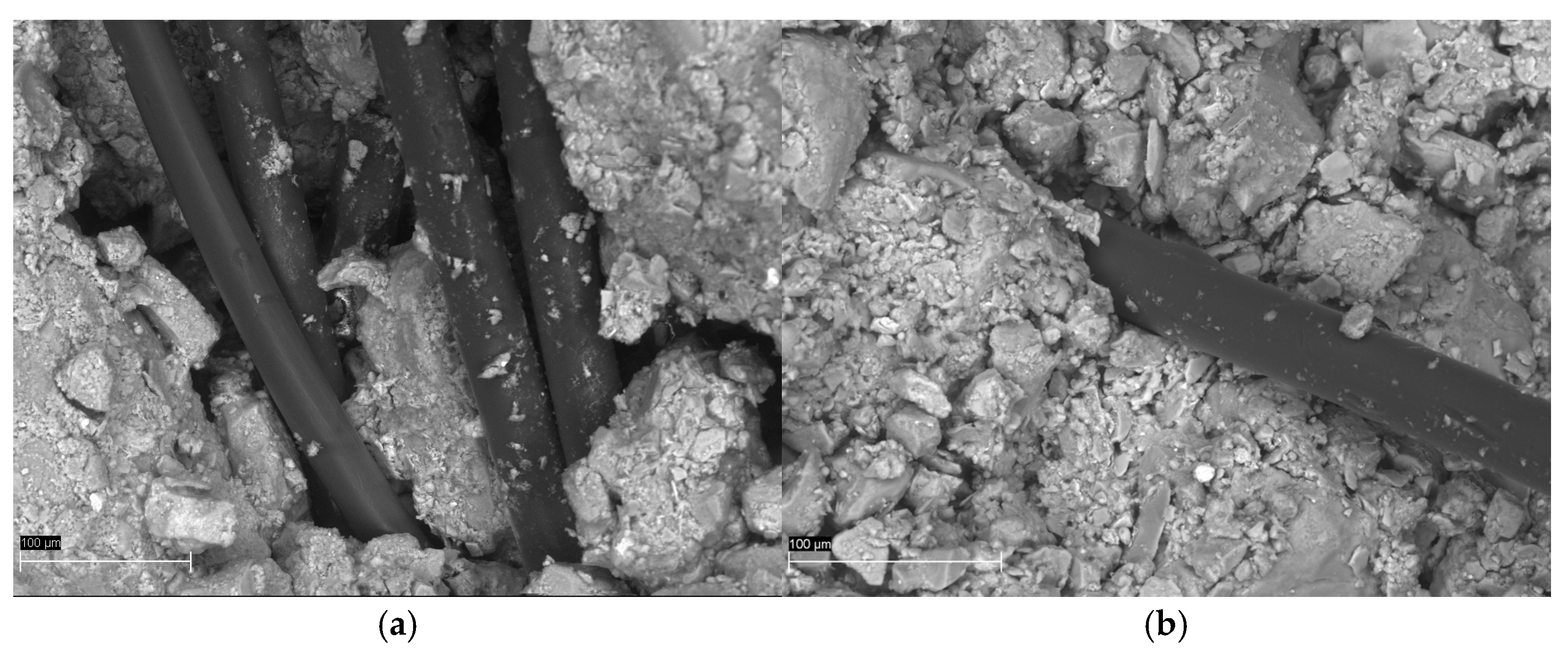

2.7. Microstructure Tests

2.8. Indicators Analyzed

3. Results

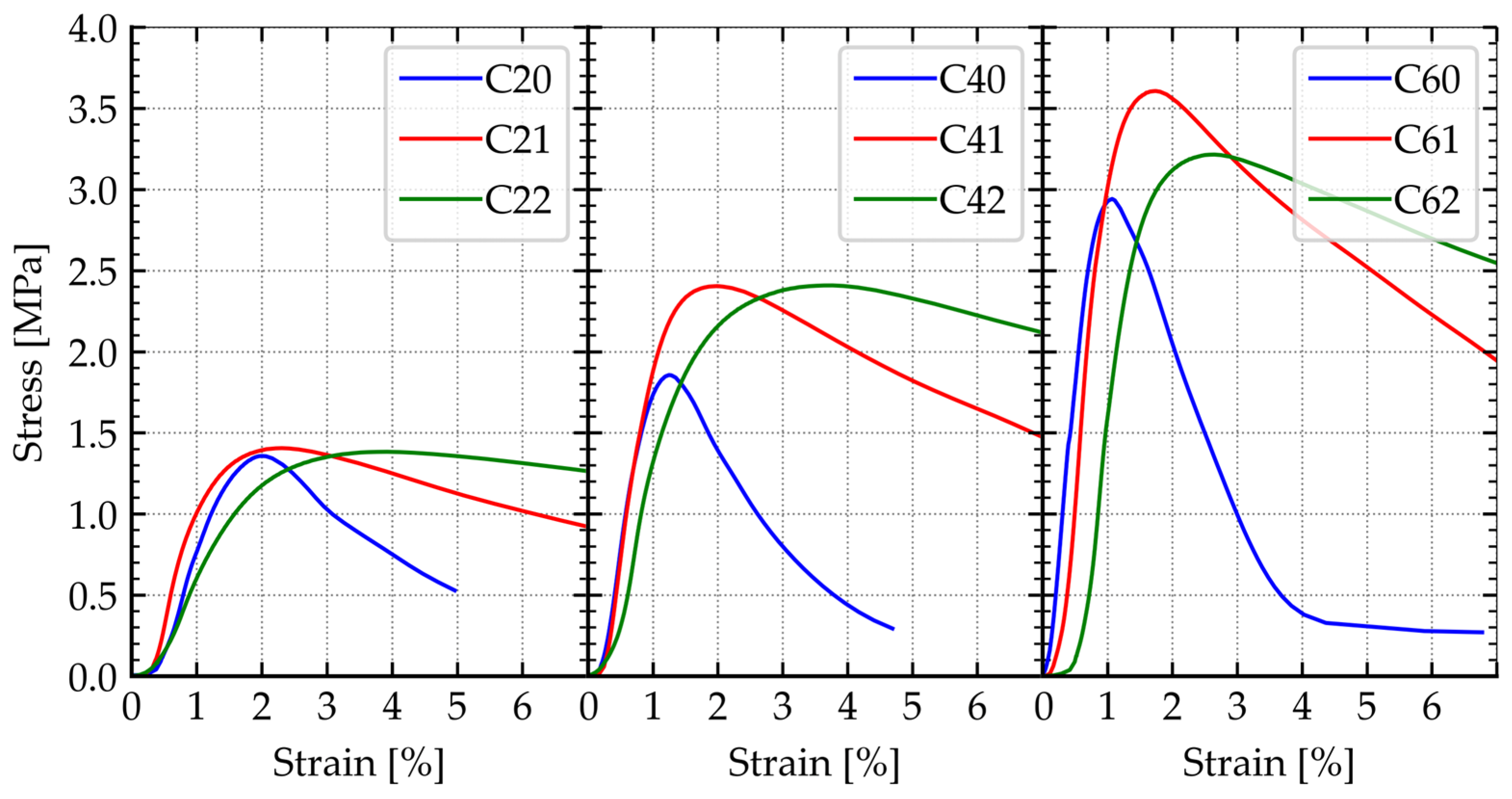

3.1. Impact of Polypropylene Fibers on Stabilized Soil

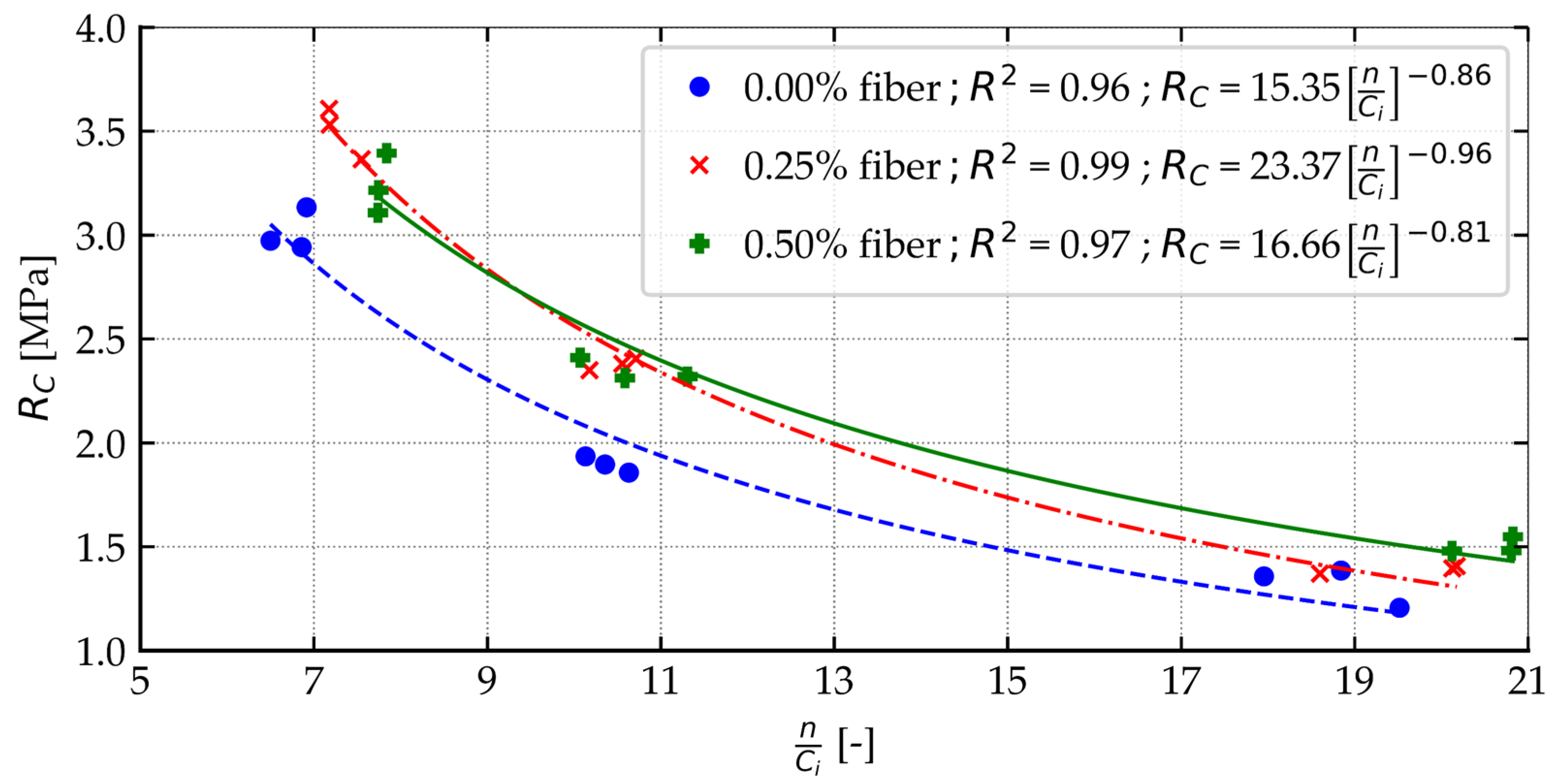

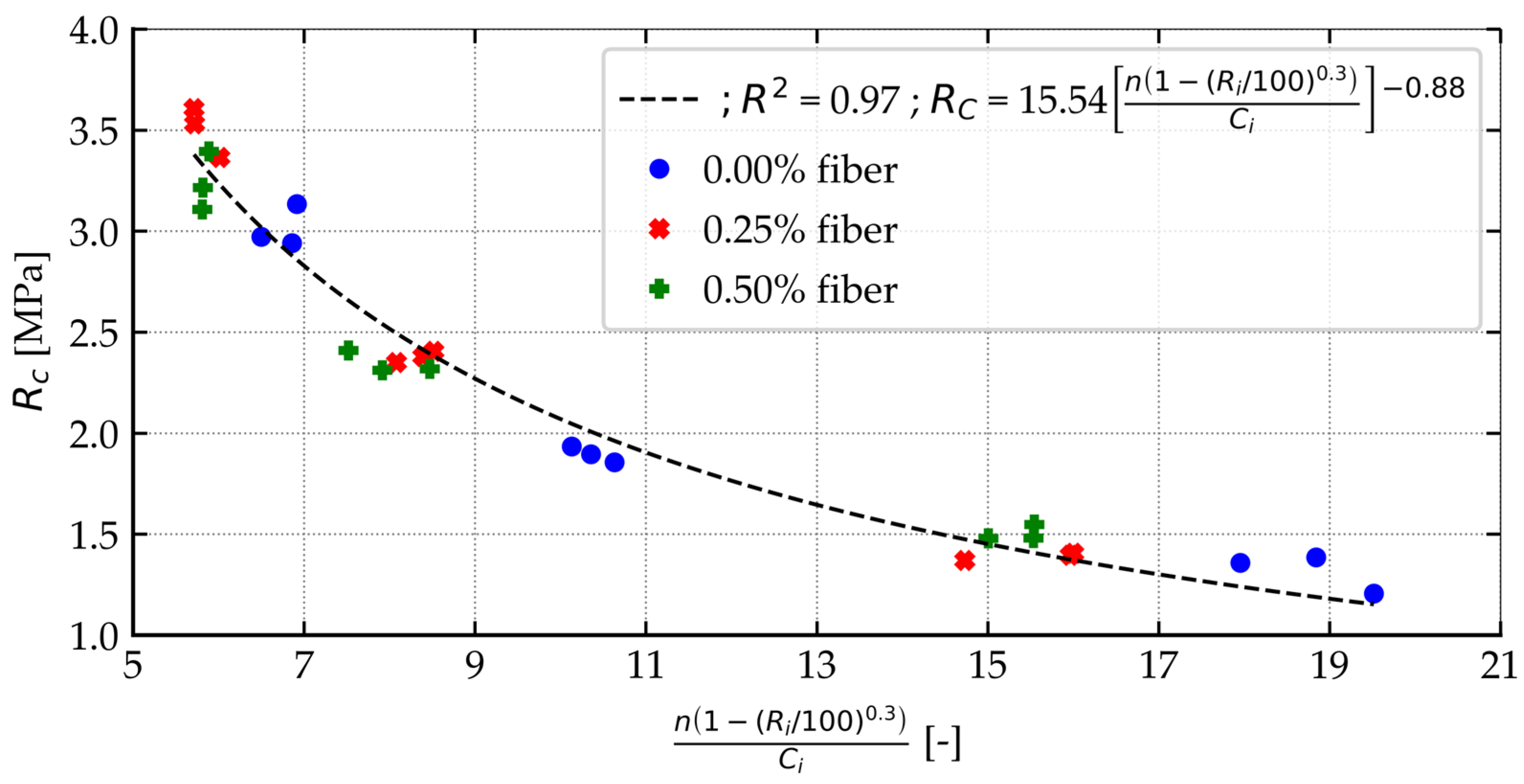

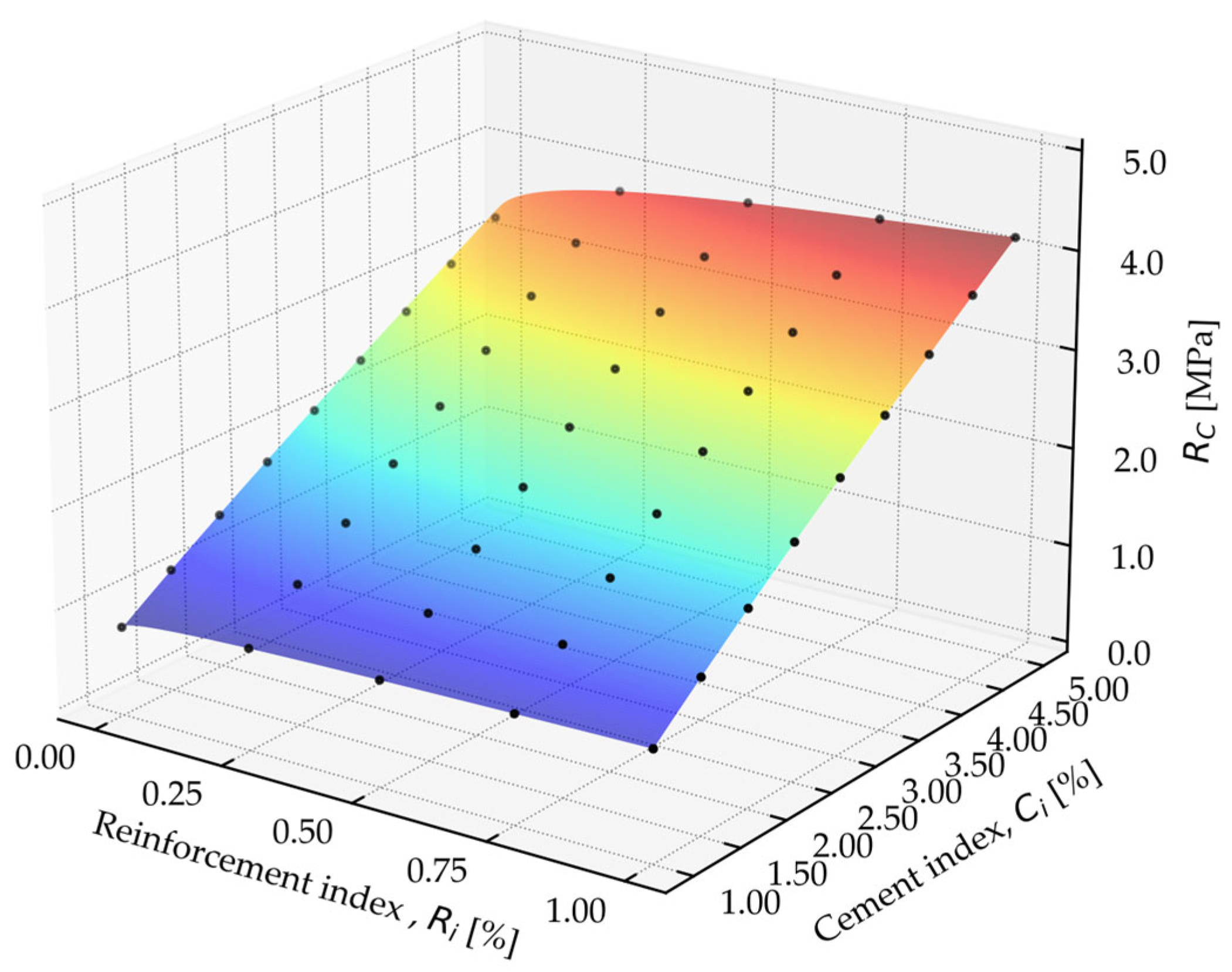

3.2. Predicting the Strength of Stabilized Soil

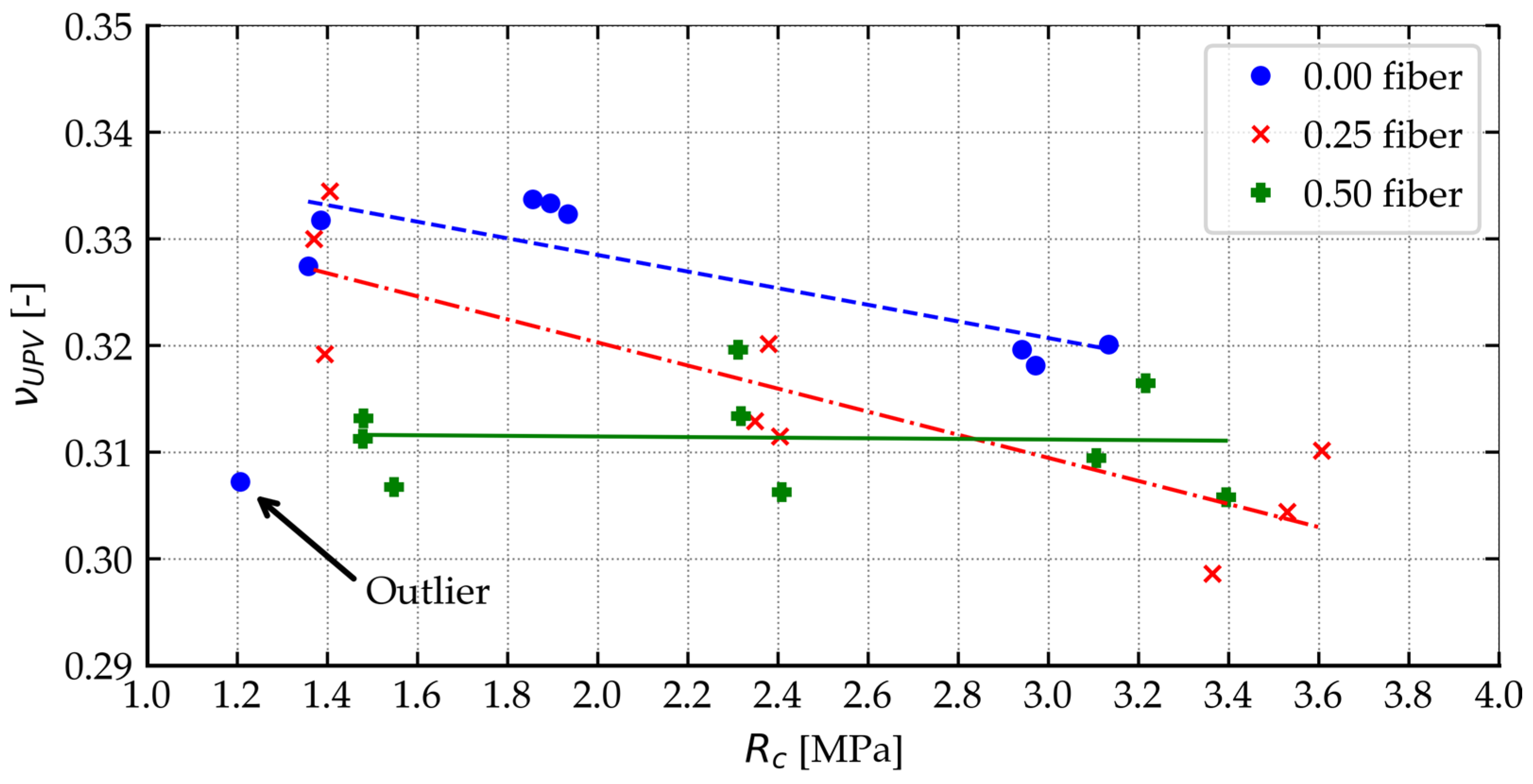

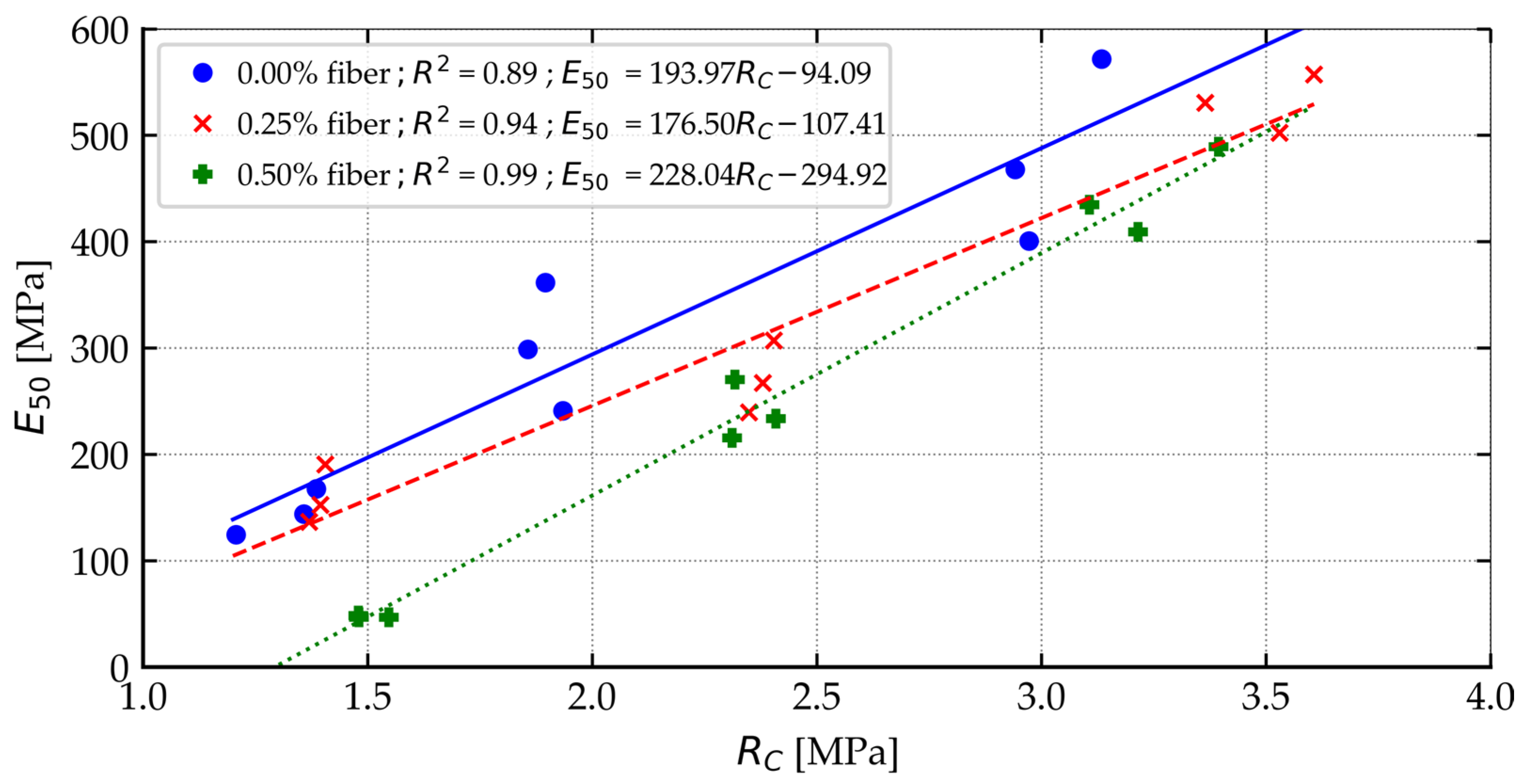

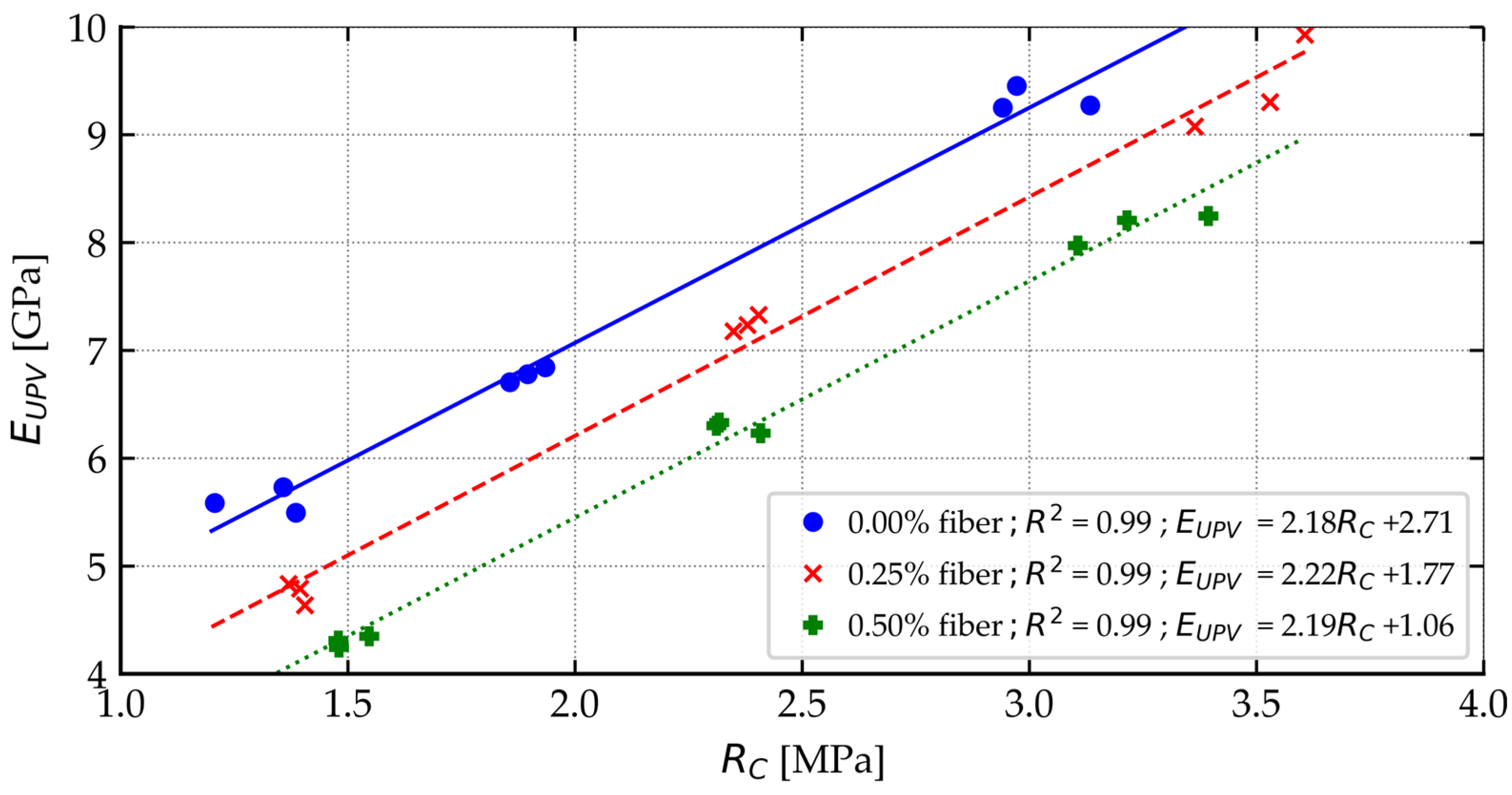

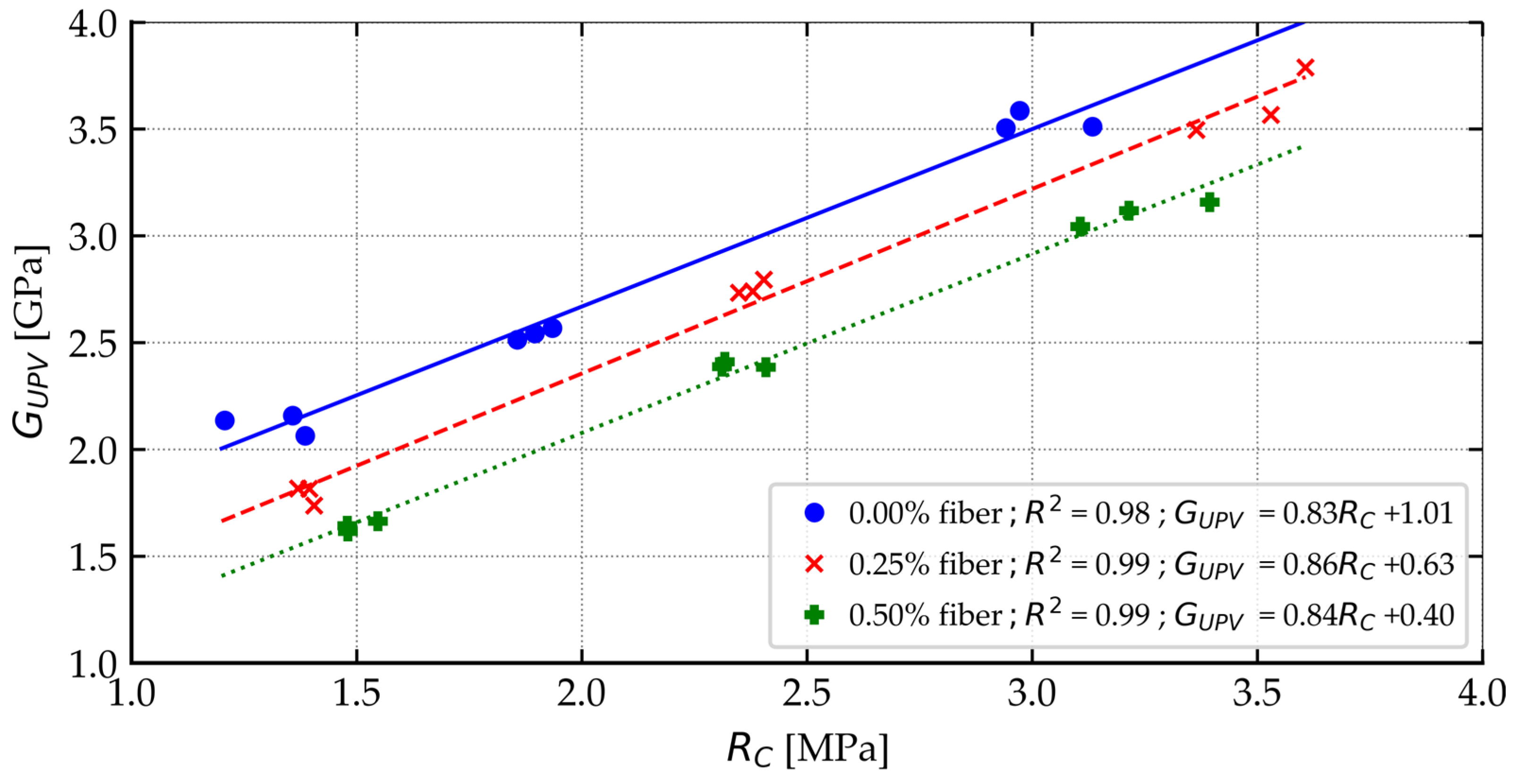

3.3. Prediction of Deformation Parameters

4. Discussion

- The inclusion of polypropylene fibers in the cement-treated soil mixture may lead to a loosening of its microstructure. This is a likely cause, as the use of polypropylene fibers decreased the dry unit weight, which in turn increased the porosity of the compacted mixture. Consequently, a more porous and less homogeneous cement-ground structure may have a lower stiffness, which translates into a reduction in the value of the deformation modulus.

- A smooth and hydrophobic surface characterizes polypropylene fibers, so the bond between the fiber and the cement matrix may be limited. Such factors can form a zone with weaker cohesion, making it more susceptible to microcracks. As a consequence, the fibers may slip out or detach from the cement matrix before the test material reaches complete failure.

- Polypropylene fibers can affect the homogeneity of the cement-ground mixture, especially when using a higher amount of dispersed reinforcement or longer fibers. In such cases, the risk of forming local aggregations of dispersed reinforcement increases, which can lead to local weakening of the material. The effect of such a phenomenon can be a reduction in the modulus of elasticity of the test material.

5. Conclusions

- The addition of polypropylene fibers reduced the maximum dry density of the mixtures, regardless of the cement content used.

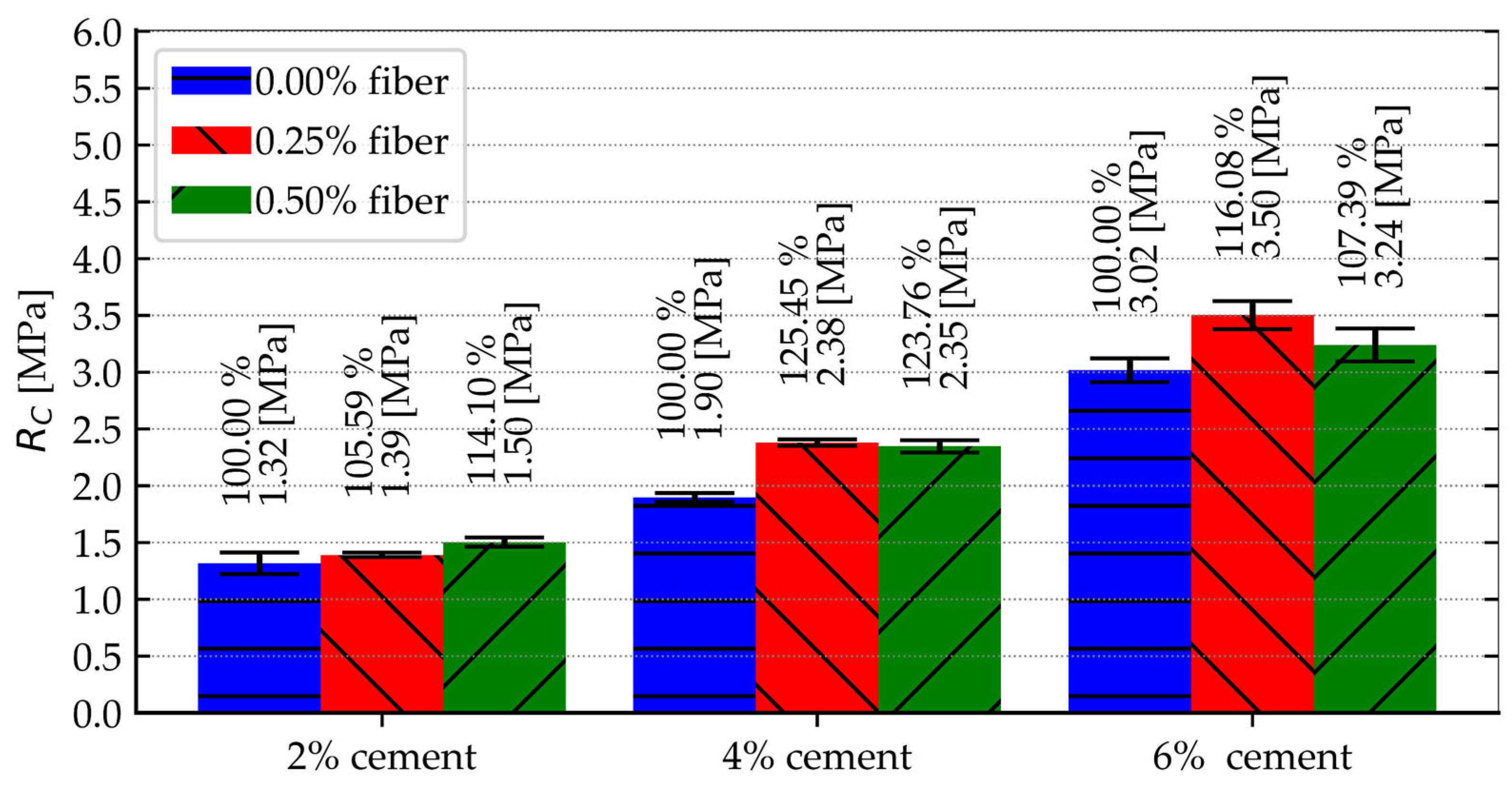

- The use of polypropylene fibers increased the unconfined compressive strength of cement-stabilized soil. The increase ranged from 5.59% to 25.45%, with the greatest enhancement observed in mixtures containing 4% cement.

- The use of polypropylene fibers allowed for a significant reduction in the amount of cement without reducing the compressive strength of the tested material. The implementation of reduced the cement content by 20.4%, while increasing to 1.0% reduced it by as much as 25.12%.

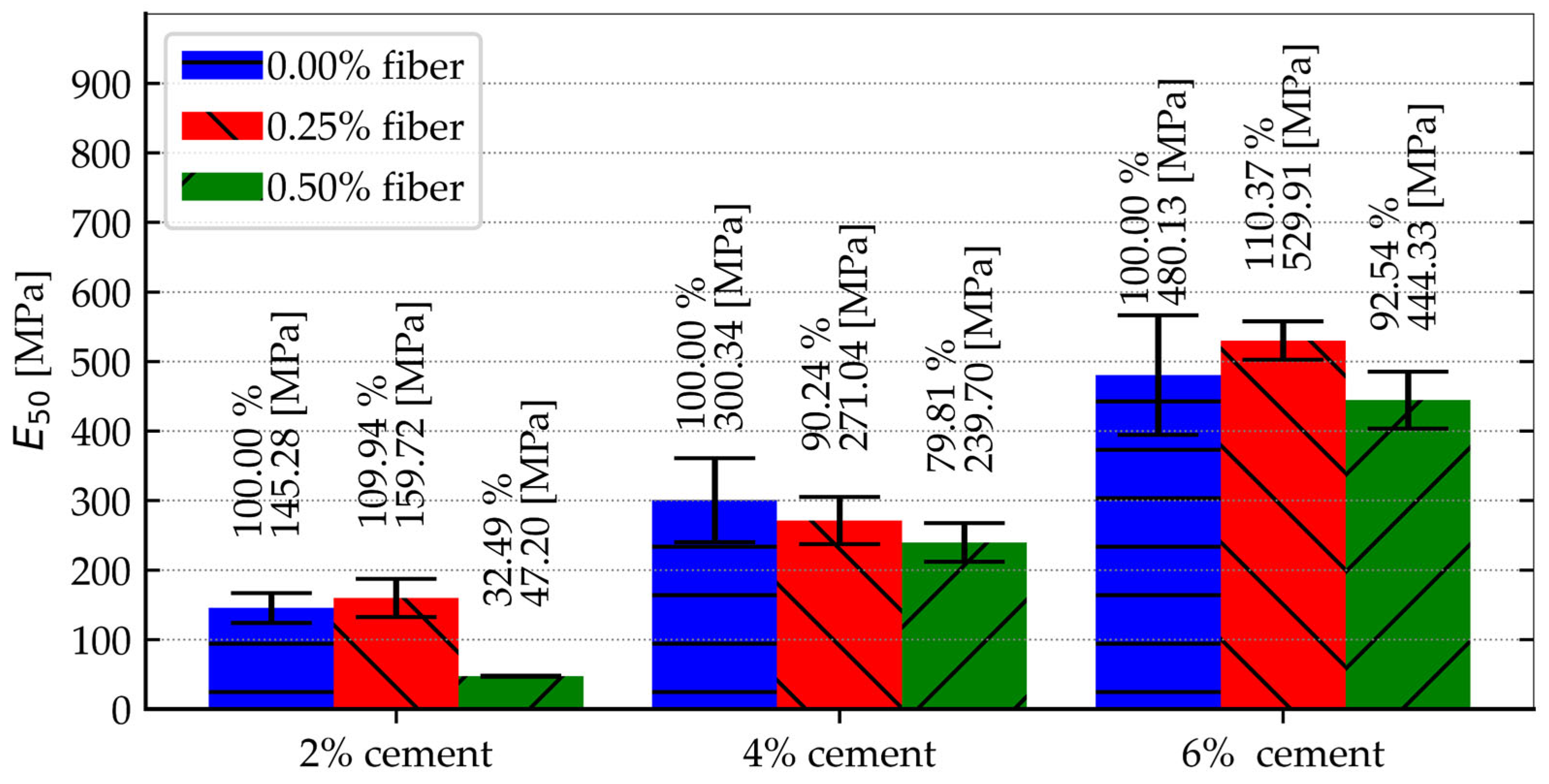

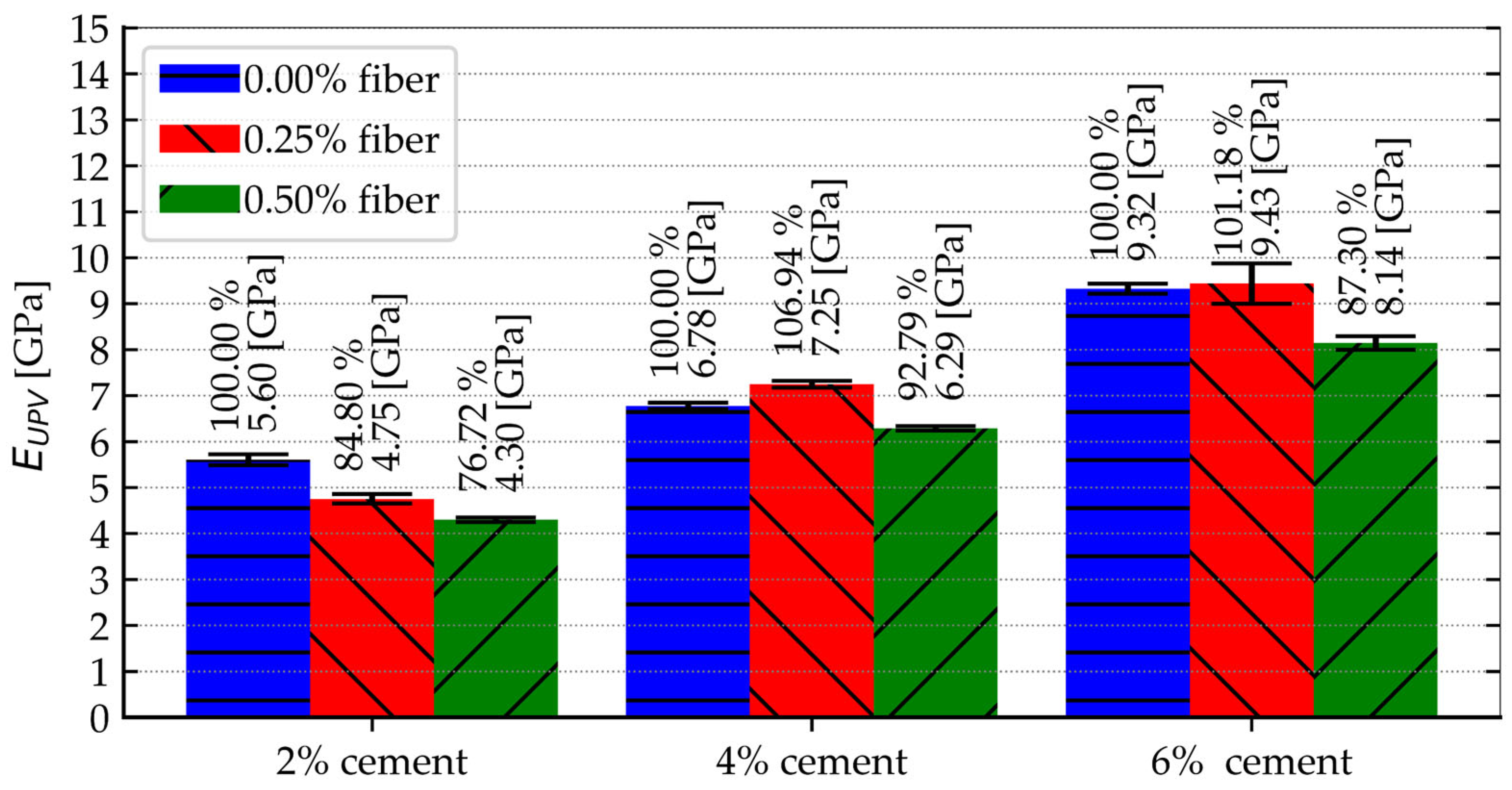

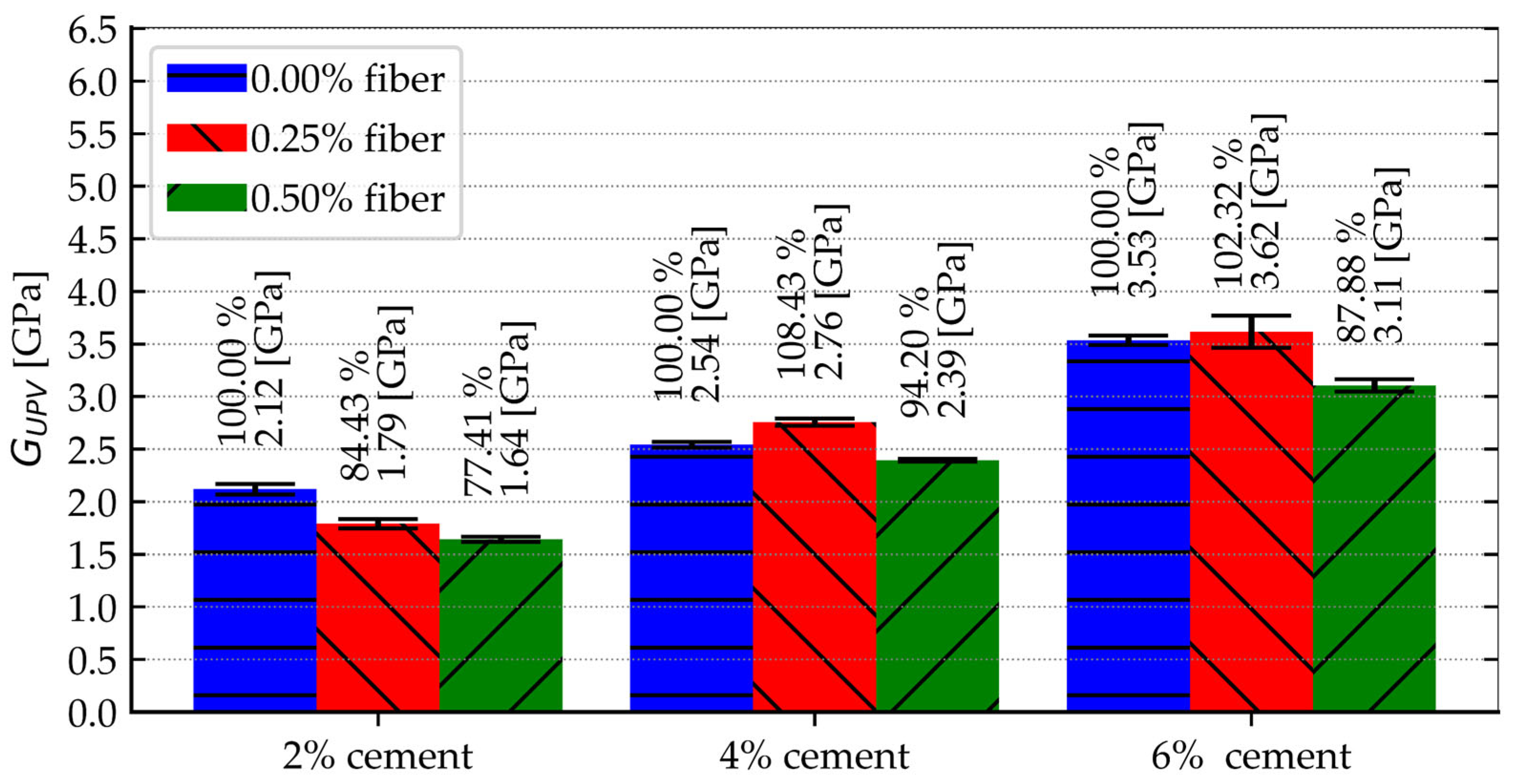

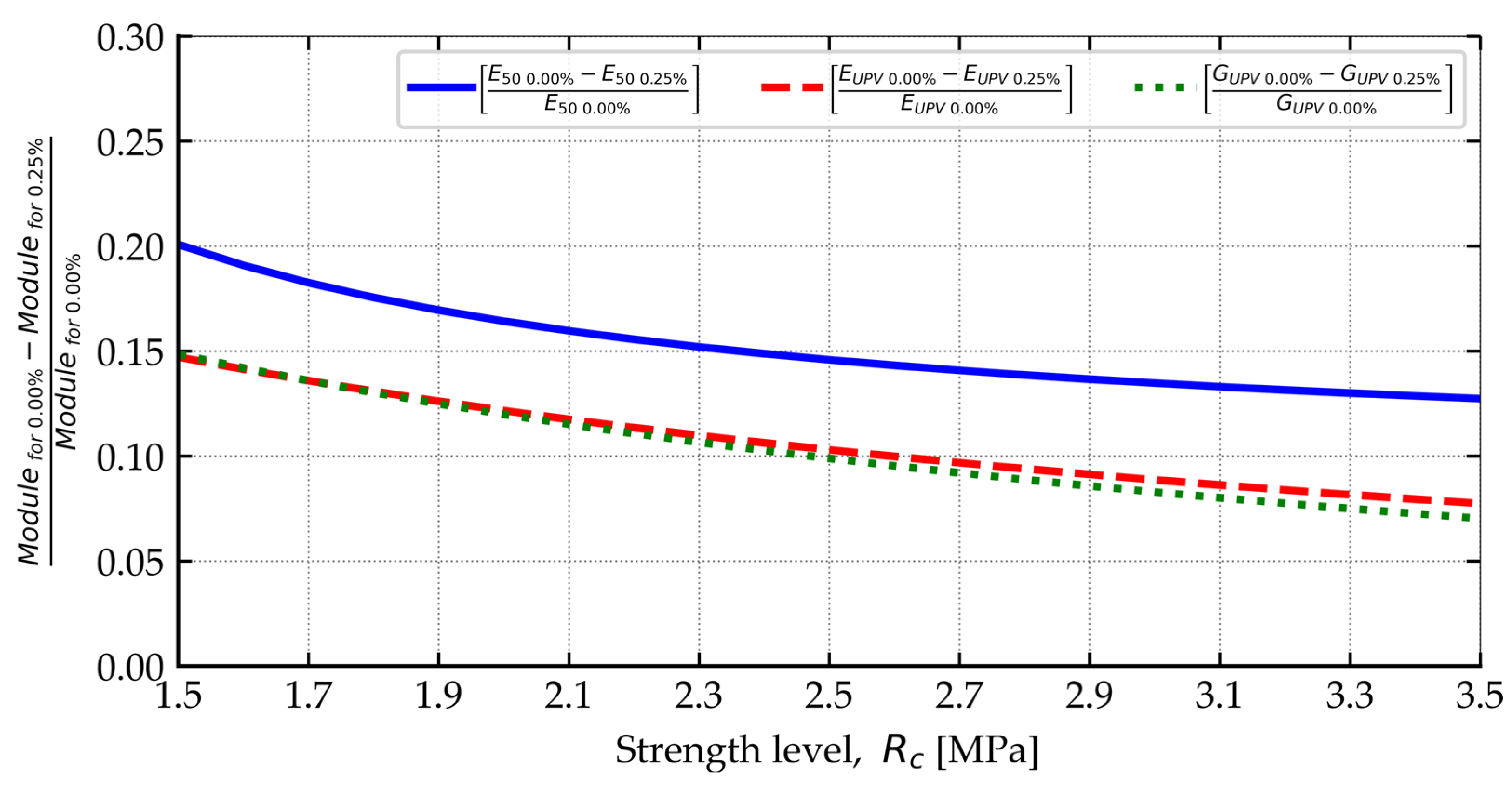

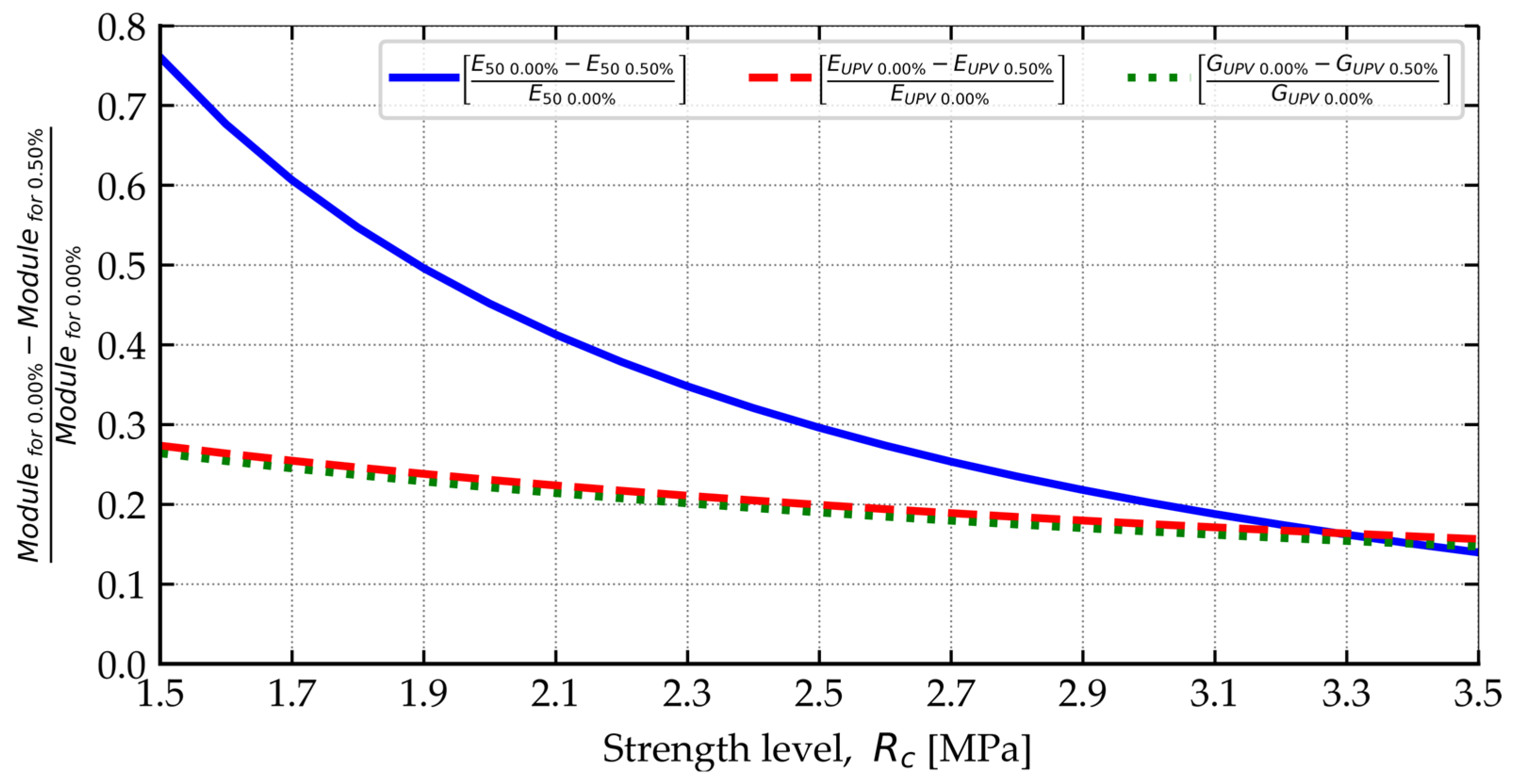

- The addition of polypropylene fibers in the amount of 0.5% caused a decrease in the values of deformation moduli: (7.46–67.51%), (7.21–23.28%), and (5.8–22.59%). For a fiber content of 0.25%, the results were inconclusive.

- The Poisson’s ratio decreased slightly as the compressive strength of the stabilized soil increased, with the addition of polypropylene fibers further contributing to its decrease.

- The use of porosity, cement, and reinforcement indexes allowed accurate prediction of the compressive strength of soil stabilized with the addition of polypropylene fibers, which confirmed the validity of this approach.

- Polypropylene fibers significantly affected the relationship between unconfined compressive strength and deformation parameters. Their presence decreased the value of elastic moduli with respect to the unit compressive strength, which indicated a modification of the material’s deformation properties. This effect intensified as the content of dispersed reinforcement increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of Soil Stabilization. Geo-Engineering 2017, 8, 26. [Google Scholar] [CrossRef]

- ACI Committee 230 State-of-the-Art Report on Soil Cement. ACI Mater. J. 1990, 87, 395–417. [CrossRef]

- Myers, B. Road Stabilization with Portland Cement. In Proceedings of the Twenty-Fifth Annual Road School; Engineering Extension Department, Extension Series No. 44; Purdue University: Lafayette, IN, USA, 1939; pp. 93–100. Available online: https://docs.lib.purdue.edu/roadschool/1939/proceedings/15 (accessed on 1 June 2025).

- Petry, T.M.; Little, D.N. Review of Stabilization of Clays and Expansive Soils in Pavements and Lightly Loaded Structures—History, Practice, and Future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Askarani, K.K.; Pakbaz, M.S. Drained Shear Strength of Over-Consolidated Compacted Soil-Cement. J. Mater. Civ. Eng. 2016, 28, 04015207. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Hara, Y.; Kitazume, M.; Negm, A. Unconfined Compressive Strength of Compacted Disturbed Cement-Stabilized Soft Clay. Int. J. Geosynth. Ground Eng. 2016, 2, 28. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.A. Comparison of Energy Consumption and Carbon Emissions from Clinker and Recycled Cement Production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 Emissions from Cement Production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, R.K. Effect of Addition of Construction–Demolition Waste on Strength Characteristics of High Plastic Clays. Innov. Infrastruct. Solut. 2019, 4, 27. [Google Scholar] [CrossRef]

- da Conceição Leite, F.; dos Santos Motta, R.; Vasconcelos, K.L.; Bernucci, L. Laboratory Evaluation of Recycled Construction and Demolition Waste for Pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Gabryś, K.; Soból, E.; Sas, W. Physical, Deformation, and Stiffness Properties of Recycled Concrete Aggregate. Sustainability 2021, 13, 4245. [Google Scholar] [CrossRef]

- Xiao, H.; Shen, W.; Lee, F.H. Engineering Properties of Marine Clay Admixed with Portland Cement and Blended Cement with Siliceous Fly Ash. J. Mater. Civ. Eng. 2017, 29, 04017177. [Google Scholar] [CrossRef]

- Rios, S.; Cristelo, N.; Viana da Fonseca, A.; Ferreira, C. Stiffness Behavior of Soil Stabilized with Alkali-Activated Fly Ash from Small to Large Strains. Int. J. Geomech. 2017, 17, 04016087. [Google Scholar] [CrossRef]

- Brand, A.S.; Singhvi, P.; Fanijo, E.O.; Tutumluer, E. Stabilization of a Clayey Soil with Ladle Metallurgy Furnace Slag Fines. Materials 2020, 13, 4251. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, H.H.; Shahin, M.A.; Walske, M.L. Review of Fly-Ash-Based Geopolymers for Soil Stabilisation with Special Reference to Clay. Geosciences 2020, 10, 249. [Google Scholar] [CrossRef]

- Disu, A.A.; Kolay, P.K. A Critical Appraisal of Soil Stabilization Using Geopolymers: The Past, Present and Future. Int. J. Geosynth. Ground Eng. 2021, 7, 23. [Google Scholar] [CrossRef]

- Amaludin, A.E.; Asrah, H.; Mohamad, H.M.; Bin Amaludin, H.Z.; Bin Amaludin, N.A. Physicochemical and Microstructural Characterization of Klias Peat, Lumadan POFA, and GGBFS for Geopolymer Based Soil Stabilization. HighTech. Innov. J. 2023, 4, 327–348. [Google Scholar] [CrossRef]

- Miturski, M.; Sas, W.; Radzevičius, A.; Šadzevičius, R.; Skominas, R.; Stelmaszczyk, M.; Głuchowski, A. Effect of Dispersed Reinforcement on Ultrasonic Pulse Velocity in Stabilized Soil. Materials 2021, 14, 6951. [Google Scholar] [CrossRef]

- Festugato, L.; Menger, E.; Benezra, F.; Kipper, E.A.; Consoli, N.C. Fibre-Reinforced Cemented Soils Compressive and Tensile Strength Assessment as a Function of Filament Length. Geotext. Geomembr. 2017, 45, 77–82. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Ulbrich, L.A. Influence of Fiber and Cement Addition on Behavior of Sandy Soil. J. Geotech. Geoenviron. Eng. 1998, 124, 1211–1214. [Google Scholar] [CrossRef]

- Su, Y.; Luo, B.; Luo, Z.; Xu, F.; Huang, H.; Long, Z.; Shen, C. Mechanical Characteristics and Solidification Mechanism of Slag/Fly Ash-Based Geopolymer and Cement Solidified Organic Clay: A Comparative Study. J. Build. Eng. 2023, 71, 106459. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of Geopolymers with Construction and Demolition Waste (CDW) Aggregates as a Building Material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- Alelvan, G.M.; Ferreira, J.W.D.S.; Casagrande, M.D.T.; Consoli, N.C. Proposal of New Construction Material: Polymer-Stabilized Gold Ore Tailings Composite. Sustainability 2022, 14, 13648. [Google Scholar] [CrossRef]

- Maher, M.H.; Gray, D.H. Static Response of Sands Reinforced with Randomly Distributed Fibers. J. Geotech. Eng. 1990, 116, 1661–1677. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance Evaluation of Silty Sand Reinforced with Fibres. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Gray, D.H.; Maher, M.H. Admixture Stabilization of Sands with Random Fibers. In Proceedings of the International Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Brazil, 13–18 August 1989; Volume 2, pp. 1363–1366. [Google Scholar]

- Maher, M.H. Static and Dynamic Force Response of Sands Reinforced with Discrete, Randomly Distributed Fibers. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 1988. [Google Scholar]

- Gray, D.H.; Al-Refeai, T. Behavior of Fabric-Versus Fiber-Reinforced Sand. J. Geotech. Eng. 1986, 112, 804–820. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A Simple Review of Soil Reinforcement by Using Natural and Synthetic Fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Jamshidi, R.; Towhata, I.; Ghiassian, H.; Tabarsa, A.R. Experimental Evaluation of Dynamic Deformation Characteristics of Sheet Pile Retaining Walls with Fiber Reinforced Backfill. Soil Dyn. Earthq. Eng. 2010, 30, 438–446. [Google Scholar] [CrossRef]

- Ghiassian, H.; Jamshidi, R.; Tabarsa, A.R. Dynamic Performance of Toyoura Sand Reinforced with Randomly Distributed Carpet Waste Strips. In Proceedings of the Geotechnical Earthquake Engineering and Soil Dynamics IV, Sacramento, CA, USA, 18–22 May 2008; American Society of Civil Engineers: Sacramento, CA, USA, 2008; pp. 1–13. [Google Scholar]

- Lukiantchuki, J.A.; de Oliveira, J.R.M.d.S.; de Almeida, M.S.S.; dos Reis, J.H.C.; Silva, T.B.; Guideli, L.C. Geotechnical Behavior of Construction Waste (CW) as a Partial Replacement of a Lateritic Soil in Fiber-Reinforced Cement Mixtures. Geotech. Geol. Eng. 2021, 39, 919–942. [Google Scholar] [CrossRef]

- Tang, C.-S.; Shi, B.; Zhao, L.-Z. Interfacial Shear Strength of Fiber Reinforced Soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and Mechanical Behavior of Short Polypropylene Fiber Reinforced and Cement Stabilized Clayey Soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Chen, M.; Shen, S.-L.; Arulrajah, A.; Wu, H.-N.; Hou, D.-W.; Xu, Y.-S. Laboratory Evaluation on the Effectiveness of Polypropylene Fibers on the Strength of Fiber-Reinforced and Cement-Stabilized Shanghai Soft Clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Tran, K.Q.; Satomi, T.; Takahashi, H. Improvement of Mechanical Behavior of Cemented Soil Reinforced with Waste Cornsilk Fibers. Constr. Build. Mater. 2018, 178, 204–210. [Google Scholar] [CrossRef]

- Olgun, M. Effects of Polypropylene Fiber Inclusion on the Strength and Volume Change Characteristics of Cement-Fly Ash Stabilized Clay Soil. Geosynth. Int. 2013, 20, 263–275. [Google Scholar] [CrossRef]

- Fatahi, B.; Khabbaz, H.; Fatahi, B. Mechanical Characteristics of Soft Clay Treated with Fibre and Cement. Geosynth. Int. 2012, 19, 252–262. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K.; Shekhwat, P. Strength Behaviour of Clayey Soil Mixed with Pond Ash, Cement and Randomly Distributed Fibres. Transp. Infrastruct. Geotech. 2018, 5, 191–209. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.W.; Tang, C. Effect of Polypropylene Fibre and Lime Admixture on Engineering Properties of Clayey Soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

- Consoli, N.C.; Vendruscolo, M.A.; Fonini, A.; Rosa, F.D. Fiber Reinforcement Effects on Sand Considering a Wide Cementation Range. Geotext. Geomembr. 2009, 27, 196–203. [Google Scholar] [CrossRef]

- Hamidi, A.; Hooresfand, M. Effect of Fiber Reinforcement on Triaxial Shear Behavior of Cement Treated Sand. Geotext. Geomembr. 2013, 36, 1–9. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, C.; Guo, J.; Li, N.; Li, Y.; Zhou, H.; Liu, Y. Investigation on the Triaxial Mechanical Characteristics of Cement-Treated Subgrade Soil Admixed with Polypropylene Fiber. Appl. Sci. 2019, 9, 4557. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Venda Oliveira, P.J.; Custódio, D.G. Effect of Polypropylene Fibres on the Compressive and Tensile Strength of a Soft Soil, Artificially Stabilised with Binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- De Paula, T.M.; Consoli, N.C.; Festugato, L.; Favretto, F.; Daronco, J.V.L. Behaviour of Fibre-Reinforced Cemented Sand under Flexural Tensile Stress. E3S Web Conf. 2019, 92, 12005. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural Behavior Evaluation and Energy Dissipation Mechanisms of Modified Iron Tailings Powder Incorporating Cement and Fibers Subjected to Freeze-Thaw Cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- Zhang, J.; Weng, X.-Z.; Liu, J.-Z. Strength and Water Stability of a Fiber-Reinforced Cemented Loess. J. Eng. Fibers Fabr. 2018, 13, 155892501801300. [Google Scholar] [CrossRef]

- Gupta, D.; Kumar, A. Strength Characterization of Cement Stabilized and Fiber Reinforced Clay–Pond Ash Mixes. Int. J. Geosynth. Ground Eng. 2016, 2, 32. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of Cement-Stabilized Fiber-Reinforced Pond Ash, Rice Husk Ash–Soil Mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Yuan, Y.Q.; Guo, T.; Li, X.C.; Li, W. Performances of Sandy Soil Stabilization with Fiber and Cement. Appl. Mech. Mater. 2013, 438–439, 266–269. [Google Scholar] [CrossRef]

- Cristelo, N.; Cunha, V.M.C.F.; Dias, M.; Gomes, A.T.; Miranda, T.; Araújo, N. Influence of Discrete Fibre Reinforcement on the Uniaxial Compression Response and Seismic Wave Velocity of a Cement-Stabilised Sandy-Clay. Geotext. Geomembr. 2015, 43, 1–13. [Google Scholar] [CrossRef]

- Zhao, J.; Zong, Z.; Cen, H.; Jiang, P. Analysis of Mechanical Properties of Fiber-Reinforced Soil Cement Based on Kaolin. Materials 2024, 17, 2153. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Fonseca, A.V.; Silva, S.R.; Cruz, R.C.; Fonini, A. Parameters Controlling Stiffness and Strength of Artificially Cemented Soils. Géotechnique 2012, 62, 177–183. [Google Scholar] [CrossRef]

- Baldovino, J.D.J.A.; Izzo, R.L.D.S.; Pereira, M.D.; Rocha, E.V.D.G.; Rose, J.L.; Bordignon, V.R. Equations Controlling Tensile and Compressive Strength Ratio of Sedimentary Soil–Cement Mixtures under Optimal Compaction Conditions. J. Mater. Civ. Eng. 2020, 32, 04019320. [Google Scholar] [CrossRef]

- Moreira, E.B.; Baldovino, J.A.; Rose, J.L.; Luis Dos Santos Izzo, R. Effects of Porosity, Dry Unit Weight, Cement Content and Void/Cement Ratio on Unconfined Compressive Strength of Roof Tile Waste-Silty Soil Mixtures. J. Rock Mech. Geotech. Eng. 2019, 11, 369–378. [Google Scholar] [CrossRef]

- Consoli, N.C.; Vaz Ferreira, P.M.; Tang, C.-S.; Veloso Marques, S.F.; Festugato, L.; Corte, M.B. A Unique Relationship Determining Strength of Silty/Clayey Soils—Portland Cement Mixes. Soils Found. 2016, 56, 1082–1088. [Google Scholar] [CrossRef]

- Consoli, N.C.; Arcari Bassani, M.A.; Festugato, L. Effect of Fiber-Reinforcement on the Strength of Cemented Soils. Geotext. Geomembr. 2010, 28, 344–351. [Google Scholar] [CrossRef]

- Rios, S.; Viana Da Fonseca, A.; Baudet, B.A. Effect of the Porosity/Cement Ratio on the Compression of Cemented Soil. J. Geotech. Geoenviron. Eng. 2012, 138, 1422–1426. [Google Scholar] [CrossRef]

- Stracke, F.; Jung, J.G.; Korf, E.P.; Consoli, N.C. The Influence of Moisture Content on Tensile and Compressive Strength of Artificially Cemented Sand. Soils Rocks 2012, 35, 303–308. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Da Silva Lopes, L.; Winter, D. Control Factors for the Long Term Compressive Strength of Lime Treated Sandy Clay Soil. Transp. Geotech. 2014, 1, 129–136. [Google Scholar] [CrossRef]

- Miturski, M. Influence of Porosity and Cement Index on the Strength of Cement-Stabilized Soil. Mod. Eng. 2024, 4, 1–10. [Google Scholar]

- ISO 12154; Determination of Density by Volumetric Displacement-Skeleton Density by Gas Pycnometry. ISO: Geneva, Switzerland, 2014.

- Witkowska-Dobrev, J.; Szlachetka, O.; Francke, B.; Chyliński, F.; Małek, M.; Šadzevičius, R.; Ramukevičius, D.; Frąk, M.; Dzięcioł, J.; Kruszewski, M.; et al. Effect of Different Water-Cement Ratios on the Durability of Prefabricated Concrete Tanks Exposed to Acetic Acid Aggression. J. Build. Eng. 2023, 78, 107712. [Google Scholar] [CrossRef]

- PN-EN 12504-4:2021; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. PKN: Warsaw, Poland, 2021; ISBN 83-243-7731-X.

- Operating Instructions Pundit Lab/Pundit Lab+ Ultrasonic Instrument 2017. Available online: https://media.screeningeagle.com/asset/Downloads/Pundit%20Lab_Operating%20Instructions_English_high.pdf (accessed on 1 June 2025).

- PN-EN ISO 16810:2014; Non-Destrutive Testing—Ultrasonic Testing—General Principles. PKN: Warsaw, Poland, 2014.

- PN-EN 14227-15:2015; Hydraulically Bound Mixtures—Specifications—Part 15: Hydraulically Stabilized Soils. PKN: Warsaw, Poland, 2015; ISBN 978-83-275-5451-2.

- Miturski, M.; Głuchowski, A.; Sas, W. Influence of Dispersed Reinforcement on Mechanical Properties of Stabilized Soil. Materials 2021, 14, 5982. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Widianti, A.; Hartono, E.; Diana, W. Engineering Properties of Silty Soil Stabilized with Lime and Rice Husk Ash and Reinforced with Waste Plastic Fiber. J. Mater. Civ. Eng. 2013, 25, 1260–1270. [Google Scholar] [CrossRef]

- Consoli, N.C.; Marques, S.F.V.; Sampa, N.C.; Bortolotto, M.S.; Siacara, A.T.; Nierwinski, H.P.; Pereira, F.; Festugato, L. A General Relationship to Estimate Strength of Fibre-Reinforced Cemented Fine-Grained Soils. Geosynth. Int. 2017, 24, 435–441. [Google Scholar] [CrossRef]

- Rios, S.; Viana da Fonseca, A. Porosity/Cement Index to Evaluate Geomechanical Properties of an Artificial Cemented Soil. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering: Challenges and Innovations in Geotechnics, ICSMGE 2013, Paris, France, 2–6 September 2013; Volume 3, pp. 2589–2592. [Google Scholar]

- Román Martínez, C.; Nuñez De La Rosa, Y.E.; Estrada Luna, D.; Baldovino, J.A.; Jordi Bruschi, G. Strength, Stiffness, and Microstructure of Stabilized Marine Clay-Crushed Limestone Waste Blends: Insight on Characterization through Porosity-to-Cement Index. Materials 2023, 16, 4983. [Google Scholar] [CrossRef] [PubMed]

- Santana, T.; Gonçalves, J.; Pinho, F.; Micaelo, R. Effects of the Ratio of Porosity to Volumetric Cement Content on the Unconfined Compressive Strength of Cement Bound Fine Grained Soils. Infrastructures 2021, 6, 96. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Prediction of Combined Effects of Fibers and Cement on the Mechanical Properties of Sand Using Particle Swarm Optimization Algorithm. J. Adhes. Sci. Technol. 2015, 29, 487–501. [Google Scholar] [CrossRef]

| Properties of Soil | Value | Units |

|---|---|---|

| Cc | 5.33 | (-) |

| Cu | 75 | (-) |

| PI | 9.15 | (-) |

| WL | 19.03 | (%) |

| WP | 9.88 | (%) |

| MDD | 1.98 | (g∙cm−3) |

| OMC | 8.64 | (%) |

| GS | 2.66 | (g∙cm−3) |

| Properties | Value | Units |

|---|---|---|

| Binder type | Composite cement | (-) |

| Designation | CEM V/A (S-V) 32,5 R-LH | (-) |

| GC | 2.97 | (g∙cm−3) |

| Cement component | Content Range | Units |

| Portland cement clinker | 40–64 | (%) |

| Granulated blast furnace slag | 18–30 | (%) |

| Siliceous fly ash | 18–30 | (%) |

| Minor constituent | 0–5 | (%) |

| Required compressive strength | Value | Units |

| After 2 days | ≥10.0 | (MPa) |

| After 28 days | ≥32.5 | (MPa) |

| Properties | Value | Units |

|---|---|---|

| Manufacturer | Belgian Fibers NV | (-) |

| Material | Polypropylene (PP) | (-) |

| Length | 12 | (mm) |

| Diameter | 34 | (μm) |

| Tensile strength | 40 | |

| GF | 0.92 | (g∙cm−3) |

| Indication of the Mixture (-) | Cement—C (%) | Fiber—F (%) |

|---|---|---|

| C20 | 2.0 | 0.00 |

| C21 | 2.0 | 0.25 |

| C22 | 2.0 | 0.50 |

| C40 | 4.0 | 0.00 |

| C41 | 4.0 | 0.25 |

| C42 | 4.0 | 0.50 |

| C60 | 6.0 | 0.00 |

| C61 | 6.0 | 0.25 |

| C62 | 6.0 | 0.50 |

| Parameter | Value | Units |

|---|---|---|

| Measurement length | 0.1–9999 | (µs) |

| Resolution | 0.1 | (µs) |

| Frequency | 24, 37, 54, 82, 150, 200, 220, 250, 500 | (kHz) |

| Voltage | 125, 250, 350, 500 | (v) |

| Used excitation voltage | 250 | (v) |

| Calibration time offset | 5.6 | (µs) |

| Parameter | Value | Units |

|---|---|---|

| Accuracy of force measurement | ±0.5 | (%) |

| Accuracy of displacement measurement | ±0.01 | (mm) |

| Accuracy of load speed | ±0.1 | (%) |

| Frequency of data recording | 2.5 | (kHz) |

| Load speed | 0.05 | (N·mm−2·s−1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miturski, M.; Dzięcioł, J.; Szlachetka, O. Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand. Sustainability 2025, 17, 5803. https://doi.org/10.3390/su17135803

Miturski M, Dzięcioł J, Szlachetka O. Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand. Sustainability. 2025; 17(13):5803. https://doi.org/10.3390/su17135803

Chicago/Turabian StyleMiturski, Maciej, Justyna Dzięcioł, and Olga Szlachetka. 2025. "Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand" Sustainability 17, no. 13: 5803. https://doi.org/10.3390/su17135803

APA StyleMiturski, M., Dzięcioł, J., & Szlachetka, O. (2025). Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand. Sustainability, 17(13), 5803. https://doi.org/10.3390/su17135803