Abstract

Value chains are facing different challenges, caused by emerging technologies as well as Industry 4.0 and Industry 5.0 principles. In order to successfully deliver valuable products to their customers, firms have to adapt, transform, and continuously improve their operational processes. Digital technologies will enable digital supply chains which will be decentralized and composed of autonomous modules. Although the elements of the value chain are independent, this paper shows how they affect each other’s performance. In this study, a model which shows how human resources management impacts customers’ satisfaction is presented. Additionally, this model reveals direct and indirect relations between human resources management, processes, supply chain actors, and customers. The conducted study was based on the variance-based method, while the model was constructed using the “PLSPM” package in R software. Additionally, the confirmatory factor analysis was applied for assessing the construct constitution. Taking into account that “A chain is only as strong as its weakest link”, firms can use these findings to seek for performance indicators and problem causes across the whole value chain and not only in one of its elements.

1. Introduction

The emergence of Industry 5.0 has brought up a discussion about whether it is a revolution or simply an evolution [1]. Since it nurtures the same digital technologies as Industry 4.0, some authors believe it is just an evolution [2]. Nonetheless, Industry 5.0 aims at reshaping the future on a broader level [3]. Going beyond individual industries and companies, the Fifth industrial revolution promotes a human-centric, sustainable, and resilient future [4,5]. These three pillars serve as a base for designing future business strategies which are developed in accordance with Sustainable Development Goals [6]. Human centricity, as a key pillar of Industry 5.0, focuses on people as a main component of production processes [7]. It has been identified that implementing digital technologies into the production processes contributed to improved efficiency, productivity, automation, and digitalization, alongside other benefits [8]. However, this implementation has neglected employees by replacing them with machines or robots which has resulted in job losses [9]. To answer this challenge, Industry 5.0 brings new concepts such as Resilient Operator 5.0 and Consumer 5.0 which involve people in processes in an innovative way [10,11]. Resilient Operator 5.0 portrays a human–robot symbiosis where employees work together with collaborative robots towards creating personalized products [12]. Bringing many benefits, this symbiosis also brings challenges, the largest ones being the trust humans have in their robot coworkers, the physical safety of the workers, as well as the security of the data which are gathered and processed in order to establish and maintain a successful human–robot interaction [13,14]. On the other side, Consumer 5.0 represents a client, customer, or consumer whose needs and wishes are intended to be met by involving it in the value creation chain [10,15]. The value of the product is increased by its personalization according to consumers’ requirements [15]. The implementation of collaborative robots into working stations enables the fulfilment of these requirements—employees can focus on activities which ensure personalization, while robots can perform repetitive, non-value-adding but needed activities [16,17]. The idea behind these two concepts is that technology has to serve people and not the other way around [18]. Although previous research recognizes concepts like Resilient Operator 5.0 and Consumer 5.0 individually, there remains a critical gap regarding their interconnected roles within value chains, especially concerning how human-centric practices, such as HR management, influence customer satisfaction through intermediate operational elements. Najam et al. [19], Kumari et al. [20], and Alnidawi and Omran [21] individually examine HR or supply chain components. However, none of them holistically analyze these constructs together, particularly emphasizing the mediating roles of organizational processes, suppliers, inventory management, and delivery. This study aims to fill this gap by developing an integrated empirical model to analyze these indirect and direct linkages systematically. To fill in the identified gap, the authors of this paper propose the following research questions:

RQ1: Does human resources management indirectly influence customer satisfaction through mediating operational processes such as inventory management, suppliers, and delivery?

RQ2: Through which specific mechanisms are human resources management practices linked to customer satisfaction within the broader value chain?

By answering the proposed research questions, this study gives insights into direct and indirect relations which emerge between (1) human resources management, (2) process organization, (3) suppliers, (4) inventory, (5) delivery, and (6) customers. These insights are helpful when establishing and developing standardized operating procedures, as well as when analyzing and improving already existing procedures.

This paper is structured as follows: Section 2 provides a literature review of human-centric engineering, product organization and management, and supply chain management. Section 3 explains the methodology of the research, followed by Section 4 that shows the modeling results. Next, Section 5 discusses the research results, and Section 6 concludes this paper and gives an overview of its theoretical and practical implications, as well as future research suggestions.

2. Literature Review

In the literature review, human-centric manufacturing, production organization and management, as well as supply chain management are discussed.

2.1. Human-Centric Engineering

Back in 2015, when Society 5.0 was mentioned for the first time, an aim of changing people’s daily life was set [22]. These changes reflect involving machines in processes, such as manufacturing, for solving tasks which are time-consuming, hard, physically challenging, not safe, or everything above [23]. While machines are fulfilling these tasks, people can focus on work which requires cognitive engagement, being more intellectually involved [14,24,25]. Several years after Society 5.0, the Fifth industrial revolution, also known as Industry 5.0, emerged [26]. These two concepts have emphasized the need for shifting focus from technology-oriented manufacturing to people-oriented manufacturing [27,28]. Accordingly, the term human centricity was coined. Human centricity represents not only prioritizing people in decision-making processes, but also when developing and organizing manufacturing processes [9]. Human centricity depicts both employees’ and customers’ needs and wishes, adapting all processes inside the organization according to them [29]. Additionally, human centricity goes beyond the organizational level and answers societal and environmental challenges identified on a global level, such as quality education, industry, innovation and infrastructure, sustainable cities and communities, responsible consumption and production, and climate action [4,30].

From the employees’ perspective, the shop floor is organized with an aim to fulfil ergonomic needs of each worker [9]. Additionally, collaborative robots are implemented into working stations [14]. The aim of this implementation lays in sharing manufacturing operations between robots and humans [31]. While robots are performing repetitive tasks, humans are focusing on more creative tasks which contribute to product personalization [16]. Operator 5.0 portrays the human–robot interaction and collaboration [11]. However, human–robot collaboration requires additional occupational safety and health research [32]. Nonetheless, trainings and education for developing and strengthening employees’ knowledge and skills need to be provided [33]. In the spirit of Industry 5.0, the term Education 5.0 was coined [34]. Education 5.0 introduces new ways of learning, where each learner has a personalized learning path [26]. Personalized learning paths are provided by Artificial Intelligence, which tracks every step of learning and evaluates the learner’s knowledge, generating tasks and exercises according to mistakes the learner makes [34].

In this study, human resources management (HR) is measured through the following parameters: (1) a program for providing suggestions for improvement is based on the employees, (2) all employees are trained to work in more than one position, (3) leaders take responsibility to ensure that every necessary task in the value creation chain is completed, (4) the workforce turnover is constantly declining, (5) absenteeism is constantly declining, and (6) the percentage of improvement suggestions that are implemented (compared to the number of suggestions given) is steadily increasing.

When it comes to human centricity from the customers’ point of view, the foundation lays in mass product personalization [35]. Contrary to Industry 4.0’s mass production and customization, the human–robot symbiosis enables mass product personalization [36]. To answer consumers’ needs, manufacturing processes are designed in a way which enables personalizing products according to specified needs [1,2]. The modern consumer is known as Consumer 5.0 and resembles integrating the costumer as a crucial part of the supply chain process [10,15]. In this way, the client, customer, or consumer is being involved in the value-creating process [15]. Additionally, the contribution to sustainability is made by delivering recyclable products to the customers and involving them in circular economy practices [37].

Parameters which are used for evaluating the customers’ satisfaction (CUS) in this research are, (1) together with our strategic and key customers, we regularly monitor and analyze feedback regarding the quality of our products, (2) based on regular monitoring and analysis, we know that customer satisfaction is constantly increasing, (3) the total number of complaints is steadily declining, (4) the percentage of repeat customers in relation to the total number of customers is steadily increasing, and (5) the market share of our products is steadily increasing. While concepts such as Resilient Operator 5.0 [11,12] and Consumer 5.0 [10,15] have been explored separately, research rarely investigates their integrative impact on HR practices and customer satisfaction. Our study contributes by explicitly linking HR practices (employee suggestion programs, training, and leadership responsibility) with customer-oriented outcomes (feedback monitoring and complaint reduction), offering novel empirical insights.

2.2. Production Organization and Management

Throughout all five industrial revolutions, the biggest improvements are noticed in production organization and management [38]. Digital technologies have not only made great changes regarding the manufacturing processes, but they have also impacted continuous improvement processes [39]. Certain technologies—Additive Manufacturing, Advanced Analytics, Internet of Things, Robotics, and Virtual and Augmented Reality—are used for adapting continuous improvement practices to new manufacturing trends [39,40]. Greatest improvements are identified in managing and analyzing data related to the manufacturing process itself, which positively affects the quality and speed of corrective actions which should be implemented when mistakes in the processes are identified [39,41]. Additionally, digital technologies can be used for identifying which process improvement tools should be used [42]. These technologies contribute to additional waste reduction, the collection of data amongst all operations in the production process, the use of e-Kanban, and the digitalization of Value Stream mapping [43]. Nonetheless, before deciding to invest into new technologies, the production processes should be improved manually [44].

Although previous research has shown a positive connection between continuous improvement and Industry 4.0, this relation is strengthened when transitioning from Industry 4.0 to Industry 5.0 [43]. Industry 5.0’s human centricity aligns with the continuous improvement philosophy because both emphasize the importance of employees—from shopfloor workers to C-level managers [45]. Additionally, Industry 5.0 and continuous improvement demand minimizing waste and negative environmental impacts, and contribute to sustainable practices [46]. When it comes to resilience, continuous improvement has proven to be a key factor for successfully handling industrial transitions, no matter the transition scope [47]. One of challenges which manufacturing firms will face is the optimization of production technologies which ensures a continual improvement of products that have a longer life cycle [35]. Additionally, product personalization according to customer needs requires complex production systems, which can be achieved by implementing emerging technologies into the systems [48].

In this study, production organization and management (PRC) was evaluated through the following parameters: (1) we used Kanban signals to manage the production process, (2) the layout of the equipment in the workspace was organized to ensure a continuous product flow, (3) the process performance results were regularly published on notice boards in the workspace, (4) we used statistical process control tools to reduce variations in processes, (5) 5S (a system for achieving and maintaining workplace cleanliness and order) was an integral part of the business, (6) value-stream mapping was applied to every process within the organization, (7) problem-solving through identifying and eliminating root causes was an integral part of the business, (8) all work activities were standardized, documented, and available at every workstation, and (9) equipment utilization rates steadily increased. The previous literature extensively discusses continuous improvement methods like Kanban, 5S, and value-stream mapping [38,40,42]. However, a holistic exploration linking these operational practices directly and indirectly to HR and downstream customer satisfaction is lacking. This study bridges the identified gap by empirically examining these relationships within the integrated value chain.

2.3. Supply Chain Management

Under the impact of digital technologies, supply chains are being digitally transformed [49]. Although the digital transformation of supply chains requires financial investments and causes short-term productivity losses, the benefits reflect data-driven decision making and improved efficiency [49]. Most common changes reflect the use of collaborative robots, incorporating artificial intelligence into systems, and the demand for mass personalization [3]. Additionally, the big data and digital twin technologies have enabled virtual supply chain optimization [50]. In these and many other ways, Industry 4.0 has contributed to better supply chain management [51]. However, Industry 5.0 brings back the human touch and proposes the creation of Human–Cyber–Physical Systems focused on sustainability [52]. By incorporating Industry 5.0 technologies and principles, supply chain management is becoming decentralized which allows supply chain actors to operate autonomously, based on independent decisions [37]. Additionally, these technologies will support the creation of digital supply chains which will make supply chains customizable and contribute to customer satisfaction and business efficiency [28].

Human centricity impacts supply chain management by taking into consideration how technology can be used to serve humans which are actors in the supply chain instead of requiring that humans adapt to new technologies [28,29]. Accordingly, data-driven technologies are used to support managers when making decisions, which helps in strengthening supply chain resilience [53]. Also, supply chain aspects—logistics, inventory, and retail—are subject to becoming more personalized and efficient [54]. Nonetheless, data-driven technologies face certain challenges such as security and trust which have yet to be addressed [55].

Collaborative robots are driving changes across the whole supply chain and improving the production workflow [28]. They are used in dangerous and repetitive tasks which could harm humans, such as carrying loads of inventory or transportation [51]. Not to neglect suppliers and distributors that cooperate with the manufacturing firms, newly established or digitally transformed supply chains will treat suppliers and distributors as reconfigurable modules that aligns with Industry 5.0 principles [37].

In this study, supply chain management was evaluated according to the delivery process, suppliers, and inventory. The parameters used for delivery (DEL) are as follows: (1) the work process is planned based on the delivery deadlines for finished products, (2) work at one workstation is initiated by a request from the next workstation in the process, (3) the organization operates exclusively on a made-to-order basis and the delivery deadline is at most two days longer than the production/preparation process, and (4) the percentage of orders with delayed delivery is continuously decreasing. Suppliers (SUP) was measured through the following: (1) the organization makes continuous efforts to establish long-term partnerships with all of its suppliers, (2) suppliers actively participate in resolving raw material delivery issues, (3) key suppliers are included in continuous improvement programs, (4) key suppliers are involved in the planning processes and setting long-term goals, and (5) the organization regularly sends delivery quality reports (deadlines, quantities, quality, etc.) to each supplier. Finally, inventory (INV) was measured through the following: (1) the total number of suppliers is continuously decreasing, (2) the total annual inventory turnover is steadily increasing, (3) the ratio of the inventory value to the total revenue is constantly decreasing, (4) the ratio of the unfinished production value to total sales is steadily decreasing, and (5) the ratio of the finished goods inventory value to the raw material inventory value is steadily decreasing (for manufacturing organizations only). Existing research has identified digital transformation and collaborative robots in supply chains [48,49,50], but often neglects comprehensive empirical examinations of how HR management indirectly shapes customer satisfaction through the inventory, supplier relations, and delivery performance. This study specifically addresses this empirical void, contributing to a clearer understanding of the interconnectedness of human-centric practices and supply chain efficiency.

3. Methodology

3.1. Measures, Questionnaire Development, and Response Collection

To develop a questionnaire, research dimensions along with their manifest variables were operationalized, following the aforementioned literature sources. Hence, they were built upon a theoretical backbone and substantial confirmation in the previous study results in constituting the dimensions of a research instrument. The face validity of the questionnaire was conducted with academics, scholars, and practitioners, followed by the pilot test, in a small number of companies [56]. Some minor corrections were made; however, there were no major complaints regarding the instrument’s length and clarity. The full questionnaire is provided as an Appendix A to ensure clarity regarding the exact measurement items used. Respondents’ subjective estimates were collected with a five-point Likert scale [57].

Each organization was contacted to take part in this study. If they expressed a desire to take part in this study, an invitation letter was sent to their manufacturing managers, following the electronic version of the questionnaire. To minimize the bias effect, only one reply per email address (i.e., organization) was accepted. The activities of collecting responses from responders were conducted following Dillman’s Design Survey Method [58].

3.2. Sample Demographic

This study included 240 small, medium, and large organizations from various industry sectors. In most cases, they were manufacturing firms. This is shown in Table 1 and Table 2, respectively.

Table 1.

Sample distribution by industry sector.

Table 2.

Sample distribution by organization type.

4. Modeling Results

Given the exploratory nature of this study and the limited prior empirical validation of the specific constructs within the targeted industrial context, a variance-based analytical approach was adopted [59]. This approach is particularly suited for early-stage theory development, where relationships among constructs are not yet well-established and where the goal is to uncover potential patterns rather than to confirm a fully specified theoretical model.

While structural equation modeling (SEM) techniques offer robust tools for examining complex relationships between latent variables, the use of covariance-based SEM requires strong assumptions regarding the sample representativeness and construct measurement, which were not fully met in this case. Our sample is primarily drawn from industrial supply chains, with insufficient representation from other sectors to support the generalizability needed for the confirmatory analysis. Furthermore, empirical studies validating these constructs in the same or similar research populations are rare, leaving the construct constitution and structural relationships underexplored in this domain.

These considerations support the decision to apply a variance-based method, which is more appropriate for exploratory models with emerging theoretical structures and sector-specific limitations. This approach enables the analysis of the relative strengths of relationships among constructs without requiring multivariate normality or large, representative samples across multiple industries. The research model evaluation was carried out in two phases [59,60,61]. The measurement model was assessed first. The research model followed afterward. For the modeling purposes, the “PLSPM” package in R software was used (https://cran.r-project.org/web/packages/plspm/index.html (accessed on 1 February 2025), 2024).

4.1. The Measurement (Outer) Model

The construct constitution by its respectful manifest variables and reflective nature of research constructs was assessed under confirmatory factor analysis (CFA). According to the literature recommendations, the unidimensionality analysis included the assessment of Cronbach’s α, Dillon–Goldstein’s Ρρ, the 1st eigenvalue of the indicators’ correlation matrix, the indicators’ outer loadings, indicators’ cross-loadings, and average variance extracted—AVE [59,60,61]. These values are shown in Table 3. All indices followed the recommended values, including the values of the indicators’ cross-loadings, which were much higher in the case of their respectful constructs than with others [59,60,61].

Table 3.

CFA results.

For every manifest variable, a related measure for collinearity was checked via the Variance Inflation Factor—VIF (Table 3). Collinearity analysis was conducted in SPSS V26, in the “Regression” package, by projecting manifest variables (independent variables), on their respectful latent variable scores (dependent variables). Latent variable scores were extracted with the “$scores” sample command. In the context of variance-based SEM, a VIF value of 5 or higher may indicate a potential collinearity problem [59]. However, this was not the case, given that the VIF values for every manifest variable were significantly lower.

4.2. Structural (Inner) Model

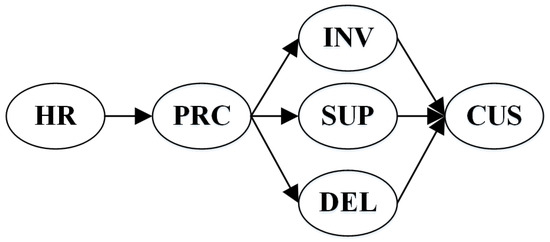

The structural model results provide statistically significant relationships between research constructs. The values are given in Table 4. The total effects are provided in Table 5. Finally, the empirically tested model is shown in Figure 1.

Table 4.

Model results.

Table 5.

Model results—total effects.

Figure 1.

Empirically tested model. Note: HR—Human Resources Management; PRC—Processes; INV—Inventory; SUP—Suppliers; DEL—Delivery; CUS—Customer.

Given that the overall predictive power (R2) for most endogenous variables is relatively low, ranging between 10% and 20%, this indicates that while the model reveals statistically significant and positive relationships among the research constructs, it does not fully explain the variance in customer-related outcomes. However, this finding must be interpreted within the exploratory nature of this study and the methodological framework adopted. Despite the positive results from the CFA, which support the internal consistency and reliability of the constructs, the limited R2 values suggest that these constructs, though interrelated, should be understood as independent management domains that each contribute uniquely to performance outcomes.

This insight aligns with the principle that “a chain is only as strong as its weakest link”, which suggests that each element in the value creation process must deliver the expected quality results to produce desirable customer outcomes. A deficiency in any single element can diminish the effectiveness of the overall system. These findings raise important questions for further research, particularly regarding the influence of external forces, such as contextual, environmental, and organizational ecosystem variables, on the organizational performance. This stands in contrast to certain academic perspectives that attribute organizational success predominantly to internal, intrinsic factors. Our results suggest a more complex interplay between internal practices and external conditions, calling for future studies with a broader scope, representative sampling, and confirmatory models to better understand these dynamics.

5. Discussion

Supply chain complexity describes the interdependence of the supply chain elements—how changing one of the elements affects all the other supply chain actors [55]. Reflecting on the value chain, in order to meet customers’ requirements, all elements of the chain have to provide expected quality performance results. In this study a model which shows how managing human resources affects customer satisfaction has been developed and tested. The model shows six constructs: (1) HR—human resources management, (2) PRC—processes, (3) INV—inventory, (4) SUP—suppliers, (5) DEL—delivery, and (6) CUS—customer.

Direct relations have been identified between HR and PRC, PRC and INV, PRC and SUP, PRC and DEL, as well as INV and CUS, SUP and CUS, and DEL and CUS. The strongest direct connection is identified between PRC and DEL (0.3123) and PRC and SUP (0.3028), while the weakest direct connection is identified between SUP and DEL (0.1561). All of these directly connected elements are interdependent in the value chain and changes in the preceding elements in the model affect the following elements. According to the developed model, changes in human resources management affect processes, which then has an impact on supply chain actors—inventory, suppliers, and delivery—that are influencing customers’ overall impression.

Indirect relations have been identified between HR and INV, HR and SUP, HR and DEL, HR and CUS, and PRC and CUS. In other words, changes in human resources management indirectly affect customers’ satisfaction through processes which directly influence the inventory, suppliers, and delivery, which impacts customers’ satisfaction. Additionally, following the same path, processes which are established inside the company have an indirect impact on the customers’ final impression and satisfaction. Even though these constructs are independent, they affect each other’s performance. The strongest indirect relation is identified between PRC and CUS (0.1776), while the weakest indirect relation is identified between HR and CUS (0.0470). The results of this study empirically confirm the indirect relationship between human resources management and customer satisfaction, mediated by internal processes, the suppliers, inventory, and delivery. This finding of an indirect relationship between human resources management and customer satisfaction confirms the previous research carried out by Azhar et al. [62] and Najam et al. [19]. This holistic approach extends the findings of Najam et al. [19], who primarily focused on internal employee perceptions and job satisfaction, by illustrating operational mediators explicitly. Similarly, the results of this study refine insights from Kumari et al. [20] by empirically substantiating the role of multiple intermediate supply chain elements beyond mere customer satisfaction metrics. The findings in this study further expand Alnidawi and Omran’s [21] investigation by clearly delineating pathways and the strength of their relationships, thus enhancing the understanding of how HR practices contribute indirectly but significantly to the organizational performance.

From a managerial perspective, the findings of this study highlight specific areas for strategic action. For instance, managers should prioritize improvements in internal processes, particularly the implementation of Kanban, value stream mapping, and standardized work procedures, as these have the strongest mediating impact on the downstream supplier and delivery performance. Furthermore, fostering deeper supplier relationships and optimizing inventory practices should be viewed as crucial managerial interventions, directly translating into enhanced customer satisfaction. HR initiatives such as cross-training, employee-led continuous improvement programs, and leadership accountability emerge as key levers for driving improvements across the value chain.

The presented model applies a holistic approach to all constructs and provides information about how the constructs impact each other. With the knowledge of direct and indirect relations that rule between the six constructs, companies will know how to strategically organize their value creation chain in the most efficient way. Through this model, companies will understand and know how changes which are made in one of these constructs impact the others. Additionally, they will know where to seek for performance indicators when implementing newly designed strategies aimed at human resources management, processes, supply chain actors (i.e., inventory, suppliers, and delivery), and customers. Additionally, this model’s findings can be further contextualized within broader theoretical frameworks such as complex adaptive systems theory, underscoring how interconnectedness among seemingly independent constructs leads to emergent, system-wide impacts. Future studies might further investigate these dynamics using longitudinal or simulation-based approaches, contributing to richer theoretical discourse.

6. Conclusions

This paper presents an empirically tested model which shows the interdependencies of value chain actors. These actors are (1) human resources management, (2) processes, (3) inventory, (4) supplier, (5) delivery, and (6) customer. This model provides answers to two research questions. According to the analyzed data, the answer to RQ1—Does human resources management indirectly influence customer satisfaction through mediating operational processes such as inventory management, suppliers, and delivery?—is positive, confirming an indirect influence of human resources management on customer satisfaction. The answer to RQ2—Through which specific mechanisms are human resources management practices linked to customer satisfaction within the broader value chain?—is the list of the mentioned specific mechanisms that includes processes management, inventory management, supplier relations, and delivery performance.

While individual elements of this model are well-established, the novelty of this study lies in empirically demonstrating their integrative, indirect interdependencies within the emerging context of Industry 5.0. Unlike prior linear analyses, the authors’ comprehensive approach provides nuanced insights into operational mediators that critically shape customer-oriented outcomes.

Theoretically, this study contributes by empirically validating a comprehensive, integrative model explicitly connecting HR management to customer satisfaction through critical operational intermediaries, thus refining existing frameworks within Industry 5.0, HRM, and supply chain research. This holistic analysis underscores the necessity of human-centric practices as foundational to achieving high customer satisfaction through indirect value chain effects. Human centricity emphasizes the importance of humans no matter their position, reflecting it into value chains—providing better working conditions to employees will positively impact their work. These positive changes will be recognized in their work and improved processes. As processes affect supply chain actors, which are directly connected to customers, processes indirectly affect customers as well.

Practically, firms should strategically invest in enhancing internal operational processes, strengthening supplier collaborations, and refining inventory management and delivery practices. Specifically, implementing structured HR interventions (multi-position training, employee-driven improvement initiatives, and leadership accountability mechanisms) will indirectly, but significantly, boost customer satisfaction, creating a competitive advantage in human-centric Industry 5.0 environments. Since “A chain is only as strong as its weakest link”, strengthening all elements of the value chain will secure synergistical effects on the value chain as a whole—approaching the value chain should be holistic. The synergistical effects are determined by the strength of the relation between the elements in the value chain.

This research has several limitations. The biggest limitation of this paper is that it examines the relation between elements of the value chain, neglecting external elements which have an impact on it. Furthermore, the data in this study are mainly based on companies coming from the manufacturing sector. Additional sample characteristics, such as the firm size, geographic scope, and response rate, present another limitation of this paper and should be included in future research. This paper is based on exploratory research which serves as a basis for further investigations. Future research should analyze how external elements, such as contextual, environmental, and organizational ecosystem variables, affect the market performance. Future research should adopt longitudinal methodologies to observe the sustained impacts of human-centric HR practices across diverse industries. Additionally, interdisciplinary studies exploring sector-specific adaptations of this integrated model could provide deeper insights into contextual differences. Incorporating external ecosystem variables into future models would further enhance the understanding of broader market performance determinants, responding comprehensively to limitations acknowledged in this research. Discussing trade-offs can also be a topic to focus on in future research.

Author Contributions

Conceptualization, M.D., N.M. and D.S.; methodology, N.T.; software, M.D.; validation, J.C. and N.M.; formal analysis, M.D. and D.S.; investigation, N.T.; resources, J.C.; data curation, N.M., N.T. and J.C.; writing—original draft preparation, D.S., N.M. and N.T.; writing—review and editing, N.M., J.C. and M.D.; visualization, J.C.; supervision, M.D. and N.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by the Ministry of Science, Technological Development and Innovation (Contract No. 451-03-137/2025-03/200156) and the Faculty of Technical Sciences, University of Novi Sad through the project, “Scientific and Artistic Research Work of Researchers in Teaching and Associate Positions at the Faculty of Technical Sciences, University of Novi Sad 2025” (No. 01-50/295).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Ethical Commission at the University of Novi Sad (protocol code Faculty of Technical Sciences 01-1640/2 and date of approval 6 June 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. Questionnaire

| Encoded | Latent Variable | Manifest Variable |

| U1 | Customer (CUS) | Together with our strategic and key customers, we regularly monitor and analyze feedback regarding the quality of our products |

| U2 | Based on regular monitoring and analysis, we know that customer satisfaction is constantly increasing | |

| U3 | The total number of complaints is consistently decreasing | |

| U4 | The percentage of regular customers in relation to the total number of customers is constantly increasing | |

| U5 | The market share of our products is constantly increasing | |

| U6 | Processes (PRC) | We use kanban signals to manage the production process |

| U7 | The layout of equipment in the workspace is organized to ensure a continuous product flow | |

| U8 | Process performance results are regularly posted on bulletin boards in the workspace | |

| U9 | We use statistical process control tools to reduce process variations | |

| U10 | 5S (a system for achieving and maintaining cleanliness and order in the workplace) is an integral part of our operations | |

| U11 | Value-stream mapping is applied in every organizational process | |

| U12 | Problem solving through identification and elimination of root causes is an integral part of our operations | |

| U13 | All work activities are standardized, documented, and available at every workstation | |

| U14 | The level of equipment capacity utilization is constantly increasing | |

| U15 | Human resources management (HR) | Our suggestion program for improvements is based on employees |

| U16 | All employees are trained to work at more than one workstation | |

| U17 | Leaders take responsibility to ensure that every necessary task in the value-creation chain is completed | |

| U18 | Employee turnover is consistently decreasing | |

| U19 | Absenteeism is consistently decreasing | |

| U20 | The percentage of implemented improvement suggestions (in relation to the number of submitted suggestions) is constantly increasing | |

| U21 | Delivery (DEL) | Work processes are planned based on delivery deadlines for finished products |

| U22 | Work at one station is initiated by a request from the next station in the process | |

| U23 | The organization operates strictly on a make-to-order basis and delivery time exceeds production/preparation time by a maximum of two days | |

| U24 | The percentage of orders with delayed delivery is consistently decreasing | |

| U25 | Suppliers (SUP) | The organization makes continuous efforts to establish long-term partnerships with all its suppliers |

| U26 | Suppliers actively participate in solving problems related to raw material deliveries | |

| U27 | Key suppliers are involved in continuous improvement programs | |

| U28 | Key suppliers are involved in planning and setting long-term goals | |

| U29 | The organization regularly sends delivery quality reports to each supplier | |

| U30 | Inventory (INV) | The total number of suppliers is consistently decreasing |

| U31 | The total annual inventory turnover is consistently increasing | |

| U32 | The ratio of inventory value to total revenue is consistently decreasing | |

| U33 | The ratio of the value of work-in-progress to total sales is consistently decreasing | |

| U34 | The ratio of finished goods inventory value to raw material inventory value is consistently decreasing |

References

- Golovianko, M.; Terziyan, V.; Branytskyi, V.; Malyk, D. Industry 4.0 vs. Industry 5.0: Co-Existence, Transition, or a Hybrid. Procedia Comput. Sci. 2023, 217, 102–113. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- European Commission. Directorate General for Research and Innovation. In Industry 5.0: Towards a Sustainable, Human Centric and Resilient European Industry; Publications Office: Luxembourg, 2021. [Google Scholar]

- Mahiri, F.; Najoua, A.; Souda, S.B.; Amini, N. From Industry 4.0 to Industry 5.0: The Transition to Human Centricity and Collaborative Hybrid Intelligence. J. Hunan Univ. Nat. Sci. 2023, 50, 84–94. [Google Scholar] [CrossRef]

- Costa, E. Industry 5.0 and SDG 9: A Symbiotic Dance towards Sustainable Transformation. Sustain. Earth Rev. 2024, 7, 4. [Google Scholar] [CrossRef]

- Slavic, D. The Main Concepts of Industry 5.0: A Bibliometric Analysis Approach. In Proceedings of the 2023 22nd International Symposium Infoteh—Jahorina, East Sarajevo, Bosnia and Herzegovina, 15–17 March 2023. [Google Scholar]

- Trstenjak, M.; Hegedić, M.; Tošanović, N.; Opetuk, T.; Đukić, G.; Cajner, H. Key Enablers of Industry 5.0—Transition from 4.0 to the New Digital and Sustainable System. In Manufacturing Driving Circular Economy; Kohl, H., Seliger, G., Dietrich, F., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023; pp. 614–621. ISBN 978-3-031-28838-8. [Google Scholar]

- Briken, K.; Moore, J.; Scholarios, D.; Rose, E.; Sherlock, A. Industry 5 and the Human in Human-Centric Manufacturing. Sensors 2023, 23, 6416. [Google Scholar] [CrossRef]

- Sarıoğlu, C.İ. Industry 5.0, Digital Society, and Consumer 5.0: In Advances in Human and Social Aspects of Technology; Sine Nazlı, R., Sari, G., Eds.; IGI Global: Hershey, PA, USA, 2023; pp. 11–33. ISBN 978-1-6684-8397-8. [Google Scholar]

- Romero, D.; Stahre, J. Towards The Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

- Zambiasi, L.P.; Rabelo, R.J.; Zambiasi, S.P.; Lizot, R. Supporting Resilient Operator 5.0: An Augmented Softbot Approach. In Advances in Production Management Systems. Smart Manufacturing and Logistics Systems: Turning Ideas into Action; Kim, D.Y., Von Cieminski, G., Romero, D., Eds.; IFIP Advances in Information and Communication Technology; Springer Nature Switzerland: Cham, Switzerland, 2022; Volume 664, pp. 494–502. ISBN 978-3-031-16410-1. [Google Scholar]

- Cioch, M.; Kulisz, M.; Kański, Ł. Implementing AI Collaborative Robots in Manufacturing—Modeling Enterprise Challenges in Industry 5.0 with Fuzzy Logic. Adv. Sci. Technol. Res. J. 2024, 18, 229–238. [Google Scholar] [CrossRef]

- Doyle-Kent, M.; Kopacek, P. Adoption of Collaborative Robotics in Industry 5.0. An Irish Industry Case Study. IFAC-Pap. 2021, 54, 413–418. [Google Scholar] [CrossRef]

- Durmaz, A.; Kitapcı, H. Revisiting Customer Involved Value Chains Under the Conceptual Light of Industry 5.0. Proc. Eng. Sci. 2022, 3, 207–216. [Google Scholar] [CrossRef]

- Liao, S.; Lin, L.; Chen, Q. Research on the Acceptance of Collaborative Robots for the Industry 5.0 Era—The Mediating Effect of Perceived Competence and the Moderating Effect of Robot Use Self-Efficacy. Int. J. Ind. Ergon. 2023, 95, 103455. [Google Scholar] [CrossRef]

- Pizoń, J.; Cioch, M.; Kański, Ł.; Sánchez García, E. Cobots Implementation in the Era of Industry 5.0 Using Modern Business and Management Solutions. Adv. Sci. Technol. Res. J. 2022, 16, 166–178. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Najam, U.; Ishaque, S.; Irshad, S.; Salik, Q.; Khakwani, M.S.; Liaquat, M. A Link Between Human Resource Management Practices and Customer Satisfaction: A Moderated Mediation Model. Sage Open 2020, 10, 2158244020968785. [Google Scholar] [CrossRef]

- Kumari, K.; Usmani, S.; Husain, J. HR Management Practices and Customer Satisfaction: The Mediating Effect of Effective Supply Chain Management Practices. Glob. Bus. Manag. Res. 2013, 5, 137–160. [Google Scholar]

- Alnidawi, A.A.B.; Omran, F.M. Human Resources Management Activities Adopted in the Value Chain Model and Their Impact on the Organizational Sustainability-An Empirical Study in the Jordanian Pharmaceutical Companies. Int. Bus. Res. 2016, 9, 106. [Google Scholar] [CrossRef]

- Aquilani, B.; Piccarozzi, M.; Abbate, T.; Codini, A. The Role of Open Innovation and Value Co-Creation in the Challenging Transition from Industry 4.0 to Society 5.0: Toward a Theoretical Framework. Sustainability 2020, 12, 8943. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-Working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Fukuda, K. Science, Technology and Innovation Ecosystem Transformation toward Society 5.0. Int. J. Prod. Econ. 2020, 220, 107460. [Google Scholar] [CrossRef]

- Chandel, A.; Sharma, B. Technology Aspects of Artificial Intelligence: Industry 5.0 for Organization Decision Making. In Information Systems and Management Science; Garg, L., Sisodia, D.S., Kesswani, N., Vella, J.G., Brigui, I., Xuereb, P., Misra, S., Singh, D., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2023; Volume 521, pp. 79–90. ISBN 978-3-031-13149-3. [Google Scholar]

- Carayannis, E.G.; Morawska, J. University and Education 5.0 for Emerging Trends, Policies and Practices in the Concept of Industry 5.0 and Society 5.0. In Industry 5.0; Machado, C.F., Davim, J.P., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–25. ISBN 978-3-031-26231-9. [Google Scholar]

- Ćoćkalo, D.; Tadić, D.; Bakator, M.; Stanisavljev, S.; Makitan, V. Managing the Transition Process to Society 5.0. Manag. J. Sustain. Bus. Manag. Solut. Emerg. Econ. 2023, 29, 71–90. [Google Scholar] [CrossRef]

- Adel, A. Future of Industry 5.0 in Society: Human-Centric Solutions, Challenges and Prospective Research Areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef] [PubMed]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Bali Swain, R.; Yang-Wallentin, F. Achieving Sustainable Development Goals: Predicaments and Strategies. Int. J. Sustain. Dev. World Ecol. 2020, 27, 96–106. [Google Scholar] [CrossRef]

- Slavic, D.; Marjanovic, U.; Medic, N.; Simeunovic, N.; Rakic, S. The Evaluation of Industry 5.0 Concepts: Social Network Analysis Approach. Appl. Sci. 2024, 14, 1291. [Google Scholar] [CrossRef]

- Park, J.-S.; Lee, D.-G.; Jimenez, J.A.; Lee, S.-J.; Kim, J.-W. Human-Focused Digital Twin Applications for Occupational Safety and Health in Workplaces: A Brief Survey and Research Directions. Appl. Sci. 2023, 13, 4598. [Google Scholar] [CrossRef]

- Gürdür Broo, D.; Kaynak, O.; Sait, S.M. Rethinking Engineering Education at the Age of Industry 5.0. J. Ind. Inf. Integr. 2022, 25, 100311. [Google Scholar] [CrossRef]

- Ahmad, S.; Umirzakova, S.; Mujtaba, G.; Amin, M.S.; Whangbo, T. Education 5.0: Requirements, Enabling Technologies, and Future Directions. arXiv 2023, arXiv:2307.15846. [Google Scholar]

- Saniuk, S.; Grabowska, S.; Fahlevi, M. Personalization of Products and Sustainable Production and Consumption in the Context of Industry 5.0. In Industry 5.0; Machado, C.F., Davim, J.P., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 55–70. ISBN 978-3-031-26231-9. [Google Scholar]

- Alenljung, B.; Lindblom, J.; Zaragoza-Sundqvist, M.; Hanna, A. Towards a Framework of Human-Robot Interaction Strategies from an Operator 5.0 Perspective. In Advances in Transdisciplinary Engineering; Thomas, A., Murphy, L., Morris, W., Dispenza, V., Jones, D., Eds.; IOS Press: Amsterdam, The Netherlands, 2023; ISBN 978-1-64368-466-6. [Google Scholar]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying Industry 5.0 Contributions to Sustainable Development: A Strategy Roadmap for Delivering Sustainability Values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- Lachvajderová, L.; Kádárová, J. Industry 4.0 Implementation and Industry 5.0 Readiness in Industrial Enterprises. Manag. Prod. Eng. Rev. 2022, 13, 102–109. [Google Scholar] [CrossRef]

- Cifone, F.D.; Hoberg, K.; Holweg, M.; Staudacher, A.P. ‘Lean 4.0’: How Can Digital Technologies Support Lean Practices? Int. J. Prod. Econ. 2021, 241, 108258. [Google Scholar] [CrossRef]

- Frank, A.G.; Thürer, M.; Godinho Filho, M.; Marodin, G.A. Beyond Industry 4.0—Integrating Lean, Digital Technologies and People. Int. J. Oper. Prod. Manag. 2024, 44, 1109–1126. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Hegedić, M.; Gudlin, M.; Golec, M.; Tošanović, N. Lean and Green Decision Model for Lean Tools Selection. Sustainability 2024, 16, 1173. [Google Scholar] [CrossRef]

- Eriksson, K.M.; Olsson, A.K.; Carlsson, L. Beyond Lean Production Practices and Industry 4.0 Technologies toward the Human-Centric Industry 5.0. Technol. Sustain. 2024, 3, 286–308. [Google Scholar] [CrossRef]

- Alves, A.C. Lean Thinking: An Essential Mindset. IEEE Eng. Manag. Rev. 2022, 50, 127–133. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.-K.; Lo, S.-C.; Chu, T.-H. A Sustainable Innovation Framework Based on Lean Six Sigma and Industry 5.0. Arab. J. Sci. Eng. 2024, 49, 7625–7642. [Google Scholar] [CrossRef]

- Moraes, A.; Carvalho, A.M.; Sampaio, P. Lean and Industry 4.0: A Review of the Relationship, Its Limitations, and the Path Ahead with Industry 5.0. Machines 2023, 11, 443. [Google Scholar] [CrossRef]

- Langlotz, P.; Aurich, J.C. Causal and Temporal Relationships within the Combination of Lean Production Systems and Industry 4.0. Procedia CIRP 2021, 96, 236–241. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 Digital Manufacturing to Industry 5.0 Digital Society: A Roadmap Toward Human-Centric, Sustainable, and Resilient Production. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Bodi, S. Virtual Quality Management in the Era of Industry 4.0; UTPRESS: Cluj-Napoca, Romania, 2020; ISBN 978-606-737-438-4. [Google Scholar]

- Khan, M.; Haleem, A.; Javaid, M. Changes and Improvements in Industry 5.0: A Strategic Approach to Overcome the Challenges of Industry 4.0. Green Technol. Sustain. 2023, 1, 100020. [Google Scholar] [CrossRef]

- Chen, X.; Eder, M.A.; Shihavuddin, A.; Zheng, D. A Human-Cyber-Physical System toward Intelligent Wind Turbine Operation and Maintenance. Sustainability 2021, 13, 561. [Google Scholar] [CrossRef]

- Agrawal, S.; Agrawal, R.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A. Can Industry 5.0 Technologies Overcome Supply Chain Disruptions?—A Perspective Study on Pandemics, War, and Climate Change Issues. Oper. Manag. Res. 2024, 17, 453–468. [Google Scholar] [CrossRef]

- Nguyen, T.; Duong, Q.H.; Nguyen, T.V.; Zhu, Y.; Zhou, L. Knowledge Mapping of Digital Twin and Physical Internet in Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 244, 108381. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or Industry 4.0S? Introduction to Industry 4.0 and a Peek into the Prospective Industry 5.0 Technologies. Int. J. Interact. Des. Manuf. 2023, 17, 947–979. [Google Scholar] [CrossRef] [PubMed]

- Lawshe, C.H. A Quantitative Approach to Content Validity. Pers. Psychol. 1975, 28, 563–575. [Google Scholar] [CrossRef]

- Nunnally, J.; Bernstein, H. Psychometric Theory; McGraw-Hill Inc.: New York, NY, USA, 1994. [Google Scholar]

- Dillman, D.A. Smyth Internet, Mail, and Mixed-Mode Surveys: The Tailored Design Method; John Wiley and Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Hair, J.F.J.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM). Long Range Plan. 2013, 46, 184–185. [Google Scholar] [CrossRef]

- Tenenhaus, M.; Vinzi, V.E.; Chatelin, Y.-M.; Lauro, C. PLS Path Modeling. Comput. Stat. Data Anal. 2005, 48, 159–205. [Google Scholar] [CrossRef]

- Sanchez, G. PLS Path Modeling with R; Trowchez Editions: Berkley, CA, USA, 2013. [Google Scholar]

- Azhar, S.; Sarwar, F.; Ali, S. Relationship Between Motivation-Enhancing HR Practices and Customer Satisfaction: The Mediating Role of Emotional Intelligence. Rev. Educ. Adm. Law 2021, 4, 421–433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).