Chitosan-Modified Biochar for Improving Water Retention in Karst Quarries: A Potential Solution for Soil Remediation

Abstract

1. Introduction

2. Materials and Methods

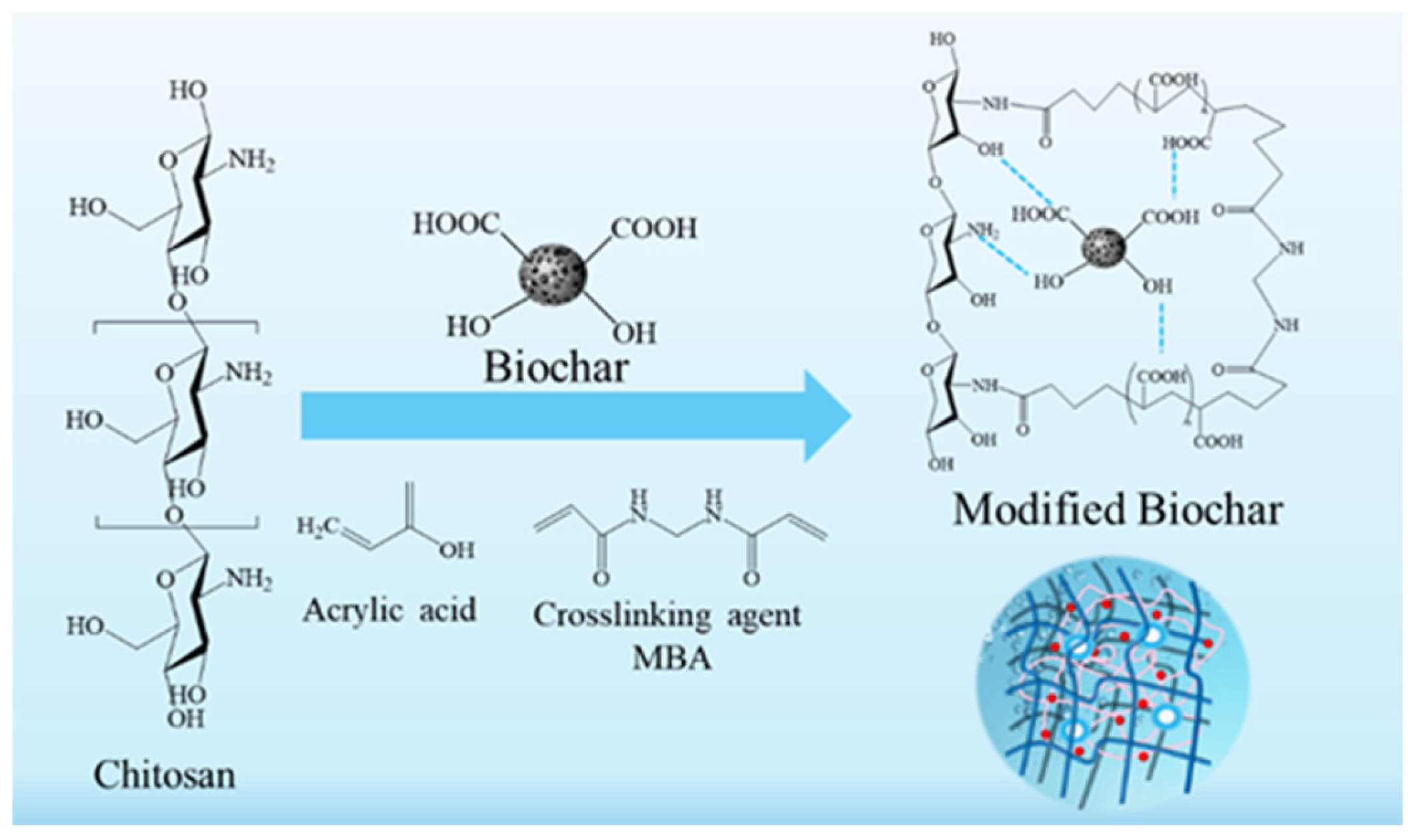

2.1. Preparation and Modification of Biochar

2.2. Soil Collection

2.3. Material Characterization

2.4. Experimental Design

2.4.1. Water Absorption Capacity Test

2.4.2. Cyclic Water Absorption Capacity Test

2.4.3. Water Retention Capacity

2.4.4. Soil Evaporation Experiment

2.4.5. Pot Experiment

3. Results and Discussion

3.1. Characterization and Analysis of Biochar

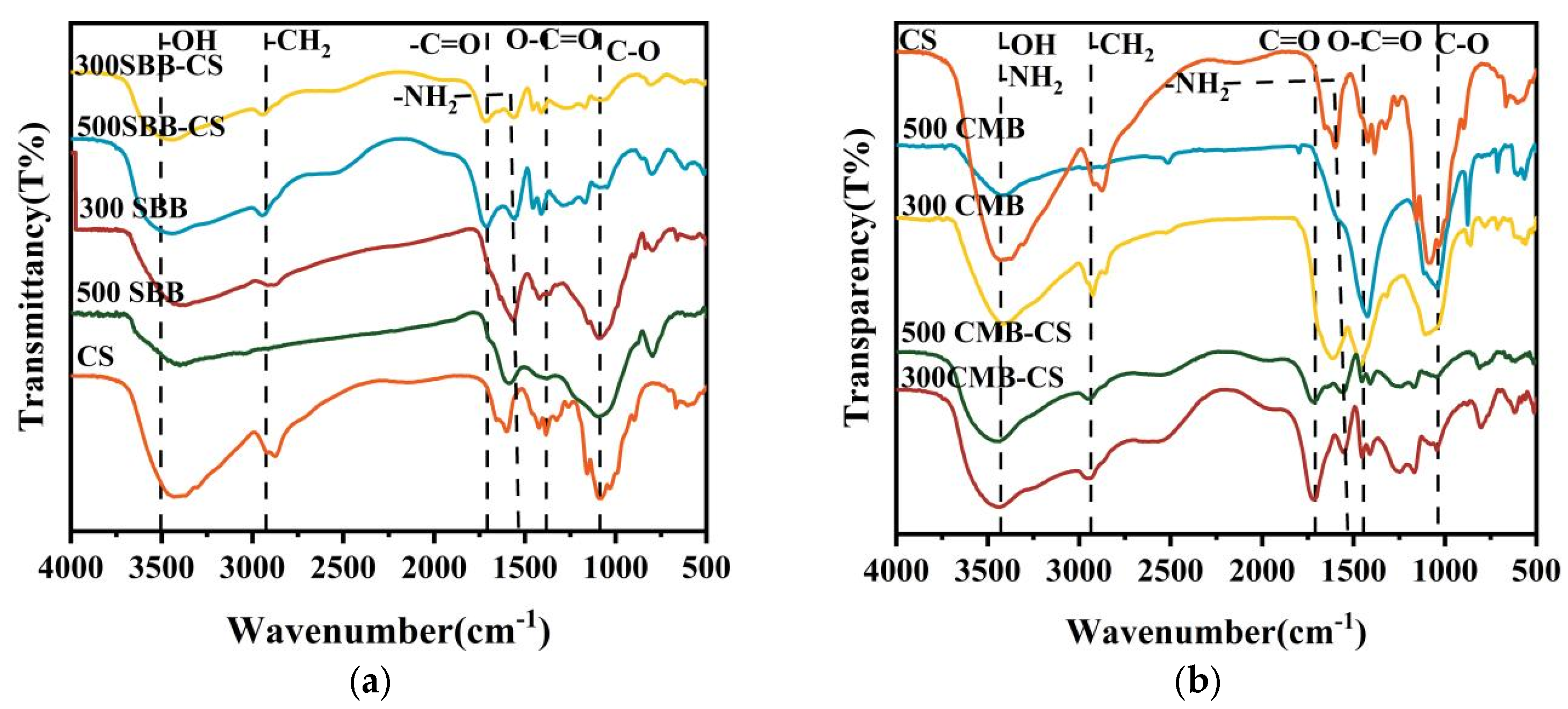

3.1.1. FT-IR Analysis of Biochar

3.1.2. Contact Angle and Elemental Analysis of Biochar

3.1.3. The Specific Surface Area and Porosity of Biochar

3.1.4. Cation Exchange Capacity (CEC) of Biochar

3.1.5. Water Absorption Capacity of Biochar

3.2. Influence of Biochar on Soil Water Retention

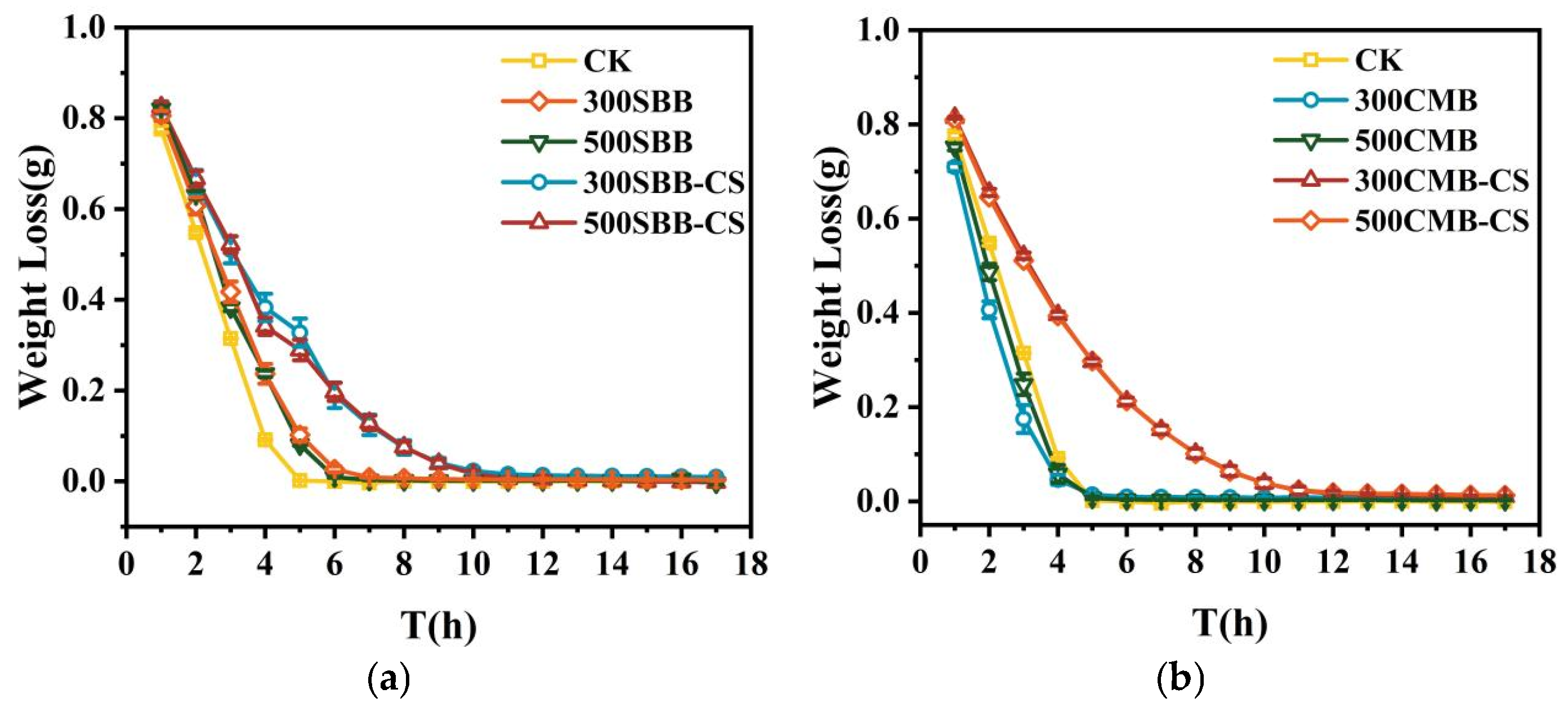

3.2.1. Influence of Biochar on Soil Evaporation

3.2.2. Influence of Biochar on Soil Cumulative Evaporation

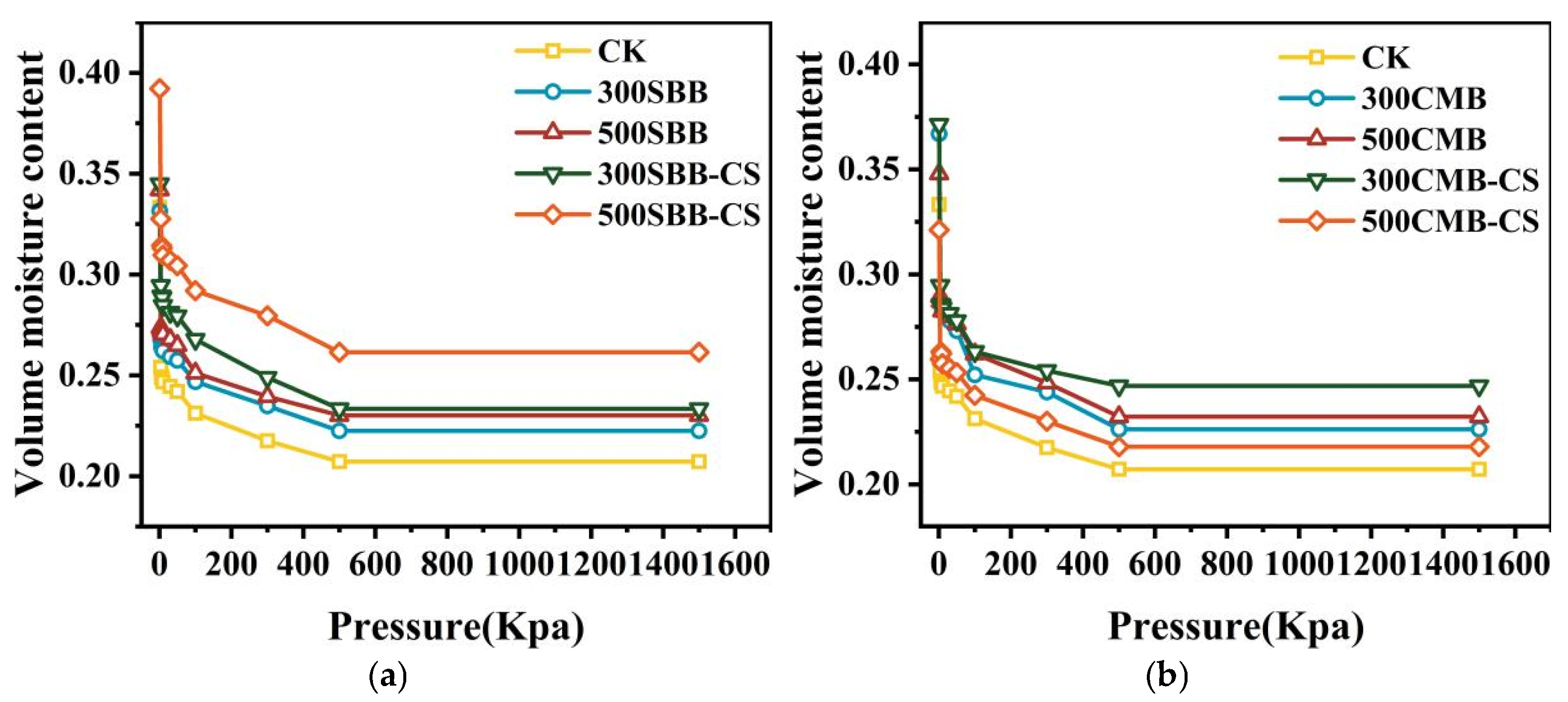

3.2.3. Influence of Biochar on Soil Water Characteristic Curve

3.3. Influence of Biochar on Soil Physical and Chemical Properties

3.3.1. Influence of Biochar on Plant Height

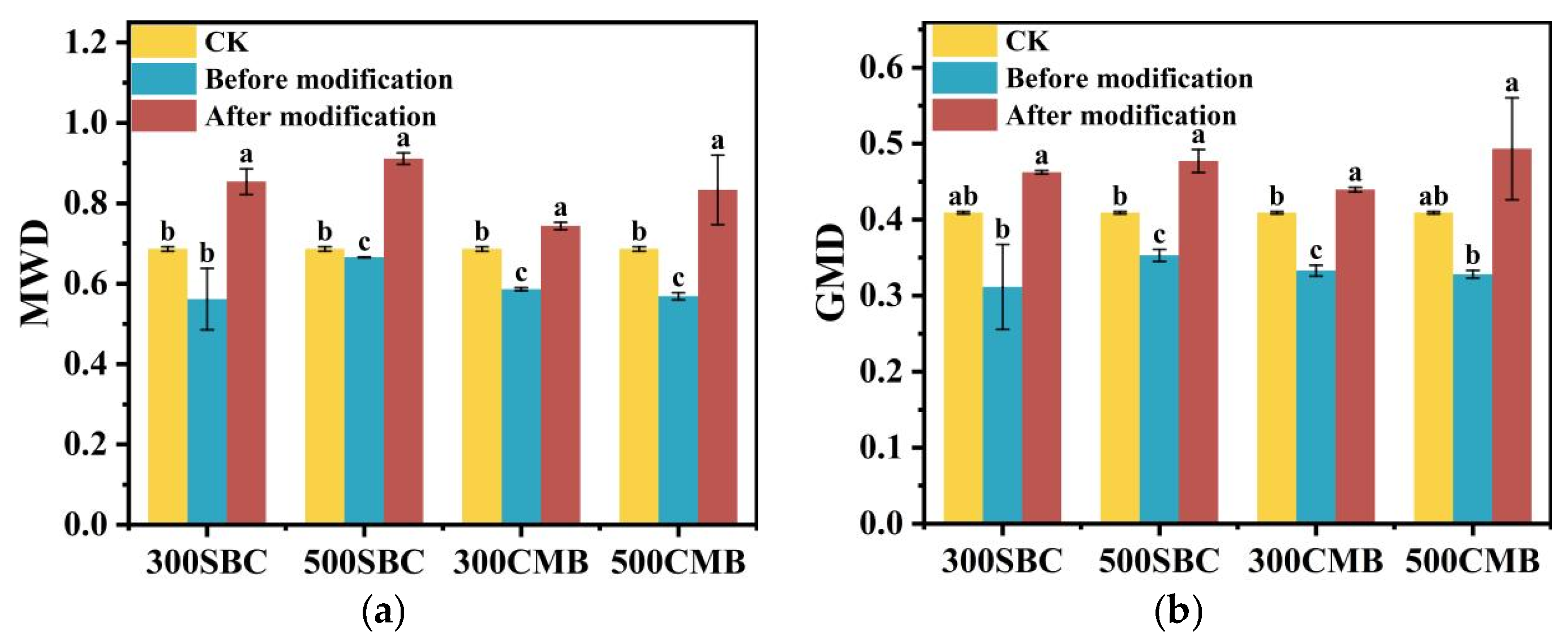

3.3.2. Influence of Biochar on Soil Aggregate Stability and Cation Exchange Capacity

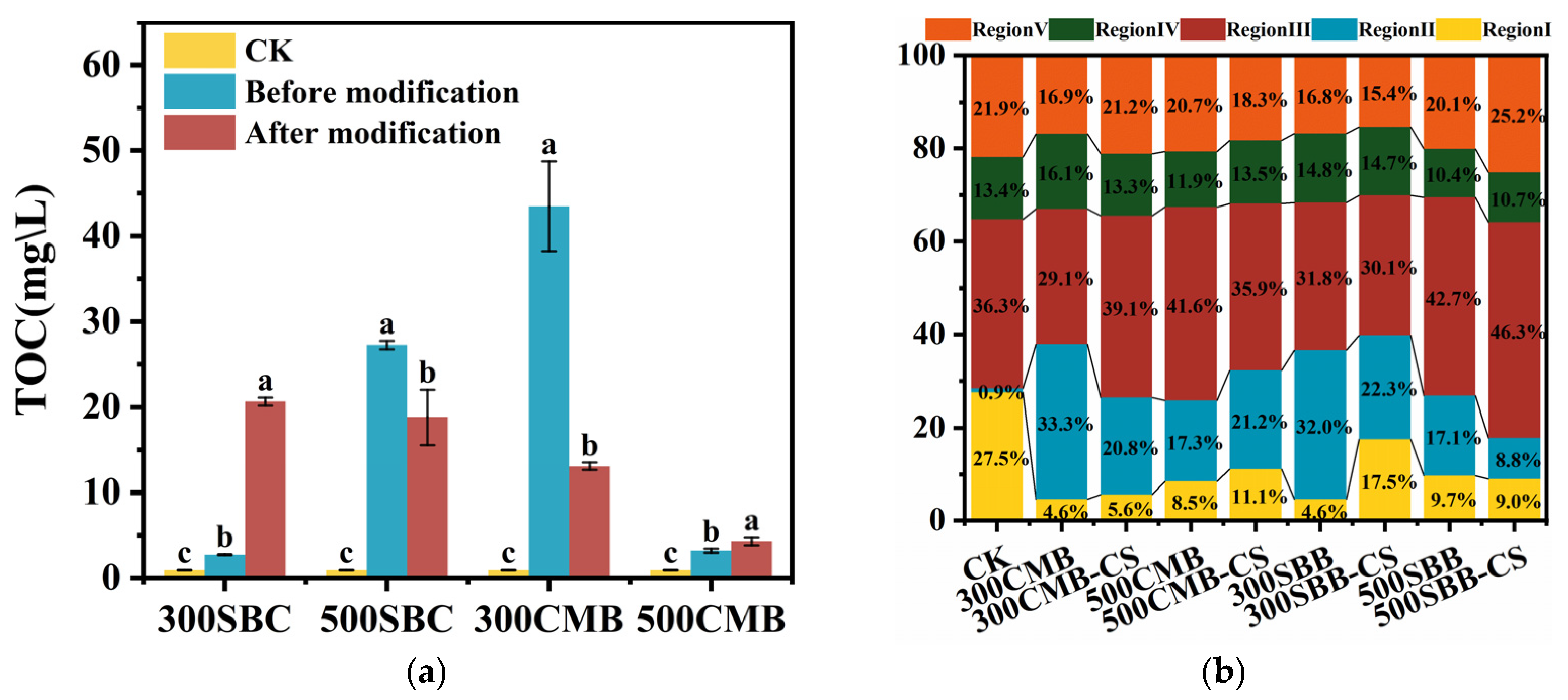

3.3.3. Influence of Biochar on Soil Dissolved Organic Matter

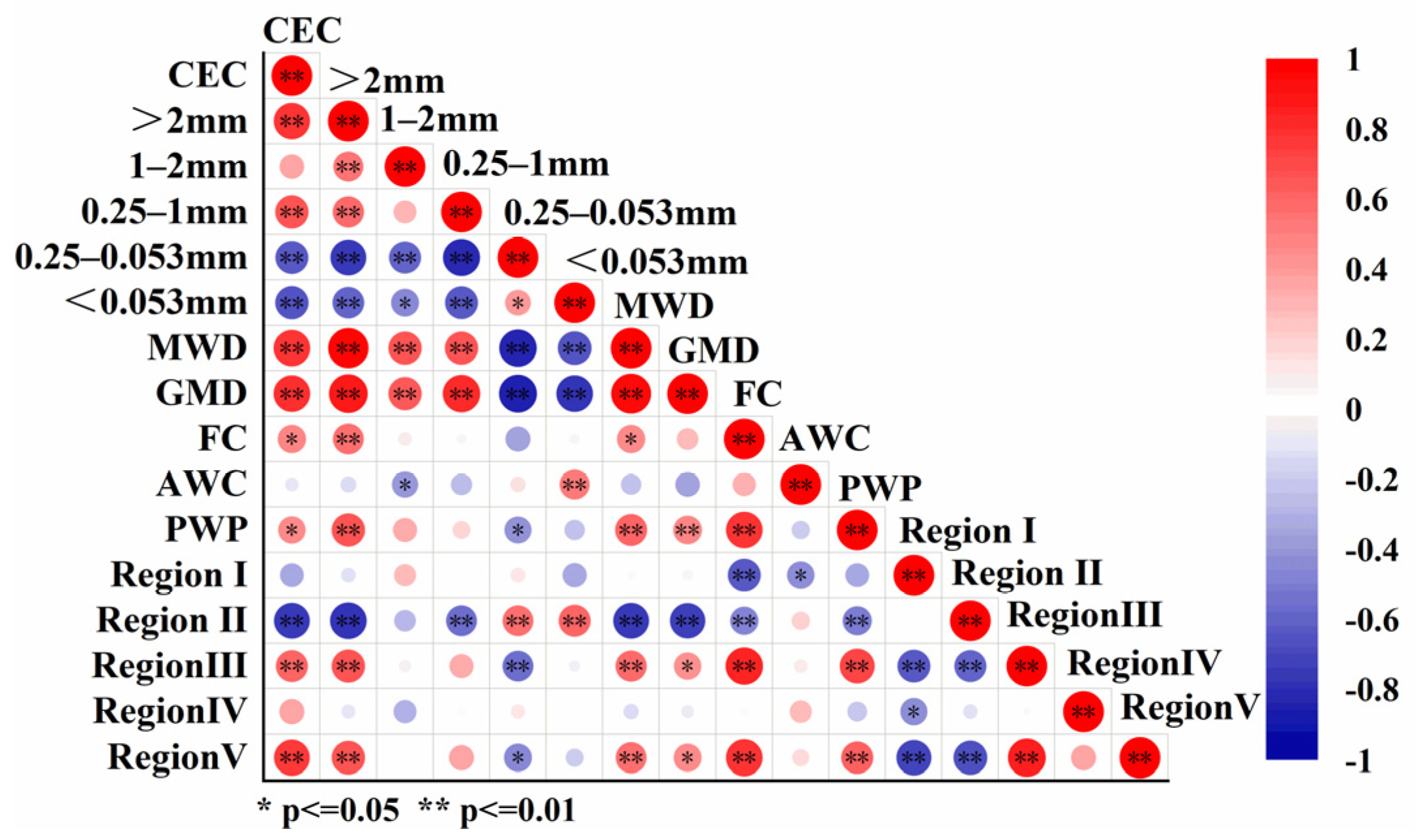

3.4. Correlation Analysis Between Soil Physical and Chemical Properties and Water Retention Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Cheng, C.; Xiong, K.; Rong, L.; Zhang, S. Quantifying the biodiversity and ecosystem service outcomes of karst ecological restoration: A meta-analysis of South China Karst. CATENA 2024, 245, 108278. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, Q.; Wan, Y.; Yang, R.; Mou, J.; Li, Y.; Meng, L.; Zhu, T.; Elrys, A.S. Afforestation improves soil organic carbon and total nitrogen stocks mainly through increasing > 2 mm aggregate fractions and stimulating carbon and nitrogen transformations within aggregates in subtropical karst region. Catena 2024, 243, 108220. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Jing, J. Soil erosion gradient and quantitative attribution in southwest China based on karst development degree. Ecol. Indic. 2022, 144, 109496. [Google Scholar] [CrossRef]

- Guo, B.; Yang, F.; Fan, Y.; Zang, W. The dominant driving factors of rocky desertification and their variations in typical mountainous karst areas of southwest China in the context of global change. Catena 2022, 220, 106674. [Google Scholar] [CrossRef]

- Al-Fugara, A.k.; Al-Adamat, R.; Al-Kouri, O.; Taher, S. DSM derived stereo pair photogrammetry: Multitemporal morphometric analysis of a quarry in karst terrain. Egypt. J. Remote Sens. Space Sci. 2016, 19, 61–72. [Google Scholar] [CrossRef][Green Version]

- Cai, J.; Yu, W.; Fang, Q.; Zi, R.; Fang, F.; Zhao, L. Extraction of Rocky Desertification Information in the Karst Area Based on the Red-NIR-SWIR Spectral Feature Space. Remote Sens. 2023, 15, 3056. [Google Scholar] [CrossRef]

- Qian, C.; Qiang, H.; Qin, C.; Wang, Z.; Li, M. Spatiotemporal Evolution Analysis and Future Scenario Prediction of Rocky Desertification in a Subtropical Karst Region. Remote Sens. 2022, 14, 292. [Google Scholar] [CrossRef]

- Yan, T.; Xue, J.; Zhou, Z.; Wu, Y. Biochar-based fertilizer amendments improve the soil microbial community structure in a karst mountainous area. Sci. Total Environ. 2021, 794, 148757. [Google Scholar] [CrossRef]

- Xie, T.; Reddy, K.R.; Wang, C.; Yargicoglu, E.; Spokas, K. Characteristics and Applications of Biochar for Environmental Remediation: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 939–969. [Google Scholar] [CrossRef]

- Hagner, M.; Kemppainen, R.; Jauhiainen, L.; Tiilikkala, K.; Setälä, H. The effects of birch (Betula spp.) biochar and pyrolysis temperature on soil properties and plant growth. Soil Tillage Res. 2016, 163, 224–234. [Google Scholar] [CrossRef]

- Baiamonte, G.; Crescimanno, G.; Parrino, F.; De Pasquale, C. Effect of biochar on the physical and structural properties of a sandy soil. Catena 2018, 175, 294–303. [Google Scholar] [CrossRef]

- Ouyang, P.; Narayanan, M.; Shi, X.; Chen, X.; Li, Z.; Luo, Y.; Ma, Y. Integrating biochar and bacteria for sustainable remediation of metal-contaminated soils. Biochar 2023, 5, 63. [Google Scholar] [CrossRef]

- Zhou, H.; Fang, H.; Zhang, Q.; Wang, Q.; Chen, C.; Mooney, S.J.; Peng, X.; Du, Z. Biochar enhances soil hydraulic function but not soil aggregation in a sandy loam. Eur. J. Soil Sci. 2018, 70, 291–300. [Google Scholar] [CrossRef]

- Wang, D.; Li, C.; Parikh, S.J.; Scow, K.M. Impact of biochar on water retention of two agricultural soils—A multi-scale analysis. Geoderma 2019, 340, 185–191. [Google Scholar] [CrossRef]

- Huang, H.; Reddy, N.G.; Huang, X.; Chen, P.; Wang, P.; Zhang, Y.; Huang, Y.; Lin, P.; Garg, A. Effects of pyrolysis temperature, feedstock type and compaction on water retention of biochar amended soil. Sci. Rep. 2021, 11, 7419. [Google Scholar] [CrossRef]

- Aborisade, M.A.; Oba, B.T.; Kumar, A.; Liu, J.; Chen, D.; Okimiji, O.P.; Zhao, L. Remediation of metal toxicity and alleviation of toxic metals-induced oxidative stress in Brassica chinensis L. using biochar-iron nanocomposites. Plant Soil 2023, 493, 629–645. [Google Scholar] [CrossRef]

- Aborisade, M.A.; Feng, A.; Zheng, X.; Oba, B.T.; Kumar, A.; Battamo, A.Y.; Kavwenje, S.; Liu, J.; Chen, D.; Okimiji, O.P.; et al. Carbothermal reduction synthesis of eggshell-biochar modified with nanoscale zerovalent iron/activated carbon for remediation of soil polluted with lead and cadmium. Environ. Nanotechnol. Monit. Manag. 2022, 18, 100726. [Google Scholar] [CrossRef]

- Albalasmeh, A.A.; Hamdan, E.H.; Gharaibeh, M.A.; Hanandeh, A.E. Improving aggregate stability and hydraulic properties of Sandy loam soil by applying polyacrylamide polymer. Soil Tillage Res. 2020, 206, 104821. [Google Scholar] [CrossRef]

- Yang, Y.; Zhong, M.; Bian, X.; You, Y.; Li, F. Preparation of carbon-based material with high water absorption capacity and its effect on the water retention characteristics of sandy soil. Biochar 2023, 5, 61. [Google Scholar] [CrossRef]

- Gao, N.; Du, W.; Zhang, M.; Ling, G.; Zhang, P. Chitosan-modified biochar: Preparation, modifications, mechanisms and applications. Int. J. Biol. Macromol. 2022, 209, 31–49. [Google Scholar] [CrossRef]

- Adamczuk, A.; Jozefaciuk, G. Impact of Chitosan on the Mechanical Stability of Soils. Molecules 2022, 27, 2273. [Google Scholar] [CrossRef]

- Wei, B.; Peng, Y.; Lin, L.; Zhang, D.; Ma, L.; Jiang, L.; Li, Y.; He, T.; Wang, Z. Drivers of biochar-mediated improvement of soil water retention capacity based on soil texture: A meta-analysis. Geoderma 2023, 437, 116591. [Google Scholar] [CrossRef]

- Shu, X.; Tian, W.; Xiong, S.; Zhang, W.; Zhang, Q. Straw Biochar at Different Pyrolysis Temperatures Passivates Pyrite by Promoting Electron Transfer from Biochar to Pyrite. Processes 2022, 10, 2148. [Google Scholar] [CrossRef]

- Pasumarthi, R.; Sawargaonkar, G.; Kale, S.; Kumar, N.V.; Choudhari, P.L.; Singh, R.; Davala, M.S.; Rani, C.S.; Mutnuri, S.; Jat, M.L. Innovative bio-pyrolytic method for efficient biochar production from maize and pigeonpea stalks and their characterization. J. Clean. Prod. 2024, 448, 141573. [Google Scholar] [CrossRef]

- Xu, X.; Bai, B.; Ding, C.; Wang, H.; Suo, Y. Synthesis and Properties of an Ecofriendly Superabsorbent Composite by Grafting the Poly(acrylic acid) onto the Surface of Dopamine-Coated Sea Buckthorn Branches. Ind. Eng. Chem. Res. 2015, 54, 3268–3278. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, S.; Yuan, R.; Wang, P. Biomass pyrolysis with alkaline-earth-metal additive for co-production of bio-oil and biochar-based soil amendment. Sci. Total Environ. 2020, 743, 140760. [Google Scholar] [CrossRef] [PubMed]

- Bombuwala Dewage, N.; Fowler, R.E.; Pittman, C.U.; Mohan, D.; Mlsna, T. Lead (Pb2+) sorptive removal using chitosan-modified biochar: Batch and fixed-bed studies†. RSC Adv. 2018, 8, 25368–25377. [Google Scholar] [CrossRef]

- Afzal, M.Z.; Yue, R.; Sun, X.-F.; Song, C.; Wang, S.-G. Enhanced removal of ciprofloxacin using humic acid modified hydrogel beads. J. Colloid Interface Sci. 2019, 543, 76–83. [Google Scholar] [CrossRef]

- Afzal, M.Z.; Zu, P.; Zhang, C.-M.; Guan, J.; Song, C.; Sun, X.-F.; Wang, S.-G. Sonocatalytic degradation of ciprofloxacin using hydrogel beads of TiO2 incorporated biochar and chitosan. J. Hazard. Mater. 2022, 434, 128879. [Google Scholar] [CrossRef]

- Fang, L.; Li, J.-s.; Donatello, S.; Cheeseman, C.R.; Poon, C.S.; Tsang, D.C.W. Use of Mg/Ca modified biochars to take up phosphorus from acid-extract of incinerated sewage sludge ash (ISSA) for fertilizer application. J. Clean. Prod. 2019, 244, 118853. [Google Scholar] [CrossRef]

- de Castro, A.E.; da Silva Martinho, F.; Barbosa, M.L.; Franca, J.R.; Ribeiro-Soares, J.; Ferreira, G.M.D.; Ferreira, G.M.D. Influence of Methyl Groups in Triphenylmethane Dyes on Their Adsorption on Biochars from Coffee Husks. Water Air Soil Pollut. 2022, 233, 180. [Google Scholar] [CrossRef]

- Meng, Y.; Ye, L. Synthesis and swelling property of superabsorbent starch grafted with acrylic acid/2-acrylamido-2-methyl-1-propanesulfonic acid. J. Sci. Food Agric. 2017, 97, 3831–3840. [Google Scholar] [CrossRef] [PubMed]

- Baki, M.; Abedi-Koupai, J. Preparation and characterization of a superabsorbent slow-release fertilizer with sodium alginate and biochar. J. Appl. Polym. Sci. 2017, 135, 45966. [Google Scholar] [CrossRef]

- Cely, P.; Gascó, G.; Paz-Ferreiro, J.; Méndez, A. Agronomic properties of biochars from different manure wastes. J. Anal. Appl. Pyrolysis 2015, 111, 173–182. [Google Scholar] [CrossRef]

- Wang, S.; Gao, B.; Li, Y.; Mosa, A.; Zimmerman, A.R.; Ma, L.Q.; Harris, W.G.; Migliaccio, K.W. Manganese oxide-modified biochars: Preparation, characterization, and sorption of arsenate and lead. Bioresour. Technol. 2015, 181, 13–17. [Google Scholar] [CrossRef]

- Woods, S.W.; Balfour, V.N. The effect of ash on runoff and erosion after a severe forest wildfire, Montana, USA. Int. J. Wildland Fire 2008, 17, 535–548. [Google Scholar] [CrossRef]

- Jung, J.-M.; Lee, S.-R.; Lee, J.; Lee, T.; Tsang, D.C.W.; Kwon, E.E. Biodiesel synthesis using chicken manure biochar and waste cooking oil. Bioresour. Technol. 2017, 244, 810–815. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K. Influence of high carbonization temperatures on microstructural and physicochemical characteristics of herbaceous biomass derived biochars. J. Environ. Chem. Eng. 2020, 8, 104169. [Google Scholar] [CrossRef]

- Zouari, M.; Marrot, L.; DeVallance, D.B. Evaluation of properties and formaldehyde removal efficiency of biocarbon prepared at variable pyrolytic temperatures. Front. Environ. Sci. 2023, 11, 1252926. [Google Scholar] [CrossRef]

- Obia, A.; Mulder, J.; Martinsen, V.; Cornelissen, G.; Børresen, T. In situ effects of biochar on aggregation, water retention and porosity in light-textured tropical soils. Soil Tillage Res. 2016, 155, 35–44. [Google Scholar] [CrossRef]

- Wang, F.; Yang, W.; Lu, H.; Chen, J.; Gao, S.; Shen, C. Preparation and Property Investigation of Chitosan-Based Anion-Exchange Membranes with Different Cross-Linking Structures. Energy Fuels 2024, 7, 13275–13283. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, Y.; Zhong, Y.; Ni, J.; Wei, R.; Chen, W. Roles of biochars’ properties in their water-holding capacity and bound water evaporation: Quantitative importance and controlling mechanism. Biochar 2024, 6, 30. [Google Scholar] [CrossRef]

- Ibn Ferjani, A.; Jellali, S.; Akrout, H.; Limousy, L.; Hamdi, H.; Thevenin, N.; Jeguirim, M. Nutrient retention and release from raw exhausted grape marc biochars and an amended agricultural soil: Static and dynamic investigation. Environ. Technol. Innov. 2020, 19, 100885. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vazvani, M.G.; Kennedy, J.F. The application of chitosan as a carrier for fertilizer: A review. Int. J. Biol. Macromol. 2023, 252, 126483. [Google Scholar] [CrossRef]

- Jagtap, M.P.; Shinde, Y.A.; Khatri, N. An investigation on the effect of soil solarization on soil temperature and soil moisture conservation. Arab. J. Geosci. 2022, 15, 1778. [Google Scholar] [CrossRef]

- Herath, H.M.S.K.; Camps-Arbestain, M.; Hedley, M. Effect of biochar on soil physical properties in two contrasting soils: An Alfisol and an Andisol. Geoderma 2013, 209, 188–197. [Google Scholar] [CrossRef]

- Andrenelli, M.C.; Maienza, A.; Genesio, L.; Miglietta, F.; Pellegrini, S.; Vaccari, F.P.; Vignozzi, N. Field application of pelletized biochar: Short term effect on the hydrological properties of a silty clay loam soil. Agric. Water Manag. 2016, 163, 190–196. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, Y.; Huang, S.; Zhao, Y. Synthesis composite hydrogels from inorganic-organic hybrids based on leftover rice for environment-friendly controlled-release urea fertilizers. Sci. Total Environ. 2018, 615, 422–430. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.T.F.; Chen, Z.; Chen, X.; Ng, C.W.W.; Wong, M.H. Soil-water retention behavior of compacted biochar-amended clay: A novel landfill final cover material. J. Soils Sediments 2016, 17, 590–598. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, K.; Li, J.; Tang, C.; Shen, Z.; Shi, B. Effect of biochar on desiccation cracking characteristics of clayey soils. Geoderma 2020, 364, 114182. [Google Scholar] [CrossRef]

- Han, F.; An, S.-Y.; Liu, L.; Ma, L.-Q.; Wang, Y.; Yang, L. Simultaneous enhancement of soil properties along with water-holding and restriction of Pb–Cd mobility in a soil-plant system by the addition of a phosphorus-modified biochar to the soil. J. Environ. Manag. 2023, 345, 118827. [Google Scholar] [CrossRef] [PubMed]

- Ma, N.; Zhang, L.; Zhang, Y.; Yang, L.; Yu, C.; Yin, G.; Doane, T.A.; Wu, Z.; Zhu, P.; Ma, X. Biochar Improves Soil Aggregate Stability and Water Availability in a Mollisol after Three Years of Field Application. PLoS ONE 2016, 11, e0154091. [Google Scholar] [CrossRef]

- Ngo, A.T.; Mori, Y.; Bui, L.T. Effects of cellulose nanofibers on soil water retention and aggregate stability. Environ. Technol. Innov. 2024, 35, 103650. [Google Scholar] [CrossRef]

- Bashir, A.; Rizwan, M.; Zia ur Rehman, M.; Zubair, M.; Riaz, M.; Qayyum, M.F.; Alharby, H.F.; Bamagoos, A.A.; Ali, S. Application of co-composted farm manure and biochar increased the wheat growth and decreased cadmium accumulation in plants under different water regimes. Chemosphere 2020, 246, 125809. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, S.; Parthasarathy, P.; Mackey, H.R.; Al-Ansari, T.; McKay, G. Effect of Pistachio Shell Biochar and Organic Cow Manure Application on Plant Growth, Water Retention Capacity and Nutrient Stress Mitigation. Waste Biomass Valorization 2024, 16, 761–772. [Google Scholar] [CrossRef]

- Situ, G.; Zhao, Y.; Zhang, L.; Yang, X.; Chen, D.; Li, S.; Wu, Q.; Xu, Q.; Chen, J.; Qin, H. Linking the chemical nature of soil organic carbon and biological binding agent in aggregates to soil aggregate stability following biochar amendment in a rice paddy. Sci. Total Environ. 2022, 847, 157460. [Google Scholar] [CrossRef]

- Huang, W.; Lai, H.; Du, J.; Zhou, C.; Liu, Z.; Ni, Q. Effect of polymer water retaining agent on physical properties of silty clay. Chem. Biol. Technol. Agric. 2022, 9, 47. [Google Scholar] [CrossRef]

- Sun, Q.; Meng, J.; Lan, Y.; Shi, G.; Yang, X.; Cao, D.; Chen, W.; Han, X. Long-term effects of biochar amendment on soil aggregate stability and biological binding agents in brown earth. Catena 2021, 205, 105460. [Google Scholar] [CrossRef]

- Du, Z.-L.; Zhao, J.-K.; Wang, Y.-D.; Zhang, Q.-Z. Biochar addition drives soil aggregation and carbon sequestration in aggregate fractions from an intensive agricultural system. J. Soils Sediments 2016, 17, 581–589. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Wang, J. Formation and Stability Mechanism of Soil Aggregates: Progress and Prospect. Acta Pedol. Sin. 2023, 60, 627–643. [Google Scholar]

- Rombolà, A.G.; Torri, C.; Vassura, I.; Venturini, E.; Reggiani, R.; Fabbri, D. Effect of biochar amendment on organic matter and dissolved organic matter composition of agricultural soils from a two-year field experiment. Sci. Total Environ. 2021, 812, 151422. [Google Scholar] [CrossRef] [PubMed]

- Smebye, A.; Alling, V.; Vogt, R.D.; Gadmar, T.C.; Mulder, J.; Cornelissen, G.; Hale, S.E. Biochar amendment to soil changes dissolved organic matter content and composition. Chemosphere 2016, 142, 100–105. [Google Scholar] [CrossRef]

- Zhang, X.; Su, C.; Liu, X.; Liu, Z.; Gu, P.; Deng, M.; Liu, Q. Periodical changes of dissolved organic matter (DOM) properties induced by biochar application and its impact on downward migration of heavy metals under flood conditions. J. Clean. Prod. 2020, 275, 123787. [Google Scholar] [CrossRef]

- Williams, C.J.; Yamashita, Y.; Wilson, H.F.; Jaffé, R.; Xenopoulos, M.A. Unraveling the role of land use and microbial activity in shaping dissolved organic matter characteristics in stream ecosystems. Limnol. Oceanogr. 2010, 55, 1159–1171. [Google Scholar] [CrossRef]

- Liu, M.; Han, X.; Liu, C.-Q.; Guo, L.; Ding, H.; Lang, Y. Differences in the spectroscopic characteristics of wetland dissolved organic matter binding with Fe3+, Cu2+, Cd2+, Cr3+ and Zn2+. Sci. Total Environ. 2021, 800, 149476. [Google Scholar] [CrossRef]

- Zhu, M.; Kong, F.; Li, Y.; Li, M.; Zhang, J.; Xi, M. Effects of moisture and salinity on soil dissolved organic matter and ecological risk of coastal wetland. Environ. Res. 2020, 187, 109659. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Y.; Yang, C.; Wang, Q.; Jiang, D. Variations of DOM quantity and compositions along WWTPs-river-lake continuum: Implications for watershed environmental management. Chemosphere 2018, 218, 468–476. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, L.; Wu, D.; Pan, B. Mechanisms of soil minerals enhance biochar stability: A review. J. Agro-Environ. Sci. 2023, 42, 490–499. [Google Scholar]

- Youn, Y.; Yoon, S.; Kim, T.W.; Hong, S.K.; Cho, K. Significant improvement of adsorption thermal energy storage of zeolite by simple cation exchange, inducing strong polarization of water. J. Energy Storage 2024, 89, 111805. [Google Scholar] [CrossRef]

- Jones, B.E.H.; Haynes, R.J.; Phillips, I.R. Effect of amendment of bauxite processing sand with organic materials on its chemical, physical and microbial properties. J. Environ. Manag. 2010, 91, 2281–2288. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Asano, M.; Huang, Y.; Tamura, K.; Teni, G.; Gong, W.; Jiang, Q. Effects of dissolved organic matter on soil aggregate dynamics using rare earth oxides as tracers in A Japanese Andisol. Plant Soil 2024, 505, 667–686. [Google Scholar] [CrossRef]

- Piash, M.I.; Iwabuchi, K.; Itoh, T. Synthesizing biochar-based fertilizer with sustained phosphorus and potassium release: Co-pyrolysis of nutrient-rich chicken manure and Ca-bentonite. Sci. Total Environ. 2022, 822, 153509. [Google Scholar] [CrossRef] [PubMed]

| Elemental Composition | C (%) | H (%) | O% | H/C | Ash (%) | O/C | (O + N)/C | |

|---|---|---|---|---|---|---|---|---|

| Biochar | ||||||||

| 300SBB | 44.82 | 3.69 | 14.75 | 0.08 | 33.71 | 0.33 | 0.37 | |

| 500SBB | 43.98 | 1.74 | 8.96 | 0.04 | 43.14 | 0.20 | 0.24 | |

| 300SBB-CS | 41.10 | 4.89 | 35.09 | 0.12 | 16.96 | 0.85 | 0.87 | |

| 500SBB-CS | 40.41 | 5.29 | 33.28 | 0.13 | 19.08 | 0.82 | 0.84 | |

| 300CMB | 38.79 | 3.29 | 22.62 | 0.08 | 31.03 | 0.58 | 0.66 | |

| 500CMB | 34.91 | 1.09 | 13.38 | 0.03 | 47.51 | 0.38 | 0.44 | |

| 300CMB-CS | 44.82 | 5.39 | 37.24 | 0.12 | 10.26 | 0.83 | 0.85 | |

| 500CMB-CS | 41.70 | 5.45 | 34.66 | 0.13 | 16.06 | 0.83 | 0.85 | |

| BET (m2/g) | Porosity Volume (m3/g) | Pore Size (nm) | |

|---|---|---|---|

| 300SBB | 74.381 | 0.143 | 1.881 |

| 500SBB | 14.100 | 0.182 | 6.356 |

| 300SBB-CS | 3.569 | 0.200 | 10.781 |

| 500SBB-CS | 4.476 | 0.254 | 11.549 |

| 300CMB | 47.148 | 0.135 | 3.169 |

| 500CMB | 5.254 | 0.035 | 22.446 |

| 300CMB-CS | 3.588 | 0.250 | 8.452 |

| 500CMB-CS | 3.259 | 0.283 | 8.872 |

| FC | AWC | PWP | |

|---|---|---|---|

| CK | 0.208 ± 0.013 d | 0.011 ± 0.006 b | 0.197 ± 0.009 d |

| 300SBB | 0.259 ± 0.006 bc | 0.039 ± 0.005 a | 0.219 ± 0.003 cd |

| 500SBB | 0.263 ± 0.002 bc | 0.022 ± 0.012 ab | 0.240 ± 0.010 bc |

| 300CMB | 0.243 ± 0.002 c | 0.018 ± 0.001 ab | 0.225 ± 0.001 c |

| 500CMB | 0.268 ± 0.006 b | 0.034 ± 0.006 a | 0.233 ± 0.001 bc |

| 300SBB-CS | 0.272 ± 0.007 b | 0.029 ± 0.024 ab | 0.252 ± 0.018 b |

| 500SBB-CS | 0.315 ± 0.015 a | 0.025 ± 0.014 ab | 0.290 ± 0.028 a |

| 300CMB-CS | 0.259 ± 0.006 bc | 0.019 ± 0.007 ab | 0.240 ± 0.007 bc |

| 500CMB-CS | 0.256 ± 0.003 bc | 0.019 ± 0.003 ab | 0.237 ± 0.001 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, X.; Xiong, S.; Wang, Q.; Yang, M.; Zhang, Q. Chitosan-Modified Biochar for Improving Water Retention in Karst Quarries: A Potential Solution for Soil Remediation. Sustainability 2025, 17, 4815. https://doi.org/10.3390/su17114815

Shu X, Xiong S, Wang Q, Yang M, Zhang Q. Chitosan-Modified Biochar for Improving Water Retention in Karst Quarries: A Potential Solution for Soil Remediation. Sustainability. 2025; 17(11):4815. https://doi.org/10.3390/su17114815

Chicago/Turabian StyleShu, Xiaohua, Shiqing Xiong, Qiulei Wang, Mingyu Yang, and Qian Zhang. 2025. "Chitosan-Modified Biochar for Improving Water Retention in Karst Quarries: A Potential Solution for Soil Remediation" Sustainability 17, no. 11: 4815. https://doi.org/10.3390/su17114815

APA StyleShu, X., Xiong, S., Wang, Q., Yang, M., & Zhang, Q. (2025). Chitosan-Modified Biochar for Improving Water Retention in Karst Quarries: A Potential Solution for Soil Remediation. Sustainability, 17(11), 4815. https://doi.org/10.3390/su17114815