Abstract

The advancement of digital technology is driving high-quality and sustainable development in China’s manufacturing sector. This study investigates the role of digitalization in this transformation, using provincial panel data from China spanning 2011 to 2022. A comprehensive theoretical framework is developed to examine both the direct effects of digitalization and its indirect pathways through innovation factor mobility and industrial structure upgrading. The results show that digitalization significantly enhances high-quality manufacturing development, supported by robust empirical evidence. Mechanism analysis confirms that digitalization accelerates innovation diffusion and structural optimization, promoting sustainable industrial transformation. Heterogeneity analysis reveals stronger effects in central and western regions, and in areas with lower economic development and human capital levels. The findings provide valuable insights for aligning digitalization strategies with sustainable development objectives, particularly SDG 9 (Industry, Innovation, and Infrastructure) and SDG 12 (Responsible Consumption and Production). While grounded in the Chinese context, this study offers lessons for other emerging economies pursuing sustainable industrial modernization.

1. Introduction

Since the 18th National Congress of the Communist Party of China, significant emphasis has been placed on Chinese manufacturing industry’s development. By implementing supply-side structural reforms and other policy measures, China’s manufacturing industry has experienced stable growth, structural optimization, and an enhanced role in the global division of labor. Significant gains have been made in both quality and efficiency [1]. However, in the face of the inherent instability and future uncertainty brought about by the increasingly complex and volatile international environment as well as China’s own economic transformation and upgrading, the issue of development quality in China’s manufacturing industry has become even more prominent and urgent. This is specifically manifested in the “double squeeze” faced by manufacturing from both declining revenues and rising costs, the “double squeeze” from the virtual economy and monopolistic sectors, and the “double squeeze” exerted by both developed and emerging countries [2]. According to data from the NBS of China, between 2012 and 2022, the average annual wage in China’s manufacturing sector grew by more than 8% per year, gradually eroding the low-cost advantage that had once bolstered its international competitiveness. As a result, some low-end manufacturing industries have already begun relocating to lower-cost countries such as those in Southeast Asia.

To address these challenges, China’s manufacturing sector must enhance its capacity for independent innovation, accelerate the development of high-end manufacturing, and elevate its position in the global value chain. In addition, it should advance green transformation, strengthen sustainable production capabilities, pursue a strategic global presence, and ensure stable and secure development—ultimately achieving high-quality development that aligns with long-term sustainability goals. Drawing on the work of scholars such as Jin Bei (2018) [3], this study defines the connotation of high-quality development in manufacturing (MHD) as a development paradigm that embodies the principles of the new development philosophy while being compatible with the United Nations Sustainable Development Goals (SDGs). Specifically, MHD balances “quality” and “quantity,” emphasizes coordinated and secure growth, and integrates sustainability as a guiding objective. It is characterized by innovation as the primary driving force, coordination as an intrinsic feature, green practices as a widespread form, openness as a necessary path, and shared development as the fundamental goal. It also prioritizes development quality, efficiency, and safety while promoting responsible industrial upgrading and environmental stewardship.

In the meantime, the world is experiencing yet another wave of industrial and technological revolution, which is based on new-generation digital technologies. The real economy is undergoing a digital revolution thanks to the digital economy and this allows for the integrated growth of both the real and digital economies [4]. According to pertinent data, China’s digital economy now has a CNY 50.2 trillion valuation, with industrial digitalization accounting for 81.7% [5]. The digitalization of traditional industries is the primary way to empower high-quality economic development. Due to its characteristics of high diffusibility, strong synergy, and deep penetration, digital technology exerts a comprehensive and multi-level impact on the real economy. Digital technology not only empowers smart manufacturing and green manufacturing, becoming a new engine for growth in the manufacturing sector, but also optimizes the elements of economic systems and industrial structures. It accelerates the flow of innovation factors, promotes industrial upgrading, and facilitates the high-quality development of manufacturing.

As a crucial part of the real economy, whether the manufacturing industry can benefit from digitalization is crucial to whether China can achieve high-quality growth of its manufacturing industry at this stage. So, can digitalization become a new opportunity to achieve high-quality development of the manufacturing industry? Through what paths does it influence superior development in the manufacturing industry? What heterogeneous characteristics does it possess? Answering these questions can contribute to feasible paths and new ideas for the high-quality development of China’s manufacturing industry in the new era.

Based on the above problems, the research content of this paper is as follows: Firstly, it combines the measurement methods of high-quality development of the manufacturing industry and the impact of digitization on MHD through a literature review, on the basis of which a theoretical analysis framework of the impact of digitization on MHD as well as a comprehensive evaluation index system of MHD are constructed in this study. Based on the panel data of 30 provinces in China from 2011 to 2022, the impact of digitization on MHD is empirically investigated through a panel model, as well as the dimensions through which this impact is realized. Next, it empirically examines how digitization realizes MHD in the factor and industry dimensions through a mediation model. Finally, it finds out whether the impact of digitization on MHD exhibits variability across regions with different regional divisions, different levels of economic development, and different levels of human capital.

The marginal contributions of this paper are threefold, with a clear focus on the Chinese provincial context of digital and industrial transformation.

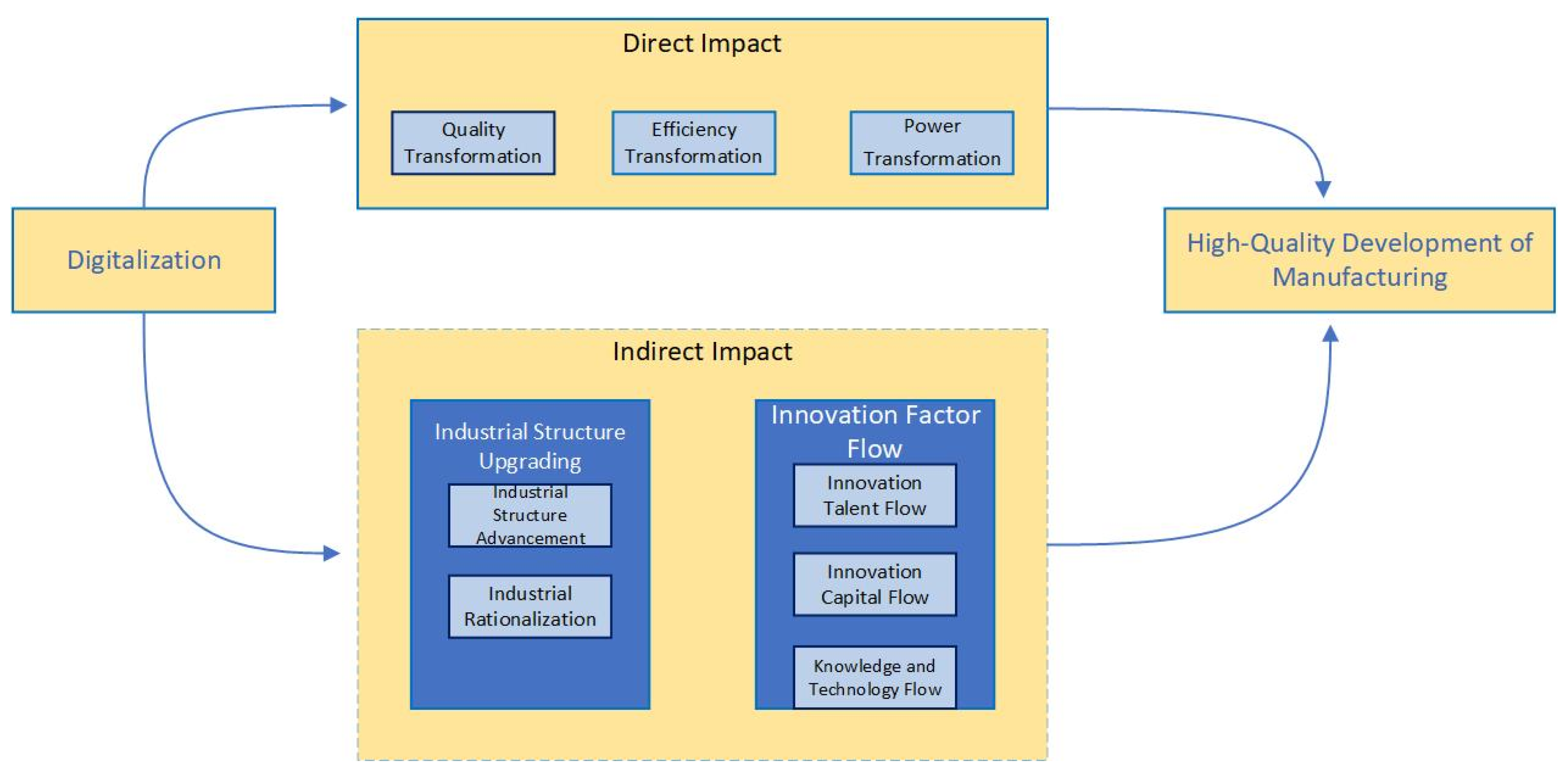

Firstly, this study enriches the theoretical research on how digitalization empowers the high-quality development of the manufacturing industry in emerging economies like China. It develops a conceptual framework that incorporates both direct effects and underlying transmission mechanisms. Specifically, this paper constructs a multidimensional theoretical model from the perspectives of quality improvement, efficiency enhancement, and power transformation, explaining how digitalization affects manufacturing through two core industrial system dimensions: innovation factor mobility and industrial structure upgrading. This framework reflects the unique transformation pressures and opportunities facing China’s manufacturing sector under digitalization.

Secondly, this study enhances the evaluation system of high-quality manufacturing development by constructing a comprehensive index comprising seven dimensions: innovation-driven growth, structural coordination, environmental friendliness, openness to the world, shared development, economic efficiency, and foundational strength. This system is calibrated using provincial-level data from China, offering a reliable tool for empirically measuring regional disparities and dynamics in high-quality development. The index reflects the diverse development trajectories across China’s regions and supports more targeted spatial policy assessments.

Lastly, this paper validates the proposed theoretical mechanisms and hypotheses through rigorous empirical analysis using a balanced panel dataset covering 2011 to 2022 in China. The findings provide detailed empirical evidence grounded in the Chinese context, offering insights that are particularly relevant for countries undergoing industrial upgrading through digital means. This study not only confirms the significance and robustness of digitalization’s impact on high-quality manufacturing development, but also reveals the transmission channels—namely, factor reallocation and structural optimization—through which this effect materializes. These findings contribute to the design of more region-sensitive and sustainability-oriented policy strategies.

Although a growing body of research has explored the relationship between digitalization and industrial performance, most existing studies either focus on macro-level industrial policies or examine single dimensions such as productivity or efficiency. Few studies construct a multidimensional framework that captures the complexity of high-quality development in manufacturing. Moreover, the transmission mechanisms through which digitalization exerts its influence—particularly innovation factor mobility and structural upgrading—remain under-investigated in the Chinese context.

This study addresses these gaps by developing a comprehensive evaluation system for manufacturing high-quality development and empirically testing a dual-path mechanism involving both innovation and structural change. Unlike prior work, it also considers regional heterogeneity in digitalization outcomes, offering more nuanced insights into how policy design can be adapted to local industrial ecosystems.

This study focuses on the Chinese context, where the manufacturing sector is undergoing rapid transformation under the dual pressures of digitalization and high-quality development. China provides a representative case due to its large industrial base, diverse regional development levels, and proactive digital policy agenda. While the findings are specific to China’s provincial-level data, the mechanisms explored—particularly those related to innovation factor mobility and structural upgrading—may offer valuable insights for other emerging economies seeking sustainable industrial modernization.

The practical significance of this study lies in its direct relevance to regional policy design and enterprise strategy formulation in China’s manufacturing sector. First, the multidimensional evaluation index system can serve as a practical tool for local governments to monitor progress toward high-quality and sustainable manufacturing development, enabling more targeted and adaptive policymaking. Second, the findings on innovation-driven pathways and structural upgrading provide actionable insights for designing fiscal incentives, talent development programs, and industry support schemes. Third, manufacturing firms can leverage these insights to align their digital transformation initiatives with sustainability goals, improving competitiveness while contributing to SDG-aligned industrial growth. Overall, this study offers concrete guidance for policymakers and industry practitioners seeking to balance technological advancement with sustainable industrial modernization.

2. Literature Review

The research landscape on digitalization and its contribution to the growth of the manufacturing sector is complex and diverse. At its heart, the scholarly work splits into two main aspects. Firstly, it probes the evaluation of MHD. These indicators are foundational for grasping the intricate aspects of quality in the sector. Secondly, the research explores the effects of digitalization on enhancing quality, examining the influences from both the supply and the demand sides.

2.1. Literature Review on Measurement of High-Quality Development of Manufacturing

The measurement of MHD is multifaceted, typically viewed from three perspectives: industrial structure, total factor productivity (TFP), and a comprehensive evaluation index system.

Researchers have quantified the advancements, rationalization, and efficiency of the industrial structure to depict the level of MHD from an industrial economics standpoint. For instance, Fu et al. (2016) measured the benefit and rationality of the manufacturing structure across multiple dimensions such as gross output, added value, and net fixed assets [6]. Ren & Deng (2022) employed the concepts of manufacturing structural upgrading and value chain climbing as metrics to assess MHD [7].

Additionally, MHD can be gauged by the improvement in total factor productivity or individual factor productivity, further broadening the scope of assessment in the manufacturing sector. Furthermore, scholars like Yu & Wang (2022) argue that the essential characteristic of MHD lies in the enhancement of efficiency improvement, with TFP serving as a comprehensive and thorough measure of efficiency [8].

A third approach involves the construction of comprehensive evaluation index systems to measure MHD. These studies typically base their indicators on the theory of economic growth quality and new development concepts. For example, Zhou et al. (2023) assessed high-quality development from the angle of resource allocation efficiency, innovation upgrade capability, and inclusive development [9]. Wu et al. (2023) established a comprehensive evaluation system covering four dimensions: efficiency improvement, quality enhancement, power transformation, and structural optimization [10]. Wang et al. (2023) devised an evaluation index system including six sub-dimensions and 24 basic indicators aligned with the connotation of new development concepts [11]. Liu & He (2024) constructed an MHD index system comprising five dimensions: Ballpark, Innovations, Efficiency, Structures, and Ecology [12].

Upon reviewing the existing literature, it becomes evident that while concepts such as innovation, coordination, green, openness, and sharing fundamentally emphasize quality, the current evaluation systems based on them do not adequately coordinate the assessment of quality and quantity. Thus, the dimension of economic growth quantity needs further elaboration, and the foundations of MHD, such as infrastructure and supply chain security, should also be integrated into the comprehensive evaluation system [13].

2.2. Literature Review on Digitalization’s Impact on Manufacturing Excellence

The impact of digitalization on MHD is a multifaceted subject, explored from both demand-side pull and supply-side push.

On the demand side, the early digitalization of the tertiary industry developed earlier during the Internet era, and Internet business models driven by demand and value creation emerged. The economic principles of enterprises have changed, and the bonus gained from connection has become the focus of Internet business models [14]. Digitalization penetrated the demand side, triggering a matching transformation between production and demand, forcing the manufacturing production side to capture and arrange production flexibly [15], thus fostering the demand for digital transformation in manufacturing.

On the supply side, digitalization’s influence on MHD manifests at three levels: macro, meso, and micro. At the macro level, digitalization improves labor productivity and social production efficiency [16], transforms social production relations, and has a significant effect on production, distribution, exchange, and consumption [17]. The establishment of a digital government framework can significantly increase per capita output [9]. Moreover, at the meso level, digitalization is found to encourage the movement of elements between industries and areas [18], improve TFP [19], and provide strong momentum for industrial integration and structural upgrading [20]. Utilizing digital technology is essential for integrating manufacturing with the digital economy, achieving digital empowerment [21]. In addition, at the micro level, within enterprises, digital transformation is driving disruptive innovation in production, operation, and management [22]. Within the micro-level sphere, digital finance and platforms are prime examples of how digitalization spurs change. Digital finance significantly influences production, operation, and management by alleviating corporate financing constraints and optimizing corporate financing behaviors [23]. Digital platforms provide convenience for companies to expand markets and improve services, thereby enhancing business profits and promoting MHD [24].

From the perspectives of these three levels, research on the impact of digitalization on manufacturing is relatively extensive. However, the specific mechanisms and boundaries of digitalization’s impact on MHD still need further exploration and clarification.

3. Theoretical Framework and Hypothesis Development

To systematically explain the influence of digitalization on high-quality manufacturing development, this study draws on the Techno-Economic Paradigm (TEP) theory. As proposed by Perez (2002) [25], each wave of technological revolution reconfigures the prevailing production and institutional systems, establishing a new paradigm for economic growth and industrial transformation. In this context, digitalization represents the core technological driver of the current paradigm shift.

Guided by the TEP framework, we argue that digitalization reshapes manufacturing through two primary channels: (1) by enhancing the mobility and productivity of innovation factors, including knowledge, capital, and skilled labor, and (2) by facilitating industrial structure upgrading, enabling the transition from low-end, resource-dependent industries toward technology-intensive, green, and service-integrated sectors. These two mechanisms jointly drive the transformation of quality, efficiency, and development dynamics—the core dimensions of high-quality growth.

The role of digitalization in shaping the manufacturing landscape cannot be overstated. By exploring key areas—efficiency, innovation, and structural upgrades—valuable insights into how digitalization drives positive change can be gained. Digital transformation certainly acts as a catalyst for MHD in this dynamic sector by enhancing product quality to accelerate research and development.

3.1. Digitalization and High-Quality Development of the Manufacturing Industry

Due to the characteristics of high growth, high technicality, high diffusion, high synergy, and strong penetration of digital technology, digitalization has significantly influenced MHD by achieving quality transformation, efficiency transformation, and power transformation [26].

3.1.1. Quality Transformation

Digitization promotes quality transformation, comprehensively enhances product quality and market competitiveness, and expands effective and mid-to-high-end supply [27,28]. This not only helps the manufacturing industry to improve profitability but also helps promote the transformation and upgrading of the manufacturing industry [20].

Digitization strengthens and improves product or service quality [29]. For instance, real-time data collection is made possible by IoT technologies and analysis by interconnecting equipment and systems, while big data analytics and AI technologies can analyze large amounts of data generated during the production process to enable the timely identification and correction of potential quality issues, thereby avoiding the production of defective products. Again, blockchain technology and other digital means can achieve full traceability of product quality [30]. Once quality issues are detected, the problem can be quickly located for effective rectification and prevention.

Similarly, digitalization accelerates brand building and enhances market competitiveness [31,32]. In addition, digital technology provides enterprises with broader boundaries for market expansion. Through digital platforms, enterprises can quickly enter emerging and overseas markets, realizing a globalization layout [33]. Digital technology also helps enterprises establish a digital brand image. Through the use of social media, digital marketing platforms, and other channels, enterprises can disseminate brand stories and core values, enhancing brand awareness and reputation [34].

3.1.2. Efficiency Transformation

Several studies have shown that digitization promotes transformation efficiency, improves value creation efficiency, expands value creation carriers, and empowers MHD.

Moreover, digitization enhances production efficiency and accelerates value creation [35]. For example, the application of automated equipment and industrial robots significantly improves the efficiency and accuracy of production lines [36]. Equally, automated production lines can run continuously, reducing errors and downtime caused by human operation [37]. Correspondingly, manufacturing enterprises can simulate production processes and equipment operation in digital twins, identify potential problems in advance, and make adjustments, thereby reducing the cost of trial and error in actual production [38].

Likewise, digitization assists in building a collaborative network for the supply chain, expanding value-creation carriers [39]. In the same vein, digitization enhances the efficiency, flexibility, and competitiveness of the supply chain, promoting its upgrading and optimization, thereby empowering MHD [40]. Moreover, digitization enables real-time information sharing among the supply chain’s upstream and downstream enterprises, improving the efficiency and response speed of collaboration between various links [41]. Also, intelligent supply chain management systems optimize resource allocation and efficient collaboration, enabling cross-departmental and cross-enterprise collaborative production and optimizing resource utilization and production scheduling [42]. Digitization supports intelligent demand forecasting and supply planning. Again, it is worth noting that big data analytics and predictive models allow enterprises to more adeptly predict market demand and supply risks and optimize inventory management and product planning, thereby improving the supply chain’s flexibility and adaptability [43].

3.1.3. Power Transformation

Digitization also promotes power transformation, nurtures new momentum, and achieves the succession and metamorphosis of old and new driving forces [44].

Scholarly works have found that digitization empowers innovation-driven development, realizing the ‘multiplication’ effect of technological innovation on MHD, mainly manifested in accelerating innovation cycles, reducing innovation costs, and promoting collaborative innovation, injecting new dynamism and vitality into technological innovation and R&D activities and assisting MHD. Xie et al. (2024) affirm that digitization provides faster and more efficient research and development tools and platforms, greatly shortening the innovation cycle [45]. Also, Zhang et al. (2021) discovered that digitization reduces the cost of technological innovation and R&D, and lowers the threshold for R&D [46]. Zheng & He (2023) assert that digital technology promotes collaborative innovation and cross-industry cooperation [47]. They further argue that the benefit of digital transformation to cooperative innovation has improved enterprises’ total factor productivity. Internet and digital platforms enable enterprises to cooperate beyond geographical and industry boundaries, jointly conducting technological innovation and realizing resource sharing and complementary advantages [48].

Digitization empowers green manufacturing, achieving the ‘addition’ of energy features between traditional and emerging industries, and such as can improve energy efficiency [49]. Researchers have reiterated that by applying Internet of Things technology to manufacturing equipment and factory management, enterprises can monitor energy consumption and optimize usage. It has also been pointed out that CPS can provide energy-saving suggestions and automatically adjust energy usage strategies [50]. Zhao et al. (2024) revealed that, through big data and AI technologies, enterprises can optimize production procedures and reduce pollutant emissions during production [51]. According to Kurniawan et al. (2023), big data and blockchain can be used to track and manage resource flows and promote resource recycling and reuse [52].

Based on this, the following research hypothesis is proposed:

Hypothesis 1.

Digitization significantly promotes MHD.

3.2. The Intermediary Mechanism of Digitization and High-Quality Development of the Manufacturing Industry

Due to historical legacies such as local protectionism and interprovincial market fragmentation in China, the national allocation of factors and an imbalance in industrial structure have seriously hindered MHD [53]. However, with the support of digital technology, the competitive mechanism for innovation factor allocation is strengthened, and information frictions are alleviated [54]. As competitive mechanisms to improve innovation factor allocation efficiency, the role of technological progress and capital deepening in promoting industrial structure upgrading is strengthened [55]. At the same time, the industrial structure transformation provides direction and opportunities for innovation factor flow, and the two mutually promote and depend on each other [56]. Therefore, this work analyzes the intermediary mechanism of digitization on MHD from the perspectives of innovation factor flow and industrial structure upgrading.

3.2.1. Digitalization, Innovation Factor Flow, and High-Quality Development in Manufacturing Industry

Digitization has facilitated market integration, transcended geographical limitations, and promoted the flow of innovation factors. Firstly, it has facilitated market integration through online consolidation, optimized allocation, and standardized competition [57]. Digitization provides more convenient and real-time channels for information exchange, enabling the rapid dissemination and sharing of innovation factor information over a larger scope [58], thereby promoting the flow of innovation factors. Secondly, digitization has rendered geographic location no longer a limiting factor for collaboration [59]. Through remote work and virtual teams, people can engage in cross-geographical cooperation and collaboration, forming an industry ecosystem based on cyberspace. This breakthrough overcomes the spatial market size constraints of “Smith’s theorem”, significantly expanding the range of factor allocation and enhancing the cross-regional flow and exchange of talent and technology. In other words, the fairness and real-time interaction of digitization enable both supply and demand sides of factors to access information without the constraints of time and space, helping to break market segmentation, alleviate information asymmetry, and reduce search costs for factors. Consequently, this promotes the flow of factors between regions, with capital freely flowing to regions with higher utilization efficiency, and individuals promptly accessing recruitment information matching their skills and salary requirements [60].

Accelerating innovation factor flow strengthens the competitive mechanism, leading to knowledge spillover effects, division of labor effects, and resource optimization effects, thus promoting MHD. In the first instance, the flow of innovation factors strengthens regional competition. Against the backdrop of building a unified national market, competition among regional governments and enterprises has intensified, resulting in “innovation competition” [61]. Inter-regional competition for innovation fosters chances for innovation activities, which can drive technological progress and accelerate market innovation [62]. Therefore, the flow of innovation factors promotes MHD through competitive effects. Moreover, innovation factor flow also has knowledge spillover effects, division of labor effects, and resource optimization effects [63]. Specifically, the flow of R&D factors can shift from innovation activities with weaker comparative advantages to those with stronger ones, achieving effective allocation of innovation factors [64]. As innovation factors flow, technology and knowledge dissemination occur, and the shared nature of knowledge and technology accelerates technological progress [65]. As the market scope expands, the division of labor in innovation activities becomes more refined, leading to improved innovation efficiency and further promoting MHD.

Based on this, the following research hypothesis is proposed:

Hypothesis 2.

Digitization can promote MHD by accelerating the flow of innovation factors.

3.2.2. Digitalization, Industrial Structure Upgrading, and High-Quality Development of the Manufacturing Industry

The inherent logic of industrial structure upgrading indicates that technological advancement is an internal motivating factor behind such upgrades, with each technological revolution bringing forth a transformation in economic paradigms [66]. Under the digital economy’s economic paradigm, digitization can reshape traditional industries and promote emerging industry formats, thereby driving industrial structure upgrading. Firstly, digitization reshapes traditional industries. While driving industrial efficiency, digitization also changes the management philosophy of traditional industries, shifting towards a user-value-oriented approach [67]. Digitization promotes cross-industry integration, accelerates factor flow, and compels enterprises to enhance their technological innovation capabilities, thereby promoting industrial structure upgrading [68]. Secondly, digitization promotes the formation of emerging industries. Digitization enables the integration and restructuring of different industries with high correlation, transforming low-level industries into advanced forms and fostering the emergence of new industries, thus accelerating the transformation and upgrading of industrial structures. Digitization facilitates the convergence of manufacturing and digital economic industries through digital technologies such as industrial clouds, leading to industrial upgrading [69]. Digital inclusive finance can broaden financial service coverage, optimizing fund allocation and promoting industrial structure upgrading.

Once more, upgrading China’s industrial structure is seen as a key component in advancing the country’s transition to high-quality development. One benefit of changing the industrial structure is that it can encourage the economy to allocate resources rationally and raise China’s green total factor productivity. These developments will support sustainable development and green manufacturing, as well as MHD [70]. Furthermore, technological advancement and innovation frequently accompany industrial structure upgrading. These developments introduce sophisticated machinery and automated systems to the manufacturing sector, propel smart manufacturing’s growth, and support MHD [71]. Moreover, the upgrading of the industrial structure necessitates that the manufacturing sector expand into high-value sectors including R&D, design, and branding. In order to increase the manufacturing sector’s competitiveness, this further calls for the development of a more comprehensive and effective industrial chain [72]. Finally, in order to satisfy the market’s demand for high-quality products, industrial structure upgrading necessitates a continuous improvement in product quality from the manufacturing sector. This encourages manufacturing companies to spend more on innovation, which results in new goods creation with significant added value and technological content.

Based on these factors, the following research hypothesis is proposed:

Hypothesis 3.

Digitization can promote MHD by facilitating industrial structure upgrading.

Based on the theoretical analysis in this paper, a mechanism analysis diagram is constructed, as shown in Figure 1.

Figure 1.

Mechanism diagram.

4. Research Design

4.1. Model Construction

To empirically examine the impact of digitization on MHD, we construct the following baseline regression model:

In this model, represents the level of MHD in province at time ; represents the level of digitization in province at time ; represents control variables; indicates unobserved factors specific to each province that do not vary over time, controlling for regional fixed effects; controls for time fixed effects; and represents the error term.

4.2. Variable Selection and Measurement

4.2.1. Dependent Variable: Level of High-Quality Development in the Manufacturing Industry

Based on this definition, this study constructs a comprehensive index system for MHD, which includes seven dimensions: innovation-driven, structural coordination, environmental friendliness, openness, shared development, economic benefits, and development foundation. This system incorporates 7 secondary-level indicators and 20 tertiary-level indicators, as outlined in Table 1.

Table 1.

Comprehensive evaluation indicator system for MHD.

In the dimension of innovation-driven development, to enhance the role of innovation, it is necessary to increase innovation input, improve innovation output efficiency, and enhance research and development efficiency [73]. Thus, tertiary-level indicators are chosen from the following three perspectives: innovation input, innovation output, and R&D efficiency.

For structural coordination, achieving structural coordination in the manufacturing industry involves not only internal coordination of industrial structures but also the coordination of enterprise income structures and ownership structures [11]. Therefore, three tertiary-level indicators are selected: industrial structure, income structure, and ownership structure. In the “structural coordination” dimension of the MHD index, we include the share of revenue from non-state-owned enterprises (non-SOEs) as an indicator. This reflects the degree of market-oriented reform and structural diversification within the manufacturing sector. A higher proportion of non-SOE revenue generally implies greater participation of private capital, more flexible institutional arrangements, and more competitive dynamics, all of which contribute to a more adaptive and resilient industrial structure.

Regarding environmental friendliness, achieving environmentally friendly manufacturing requires not only low-pollution and low-energy consumption green development but also pollution control measures [45]. Hence, tertiary-level indicators are chosen from three perspectives: resource consumption, pollution emissions, and pollution control.

In terms of openness, this study measures the degree of openness in the manufacturing industry from the perspectives of “bringing in” and “going out.” “Bringing in” considers the attractiveness of foreign investment, measured by foreign investment intensity; “going out” considers China’s exports as the “world’s factory,” measured by foreign trade competitiveness [74].

For shared development, a solid material foundation is essential for achieving common prosperity. The manufacturing industry can not only absorb employment and provide income, but also drive employment in the producer service industry. Therefore, this study selects tertiary-level indicators from the following three perspectives: employment absorption, income guarantee, and industrial linkage.

Regarding economic benefits, good economic benefits in manufacturing require maintaining a certain growth rate to achieve the policy goal of “steady progress”, while further improving efficiency benefits, such as labor efficiency and capital investment efficiency, to get rid of the economic inertia of extensive development [75]. Thus, tertiary-level indicators are chosen from speed benefits and efficiency benefits.

Lastly, for development foundation, as safety is the foundation of development, manufacturing’s development must pay attention to industrial safety. Industrial chain security and industrial chain resilience are the key issues of academic attention [76]. And good infrastructure is also manufacturing’s cornerstone to achieve industry stable development. Therefore, this study selects tertiary-level indicators from infrastructure and safety development.

To assess the level of MHD, the entropy weight method is used. We calculate the comprehensive evaluation scores as the level of MHD. Additionally, referring to the study [77], a combining method is employed to derive MHD2, utilized for robustness testing, which contains subjective and objective factors.

4.2.2. Explanatory Variable: Level of Digital Development

Given how widely used digital technology is, digitization’s effect on socio-economic life is widespread. Firstly, digital infrastructure is an essential basis for the transformation of other aspects into digital forms. Secondly, the flourishing development of digital industries acts as a significant driving force behind digitization. Lastly, the widespread application of digital thinking and tools is integral to the value creation and realization processes of various economic organizations. Thus, this research constructs a digital assessment index system containing the following three secondary indicators, digital infrastructure, digital industry development, and digital application, referring to relevant research [78], and identifies ten tertiary indicators. Specifically, for digital infrastructure, indicators such as mobile phone penetration rate, internet broadband access rate, and optical cable line density are used. For digital industry development, indicators include per capita telecommunication service volume, software business revenue, and revenue from large-scale electronic information manufacturing enterprises. For digital application, indicators such as per capita postal service volume, computer usage per hundred people, number of enterprises with websites per hundred, and e-commerce sales are utilized. The level of digitalization (Dig) is calculated by employing the entropy weight method.

4.2.3. Control Variables

It is worth noting that while digitalization may also affect manufacturing through cross-sector spillovers—for example, via financial technology or digital service platforms—this study focuses only on the direct effect of digitalization on the manufacturing sector itself. To mitigate potential bias from such indirect influences, we incorporate control variables such as financial development, foreign direct investment, and education level, which proxy for the broader economic environment. This ensures that the estimated coefficients for digitalization reflect its core impact on manufacturing development.

To provide a more accurate and scientifically rigorous analysis of digitization’s impact on MHD, controlling other economic factors that may affect MHD is necessary. Drawing on relevant research [45,79], the following control variables are chosen: 1. Government Support (Support): Measured by the ratio of general budget expenditures of local governments to regional GDP. 2. Financial Development Level (Fin): Represented by the ratio of the balance of loans and deposits of financial institutions at the end of the year to regional GDP. 3. Tax Burden Level (Tax): Measured by the ratio of local fiscal tax revenue to regional GDP. 4. Environmental Regulation (Ruge): Indicated by the ratio of investment in industrial pollution control to industrial value added. 5. Marketization Level (Market): Assessed by the marketization index of provinces in China.

4.3. Data Source and Descriptive Statistics

This research selects 30 provincial units in China from 2011 to 2022 as research samples (excluding the Tibet Autonomous Region due to significant missing indicators), forming a balanced panel dataset of province–year. The data mainly comes from the National Bureau of Statistics in China, provincial statistical yearbooks, CSMAR database, and EPS database. Interpolation methods are used to calculate some missing data.

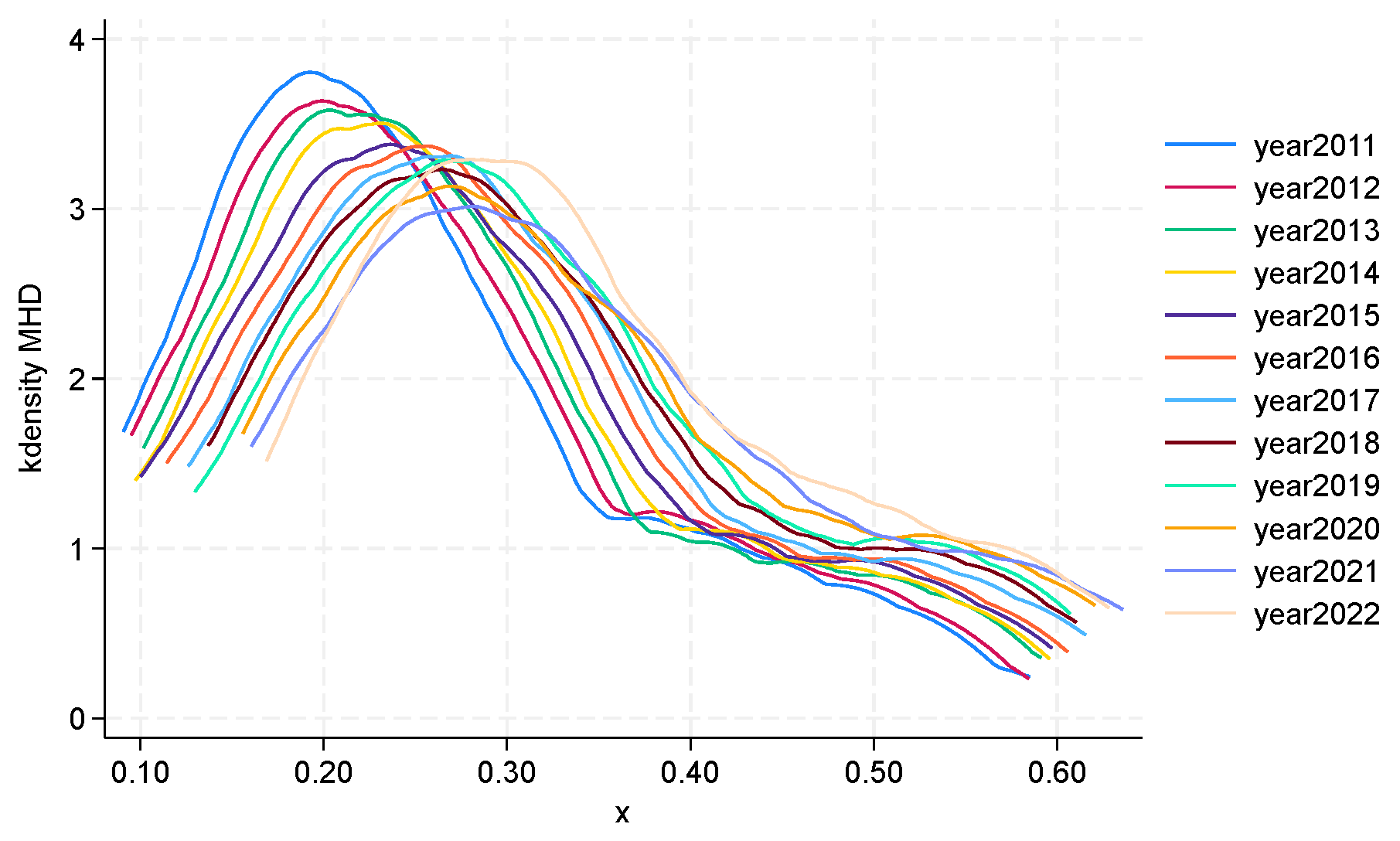

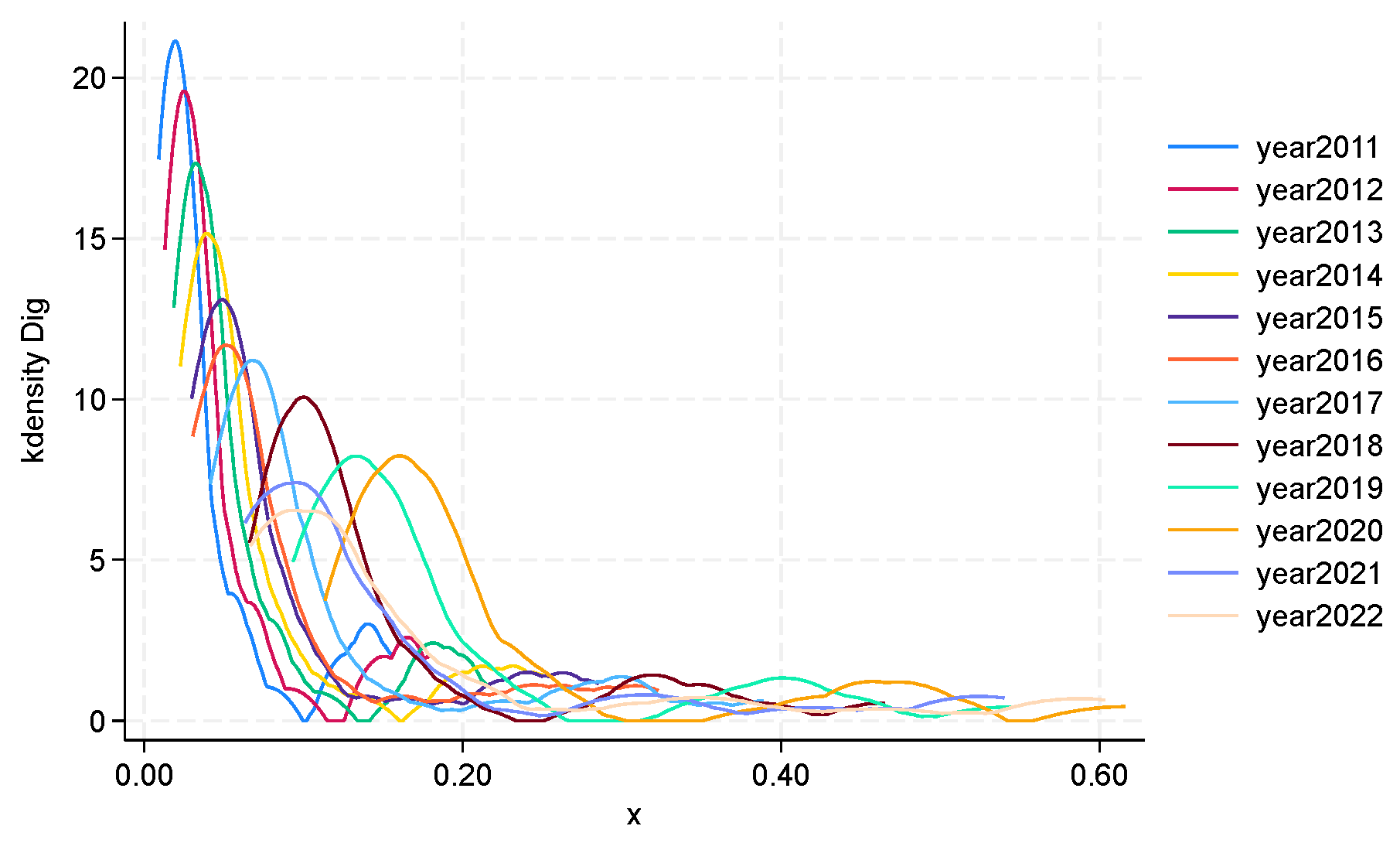

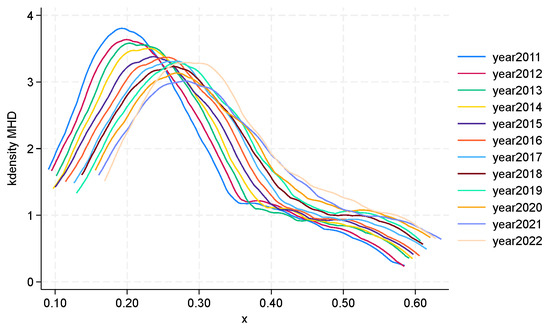

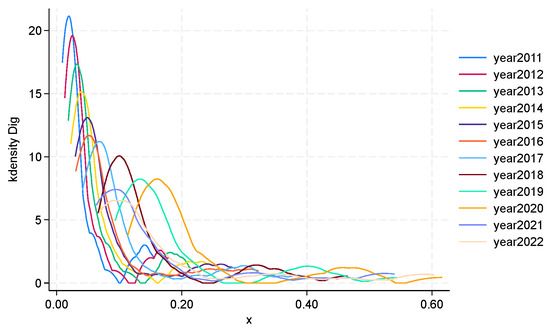

The primary variables’ descriptive statistics are shown in Table 2, while Figure 2 and Figure 3 depict the kernel density plots of MHD and digitization. The results indicate that the MHD ranges from 0.0908 to 0.636, with a coefficient of variation of 0.428, suggesting relatively low differentiation among the provinces regarding the level of MHD. Over the study period, the manufacturing MHD level shifts to the right, with a peak initially decreasing and then increasing, demonstrating a distribution that approximates a standard normal distribution. This implies a well-distributed geographic pattern of MHD across China.

Table 2.

Descriptive statistics of main variables.

Figure 2.

Kernel density plot of MHD level.

Figure 3.

Kernel density plot of digital development level.

Regarding the level of digitization (Dig), the minimum is 0.00907, the maximum is 0.616, and the variation is 0.9487, indicating significant variation in digitization levels among different provinces. The distribution of digitization levels exhibits a pronounced right-skewed pattern, with the peak concentrated on the left side. This suggests substantial disparities between advanced provinces and ordinary provinces, with most provinces clustered at lower levels of development. Additionally, the peak gradually decreases and shifts to the right, indicating an improving trend in digitization development among ordinary provinces, albeit with a clear trend of internal differentiation.

The kernel density plots of MHD (manufacturing high-quality development) and digitalization were constructed using annual provincial-level index values over the study period. Specifically, the composite MHD index and the digitalization index were first calculated for each province and year based on standardized indicators. To visualize the dynamic evolution and distributional shifts over time, we selected representative years (e.g., 2011, 2016, and 2022) and employed kernel density estimation (KDE) using a Gaussian kernel and default bandwidth selection.

These plots were generated using Stata 16.0 and are based on non-parametric density estimation techniques, which allow for flexible characterization of the data distribution without assuming a specific functional form. The purpose of these visualizations is to reveal trends such as polarization, convergence, or divergence in regional development levels.

5. Empirical Results Analysis

5.1. Benchmark Regression Analysis

Given Hausman test’s results, this paper chooses an individual and time fixed effects model. This approach controls for potential endogeneity issues arising from unobserved individual heterogeneity and time trends. The outcomes of the benchmark regression are shown in Table 3. Columns (1) to (5) in Table 3 show the regression results with the gradual addition of individual fixed effects, time fixed effects, control variables, and robust standard errors. Throughout these regression results, the coefficient of digitalization for MHD is consistently and significantly positive. This indicates that digitalization can transform manufacturing production and operation processes, enhance production efficiency, and significantly promote MHD, thereby confirming research hypothesis 1 of this paper.

Table 3.

Baseline regression results.

This result confirms the conclusion of Li & Qu (2022) [78], who argue that digitalization can promote MHD.

Among the control variables, the impact of government support on MHD is significantly negative. This could be due to excessive government support potentially causing market distortions, hindering effective market operations and affecting the competitiveness and innovation drive of enterprises. Additionally, the coefficient for the level of financial services for MHD is significantly negative. This suggests that in regions with higher financial development, there is a greater degree of economic servitization and virtualization, meaning that funds may flow into financial markets, real estate, and other non-real sectors, rather than into the manufacturing industry.

5.2. Regression Analysis by Dimensions

To thoroughly understand the intrinsic mechanisms through which digitalization affects MHD, this paper conducts dimensional regression analyses on seven aspects of MHD. The regression results are displayed in Table 4. Columns (1) to (7) correspond to the following seven aspects: innovation-driven, structural coordination, environmental friendliness, openness to the outside world, shared development, economic efficiency, and development foundation.

Table 4.

Results of dimensional regression.

The coefficients for digitalization for innovation-driven, structural coordination, environmental friendliness, shared development, economic efficiency, and development foundation are all significantly positive. This demonstrates that digitalization promotes MHD by enhancing innovation, structural coordination, environmental sustainability, shared development, economic efficiency, and the development foundation. However, the impact of digitalization on openness is significantly negative. This could be because, as digital technologies progress, manufacturing enterprises place greater emphasis on protecting intellectual property. To prevent technology leaks, they may become more cautious in selecting partners and may even limit the external transfer of technology.

5.3. Endogeneity and Robustness Tests

5.3.1. Endogeneity Test

Endogeneity is an unavoidable issue in economic research. The advancement of digitalization relies on high-quality manufacturing to provide products and equipment, and MHD also depends on the rapid development of digitalization. Therefore, there is an inherent causal relationship between the two. Additionally, issues such as omitted variables can also lead to endogeneity. This paper conducts endogeneity tests through instrumental variable verification, lagged dependent variable regression, and exogenous shock testing.

To mitigate endogeneity, we first employ the instrumental variable. Following the studies [77,80], we select the number of fixed telephones per 100 people in 1984 and the number of per capita mobile text messages in each region as instrumental variables. Since fixed telephone number in 1984 is cross-sectional data, this study follows the common practice of multiplying it by the internet access penetration rate to convert it into panel data.

As shown in column (1) of the first-stage regression, both the number of mobile text messages per capita and the number of fixed telephone lines per 100 people in 1984 are significantly correlated with the digitalization variable. This confirms the relevance of the selected instruments. Furthermore, the instrumental variables passed several diagnostic tests: the Kleibergen–Paap rk LM statistic has a p-value of 0.000, rejecting the null hypothesis of under-identification; the Kleibergen–Paap rk Wald F statistic is 59.321, which exceeds the Stock–Yogo 10% critical value of 19.93, indicating no weak instrument problem; and the Hansen J statistic has a p-value of 0.01, suggesting that the instruments satisfy the over-identification restriction. These results support the validity and suitability of the chosen instruments for addressing potential endogeneity. According to the regression results in column (2), after accounting for endogeneity, the empowering effect of digitalization on MHD remains significant.

To further mitigate the potential bias from instrumental variables, this paper also adheres to the method of Hui & Yang (2022) by using lagged explanatory variables to reduce the possibility of reverse causality [79]. Regressions are conducted using the first and second lags of digitalization. Column (3) of Table 5 shows the regression result for the first lag of the explanatory variable, and column (4) shows the result for the second lag of the explanatory variable. The result indicates that the promoting effect of digitalization on MHD remains significantly valid.

Table 5.

Endogeneity test.

In the process of digitalization, challenges such as weak digital infrastructure and a shortage of talent are evident, necessitating support and guidance from government policies. Referencing Sun et al. (2023) [81], who used the establishment of the National Big Data Pilot Zone as a quasi-natural experiment, this paper utilizes this policy shock after conducting a parallel trend test. A DID model is used to examine digitalization policies’ impact on MHD. Column (5) shows that the parallel trend test has passed. The regression results are shown in column (6). They indicate that the establishment of the National Big Data Pilot Zone significantly promotes MHD in the pilot zones.

5.3.2. Robustness Test

This paper primarily conducts robustness tests by changing the estimation method, replacing the dependent variable, replacing the explanatory variable, and excluding outliers.

First, the estimation method of the model is changed. Referring to Huang et al. (2023) [82], the FGLS method is used for robustness testing, and the results are presented in column (1) of Table 6. They show that after changing the estimation method, digitalization still significantly promotes MHD.

Table 6.

Robustness test.

Second, the dependent variable is replaced. Specifically, the measurement method of the dependent variable is changed, using a combined subjective and objective weighting method. Column (2) of Table 6 displays results for MHD2 measured using this combined method. The results indicate that after replacing the dependent variable, digitalization still significantly promotes MHD.

Third, the explanatory variable is replaced. The number of employees in the urban units of the information transmission, software, and information technology services industry is used to measure digitalization’s level. The results shown in column (3) of Table 6 demonstrate that the promoting effect of digitalization on MHD remains significant after replacing the explanatory variable.

Fourth, considering that municipalities directly under the central government have unique advantages in political status and resource conditions, the sample of municipalities is excluded, and regression is conducted for other provinces. The results shown in column (4) of Table 6 show that after excluding the samples of municipalities, digitalization still significantly promotes MHD.

5.4. Mechanism Analysis

Based on the discussion of the mechanisms in the theoretical analysis, digitalization can drive MHD by accelerating the flow of innovation elements and promoting industrial structure upgrading. To empirically test mechanisms of innovation element flow and industrial structure upgrading, this research employs the two-step method proposed by Jiang (2022) [83], and the mediation effect models are as follows:

Among them, represents the mediating variables, which are flow of innovation factors and industrial structure upgrading in this paper.

In terms of innovation factor flow, this study measures it from three perspectives: innovation capital flow, innovation talent flow, and knowledge and technology flow. Innovation capital flow () and innovation talent flow () are calculated using a gravity model approach, as referenced from the study by Hao et al. (2024) [84]. The formulas are as follows:

Among them, and , respectively, represent the accumulated stock of R&D capital in regions and calculated using the perpetual inventory method. denotes the geographical distance between the provincial capitals of regions and . represents the number of R&D personnel in region , while indicates the average wage level in region .

Knowledge and technology flow () is presented by the ratio of technology market turnover to regional GDP for each province.

In terms of industrial structure upgrading, we measure it from two aspects: industrial structure rationalization () and industrial structure supererogation (). The Theil index is used to evaluate the rationalization of industrial structures, as referenced by Gan et al. (2011) [85]. A lower Theil index indicates a more rational industrial structure, though traditionally it is a negative indicator. This study converts it into a positive indicator by taking its reciprocal [77]. For industrial structure supererogation, both quantitative and qualitative aspects are considered, specifically the ratio of industrial output and labor productivity [86]. This approach better reflects the essence of industrial structure upgrading. The calculation formulas are as follows:

Here, represents provinces, represents time periods, and represents sectors of the economy. denotes output, and denotes employees’ number.

Based on the theoretical analysis, digitalization can promote the flow of innovation factors, thereby facilitating MHD. This aligns with one of the study goals: examining the mediating role of innovation factor flow through three dimensions, flow of innovation capital (), flow of innovation talents (), and flow of knowledge and technology (). The regression results are presented in Table 7.

Table 7.

Regression results of the mechanism of innovation factor mobility.

The regression results demonstrate that digitalization can promote MHD through the flow of innovation capital, innovation talents, and knowledge and technology. This validates hypothesis 2.

Based on the theoretical analysis, digitalization can promote MHD by driving industrial structure upgrading. Therefore, this study examines industrial structure upgrading’s mediating role through two dimensions: industrial structure intensification and industrial structure rationalization. The results in Table 8 demonstrate that digitalization can promote MHD through the intensification and rationalization of industrial structure, validating hypothesis 3. The empirical results are consistent with the findings of Hui & Yang (2022) [79].

Table 8.

Regression results of the mechanism of industrial structure upgrading.

5.5. Heterogeneity Analysis

5.5.1. Regional Heterogeneity

Due to the diverse resource endowments and developmental stages across different regions, both digitalization levels and MHD exhibit distinct heterogeneity. Therefore, this paper conducts an analysis of regional heterogeneity. Following standard research methods in the literature, the nation is divided into four regions, east, central, west, and northeast, for regression analysis. The regression results are presented in Table 9, columns (1) to (4).

Table 9.

Heterogeneity analysis: regional heterogeneity.

The regression results indicate that digitalization significantly promotes MHD in the central and western regions, with the central region showing greater effectiveness compared to the western region. This could be attributed to substantial policy support and initiatives for digital and smart manufacturing in these regions as part of China’s national development strategy. Such policies provide robust financial and technological support to the manufacturing sectors in the central and western regions. Additionally, the central region plays a crucial role in industrial structure optimization and upgrading as part of regional coordinated development strategies, particularly benefiting from digital empowerment effects.

In contrast, the eastern region did not see significant improvements in MHD despite its high level of technological management and position at the forefront of technology. This may be due to partial industrial relocation to other regions and limited room for improvement in digitalization. Similarly, digitalization did not significantly impact MHD in the northeast region, possibly due to aging industrial structures, lagging infrastructure, and significant talent outflows, which hindered deep integration of digitalization with the manufacturing industry in the northeast. The insignificant impact of digitalization in the eastern and northeastern regions may be attributed to several contextual factors. First, the eastern provinces have already achieved a relatively high level of digital infrastructure and industrial upgrading, which may lead to diminishing marginal returns from further digital investments. In other words, the baseline level of digitalization is already high, and additional digital input yields less pronounced improvements in manufacturing performance. Second, the northeastern region, despite having certain industrial foundations, suffers from structural rigidities and relatively slow adoption of digital technologies. The transformation process in this region is hindered by legacy industries, aging infrastructure, and weaker innovation ecosystems, which reduce the efficacy of digitalization in promoting high-quality development. Furthermore, regional policy priorities may differ. Eastern provinces tend to focus more on platform economy and service-oriented digitalization, which might divert digital resources away from traditional manufacturing. Meanwhile, the northeastern region lacks sufficient policy support and fiscal investment to fully leverage digital transformation in manufacturing sectors.

These findings suggest that digitalization’s impact is highly context-dependent, and effective policy design must consider the specific developmental stage and structural challenges of each region.

5.5.2. Heterogeneity in the Level of Economic Development

Due to the varying capabilities and efforts in supporting MHD across regions with different economic development levels, the impact of digitalization on promoting MHD differs significantly. Therefore, this study categorizes the nation into economically less developed provinces and economically more developed provinces based on the median per capita GDP of each region. The regression results are presented in Table 10, columns (1) and (2).

Table 10.

Heterogeneity analysis: heterogeneity of economic development level and heterogeneity of human capital level.

From the results, it is observed that digitalization significantly enhances MHD in economically less developed provinces, showing a positive effect. In contrast, digital empowerment is not significant in economically more developed provinces. This disparity arises because economically less developed regions can leapfrog traditional industrial stages by directly adopting the latest digital technologies, thus achieving rapid technological advancements that enhance production efficiency and product quality significantly. On the other hand, economically more developed provinces exhibit a noticeable trend towards economic servitization, where the primary applications of digitalization may not be in the manufacturing sector. This situation limits the significant empowerment of MHD by digitalization in these regions.

The empirical results of this study are different from those of Hui & Yang (2022) [79], who found that digitalization can promote MHD in both economically developed and developing regions, and that regions with high levels of economic development are more empowered.

5.5.3. Heterogeneity in Human Capital Levels

Due to varying levels of human capital across regions, different types of industries are suitable for development, each facing unique development tasks. Regions with lower human capital levels need to transition from labor-intensive industries to high-end manufacturing, while regions with higher human capital levels should shift from high-end manufacturing to high-tech industries. This study measures human capital levels in each province using the average number of university students per 100,000 population. Based on the median human capital level, provinces are categorized into those with lower human capital and those with higher human capital, as shown in Table 10, columns (3) and (4).

The regression results indicate that digitalization significantly promotes MHD in provinces with lower human capital. This is because moderate human capital is conducive to developing high-end manufacturing industries such as automobile manufacturing, electronics assembly, and machinery manufacturing—key industries in China with a substantial scale, thus yielding significant empowerment effects. On the other hand, digitalization’s impact on MHD in provinces with higher human capital is not significant. This is partly due to a preference for employment and higher salaries in the financial services sector among talented individuals. Moreover, China is currently in the process of becoming a world-class innovation-oriented country, where high-tech fields such as information technology, biotechnology, and new materials are still in the challenging R&D stage with smaller industry scales, limiting their ability to drive MHD effectively.

It is acknowledged that digitalization is not the sole factor influencing manufacturing development, especially in regions with complex economic structures. To mitigate this concern, our regression models incorporate several control variables—including financial development, education level, foreign direct investment, and government support—to isolate the impact of digitalization. Moreover, the fixed-effects design helps control for time-invariant unobserved heterogeneity across provinces.

Therefore, while the observed regional differences may still be influenced by broader structural or institutional factors, the patterns we identify can be reasonably interpreted as the relative effects of digitalization under comparable conditions.

6. Research Conclusions and Policy Recommendations

Digitization, through economic paradigm shifts, has fostered new business models and disrupted traditional industries, thereby enhancing productivity and innovation capabilities, and consequently promoting MHD. To validate digitalization’s empowerment of MHD, the theoretical analysis in this study begins by examining the impact of digitization on MHD and its mechanisms. It establishes a theoretical framework encompassing both the direct effects of digitization on MHD and its external mechanisms.

Empirically, based on provincial panel data from 2011 to 2022, a comprehensive evaluation index system for digitization and MHD is constructed. Development levels are measured, and from a multidimensional perspective, this study explores the internal mechanisms through which digitization affects MHD. It conducts robustness tests for endogeneity and analyzes heterogeneity. Furthermore, it investigates innovation element flows through three mediating variables—innovation capital flow, innovation talent flow, and knowledge and technology flow—and explores the external mechanisms of industrial structure upgrading through two mediating variables—industrial structure intensification and rationalization—in enhancing digitization-enabled MHD. The main research conclusions are as follows.

First, digitization can promote MHD, a conclusion that holds even after robustness tests for endogeneity. From a multidimensional perspective, digitization drives MHD through six dimensions: innovation-driven, structural coordination, environmental friendliness, inclusive development, economic benefits, and foundational development. However, digitization has a negative impact on manufacturing openness.

Second, the analysis of mechanisms reveals that digitization promotes MHD through fostering the flow of innovation capital, innovation talent, knowledge, and technology. Moreover, digitization enhances MHD by promoting industrial structure intensification and rationalization.

Third, regional heterogeneity analysis shows that digitization significantly empowers MHD in the central and western regions of China, with a stronger effect in the central region and less significant impact in the eastern and northeastern regions. Considering heterogeneity in economic development levels, digitization notably promotes MHD in economically less developed regions. Similarly, concerning heterogeneity in human capital levels, digitization significantly empowers MHD in provinces with lower human capital levels.

This study validates through theoretical analysis and empirical testing the mechanism pathways and heterogeneous characteristics of digitalization empowering MHD, offering insights for government policy formulation.

Based on the findings of this study, the following policy recommendations are proposed to promote the high-quality and sustainable development of the manufacturing industry through digital transformation.

First, regional governments should tailor digital development strategies to their local industrial conditions. For less-developed areas with lower levels of digital infrastructure, efforts should focus on building basic digital capabilities and improving accessibility for small and medium-sized enterprises (SMEs). This will help bridge the regional digital divide and ensure equitable access to the benefits of digital transformation. In contrast, advanced regions should prioritize deeper integration of digital technologies—such as artificial intelligence, big data, and industrial Internet—into production systems to enhance productivity and environmental efficiency.

Second, policies should aim to strengthen the mobility and efficient allocation of innovation factors, which is a key driver for sustainable industrial upgrading. This includes supporting the development of talent-sharing platforms, improving technology transfer mechanisms, and facilitating cross-regional cooperation in innovation networks to ensure a balanced innovation ecosystem.

Third, industrial upgrading should be promoted through targeted incentives for high-end, green, and low-carbon manufacturing. Governments could offer fiscal and tax support to firms engaging in sustainable digital upgrading, encourage collaboration between traditional and high-tech sectors, and remove institutional barriers for firms to transition into higher-value, cleaner segments of the value chain. These measures contribute to the goals of responsible production and resource efficiency, as outlined in SDG 9 and SDG 12.

Finally, a differentiated evaluation system should be adopted to monitor the impact of digitalization at the regional level. This system should incorporate indicators of both economic performance and environmental sustainability, providing real-time feedback for dynamic policy adjustments. Such a system would help ensure that digital transformation not only enhances competitiveness, but also contributes inclusively to long-term sustainable manufacturing development.

Author Contributions

Conceptualization, X.C. and K.F.; methodology, X.C.; software, K.F.; validation, X.C. and K.F.; formal analysis, X.C.; investigation, K.F.; resources, X.C.; data curation, K.F.; writing—original draft preparation, K.F.; writing—review and editing, X.C. and M.C.; visualization, K.F.; supervision, X.C. and M.C.; project administration, X.C. and K.F.; funding acquisition, X.C. and K.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Major Project of Philosophy and Social Science Research in Colleges and Universities of Jiangsu Province (2024SJZD063), Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX24_3880).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank Zihe Yang, Zhen Liu, Genghao Zhong, Jing Cui, and Yaolong Xiao for their help in the writing and submission of papers.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MHD | High-Quality Development of the Manufacturing |

| Dig | Digitalization |

References

- Shi, D.; Li, P. The evolution and current evaluation of the development quality of China’s industry over 70 years. China Ind. Econ. 2019, 9, 5–23. [Google Scholar]

- Sheng, C. Problems and countermeasures of China’s manufacturing development from a comparative perspective between China and the United States. J. Hubei Univ. (Philos. Soc. Sci.) 2020, 47, 153–162. [Google Scholar]

- Jin, B. Economic research on “high-quality development”. China Ind. Econ. 2018, 4, 5–18. [Google Scholar]

- Chen, Y. Theoretical exploration on the integration of the digital economy and the real economy. Econ. Res. J. 2023, 58, 22–30. [Google Scholar]

- China Academy of Information and Communications Technology, China Digital Economy Development Report. 2023. Available online: https://www.caict.ac.cn/kxyj/qwfb/bps/202304/P020240326636461423455.pdf (accessed on 10 June 2025).

- Fu, Y.; Ye, X.; Wang, Z. Structural changes in the manufacturing industry and the improvement of economic growth efficiency. Econ. Res. J. 2016, 51, 86–100. [Google Scholar]

- Ren, Z.; Deng, F. Internet development, factor structure transformation and high-quality development of the manufacturing industry. Stat. Decis. 2022, 38, 100–104. [Google Scholar]

- Yu, D.; Wang, M. Digital economy, entrepreneurship and high-quality development of the manufacturing industry. Reform 2022, 7, 61–81. [Google Scholar]

- Zhou, Z.; Men, B.; Wang, B. Growth effects of the digital economy in driving high-quality development of the manufacturing industry: Empirical evidence from China’s digital economy and manufacturing. J. Henan Norm. Univ. (Philos. Soc. Sci.) 2023, 50, 72–78. [Google Scholar]

- Wu, G.; Gong, R.; Feng, D. Regional differences, dynamic evolution, and convergence characteristics of high-quality development in China’s manufacturing industry. Stat. Decis. 2023, 39, 84–90. [Google Scholar]

- Wang, S.; Liu, W.; Yu, D. Measuring imbalance and insufficiency in China’s high-quality manufacturing development and analyzing their sources. Sci. Technol. Prog. Policy 2023, 40, 1–12. [Google Scholar]

- Liu, Y.; He, Z. Synergistic industrial agglomeration, new quality productive forces and high-quality development of the manufacturing industry. Int. Rev. Econ. Financ. 2024, 94, 103373. [Google Scholar] [CrossRef]

- Huang, Q. The new development philosophy: A systematic theoretical framework of development. Econ. Perspect. 2022, 8, 13–24. [Google Scholar]

- Luo, M.; Li, L. Business model innovation in the Internet era: A value creation perspective. China Ind. Econ. 2015, 1, 95–107. [Google Scholar]

- Li, C.; Li, D.; Zhou, C. The mechanism of digital economy driving the transformation and upgrading of manufacturing: An industrial chain perspective. Bus. Res. 2020, 2, 73–82. [Google Scholar]

- Guo, D.; Chen, B.; Wu, N. Income and welfare effects of urban-rural integration: From the perspective of factor allocation. Manag. World 2023, 39, 22–46. [Google Scholar]

- Wen, F. Digital economy development, factor allocation efficiency, and urban green production efficiency. Ind. Econ. Res. 2023, 3, 57–71+86. [Google Scholar]

- Xiong, Z.; Zhang, K.; He, Y. Digital economy development and urban–rural income gap: An empirical analysis from the perspective of factor mobility. World Agric. 2022, 10, 111–123. [Google Scholar]

- Cheng, Y.; Zhou, X.; Li, Y. The effect of digital transformation on real economy enterprises’ total factor productivity. Int. Rev. Econ. Financ. 2023, 85, 488–501. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L. Digital economy, industrial structure upgrading, and residents’ consumption: Empirical evidence from prefecture-level cities in China. Int. Rev. Econ. Financ. 2024, 92, 1045–1058. [Google Scholar] [CrossRef]

- Zheng, Y. Research on digital empowerment of advanced manufacturing from the perspective of high-quality economic development. Theor. Explor. 2020, 6, 134–137. [Google Scholar]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Q. The impact and mechanism of digital finance on corporate financing behavior. Reform 2023, 9, 34–52. [Google Scholar]

- Xiong, Q.; Tang, K.; Zhang, F. Can third-party digital platforms help micro, small, and medium-sized enterprises improve business returns? Evidence from big data on a million merchants. China Econ. Q. 2023, 23, 1704–1722. [Google Scholar]

- Perez, C. Technological Revolutions and Financial Capital: The Dynamics of Bubbles and Golden Ages; Edward Elgar Publishing: Cheltenham, UK, 2022. [Google Scholar]

- Ren, B. The logic, mechanism, and path of the digital economy leading high-quality development. J. Xi’an Univ. Financ. Econ. 2020, 33, 5–9. [Google Scholar]

- Zhang, H.; Liu, Q.; Wei, Y. Digital product imports and export product quality: Firm-level evidence from China. China Econ. Rev. 2023, 79, 101981. [Google Scholar] [CrossRef]

- Che, T.; Cai, J.; Yang, R.; Lai, F. Digital transformation drives product quality improvement: An organizational transparency perspective. Technol. Forecast. Soc. Chang. 2023, 197, 122888. [Google Scholar] [CrossRef]

- Chen, L.; Dai, Y.; Ren, F.; Dong, X. Data-driven digital capabilities enable servitization strategy—From service supporting the product to service supporting the client. Technol. Forecast. Soc. Chang. 2023, 197, 122901. [Google Scholar] [CrossRef]

- Elapolu, M.S.R.; Rai, R.; Gorsich, D.J.; Rizzo, D.; Rapp, S.; Castanier, M.P. Blockchain technology for requirement traceability in systems engineering. Inf. Syst. 2024, 123, 102384. [Google Scholar] [CrossRef]

- Shams, R.; Chatterjee, S.; Chaudhuri, R. Developing brand identity and sales strategy in the digital era: Moderating role of consumer belief in brand. J. Bus. Res. 2024, 179, 114689. [Google Scholar] [CrossRef]

- Manjunath, C.; Padigar, M.; Pedada, K. The role of digital orientation and strategic emphasis in creating brand competitiveness. J. Retail. Consum. Serv. 2024, 80, 103906. [Google Scholar] [CrossRef]

- Wang, X.; Huang, S.; Fu, Y. The impact mechanism of corporate digitalization on internationalization: An integrated framework. Econ. Manag. Res. 2023, 44, 109–125. [Google Scholar]

- Jiang, X.; Lin, J.; Wang, C.; Zhou, L. How far is reality from vision: An online data-driven method for brand image assessment and maintenance. Inf. Process. Manag. 2024, 61, 103769. [Google Scholar] [CrossRef]

- Wang, D.; Shao, X. Research on the impact of digital transformation on the production efficiency of manufacturing enterprises: Institution-based analysis of the threshold effect. Int. Rev. Econ. Financ. 2024, 91, 883–897. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, J.; Zhang, J.Z.; Liu, Y.; Kamal, M.M.; Cao, Y. Unleashing the power of AI in manufacturing: Enhancing resilience and performance through cognitive insights, process automation, and cognitive engagement. Int. J. Prod. Econ. 2024, 270, 109175. [Google Scholar] [CrossRef]

- Wang, X.; Liu, M.; Liu, C.; Ling, L.; Zhang, X. Data-driven and Knowledge-based predictive maintenance method for industrial robots for the production stability of intelligent manufacturing. Expert Syst. Appl. 2023, 234, 121136. [Google Scholar] [CrossRef]

- Ouahabi, N.; Chebak, A.; Kamach, O.; Laayati, O.; Zegrari, M. Leveraging digital twin into dynamic production scheduling: A review. Robot. Comput.-Integr. Manuf. 2024, 89, 102778. [Google Scholar] [CrossRef]

- Al-Omoush, K.S.; de Lucas, A.; del Val, M.T. The role of e-supply chain collaboration in collaborative innovation and value-co creation. J. Bus. Res. 2023, 158, 113647. [Google Scholar] [CrossRef]

- Enrique, D.V.; Lerman, L.V.; Sousa, P.R.d.; Benitez, G.B.; Bigares Charrua Santos, F.M.; Frank, A.G. Being digital and flexible to navigate the storm: How digital transformation enhances supply chain flexibility in turbulent environments. Int. J. Prod. Econ. 2022, 250, 108668. [Google Scholar] [CrossRef]

- Rong, K.; Luo, Y. Toward born sharing: The sharing economy evolution enabled by the digital ecosystems. Technol. Forecast. Soc. Chang. 2023, 196, 122776. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Xie, X.; Mei, S. Affording digital transformation: The role of industrial Internet platform in traditional manufacturing enterprises digital transformation. Heliyon 2024, 10, e28772. [Google Scholar] [CrossRef]

- Song, H.; Chang, R.; Cheng, H.; Liu, P.; Yan, D. The impact of manufacturing digital supply chain on supply chain disruption risks under uncertain environment—Based on dynamic capability perspective. Adv. Eng. Inform. 2024, 60, 102385. [Google Scholar] [CrossRef]

- Li, X. New characteristics of the digital economy and the formation mechanism of new digital economic momentum. Reform 2019, 11, 40–51. [Google Scholar]

- Xie, W.; Zou, Y.; Guo, H.; Li, Z. What drives digital innovation cycles? Evidence from manufacturing enterprises in China. Technol. Forecast. Soc. Change 2024, 204, 123449. [Google Scholar] [CrossRef]

- Zhang, G.; Du, P.; Chen, M. Digital empowerment and corporate technological innovation: Empirical evidence from China’s manufacturing industry. Contemp. Econ. Sci. 2021, 43, 65–76. [Google Scholar]

- Zheng, Z.; He, J. The impact of corporate digital transformation on technological innovation models. Foreign Econ. Manag. 2023, 45, 54–68. [Google Scholar]

- Wu, L.; Sun, L.; Chang, Q.; Zhang, D.; Qi, P. How do digitalization capabilities enable open innovation in manufacturing enterprises? A multiple case study based on resource integration perspective. Technol. Forecast. Soc. Chang. 2022, 184, 122019. [Google Scholar] [CrossRef]

- Ball, P.; Badakhshan, E. Sustainable Manufacturing Digital Twins: A Review of Development and Application. In Proceedings of the 8th KES International Conference on Sustainable Design and Manufacturing (KES-SDM), Split, Croatia, 15–17 September 2021; Springer: Singapore, 2021; pp. 159–168. [Google Scholar]

- Xu, W.; Liu, S. Novel economic models for advancing urban energy management and transition: Simulation of urban energy system in digital twin. Sustain. Cities Soc. 2024, 101, 105154. [Google Scholar] [CrossRef]