Artificial-Intelligence-Enabled Innovation Ecosystems: A Novel Triple-Layer Framework for Micro, Small, and Medium-Sized Enterprises in the Chinese Apparel-Manufacturing Industry

Abstract

1. Introduction

2. Research Background

2.1. Innovation Ecosystem

2.2. AI Capabilities and Open-Innovation Ecosystems

2.3. TH in Innovation Ecosystems

2.4. Synthesis of the Existing Research Gaps

3. Methodology

3.1. Data Collection Procedure

3.2. Coding for Data Analysis

4. Findings

4.1. Overview of the Structure of the Data

4.2. Required AI Capabilities

4.2.1. Adaptive Production Capability

4.2.2. Augmented Human–AI Collaboration Capability

4.3. Factors Hindering AI Adoption

4.3.1. Industry Factors

4.3.2. University Factors

4.3.3. Government Factors

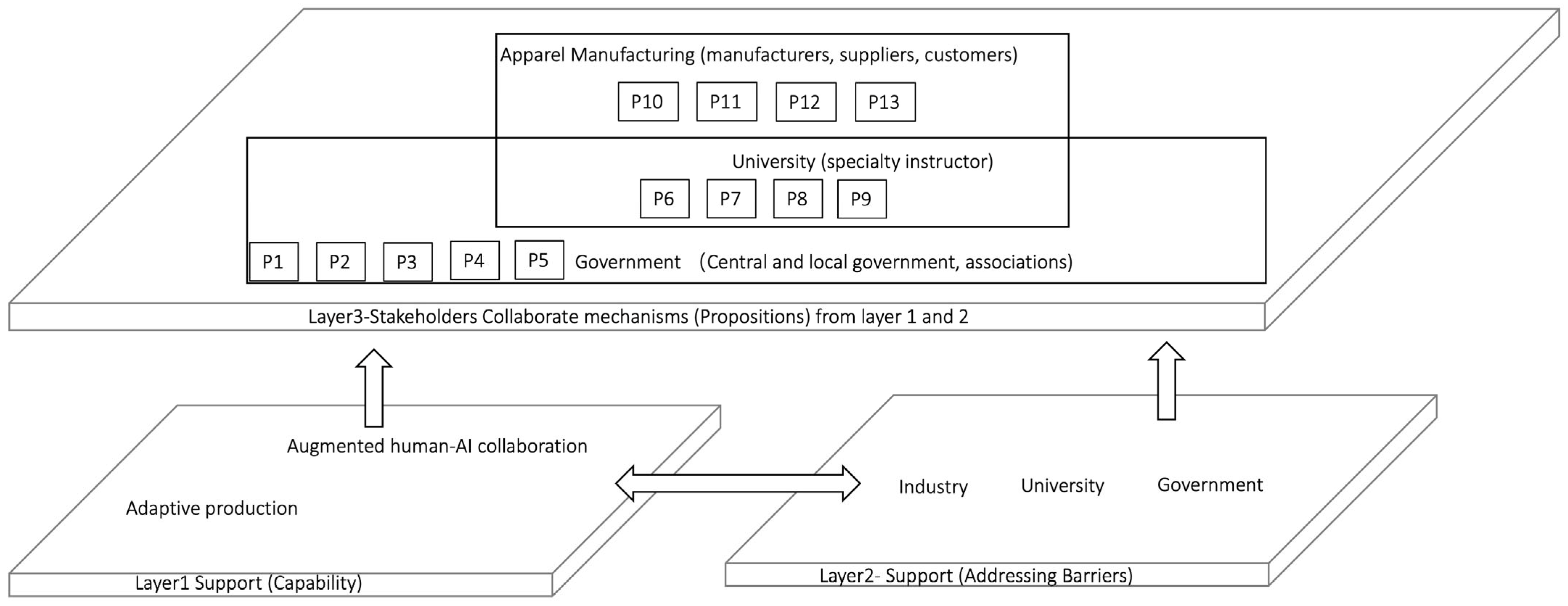

4.4. Conceptual Framework Development

5. Discussion

5.1. Categorizing Required AI Capabilities and Barriers to Adopting AI in Chinese Apparel-Manufacturing MSMEs

5.2. Developing an AI-Enabled Innovation Ecosystem Framework with Propositions for Chinese Apparel-Manufacturing MSMEs

5.2.1. Mechanism 1 of Layer 3: Government Policies as Enablers for Collaboration

5.2.2. Mechanism 2 of Layer 3: Universities as Knowledge Hubs in Addressing Talent and Knowledge Gaps

5.2.3. Mechanism 3 of Layer 3: Collaboration and Competition as Drivers of AI Adoption

5.2.4. Knowledge Absorptive Capacity as the Outcome of Layer 3 Interactions

5.3. Theoretical Contributions

5.4. Managerial Contributions

6. Conclusions, Limitations, and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Chang, H.; Forrest, J.Y.-L.; Yang, B. Influence of Artificial Intelligence on Technological Innovation: Evidence from the Panel Data of China’s Manufacturing Sectors. Technol. Forecast. Soc. Change 2020, 158, 120142. [Google Scholar] [CrossRef]

- Goedhuys, M.; Janz, N.; Mohnen, P. Knowledge-Based Productivity in “Low-Tech” Industries: Evidence from Firms in Developing Countries. Ind. Corp. Change 2014, 23, 1–23. [Google Scholar] [CrossRef]

- Hansen, T.; Winther, L. Manufacturing in the Knowledge Economy: Innovation in Low-Tech Industries. In Handbook of Manufacturing Industries in the World Economy; Bryson, J.R., Clark, J., Vanchan, V., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2015; ISBN 978-1-78100-393-0. [Google Scholar]

- Piana, J.; Brustolin, L.T. Firm-Level Technological Upgrading Process in Low-Tech Industries: The Case of Clothing Industry in Brazil. J. Innov. Manag. 2023, 11, 18–35. [Google Scholar] [CrossRef]

- Lu, Y.; Karpova, E. Comparative Advantages of the Indian and Chinese Apparel Industries: An Analysis of the Global Value Chain. Int. J. Fash. Des. Technol. Educ. 2011, 4, 197–211. [Google Scholar] [CrossRef]

- Qu, C.; Kim, E. Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions. Sustainability 2024, 16, 6186. [Google Scholar] [CrossRef]

- Giri, C.; Jain, S.; Zeng, X.; Bruniaux, P. A Detailed Review of Artificial Intelligence Applied in the Fashion and Apparel Industry. IEEE Access 2019, 7, 95376–95396. [Google Scholar] [CrossRef]

- Arenal, A.; Armuña, C.; Feijoo, C.; Ramos, S.; Xu, Z.; Moreno, A. Innovation Ecosystems Theory Revisited: The Case of Artificial Intelligence in China. Telecommun. Policy 2020, 44, 101960. [Google Scholar] [CrossRef]

- Hailu, A.T. The Role of University–Industry Linkages in Promoting Technology Transfer: Implementation of Triple Helix Model Relations. J. Innov. Entrep. 2024, 13, 25. [Google Scholar] [CrossRef]

- Yu, Z.; Liang, Z.; Wu, P. How Data Shape Actor Relations in Artificial Intelligence Innovation Systems: An Empirical Observation from China. Ind. Corp. Change 2021, 30, 251–267. [Google Scholar] [CrossRef]

- Broekhuizen, T.; Dekker, H.; de Faria, P.; Firk, S.; Nguyen, D.K.; Sofka, W. AI for Managing Open Innovation: Opportunities, Challenges, and a Research Agenda. J. Bus. Res. 2023, 167, 114196. [Google Scholar] [CrossRef]

- Sahoo, S.; Kumar, S.; Donthu, N.; Singh, A.K. Artificial Intelligence Capabilities, Open Innovation, and Business Performance—Empirical Insights from Multinational B2B Companies. Ind. Mark. Manag. 2024, 117, 28–41. [Google Scholar] [CrossRef]

- Costa, J.; Matias, J.C.O. Open Innovation 4.0 as an Enhancer of Sustainable Innovation Ecosystems. Sustainability 2020, 12, 8112. [Google Scholar] [CrossRef]

- Audretsch, B.D.; Belitski, M. The Limits to Open Innovation and Its Impact on Innovation Performance. Technovation 2023, 119, 102519. [Google Scholar] [CrossRef]

- Encyclopedia of Creativity, Invention, Innovation and Entrepreneurship; Carayannis, E.G., Ed.; Springer New York: New York, NY, USA, 2013; ISBN 978-1-4614-3857-1. [Google Scholar]

- Adner, R. Match Your Innovation Strategy to Your Innovation Ecosystem. Harv. Bus. Rev. 2006, 84, 98–107. [Google Scholar]

- Adner, R.; Kapoor, R. Value Creation in Innovation Ecosystems: How the Structure of Technological Interdependence Affects Firm Performance in New Technology Generations. Strat. Mgmt. J. 2010, 31, 306–333. [Google Scholar] [CrossRef]

- Gomes, L.A.D.V.; Facin, A.L.F.; Salerno, M.S.; Ikenami, R.K. Unpacking the Innovation Ecosystem Construct: Evolution, Gaps and Trends. Technol. Forecast. Soc. Change 2018, 136, 30–48. [Google Scholar] [CrossRef]

- Granstrand, O.; Holgersson, M. Innovation Ecosystems: A Conceptual Review and a New Definition. Technovation 2020, 90–91, 102098. [Google Scholar] [CrossRef]

- Pushpananthan, G.; Elmquist, M. Joining Forces to Create Value: The Emergence of an Innovation Ecosystem. Technovation 2022, 115, 102453. [Google Scholar] [CrossRef]

- Chesbrough, H.; Kim, S.; Agogino, A. Chez Panisse: Building an Open Innovation Ecosystem. Calif. Manag. Rev. 2014, 56, 144–171. [Google Scholar] [CrossRef]

- Dedehayir, O.; Mäkinen, S.J.; Ortt, J.R. Roles during Innovation Ecosystem Genesis: A Literature Review. Technol. Forecast. Soc. Change 2018, 136, 18–29. [Google Scholar] [CrossRef]

- Rohrbeck, R.; Hölzle, K.; Gemünden, H.G. Opening up for Competitive Advantage—How Deutsche Telekom Creates an Open Innovation Ecosystem. R. D Manag. 2009, 39, 420–430. [Google Scholar] [CrossRef]

- Mikalef, P.; Gupta, M. Artificial Intelligence Capability: Conceptualization, Measurement Calibration, and Empirical Study on Its Impact on Organizational Creativity and Firm Performance. Inf. Manag. 2021, 58, 103434. [Google Scholar] [CrossRef]

- Ahn, J.M.; Lee, W.; Mortara, L. Do Government R&D Subsidies Stimulate Collaboration Initiatives in Private Firms? Technol. Forecast. Soc. Change 2020, 151, 119840. [Google Scholar] [CrossRef]

- Magas, M.; Kiritsis, D. Industry Commons: An Ecosystem Approach to Horizontal Enablers for Sustainable Cross-Domain Industrial Innovation (a Positioning Paper). Int. J. Prod. Res. 2022, 60, 479–492. [Google Scholar] [CrossRef]

- Petrescu, M.; Krishen, A.S.; Kachen, S.; Gironda, J.T. AI-Based Innovation in B2B Marketing: An Interdisciplinary Framework Incorporating Academic and Practitioner Perspectives. Ind. Mark. Manag. 2022, 103, 61–72. [Google Scholar] [CrossRef]

- Kuzior, A.; Sira, M.; Brożek, P. Use of Artificial Intelligence in Terms of Open Innovation Process and Management. Sustainability 2023, 15, 7205. [Google Scholar] [CrossRef]

- Etzkowitz, H.; Leydesdorff, L. The Triple Helix-University-Industry-Government Relations: A Laboratory for Knowledge Based Economic Development. EASST Rev. 1995, 14, 14–19. [Google Scholar]

- Etzkowitz, H. Innovation in Innovation: The Triple Helix of University-Industry-Government Relations. Soc. Sci. Inf. 2003, 42, 293–337. [Google Scholar] [CrossRef]

- Neves, A.R.; Costa, J.; Reis, J. Using a Systematic Literature Review to Build a Framework for University-Industry Linkages Using Open Innovation. Procedia Comput. Sci. 2021, 181, 23–33. [Google Scholar] [CrossRef]

- Li, Z.; Chu, Y. Is Hierarchical Education Investment Synergistic? Evidence from China’s Investment in General and Advanced Education. J. Knowl. Econ. 2022, 14, 1522–1537. [Google Scholar] [CrossRef]

- Noya, S.; Taneo, S.Y.M.; Melany, M. Triple Helix Innovation Ecosystem: The Role of Small and Medium Enterprises Community in Enhancing Performance. Qual. Innov. Prosper. 2023, 27, 46–61. [Google Scholar] [CrossRef]

- Guerrero, M.; Urbano, D. The Impact of Triple Helix Agents on Entrepreneurial Innovations’ Performance: An inside Look at Enterprises Located in an Emerging Economy. Technol. Forecast. Soc. Change 2017, 119, 294–309. [Google Scholar] [CrossRef]

- Barton, D.; Woetzel, J.; Seong, J.; Tian, Q. Artificial Intelligence: Implications for China; Mickinsey Global Institute, 2017; p. 20. Available online: http://dln.jaipuria.ac.in:8080/jspui/handle/123456789/1888 (accessed on 28 May 2025).

- Bhattacherjee, A. Social Science Research: Principles, Methods, and Practices, 2nd ed.; Anol Bhattacherjee: Tampa, FL, USA, 2012; ISBN 978-1-4751-4612-7. [Google Scholar]

- Bell, E.; Bryman, A.; Harley, B. Business Research Methods, 6th ed.; Oxford University Press: Oxford, UK; New York, NY, USA, 2022; ISBN 978-0-19-886944-3. [Google Scholar]

- Clark, T.; Foster, L.; Sloan, L.; Bryman, A.; Bryman, A. Bryman’s Social Research Methods, 6th ed.; Oxford University Press: Oxford, UK, 2021; ISBN 978-0-19-879605-3. [Google Scholar]

- Greguletz, E.; Diehl, M.-R.; Kreutzer, K. Why Women Build Less Effective Networks than Men: The Role of Structural Exclusion and Personal Hesitation. Hum. Relat. 2019, 72, 1234–1261. [Google Scholar] [CrossRef]

- Lin, S. The Structural Characteristics of Innovation Ecosystem: A Fashion Case. Eur. J. Innov. Manag. 2018, 21, 620–635. [Google Scholar] [CrossRef]

- Nelson, J. Using Conceptual Depth Criteria: Addressing the Challenge of Reaching Saturation in Qualitative Research. Qual. Res. 2017, 17, 554–570. [Google Scholar] [CrossRef]

- Bryant, A.; Charmaz, K. The Sage Handbook of Grounded Theory; Sage Publications: Los Angeles, CA, USA, 2008; ISBN 978-1-4129-2346-0. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Routledge: London, UK; New York, NK, USA, 2017; ISBN 978-0-202-30260-7. [Google Scholar]

- Sjödin, D.; Parida, V.; Palmié, M.; Wincent, J. How AI Capabilities Enable Business Model Innovation: Scaling AI through Co-Evolutionary Processes and Feedback Loops. J. Bus. Res. 2021, 134, 574–587. [Google Scholar] [CrossRef]

- Birks, M.; Mills, J. Grounded Theory: A Practical Guide, 2nd ed.; SAGE: Los Angeles, CA, USA, 2015; ISBN 978-1-4462-9577-9. [Google Scholar]

- Bryant, A. The Varieties of Grounded Theory; Sage Swifts: Thousand Oaks, CA, USA, 2019; ISBN 978-1-5264-7431-5. [Google Scholar]

- Foley, G.; Timonen, V.; Conlon, C.; O’dare, C.E. Interviewing as a Vehicle for Theoretical Sampling in Grounded Theory. Int. J. Qual. Methods 2021, 20, 160940692098095. [Google Scholar] [CrossRef]

- Makri, C.; Neely, A. Grounded Theory: A Guide for Exploratory Studies in Management Research. Int. J. Qual. Methods 2021, 20, 160940692110136. [Google Scholar] [CrossRef]

- Orlikowski, W.J.; Baroudi, J.J. Studying Information Technology in Organizations: Research Approaches and Assumptiohts. Inf. Syst. Res. 1991, 2, 1–18. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and Retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Lee, W.-J.; Choi, B.; Lew, Y.K. Fostering Collaborative Opportunities for AI Start-Ups: The Case of a Hybrid Business Incubator in Seoul. J. Technol. Transf. 2024, 50, 552–581. [Google Scholar] [CrossRef]

- Neto, J.R.; Figueiredo, C.; Gabriel, B.C.; Valente, R. Factors for Innovation Ecosystem Frameworks: Comprehensive Organizational Aspects for Evolution. Technol. Forecast. Soc. Change 2024, 203, 123383. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive Capacity: A New Perspective on Learning and Innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Schubert, G.; Alpermann, B. Studying the Chinese Policy Process in the Era of ‘Top-Level Design’: The Contribution of ‘Political Steering’ Theory. J. Chin Polit Sci. 2019, 24, 199–224. [Google Scholar] [CrossRef]

- Wang, J. Institutional Change and the Development of Industrial Clusters in China: Case Studies from the Textile and Clothing Industry; Volume Series on Economic Development and Growth; World Scientific: Singapore, 2013; Volume 8. [Google Scholar]

- Trieu, D.T. Decoding the Fast Fashion Phenomenon in Vietnam: A Multidimensional Analysis of Impulse Buying Dynamics and Price Sensitivity in Consumer Purchase Behavior. Int. J. Econ. Bus. Manag. Res. 2024, 8, 314–339. [Google Scholar] [CrossRef]

- Irfan, M.; Wang, M.; Akhtar, N. Enabling Supply Chain Agility through Process Integration and Supply Flexibility: Evidence from the Fashion Industry. Asia Pac. J. Mark. Logist. 2019, 32, 519–547. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a Knowledge-Based Theory of the Firm. Strateg. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

| Interviewee ID. | Organizational Affiliations | Positions | Working Experience | Firm Location |

|---|---|---|---|---|

| A1 | Associations | Secretary general | 16–20 years | North |

| A2 | Director | 16–20 years | North | |

| I1 | Industries | Production manager | >20 years | North |

| I2 | OEM business manager | 10–15 years | North | |

| I3 | Fabric supplier | 16–20 years | YRD | |

| I4 | ODM business manager | 10–15 years | PRD | |

| I5 | Customer (retail) | 10–15 years | PRD | |

| I6 | ODM business manager | 10–15 years | North | |

| I7 | Customer (retail) | 16–20 years | North | |

| I8 | OBM business manager | 16–20 years | North | |

| U1 | Universities | Dean/professor | >20 years | North |

| U2 | Professor | >20 years | North | |

| U3 | Dean/professor | 16–20 years | YRD | |

| U4 | Specialized course instructor | 10–15 years | North | |

| U5 | Specialized course instructor | 10–15 years | YRD |

| Interviewee ID. | Organizational Affiliations | Positions | Working Experience | Locations |

|---|---|---|---|---|

| I9 | Industries | ODM business manager | 10–15 years | North |

| I10 | OEM production manager | >20 years | YDT | |

| I11 | OBM CEO | >20 years | YDT | |

| U6 | Universities | Specialized course instructor | 10–15 years | North |

| U7 | Specialized course instructor | 10–15 years | North |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, C.; Kim, E. Artificial-Intelligence-Enabled Innovation Ecosystems: A Novel Triple-Layer Framework for Micro, Small, and Medium-Sized Enterprises in the Chinese Apparel-Manufacturing Industry. Sustainability 2025, 17, 5019. https://doi.org/10.3390/su17115019

Qu C, Kim E. Artificial-Intelligence-Enabled Innovation Ecosystems: A Novel Triple-Layer Framework for Micro, Small, and Medium-Sized Enterprises in the Chinese Apparel-Manufacturing Industry. Sustainability. 2025; 17(11):5019. https://doi.org/10.3390/su17115019

Chicago/Turabian StyleQu, Chen, and Eunyoung Kim. 2025. "Artificial-Intelligence-Enabled Innovation Ecosystems: A Novel Triple-Layer Framework for Micro, Small, and Medium-Sized Enterprises in the Chinese Apparel-Manufacturing Industry" Sustainability 17, no. 11: 5019. https://doi.org/10.3390/su17115019

APA StyleQu, C., & Kim, E. (2025). Artificial-Intelligence-Enabled Innovation Ecosystems: A Novel Triple-Layer Framework for Micro, Small, and Medium-Sized Enterprises in the Chinese Apparel-Manufacturing Industry. Sustainability, 17(11), 5019. https://doi.org/10.3390/su17115019