An Overview of Critical Success Factors for Digital Shipping Corridors: A Roadmap for Maritime Logistics Modernization

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Design

2.2. Data Sources and Selection

2.3. Analytical Framework

3. Background

3.1. Logistics Evolution

3.2. Digital Transformation Within the Maritime Logistics Sector

3.3. Digital Transformation Case Studies in Maritime Sector

3.3.1. MSC Mediterranean Shipping Company’s Digital Revamp

3.3.2. Maersk’s Digital Supply Chain Transformation

3.3.3. CMA CGM’s Digital Innovation

3.3.4. Hapag-Lloyd’s Digital Transformation Strategy

3.3.5. NYK Line’s Digital Transformation

3.3.6. YILPORT’s Integration with TradeLens

3.3.7. Comparative Analysis of Case Studies

4. Findings

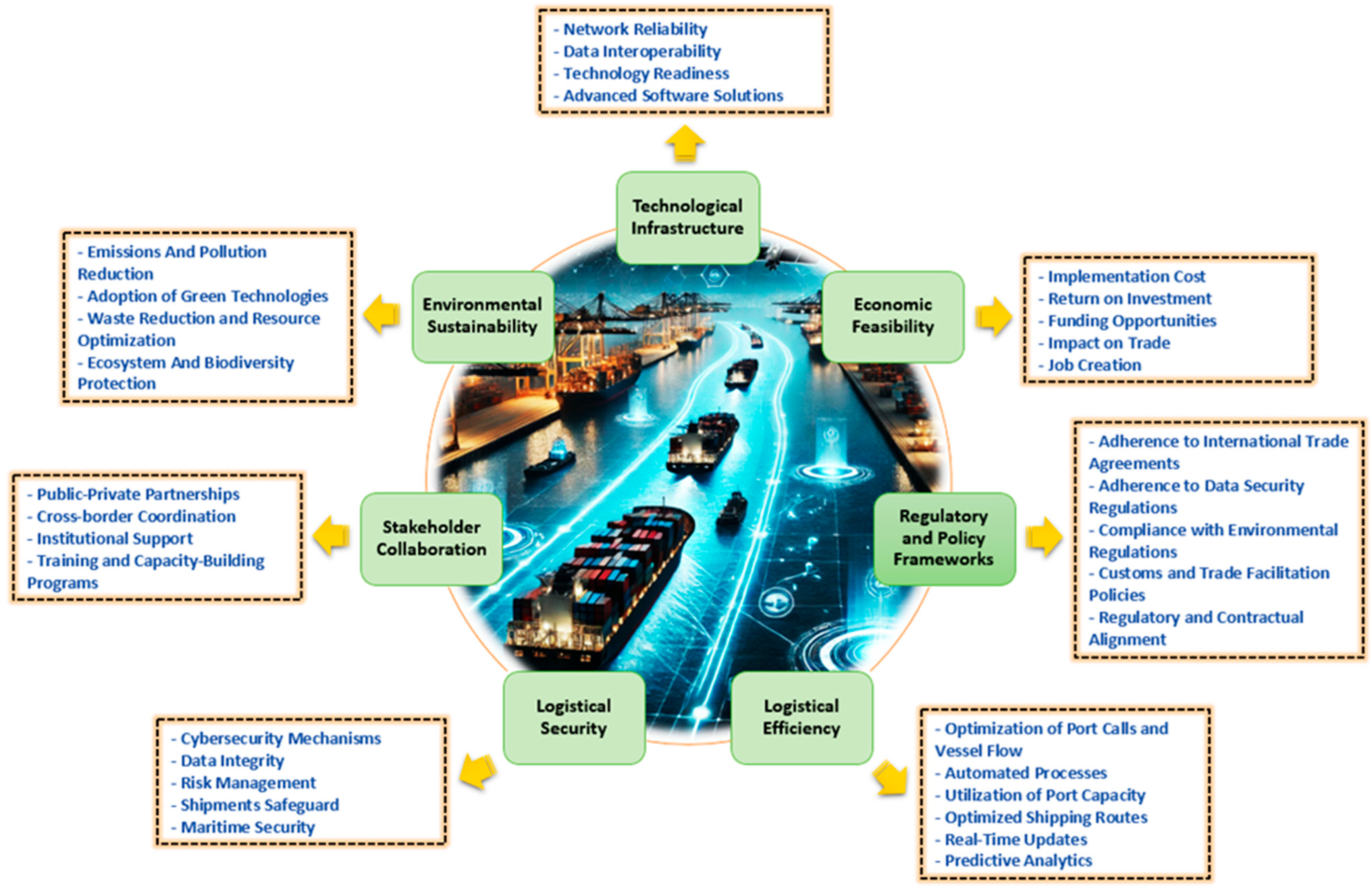

4.1. Key Success Factors for Digital Shipping Corridors

4.1.1. Technological Infrastructure

4.1.2. Economic Feasibility

4.1.3. Regulatory and Policy Frameworks

4.1.4. Logistical Efficiency

4.1.5. Logistical Security

4.1.6. Stakeholder Collaboration

4.1.7. Environmental Sustainability

4.2. Dynamic Interaction Among Critical Success Factors

5. Discussion

6. Practical Implications

6.1. Policymakers and Regulatory Bodies

- Standardization and Regulatory Harmonization: Facilitate the alignment of national and international standards in areas such as customs procedures, data interoperability, and environmental compliance. The adoption of international instruments—such as the WTO Trade Facilitation Agreement and IMO conventions—can streamline cross-border operations and promote uniformity.

- Incentive Design and Policy Support: Develop fiscal and regulatory incentives to promote investment in digital infrastructure, including tax credits, green subsidies, and public innovation grants. This is especially vital for encouraging private sector participation in early-stage technological adoption.

- Data Governance and Cybersecurity: Establish robust transparent data-sharing policies and cybersecurity protocols aligned with global frameworks (e.g., GDPR) to foster trust among stakeholders while ensuring digital resilience.

6.2. Port Authorities and Terminal Operators

- Smart Infrastructure Investment: Prioritize investments in automation, IoT-enabled systems, and real-time analytics to enhance operational efficiency. Notable precedents include the TradeLens integration by YILPORT and AI-driven terminal operations piloted by NYK Line.

- Digital Interoperability Enhancement: Adopt open API-based systems to enable seamless communication across port communities and logistics chains, thus minimizing friction in cargo handling and documentation.

- Workforce Development: Implement continuous training and upskilling initiatives focused on digital competencies to ensure the effective use of advanced systems, and support organizational change.

6.3. Shipping Lines and Logistics Providers

- Scalable Technology Deployment: Begin with modular cost-effective solutions such as electronic Bills of Lading (eBL), predictive analytics, and container tracking systems. MSC’s successful use of smart containers and eBL platforms exemplifies achievable early-stage digitalization.

- Participation in Collaborative Frameworks: Engage in public–private partnerships (PPPs) and international consortia to share investment burdens, accelerate adoption, and standardize processes across shipping routes.

- Digital Strategy Benchmarking: Evaluate and adapt best practices from digital frontrunners—such as Maersk’s TradeLens ecosystem or Hapag-Lloyd’s customer-oriented digital interfaces—to align with internal strategic priorities.

6.4. International Organizations and Development Agencies

- Technical Assistance and Capacity Building: Provide low-resource stakeholders with access to technical knowledge, policy toolkits, and implementation models tailored to their developmental context.

- Promotion of Best Practices: Curate and disseminate case studies and digital maturity frameworks to facilitate knowledge exchange and learning among global stakeholders.

- Inclusive Financing Mechanisms: Coordinate donor funding and concessional finance to ensure that ports in emerging economies are not excluded from digital transformation due to infrastructure or funding gaps.

6.5. Implementation Pathway

7. Future Research Direction

- (a)

- Decision Support Methodologies for DSC Implementation:

- Prioritizing success factors under varying operational conditions;

- Balancing competing stakeholder preferences in corridor design;

- Evaluating trade-offs between economic, technological, and sustainability objectives.

- (b)

- Dynamic Interaction Modeling:

- Simulate the ripple effects of interventions across multiple success factors;

- Identify leverage points with disproportionate system-wide impacts;

- Test resilience under different disruption scenarios.

- (c)

- Context-Specific Implementation Frameworks:

- Regional adaptation models accounting for infrastructure disparities;

- Maturity assessment tools for different implementation phases;

- Best practice transfer mechanisms between established and emerging corridors.

- (d)

- Human–Technology Integration Studies:

- Optimal human–AI collaboration models for maritime operations;

- Digital skill development trajectories for maritime professionals;

- Organizational change management in digital transformation.

- (e)

- Next-Generation Technology Integration:

- Quantum-resistant cybersecurity frameworks for maritime IoT;

- Blockchain applications beyond documentation (e.g., carbon credit trading);

- AI-driven predictive maintenance for smart port infrastructure.

- (f)

- Advanced Policy Analysis:

- Regulatory sandbox methodologies for testing DSC innovations;

- Machine learning applications in policy impact assessment;

- Dynamic compliance systems using smart contracts.

- (g)

- Sustainability Measurement Innovation:

- Standardized digital twins for environmental impact assessment;

- Integrated metrics combining operational and sustainability performance;

- Life cycle analyses of digital versus conventional processes;

- Circular economy models for assessing resource efficiency.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tabaklar, T. Transformation in Maritime Supply Chains: Innovative Strategies for Disruption Management. Marit. Fac. J. 2024, 16, 300–334. [Google Scholar] [CrossRef]

- Wolf, D.E.; Louw, L.; Palm, D. An Analysis of Blockchain versus Relational Databases for Digitalising Information Flows in Global Supply Chains Using the Analytic Network Process. Int. J. Prod. Res. 2024, 62, 5016–5035. [Google Scholar] [CrossRef]

- Szczepański, E.; Lewczuk, K.; Żak, J. Documents Flow Digitization in the Supply Chains. WUT J. Transp. Eng. 2022, 135, 87–100. [Google Scholar] [CrossRef]

- Alavi-Borazjani, S.A.; Adeel, S.; Chkoniya, V. Hydrogen as a Sustainable Fuel: Transforming Maritime Logistics. Energies 2025, 18, 1231. [Google Scholar] [CrossRef]

- Deng, S.; Mi, Z. A Review on Carbon Emissions of Global Shipping. Mar. Dev. 2023, 1, 4. [Google Scholar] [CrossRef]

- Fagerholt, K.; Laporte, G.; Norstad, I. Reducing Fuel Emissions by Optimizing Speed on Shipping Routes. J. Oper. Res. Soc. 2010, 61, 523–529. [Google Scholar] [CrossRef]

- Cacciari, M.; Singhal, R. How Can Digital Technologies Help Companies Overcome the Decarbonization Challenges? In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 31 October 2022.

- Adama, H.E.; Popoola, O.A.; Okeke, C.D.; Akinoso, A.E. Economic Theory and Practical Impacts of Digital Transformation in Supply Chain Optimization. Int. J. Adv. Econ. 2024, 6, 95–107. [Google Scholar] [CrossRef]

- Han, Y.; Yang, J.; Ying, L.; Niu, Y. The Impact of Corporate Digital Transformation on Labor Employment. Financ. Res. Lett. 2024, 60, 104888. [Google Scholar] [CrossRef]

- Krishna, I.M.; Prabha, R.; Shravani, M.; Sri, A.S.; Tejaswini, V.; Vyshnavi, T.S. A Business Strategy for Ensuring Trust and Transparency in Supply Chain Management Using Blockchain Based Data Security. In Proceedings of the 2024 2nd International Conference on Disruptive Technologies (ICDT), Greater Noida, India, 15–16 March 2024; pp. 121–127. [Google Scholar]

- Ran, L.; Shi, Z.; Geng, H. Blockchain Technology for Enhanced Efficiency in Logistics Operations. IEEE Access 2024, 12, 152873–152885. [Google Scholar] [CrossRef]

- Pavlova, K.S.; Smolina, E.S. Digitalization of Tax and Customs Control of Foreign Trade Operations. In Economic Systems in the New Era: Stable Systems in an Unstable World; Springer: Cham, Switzerland, 2021; pp. 684–691. [Google Scholar]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply Chain Resilience: Definition, Review and Theoretical Foundations for Further Study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Li, K.X.; Wang, H.; Yang, Y.; Li, M. Resilience in Maritime Logistics: Theoretical Framework, Research Methodology, and Indicator System. Ocean. Coast. Manag. 2024, 259, 107465. [Google Scholar] [CrossRef]

- Liu, J.; Wu, J.; Gong, Y. Maritime Supply Chain Resilience: From Concept to Practice. Comput. Ind. Eng. 2023, 182, 109366. [Google Scholar] [CrossRef]

- Filipović, M.; Tijan, E.; Aksentijević, S.; Filipović, M. Blockchain for Secure and Transparent Maritime Supply Chains. In Proceedings of the 2024 47th MIPRO ICT and Electronics Convention (MIPRO), Opatija, Croatia, 20–24 May 2024; pp. 1071–1075. [Google Scholar]

- Elmay, F.K.; Salah, K.; Yaqoob, I.; Jayaraman, R.; Battah, A.; Maleh, Y. Blockchain-Based Traceability for Shipping Containers in Unimodal and Multimodal Logistics. IEEE Access 2022, 10, 133539–133556. [Google Scholar] [CrossRef]

- Priya, S.; Sairam, A.; Azath, H.; Manivannan, S.K.; Mohankumar, N.; Vedasundara Vinayagam, P. Smart Ports Solutions for Cargo Container Tracking and Vessel Traffic Counting Systems Using IoT and Cloud Computing. In Proceedings of the 2024 10th International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 12–14 April 2024; pp. 1106–1111. [Google Scholar]

- Rahadi, S.J.A.; Prasetyo, D.F.; Hakim, M.L.; Sari, D.P.; Virliani, P.; Rahadi, C.W.K.; Rina, R.; Yulfani, R.D.; Mohammad, L.; Kurnianingtyas, D. The Necessity of Implementing AI for Enhancing Safety in the Indonesian Passenger Shipping Fleet. Kapal J. Ilmu Pengetah. Dan Teknol. Kelaut. 2024, 21, 31–46. [Google Scholar] [CrossRef]

- Golgota, A.; Çerma, U. Securing Durres Port’s Digital Transformation: Cybersecurity Strategy for Maritime Industry. In Proceedings of the 2024 13th Mediterranean Conference on Embedded Computing (MECO), Budva, Montenegro, 11–14 June 2024; pp. 1–4. [Google Scholar]

- Sakita, B.M.; Helgheim, B.I.; Bråthen, S. The Principal-Agent Theoretical Ramifications on Digital Transformation of Ports in Emerging Economies. Logistics 2024, 8, 51. [Google Scholar] [CrossRef]

- Gillani, F.; Chatha, K.A.; Jajja, S.S.; Cao, D.; Ma, X. Unpacking Digital Transformation: Identifying Key Enablers, Transition Stages and Digital Archetypes. Technol. Forecast. Soc. Change 2024, 203, 123335. [Google Scholar] [CrossRef]

- Olavarrieta, S.; Ellinger, A.E. Resource-based Theory and Strategic Logistics Research. Int. J. Phys. Distrib. Logist. Manag. 1997, 27, 559–587. [Google Scholar] [CrossRef]

- Artemenko, E.; Benchabane, M.L. Digital Transformation of an Institutional Environment. In Proceedings of the International Scientific Conference—Digital Transformation on Manufacturing, Infrastructure and Service, New York, NY, USA, 18–19 November 2020; pp. 1–9. [Google Scholar]

- Hallion, R.P. The History of Air Transportation. In International Encyclopedia of Transportation; Elsevier: Amsterdam, The Netherlands, 2021; pp. 192–197. [Google Scholar]

- Kaukiainen, Y. The Advantages of Water Carriage: Scale Economies and Shipping Technology, c. 1870–2000. In The World’s Key Industry; Palgrave Macmillan UK: London, UK, 2012; pp. 64–87. [Google Scholar]

- Friedman, W.A. Modern Companies, 1910–1930. In American Business History: A Very Short Introduction; Oxford University Press: Oxford, UK, 2020; pp. 68–84. [Google Scholar]

- Khudokormov, A.G. History of the Second Industrial Revolution. Scientific Research of Faculty of Economics. Sci. Res. Fac. Econom. Electron. J. 2022, 14, 25–41. [Google Scholar] [CrossRef]

- Colombo, A.W.; Karnouskos, S.; Yu, X.; Kaynak, O.; Luo, R.C.; Shi, Y.; Leitao, P.; Ribeiro, L.; Haase, J. A 70-Year Industrial Electronics Society Evolution Through Industrial Revolutions: The Rise and Flourishing of Information and Communication Technologies. IEEE Ind. Electron. Mag. 2021, 15, 115–126. [Google Scholar] [CrossRef]

- Cudahy, B.J. The Containership Revolution: Malcom McLean’s 1956 Innovation Goes Global; TR News; Transportation Research Board: Washington, DC, USA, 2006; pp. 5–9. [Google Scholar]

- Kaukiainen, Y. The Container Revolution and Liner Freights. Int. J. Marit. Hist. 2009, 21, 43–74. [Google Scholar] [CrossRef]

- Bielecki, M.; Galińska, B.; Tokarski, D. Determinants and Trends of Logistics Paradigms in Industrial Revolutions. Econ. Environ. 2024, 90, 780. [Google Scholar] [CrossRef]

- Tsikh, H.; Suhoversha, V. Logistics in the Context of Digital Transformation. Galician Econ. J. 2024, 91, 40–48. [Google Scholar] [CrossRef]

- Samuels, A. Human-Centric Technologies in Sustainable Supply Chain Management: A Systematic Review of the Evolution from Industry 4.0 to 5.0. Int. J. Bus. Ecosyst. Strategy (2687-2293) 2024, 6, 285–302. [Google Scholar] [CrossRef]

- Grosse, E.H.; Sgarbossa, F.; Berlin, C.; Neumann, W.P. Human-Centric Production and Logistics System Design and Management: Transitioning from Industry 4.0 to Industry 5.0. Int. J. Prod. Res. 2023, 61, 7749–7759. [Google Scholar] [CrossRef]

- Andres, B.; Diaz-Madroñero, M.; Soares, A.L.; Poler, R. Enabling Technologies to Support Supply Chain Logistics 5.0. IEEE Access 2024, 12, 43889–43906. [Google Scholar] [CrossRef]

- Szeredi, V.V.; Trenka, Z.J.; Pogatsnik, M. Smart Logistics and Sustainability in Logistics 5.0. In Proceedings of the 6th IEEE International Symposium on Logistics and Industrial Informatics, Karaganda, Kazakhstan, 23–25 October 2024; pp. 109–114. [Google Scholar]

- Nicoletti, B.; Appolloni, A. Green Logistics 5.0: A Review of Sustainability-Oriented Innovation with Foundation Models in Logistics. Eur. J. Innov. Manag. 2024, 27, 542–561. [Google Scholar] [CrossRef]

- Heilig, L.; Schwarze, S.; Voss, S. An Analysis of Digital Transformation in the History and Future of Modern Ports. In Proceedings of the 50th Hawaii International Conference on System, Waikoloa Village, HI, USA, 4–7 January 2017; pp. 1341–1350. [Google Scholar]

- Quitzau, J.; Tontara, N.; Vöpel, H.; Jahn, M.; Otto, A.; Wolf, A. Shipping in an Era of Digital Transformation; Strategy 2030—Capital and Life in the Next Generation; Berenberg Bank und Hamburgisches WeltWirtschaftsInstitut (HWWI): Hamburg, Germany, 2018. [Google Scholar]

- Raza, Z.; Woxenius, J.; Vural, C.A.; Lind, M. Digital Transformation of Maritime Logistics: Exploring Trends in the Liner Shipping Segment. Comput. Ind. 2023, 145, 103811. [Google Scholar] [CrossRef]

- MSC. The MSC Group; MSC: Geneva, Switzerland, 2025. [Google Scholar]

- MaritimEducation MSC Reaches 900 Ships in Its Fleet. Available online: https://maritimeducation.com/about-us/ (accessed on 22 May 2025).

- DigitalDefynd Team 5 Digital Transformation in Shipping Case Studies. 2025. Available online: https://digitaldefynd.com/IQ/digital-transformation-in-shipping-case-studies/ (accessed on 23 March 2025).

- Becha, H.; Schröder, M.; Voorspuij, J.; Frazier, T.; Lind, M. Global Data Exchange Standards: The Basis for Future Smart Container Digital Services. In Maritime Informatics; Springer: Cham, Switzerland, 2021; pp. 293–307. [Google Scholar]

- A.P. Moller—Maersk Maersk at a Glance. Available online: https://www.maersk.com/about (accessed on 22 May 2025).

- Iversen, M.J.; Buhl, J. Maersk: Steering Clear of the Commodity Trap. In Danish Shipping in the 21st Century; Palgrave Macmillan: Cham, Switzerland, 2020; pp. 53–65. [Google Scholar]

- Greve, M. Container Shipping and Economic Development: A Case Study of A.P. Moller—Maersk in South East Asia; Copenhagen Business School Press: Copenhagen, Denmark, 2007; ISBN 8763002132. [Google Scholar]

- Sornn-Friese, H. ‘Containerization in Globalization’: A Case Study of How Maersk Line Became a Transnational Company. In Shipping and Globalization in the Post-War Era: Contexts, Companies, Connections; Palgrave Macmillan: Cham, Switzerland, 2019; pp. 103–131. [Google Scholar]

- Lorenz-Meyer, F.; Santos, V. Blockchain in the Shipping Industry: A Proposal for the Use of Blockchain for SMEs in the Maritime Industry. Procedia Comput. Sci. 2023, 219, 807–814. [Google Scholar] [CrossRef]

- Rukanova, B.; Tan, Y.-H. Digital Trade Infrastructures and Big Data Analytics: The Concept of Value as a Linking Pin. In Proceedings of the 6th Innovation in Information Infrastructures (III) Workshop, Surrey, UK, 18–20 September 2019. [Google Scholar]

- Ozturk, O. The Impact of AI on International Trade: Opportunities and Challenges. Economies 2024, 12, 298. [Google Scholar] [CrossRef]

- CMA CGM. BETTER WAYS, Making Supply Chains More Sustainable Every Day. Available online: https://www.cma-cgm.com/about/the-group (accessed on 22 May 2025).

- CEVA Logistics. The CMA CGM Group Unveils Its Corporate Purpose. Available online: https://www.cevalogistics.com/en/news-and-media/newsroom/press-release/cma-cgm-group-unveils-corporate-purpose (accessed on 22 May 2025).

- Paridaens, H.; Notteboom, T. Logistics Integration Strategies in Container Shipping: A Multiple Case-Study on Maersk Line, MSC and CMA CGM. Res. Transp. Bus. Manag. 2022, 45, 100868. [Google Scholar] [CrossRef]

- Hapag-Lloyd. Investor Report; Hapag-Lloyd: Hamburg, Germany, 2025. [Google Scholar]

- Hapag-Lloyd. About Hapag-Lloyd. Available online: https://www.hapag-lloyd.com/en/company/ir/company/factsheet.html (accessed on 22 May 2025).

- Hapag-Lloyd. Hapag-Lloyd with Good Start to the Year, Market Environment Remains Highly Volatile. Available online: https://www.hapag-lloyd.com/en/company/press/releases/2025/05/hapag-lloyd-with-good-start-to-the-year.html (accessed on 22 May 2025).

- Hapag-Lloyd. Setting Sail for the Future: Hapag-Lloyd Unveils Its New Strategy 2030. Available online: https://www.hapag-lloyd.com/en/company/press/releases/2024/04/setting-sail-for-the-future--hapag-lloyd-unveils-its-new-strateg.html (accessed on 23 March 2025).

- Alfa Global Family. Hapag-Lloyd to Equip Entire Container Fleet with Real-Time Tracking Devices. Available online: https://www.alfa-global-family.com/hapag-lloyd-to-equip-entire-container-fleet-with-real-time-tracking-devices/ (accessed on 23 March 2025).

- Gruner, J. Digital Transformation in Shipping: The Hapag-Lloyd Story. In B2B Marketing; Springer: Cham, Switzerland, 2021; pp. 545–557. [Google Scholar]

- Elkafas, A.G.; Elgohary, M.M.; Shouman, M.R. Numerical Analysis of Economic and Environmental Benefits of Marine Fuel Conversion from Diesel Oil to Natural Gas for Container Ships. Environ. Sci. Pollut. Res. 2021, 28, 15210–15222. [Google Scholar] [CrossRef] [PubMed]

- NYK Group. Nippon Yusen Kabushiki Kaisha NYK Report 2024; NYK Group: Tokyo, Japan, 2024. [Google Scholar]

- Kutsuna, K.; Ando, H.; Nakashima, T.; Kuwahara, S.; Nakamura, S. NYK’s Approach for Autonomous Navigation—Structure of Action Planning System and Demonstration Experiments. J. Phys. Conf. Ser. 2019, 1357, 012013. [Google Scholar] [CrossRef]

- Orca, A.I. NYK Upgrades Its Fleet with Orca AI Technology to Enhance Navigation Safety and Operational Efficiency. Available online: https://www.orca-ai.io/resource/nyk-upgrades-its-fleet-with-orca-ai-technology-to-enhance-navigation-safety-and-operational-efficiency/ (accessed on 20 May 2025).

- Asteria, I.R. Major Shipping Company NYK Line Adopts ASTERIA Warp to Build Platform for Integrating Data from Internal Systems without Coding, Reducing Development Person-Hours to One-Sixth. Available online: https://en.asteria.com/news/202307116197/ (accessed on 23 March 2025).

- Hirata, E.; Watanabe, D.; Lambrou, M. Shipping Digitalization and Automation for the Smart Port. In Supply Chain—Recent Advances and New Perspectives in the Industry 4.0 Era; IntechOpen: London, UK, 2022; pp. 1–21. [Google Scholar]

- ShipDC. NYK to Expand the Number of Ships Sharing Data via ShipDC’s IoS-OP. Available online: https://www.shipdatacenter.com/en/news/20201217 (accessed on 20 May 2025).

- NYK Group. NYK Selected as a Digital Transformation Stock for 2024. Available online: https://www.nyk.com/english/news/2024/20240528_01.html (accessed on 23 March 2025).

- LeadIQ YILPORT Holding Inc. Available online: https://leadiq.com/c/yilport-holding-inc/5a1d8a7c2400002400640154 (accessed on 23 May 2025).

- Yılport Holding Inc. Maersk Blockchain Tradelens Program Is Now Active on YILPORT. Available online: https://www.yilport.com/en/media/detail/Maersk-Blockchain-Tradelens-Program-is-Now-Active-on-YILPORT/55/2078/0 (accessed on 23 March 2025).

- Jensen, T.; Hedman, J.; Henningsson, S. How TradeLens Delivers Business Value with Blockchain Technology. MIS Q. Exec. 2019, 18, 221. [Google Scholar] [CrossRef]

- Dalaklis, D.; Katsoulis, G.; Kitada, M.; Schröder-Hinrichs, J.-U.; Ölcer, A.I. A “Net-Centric” Conduct of Navigation and Ship Management. Marit. Technol. Res. 2020, 2, 90–107. [Google Scholar] [CrossRef]

- Du, Y.; Li, C.; Wang, T.; Xu, Y. Special Issue on “Smart Port and Shipping Operations” in Maritime Policy & Management. Marit. Policy Manag. 2023, 50, 413–414. [Google Scholar] [CrossRef]

- Šakalys, R.; Batarlienė, N. Investigation of Solutions for Interoperability between Intermodal Transport Terminals. Moksl.—Liet. Ateitis 2020, 12, 1–6. [Google Scholar] [CrossRef][Green Version]

- Muñuzuri, J.; Onieva, L.; Cortés, P.; Guadix, J. Using IoT Data and Applications to Improve Port-Based Intermodal Supply Chains. Comput. Ind. Eng. 2020, 139, 105668. [Google Scholar] [CrossRef]

- Acciaro, M.; Renken, K.; El Khadiri, N. Technological Change and Logistics Development in European Ports. In European Port Cities in Transition. Strategies for Sustainability; Springer: Cham, Switzerland, 2020; pp. 73–88. [Google Scholar]

- Gurenko, A.; Zubov, S. Implementation of Intellectual Logistics Technologies into the Infrastructure Complex of Sea Transport. Econ. Her. Donbas 2020, 3, 146–153. [Google Scholar] [CrossRef]

- El Idrissi, A.; Haidine, A.; Aqqal, A.; Dahbi, A. Deployment Strategies of Mobile Networks for Internet-of-Things in Smart Maritime Ports. In Proceedings of the 2022 11th International Symposium on Signal, Image, Video and Communications (ISIVC), El Jadida, Morocco, 18–20 May 2022; pp. 1–6. [Google Scholar]

- Casino, F.; Dasaklis, T.K.; Patsakis, C. A Systematic Literature Review of Blockchain-Based Applications: Current Status, Classification and Open Issues. Telemat. Inform. 2019, 36, 55–81. [Google Scholar] [CrossRef]

- Kuzmenko, K. Economic Decision Making Peculiarities in Transport Complexes Integration Processes. Dev. Manag. Entrep. Methods Transp. (ONMU) 2021, 76, 17–28. [Google Scholar] [CrossRef]

- Banerjee, P. Development of East Coast Economic Corridor and Vizag-Chennai Industrial Corridor; ADB South Asia Working Paper Series; ADB: Manila, Philippines, 2017. [Google Scholar]

- Monteiro Moraes, R.d.C.; Negrão MAcedo, A.; Azevedo Montenegro Duarte, A.A.; Braga de Moraes, H.; Pinto de Moraes Neto, L.; Pinto Soares, R. Uncertanties and Risk Analysis on Ports Construction Projects Considering Technological and Market Strategic Factors. Int. J. Innov. Educ. Res. 2021, 9, 592–626. [Google Scholar] [CrossRef]

- Gottschalk, R. Financing Regional Digital Infrastructures in the South: Development Banks, Funds and Other Policy Options; UNCTAD: Geneva, Switzerland, 2020. [Google Scholar]

- Mwakapala, L.; Sun, B. Public–Private Partnership in Developing Countries: Seeking Available Domestic Financing Options. J. Econ. Bus. Manag. 2019, 7, 77–82. [Google Scholar] [CrossRef]

- Shcherbinin, N.V.; Rusinov, I.A. Diversification of Transport Links in the “Asia—Europe” Container Shipping Traffic. EURASIAN INTEGRATION Econ. Law Politics 2023, 17, 71–81. [Google Scholar] [CrossRef]

- Monios, J.; Notteboom, T.; Wilmsmeier, G.; Rodrigue, J.-P. Competition and Complementarity Between Seaports and Hinterlands for Locating Distribution Activities; PortEconomics: Antwerp, Belgium, 2016. [Google Scholar]

- Aerts, G.; Mathys, G. Discovering Trends in the Digitalization of Shipping: An Exploratory Study into Trends Using Natural Language Processing. J. Mar. Sci. Eng. 2024, 12, 618. [Google Scholar] [CrossRef]

- Leal, R.A.; Feijó, F.T.; Pereira, R.M. Heterogeneous Effects of Public Investments in the Rio Grande Naval Complex (Brazil): An Analysis of Local Employment for the Period from 2007 to 2017. Espaço Econ. 2023, 25, 1–18. [Google Scholar] [CrossRef]

- Anwer, S.A. Modernising Pakistan’s Shipping Regulations and Trade Facilitation Authorities under Convention on the Facilitation of International Maritime Traffic 1965. ISSRA Pap. 2024, 16, 39–53. [Google Scholar] [CrossRef]

- Kumar, U.; Shepherd, B. Implementing the Trade Facilitation Agreement: From Global Impacts to Value Chains No. 67; About South Asia; ADB: Manila, Philippines, 2019. [Google Scholar]

- de Melo, J.; Sorgho, Z.; Wagner, L. Reducing Wait Times at Customs to Boost Trade: How Implementing the Trade Facilitation Agreement Can Expand Trade among AfCFTA Countries? J. Afr. Econ. 2024, 34, 265–294. [Google Scholar] [CrossRef]

- Shi, Y. China’s Shipping Market Supervision System under TheRCEP: Influence, Challenges and Countermeasures. Front. Mar. Sci. 2023, 10, 1155452. [Google Scholar] [CrossRef]

- Yungratog, S.; Goerlandt, F.; Punurai, W.; Thammaboosadee, S. A Conceptual Framework for Assessing Risks for Data Protection Impact Assessment Process in Maritime Industries. In Proceedings of the 2022 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Kuala Lumpur, Malaysia, 7–10 December 2022; pp. 1083–1087. [Google Scholar]

- Palippui, H. Integration of Technology and Regulations for Safe and Efficient Marine Logistics. Collab. Eng. Dly. Book Ser. 2024, 2, 1–7. [Google Scholar] [CrossRef]

- Lister, J.; Poulsen, R.T.; Ponte, S. Orchestrating Transnational Environmental Governance in Maritime Shipping. Glob. Environ. Change 2015, 34, 185–195. [Google Scholar] [CrossRef]

- Bui, K.Q.; Perera, L.P. A Decision Support Framework for Cost-Effective and Energy-Efficient Shipping. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual, 3–7 August 2020; pp. 1–10. [Google Scholar]

- Alamoush, A.S.; Ölçer, A.I.; Ballini, F. Ports’ Role in Shipping Decarbonisation: A Common Port Incentive Scheme for Shipping Greenhouse Gas Emissions Reduction. Clean. Logist. Supply Chain 2022, 3, 100021. [Google Scholar] [CrossRef]

- Bell, S.L.; Anene, A. Meeting the Challenges of Customs Compliance in a Post TFTEA and Reinvigorated Trade Enforcement Environment: Go Beyond by Returning to Basics. Glob. Trade Cust. J. 2022, 17, 105–112. [Google Scholar] [CrossRef]

- Veenstra, A.W. International Trade, Global Supply Chains and Compliance. In Operations, Logistics and Supply Chain Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 131–161. [Google Scholar]

- Yong, V. ‘Nudging’ Voluntary Compliance in Border Customs. Bord. Glob. Rev. 2023, 4, 127–131. [Google Scholar] [CrossRef]

- Usynin, M. Sailing in All Winds: Extraterritorial Regulation as a Trigger for Self-Regulatory Practices in Shipping Industry. SSRN Electron. J. 2020, 1–31. [Google Scholar] [CrossRef]

- Fedorenko, R.; Pokrovskaya, O. East-West Transport Corridor: Issues of Customs and Logistics Infrastructure Development. In Proceedings of the International Session on Factors of Regional Extensive Development (FRED 2019), Irkutsk, Russia, 27 May–1 June 2019; Atlantis Press: Paris, France, 2020; pp. 88–93. [Google Scholar]

- Pelevic, D.; Draskovic, M.; Krivokapic, R. Implementation of Modern Information Solution for Greater Efficiency of Intermodal Transport through Port of Bar Case Study NAVIS. In Proceedings of the First International Conference on Advances in Traffic and Communication Technologies (ATCT 2022), Sarajevo, Bosnia and Herzegovina, 26–27 May 2022; pp. 15–20. [Google Scholar]

- Lehmacher, W. Digitizing and Automating Processes in Logistics. In Disrupting Logistics: Startups, Technologies, and Investors Building Future Supply Chains; Springer: Cham, Switzerland, 2021; pp. 9–27. [Google Scholar]

- Karunasena, C.; Widyalankara, R.; Sedrick, P.; Disanayaka, S.M.; Perera, H.; Medagama, P. Optimization of Digital Transformation in Shipping. In Proceedings of the OCEANS 2022—Chennai, Chennai, India, 21–24 February 2022; pp. 1–5. [Google Scholar]

- Gizetdinov, R. Automation and Digitalisation of Transport Forwarding Services or Logistics. Infrastruct. Asset Manag. 2024, 11, 100–107. [Google Scholar] [CrossRef]

- Zamaraeva, E.; Khmelnitskaya, Z. Methods of Efficiency Evaluation of Transport and Logistics Services within the Logistics Systems of International Transport Corridors Framework. AIP Conf. Proc. 2021, 2389, 050008. [Google Scholar]

- Chechenova, L.M. Substantiation of Solutions in the Field of Digitalization of Container Services of the Oktyabrskaya Railway. Mod. Transp. Syst. Technol. 2022, 8, 126–139. [Google Scholar] [CrossRef]

- Tongzon, J.L.; Nguyen, H.-O. Effects of Port-Shipping Logistics Integration on Technical and Allocative Efficiency. Asian J. Shipp. Logist. 2021, 37, 109–116. [Google Scholar] [CrossRef]

- Perera, L.P.; Czachorowski, K. Decentralized System Intelligence in Data Driven Networks for Shipping Industrial Applications: Digital Models to Blockchain Technologies. In Proceedings of the OCEANS 2019—Marseille, Marseille, France, 17–20 June 2019; pp. 1–6. [Google Scholar]

- Li, S. Research on International Shipping Logistics Based on Big Data Exchange System. In Proceedings of the International Conference on Computer Vision and Pattern Analysis (ICCPA 2021), Guangzhou, China, 19–21 November 2021; p. 2. [Google Scholar]

- Mekala, V.; Abinaya, S.; Abinivesh, M.R.; Surya, B.C. Cargo Monitoring and Tracking Based on IoT. In Proceedings of the 2023 14th International Conference on Computing Communication and Networking Technologies (ICCCNT), Delhi, India, 6–8 July 2023; pp. 1–5. [Google Scholar]

- Malyshev, M.I. Research Review on Improving the Efficiency of Multimodal Transportation Based on Technological Solutions. Civ. Aviat. High Technol. 2020, 23, 58–71. [Google Scholar] [CrossRef]

- Saleh, H.H.; Chyad, A.K.; Barakat, M.; Naamo, G.S. Enhancing Business Operations Efficiency Thorough Predictive Analytics. J. Ecohumanism 2024, 3, 700–714. [Google Scholar] [CrossRef]

- Ibiyemi, M.O.; Olutimehin, D.O. Utilizing Predictive Analytics to Enhance Supply Chain Efficiency and Reduce Operational Costs. Int. J. Eng. Res. Updates 2024, 7, 1–21. [Google Scholar] [CrossRef]

- Sulova, S.; Aleksandrova, Y.; Stoyanova, M.; Radev, M. A Predictive Analytics Framework Using Machine Learning for the Logistics Industry. In Proceedings of the International Conference on Computer Systems and Technologies 2022, Ruse, Bulgaria, 17–18 June 2022; ACM: New York, NY, USA; pp. 39–44. [Google Scholar]

- Odimarha, A.C.; Ayodeji, S.A.; Abaku, E.A. Securing the Digital Supply Chain: Cybersecurity Best Practices for Logistics and Shipping Companies. World J. Adv. Sci. Technol. 2024, 5, 026–030. [Google Scholar] [CrossRef]

- Kavallieratos, G.; Katsikas, S. Managing Cyber Security Risks of the Cyber-Enabled Ship. J. Mar. Sci. Eng. 2020, 8, 768. [Google Scholar] [CrossRef]

- Junejo, A.K.; Breza, M.; McCann, J.A. Threat Modeling for Communication Security of IoT-Enabled Digital Logistics. Sensors 2023, 23, 9500. [Google Scholar] [CrossRef] [PubMed]

- Brandt, T.; Hutter, D.; Maeder, C.; Müller, R. Towards a Secure and Reliable IT-Ecosystem in Seaports. In Proceedings of the 29th Conference of the International Association of Maritime Economists, Rotterdam, The Netherlands, 24–26 November 2021; pp. 1–20. [Google Scholar]

- Morev, A.A. International Transport Corridors of Current Times. Lizing (Leasing) 2024, 10–13. [Google Scholar] [CrossRef]

- Oliveira, R.R.; Cardoso, I.M.G.; Barbosa, J.L.V.; da Costa, C.A.; Prado, M.P. An Intelligent Model for Logistics Management Based on Geofencing Algorithms and RFID Technology. Expert Syst. Appl. 2015, 42, 6082–6097. [Google Scholar] [CrossRef]

- Baygin, M.; Yaman, O.; Baygin, N.; Karakose, M. A Blockchain-Based Approach to Smart Cargo Transportation Using UHF RFID. Expert Syst. Appl. 2022, 188, 116030. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, Z.; Zhu, J. Research on the Importance of Maritime Energy Shipping Corridors of China Based on Ship Operation Data. In Proceedings of the Sixth International Conference on Traffic Engineering and Transportation System (ICTETS 2022), Guangzhou, China, 23–25 September 2022; Zhou, J., Sheng, J., Eds.; SPIE: Bellingham, WA, USA, 2023; p. 125911F. [Google Scholar]

- Ronczka, J. System Engineering and Logistical UAS Corridors: Challenge the Present to Drive the Future. In Proceedings of the 2018 26th International Conference on Systems Engineering (ICSEng), Sydney, Australia, 18–20 December 2018; pp. 1–8. [Google Scholar]

- Linder, N.V.; Kuznetsova, M.O. Interaction with Stakeholders as a Factor in Increasing the Competitiveness of Trans-Eurasian Container Rail Freight Transportation along Transport Corridors from the Far East to the Western Border of the Russian Federation: Results of an Empirical Study. J. Mod. Compet. 2020, 14, 89–105. [Google Scholar] [CrossRef]

- Tinoco, S.V.P.; Creemers, S.; Boute, R.N. Collaborative Shipping under Different Cost-Sharing Agreements. Eur. J. Oper. Res. 2017, 263, 827–837. [Google Scholar] [CrossRef]

- Zillmer, S.; Lüer, C. Transnational Cooperation along Core Network Corridors: The Role of Corridor Fora. In Spatial and Transport Infrastructure Development in Europe: Example of the Orient/East-Med Corridor; Scholl, B., Perić, A., Niedermaier, M., Eds.; Verl. d. ARL: Hannover, Germany, 2019; Volume 12, pp. 106–132. ISBN 978-3-88838-095-2. [Google Scholar]

- Au-Yong-Oliveira, M.; Marinho, C.; Chkoniya, V. The NEXUS Story and Its Stakeholder Analysis: Digitalising Multimodal Logistics and the Associated Value Chain Worldwide. Eur. Conf. Innov. Entrep. 2024, 19, 71–80. [Google Scholar] [CrossRef]

- Banomyong, R. Collaboration in Supply Chain Management: A Resilience Perspective; International Transport Forum Discussion Papers; Organisation for Economic Co-operation and Development (OECD), International Transport Forum: Paris, France, 2018. [Google Scholar]

- Diaz, S.; Al Hammadi, N.; El Nasr, A.S.; Villasuso, F.; Prakash, S.; Baobaid, O.; Gracias, D.; Mills, R. Green Corridor: A Feasible Option for the UAE Decarbonization Pathway, Opportunities & Challenges. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023; Society of Petroleum Engineers (SPE): Houston, TX, USA, 2023. [Google Scholar]

- Lind, M.; Ward, R.; Bergmann, M.; Haraldson, S.; Zerem, A.; Hoffmann, J.; Eklund, E. Maritime Informatics for Increased Collaboration. In Maritime Informatics; Springer International Publishing: Cham, Switzerland, 2021; pp. 113–136. [Google Scholar]

- Dias Kristiana, S.P.; Natalia, C.; Silalahi, A.; Aldi, B.E. Strategic Collaboration with Shipping Companies. Int. Inst. Sci. Technol. Educ. (IISTE) 2015, 5, 37–45. [Google Scholar]

- Cullinane, K.; Cullinane, S. Policy on Reducing Shipping Emissions. In Green Ports; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–62. [Google Scholar]

- IMO. IMO Approves Net-Zero Regulations for Global Shipping. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/pages/IMO-approves-netzero-regulations.aspx (accessed on 25 May 2025).

- IMO. IMO’s Work to Cut GHG Emissions from Ships. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-GHG-emissions.aspx (accessed on 25 May 2025).

- European Commission. Landmark Agreement Towards Achieving Net-Zero Emissions from Global Shipping by 2050. Available online: https://transport.ec.europa.eu/news-events/news/landmark-agreement-towards-achieving-net-zero-emissions-global-shipping-2050-2025-04-11_en (accessed on 25 May 2025).

- Baumgurtel, M.; van der Merwe, A.; Chau, M.; John, A.S.; Parthiban, A. What the IMO’s 2025 Reforms Mean for Global Shipping. Available online: https://hamiltonlocke.com.au/what-the-imos-2025-reforms-mean-for-global-shipping/ (accessed on 25 May 2025).

- Pozniak, O.; Olexiy, A. Greening of the Maritime Transport Process. Electron. Sci. J. Intellectualization Logist. Supply Chain. Manag. #1 2020 2022, 1, 34–54. [Google Scholar] [CrossRef]

- Georgopoulou, C.; Kakalis, N.M.P.; Psaraftis, H.N.P.; Recagno, V.; Fozza, S.; Zacharioudakis, P.; Eiband, A. Green Technologies and Smart ICT for Sustainable Freight Transport. In Efficiency and Innovation in Logistics; Springer International Publishing: Cham, Switzerland, 2014; pp. 15–33. [Google Scholar]

- Psaraftis, H.N.; Minsaas, A.; Panagakos, G.; Pålsson, C.; Salanne, I. Green Corridors in European Surface Freight Logistics. In Handbook of Global Logistics; Springer: New York, NY, USA, 2013; pp. 193–218. [Google Scholar]

- Prause, G. Sustainable Development of Logistics Clusters in Green Transport Corridors. J. Secur. Sustain. Issues 2014, 4, 59–68. [Google Scholar] [CrossRef]

- Filippopoulos, I.; Christodoulidou, X.; Kiouvrekis, Y. How Can Shipping Companies Manage Environmentally Beneficial Operations in a Sustainable Way? In Proceedings of the 2024 ASU International Conference in Emerging Technologies for Sustainability and Intelligent Systems (ICETSIS), Manama, Bahrain, 28–29 January 2024; pp. 1579–1583. [Google Scholar]

- Jensen, H.H.; Andersen, M.M.; Dao, A.; Lind, M.; Pandey, V.; Bapuji, G.; Petersen, M.; Hobson, B.; Lehmacher, W.; Turos, A. Digitalisation in a Maritime Circular Economy. In Maritime Informatics; Springer International Publishing: Cham, Switzerland, 2021; pp. 17–37. [Google Scholar]

- Scarlat, C.; Ioanid, A.; Andrei, N. Use of the Geospatial Technologies and Its Implications in the Maritime Transport and Logistics. Int. Marit. Transp. Logist. J. 2023, 12, 19–30. [Google Scholar] [CrossRef]

- Ranganathan, C.S.; Raman, R.; Parikh, S.; Rajesh, S.; Meenakshi, R.; Muthulekshmi, M. IoT Applications in Marine Monitoring: Protecting Ocean Health and Biodiversity. In Proceedings of the 2023 International Conference on Sustainable Communication Networks and Application (ICSCNA), Theni, India, 15–17 November 2023; pp. 305–310. [Google Scholar]

- Chalkias, K.; Kostis, A.; Alnuaimi, A.; Knez, P.; Naulty, J.; Salmasi, A.; Servatius, R.; Veloso, R. Preserving Nature’s Ledger: Blockchains in Biodiversity Conservation. arXiv 2024, arXiv:2404.12086. [Google Scholar]

- Komathy, K. Ballast Water Quality Compliance Monitoring Using IoT. In Information and Communication Technology for Sustainable Development: Proceedings of ICT4SD 2018; Springer: Singapore, 2020; pp. 443–451. [Google Scholar]

- Sony, M.; Naik, S. Industry 4.0 Integration with Socio-Technical Systems Theory: A Systematic Review and Proposed Theoretical Model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Govers, M.; van Amelsvoort, P. A Theoretical Essay on Socio-Technical Systems Design Thinking in the Era of Digital Transformation. Gruppe. Interaktion. Organisation. Z. Angew. Organ. (GIO) 2023, 54, 27–40. [Google Scholar] [CrossRef]

- Al Shamakhi, A.; Akintola, A.; Boughanmi, H. Assessing the Impact of WTO Trade Facilitation Agreement on Oman’s Economy. Int. J. Trade Econ. Financ. 2018, 9, 244–250. [Google Scholar] [CrossRef]

- Mba, J.U. Advancing Sustainability and Efficiency in Maritime Operations: Integrating Green Technologies and Autonomous Systems in Global Shipping. Int. J. Sci. Res. Arch. 2024, 13, 2059–2079. [Google Scholar] [CrossRef]

- Hall, P.V.; O’Brien, T.; Woudsma, C. Environmental Innovation and the Role of Stakeholder Collaboration in West Coast Port Gateways. Res. Transp. Econ. 2013, 42, 87–96. [Google Scholar] [CrossRef]

- Wu, J.; Haasis, H.-D. Knowledge-Based Stakeholder Collaboration for Sustainable Development of Freight Villages. In Proceedings of the 2011 17th International Conference on Concurrent Enterprising (ICE 2011), Aachen, Germany, 20–22 June 2011; pp. 1–8. [Google Scholar]

- Dapkus, R.; Jaison, J. Increasing the Manifestation of the Sustainable Development Principles in Logistics Organizations. Electron. Sci. J. Intellectualization Logist. Supply Chain. Manag. #1 2020 2024, 27–36. [Google Scholar] [CrossRef]

- Alsheikh Yousef, A.N. The Impact of the Development of Maritime Logistics on the Aqaba Port’s Trade Movement and the Sustainability. Strateg. Financ. Rev. 2024, 1, 108–161. [Google Scholar] [CrossRef]

- Brrar, S.; Lee, E.; Yip, T.L. An Exploratory Study of the Critical Success Factors of the Global Shipping Industry in the Digital Era. J. Theor. Appl. Electron. Commer. Res. 2023, 18, 795–813. [Google Scholar] [CrossRef]

- Wohlleber, A.J.; Bock, M.; Birkel, H.; Hartmann, E. Implementing Vital Dynamic Capabilities to Succeed in Digital Transformation: A Multiple-Case Study in Maritime Container Shipping. IEEE Trans. Eng. Manag. 2024, 71, 13627–13645. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Aksentijević, S.; Pucihar, A. Digital Transformation in the Maritime Transport Sector. Technol. Forecast. Soc. Change 2021, 170, 120879. [Google Scholar] [CrossRef]

- Akhavan, M. Decarbonising Maritime Transport: The Role of Green Shipping Corridors in Making Sustainable Port-City Ecosystems. Ocean Soc. 2025, 2, 1–16. [Google Scholar] [CrossRef]

- Su, Z.; Liu, Y.; Gao, Y.; Park, K.-S.; Su, M. Critical Success Factors for Green Port Transformation Using Digital Technology. J. Mar. Sci. Eng. 2024, 12, 2128. [Google Scholar] [CrossRef]

- D’Amico, G.; Szopik-Depczyńska, K.; Dembińska, I.; Ioppolo, G. Smart and Sustainable Logistics of Port Cities: A Framework for Comprehending Enabling Factors, Domains and Goals. Sustain. Cities Soc. 2021, 69, 102801. [Google Scholar] [CrossRef]

- Ismail, A.M.; Ballini, F.; Ölçer, A.I.; Alamoush, A.S. Integrating Ports into Green Shipping Corridors: Drivers, Challenges, and Pathways to Implementation. Mar. Pollut. Bull. 2024, 209, 117201. [Google Scholar] [CrossRef]

- Lee, P.T.-W.; Song, Z.-Y.; Lin, C.-W.; Lam, J.S.L.; Chen, J. New Framework of Port Logistics in the Post-COVID-19 Period with 6th-Generation Ports (6GP) Model. Transp. Rev. 2025, 45, 77–93. [Google Scholar] [CrossRef]

- Al Mazroui, T.S.S.; Al Alawi, M.M.S.; Al Wahaibi, K.S.H.; Al Amri, B.B.S.; Thottoli, M.M.; Thottoli, M.M. Maturity of Digital Transformation in the Shipping Industry: Case Study among Enterprises in Gulf Cooperation Council Countries. Kapal J. Ilmu Pengetah. Dan Teknol. Kelaut. 2023, 20, 115–123. [Google Scholar] [CrossRef]

- Lambrou, M.; Watanabe, D.; Iida, J. Shipping Digitalization Management: Conceptualization, Typology and Antecedents. J. Shipp. Trade 2019, 4, 11. [Google Scholar] [CrossRef]

- Heilig, L.; Voß, S. Status Quo and Innovative Approaches for Maritime Logistics in the Age of Digitalization: A Guest Editors’ Introduction. Inf. Technol. Manag. 2017, 18, 175–177. [Google Scholar] [CrossRef]

- Willie, M. Leveraging Digital Resources: A Resource-Based View Perspective. Gold. Ratio Hum. Resour. Manag. 2024, 5, 1–14. [Google Scholar] [CrossRef]

- Laradi, S.; Elfekair, A.; Shneikat, B. Understanding Sustainable Outcomes in the Digital Age: The Vital Role of Digital Leadership in Leveraging the Impact of Green Innovation. Uncertain Supply Chain Manag. 2024, 12, 2413–2428. [Google Scholar] [CrossRef]

- Macdonald, J.R.; Zobel, C.W.; Melnyk, S.A.; Griffis, S.E. Supply Chain Risk and Resilience: Theory Building through Structured Experiments and Simulation. Int. J. Prod. Res. 2018, 56, 4337–4355. [Google Scholar] [CrossRef]

- Zhang, D.; Tao, J.; Wan, C.; Huang, L.; Yang, M. Resilience Analysis of Maritime Transportation Networks: A Systematic Review. Transp. Saf. Environ. 2024, 6, tdae009. [Google Scholar] [CrossRef]

| Case Study | Core Focus Areas | Key Technologies | Unique Strategy/Outcomes | Refs. |

|---|---|---|---|---|

| MSC | Cargo visibility, e-documentation, sustainability | IoT (Smart Containers), AI, Electronic Bill of Lading (eBL) |

| [44,45] |

| Maersk | End-to-end visibility, customs automation, sustainability | Blockchain (TradeLens), AI, IoT via Remote Container Management (RCM) |

| [44,50,51,52,55] |

| CMA CGM | Fleet optimization, customer engagement, automation | Predictive Analytics, AI, Smart Containers, Customer Relationship Management (CRM) |

| [44,55] |

| Hapag-Lloyd | Booking digitization, container tracking, customer interface | IoT, Robotic Process Automation (RPA), Mobile Apps |

| [44,61] |

| NYK Line | Automation, emissions reduction, operational efficiency | AI, Autonomous Vessels, Blockchain |

| [44,64] |

| YILPORT | Port-level transparency, stakeholder integration | Blockchain (TradeLens), Application Programming Interface (API)-Based Messaging |

| [71,72] |

| Critical Success Factor | Interacting Factors | Nature of Interaction and Dynamic Symbol(s) * |

|---|---|---|

| Technological Infrastructure | Stakeholder Collaboration, Economic Feasibility, Logistical Efficiency, Logistical Security. | ↔ (Stakeholder Collaboration); → (Economic Feasibility, Logistical Efficiency, Logistical Security); ⟳ (Economic Feasibility) |

| Stakeholder Collaboration | Technological Infrastructure, Regulatory Frameworks, Environmental Sustainability. | ↔ (Technological Infrastructure, Regulatory Frameworks); → (Environmental Sustainability); ⟳ (Environmental Sustainability) |

| Economic Feasibility | Technological Infrastructure, Environmental Sustainability, Logistical Efficiency. | ⟳ (Technological Infrastructure); → (Environmental Sustainability, Logistical Efficiency); ⟳ (Logistical Efficiency) |

| Regulatory and Policy Frameworks | Stakeholder Collaboration, Logistical Efficiency, Logistical Security, Environmental Sustainability. | ↔ (Stakeholder Collaboration); → (Logistical Efficiency, Logistical Security, Environmental Sustainability); ⟳ (Environmental Sustainability) |

| Logistical Efficiency | Technological Infrastructure, Regulatory Frameworks, Environmental Sustainability, Economic Feasibility. | → (from Technological Infrastructure, Regulatory Frameworks, Environmental Sustainability); ⟳ (Economic Feasibility) |

| Logistical Security | Technological Infrastructure, Regulatory Frameworks. | → (from Technological Infrastructure, Regulatory Frameworks) |

| Environmental Sustainability | Economic Feasibility, Regulatory Frameworks, Logistical Efficiency, Stakeholder Collaboration. | ⟳ (Economic Feasibility); → (Regulatory Frameworks, Logistical Efficiency); ↔ (Stakeholder Collaboration) |

| Phase | Strategic Objective | Recommended Actions | Primary Stakeholders |

|---|---|---|---|

| Phase 1: Diagnostic Assessment | Establish a baseline understanding of digital maturity and infrastructural readiness. | Conduct comprehensive digital readiness audits; identify technological gaps, institutional constraints, and stakeholder capacities. | Port authorities, maritime agencies, consultancy firms |

| Phase 2: Regulatory and Financial Alignment | Enable supportive policy and investment environments. | Harmonize regulatory frameworks; introduce digital trade policies; mobilize funding through PPPs or multilateral financial instruments. | National governments, development banks, trade ministries |

| Phase 3: Pilot Implementation of Core Technologies | Validate technologies and institutional arrangements through controlled application. | Deploy modular digital tools (e.g., eBL, IoT tracking, API-based systems) in selected ports or corridors; monitor performance metrics. | Port operators, shipping lines, IT providers |

| Phase 4: Corridor-Wide Integration and Scaling | Expand successful pilots into integrated interoperable systems across regions. | Scale proven digital solutions; promote cross-border data standards; establish governance mechanisms for long-term corridor coordination. | Multilateral institutions, regional port networks, logistics alliances |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alavi-Borazjani, S.A.; Bengue, A.A.; Chkoniya, V.; Shafique, M.N. An Overview of Critical Success Factors for Digital Shipping Corridors: A Roadmap for Maritime Logistics Modernization. Sustainability 2025, 17, 5537. https://doi.org/10.3390/su17125537

Alavi-Borazjani SA, Bengue AA, Chkoniya V, Shafique MN. An Overview of Critical Success Factors for Digital Shipping Corridors: A Roadmap for Maritime Logistics Modernization. Sustainability. 2025; 17(12):5537. https://doi.org/10.3390/su17125537

Chicago/Turabian StyleAlavi-Borazjani, Seyedeh Azadeh, Alberto Antonio Bengue, Valentina Chkoniya, and Muhammad Noman Shafique. 2025. "An Overview of Critical Success Factors for Digital Shipping Corridors: A Roadmap for Maritime Logistics Modernization" Sustainability 17, no. 12: 5537. https://doi.org/10.3390/su17125537

APA StyleAlavi-Borazjani, S. A., Bengue, A. A., Chkoniya, V., & Shafique, M. N. (2025). An Overview of Critical Success Factors for Digital Shipping Corridors: A Roadmap for Maritime Logistics Modernization. Sustainability, 17(12), 5537. https://doi.org/10.3390/su17125537