1. Introduction

Limiting global temperature rise to 1.5 °C above pre-industrial levels consistent with the goals of the Paris Agreement requires a 45% reduction in greenhouse gas emissions by 2030 and achieving net-zero emissions by mid-century [

1]. CO

2, predominantly resulting from fossil fuel combustion and industrial activities, constitutes approximately 76% of global greenhouse gas emissions, underscoring the urgent need for scalable decarbonization strategies across energy and industrial sectors [

2,

3].

Among the most promising technologies for deep decarbonization are carbon capture and storage (CCS) and hydrogen storage. CCS has demonstrated the potential to reduce CO

2 emissions from industrial sources by 85–95%, offering a critical lever for mitigating hard-to-abate emissions [

4]. Meanwhile, hydrogen, especially low-carbon “blue hydrogen”, produced via steam methane reforming (SMR) integrated with CCS provides a versatile energy carrier capable of decarbonizing sectors ranging from heavy industry to long-haul transport [

5]. The integration of CCS with hydrogen production presents significant synergies, including shared infrastructure such as pipelines, geological storage sites, and processing facilities, which can lower system-wide costs by 30–60% [

6,

7].

The scalability and efficiency of these integrated systems are being further enhanced through artificial intelligence (AI). AI-driven tools encompassing predictive modeling, real-time anomaly detection, and intelligent optimization are enabling more efficient capture, transport, and monitoring of CO

2 and hydrogen flows [

8,

9]. Early implementations, such as at Petra Nova and Fukushima FH2R, have reported efficiency improvements of 10–30% through AI integration [

10,

11].

This review provides a comprehensive synthesis of the technical, economic, and policy dimensions shaping the deployment of integrated CCS–hydrogen systems. With a particular focus on AI-enabled innovations, we examine current challenges including high capture costs (USD 50–100 per ton of CO2) and energy penalties (20–40%) and explore emerging opportunities for system optimization and cost reduction. Drawing on global case studies and evolving policy frameworks, including the European Union’s EUR 7 billion Hydrogen Strategy, this paper proposes a digitally augmented, scalable pathway toward a sustainable, net-zero energy future.

1.1. Climate Change Context and the Need for Decarbonization

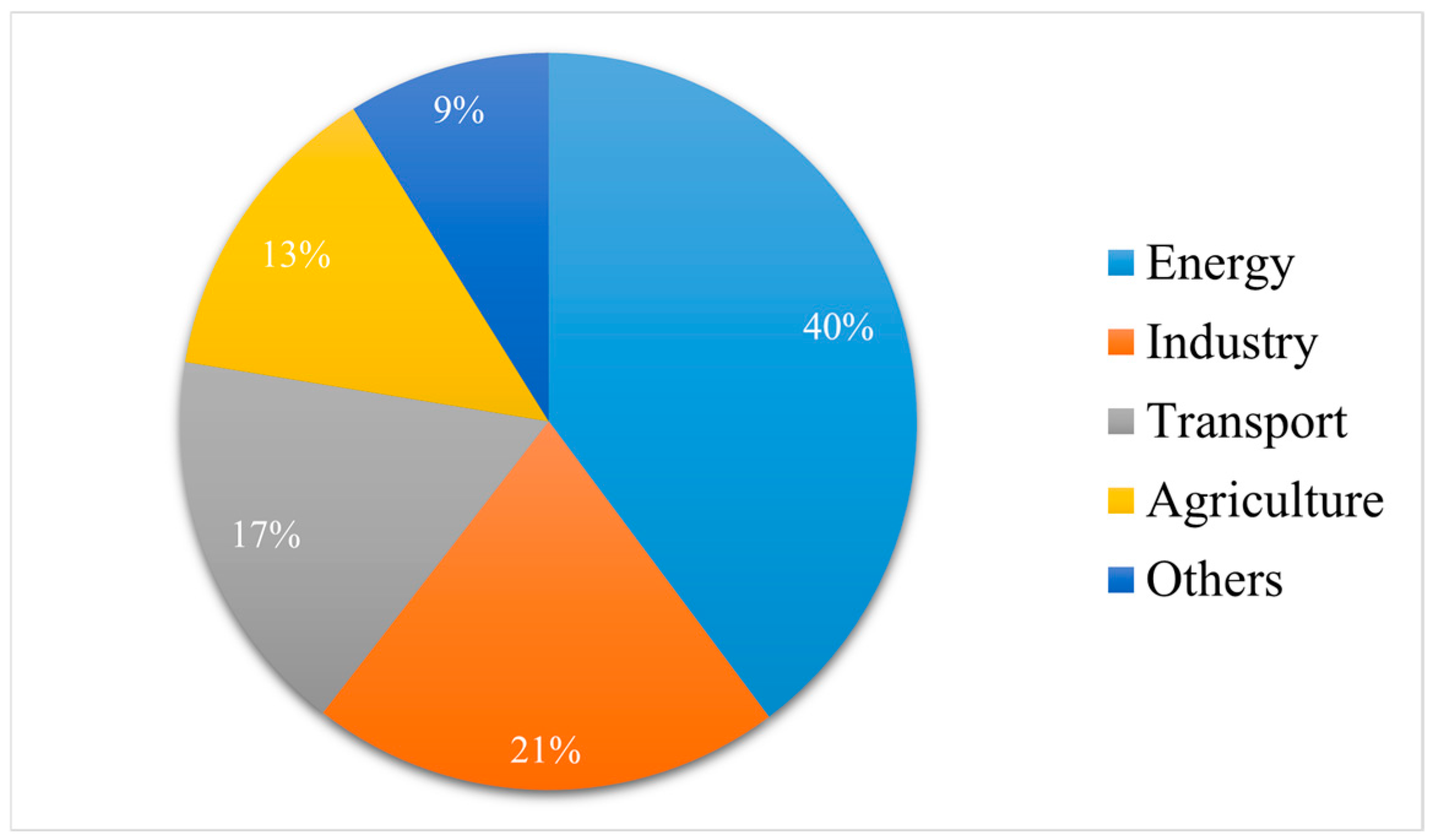

Anthropogenic CO

2 emissions primarily driven by energy production (34%), industrial processes (31%), and transportation (15%) remain the leading cause of global climate change [

12,

13]. In 2023, atmospheric CO

2 concentrations reached 420 ppm, representing a 50% increase from pre-industrial levels in 1750 [

14]. This rapid accumulation of greenhouse gases has intensified global warming, with the Intergovernmental Panel on Climate Change (IPCC) projecting temperature increases of 3–5 °C by 2100 in the absence of decisive mitigation measures. Such warming trajectories threaten to exacerbate extreme weather events, accelerate sea-level rise, and drive irreversible biodiversity loss [

15,

16].

To curb these impacts, deep decarbonization across all sectors is imperative. CCS plays a pivotal role in reducing emissions from hard-to-abate industries such as cement, steel, and chemicals, where alternative low-carbon technologies are limited or cost-prohibitive [

17]. The International Energy Agency (IEA) estimates that CCS could capture up to 7 gigatons (Gt) of CO

2 annually by 2050, making it a cornerstone technology for achieving net-zero emissions [

18].

Simultaneously, hydrogen particularly low-carbon “blue” and zero-emission “green” hydrogen offers a versatile energy carrier with a high gravimetric energy density (~120 MJ/kg), positioning it as a key enabler for sectoral decarbonization. Hydrogen can support long-duration energy storage, decarbonize heavy transport, and replace fossil fuels in industrial heat applications [

19].

The strategic integration of CCS and hydrogen storage systems not only enhances emission reductions but also unlocks synergistic benefits in infrastructure sharing, cost efficiency, and system resilience. As explored in detail in

Section 4, this integration represents a promising pathway toward achieving global net-zero goals [

20].

For better understanding,

Figure 1 illustrates the distribution of global CO

2 emissions by sector in 2023, underscoring the urgent need for scalable decarbonization strategies such as CCS and hydrogen-based solutions.

1.2. Role of CCS and Hydrogen Storage in Low-Carbon Energy Systems

CCS is a critical technology for reducing industrial CO

2 emissions at scale. The process involves capturing CO

2 from point sources such as power plants and industrial facilities, transporting it via pipelines or ships, and permanently storing it in deep geological formations such as saline aquifers or depleted oil and gas reservoirs with secure containment expected to last over 1000 years [

21,

22]. This capability makes CCS one of the few viable solutions for decarbonizing emission-intensive sectors like cement, steel, and chemical production [

4].

Hydrogen, meanwhile, serves as a flexible and high-energy-density energy carrier that can be produced through various pathways, including SMR and water electrolysis. It can be stored in compressed gaseous or liquefied form, enabling dispatchable energy supply for applications ranging from transportation to industrial heat and long-duration energy storage [

23].

Of particular strategic importance is blue hydrogen, which combines SMR with CCS to achieve emission reductions of up to 90% compared to conventional “gray” hydrogen [

24,

25]. Blue hydrogen leverages shared infrastructure such as CO

2 transport pipelines and subsurface storage sites offering a near-term, scalable solution for transitioning toward low-carbon energy systems [

26].

As detailed in

Section 2 (CCS) and

Section 3 (hydrogen storage), these technologies are not only technically mature but also highly complementary. Their integration, explored further in

Section 4, enables cost synergies, operational efficiencies, and accelerated deployment pathways, positioning them as cornerstones of future net-zero energy systems [

20].

1.3. AI as a Transformative Tool for Optimization

AI, encompassing techniques such as machine learning, neural networks, and reinforcement learning, is emerging as a transformative enabler for optimizing CCS and hydrogen storage systems [

8,

9,

27]. By leveraging data-driven modeling and real-time analytics, AI enhances system performance across the value chain, reducing energy consumption, enabling predictive maintenance, improving leak detection, and streamlining regulatory compliance [

28,

29].

Beyond technical optimization, AI also supports strategic decision-making and policy design by modeling techno-economic scenarios, forecasting infrastructure needs, and identifying risk factors in large-scale deployment. As explored in

Section 5, integrating AI across capture, transport, storage, and governance frameworks can significantly enhance the scalability, cost-effectiveness, and reliability of integrated CCS–hydrogen systems [

20].

This review underscores AI’s pivotal role in overcoming persistent technical and economic barriers, thereby accelerating industry adoption and advancing the transition toward a scalable, low-carbon energy future.

1.4. The Scope and Objectives of the Review

This review synthesizes the integration of CCS and hydrogen storage, focusing on AI-driven optimization to achieve efficiency and scalability. The objectives include the following:

Analyzing integration benefits, challenges, and requirements (

Section 4).

Proposing a scalable, AI-enhanced solution for decarbonization (

Section 9).

The manuscript addresses technical, economic, and social dimensions, providing a comprehensive resource for researchers, policymakers, and industry stakeholders.

Table 1 provides a summary of selected studies demonstrating AI applications in CCS, hydrogen systems, and their integration, highlighting efficiency and scalability improvements.

1.5. Novel Contributions of This Review

This review offers a distinctive contribution to the growing body of literature on decarbonization technologies by focusing on the integrated deployment of CCS and hydrogen systems enhanced through AI. The key novel contributions of this review include the following:

A systematic synthesis of CCS and hydrogen storage technologies, emphasizing their strategic integration for infrastructure optimization, cost reduction, and scalability.

A dedicated analysis of AI applications across CCS, hydrogen, and integrated systems, showcasing how machine learning, predictive modeling, and digital twins can enhance system efficiency, safety, and deployment readiness.

A unified presentation of global case studies (e.g., Petra Nova, Northern Lights, Fukushima FH2R, and H21 North) that illustrate real-world implementation of integrated systems with AI augmentation.

A forward-looking assessment of future trends and policy frameworks, highlighting innovation pathways, investment needs, and governance requirements for successful deployment.

The development of a scalable, AI-augmented roadmap for integrated CCS–hydrogen deployment, addressing persistent challenges in technical, economic, and regulatory domains.

Together, these contributions provide a comprehensive, cross-disciplinary perspective that advances the understanding of how AI can accelerate decarbonization through integrated energy systems.

2. Carbon Capture and Storage

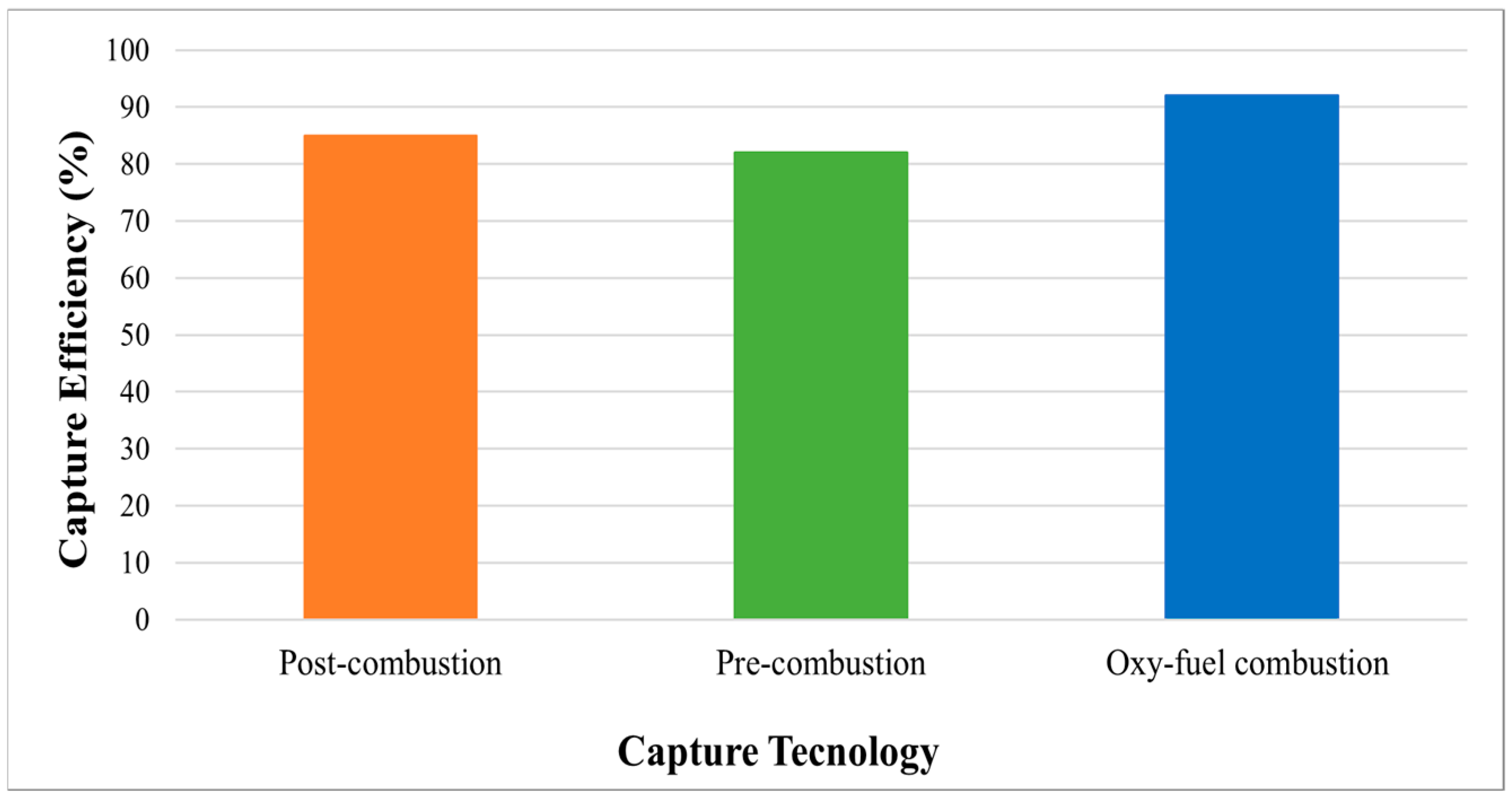

CCS is a critical decarbonization technology capable of capturing 85–95% of CO

2 emissions from point sources such as power plants, cement factories, and steel plants. The process includes three main stages: (1) capturing CO

2 using post-combustion solvents, pre-combustion syngas separation, or oxy-fuel combustion; (2) transporting CO

2 via pipeline or ship; and (3) injecting it into geological formations such as saline aquifers or depleted oil and gas fields for long-term storage [

38,

39,

40,

41,

42,

43,

44].

Post-combustion capture is well-suited for retrofitting existing facilities, while pre-combustion and oxy-fuel methods offer higher concentrations of CO

2 but require new infrastructure. Projects like Petra Nova and Sleipner have demonstrated the technical feasibility of CCS at an industrial scale [

45,

46,

47].

CCS enables substantial emissions reductions in hard-to-abate sectors and is a pillar of net-zero roadmaps by 2050 [

4,

48]. Integration with AI is improving operational efficiency, reducing energy penalties, and enhancing monitoring capabilities through predictive analytics and anomaly detection [

49].

Figure 2 is a comparison of the key CO

2 capture technologies such as post-combustion, pre-combustion, and oxy-fuel combustion based on efficiency and application readiness. This figure illustrates conceptually the performance trade-offs relevant to CCS integration.

Table 2 is a summary of the major geological CO

2 storage types, including saline aquifers, depleted oil and gas fields, and coal seams. It includes estimated storage capacity, costs, case studies, and applications of AI in monitoring and optimization.

3. Hydrogen Storage Systems

Hydrogen is a clean energy carrier with a high gravimetric energy density (~120 MJ/kg), making it attractive for decarbonizing sectors such as heavy transport, industry, and energy storage [

55,

56,

57]. Hydrogen can be produced via fossil-based methods like SMR, often combined with CCS to create “blue hydrogen”, or from renewable electricity via electrolysis to produce “green hydrogen” [

58,

59,

60].

Storage options include compressed gas (for transport and mobility), cryogenic liquid hydrogen (for space-limited applications), and emerging solid-state methods such as metal hydrides [

61]. Subsurface geological formations such as salt caverns and aquifers are also gaining attention for seasonal or strategic hydrogen reserves [

62,

63].

AI is increasingly applied across hydrogen systems to optimize electrolysis efficiency, predict tank failures, and manage distribution logistics. Projects like Fukushima FH2R illustrate how AI can enhance both the production and storage of hydrogen, leading to improved energy efficiency and system resilience [

64].

Table 3 is an overview of hydrogen storage technologies including compressed gas, liquid hydrogen, and metal hydrides. It includes energy losses, cost range, example applications, and AI-driven enhancements for safety and performance.

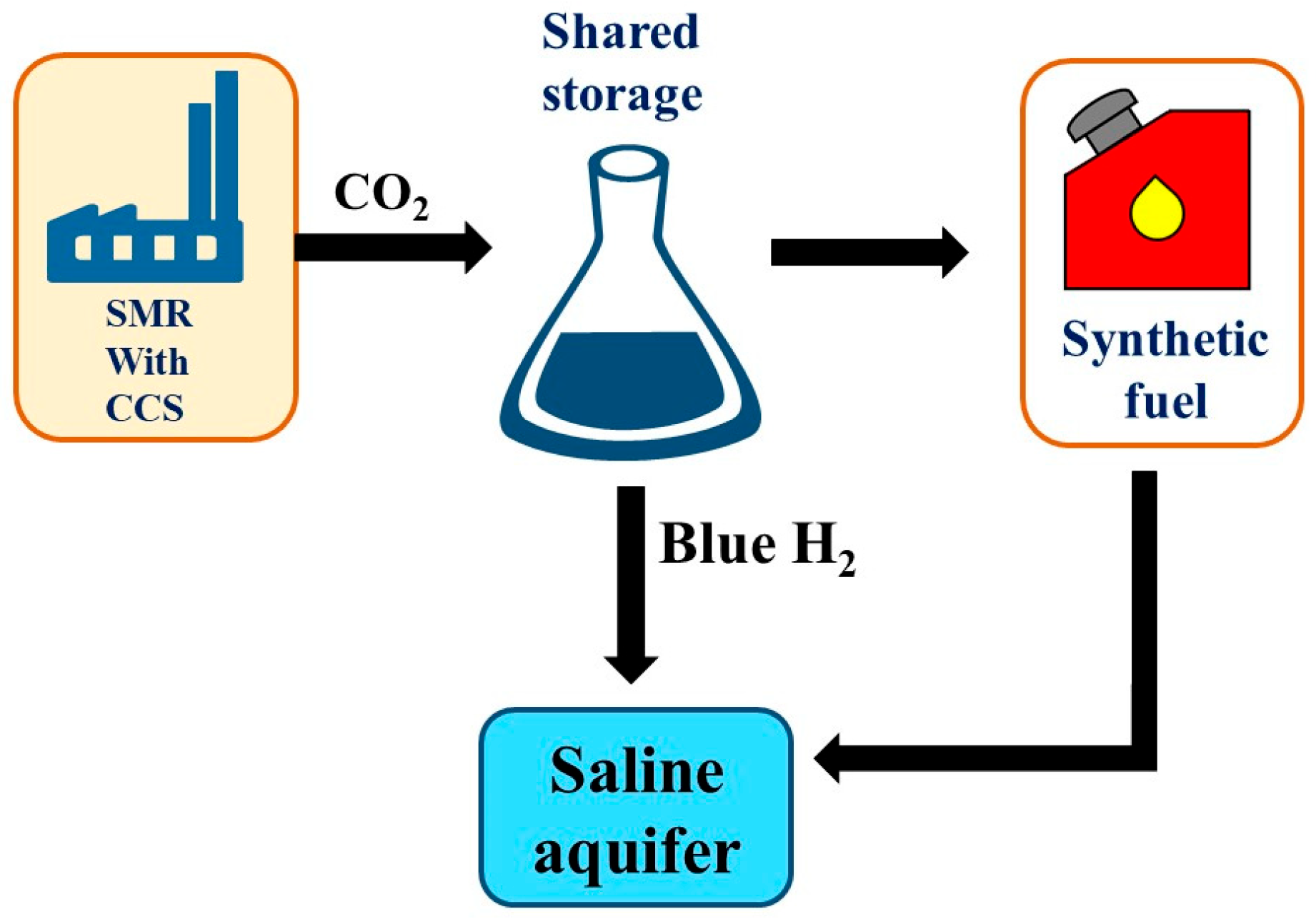

4. Integration of CCS and Hydrogen Storage

The strategic integration of CCS with hydrogen systems presents a powerful pathway for achieving net-zero emissions. Blue hydrogen, produced by combining SMR with CCS, can reduce lifecycle CO

2 emissions by up to 90%. Co-deployment enables infrastructure sharing pipelines, compression facilities, and geological formations, resulting in capital cost savings of 30–60%. This approach is central to emerging decarbonization hubs across Europe, Asia, and North America [

20,

24,

67,

68,

69].

Artificial intelligence amplifies these synergies by enabling predictive control, infrastructure optimization, and real-time system coordination. Case studies such as Northern Lights (Norway) and H21 North of England (UK) demonstrate that AI-driven integration can yield 10–30% efficiency improvements while lowering risk and operational costs [

8,

10].

Figure 3 illustrates an integrated CCS–hydrogen cycle conceptually where SMR with CCS produces blue hydrogen and captures CO

2. The CO

2 is stored in a shared facility and injected into a saline aquifer, while the blue hydrogen is directed toward synthetic fuel production.

4.1. Benefits of Integration

CCS with hydrogen systems creates a range of synergistic benefits that enhance the sustainability and efficiency of both technologies [

20]. By capturing up to 90% of CO

2 emissions during hydrogen production, blue hydrogen plays a key role in reducing greenhouse gas emissions [

10,

70]. Combining CCS and hydrogen infrastructure also leads to significant cost savings, as shared pipelines, compressors, and storage facilities can reduce overall investment by 30–60%. The use of dual-purpose transport and storage systems further improves asset utilization and operational efficiency [

71,

72].

In addition, hydrogen storage offers valuable long-duration energy storage capabilities, helping to balance supply and demand as more renewable energy comes online [

73,

74]. This integration also aligns well with key policy frameworks such as the EU Hydrogen Strategy and the U.S. Inflation Reduction Act, supporting broader climate and energy goals [

75,

76].

Together, these advantages make the integration of CCS and hydrogen a powerful approach for decarbonizing industries, transportation networks, and energy systems at scale.

4.2. Challenges and Barriers to Integration

Despite its significant potential, the integrated deployment of CCS and hydrogen systems faces a range of technical, economic, regulatory, and social challenges [

20].

From a technical perspective, the processes of capturing, compressing, and liquefying CO

2 and hydrogen can impose substantial energy penalties ranging from 20% to 40%, which reduce the overall efficiency of the system [

77,

78]. Economically, both CCS and hydrogen production remain capital-intensive, with CCS costs estimated at USD 50–100 per ton of CO

2 captured, and hydrogen production ranging from USD 1 to USD 5 per kilogram. Scaling up the necessary infrastructure requires major investment, which can be a barrier to widespread adoption [

79,

80].

Regulatory uncertainty also poses a challenge. There is currently no unified international framework for certifying CO

2 storage sites, governing cross-border CO

2 pipelines, or establishing consistent hydrogen safety standards. These gaps create legal and operational risks that can hinder project development [

44,

81,

82].

Public perception and social acceptance further complicate integration efforts. Concerns about the potential for CO

2 leakage, the flammability of hydrogen, and long-term liability for stored CO

2 can lead to public opposition, delaying projects and increasing scrutiny [

20,

83].

Moreover, the integration of these technologies introduces significant operational complexity. It requires coordination across multiple systems, markets, and jurisdictions, making real-time optimization and flexible management essential for reliable performance [

35].

While artificial intelligence and other technological innovations can help address some of these issues, overcoming the broader challenges will require coordinated policy action, active stakeholder engagement, and the development of standardized protocols across the value chain [

20,

84].

4.3. Infrastructure and Safety Requirements

Successful integration of CCS and hydrogen systems relies heavily on shared, standardized infrastructure to ensure efficiency and scalability [

20,

84]. Geological formations such as saline aquifers can serve dual purposes storing both captured CO

2 and hydrogen, enhancing the flexibility and viability of these systems [

63,

85]. Dual-use pipelines are not only technically feasible but also offer significant cost advantages by reducing the need for separate transport networks [

86].

In addition, AI-powered monitoring systems play a key role in ensuring safe and reliable operations. These systems can track flow dynamics, detect leaks early, and predict maintenance requirements, helping to prevent disruptions and reduce operational risks [

87,

88].

Safety remains a top priority, and adherence to international standards such as ISO and EN for handling CO

2 and hydrogen is essential [

89,

90]. Real-time anomaly detection powered by AI can achieve up to 95% accuracy, significantly improving system reliability and enhancing public confidence in the long-term safety of integrated CCS and hydrogen infrastructure [

91].

4.4. Key Market Applications

Integrated CCS–hydrogen (CCS-H

2) systems have significant potential in several key sectors where deep decarbonization is essential and electrification is not a viable option. These systems are particularly impactful in heavy industries such as steel, ammonia, and cement production, which rely on high-temperature processes and carbon-intensive feedstocks [

92]. Additionally, they play a crucial role in long-haul transport including trucking, shipping, and aviation where energy-dense, low-emission fuels are necessary to replace conventional hydrocarbons [

93,

94].

Furthermore, integrated CCS-H

2 systems enable large-scale energy storage, offering flexibility to the power grid by storing excess renewable energy in the form of hydrogen. They also support the production of power-to-liquid fuels, which synthesize liquid hydrocarbons using CO

2 and hydrogen, providing sustainable alternatives for sectors that depend on traditional fuels [

95,

96,

97].

These applications are not only critical for reducing emissions in hard-to-abate sectors but are also well-aligned with national and international net-zero strategies around the world [

98].

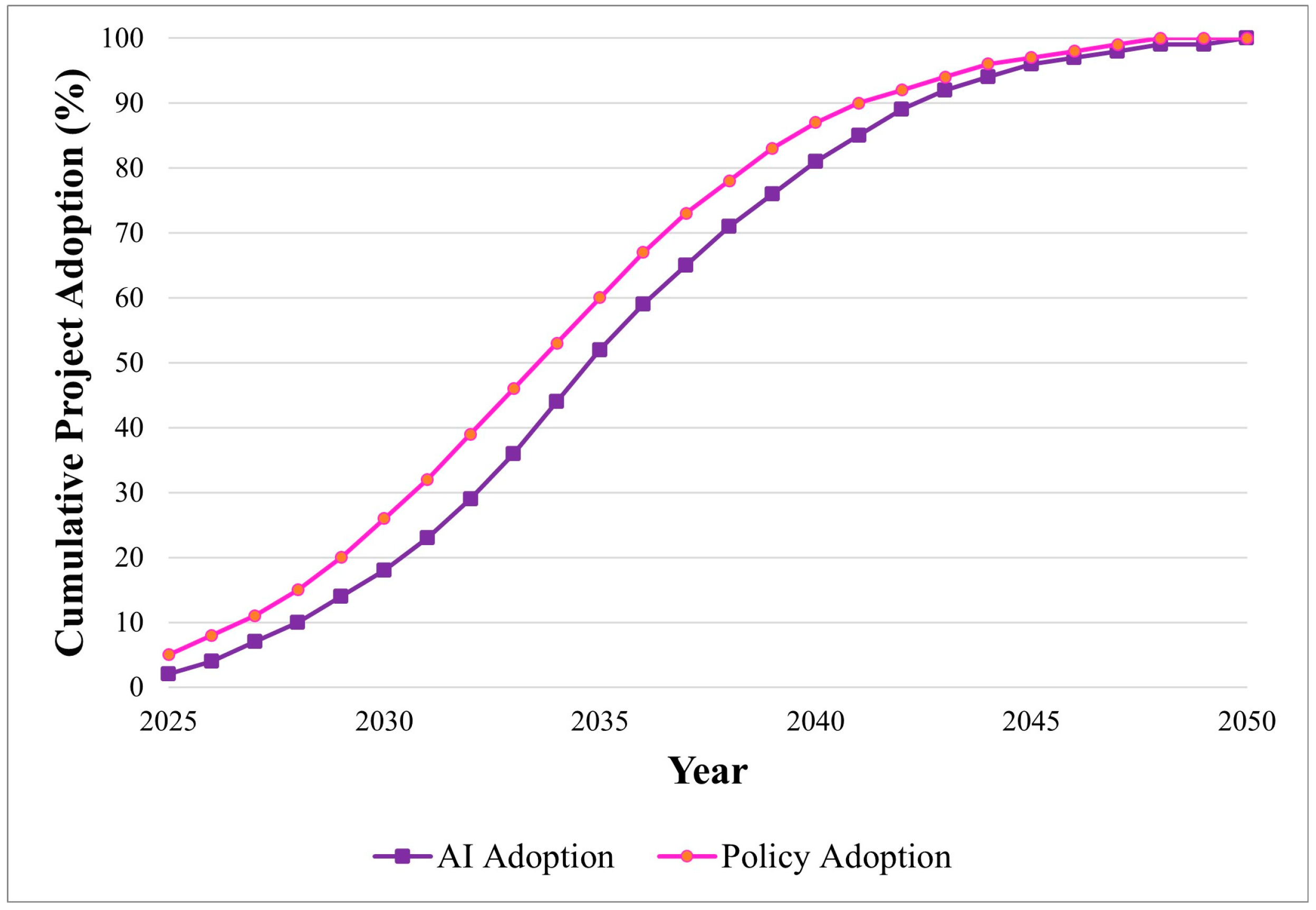

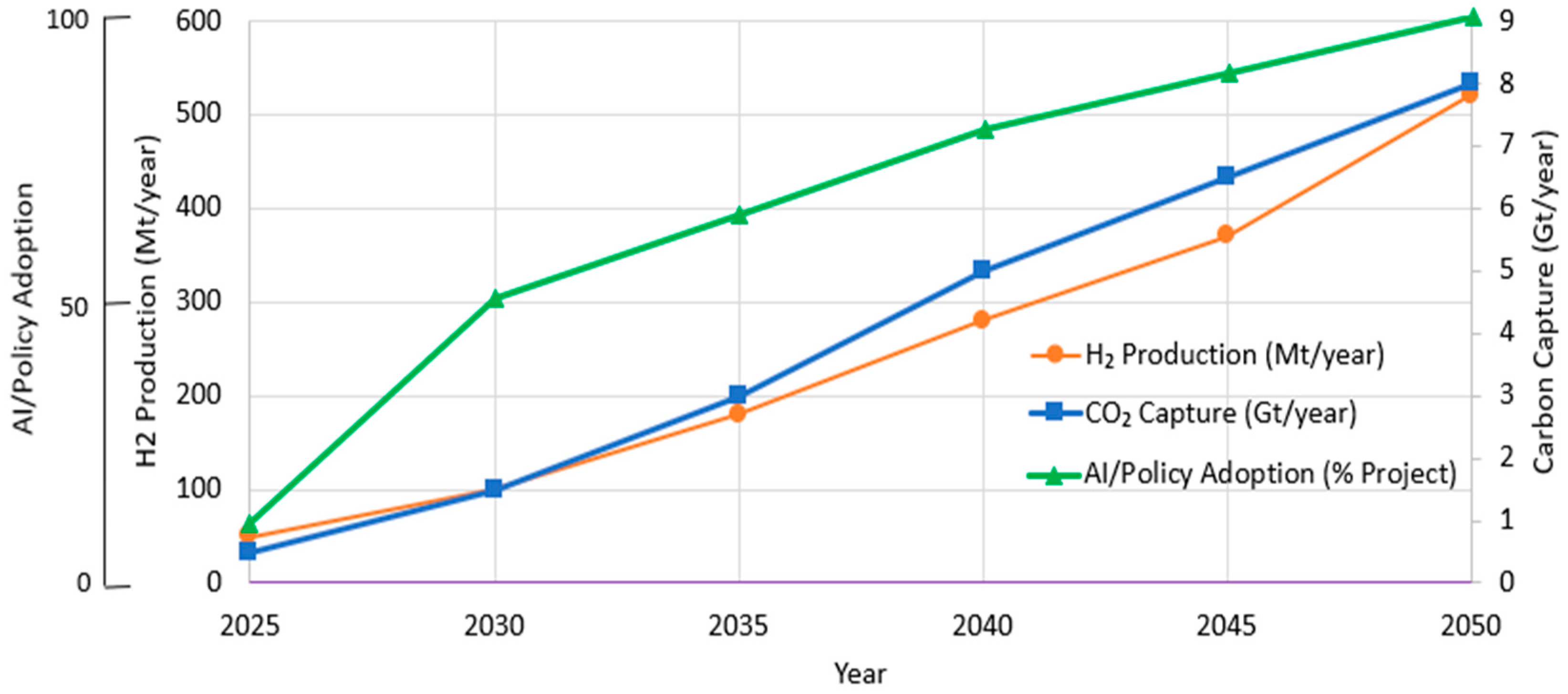

Figure 4 shows the projected timeline for AI and policy adoption in CCS–hydrogen integration. It visualizes the anticipated alignment of enabling technologies and policy frameworks to support large-scale deployment.

Table 4 is a summary of the integration-related benefits, key challenges, and AI solutions across CCS and hydrogen systems. It highlights the emissions impact, cost reductions, risk management improvements, and technical barriers to large-scale deployment.

5. Artificial Intelligence Applications in Integrated CCS and Hydrogen Systems

AI is emerging as a transformative enabler in the optimization of integrated CCS and hydrogen systems. By leveraging advanced computational techniques including machine learning (ML), neural networks, and reinforcement learning, AI enhances system efficiency, reduces operational costs, and improves safety across the entire value chain [

8,

9,

27].

AI-driven solutions are particularly effective in predictive modeling, real-time anomaly detection, and process optimization, enabling intelligent decision-making at scale. These capabilities have already demonstrated tangible benefits in real-world deployments [

8]. For example, AI-enhanced control systems at the Petra Nova CCS facility in the United States achieved capture energy savings of up to 15%, while the Fukushima FH2R hydrogen project in Japan improved hydrogen production efficiency by 12% through intelligent load management and predictive maintenance. Collectively, such applications have yielded efficiency gains of 10–30% in key decarbonization projects [

10].

With global carbon dioxide emissions reaching an alarming 37 gigatons per year, and hydrogen demand projected to surge to 500 million metric tons annually by 2050, the need for scalable, cost-effective decarbonization strategies has never been greater [

102,

103]. In this context, AI serves as a critical catalyst transforming traditionally capital- and energy-intensive CCS and hydrogen operations into more agile, data-driven systems capable of supporting rapid deployment [

8,

9].

This section explores the expanding role of AI across CCS, hydrogen production, and storage, and their integrated deployment. Building upon the technological overviews provided in

Section 2 and

Section 3, and the consolidated challenges discussed in

Section 4.2, this section highlights how AI can address persistent technical, economic, and safety barriers. From optimizing CO

2 capture efficiency in solvent systems to improving hydrogen leak detection, asset monitoring, and infrastructure forecasting, AI-enabled tools offer promising pathways to enhance system performance and reduce lifecycle costs across integrated decarbonization systems.

Furthermore, AI supports strategic planning and risk mitigation through advanced scenario modeling, infrastructure forecasting, and safety analytics, which are essential for investor confidence and regulatory compliance. These themes are further explored through practical case studies in

Section 6 and policy considerations in

Section 8.

Ultimately, the integration of AI into CCS and hydrogen systems represents a paradigm shift in energy system design, enabling smarter, safer, and more responsive infrastructure that aligns with global net-zero goals [

104]. This section underscores AI’s pivotal role in accelerating the transition toward a scalable, low-carbon energy future.

5.1. AI in CO2 Capture and Storage

AI is increasingly instrumental in enhancing the efficiency, safety, and economic viability of CCS systems [

105]. By applying advanced machine learning techniques from predictive modeling to real-time monitoring, AI addresses some of the most persistent challenges in CCS, particularly high energy penalties and operational uncertainties [

8,

9].

In CO

2 capture processes, AI-driven optimization significantly improves performance [

27,

105,

106]. CNNs have been successfully deployed to model solvent behavior in amine-based capture systems, enabling more efficient process control and reducing energy consumption by up to 15% [

8,

107,

108]. This was notably demonstrated at the Petra Nova facility in the United States, which captures approximately 1.4 million metric tons of CO

2 annually [

10]. Similarly, RNNs, particularly those using Long Short-Term Memory (LSTM) architectures, have proven effective in predicting solvent degradation rates. At the Quest CCS project in Canada, such models have increased solvent replacement efficiency by 30%, thereby extending equipment life and reducing maintenance costs [

109].

For geological storage operations, AI enhances both safety and reliability [

110]. SVMs are being used to detect anomalies in subsurface conditions, identifying potential CO

2 leakage events with up to 95% accuracy. This capability has been validated at the Sleipner storage site in Norway, where continuous monitoring ensures long-term containment security in saline aquifers [

36]. Additionally, LSTM networks enable dynamic modeling of injection pressures and reservoir responses, supporting real-time adjustments that can reduce operational costs by up to 18% [

111].

In transport logistics, AI further contributes to cost reductions and system resilience. Random Forest algorithms and other ensemble learning methods are applied to optimize pipeline flow dynamics, minimizing pressure losses and improving throughput. These techniques have contributed to a 15% reduction in transport costs in large-scale projects such as Gorgon in Australia, where CO

2 is transported over long distances under complex operational conditions [

9,

36].

By addressing critical issues such as the 20–30% energy penalty associated with capture and enhancing the long-term safety of storage sites, AI plays a pivotal role in making CCS a more viable and scalable solution for deep decarbonization. These advancements not only improve technical performance but also bolster investor confidence and regulatory acceptance [

6,

8,

9].

5.2. AI in Hydrogen Production and Storage

AI is playing an increasingly vital role in optimizing hydrogen production and storage systems, enhancing both efficiency and safety across the value chain [

112,

113]. By applying advanced machine learning techniques including deep learning, reinforcement learning, and probabilistic modeling, AI enables smarter process control, predictive maintenance, and material innovation, addressing key technical and economic barriers in hydrogen deployment [

114,

115].

In hydrogen production, AI-driven optimization significantly improves system performance. Deep learning models have been successfully implemented at the Fukushima FH2R project in Japan, where they reduce energy consumption in electrolysis by up to 10%, contributing to overall efficiency improvements in the range of 70–80%. Similarly, reinforcement learning algorithms are being used to optimize SMR processes in blue hydrogen production, enabling more precise control over reaction conditions and reducing associated emissions by approximately 12% [

116].

For hydrogen storage and distribution, AI enhances operational safety and supply chain resilience [

88,

117]. Ensemble learning methods are deployed to predict pipeline failures and tank integrity issues, significantly reducing incident rates by as much as 40% in Japan’s national hydrogen refueling station network. Meanwhile, Bayesian networks support demand forecasting and logistics planning, improving supply chain coordination and boosting efficiency by up to 15% [

88,

118].

Beyond operations, AI also contributes to material innovation in hydrogen storage technologies [

119]. Genetic algorithms and other evolutionary computing techniques are being applied to design and optimize metal hydride materials, increasing their hydrogen absorption capacity by up to 20% [

114,

119]. These advancements help lower the cost of solid-state hydrogen storage, which currently ranges between USD 2 and USD 5 per kilogram of H

2, while also mitigating energy losses inherent in conventional storage methods [

119,

120].

By addressing challenges such as energy losses during compression and liquefaction (10–40%) and safety risks related to hydrogen’s flammability and material embrittlement, AI plays a critical role in advancing hydrogen systems toward commercial scalability and safer deployment. These challenges are now discussed in the consolidated

Section 4.2 on integration barriers [

121,

122].

5.3. AI in Integrated CCS–Hydrogen Systems

The integration of CCS with hydrogen systems creates complex, multi-component energy infrastructures that require advanced coordination to maximize efficiency, reduce costs, and ensure safe operation. AI plays a pivotal role in enabling this synergy by optimizing system design, enhancing process integration, and supporting strategic decision-making across shared infrastructure [

123,

124].

In system design and planning, AI-driven optimization models significantly improve the scalability and economic viability of integrated blue hydrogen hubs. Genetic algorithms have been applied to optimize facility layout, resource allocation, and pipeline routing, achieving up to a 25% improvement in scalability in projects such as the H21 North of England initiative. These models enable planners to identify cost-effective configurations that balance production capacity, storage needs, and transport logistics [

125,

126,

127].

For infrastructure cost optimization, machine learning techniques such as Random Forests are used to model investment trade-offs and operational risks [

8,

9]. In the Northern Lights project in Norway, a flagship cross-border CO

2 transport and storage initiative, such models have contributed to a 20% reduction in shared infrastructure costs, demonstrating the value of data-driven planning in large-scale decarbonization efforts [

128,

129,

130].

At the process level, reinforcement learning has emerged as a powerful tool for real-time coordination between CCS and hydrogen production units [

116,

131]. By dynamically adjusting capture rates, compression settings, and hydrogen flow based on fluctuating energy prices and demand patterns, these AI systems achieve significant efficiency gains. For instance, in Rotterdam’s Porthos project, reinforcement learning has enabled a 15% improvement in overall system efficiency, reducing energy penalties and improving responsiveness to grid conditions [

112,

113,

132,

133,

134].

Beyond technical operations, AI also supports policy and market development for integrated CCS–hydrogen systems [

112]. AI-driven forecasting models analyze historical trends, regulatory scenarios, and energy market dynamics to predict hydrogen demand and inform investment strategies. These insights are instrumental in shaping large-scale policy initiatives such as the European Union’s EUR 7 billion Hydrogen Strategy, which aims to deploy integrated hydrogen and carbon management systems at scale [

135,

136].

By addressing key integration challenges ranging from high capital costs to complex interdependencies, AI not only enhances system performance but also accelerates deployment readiness [

8,

9]. These applications are further validated through real-world case studies explored in

Section 6.

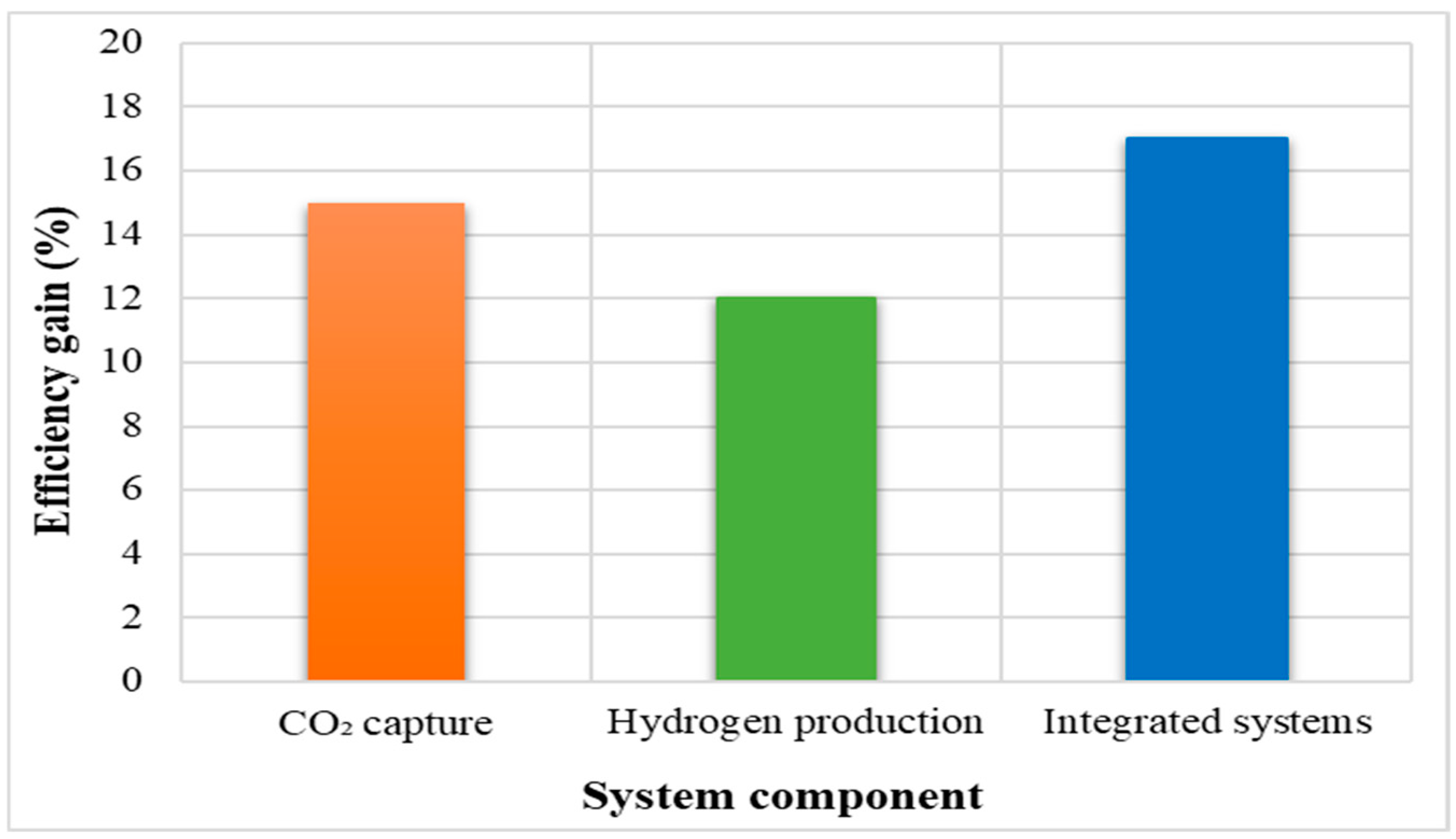

To visually and conceptually illustrate the comparative impact of AI across different components of CCS and hydrogen systems,

Figure 5 presents a bar chart comparing the efficiency gains achieved through AI applications in CO

2 capture, hydrogen production, and fully integrated systems.

5.4. Future Directions for AI in CCS and Hydrogen Systems

As integrated CCS and hydrogen systems move toward large-scale deployment, the next generation of AI technologies is poised to play an even greater role in enabling smarter, safer, and more scalable decarbonization solutions. Emerging AI trends offer transformative capabilities that extend beyond traditional optimization and monitoring, addressing complex challenges related to system interoperability, data governance, and regulatory transparency [

20,

103].

One of the most promising advancements is the development of digital twins’ virtual replicas of physical CCS–hydrogen systems that simulate real-time behavior using sensor data and physics-based models. These digital twins enable predictive analytics, scenario testing, and performance forecasting with up to 90% accuracy, allowing operators to optimize operations and preempt failures before they occur. As these models evolve, they will be essential tools for cross-system coordination, particularly in industrial clusters where multiple CCS and hydrogen assets must operate in synchrony [

20,

137,

138].

Another growing trend is federated learning, a decentralized machine learning approach that enables collaborative model training across multiple projects or stakeholders without sharing raw data. This technique enhances privacy and regulatory compliance while improving model robustness and generalizability by up to 20%, making it especially valuable for international or multi-operator CCS–hydrogen networks [

139,

140].

In parallel, Explainable AI (XAI) is gaining traction as a key component for building trust among regulators, investors, and the public. By providing transparent insights into how AI-driven decisions are made such as predicting CO

2 leakage risks or optimizing hydrogen flow paths, XAI improves accountability and facilitates regulatory acceptance. This is particularly important in high-stakes applications like subsurface storage and pipeline safety, where interpretability can be as critical as accuracy [

141,

142,

143].

These emerging AI capabilities align closely with the innovation pathways explored in

Section 7 and support the policy and scalability objectives outlined in

Section 8. As AI continues to evolve, its integration into CCS and hydrogen systems will not only enhance technical performance but also foster the regulatory confidence and cross-sectoral collaboration needed for global decarbonization [

144].

To provide a comprehensive overview of current and future AI capabilities,

Table 5 summarizes the key AI techniques, their applications, and the demonstrated outcomes across CCS, hydrogen, and integrated systems, highlighting improvements in efficiency, cost, and safety.

6. Case Studies of Integrated CCS and Hydrogen Systems

Real-world implementations of integrated CCS and hydrogen systems provide critical insights into the technical feasibility, economic viability, and operational efficiency of these decarbonization strategies [

20]. As global CO

2 emissions reached 37 gigatons per year in 2023, and hydrogen demand is projected to surge to 500 million metric tons annually by 2050, the need for scalable, low-carbon energy solutions has never been more urgent [

149,

150]. These case studies illustrate how shared infrastructure such as saline aquifers, pipelines, and regional hubs can be effectively deployed alongside AI tools like predictive modeling and anomaly detection to enhance system performance.

This section presents four representative projects that exemplify diverse integration strategies across different regions and applications:

Petra Nova (USA) demonstrates AI-enhanced CCS applied to power generation, offering lessons on retrofitting existing facilities [

10].

Northern Lights (Norway) showcases cross-border CO

2 transport and storage infrastructure, highlighting opportunities for international collaboration [

129].

Fukushima FH2R (Japan) represents a cutting-edge green hydrogen production and storage facility, optimized through intelligent control systems [

151].

H21 North of England (UK) explores large-scale blue hydrogen deployment in urban energy systems, emphasizing scalability and safety [

125,

152].

Collectively, these projects demonstrate efficiency gains of 10–30% and cost reductions of 20–40% through strategic integration and AI-driven optimization. Each case study provides valuable insights into overcoming technical, economic, and regulatory challenges, while informing future innovation trends (discussed in

Section 7) and policy development (explored in

Section 8).

By analyzing their successes and limitations, this section lays a foundation for replicating and scaling integrated CCS–hydrogen systems globally, supporting the transition toward a resilient, low-carbon energy future.

6.1. Petra Nova (USA): AI-Optimized CO2 Capture for Blue Hydrogen

The Petra Nova project, located at the W.A. Parish Generating Station in Texas, represents one of the most prominent large-scale CCS installations in the world [

10,

153]. Operational since 2017, the facility captures approximately 1.4 million metric tons of CO

2 annually from a coal-fired power plant using a post-combustion amine-based capture system. While the majority of the captured CO

2 is currently utilized for EOR, feasibility studies have explored its potential integration with blue hydrogen production via SMR, offering a pathway to expand the site’s decarbonization impact [

154,

155].

A key strength of the Petra Nova project lies in its integration potential with hydrogen systems. The existing CO

2 transport infrastructure could be adapted to support blue hydrogen production, enabling shared pipeline usage that has been shown to reduce transport costs by up to 20% in similar integrated projects [

153,

156].

The deployment of AI has significantly enhanced operational efficiency at Petra Nova [

10]. CNNs have been applied to model and optimize solvent performance in the capture process, resulting in an estimated 15% reduction in energy consumption. Additionally, RNNs are used to predict equipment degradation and maintenance requirements, improving system uptime by approximately 25% and reducing unplanned downtime [

10,

105].

These AI-driven enhancements have contributed to the project’s strong technical performance, achieving a CO

2 capture efficiency of around 90%, with reported capture costs of approximately USD 80 per metric ton of CO

2. If expanded to include hydrogen production, the facility has the potential to produce up to 1 million metric tons of blue hydrogen per year, further strengthening its role in regional decarbonization efforts [

8,

10].

However, the project also highlights significant challenges. The capital cost of retrofitting the existing power plant exceeded USD 1 billion, and the energy penalty associated with CO

2 capture remains high at around 20%, both of which constrain broader scalability [

10]. These limitations underscore the importance of continued innovation in capture technologies and AI-based optimization strategies, as discussed in

Section 5.1.

As a pioneering example of AI-enhanced CCS operation, Petra Nova provides valuable insights into the technical and economic viability of integrating carbon capture with hydrogen systems, lessons that can inform future deployments across industrial and energy sectors [

6,

10].

6.2. Northern Lights (Norway): Shared Storage for CCS and Hydrogen

The Northern Lights project, launched in 2024, represents a flagship initiative under the European Union’s broader CCS strategy [

157]. Designed as a cross-border CO

2 transport and storage hub, it currently has the capacity to store 1.5 million metric tons of CO

2 annually in deep saline aquifers beneath the North Sea, with long-term plans to integrate hydrogen storage and support blue hydrogen production from industrial sources across Europe [

127,

129].

One of the defining features of Northern Lights is its shared infrastructure model, which enables multiple emitters to access centralized CO

2 transport and storage facilities [

157,

158,

159]. This approach not only reduces individual project risk but also enhances economies of scale. The site’s subsurface geology, particularly its saline aquifers, is being evaluated for dual-purpose use, storing both CO

2 and hydrogen. Early assessments suggest that shared pipeline networks could reduce infrastructure costs by up to 30%, reinforcing the economic rationale for integrated systems [

160].

AI plays a key role in optimizing operations at Northern Lights [

158]. Random Forest algorithms are used to model subsurface conditions and optimize injection strategies, contributing to an estimated 20% reduction in operational costs [

161]. Additionally, SVMs have been deployed for real-time monitoring of storage integrity, achieving 95% accuracy in detecting potential leakage events, thereby enhancing safety and regulatory compliance [

8].

From a performance standpoint, Northern Lights demonstrates high levels of storage permanence (around 95%), with projected full-chain CO

2 storage costs ranging between USD 50 and USD 70 per metric ton a significant improvement over standalone CCS deployment [

80,

162]. The site also has an initial hydrogen storage capacity of 0.5 million metric tons, positioning it as a potential cornerstone for future hydrogen valleys and regional decarbonization clusters [

127,

163].

Despite these promising outcomes, the project faces notable challenges. Regulatory frameworks for hydrogen storage permanence and liability remain underdeveloped, creating uncertainty for investors and operators alike. Moreover, the capital investment required, estimated at USD 1.5 billion, highlights the need for public–private partnerships and supportive policy mechanisms to ensure replicability in other regions [

20,

81].

As a pioneering example of shared geological storage for both CO

2 and hydrogen, Northern Lights provides critical insights into the design and operation of integrated CCS–hydrogen systems [

20,

164]. It serves as a practical demonstration of the concepts discussed in

Section 4.1 and

Section 4.4, particularly the benefits of shared infrastructure, cost synergies, and market applications in large-scale decarbonization efforts.

6.3. Fukushima FH2R (Japan): AI-Enhanced Hydrogen Production and Storage

FH2R, operational since 2020, represents a flagship initiative in Japan’s national hydrogen strategy. Located in Fukushima Prefecture, the facility produces 1.200 Nm

3/h of green hydrogen using renewable-powered water electrolysis, demonstrating the potential of hydrogen as a key enabler of energy transition in post-nuclear recovery contexts. The project also includes a hydrogen storage system that stores compressed gaseous hydrogen for use in grid balancing and fuel cell applications [

165].

A forward-looking aspect of Fukushima FH2R is its planned integration with CCS, which could enable the production of blue hydrogen alongside its current green hydrogen output. This hybrid approach would allow the facility to maintain high hydrogen availability even during periods of low renewable generation, while leveraging shared pipeline infrastructure for transport optimization, aligning with the broader integration strategies discussed in

Section 4 [

20].

AI plays a central role in enhancing both the efficiency and responsiveness of hydrogen operations at FH2R. Deep learning models have been deployed to optimize electrolysis system performance, resulting in an approximate 10% reduction in energy consumption and improving overall electrolysis efficiency to around 70%. Additionally, Bayesian networks are used to forecast hydrogen demand patterns, enabling better coordination between production, storage, and distribution, and contributing to a 15% improvement in system-wide efficiency [

138].

These AI-driven enhancements support the project’s operational outcomes, including a production cost of approximately USD 3 per kilogram of H

2 and an annual output capacity of 100 metric tons of hydrogen. These metrics underscore the growing competitiveness of large-scale electrolysis when supported by intelligent control systems [

166].

However, challenges remain. Despite technological advancements, green hydrogen production costs are still relatively high, and the lack of mature CCS infrastructure in Japan limits near-term blue hydrogen development. Addressing these barriers will require further investment in carbon management systems and supportive policy frameworks [

164].

As a pioneering example of AI-enhanced hydrogen production and storage, Fukushima FH2R highlights the critical role of digital technologies in advancing decarbonization strategies. It exemplifies the innovations described in

Section 5.2, while reinforcing the integration opportunities explored in

Section 4 [

167,

168].

6.4. H21 North of England (UK): Blue Hydrogen Hub with CCS

The H21 North of England project represents one of the most ambitious large-scale blue hydrogen initiatives in Europe. Designed to decarbonize domestic heating for approximately 3.7 million households, the project aims to produce 3.7 million metric tons of blue hydrogen annually by 2030, using SMR integrated with CCS. Captured CO

2 will be transported and permanently stored in saline aquifers beneath the North Sea, aligning with regional efforts to repurpose offshore oil and gas infrastructure for climate mitigation [

169,

170].

A core strength of the H21 initiative lies in its integrated system design, which leverages shared infrastructure including pipelines and storage sites to achieve significant cost reductions. By co-locating hydrogen production and carbon capture facilities, the project estimates that cost savings of up to 40% can be realized compared to standalone deployments [

67].

AI plays a key role in optimizing both the planning and operation of this integrated system. Genetic algorithms have been employed to optimize the spatial and operational layout of the hydrogen hub, improving scalability and reducing long-term investment risk by an estimated 25%. Additionally, reinforcement learning models are used to enhance process control during SMR and CO

2 compression, resulting in 15% improvements in overall system efficiency [

171,

172].

These AI-driven strategies support strong environmental and economic outcomes. The H21 project is projected to achieve a 90% reduction in emissions compared to conventional natural gas use, with an estimated hydrogen production cost of USD 2 per kilogram. In addition, it will contribute significantly to UK-wide carbon removal targets by storing approximately 10 million metric tons of CO

2 annually [

166].

Despite these promising outcomes, several challenges remain. Public acceptance of blue hydrogen as a long-term decarbonization solution has been mixed, with concerns around methane leakage and the permanence of CO

2 storage. Furthermore, the capital investment required, estimated at GBP 2 billion, highlights the importance of policy support and regulatory alignment to ensure successful deployment and replication [

173].

As a flagship example of a large-scale blue hydrogen hub, H21 provides valuable insights into the technical, economic, and social dimensions of integrating hydrogen and CCS systems at scale [

20,

126]. It directly informs discussions on market applications in

Section 4.4 and underscores the policy considerations explored in

Section 8.

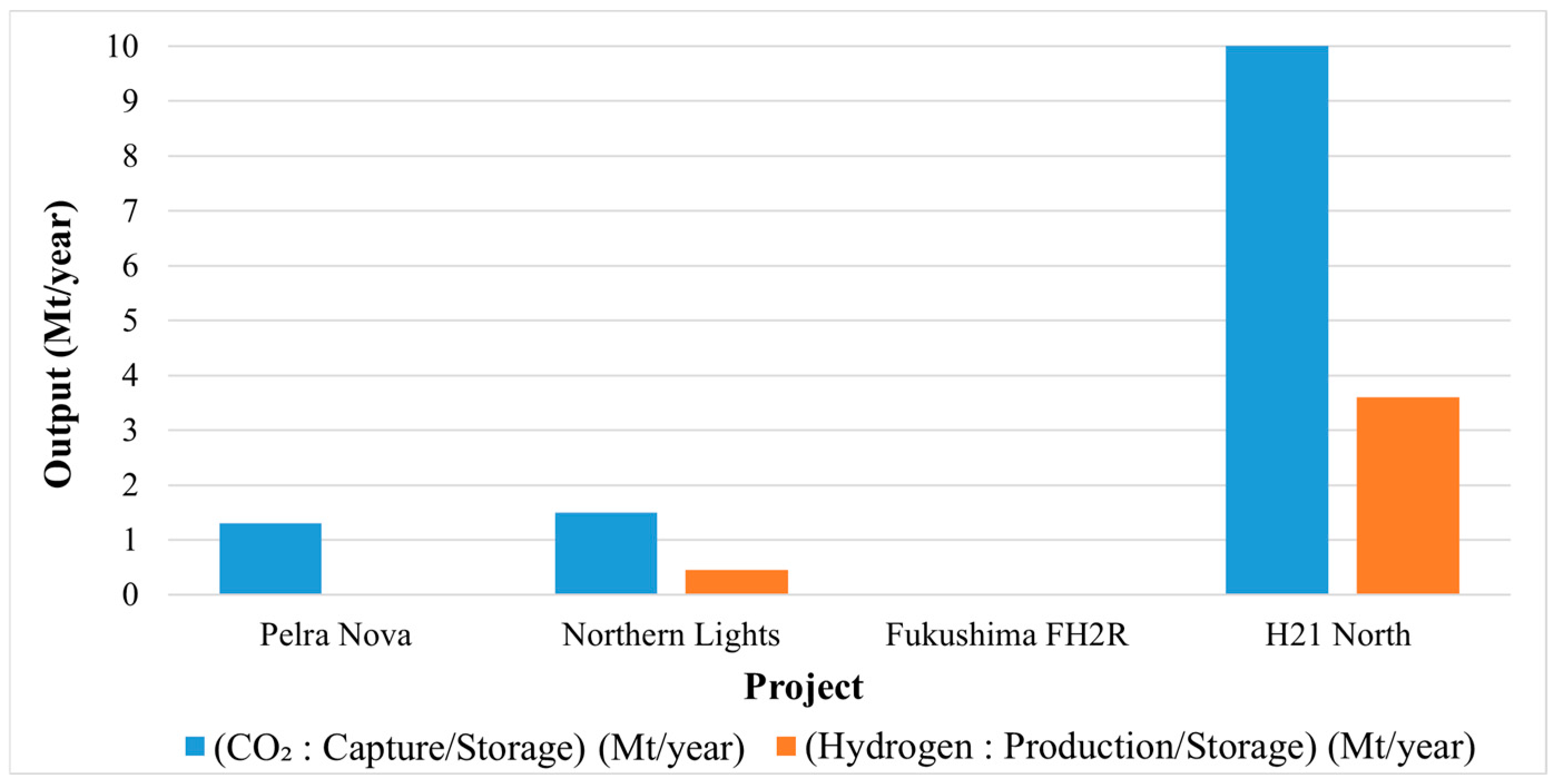

To visually compare the output capacities across all case studies presented in

Section 6 and for better understanding,

Figure 6 presents a bar chart illustrating annual CO

2 capture and storage volumes alongside hydrogen production and storage figures for Petra Nova, Northern Lights, Fukushima FH2R, and H21.

Table 6 provides a summary of the integration types, AI applications, outcomes, and challenges in the case study projects, highlighting pathways to scalability.

7. Future Trends

The integration of CCS with hydrogen storage systems is emerging as a cornerstone strategy in the global effort to achieve net-zero emissions by 2050. With current global CO

2 emissions reaching 37 gigatons per year, and hydrogen demand projected to rise to 500 million metric tons annually by mid-century, scalable decarbonization solutions are urgently needed [

175]. Integrated CCS–hydrogen systems offer a synergistic pathway to address both challenges enabling deep emissions reductions while supporting the transition to a low-carbon energy system [

176].

Building on insights from real-world case studies (

Section 6), several emerging trends are expected to enhance the performance, cost-effectiveness, and scalability of these integrated systems:

Next-generation capture technologies such as solid sorbents, membrane separation, and chemical looping combustion are reducing energy penalties and capital costs, making CCS more viable for industrial and power applications. Similarly, advances in electrolysis system efficiency, low-pressure metal hydride storage, and underground hydrogen storage in salt caverns and saline aquifers are expanding the technical feasibility of large-scale hydrogen deployment [

177,

178].

- 2.

AI-Driven Optimization

AI is increasingly central to system optimization, offering tools for predictive maintenance, real-time monitoring, and dynamic control of integrated operations. AI-driven digital twins, federated learning models, and reinforcement learning algorithms are enabling smarter resource allocation, improved safety, and reduced operational costs across the value chain. These innovations are critical for managing the complexity of shared infrastructure and fluctuating renewable inputs [

179,

180].

- 3.

Market and Policy Convergence

The growing convergence of carbon markets, hydrogen economies, and clean energy mandates is reshaping investment landscapes [

6,

20]. Initiatives such as the European Union’s Hydrogen Strategy, the U.S. Inflation Reduction Act tax credits, and Japan’s strategic hydrogen roadmap are creating favorable conditions for cross-sectoral integration and international collaboration [

181,

182].

Despite progress, persistent challenges remain including high capital costs (USD 50–100 per ton of CO

2; USD 1–5 per kg of H

2), energy penalties (20–40%), and regulatory uncertainties. However, the ongoing evolution of technology, data analytics, and policy frameworks presents a clear trajectory toward overcoming these barriers [

20,

75].

This section sets the stage for examining policy enablers in

Section 8 and proposes a scalable, AI-enhanced solution for the industry in

Section 9. By synthesizing technological, digital, and economic trends, it offers a forward-looking perspective on the future of integrated CCS–hydrogen systems in the global energy transition.

7.1. Future Trends in Integrated CCS and Hydrogen Systems

The future scalability and efficiency of integrated CCS and hydrogen systems will be significantly influenced by rapid advancements in core technologies across capture, production, storage, and utilization pathways [

20,

183]. These innovations are not only reducing costs and energy penalties but also expanding the technical feasibility of large-scale deployment, supporting the synergistic cycle outlined in

Section 4.

One of the most transformative developments in carbon management is the emergence of next-generation capture technologies, such as Direct Air Capture (DAC) and Bioenergy with CCS (BECCS) [

184,

185]. These approaches offer the potential to remove 1–2 gigatons of CO

2 annually by 2050, contributing to net-negative emissions strategies. With projected cost reductions to USD 30–50 per metric ton of CO

2, these technologies are becoming increasingly viable for both industrial and atmospheric decarbonization [

43,

186]. In parallel, membrane-based capture systems are gaining traction due to their ability to improve process efficiency by 10–15%, offering a promising alternative to conventional solvent-based methods [

187,

188].

In the realm of hydrogen production, technological progress is driving down costs while increasing system efficiency [

189]. High-temperature electrolysis and photoelectrochemical cells are expected to reduce green hydrogen production costs to USD 1–2 per kilogram by 2030, with efficiencies approaching 85% under optimal conditions [

190,

191]. Meanwhile, biomass gasification combined with CCS presents an opportunity to produce hydrogen with negative lifecycle emissions, aligning with long-term climate goals and supporting deep decarbonization of hard-to-abate sectors [

4,

192].

For storage solutions, subsurface hydrogen storage in saline aquifers and depleted gas fields modeled after successful CO

2 sequestration practices is emerging as a scalable option [

26,

85]. These geological formations could support up to 100 million metric tons of hydrogen storage capacity annually, at estimated costs of USD 0.5–1 per kilogram of H

2 [

193,

194,

195,

196]. Additionally, advances in solid-state hydrogen storage, including materials like carbon nanotubes and metal–organic frameworks, are improving gravimetric density by up to 30%, enhancing safety and enabling broader deployment in transport and industrial applications [

194,

195,

196].

Finally, the integration of CO

2 and hydrogen for synthetic fuel production often referred to as e-fuels or power-to-liquid is gaining momentum [

197]. Technologies that convert captured CO

2 and renewable hydrogen into methanol, ammonia, and synthetic hydrocarbons are advancing rapidly [

198]. By 2050, e-fuel production could reach 500 million metric tons annually, with projected costs falling to USD 80–150 per barrel, making them competitive alternatives to fossil fuels in aviation, shipping, and long-haul transport [

199].

Collectively, these technological innovations are reshaping the landscape of integrated CCS and hydrogen systems, enhancing their performance, economic viability, and environmental impact. They represent critical enablers of the integrated cycle discussed in

Section 4 and lay the foundation for the policy and market developments explored in subsequent sections.

7.2. AI-Driven Advancements

AI is set to play a transformative role in accelerating the scalability, efficiency, and public acceptance of integrated CCS and hydrogen systems [

20,

112]. As these technologies mature and expand globally, AI-driven tools are increasingly being deployed to optimize operations, enhance safety, and reduce costs addressing both technical complexities and social concerns that have historically hindered deployment [

200].

One of the most promising developments is the use of digital twins, which create high-fidelity virtual replicas of physical CCS–hydrogen systems [

137]. These models simulate real-time behavior using sensor data and predictive analytics, enabling operators to forecast system performance with up to 90% accuracy [

137,

138,

201]. This capability has already been demonstrated in pilot projects such as Rotterdam’s Porthos initiative, where digital twins support dynamic decision-making and risk mitigation [

164].

To further improve model robustness across diverse operational environments, federated learning is emerging as a powerful technique. Unlike traditional centralized machine learning approaches, federated learning enables collaborative model training across multiple facilities or jurisdictions without requiring direct data sharing. This enhances privacy, regulatory compliance, and model generalizability, offering potential improvements in AI model accuracy by up to 20% [

202,

203].

In parallel, XAI is gaining prominence as a key enabler of stakeholder engagement and regulatory trust [

204]. By providing transparent insights into how AI-based decisions are made such as predicting CO

2 leakage risks or optimizing hydrogen dispatch, XAI improves accountability and facilitates broader public and institutional acceptance. This is particularly important in high-stakes applications like subsurface storage and industrial decarbonization, where interpretability can be as critical as algorithmic accuracy [

141,

205].

Beyond modeling and transparency, AI is also driving progress in autonomous system operations. Reinforcement learning algorithms are being applied to automate complex processes such as CO

2 injection control and hydrogen production scheduling, enabling adaptive responses to fluctuating energy prices, demand patterns, and environmental conditions [

206,

207]. In several large-scale deployments, these AI-enhanced strategies have reduced operational costs by 15–25%, significantly improving economic viability [

113,

171].

Collectively, these AI-driven advancements align closely with the future directions outlined in

Section 5.4, offering scalable solutions to persistent technical and social barriers discussed in

Section 4.2. As AI continues to evolve, its integration into CCS and hydrogen systems will be instrumental in achieving the efficiency, reliability, and public confidence needed for widespread adoption [

112].

7.3. Market and Policy Opportunities

The successful scaling of integrated CCS and hydrogen systems will depend not only on technological and digital advancements but also on the development of enabling market dynamics and policy frameworks. As global climate goals become more ambitious, market incentives, regulatory support, and international collaboration are emerging as critical drivers of large-scale deployment [

20,

208,

209].

One of the most significant market developments is the rapid growth of the global hydrogen economy. Forecasts suggest that by 2050, the hydrogen market could be valued at over USD 1 trillion annually, with blue and green hydrogen contributing to approximately 25% of global energy demand [

210]. This projected expansion reflects growing adoption across sectors such as heavy industry, transport, and long-duration energy storage, offering a strong economic foundation for integrated CCS–hydrogen systems [

209].

Parallel to this, carbon markets and pricing mechanisms are becoming increasingly influential in shaping investment decisions. Initiatives such as carbon pricing schemes and tax credits including the U.S. Section 45Q tax credit, which offers up to USD 85 per ton of CO

2 stored, are incentivizing private-sector participation in CCS projects [

211,

212]. Analysts project that carbon prices could rise to USD 135 per ton by 2030 under net-zero pathways, further strengthening the business case for decarbonization technologies [

211,

213].

At the regional level, the emergence of industrial decarbonization hubs is accelerating the adoption of integrated systems. Projects in locations such as Rotterdam (Netherlands) and Houston (USA) are demonstrating how coordinated infrastructure planning, shared CO

2 transport networks, and centralized hydrogen production can serve clusters of industrial and power users at scale, potentially supporting 20–50 million metric tons of hydrogen annually [

214,

215].

On a global scale, international cooperation and policy alignment are playing a pivotal role in overcoming technical and financial barriers [

216]. Initiatives such as the European Union’s EUR 7 billion Hydrogen Strategy and the Mission Innovation global partnership are facilitating cross-border knowledge sharing, joint R&D investments, and harmonized standards, thereby reducing fragmentation and fostering faster deployment [

217].

These evolving market and policy opportunities reinforce the strategic direction outlined in

Section 8 (Policy Frameworks) and provide essential enablers for the scalable deployment of integrated CCS–hydrogen systems discussed in

Section 4.

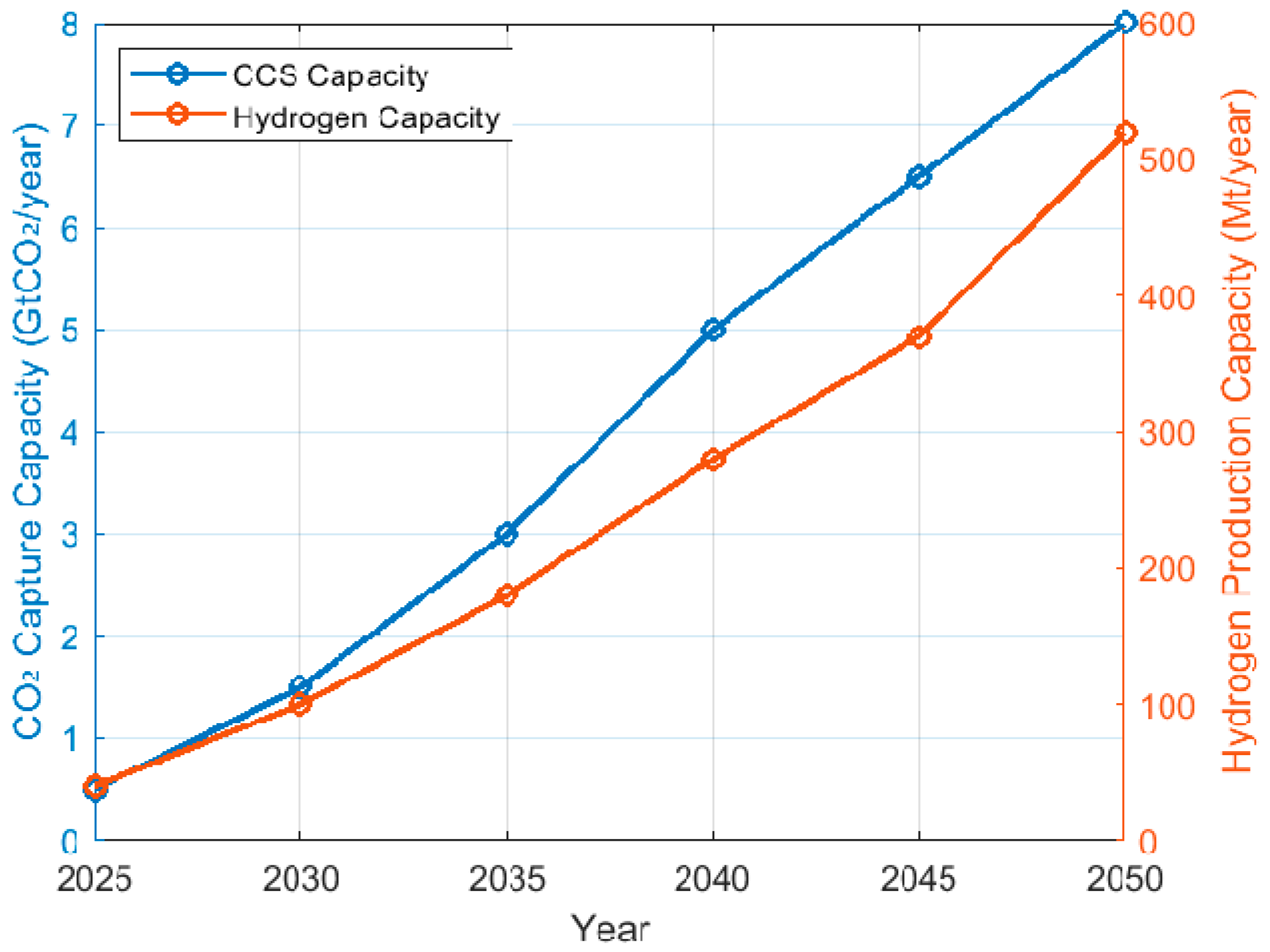

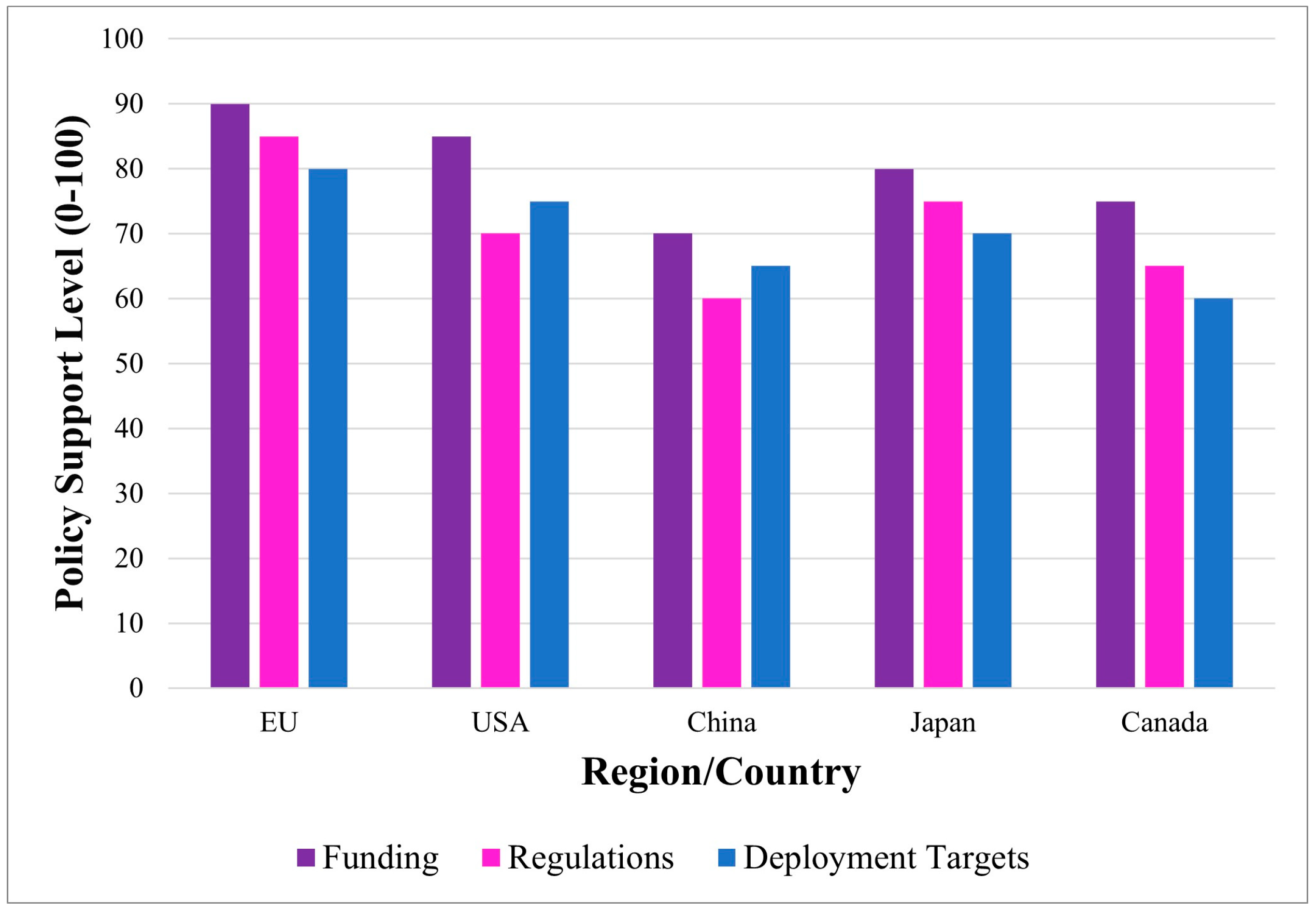

To illustrate the anticipated growth trajectory of these technologies,

Figure 7 presents a line chart showing projected increases in CO

2 capture and storage capacity, alongside hydrogen production and storage capacity, from 2025 to 2050.

Additionally,

Table 7 summarizes key emerging trends in CCS–hydrogen integration, highlighting their potential impacts and real-world examples that support the pathway toward scalable, low-carbon energy systems.

8. Policy and Regulatory Frameworks for Integrated CCS and Hydrogen Systems

The successful deployment and scaling of integrated CCS and hydrogen systems depend not only on technological maturity and market readiness but also on robust policy and regulatory frameworks. As global CO

2 emissions reached an alarming 37 gigatons per year in 2023, and hydrogen demand is projected to rise to 500 million metric tons annually by 2050, well-designed policies are essential to drive investment, reduce costs, and overcome persistent deployment barriers [

20,

38,

79].

Effective policy instruments must address key challenges such as the high capital and operational costs of CCS (USD 50–100 per ton of CO

2) and hydrogen production (USD 1–5 per kg H

2), energy penalties (20–40%), and public concerns over safety and environmental risk. These challenges require a multi-faceted regulatory response that includes financial incentives, infrastructure planning, liability frameworks, and public engagement strategies [

79,

222].

At the global level, several initiatives have emerged to support the development of integrated systems. The European Union’s EUR 7 billion Hydrogen Strategy aims to scale up both green and blue hydrogen production while aligning it with carbon capture and storage infrastructure [

223]. Similarly, the U.S. Inflation Reduction Act (IRA) has introduced expanded tax credits under Section 45Q, offering up to USD 85 per ton of stored CO

2, significantly improving the economic viability of CCS projects [

224]. In Japan, national hydrogen roadmaps and regional demonstration projects such as Fukushima FH2R are shaping a strategic pathway toward large-scale hydrogen adoption supported by CCS integration [

165].

At the regional and national levels, coordinated policy efforts are crucial for enabling industrial decarbonization clusters. Initiatives such as the Northern Lights cross-border CO

2 transport project and the H21 North of England blue hydrogen hub illustrate how supportive regulation can facilitate shared infrastructure, streamline permitting, and ensure long-term storage permanence [

129,

225]. However, gaps remain, particularly in areas such as CO

2 liability allocation, hydrogen safety codes, and cross-border regulatory harmonization, which continue to hinder international collaboration and investment flows [

226,

227].

AI also plays a growing role in policy implementation, offering tools for scenario modeling, risk assessment, and real-time compliance monitoring. AI-enhanced analytics can improve regulatory decision-making by forecasting policy impacts, optimizing subsidy targeting, and ensuring transparent reporting across complex value chains [

228]. These capabilities align with the AI-driven advancements discussed in

Section 7.2 and support the broader digital transformation of energy systems.

To fully realize the potential of integrated CCS–hydrogen systems, this section proposes a set of policy recommendations [

20]:

Establish stable and long-term financial incentives, including carbon pricing, tax credits, and grants for early-stage deployment.

Harmonize regulatory standards for CO2 storage permanence, hydrogen safety, and cross-border transport to enable scalable, interoperable systems.

Support regional decarbonization hubs through coordinated infrastructure planning and public–private partnerships.

Integrate AI into regulatory frameworks to enhance transparency, optimize policy design, and monitor system performance in real time.

Promote public engagement and stakeholder trust through education, community involvement, and explainable AI tools that clarify decision-making processes.

These policy interventions will be instrumental in enabling the scalable, AI-enhanced cycle proposed in

Section 4, and provide the foundation for the decarbonization roadmap outlined in

Section 9.

8.1. Global Policy Landscape

The global transition toward integrated CCS and hydrogen systems is being actively shaped by a growing array of national and international policy instruments. These frameworks aim to overcome economic barriers, stimulate innovation, and accelerate market adoption, aligning with the strategic objectives outlined in

Section 4.4 and supporting the market opportunities discussed in

Section 7.3 [

20].

One of the most influential tools driving decarbonization investment is carbon pricing, which creates a direct financial incentive for emissions reduction [

229]. The European Union Emissions Trading System (EU ETS), one of the most mature carbon markets, saw CO

2 prices reach USD 90 per ton in 2024, with projections indicating potential increases to USD 135 per ton by 2030 under net-zero scenarios [

43]. Similarly, Canada’s federal carbon tax, currently set at CAD 65 per ton of CO

2, provides a strong economic signal for blue hydrogen development by improving the cost competitiveness of CCS-integrated production [

20].

In parallel, tax credits and subsidy programs are playing a pivotal role in reducing capital risk and attracting private-sector participation. The U.S. Section 45Q tax credit, offering up to USD 85 per ton of stored CO

2, has been instrumental in revitalizing interest in large-scale CCS projects such as Petra Nova, demonstrating how targeted fiscal incentives can catalyze deployment [

230]. In Australia, the USD 2 billion Hydrogen Head-start program provides competitive grants to support clean hydrogen production, further illustrating the role of public finance in bridging the commercialization gap [

231].

Strategic long-term planning is also essential for scaling integrated systems. The European Union’s EUR 7 billion Hydrogen Strategy, for instance, includes ambitious targets such as deploying 40 gigawatts of electrolysis systems capacity by 2030, reinforcing the bloc’s commitment to hydrogen as a cornerstone of its energy transition. Similarly, the U.S. Department of Energy’s H2@Scale initiative aims to achieve a target hydrogen production cost of USD 1 per kilogram by 2030, focusing on both green and blue hydrogen pathways [

232].

Beyond national efforts, international collaboration is increasingly vital for accelerating technology transfer, harmonizing standards, and pooling research investments. Initiatives such as Mission Innovation and the Clean Energy Ministerial have united over 20 countries in a shared mission to scale CCS–hydrogen systems. Collectively, these partnerships have mobilized over USD 100 billion in global R&D funding by 2030, underscoring the importance of coordinated multilateral action [

20,

233].

These evolving global policies not only reduce economic and regulatory uncertainty but also create enabling environments for cross-border infrastructure development and AI-enhanced system optimization, both of which are critical for achieving scalable, low-carbon energy transitions [

234].

8.2. Regulatory Standards and Requirements

The successful deployment and safe operation of integrated CCS and hydrogen systems rely heavily on robust regulatory standards and compliance frameworks. Standardization not only ensures environmental integrity and public safety but also facilitates cross-border collaboration, investor confidence, and large-scale scalability, directly addressing the regulatory gaps outlined in

Section 4 [

20].

For CO

2 storage, international standards such as ISO 27914 [

235] provide comprehensive guidelines for site selection, injection, and long-term monitoring, ensuring secure containment for more than 1000 years. These standards are being applied in flagship projects like Northern Lights, where transnational CO

2 transport and offshore storage require high levels of technical assurance. Additionally, amendments to the London Protocol have introduced legal mechanisms, enabling cross-border transport of CO

2 for storage and removing a major policy barrier to international CCS cooperation [

236,

237].

In the hydrogen sector, safety regulations are essential due to hydrogen’s unique properties, including its low ignition energy and potential for material embrittlement. Standards such as EN 16726 [

238] govern hydrogen production, storage, and transport, playing a critical role in ensuring operational safety at facilities like Fukushima FH2R. Similarly, ASME B31.12 [

239] provides detailed specifications for hydrogen pipeline design and maintenance, supporting the development of resilient infrastructure networks [

89].

As integrated CCS–hydrogen systems become more prevalent, new standards are emerging to address shared infrastructure challenges. For example, ISO/TC 197 [

240] is developing guidelines specific to blue hydrogen production and co-located carbon capture, offering harmonized protocols for facility design, emissions accounting, and subsurface compatibility, key considerations in projects such as H21 North of England [

241,

242].

Monitoring and verification are also central to regulatory compliance. AI-driven monitoring tools, capable of detecting anomalies with up to 95% accuracy, are increasingly used to ensure real-time adherence to environmental and operational standards. In the United States, these technologies support compliance with the EPA Class VI Underground Injection Control (UIC) regulations, which govern CO

2 sequestration wells and mandate rigorous performance tracking [

243].

Furthermore, digital twins and data-driven approaches are expected to become dominant in AI applications for CCS–hydrogen system integration.

These evolving regulatory frameworks lay the foundation for the scalable, AI-enhanced integration strategies proposed in

Section 4, and support the broader decarbonization roadmap discussed in

Section 9.

8.3. Role of AI in Policy Implementation

AI is increasingly instrumental in enhancing the design, execution, and monitoring of policy frameworks that support integrated CCS and hydrogen systems. By enabling data-driven decision-making, improving regulatory compliance, and fostering public trust, AI contributes to more effective, transparent, and adaptive governance, key enablers for large-scale deployment [

9,

244].

One of the most impactful applications of AI lies in market forecasting and strategic investment planning [

245]. Probabilistic modeling techniques such as Bayesian networks are being used to simulate hydrogen demand under various economic and regulatory scenarios [

37]. These models provide policymakers with actionable insights into future infrastructure needs and market dynamics. In Europe, such tools have informed the allocation of the EUR 7 billion Hydrogen Strategy budget, ensuring alignment with long-term energy transition goals [

246].

In the realm of compliance and regulatory oversight, AI significantly enhances the efficiency and accuracy of monitoring systems [

247]. Machine learning algorithms, including SVMs, are deployed to analyze sensor data from CO

2 storage sites, detecting anomalies that may indicate leakage or operational inefficiencies [

248]. This real-time monitoring capability not only improves environmental safety but also reduces audit and verification costs by up to 20%, making long-term carbon sequestration more economically viable [

249,

250].

At the policy modeling level, AI supports more nuanced and responsive regulatory design. Reinforcement learning models, trained on historical and simulated emissions data, can project the impacts of different carbon pricing schemes, subsidy structures, and technology deployment pathways [

251]. These simulations enable policymakers to optimize incentive programs for maximum impact, potentially improving system-wide efficiency by up to 15%. Such capabilities are especially valuable in designing flexible, forward-looking climate policies that adapt to evolving technological and market conditions [

252].

Beyond technical and economic functions, AI also plays a growing role in public engagement and stakeholder communication. XAI techniques are being developed to clarify complex decision-making processes behind CCS and hydrogen projects, particularly those involving subsurface storage or industrial transformation [

8,

20]. By offering transparent, interpretable outputs, XAI helps demystify risks and benefits, thereby increasing public understanding and acceptance. Studies have shown that well-implemented XAI tools can improve community buy-in by up to 25%, addressing a critical barrier to deployment [

253].

These AI-driven approaches align closely with the integrated system optimization strategies explored in

Section 5.3, while also reflecting the emerging trends in intelligent policy support outlined in

Section 7.2. As AI continues to evolve, its integration into policy implementation will be essential for achieving scalable, equitable, and resilient decarbonization pathways.

8.4. Risk Assessment and Management Strategies for AI-Augmented Integration

To accelerate the deployment of integrated CCS and hydrogen systems at scale, policymakers must implement targeted, forward-looking strategies that reduce financial barriers, enhance regulatory clarity, and foster public confidence [

254]. These recommendations are designed to support the scalable, AI-enhanced decarbonization pathway outlined in

Section 9 and build on the global policy frameworks discussed throughout this section.

A critical first step is to expand and strengthen financial incentives across both CCS and hydrogen value chains. Extending and increasing tax credits such as the U.S. Section 45Q credit, which could be raised to USD 100 per ton of CO

2 stored, would significantly improve the economic viability of large-scale carbon capture projects [

255,

256,

257]. Similarly, direct subsidies or production-linked payments for clean hydrogen targeting a level of approximately USD 0.5 per kilogram of H

2 can help bridge the cost gap between low-carbon and fossil-based hydrogen, potentially reducing system costs by 20–30%. These measures will be instrumental in unlocking private-sector investment and achieving economies of scale [

258].

Second, harmonizing international standards is essential to facilitate cross-border collaboration and infrastructure development. Divergent regulatory requirements across jurisdictions currently hinder the interoperability of CCS–hydrogen systems. By aligning global standards such as those developed by the International Organization for Standardization (ISO) with regional frameworks, governments can enable smoother permitting, shared infrastructure planning, and more efficient project financing [

227,

259].

Third, scaling up research and development (R&D) funding is vital to advancing next-generation technologies. Strategic investments in areas such as DAC, high-efficiency electrolysis, and AI-driven optimization tools will drive down costs and improve system performance. A coordinated global R&D push targeting an aggregate investment of USD 50 billion by 2030 can catalyze innovation and shorten the timeline for commercial deployment [

6].

Finally, public engagement and social acceptance must be prioritized through transparent communication and participatory governance [

260]. The use of XAI tools already piloted in projects like H21 North of England offers a promising approach to demystifying complex technical and environmental risks, thereby improving community trust and facilitating smoother project implementation. Public education campaigns, stakeholder consultations, and open-access data platforms should complement these efforts to ensure broad-based support for decarbonization initiatives [

227,

261].

These policy interventions collectively provide a roadmap for enabling the widespread adoption of integrated CCS and hydrogen systems. They are integral to realizing the strategic vision laid out in

Section 9, which outlines a scalable, AI-enhanced decarbonization pathway for industry and energy sectors [

20].

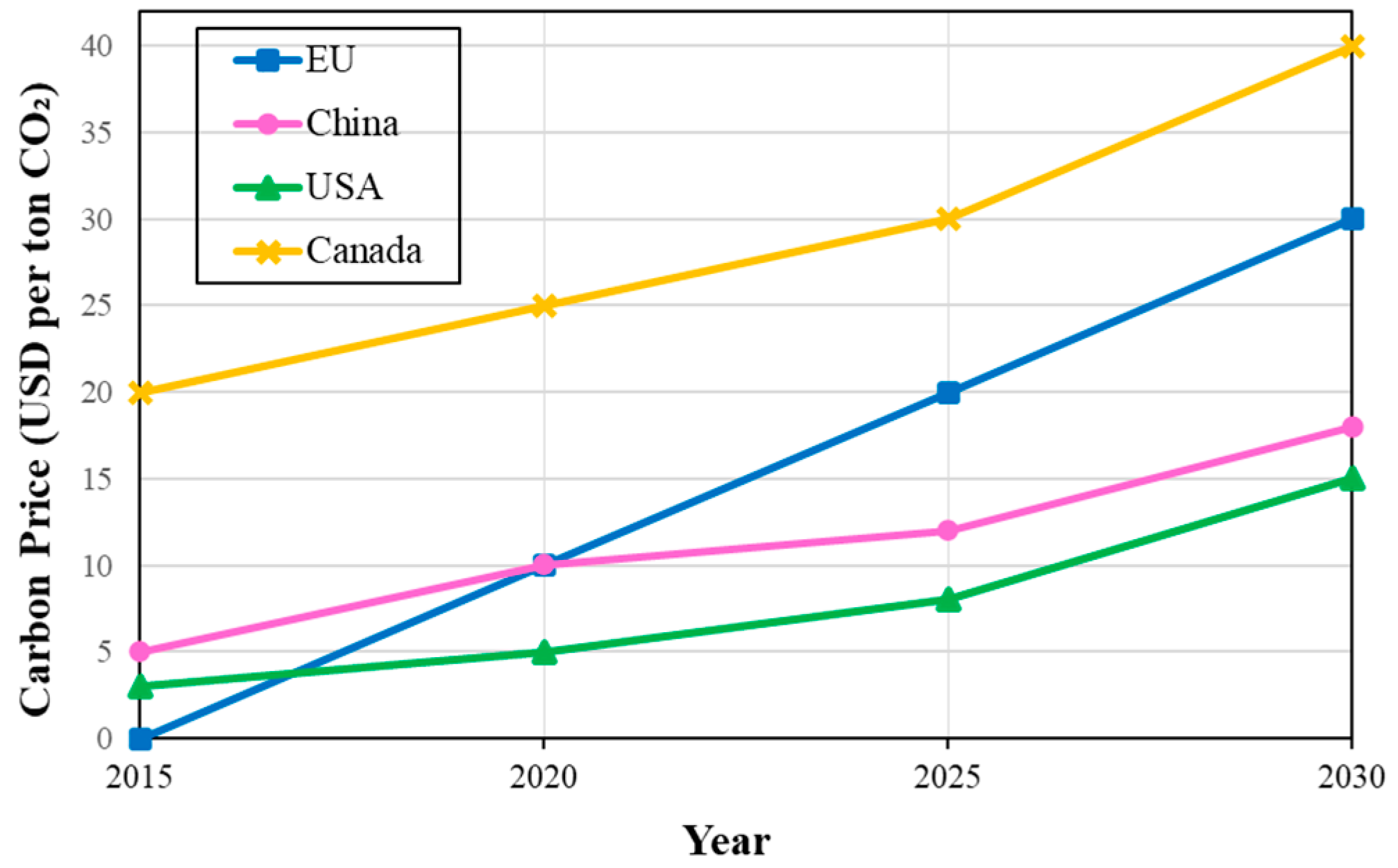

To illustrate the trajectory of one key enabler carbon pricing,

Figure 8 presents a line chart showing historical and projected CO

2 pricing trends from 2020 to 2030 across major regions.

Additionally,

Table 8 provides a summary of key policy and regulatory initiatives supporting CCS–hydrogen integration, highlighting their objectives, mechanisms, and expected impacts.

9. Roadmap for Scalable CCS–Hydrogen Integration

To enable large-scale deployment of integrated CCS and hydrogen systems by 2050, a structured, phased roadmap is proposed, aligning with global climate goals and leveraging advancements in technology, AI, and policy.

9.1. Key Findings

The review highlights the following key findings:

- (a)