Digital Intelligence in Building Lifecycle Management: A Mixed-Methods Approach

Abstract

1. Introduction

2. Data Sources and Visual Analysis

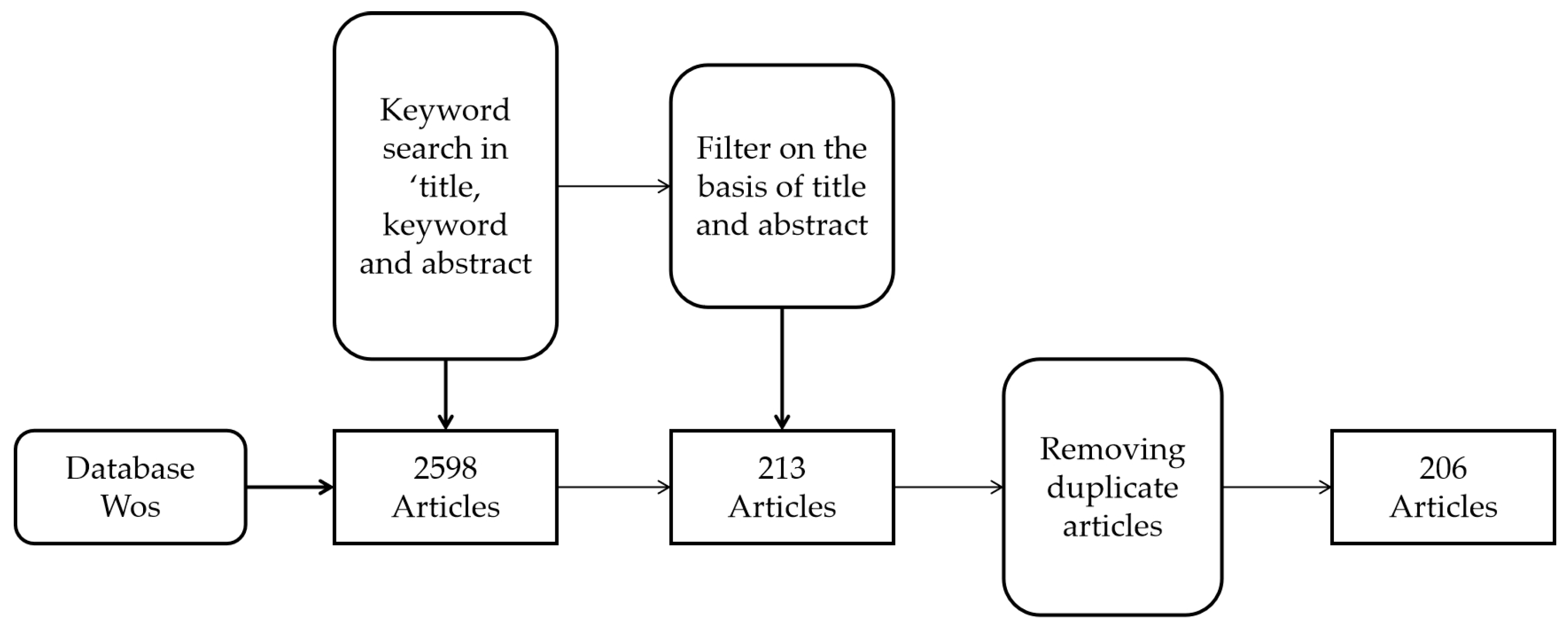

2.1. Data Source and Processing

2.2. Visual Analysis Results

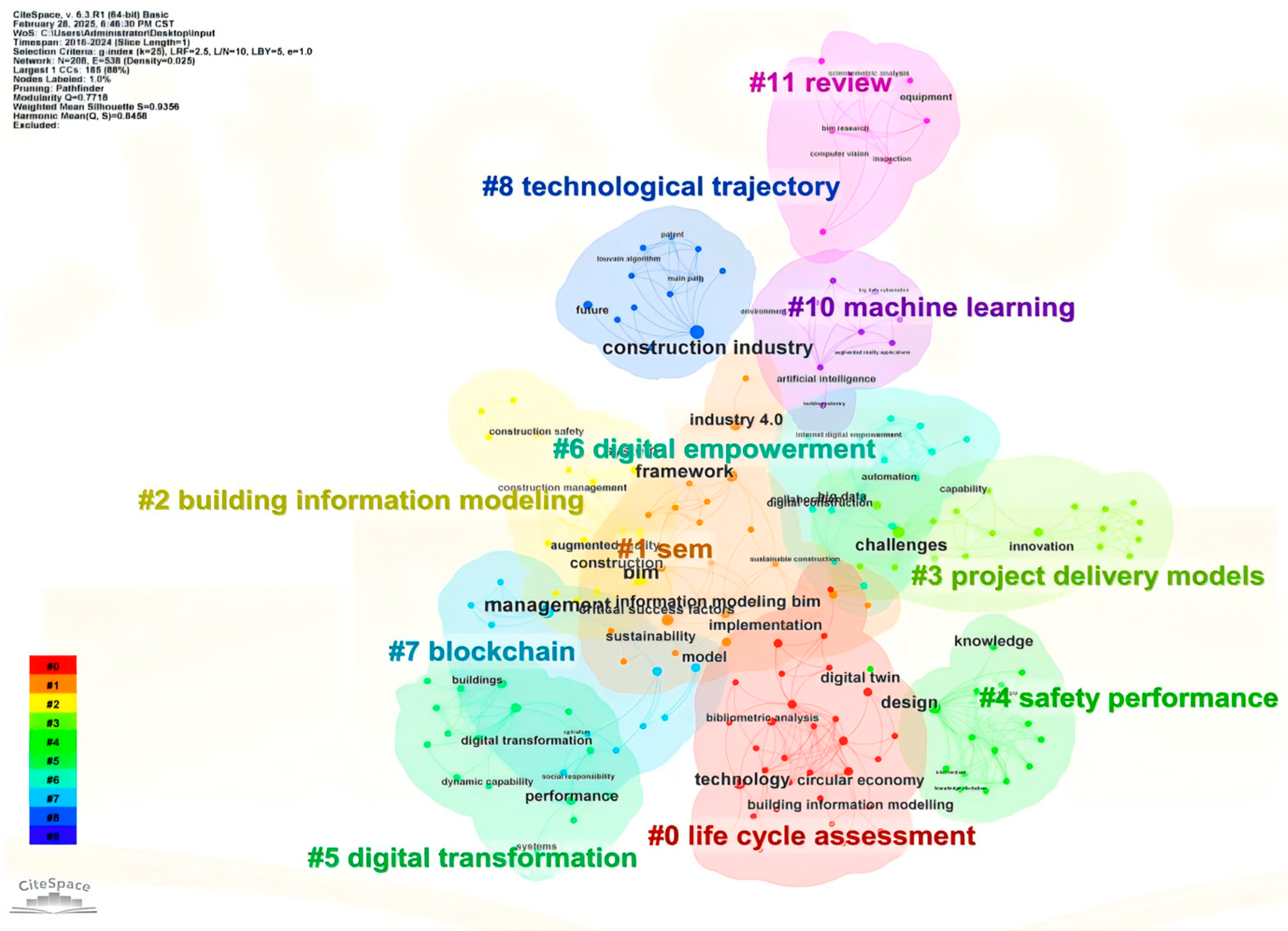

2.2.1. Keyword Cluster Analysis

2.2.2. Keyword Time Zone Analysis

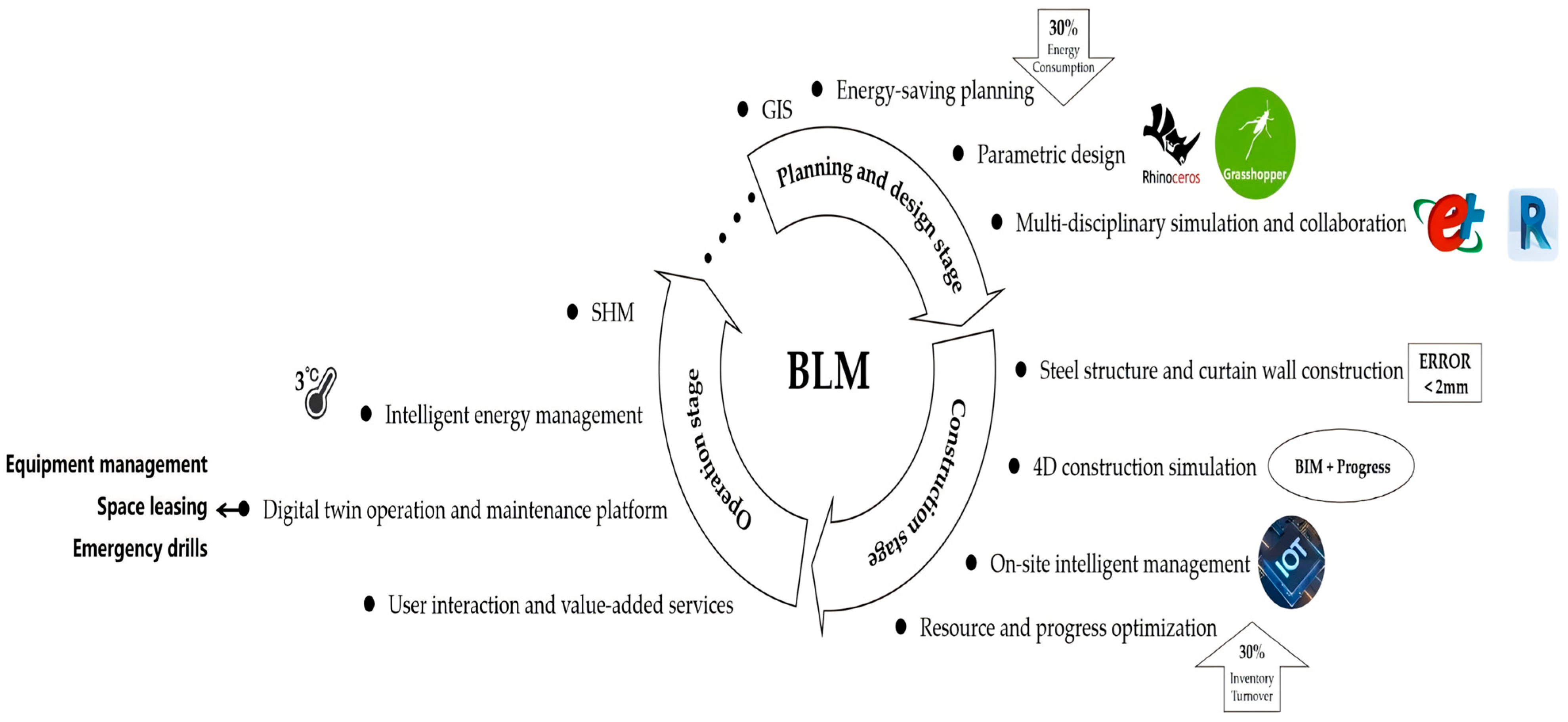

3. Research Overview of Digital Intelligence Empowerment in BLM

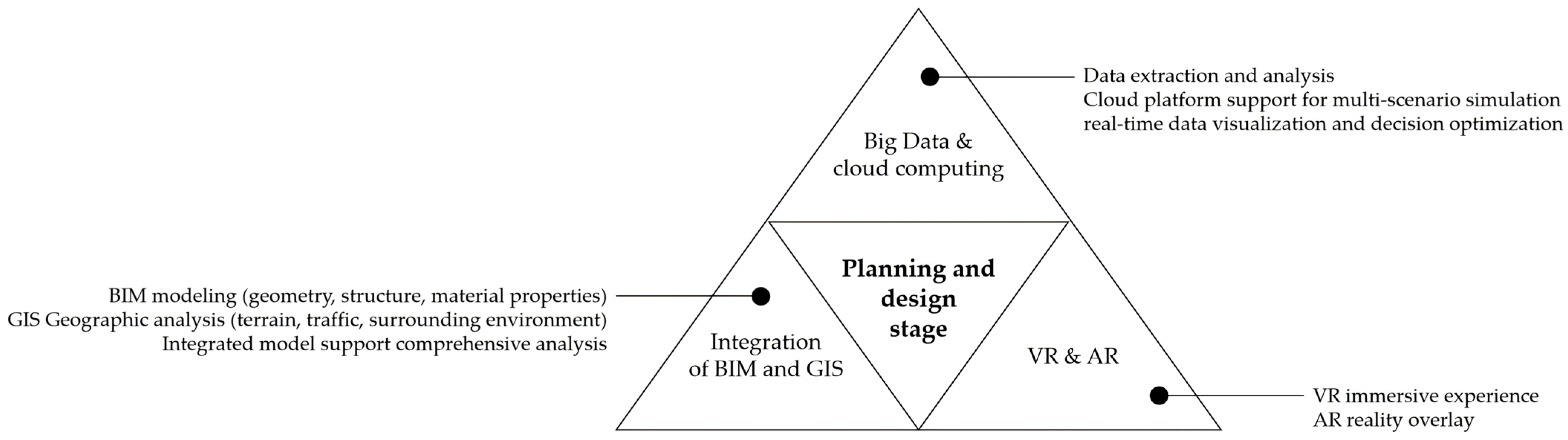

3.1. Planning and Design Stage

3.1.1. Application of Big Data and Cloud Computing in Planning

3.1.2. Application of Virtual Reality (VR) and Augmented Reality (AR) Technology in the Design Display

3.1.3. Integration of BIM and GIS

3.2. Construction Stage

3.2.1. The Internet of Things Realizes the Real-Time Monitoring of the Construction Site

3.2.2. Robotics and Automation in Intelligent Construction

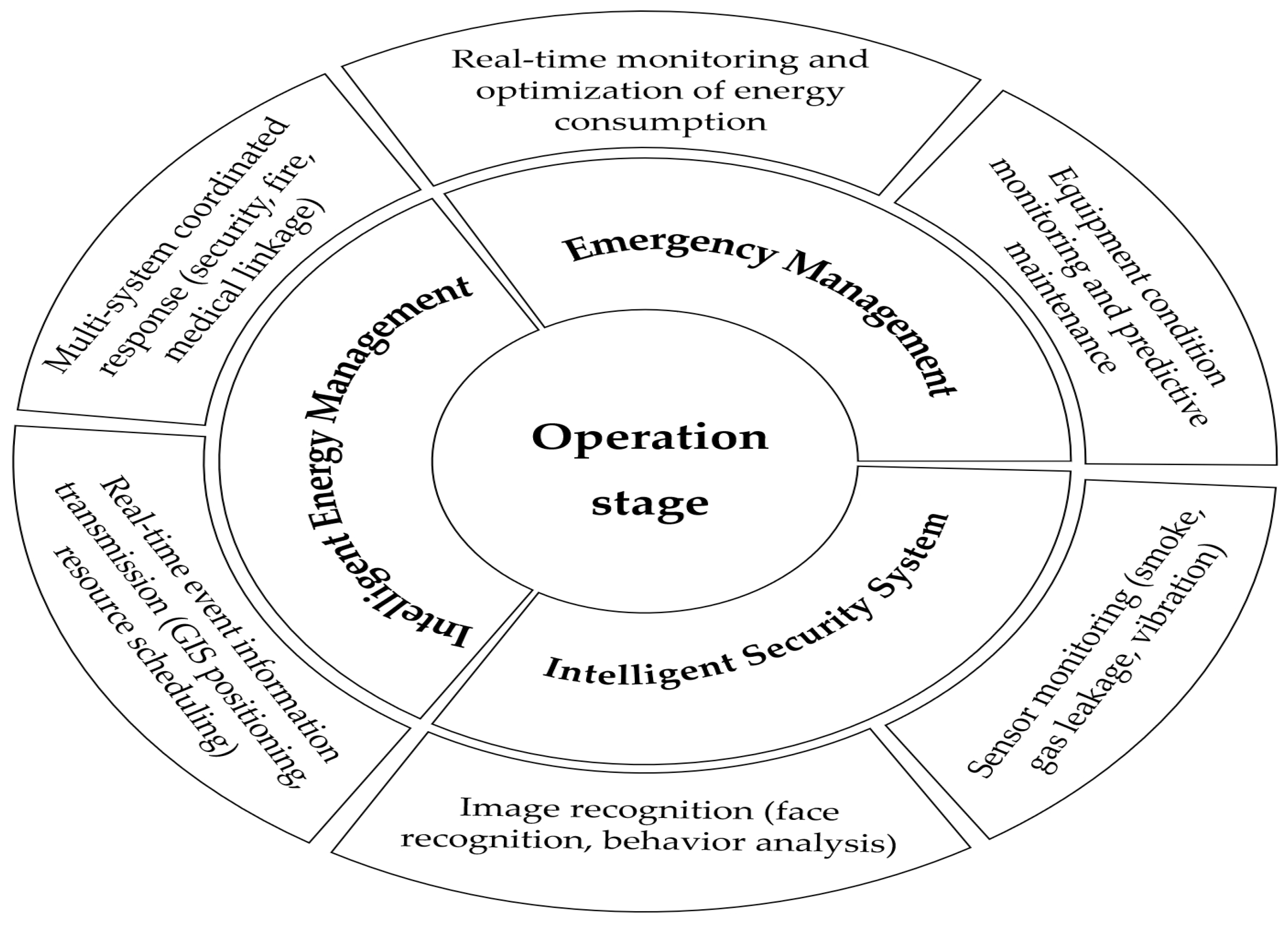

3.3. Operation Stage

4. Case Study of Shanghai Tower in China

4.1. Planning and Design Stage of Shanghai Tower

4.2. Construction Stage of Shanghai Tower

4.3. Operation Stage of Shanghai Tower

4.4. Challenges and Generalizability of Digital Intelligence Implementation in Shanghai Tower

4.4.1. Technological Challenges

4.4.2. Managerial Challenges

4.4.3. Generalizability of Solutions

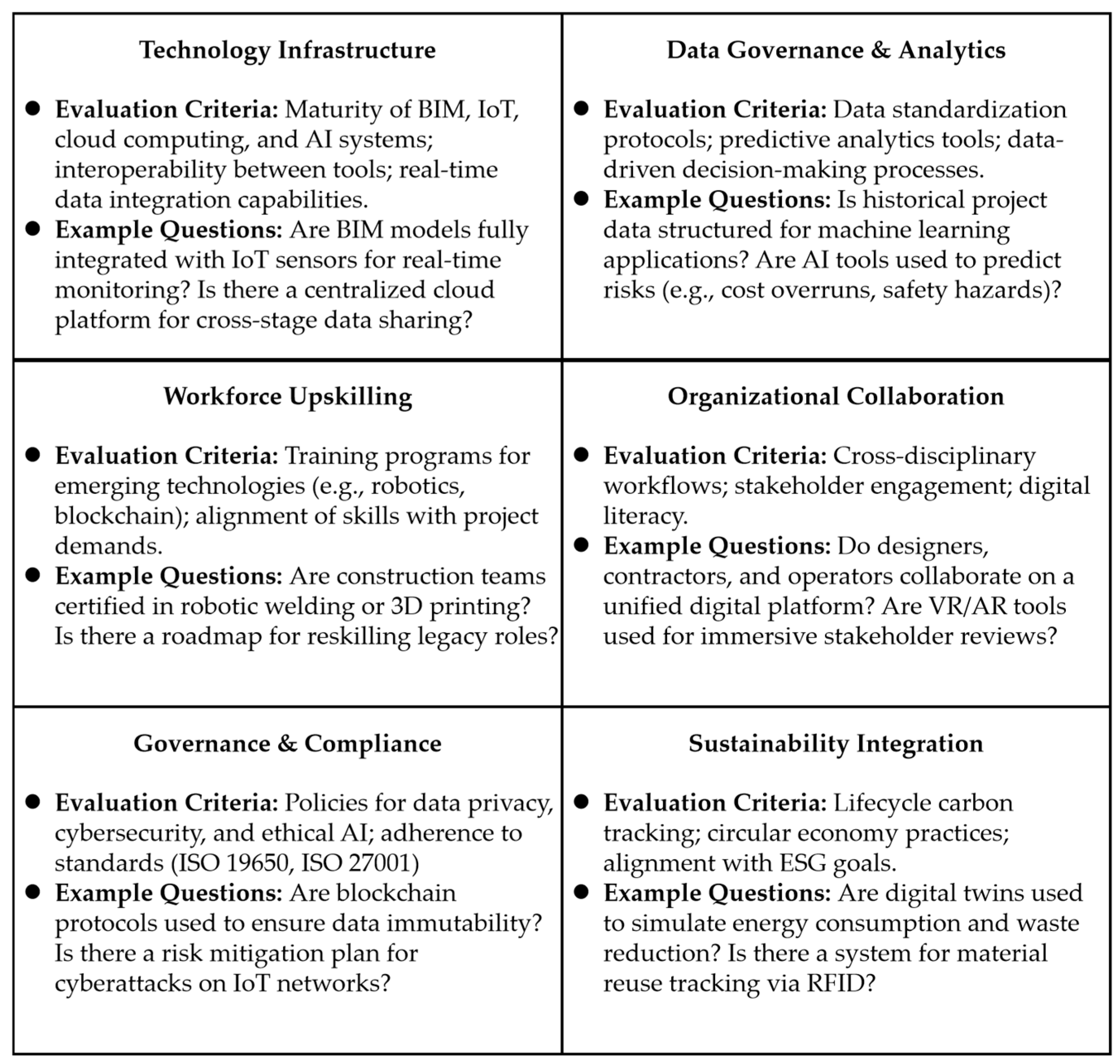

5. Discussions and Conclusions

5.1. Research Contributions

5.2. Managerial Insights

5.3. Future Research and Limitations

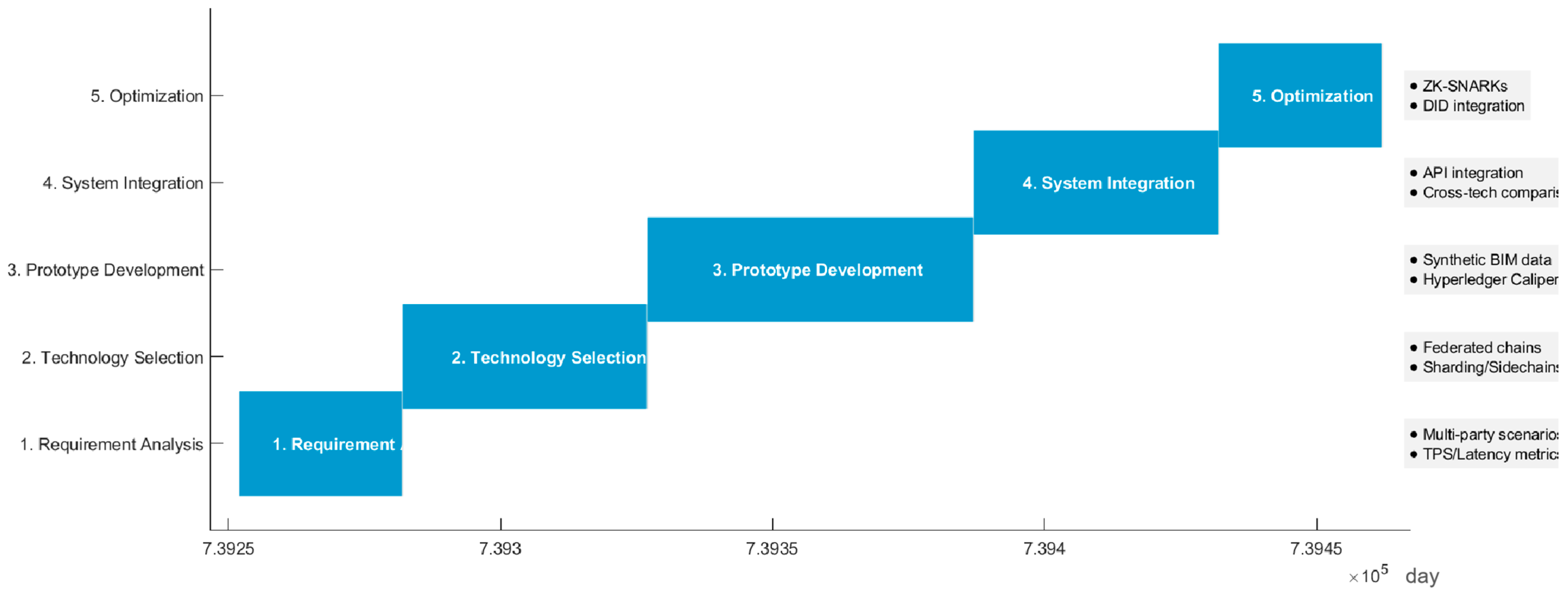

5.3.1. Integration of Blockchain for Transparent and Secure Data Sharing

5.3.2. Human–Robot Collaboration (HRC) in Construction Automation

5.3.3. Lifecycle Sustainability Assessment via Digital Twins

5.3.4. Human–Robot Collaboration Frameworks for Construction 5.0

5.4. Policy Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Berger, R. Roland Berger Digitization in the Construction Industry: Building Europe’s Road to “Construction 4.0”; Roland Berger GMBH: Munich, Germany, 2016. [Google Scholar]

- Corallo, A.; Lazoi, M.; Lezzi, M.; Luperto, A. Cybersecurity awareness in the context of the Industrial Internet of Things: A systematic literature review. Comput. Ind. 2022, 137, 103614. [Google Scholar] [CrossRef]

- Kaewunruen, S.; O’Nell, C.; Sengsri, P. Digital twin-driven strategic demolition plan for circular asset management of bridge infrastructures. Sci. Rep. 2025, 15, 10554. [Google Scholar]

- Şenol, H.İ.; Gökgöz, T. Integration of Building Information Modeling (BIM) and Geographic Information System (GIS): A new approach for IFC to CityJSON conversion. Earth Sci. Inform. 2024, 17, 3437–3454. [Google Scholar] [CrossRef]

- Adu-Amankwa, N.A.N.; Rahimian, F.P.; Dawood, N.; Park, C. Digital Twins and Blockchain technologies for building lifecycle management. Autom. Constr. 2023, 155, 105064. [Google Scholar] [CrossRef]

- Alhadi, A.; Tom, B.D.; Yacine, R. Enhancing asset management: Integrating digital twins for continuous permitting and compliance-A systematic literature review. J. Build. Eng. 2025, 99, 111515. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Chen, Y.L.; Huang, D.; Liu, Z.; Osmani, M.; Demian, P. Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City. Sustainability 2022, 14, 10028. [Google Scholar] [CrossRef]

- Jrade, A.; Jalaei, F.; Zhang, J.J.; Eirdmousa, S.J.; Jalaei, F. Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review. Sustainability 2023, 15, 15049. [Google Scholar] [CrossRef]

- Cerdá-Suárez, L.M.; Espinosa-Cristia, J.F.; Núñez-Valdés, K.; Núñez-Valdés, G. Detecting Circular Economy Strategies in the Fourth Sector: Overview of the Chilean Construction Sector as Evidence of a Sustainable Business Model. Sustainability 2023, 15, 8559. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human-Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Papadonikolaki, E.; van Oel, C.; Kagioglou, M. Organising and Managing boundaries: A structurational view of collaboration with Building Information Modelling (BIM). Int. J. Proj. Manag. 2019, 37, 378–394. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.K.; Lu, X.Y.; Zhao, H.Y.; Zhou, Z.; Cao, Y.Y. Construction of Smart City Street Landscape Big Data-Driven Intelligent System Based on Industry 4.0. Comput. Intell. Neurosci. 2021, 2021, 1716396. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef]

- Lekan, A.; Clinton, A.; Owolabi, J. The Disruptive Adaptations of Construction 4.0 and Industry 4.0 as a Pathway to a Sustainable Innovation and Inclusive Industrial Technological Development. Buildings 2021, 11, 79. [Google Scholar] [CrossRef]

- Gurgun, A.P.; Koc, K.; Kunkcu, H. Exploring the adoption of technology against delays in construction projects. Eng. Constr. Archit. Manag. 2024, 31, 1222–1253. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Irfan, M.; Sreenivasan, P.; Rabbani, M.B.A. Health and Safety Improvement through Industrial Revolution 4.0: Malaysian Construction Industry Case. Sustainability 2023, 15, 201. [Google Scholar] [CrossRef]

- Allam, A.S.; Nik-Bakht, M. Supporting circularity in construction with performance-based deconstruction. Sustain. Prod. Consum. 2024, 45, 1–14. [Google Scholar] [CrossRef]

- Wang, K.Y.; Guo, F.Y.; Zhang, C.; Schaefer, D. From Industry 4.0 to Construction 4.0: Barriers to the digital transformation of engineering and construction sectors. Eng. Constr. Archit. Manag. 2024, 31, 136–158. [Google Scholar] [CrossRef]

- Weerapperuma, U.S.; Rathnasinghe, A.P.; Jayasena, H.S.; Wijewickrama, C.S.; Thurairajah, N. A knowledge framework for blockchain-enabled smart contract adoption in the construction industry. Eng. Constr. Archit. Manag. 2025, 32, 374–408. [Google Scholar] [CrossRef]

- Pourrahimian, E.; Eltahan, A.; Salhab, D.; Crawford, J.; Abourizk, S.; Hamzeh, F. Integrating expert insights and data analytics for enhanced construction productivity monitoring and control: A machine learning approach. Eng. Constr. Archit. Manag. 2024; ahead-of-print. [Google Scholar]

- Ji, S.; Lee, B.; Yi, M.Y. Building life-span prediction for life cycle assessment and life cycle cost using machine learning: A big data approach. Build. Environ. 2021, 205, 108267. [Google Scholar] [CrossRef]

- Ngo, J.; Hwang, B.G.; Zhang, C.Y. Factor-based big data and predictive analytics capability assessment tool for the construction industry. Autom. Constr. 2020, 110, 103042. [Google Scholar] [CrossRef]

- Yu, T.; Liang, X.; Wang, Y.W. Factors Affecting the Utilization of Big Data in Construction Projects. J. Constr. Eng. Manag. 2020, 146, 04020032. [Google Scholar] [CrossRef]

- Lu, Y.S.; Zhang, J.T. Bibliometric analysis and critical review of the research on big data in the construction industry. Eng. Constr. Archit. Manag. 2022, 29, 3574–3592. [Google Scholar] [CrossRef]

- You, Z.J.; Feng, L.J. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Delgado, J.M.D.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in construction industry: Use cases, benefits and challenges. Autom. Constr. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Morawiec, P.; Soltysik-Piorunkiewicz, A. Cloud Computing, Big Data, and Blockchain Technology Adoption in ERP Implementation Methodology. Sustainability 2022, 14, 3714. [Google Scholar] [CrossRef]

- Eirinaki, M.; Dhar, S.; Mathur, S.; Kaley, A.; Patel, A.; Joshi, A.; Shah, D. A building permit system for smart cities: A cloud-based framework. Comput. Environ. Urban Syst. 2018, 70, 175–188. [Google Scholar] [CrossRef]

- Sadeq, H.; Sayed, T. Automated Roundabout Safety Analysis: Diagnosis and Remedy of Safety Problems. J. Transp. Eng. 2016, 142, 04016062. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, C.A. Thoughts on the construction of public health informatization for community health archives grass roots management system. Front. Public Health 2023, 11, 1160478. [Google Scholar] [CrossRef]

- Micieta, B.; Staszewska, J.; Kovalsky, M.; Krajcovic, M.; Binasova, V.; Papanek, L.; Antoniuk, I. Innovative System for Scheduling Production Using a Combination of Parametric Simulation Models. Sustainability 2021, 13, 9518. [Google Scholar] [CrossRef]

- Tecchio, P.; McAlister, C.; Mathieux, F.; Ardente, F. In search of standards to support circularity in product policies: A systematic approach. J. Clean. Prod. 2017, 168, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Noghabaei, M.; Han, K. Object manipulation in immersive virtual environments: Hand Motion tracking technology and snap-to-fit function. Autom. Constr. 2021, 124, 103594. [Google Scholar] [CrossRef]

- Getuli, V.; Capone, P.; Bruttini, A.; Isaac, S. BIM-based immersive Virtual Reality for construction workspace planning: A safety-oriented approach. Autom. Constr. 2020, 114, 103160. [Google Scholar] [CrossRef]

- Gunduz, M.; Laitinen, H. A 10-step safety management framework for construction small and medium-sized enterprises. Int. J. Occup. Saf. Ergon. 2017, 23, 353–359. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Zhu, W.J.; Qi, Y.H. A Lightweight Mobile Outdoor Augmented Reality Method Using Deep Learning and Knowledge Modeling for Scene Perception to Improve Learning Experience. Int. J. Hum.-Comput. Interact. 2021, 37, 884–901. [Google Scholar] [CrossRef]

- Guo, Y.J.; Li, S.; Zhang, X.D.; Fu, Y.Y.; Yuan, Y.M.; Liu, Y.Q. Embracing the Metaverse: A Survey of Virtual Reality and Augmented Reality Practices at the United States’ Top One Hundred University Libraries. Coll. Res. Libr. 2024, 85, 1006. [Google Scholar] [CrossRef]

- Hincapie, M.; Diaz, C.; Valencia, A.; Contero, M.; Güemes-Castorena, D. Educational applications of augmented reality: A bibliometric study. Comput. Electr. Eng. 2021, 93, 107289. [Google Scholar] [CrossRef]

- Yeh, H.C.; Tseng, S.S. Enhancing multimodal literacy using augmented reality. Lang. Learn. Technol. 2020, 24, 27–37. [Google Scholar]

- Mzyece, D.; Ndekugri, I.E.; Ankrah, N.A. Building information modelling (BIM) and the CDM regulations interoperability framework. Eng. Constr. Archit. Manag. 2019, 26, 2682–2704. [Google Scholar] [CrossRef]

- Wang, Z.Y. Spatial Differentiation Characteristics of Rural Areas Based on Machine Learning and GIS Statistical Analysis-A Case Study of Yongtai County, Fuzhou City. Sustainability 2023, 15, 4367. [Google Scholar] [CrossRef]

- Rall, E.; Hansen, R.; Pauleit, S. The added value of public participation GIS (PPGIS) for urban green infrastructure planning. Urban For. Urban Green. 2019, 40, 264–274. [Google Scholar] [CrossRef]

- Santos, P.A.S.; Cortez, B.; Carvalho, M.T.M. Integrating GIS and BIM with MCDM for infrastructure planning: A comprehensive framework. Eng. Constr. Archit. Manag. 2024; ahead-of-print. [Google Scholar]

- Diakite, A.A.; Zlatanova, S. Automatic geo-referencing of BIM in GIS environments using building footprints. Comput. Environ. Urban Syst. 2020, 80, 101453. [Google Scholar] [CrossRef]

- Campbell, A.; Both, A.; Sun, Q. Detecting and mapping traffic signs from Google Street View images using deep learning and GIS. Computers, Environ. Urban Syst. 2019, 77, 101350. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Pärn, E.A.; Ewards, D.J. Critical success factors for implementing building information modelling (BIM): A longitudinal review. Autom. Constr. 2018, 91, 100–110. [Google Scholar] [CrossRef]

- Gbanie, S.P.; Griffin, A.L.; Thornton, A. Impacts on the Urban Environment: Land Cover Change Trajectories and Landscape Fragmentation in Post-War Western Area, Sierra Leone. Remote Sens. 2018, 10, 129. [Google Scholar] [CrossRef]

- Lou, K.; Hu, Z.Q.; Zhang, H.W.; Li, Q.Y.; Ji, X.F. Information Storage Based on Stimuli-Responsive Fluorescent 3D Code Materials. Adv. Funct. Mater. 2022, 32, 2113274. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the relationship between Building Information Modelling (BIM) implementation barriers, usage and awareness on building project lifecycle. Build. Environ. 2022, 207, 108556. [Google Scholar] [CrossRef]

- GB/T 35645-2017; Navigation Electronic Map Framework Data Exchange Format. Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- DIN SPEC 91391; Requirements for Safety-Related Mechatronic Systems in Machinery. Deutsches Institut für Normung e.V.: Berlin, Germany, 2018.

- Cepa, J.J.; Alberti, M.G.; Pavón, R.M.; Calvo, J.A. Integrating BIM and GIS for an Existing Infrastructure. Appl. Sci. 2024, 14, 10962. [Google Scholar] [CrossRef]

- Santos, T.A.; Fonseca, M.A.; Martins, P.; Soares, C.G. Integrating short sea shipping with trans-european transport networks. J. Mar. Sci. Eng. 2022, 10, 218. [Google Scholar] [CrossRef]

- Abanda, F.H.; Balu, B.; Adukpo, S.E.; Akintola, A. Decoding ISO 19650 Through Process Modelling for Information Management and Stakeholder Communication in BIM. Buildings 2025, 15, 431. [Google Scholar] [CrossRef]

- Kazmi, Z.A.; Sodangi, M. Modeling the Constraints to the Utilization of the Internet of Things in Managing Supply Chains of Off-Site Construction: An Approach toward Sustainable Construction. Buildings 2022, 12, 388. [Google Scholar] [CrossRef]

- Tu, M.R. An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management: A mixed research approach. Int. J. Logist. Manag. 2018, 29, 131–151. [Google Scholar] [CrossRef]

- Khurshid, K.; Danish, A.; Salim, M.U.; Bayram, M.; Ozbakkaloglu, T.; Mosaberpanah, M.A. An In-Depth Survey Demystifying the Internet of Things (IoT) in the Construction Industry: Unfolding New Dimensions. Sustainability 2023, 15, 1275. [Google Scholar] [CrossRef]

- Chen, Y.T.; Sun, E.W.; Chang, M.F.; Lin, Y.B. Pragmatic real-time logistics management with traffic IoT infrastructure: Big data predictive analytics of freight travel time for Logistics 4.0. Int. J. Prod. Econ. 2021, 238, 108157. [Google Scholar] [CrossRef]

- McCartney, M. The China-Pakistan Economic Corridor (CPEC): Infrastructure, Social Savings, Spillovers, and Economic Growth in Pakistan. Eurasian Geogr. Econ. 2022, 63, 180–211. [Google Scholar] [CrossRef]

- Scuotto, V.; Ferraris, A.; Bresciani, S. Internet of Things Applications and challenges in smart cities: A case study of IBM smart city projects. Bus. Process Manag. J. 2016, 22, 357–367. [Google Scholar] [CrossRef]

- Ahmed, E.; Yaqoob, I.; Hashem, I.A.T.; Khan, I.; Ahmed, A.I.A.; Imran, M.; Vasilakos, A.V. The role of big data analytics in Internet of Things. Comput. Netw. 2017, 129, 459–471. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, X.Z.; Li, H.; Jin, R.; Fu, H.F. Real-Time Alarming, Monitoring, and Locating for Non-Hard-Hat Use in Construction. J. Constr. Eng. Manag. 2019, 145, 04019006. [Google Scholar] [CrossRef]

- Edirisinghe, R. Digital skin of the construction site Smart sensor technologies towards the future smart construction site. Eng. Constr. Archit. Manag. 2019, 26, 184–223. [Google Scholar] [CrossRef]

- Arashpour, M.; Kamat, V.; Bai, Y.; Wakefield, R.; Abbasi, B. Optimization modeling of multi-skilled resources in prefabrication: Theorizing cost analysis of process integration in off-site construction. Autom. Constr. 2018, 95, 1–9. [Google Scholar] [CrossRef]

- Xu, G.Y.; Huang, G.Q.; Fang, J.; Chen, J. Cloud-based smart asset management for urban flood control. Enterp. Inf. Syst. 2017, 11, 719–737. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.X.; Luo, L.Z. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Luo, L.Z.; Hu, S.Y.; Chen, K.; Liu, Y.L.; Li, C.Z. Exploring Safety Vulnerability in Prefabricated Construction and Mitigation Effects of Internet of Things. IEEE Trans. Eng. Manag. 2024, 71, 8531–8547. [Google Scholar] [CrossRef]

- Dindorf, R.; Wos, P. Challenges of Robotic Technology in Sustainable Construction Practice. Sustainability 2024, 16, 5500. [Google Scholar] [CrossRef]

- You, S.; Kim, J.H.; Lee, S.; Kamat, V.; Robert, L.P. Enhancing perceived safety in human-robot collaborative construction using immersive virtual environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Haghighi, A. Large-Scale Automated Additive Construction: Overview, Robotic Solutions, Sustainability, and Future Prospect. Sustainability 2022, 14, 9782. [Google Scholar] [CrossRef]

- Mitterberger, D.; Ercan Jenny, S.; Vasey, L.; Lloret-Fritschi, E.; Aejmelaeus-Lindström, P.; Gramazio, F.; Kohler, M. Interactive robotic plastering: Augmented interactive design and fabrication for on-site robotic plastering. In Proceedings of the 2022 CHI Conference on Human Factors in Computing Systems, New Orleans, LA, USA, 30 April–5 May 2020; pp. 1–18. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Yeom, D.J.; Na, E.J.; Lee, M.Y.; Kim, Y.J.; Kim, Y.S.; Cho, C.S. Performance Evaluation and Life Cycle Cost Analysis Model of a Gondola-Type Exterior Wall Painting Robot. Sustainability 2017, 9, 1809. [Google Scholar] [CrossRef]

- Ding, L.; Jiang, W.; Zhou, Y.; Zhou, C.; Liu, S. BIM-based task-level planning for robotic brick assembly through image-based 3D modeling. Adv. Eng. Inform. 2020, 43, 100993. [Google Scholar] [CrossRef]

- Brissi, S.G.; Chong, O.W.; Debs, L.; Zhang, J.S. A review on the interactions of robotic systems and lean principles in offsite construction. Eng. Constr. Archit. Manag. 2022, 29, 383–406. [Google Scholar] [CrossRef]

- Zayed, T.M.; Halpin, D.W.; Basha, I.M. Productivity and delays assessment for concrete batch plant-truck mixer operations. Constr. Manag. Econ. 2005, 23, 839–850. [Google Scholar] [CrossRef]

- Cho, K.; Ahn, S.; Park, K.; Kim, T.W. Schedule delay leading indicators in precast concrete construction projects: Qualitative comparative analysis of Korean cases. J. Manag. Eng. 2021, 37, 04021024. [Google Scholar] [CrossRef]

- Hao, Z.B.; Wang, Y.Z.; Yang, X.G. Every Second Counts: A Comprehensive Review of Route Optimization and Priority Control for Urban Emergency Vehicles. Sustainability 2024, 16, 2917. [Google Scholar] [CrossRef]

- Gomes Rossi, A.H.; Marcondes, G.B.; Pontes, J.; Leitao, P.; Treinta, F.T.; Martins De Resende, L.M.; Mosconi, E.; Yoshino, R.T. Lean Tools in the Context of Industry 4.0: Literature Review, Implementation and Trends. Sustainability 2022, 14, 12295. [Google Scholar] [CrossRef]

- Khan, S.; Panuwatwanich, K.; Usanavasin, S. Integrating building information modeling with augmented reality: Application and empirical assessment in building facility management. Eng. Constr. Archit. Manag. 2024, 31, 2809–2828. [Google Scholar] [CrossRef]

- Guo, H.L.; Yu, Y.T.; Ding, Q.H.; Skitmore, M. Image-and-Skeleton-Based Parameterized Approach to Real-Time Identification of Construction Workers’ Unsafe Behaviors. J. Constr. Eng. Manag. 2018, 144, 04018042. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, S.I. Training Set Enlargement Using Binary Weighted Interpolation Maps for the Single Sample per Person Problem in Face Recognition. Appl. Sci. 2020, 10, 6659. [Google Scholar] [CrossRef]

- Lee, W.; Lin, K.Y.; Seto, E.; Migliaccio, G.C. Wearable sensors for monitoring on-duty and off-duty worker physiological status and activities in construction. Autom. Constr. 2017, 83, 341–353. [Google Scholar] [CrossRef]

- Wu, C.K.; Chen, C.J.; Jiang, R.; Wu, P.; Xu, B.; Wang, J. Understanding laborers’ behavioral diversities in multinational construction projects using integrated simulation approach. Eng. Constr. Archit. Manag. 2019, 26, 2120–2146. [Google Scholar] [CrossRef]

- Sorensen, G.; McLellan, D.L.; Sabbath, E.L.; Dennerlein, J.T.; Nagler, E.M.; Hurtado, D.A.; Pronk, N.P.; Wagner, G.R. Integrating worksite health protection and health promotion: A conceptual model for intervention and research. Prev. Med. 2016, 91, 188–196. [Google Scholar] [CrossRef]

- Pishgar, M.; Issa, S.F.; Sietsema, M.; Pratap, P.; Darabi, H. REDECA: A Novel Framework to Review Artificial Intelligence and Its Applications in Occupational Safety and Health. Int. J. Environ. Res. Public Health 2021, 18, 6705. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.L.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef] [PubMed]

- Xiong, H.B.; Cao, J.X.; Zhang, F.L.; Ou, X.; Chen, J. Investigation of the SHM-oriented model and dynamic characteristics of a super-tall building. Smart Struct. Syst. 2019, 23, 295–306. [Google Scholar]

- CEN Technical Committee 350 (CEN TC 350); Sustainable Construction—Environmental Product Declarations and Product Category Rules. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- EN 15804:2012; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Tijani, B.; Jin, X.H.; Osei-Kyei, R. Effect of project organization elements on the mental health of project management practitioner in AEC projects. Eng. Constr. Archit. Manag. 2024, 31, 73–114. [Google Scholar] [CrossRef]

- Madureira, R.C.; Silva, C.S.; Amorim, M.; Dias, M.F.; Lins, B.; Mello, G. Think Twice to Achieve a Sustainable Project Management: From Ecological Sustainability towards the Sustainable Project Management Cube Model. Sustainability 2022, 14, 3436. [Google Scholar] [CrossRef]

- Taboada, G.L.; Seruca, I.; Sousa, C.; Pereira, A. Exploratory Data Analysis and Data Envelopment Analysis of Construction and Demolition Waste Management in the European Economic Area. Sustainability 2020, 12, 4995. [Google Scholar] [CrossRef]

- Ma, X.Z.; Xiong, F.; Olawumi, T.O.; Dong, N.; Chan, A.P.C. Conceptual Framework and Roadmap Approach for Integrating BIM into Lifecycle Project Management. J. Manag. Eng. 2018, 34, 05018011. [Google Scholar] [CrossRef]

- Morteza, A.; Chou, R.A. Distributed Matrix Multiplication: Download Rate, Randomness and Privacy Trade-Offs. In Proceedings of the 2024 60th Annual Allerton Conference on Communication, Control, and Computing, Urbana, IL, USA, 24–27 September 2024; IEEE: Piscataway, NJ, USA, 2024. [Google Scholar]

- Oyewobi, L.; Okanlawon, T.T.; Ibrahim, K.; Jimoh, R.A. Influence of blockchain adoption barriers and drivers on potential application areas in the construction lifecycle: Partial least squares structural equation modelling (PLS-SEM) approach. Eng. Constr. Archit. Manag. 2025, 32, 1798–1815. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Rahimian, F.P. Investigating the barriers to the adoption of blockchain technology in sustainable construction projects. J. Clean. Prod. 2023, 403, 136840. [Google Scholar] [CrossRef]

- Liu, C. HPCLS-BC: A novel blockchain framework using heterogeneous peer-node and cloud-based ledger storage for Internet of Things applications. Future Gener. Comput. Syst. 2024, 150, 364–379. [Google Scholar] [CrossRef]

| Category | Criterion |

|---|---|

| Inclusion Criteria | (1) Focusing on Construction 4.0 technologies; (2) Addressing Building Lifecycle Management (BLM); (3) Including empirical or case study data. |

| Exclusion Criteria | Focusing solely on manufacturing digitization OR lack empirical BLM applications. |

| Number of Articles | Select | |

|---|---|---|

| Construction 4.0 | 591 | 73 |

| digital + empowerment + construction | 49 | 4 |

| digital + enablement + construction | 1 | 0 |

| digital + enabling + construction | 305 | 54 |

| digital + empowerment + building | 125 | 2 |

| digital + enablement + building | 4 | 0 |

| digital + enabling + building | 992 | 26 |

| intelligence + empowerment + construction | 3 | 0 |

| intelligence + enablement + construction | 0 | 0 |

| intelligence + enabling + construction | 93 | 17 |

| intelligence + empowerment + building | 30 | 1 |

| intelligence + enablement + building | 0 | 0 |

| intelligence + enabling + building | 405 | 36 |

| Total | 2598 | 213 |

| Journal Title | Number |

|---|---|

| Engineering Construction and Architectural Management | 51 |

| Sustainability | 32 |

| Automation in Construction | 26 |

| Journal of Building Engineering | 5 |

| Journal of Construction Engineering and Management | 4 |

| Buildings | 3 |

| IEEE Access | 3 |

| IEEE Transactions on Engineering Management | 3 |

| Computational Intelligence and Neuroscience | 2 |

| Environmental Science and Pollution Research | 2 |

| International Journal of Environmental Research and Public Health | 2 |

| ClusterID | Size | Silhouette Mean | Year | Label (LSI) |

|---|---|---|---|---|

| #0 life cycle assessment | 31 | 0.934 | 2021 | building information; digital twin; digital transformation |

| #1 sem | 23 | 0.925 | 2020 | project management; building information modeling |

| #2 building information modeling | 22 | 0.931 | 2018 | building information modeling; unmanned aerial vehicle |

| #3 project delivery models | 20 | 0.905 | 2018 | digital maturity; project delivery models; infrastructure megaprojects |

| #4 safety performance | 18 | 0.931 | 2017 | autism intervention; knowledge exchange; knowledge elicitation |

| #5 digital transformation | 16 | 0.954 | 2021 | digital transformation; business models; dynamic capabilities |

| #6 digital empowerment | 14 | 0.931 | 2021 | digital technology; rural sustainable development; digital village |

| #7 blockchain | 12 | 0.956 | 2021 | construction industry; systematic literature evaluation; critical success |

| #8 technological trajectory | 12 | 1.000 | 2022 | construction industry; search path node pair; technological trajectory |

| #10 machine learning | 9 | 0.875 | 2020 | digital twin; artificial intelligence; machine learning; big data cybernetics |

| Dimension | Blockchain | Cloud-Based Ledger Systems |

|---|---|---|

| Decentralization | Distributed across nodes; no single point of failure | Centralized; outage risks |

| Immutability | Cryptographic hashing and consensus ensure tamper-proofing | Relies on provider’s access controls; internal tampering possible |

| Trust Mechanism | Smart contracts enforce automation; no third-party trust | Depends on provider’s credibility; manual audits needed |

| Scalability | Sharding/sidechains improve TPS but add complexity | Elastic scaling by provider; TPS limited by infrastructure |

| Storage Cost | High on-chain costs; requires off-chain storage | Lower cost but data sovereignty remains with provider |

| Privacy | Federated chains use channels for role-based access control | Encryption provided but data is monitored by provider |

| Typical BLM Use Cases | Cross-organizational collaboration (design-construction-operation data sharing), asset traceability | Single-organization workflows |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, J.; Wan, R.; Chong, H.-Y.; Liao, X. Digital Intelligence in Building Lifecycle Management: A Mixed-Methods Approach. Sustainability 2025, 17, 5121. https://doi.org/10.3390/su17115121

Lai J, Wan R, Chong H-Y, Liao X. Digital Intelligence in Building Lifecycle Management: A Mixed-Methods Approach. Sustainability. 2025; 17(11):5121. https://doi.org/10.3390/su17115121

Chicago/Turabian StyleLai, Jianying, Runnan Wan, Heap-Yih Chong, and Xiaofeng Liao. 2025. "Digital Intelligence in Building Lifecycle Management: A Mixed-Methods Approach" Sustainability 17, no. 11: 5121. https://doi.org/10.3390/su17115121

APA StyleLai, J., Wan, R., Chong, H.-Y., & Liao, X. (2025). Digital Intelligence in Building Lifecycle Management: A Mixed-Methods Approach. Sustainability, 17(11), 5121. https://doi.org/10.3390/su17115121