Blends of Sustainable Polymers and Waste Soy Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing of Soy and Polymers

2.2.1. Compounding

2.2.2. Injection Molding Methods

2.3. Characterization Methods

2.3.1. Thermogravimetric Analysis (TGA)

2.3.2. Differential Scanning Calorimetry (DSC)

2.3.3. Scanning Electron Microscopy (SEM)

2.3.4. Tensile Test Using ASTM D638

3. Results

3.1. Melt Processing

3.1.1. Micro-Compounding of the Polymer Blends with Soy Powder

3.1.2. Injection Molding

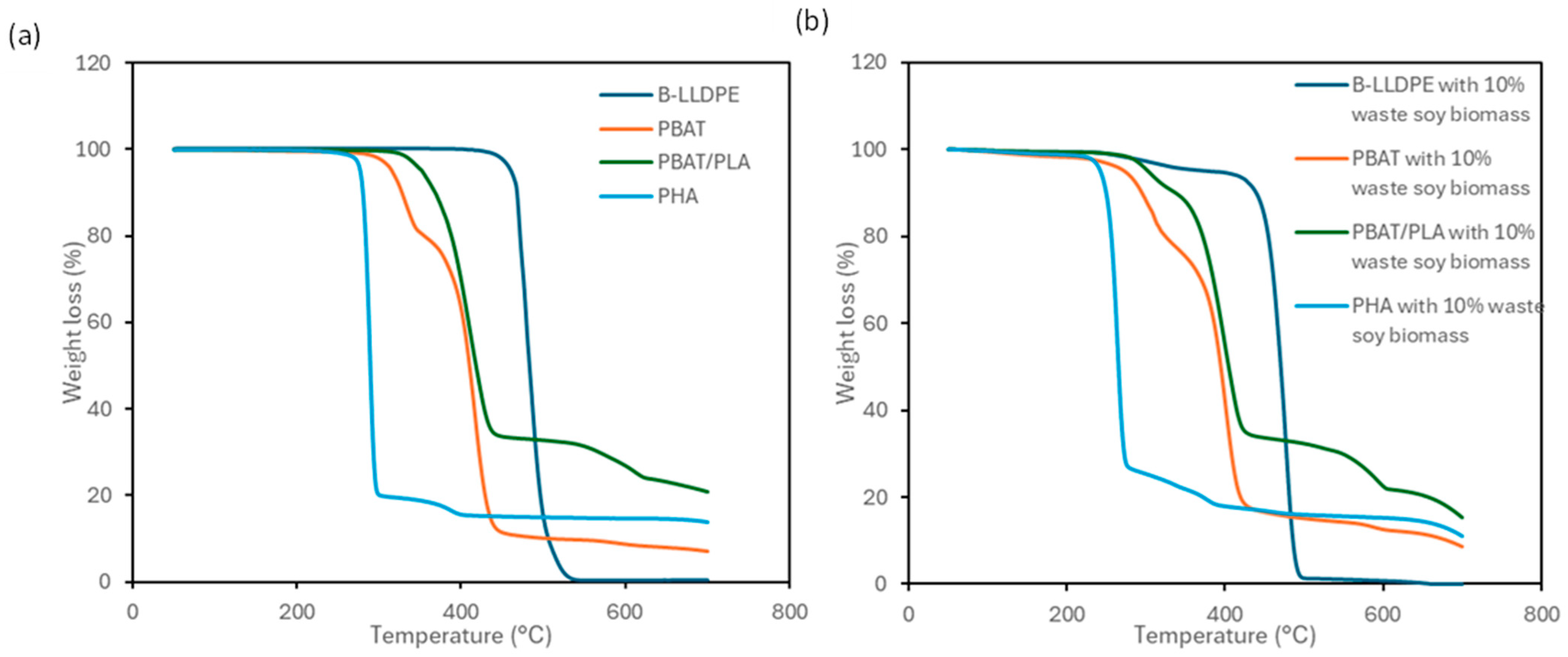

3.2. Effects of Waste Soy Biomass Soy Powder on the Thermal Properties of the Polymer

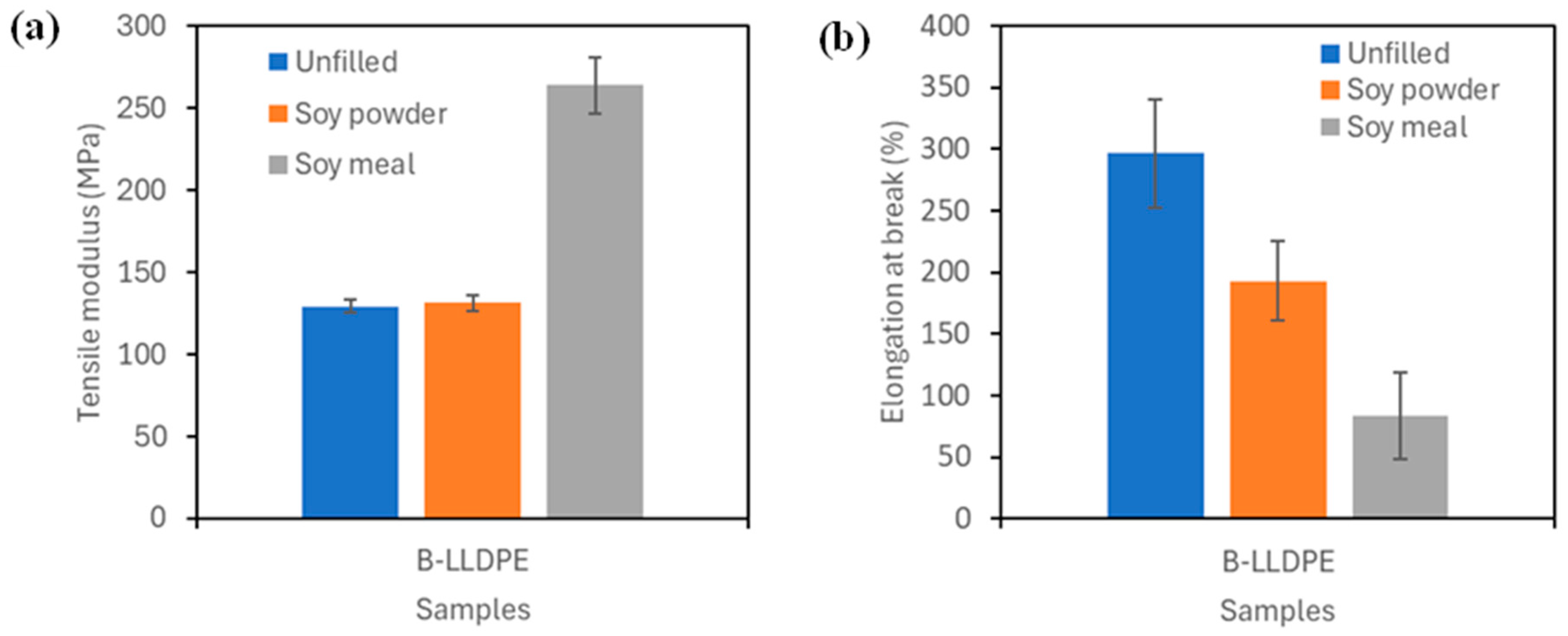

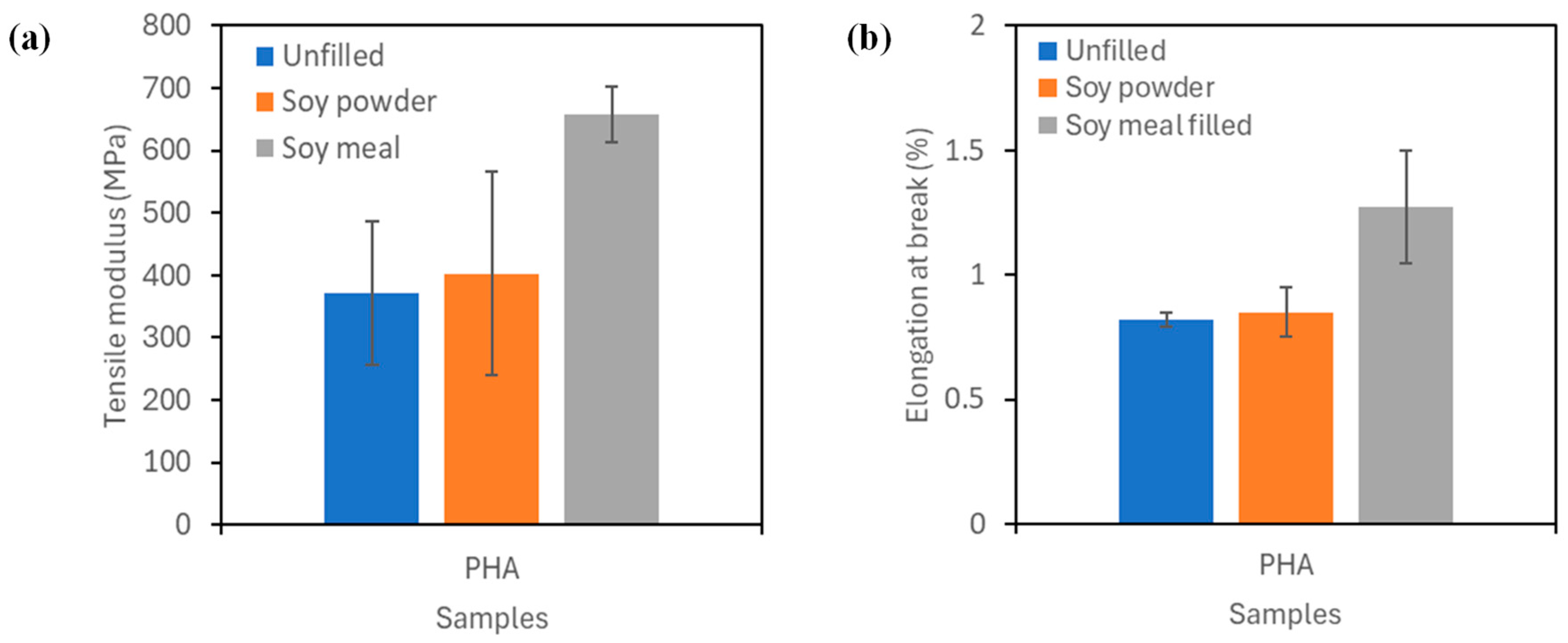

3.3. Mechanical Properties of Polymer Blends

3.4. Dispersion of Various Types of Soy Biomass in the Polymer Matrix via SEM Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, M.S.; Chang, H.; Zheng, L.; Yan, Q.; Pfleger, B.F.; Klier, J.; Nelson, K.; Majumder, E.L.W.; Huber, G.W. A Review of Biodegradable Plastics: Chemistry, Applications, Properties, and Future Research Needs. Chem. Rev. 2023, 123, 9915–9939. [Google Scholar] [CrossRef] [PubMed]

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew. Chemie Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef] [PubMed]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Ahsan, W.A.; Hussain, A.; Lin, C.; Nguyen, M.K. Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts 2023, 13, 294. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Chong, E.W.N.; Owolabi, F.A.T.; Asniza, M.; Tye, Y.Y.; Rizal, S.; Nurul Fazita, M.R.; Mohamad Haafiz, M.K.; Nurmiati, Z.; Paridah, M.T. Enhancement of basic properties of polysaccharide-based composites with organic and inorganic fillers: A review. J. Appl. Polym. Sci. 2019, 136, 47251. [Google Scholar] [CrossRef]

- Koshy, R.R.; Mary, S.K.; Pothan, L.A.; Thomas, S. Soy protein- and starch-based green composites/nanocomposites: Preparation, properties, and applications. Adv. Struct. Mater. 2015, 75, 433–467. [Google Scholar] [CrossRef]

- Candlen, K.; Haque, M.A.; Farfaras, N.; Martey, S.; Perez, P.; Ratto, J.A.; Pulis, R.; Hogan, R.; Chen, W.T. Biodegradable mulch films produced from soy-filled polymer resins. Mater. Today Commun. 2022, 31, 103331. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Kate, K.H.; Satyavolu, J. 3D printing of modified soybean hull fiber/polymer composites. Mater. Chem. Phys. 2020, 254, 123452. [Google Scholar] [CrossRef]

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.M. Structuration, selective dispersion and compatibilizing effect of (nano)fillers in polymer blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Móczó, J.; Pukánszky, B. Polymer micro and nanocomposites: Structure, interactions, properties. J. Ind. Eng. Chem. 2008, 14, 535–563. [Google Scholar] [CrossRef]

- Xu, T.; Lei, H.; Xie, C.S. Investigation of impact fracture process with particle-filled polymer materials by acoustic emission. Polym. Test. 2002, 21, 319–324. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Zeng, L.; Li, R.; Tian, H.; Fu, X.; Wang, Y.; Zhong, W.H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Rao, M.; Bast, A.; de Boer, A. Valorized food processing by-products in the EU: Finding the balance between safety, nutrition, and sustainability. Sustainability 2021, 13, 4428. [Google Scholar] [CrossRef]

- Denmark, I.; Khan, A.; Scifres, T.; Viswanathan, T.; Watanabe, F.; Siraj, N. Synthesis and Characterization of Supercapacitor Materials from Soy. Electrochem 2021, 2, 34. [Google Scholar] [CrossRef]

- Yang, K.; Fan, Q.; Song, C.; Zhang, Y.; Sun, Y.; Jiang, W.; Fu, P. Enhanced functional properties of porous carbon materials as high-performance electrode materials for supercapacitors. Green Energy Resour. 2023, 1, 100030. [Google Scholar] [CrossRef]

- Jia, B.; Mian, Q.; Wu, D.; Wang, T. Heteroatoms self-doped porous carbon from cottonseed meal using K2CO3 as activator and DES electrolyte for supercapacitor with high energy density. Mater. Today Chem. 2022, 24, 100828. [Google Scholar] [CrossRef]

- Wang, T.; Peng, L.; Wu, D.; Chen, B.; Jia, B. Crude fiber and protein rich cottonseed meal derived carbon quantum dots composite porous carbon for supercapacitor. J. Alloys Compd. 2023, 947, 169499. [Google Scholar] [CrossRef]

- Guo, G.; Zhang, C.; Du, Z.; Zou, W.; Tian, H.; Xiang, A.; Li, H. Structure and property of biodegradable soy protein isolate/PBAT blends. Ind. Crops Prod. 2015, 74, 731–736. [Google Scholar] [CrossRef]

- Huang, L.; Cai, Y.; Fang, F.; Huang, T.; Zhao, M.; Zhao, Q.; Van der Meeren, P. Recent advance in the valorization of soy-based by-products: Extraction, modification, interaction and applications in the food industry. Food Hydrocoll. 2024, 157, 110407. [Google Scholar] [CrossRef]

- Karim, A.; Osse, E.F.; Khalloufi, S. Innovative strategies for valorization of byproducts from soybean industry: A review on status, challenges, and sustainable approaches towards zero-waste processing systems. Heliyon 2025, 11, e42118. [Google Scholar] [CrossRef] [PubMed]

- Bulgariu, L.; Bulgariu, D. Functionalized soy waste biomass—A novel environmental-friendly biosorbent for the removal of heavy metals from aqueous solution. J. Clean. Prod. 2018, 197, 875–885. [Google Scholar] [CrossRef]

- Madayag, J.V.M.; Domalanta, M.R.B.; Maalihan, R.D.; Caldona, E.B. Valorization of extractible soybean by-products for polymer composite and industrial applications. J. Environ. Chem. Eng. 2025, 13, 115703. [Google Scholar] [CrossRef]

- Koshy, R.R.; Mary, S.K.; Thomas, S.; Pothan, L.A. Environment friendly green composites based on soy protein isolate—A review. Food Hydrocoll. 2015, 50, 174–192. [Google Scholar] [CrossRef]

- Dey, A.; Rahman, M.M.; Yodo, N.; Grewell, D. Development of biocomposite filament for fused filament fabrication from soy hulls and soy protein isolate. Mater. Today Commun. 2023, 34, 105316. [Google Scholar] [CrossRef]

- Rahman, M.M.; Dey, A.; Yodo, N.; Lee, C.W.; Grewell, D. Soybean By-Products Bioplastic (Polylactic Acid)-Based Plant Containers: Sustainable Development and Performance Study. Sustainability 2023, 15, 5373. [Google Scholar] [CrossRef]

- Bote, S.D.; Narayan, R. Synthesis of Biobased Polyols from Soybean Meal for Application in Rigid Polyurethane Foams. Ind. Eng. Chem. Res. 2021, 60, 5733–5743. [Google Scholar] [CrossRef]

- ASTM-D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D618-13; Standard Practice for Conditioning Plastics for Testing. ASTM International: West Conshohocken, PA, USA, 2013.

- Bossu, J.; Angellier-Coussy, H.; Totee, C.; Matos, M.; Reis, M.; Guillard, V. Effect of the Molecular Structure of Poly(3-hydroxybutyrate- co-3-hydroxyvalerate) (P(3HB-3HV)) Produced from Mixed Bacterial Cultures on Its Crystallization and Mechanical Properties. Biomacromolecules 2020, 21, 4709–4723. [Google Scholar] [CrossRef]

- Li, Z.; Yang, J.; Loh, X.J. Polyhydroxyalkanoates: Opening doors for a sustainable future. NPG Asia Mater. 2016, 8, e265. [Google Scholar] [CrossRef]

- Lingle, R. CJ Biomaterials Has Big Plans for Tunable PHA Biopolymers. Available online: https://www.plasticstoday.com/materials/cj-biomaterials-has-big-plans-for-tunable-pha-biopolymers (accessed on 12 June 2023).

- Ibáñez, M.A.; de Blas, C.; Cámara, L.; Mateos, G.G. Chemical composition, protein quality and nutritive value of commercial soybean meals produced from beans from different countries: A meta-analytical study. Anim. Feed Sci. Technol. 2020, 267, 114531. [Google Scholar] [CrossRef]

- Pigłowska, M.; Kurc, B.; Rymaniak, Ł.; Lijewski, P.; Fuć, P. Kinetics and thermodynamics of thermal degradation of different starches and estimation the OH group and H2O content on the surface by TG/DTG-DTA. Polymers 2020, 12, 357. [Google Scholar] [CrossRef] [PubMed]

- Chuah, J.A.; Yamada, M.; Taguchi, S.; Sudesh, K.; Doi, Y.; Numata, K. Biosynthesis and characterization of polyhydroxyalkanoate containing 5-hydroxyvalerate units: Effects of 5HV units on biodegradability, cytotoxicity, mechanical and thermal properties. Polym. Degrad. Stab. 2013, 98, 331–338. [Google Scholar] [CrossRef]

- Kurose, T.; Urman, K.; Otaigbe, J.U.; Lochhead, R.Y.; Thames, S.F. Effect of uniaxial drawing of soy protein isolate biopolymer film on structure and mechanical properties. Polym. Eng. Sci. 2007, 47, 374–380. [Google Scholar] [CrossRef]

- Su, J.F.; Wang, X.Y.; Huang, Z.; Yuan, X.Y.; Li, M.; Xia, W.L.; Feng, C.L. Heat-sealing properties of soy protein isolate/poly(vinyl alcohol) blend films: Effect of the heat-sealing temperature. J. Appl. Polym. Sci. 2010, 115, 1901–1911. [Google Scholar] [CrossRef]

- Su, J.F.; Huang, Z.; Yang, C.M.; Yuan, X.Y. Properties of soy protein isolate/poly(vinyl alcohol) blend “Green” Films: Compatibility, mechanical properties, and thermal stability. J. Appl. Polym. Sci. 2008, 110, 3706–3716. [Google Scholar] [CrossRef]

- Choo, J.E.; Park, T.H.; Jeon, S.M.; Hwang, S.W. The Effect of Epoxidized Soybean Oil on the Physical and Mechanical Properties of PLA/PBAT/PPC Blends by the Reactive Compatibilization. J. Polym. Environ. 2023, 31, 4007–4021. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, L.; Zhou, Z.; Wu, X.; Wang, Y. Preparation and properties of electrospun soy protein isolate/polyethylene oxide nanofiber membranes. ACS Appl. Mater. Interfaces 2012, 4, 4331–4337. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, L. Interaction and properties of highly exfoliated soy protein/montmorillonite nanocomposites. Biomacromolecules 2006, 7, 1700–1706. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U. Polymer—Graphene nanocomposites: Effect of polymer matrix and filler amount on properties. Macromol. Mater. Eng. 2015, 300, 19–26. [Google Scholar] [CrossRef]

| Sample | SuperbTM Waste Soy Powder a | Hi-Pro Solvent Extracted Waste Soy Meal b |

|---|---|---|

| Crude Protein | 38.3% | 45.0% |

| Crude Fat | 0.35% | 1.0% |

| Crude Fiber | 6.24% | 3.8% |

| Others c | 55.1% | 50.2% |

| Sample | Barrel Temperature (°C) | Mold Temperature (°C) |

|---|---|---|

| B-LLDPE | 200 | 40 |

| PHA | 150 | 40 |

| PBAT/PLA | 150 | 40 |

| PBAT | 165 | 40 |

| Sample | Onset Degradation Temperature (°C) | Percent Residue (%) |

|---|---|---|

| PBAT | 282.8 and 387.3 | 7.0 |

| PBAT + 10% soy waste | 280.9 and 376.8 | 8.6 |

| PBAT/PLA | 366.3 | 21.0 |

| PBAT/PLA + 10% soy waste | 362.7 | 15.3 |

| B-LLDPE | 464.9 | 0.5 |

| B-LLDPE + 10% soy waste | 453.5 | 0.0 |

| PHA | 279.0 | 13.9 |

| PHA + 10% soy waste | 255.4 | 11.0 |

| Sample | Melting Temperature (°C) |

|---|---|

| PBAT | 119.4 |

| PBAT/PLA | 125.8 and 146.6 |

| B-LLDPE | 125.0 |

| PHA | 155.4 and 166.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martey, S.; Hayden, B.; Jan, K.; Candlen, K.; Ratto, J.A.; Hogan, R.; Chen, W.-T. Blends of Sustainable Polymers and Waste Soy Biomass. Sustainability 2025, 17, 5122. https://doi.org/10.3390/su17115122

Martey S, Hayden B, Jan K, Candlen K, Ratto JA, Hogan R, Chen W-T. Blends of Sustainable Polymers and Waste Soy Biomass. Sustainability. 2025; 17(11):5122. https://doi.org/10.3390/su17115122

Chicago/Turabian StyleMartey, Shawn, Brooklyn Hayden, Kalsoom Jan, Kerry Candlen, Jo Ann Ratto, Robina Hogan, and Wan-Ting Chen. 2025. "Blends of Sustainable Polymers and Waste Soy Biomass" Sustainability 17, no. 11: 5122. https://doi.org/10.3390/su17115122

APA StyleMartey, S., Hayden, B., Jan, K., Candlen, K., Ratto, J. A., Hogan, R., & Chen, W.-T. (2025). Blends of Sustainable Polymers and Waste Soy Biomass. Sustainability, 17(11), 5122. https://doi.org/10.3390/su17115122