Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads

Abstract

1. Introduction

Research Significance

2. Experimental Program

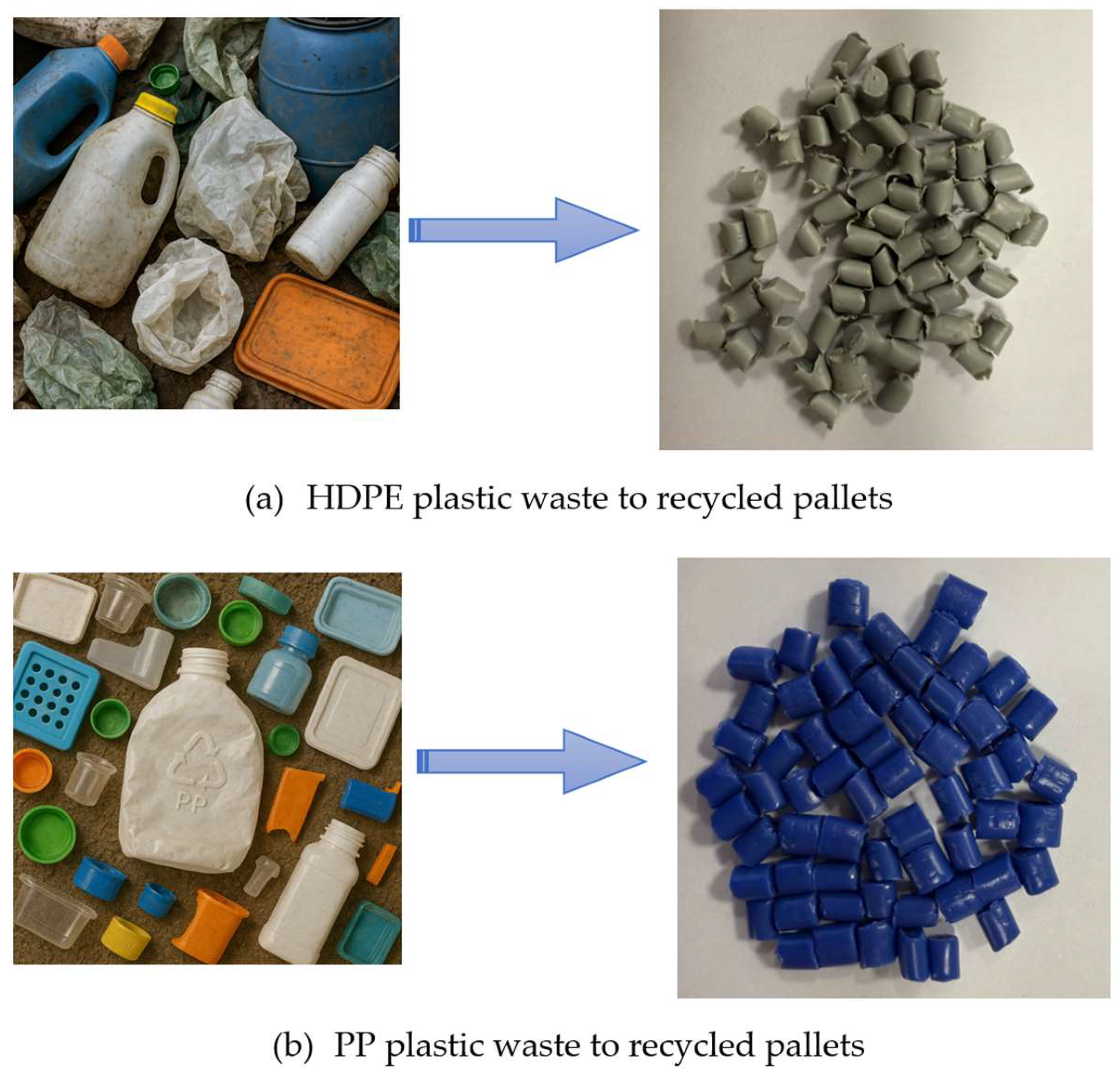

2.1. Collection and Synthesis of Recycled Plastic

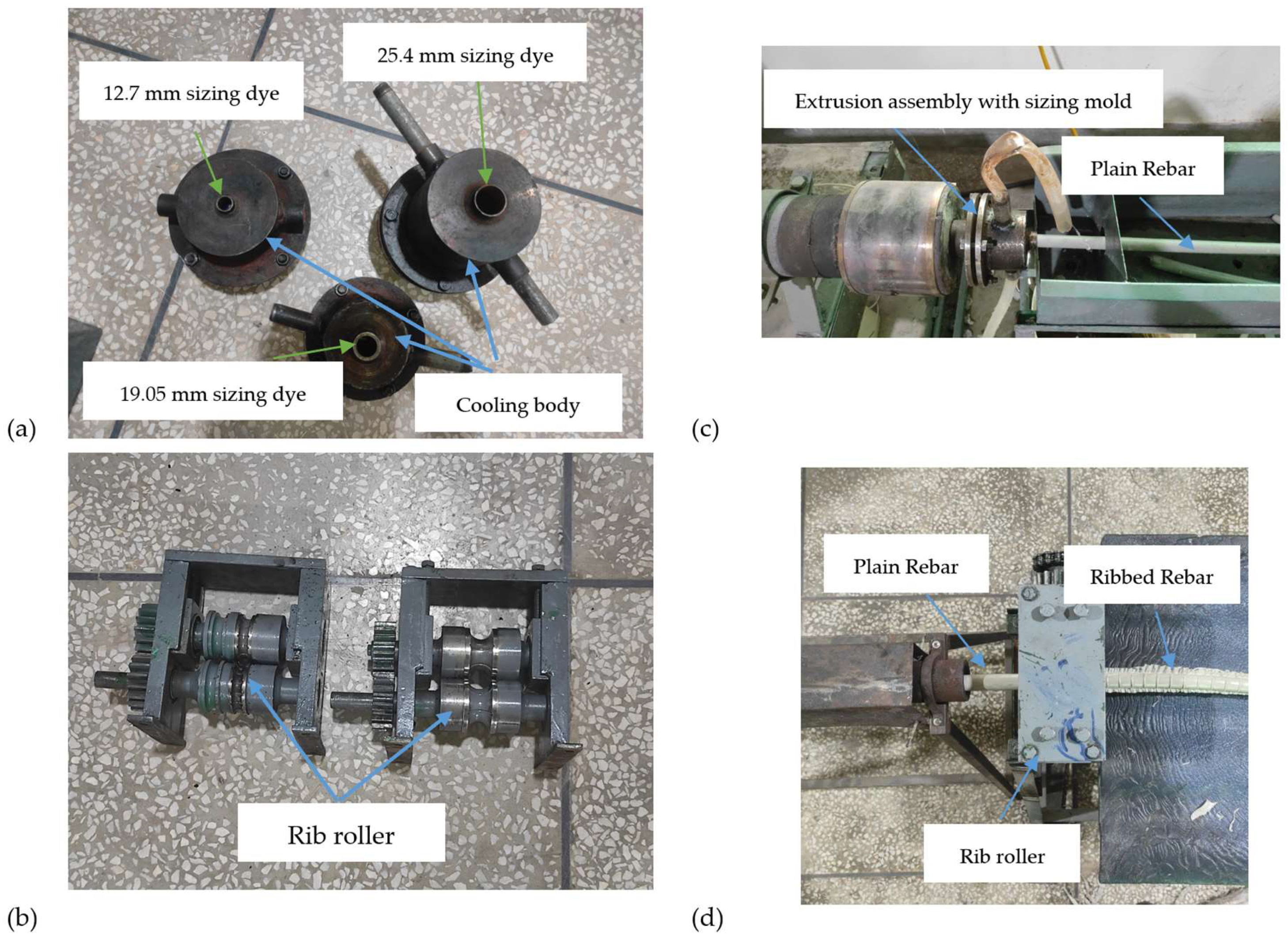

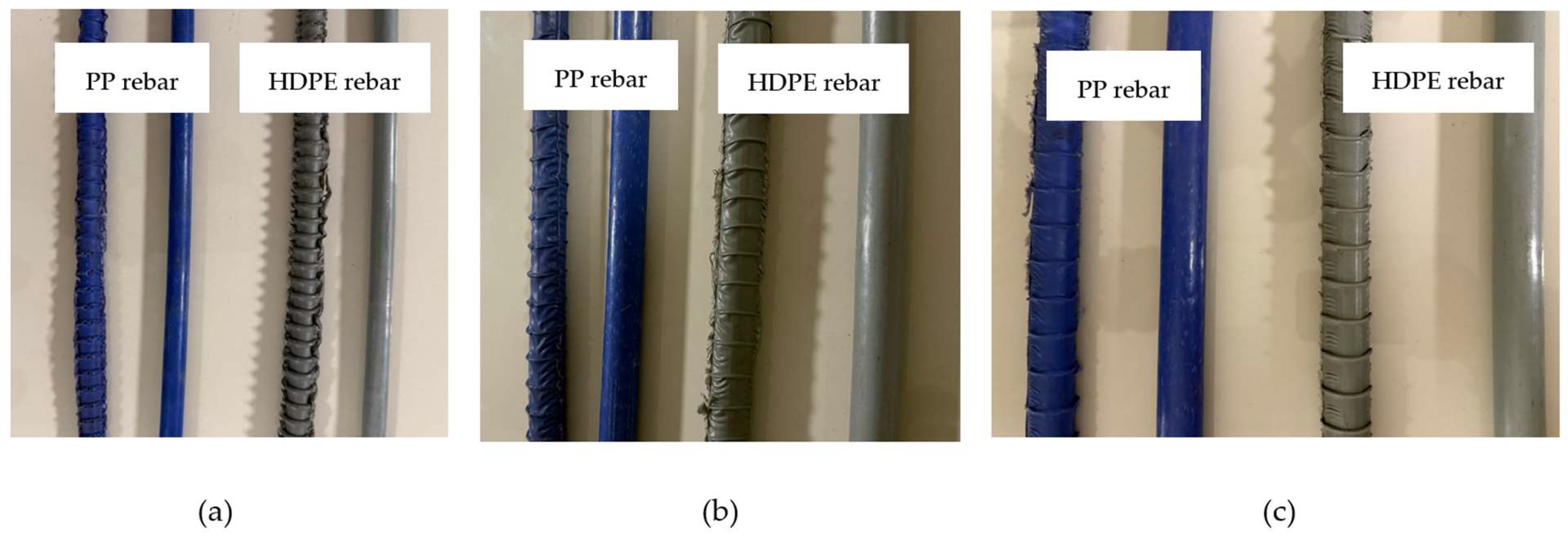

2.2. Sustainable Development of Recycled Plastic-Waste Rebars (RPR)

2.3. Test Setup

2.3.1. Tensile Tests

2.3.2. Characterization and Microstructural Analysis Procedure

2.4. Empirical Modelling Procedure for Maximum Load and Maximum Stress

3. Results

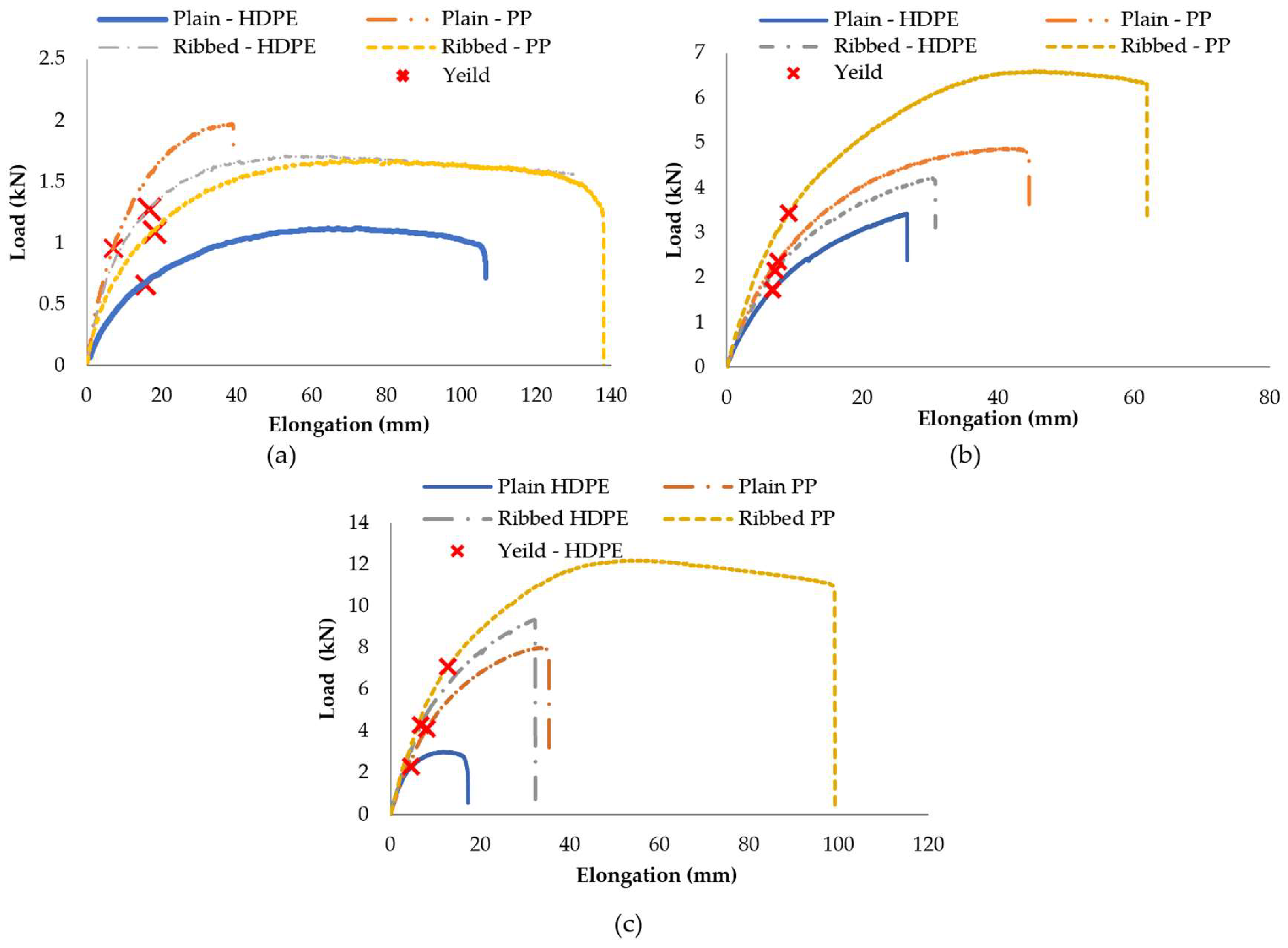

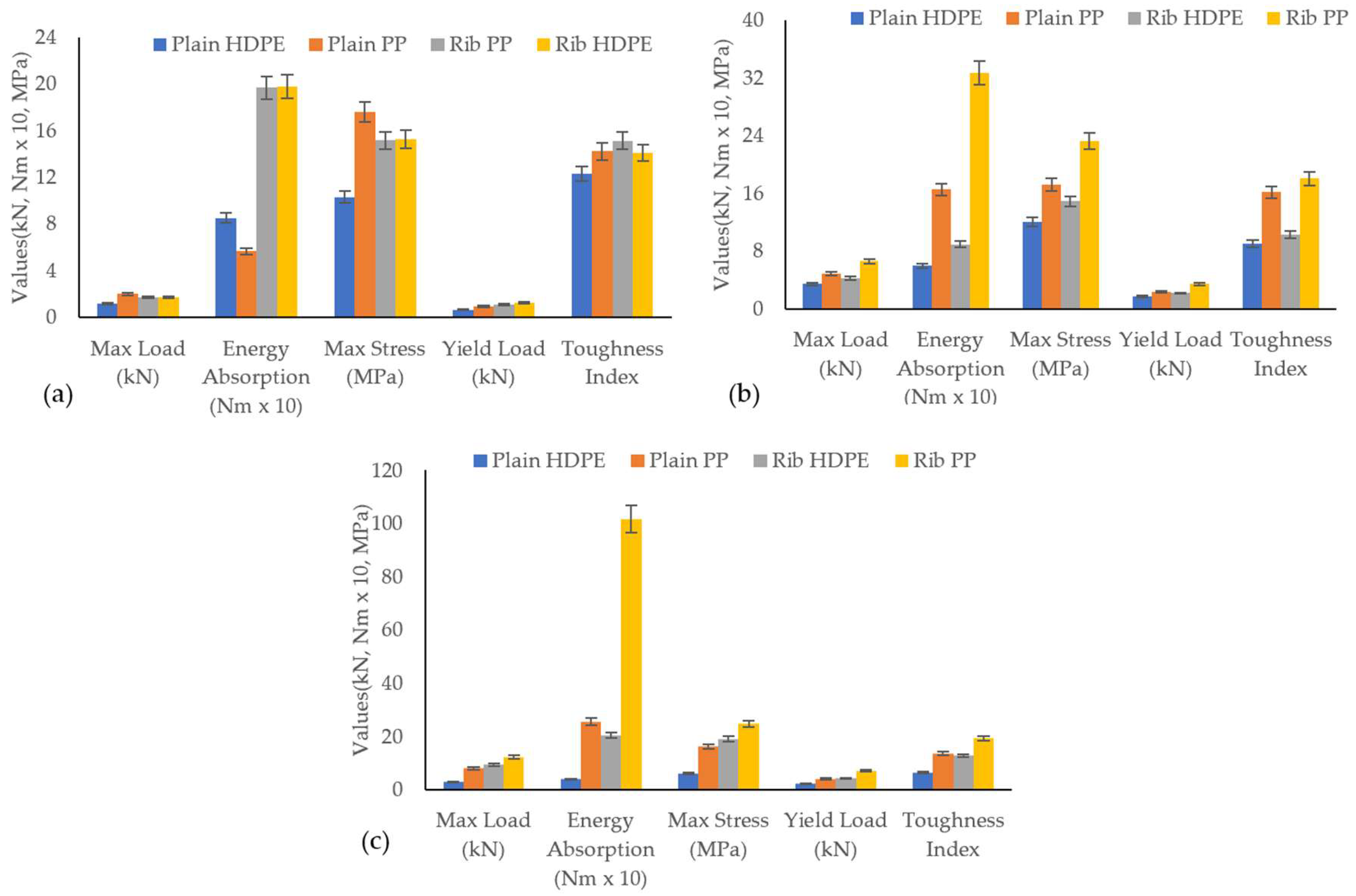

3.1. Tensile Performance of Recycled Plastic Rebars

3.1.1. Tensile Behavior

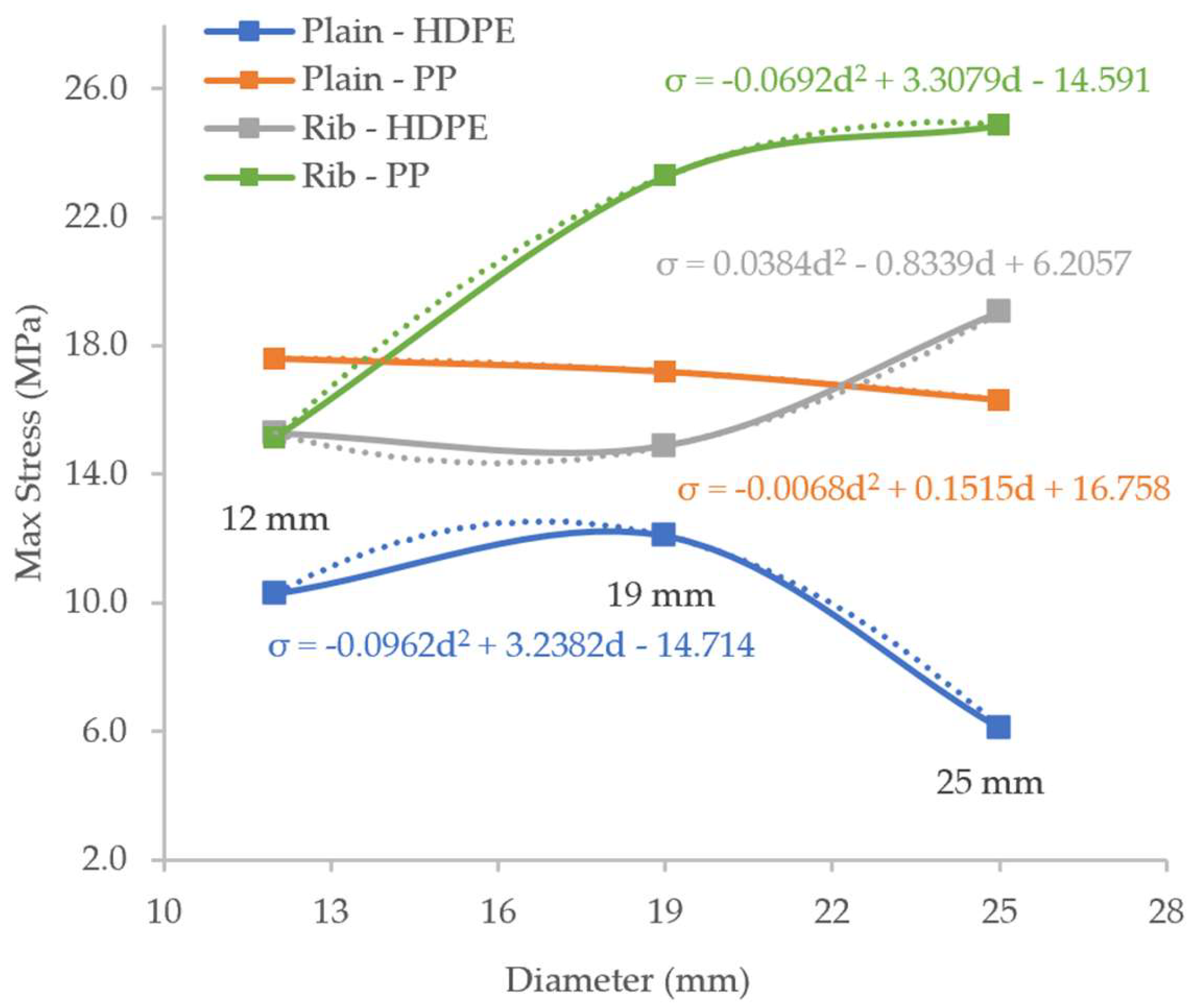

3.1.2. Empirical Modelling for Maximum Load and Maximum Stress

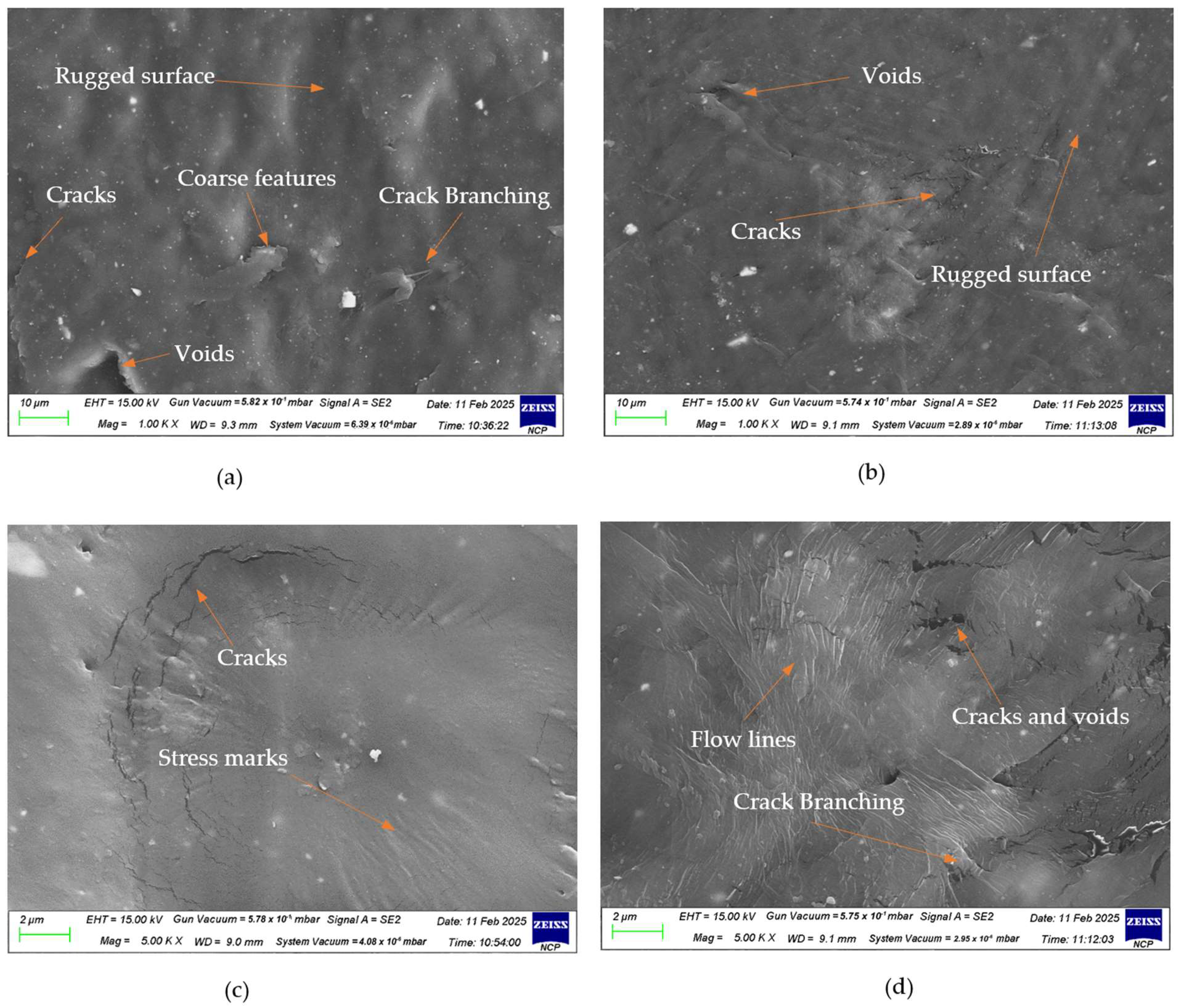

3.2. Microstructural Behviour

3.2.1. SEM Analysis

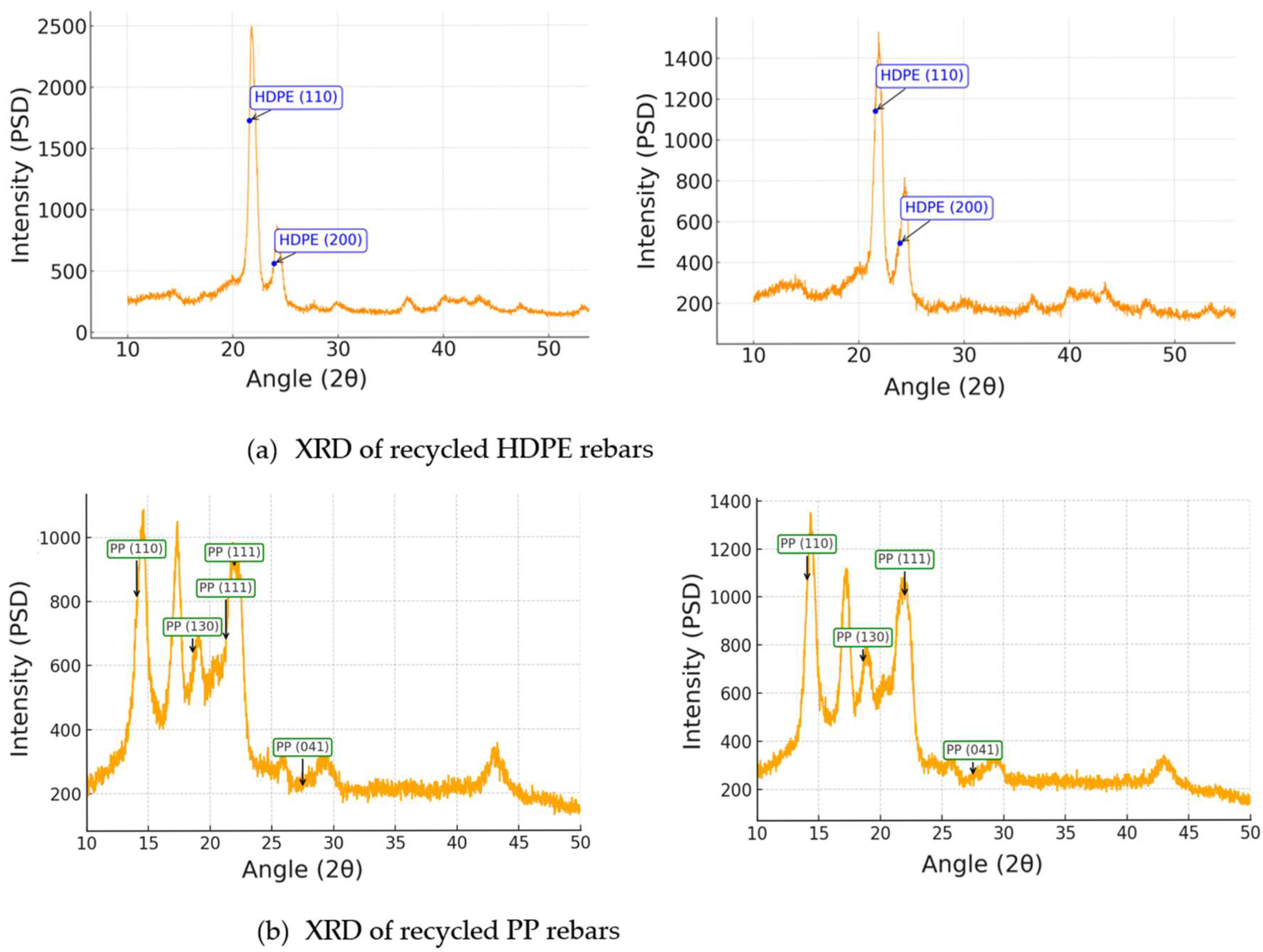

3.2.2. XRD Analysis

4. Proposed Practical Utilization of Developed Rebars for Structural Elements Under Light Loads

5. Conclusions

- Ribbed polypropylene (PP) rebars displayed the highest mechanical performance among all samples, achieving a maximum load of 12.2 ± 0.6 kN and a toughness index of 19.3 ± 1.0. The inclusion of ribs enhanced the stress distribution, delaying failure and improving ductility, making ribbed PP the most effective option for light-load reinforcement.

- SEM analysis revealed brittle fracture patterns in both polymers. HDPE exhibited irregular fracture surfaces with signs of crack branching and delamination, while PP showed smoother, trans-granular fractures, indicating rapid failure under localized stress.

- XRD analysis verified the semicrystalline structure of both materials. HDPE showed clear peaks at 2θ ≈ 21.6° and 23.9°, and PP exhibited distinct peaks near 14.1°, 16.9°, and 18.6°, reflecting structural differences influenced by polymer type and processing conditions.

- Regression modeling showed positive load trends for ribbed PP and HDPE rebars across increasing diameters, while plain HDPE showed reduced performance at larger sizes. These trends highlight the effect of geometry and material on tensile behavior.

- This study successfully demonstrated that recycled HDPE and PP can be processed into structural rebars suitable for non-critical, mortar-free construction systems. Their application in boundary walls, partition panels, and modular systems offers a sustainable alternative to conventional materials, promoting waste valorization and circular economy practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HDPE | high-density polyethylene |

| PP | Polypropylene |

| PET | Polyethylene terephthalate |

| PVC | Polyvinyl chloride |

| XRD | X-ray Diffraction |

| SEM | Scanning Electron Microscopy |

| CH | Carbon–hydrogen (C–H) bond |

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, 1700782. [Google Scholar] [CrossRef] [PubMed]

- Das, A.J.; Ali, M. Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling 2025, 10, 41. [Google Scholar] [CrossRef]

- Adam, M.; Curbach, M.; Shams, M. Behaviour of Concrete Beams Reinforced with GFRP Bars. Constr. Build. Mater. 2015, 78, 409–419. [Google Scholar]

- Ali, M. Coir Fibre Rope as Confinement in RC Columns. Constr. Build. Mater. 2014, 61, 320–327. [Google Scholar]

- Mousavi, S.R.; Esfahani, M.R. Dowel Action of GFRP Bars in Reinforced Concrete Connections. Compos. Struct. 2012, 94, 2130–2137. [Google Scholar]

- Archila, H.; Kaminski, S.; Trujillo, D.; Harries, K.A.; Salenikovich, A. Bamboo Reinforced Concrete: A Critical Review. Constr. Build. Mater. 2018, 174, 713–726. [Google Scholar] [CrossRef]

- Ali, M. Natural Fiber Rope Confinement in Reinforced Concrete Columns. Mater. Struct. 2014, 47, 135–148. [Google Scholar]

- Jawad, F.; Adarsha, C.Y.; Raghavendra, T.; Udayashankar, B.C.; Natarajan, K. Structural Behavior of Concrete Beams and Columns Reinforced with Waste Plastic Incorporated GFRP (WPGFRP) Rebars. J. Build. Eng. 2019, 23, 172–184. [Google Scholar] [CrossRef]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Intrakamhaeng, V.; Clavier, K.A.; Liu, Y.; Townsend, T.G. Antimony Mobility from E-Waste Plastic in Simulated Municipal Solid Waste Landfills. Chemosphere 2020, 241, 125042. [Google Scholar] [CrossRef] [PubMed]

- Lacerda, M.T.; Fiatkoski, M.V.; Maceno, M.M.C.; Agostinho, F.D.R.; Spier, M.R.; Kleina, M.; Marques, M.A.M. LCA and Emergy Approach to Evaluate the Environmental Performance of Plastic Bags from Fossil and Renewable Sources with the Function of Conditioning MSW. Sustainability 2024, 16, 11293. [Google Scholar] [CrossRef]

- Pluskal, J.; Šomplák, R.; Nevrlý, V.; Smejkalová, V.; Pavlas, M. Strategic Decisions Leading to Sustainable Waste Management: Separation, Sorting and Recycling Possibilities. J. Clean. Prod. 2021, 278, 123359. [Google Scholar] [CrossRef]

- Shaikh, S. A Critical Analysis of E-Waste Management and Recycling in Pakistan: A Life Cycle Assessment. Ph.D. Thesis, Victoria University, Melbourne, Australia, 2021. Available online: https://vuir.vu.edu.au/42515/ (accessed on 26 May 2025).

- Grigorescu, R.M.; Grigore, M.E.; Iancu, L.; Ghioca, P.; Ion, R.M. Waste Electrical and Electronic Equipment: A Review on the Identification Methods for Polymeric Materials. Recycling 2019, 4, 32. [Google Scholar] [CrossRef]

- Low, J.K.; Berry, S.; Hernandez, G.; Thomson, P.; Steinhorn, G.; Waghela, H.; Briggs, C.; Berry, C.; Berry, T.-A. Comprehensive Plastic Waste Characterisation to Enhance Landfill Diversion in New Zealand’s Construction Industry. Sustainability 2025, 17, 2742. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of Plastic Solid Waste: A Review. Compos. Part B Eng. 2020, 115, 419–432. [Google Scholar] [CrossRef]

- Chen, H.; Wan, K.; Zhang, Y.; Wang, Y. Waste to Wealth: Chemical Recycling and Chemical Upcycling of Waste Plastics for a Great Future. ChemSusChem 2021, 14, 4123–4136. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Ismail, I.M.I.; Nizami, A.S. Effect of Plastic Waste Types on Pyrolysis Liquid Oil. Int. Biodeterior. Biodegrad. 2017, 119, 239–252. [Google Scholar] [CrossRef]

- Tournier, V.; Topham, C.M.; Gilles, A.; David, B.; Folgoas, C.; Moya-Leclair, E.; Kamionka, E.; Desrousseaux, M.-L.; Texier, H.; Gavalda, S.; et al. An Engineered PET Depolymerase for Plastic Recycling. Nature 2020, 580, 216–219. [Google Scholar] [CrossRef]

- Kumar, B.; Pimentel, J.; Cano-Londoño, N.A.; Ruiz-Mercado, G.J.; Deak, C.T.; Cabezas, H. Designing Cost-Effective Supply Chains for Plastics at the End-of-Life. J. Clean. Prod. 2025, 501, 145227. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Laria, J.G.; Gaggino, R.; Kreiker, J.; Peisino, L.E.; Positieri, M.; Cappelletti, A. Mechanical and Processing Properties of Recycled PET and LDPE-HDPE Composite Materials for Building Components. J. Thermoplast. Compos. Mater. 2023, 36, 418–431. [Google Scholar] [CrossRef]

- Stepaniak, P.; Softić, S.; Woźniak, S.; Fabijański, M.; Nowakowski, K. Właściwości regranulatów polietylenowych wyprodukowanych z wyrobów wycofanych z użytkowania. Przem. Chem. 2023, 1, 75–79. [Google Scholar] [CrossRef]

- Hidalgo-Crespo, J.A.; Velastegui-Montoya, A.; Soto, M.; Amaya Rivas, J.L.; Zwolinski, P.; Riel, A.; Rivas-García, P. Improving Urban Waste Management: A Comprehensive Study on Household Waste Generation and Spatial Patterns in the Grand Guayaquil Metropolitan Area. Waste Manag. Res. J. Sustain. Circ. Econ. 2024, 42, 918–931. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo-Crespo, J.; Amaya, J.L.; Soto, M.; Caamaño-Gordillo, L. Domestic Plastic Waste in the City of Guayaquil: Generation Rate and Classification. In Proceedings of the 19th LACCEI International Multi-Conference for Engineering, Education, and Technology: Prospective and Trends in Technology and Skills for Sustainable Social Development—Leveraging Emerging Technologies to Construct the Future, Buenos Aires, Argentina, 21–23 July 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Blikharskyy, Y.; Selejdak, J.; Kopiika, N. Corrosion Fatigue Damages of Rebars under Loading in Time. Materials 2021, 14, 3416. [Google Scholar] [CrossRef]

- Patil, S.S.; Manjunatha, K.N. Impact Behavior of GFRP Rebars in Jute Fibre Concrete. Mater. Today Proc. 2020, 45, 3540–3545. [Google Scholar]

- Qaiser, M.H.; Yousaf, M.; Ali, S. Feasibility of Bamboo as Rebar in Concrete Members. Case Stud. Constr. Mater. 2020, 13, e00482. [Google Scholar]

- Al-Fasih, M.Y.; Khadim, A.; Hasan, S. Bamboo as Alternative to Steel in Underdeveloped Regions. J. Green Build. 2021, 16, 87–102. [Google Scholar]

- Ibrahim, H.M.; El-Hawary, M.; Nabil, M.; Ibrahim, A.A. Seismic Retrofitting of URM Walls Using Natural Fiber Ropes. Buildings 2024, 14, 1082. [Google Scholar]

- Wang, J.; Zhang, D.; He, Z.; Li, L. Review of Ferrocement Strengthening Methods for RC Structures. Materials 2024, 17, 1990. [Google Scholar]

- Shaheen, Y.A.; Al-Gahtani, H.J. Rasheeduzzafar Strengthening of RC Beams with NSM Steel Wire Strips. Structures 2023, 52, 481–495. [Google Scholar]

- Sk, M.; Singh, S.; Mahure, N. Performance of TMT Bars under Cyclic Loads. Int. J. Struct. Integr. 2016, 7, 365–374. [Google Scholar]

- Hadi, M.N.S.; Mahmoud, H.; Al-Azzawi, A. Behavior of Reinforced Concrete Members with Basalt FRP Bars. Constr. Build. Mater. 2021, 268, 121084. [Google Scholar]

- Das, A.J.; Ali, M. Energy Absorption Capabilities of Recycled-Plastic Reinforcing Bars for Earthquake Resistant Housing Construction. Aust. Earthq. Eng. Soc. Virtual Conf. 2021, 2021, 197–205. [Google Scholar]

- Lee, C.; Kim, D. Seismic Performance of Interlocking Block Structures. J. Struct. Eng. 2022, 148, 04022045. [Google Scholar]

- Ahmed, S.; Khan, M. Rapid Housing Solutions Using Interlocking Blocks. Int. J. Disaster Resil. Built Environ. 2019, 10, 234–245. [Google Scholar]

- Nguyen, T.; Tran, Q. Innovations in Interlocking Block Manufacturing. Constr. Innov. 2019, 19, 567–579. [Google Scholar]

- Garcia, L.; Martinez, P. Load-Bearing Capacity of Mortarless Walls. Eng. Struct. 2023, 256, 113989. [Google Scholar]

- Chen, X.; Huang, Z. Moisture Resistance in Dry-Stack Systems. Build. Environ. 2022, 200, 107975. [Google Scholar]

- Zhang, Y.; Li, H. Thermal Efficiency in Dry-Stack Masonry. Energy Build. 2020, 210, 109733. [Google Scholar]

- Thompson, A.; Green, R. Modular Designs in Mortar-Free Construction. Autom. Constr. 2021, 123, 103534. [Google Scholar]

- Silva, M.; Torres, L. Environmental Impact of Mortarless Building Methods. J. Clean. Prod. 2020, 275, 123456. [Google Scholar]

- Hassan Awad, A.; El Gamasy, R.; Abd El Wahab, A.; Hazem Abdellatif, M. Mechanical and Physical Properties of PP and HDPE. Eng. Sci. 2019, 4, 34. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM A615/A615M-22; ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Pang, A.L.; Husin, M.R.; Arsad, A.; Ahmadipour, M. Effect of Graphene Nanoplatelets on Structural, Morphological, Thermal, and Electrical Properties of Recycled Polypropylene/Polyaniline Nanocomposites. J. Mater. Sci. Mater. Electron. 2021, 32, 9574–9583. [Google Scholar] [CrossRef]

- Svoboda, P.; Trivedi, K.; Stoklasa, K.; Svobodova, D.; Ougizawa, T. Study of Crystallization Behaviour of Electron Beam Irradiated Polypropylene and High-Density Polyethylene. R. Soc. Open Sci. 2021, 8, 202250. [Google Scholar] [CrossRef] [PubMed]

- Kramer, D.; Huang, H.; Kriese, M.; Robach, J.; Nelson, J.; Wright, A.; Bahr, D.; Gerberich, W.W. Yield Strength Predictions from the Plastic Zone around Nanocontacts. Acta Mater. 1998, 47, 333–343. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, P.; Li, X.; Zhang, G. An Experimental Study on Deformation Behavior below 0.2% Offset Yield Stress in Some SiCp/Al Composites and Their Unreinforced Matrix Alloys. Mater. Sci. Eng. A 2001, 300, 12–21. [Google Scholar] [CrossRef]

- Faidallah, R.F.; Hanon, M.M.; Szakál, Z.; Oldal, I. Mechanical Characterization of 3D-Printed Carbon Fiber-Reinforced Polymer Composites and Pure Polymers: Tensile and Compressive Behavior Analysis. Int. Rev. Appl. Sci. Eng. 2025, 16, 22–31. [Google Scholar] [CrossRef]

- Liu, H.; Ka, T.A.; Su, N.; Zhu, Y.; Guan, S.; Long, J.; Tafsirojjaman, T. Experimental Study of Dimensional Effects on Tensile Strength of GFRP Bars. Buildings 2024, 14, 1205. [Google Scholar] [CrossRef]

- Satya, S.K.; Sreekanth, P.R. An Experimental Study on Recycled Polypropylene and High-Density Polyethylene and Evaluation of Their Mechanical Properties. Mater. Today Proc. 2020, 27, 920–924. [Google Scholar] [CrossRef]

- Wiater, A.; Siwowski, T. Comparison of Tensile Properties of Glass Fibre Reinforced Polymer Rebars by Testing According to Various Standards. Materials 2020, 13, 4110. [Google Scholar] [CrossRef] [PubMed]

- Malyuta, D.A.I.; Matteson, K.L.; Berry, M.P.; Bajwa, D.; Ryan, C. Experimental Statistical Modeling of Tensile Properties and Flexural Stiffness of Recycled High-Density Polyethylene (rHDPE) Thermoplastic Using Response Surface Methodology (RSM). Results Mater. 2023, 20, 100472. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Fracture and Failure of Polymers. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Thouless, M.D. Fracture of Polymer–Matrix Composites. Compos. Sci. Technol. 2012, 72, 1456–1460. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Huang, Y. Analysis of Fracture Behavior in Polymer Blends Using SEM and Image-Based Modeling. Polym. Test. 2019, 81, 106195. [Google Scholar] [CrossRef]

- Argon, A.S. The Physics of Deformation and Fracture of Polymers; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

| Weight (gms/m) | |||

|---|---|---|---|

| Dia (25 mm) | Dia (19 mm) | Dia (12 mm) | |

| Plain rPP | 417.5 ± 2.1 | 225.0 ± 0.9 | 116.3 ± 0.7 |

| Ribbed rPP | 442.9 ± 1.7 | 250.0 ± 1.2 | 100.0 ± 0.8 |

| Plain rHDPE | 353.2 ± 1.5 | 214.7 ± 1.3 | 110.4 ± 1.4 |

| Ribbed rHDPE | 450.4 ± 1.1 | 236.0 ± 1.8 | 105.8 ± 1.8 |

| Sample | Max Load (kN) | Max Elongation (mm) | Energy Absorption (N-m × 10) | Max Stress (MPa) | Yield Load (kN) | Elongation at Yield (mm) | Energy Absorption up to Yield (N-m) | Toughness Index |

|---|---|---|---|---|---|---|---|---|

| Dia (12 mm) | ||||||||

| Plain HDPE | 1.2 ± 0.1 (6.2) | 123.9 ± 6.2 (6.8) | 8.4 ± 0.4 (11.9) | 10.3 ± 0.5 (5.3) | 0.7 ± 0.01 (2.1) | 15.7 ± 0.8 (4.2) | 6.9 ± 0.3 (8.1) | 12.3 ± 0.6 (3.7) |

| Plain PP | 2.0 ± 0.1 (7.2) | 39.7 ± 2.0 (7.9) | 5.6 ± 0.2 (10.5) | 17.6 ± 0.9 (3.8) | 1.0 ± 0.1 (7.8) | 7.1 ± 0.4 (3.5) | 4.0 ± 0.2 (8.0) | 14.2 ± 0.7 (2.4) |

| Rib PP | 1.7 ± 0.1 (7.2) | 140.8 ± 7.0 (7.3) | 19.6 ± 0.1 (13.5) | 15.1 ± 0.8 (3.1) | 1.1 ± 0.1 (8.6) | 18.1 ± 0.9 (3.5) | 13.0 ± 0.7 (7.7) | 15.1 ± 0.8 (2.2) |

| Rib HDPE | 1.7 ± 0.1 (4.2) | 129.8 ± 6.5 (4.3) | 19.7 ± 0.9 (11.2) | 15.3 ± 0.8 (4.2) | 1.3 ± 0.1 (17.1) | 16.8 ± 0.8 (1.5) | 14.0 ± 0.7 (5.9) | 14.1 ± 0.7 (2.9) |

| Dia (19 mm) | ||||||||

| Plain HDPE | 3.4 ± 0.2 (5.2) | 28.8 ± 1.4 (5.6) | 5.9 ± 0.3 (10.2) | 12.1 ± 0.6 (4.5) | 1.7 ± 0.1 (27.1) | 6.7 ± 0.3 (7.5) | 6.6 ± 0.3 (9.5) | 9.0 ± 0.5 (2.1) |

| Plain PP | 4.9 ± 0.2 (3.2) | 45.5 ± 2.3 (9.1) | 16.5 ± 0.8 (11.4) | 17.2 ± 0.9 (2.2) | 2.3 ± 0.1 (3.1) | 7.6 ± 0.4 (8.8) | 10.2 ± 0.5 (9.5) | 16.2 ± 0.8 (2.9) |

| Rib HDPE | 4.2 ± 0.2 (7.2) | 31.9 ± 1.6 (5.3) | 8.9 ± 0.4 (9.9) | 14.9 ± 0.7 (11.2) | 2.1 ± 0.1 (3.1) | 7.2 ± 0.4 (4.2) | 8.7 ± 0.4 (8.7) | 10.2 ± 0.5 (2.4) |

| Rib PP | 6.6 ± 0.3 (4.2) | 63.4 ± 3.2 (4.6) | 32.6 ± 1.6 (5.9) | 23.3 ± 1.2 (14.3) | 3.4 ± 0.2 (7.1) | 9.1 ± 0.5 (4.3) | 18.1 ± 0.9 (3.9) | 18.0 ± 0.9 (2.1) |

| Dia (25 mm) | ||||||||

| Plain HDPE | 3.0 ± 0.1 (6.2) | 18.9 ± 0.9 (5.1) | 4.0 ± 0.2 (3.9) | 6.1 ± 0.3 (11.2) | 2.3 ± 0.1 (8.2) | 4.6 ± 0.2 (4.9) | 6.3 ± 0.3 (3.9) | 6.4 ± 0.3 (3.7) |

| Plain PP | 8.0 ± 0.4 (3.2) | 47.0 ± 2.3 (6.6) | 25.6 ± 1.2 (17.9) | 16.3 ± 0.8 (13.2) | 4.1 ± 0.2 (4.6) | 8.1 ± 0.4 (4.8) | 18.7 ± 0.9 (2.8) | 13.7 ± 0.7 (8.7) |

| Rib HDPE | 9.3 ± 0.5 (2.2) | 32.8 ± 1.6 (3.6) | 20.5 ± 1.0 (11.9) | 19.0 ± 1.0 (17.2) | 4.3 ± 0.2 (4.1) | 6.8 ± 0.3 (7.5) | 16.0 ± 0.8 (3.4) | 12.8 ± 0.6 (8.7) |

| Rib PP | 12.2 ± 0.6 (9.2) | 100.6 ± 5.0 (6.1) | 101.6 ± 5.0 (13.9) | 24.9 ± 1.2 (6.2) | 7.1 ± 0.4 (6.1) | 12.8 ± 0.6 (6.5) | 52.6 ± 2.6 (5.6) | 19.3 ± 1.0 (9.7) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, A.J.; Ali, M. Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads. Sustainability 2025, 17, 4997. https://doi.org/10.3390/su17114997

Das AJ, Ali M. Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads. Sustainability. 2025; 17(11):4997. https://doi.org/10.3390/su17114997

Chicago/Turabian StyleDas, Aaroon Joshua, and Majid Ali. 2025. "Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads" Sustainability 17, no. 11: 4997. https://doi.org/10.3390/su17114997

APA StyleDas, A. J., & Ali, M. (2025). Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads. Sustainability, 17(11), 4997. https://doi.org/10.3390/su17114997