1. Introduction

In recent years, the need for companies to consider the sustainability of their products has increased [

1,

2]. Not only are consumers demanding products with lower environmental impact that are produced under fair market conditions [

3,

4], but also policy makers are increasing the pressure on companies to consider sustainability aspects by passing new laws and regulations, like the European Green Deal [

5]. It aims to reduce the greenhouse gas emissions of the European Union by more than 55% until 2030 compared to 1990 and aims for Europe to become the first climate-neutral continent by 2050 [

5]. To achieve this goal, an important legislative initiative directly influencing product development is the Circular Economy Action Plan of the European Commission [

6]. In order to be able to develop more sustainable products and to meet the increasing reporting obligations, the assessment of the products’ sustainability plays a central role. Life cycle assessments (LCAs) are a commonly used method for sustainability assessment [

7]. Within an LCA, the life cycle inventory (LCI) model plays a central role and is the basis for calculating specific environmental impacts. The LCI is used to model the system’s life cycle, including all needed processes with all their inputs and outputs. To set up an LCI model, a large amount of data across the whole products’ life cycle is needed, which makes it an extremely time-consuming and cost-intensive task [

8,

9]. As a result, LCAs are rarely executed during development but are generally carried out after development has been completed in order to avoid additional costs due to changes that occur [

8]. This is especially problematic, since in early stages of product development, the chances for environmental improvement are high but the needed knowledge of the product design to assess the impact is low [

10]. To be able to systematically develop more sustainable products, a methodology is needed that allows the linkage of product-specific information from development with environmentally relevant data to easily create and maintain product-specific LCAs.

An approach to collect, structure and link product-related data to domain-specific models in a reusable manner during product development is model-based systems engineering (MBSE). In MBSE, a central system model is used, in which the architecture of the product is defined, modeled and linked to the different domain-specific models needed to describe the product’s properties and behavior [

11]. For modeling system models, the systems modeling language (SysML) is established [

11,

12].

MBSE promises to support a more sustainable product development since all relevant product-related data generated during development are available for all stakeholders. This has the potential to tackle the issue of data availability, which is one of the biggest challenges when performing LCA studies. Within the research with respect to MBSE, sustainability is becoming increasingly important, and there are already multiple approaches trying to utilize SysML models for sustainability assessment [

13,

14,

15,

16,

17,

18,

19,

20,

21]. Most of these approaches are only focusing on specific systems like the transportation network of Atlanta, Georgia [

13], or specific life cycle phases like the use phase [

15,

16], and most approaches are only focusing on the calculation of CO

2-equivalents [

13,

14,

15,

16] but do not consider all aspects of an LCIA. The approaches by Lipšinić and Pavković [

19] and Bassam et al. [

20] are considering LCA as a whole. However, both approaches are transferring all aspects of the assessment, from modeling the life cycle, integrating all environmentally relevant parameters, as well as the calculation of the impacts, into the SysML model. This leads to high modeling efforts and inefficient and error-prone calculation, especially for large systems. Another approach by Ghanjaoui et al. [

21] uses SysML to create a model for the sustainability assessment of a production system using live production data by digitally connecting the model with the physical production line. However, their approach is limited to production processes and requires live data since no calculations for production or sustainability data are implemented.

The existing approaches for combining SysML and LCA are either too specific in the scope that they are considering [

13,

14,

15,

16,

21] or the modeling effort is too high [

19,

20]. To allow the consideration of an LCIA and reduce the modeling effort, in this paper, an approach for utilizing SysML models to automatically generate LCI models within LCA tools during product development is developed. For this, the minimum amount of data needed to set up inventory models in LCA tools is identified by analyzing the established exchange formats for LCI models: ILCD [

22] and openLCA schema [

23]. Then, a framework for modeling a product’s life cycle in SysML is developed, and an interface linking a SysML modeling tool (Cameo Systems Modeler [

24]) with an LCA tool (openLCA [

25]) is defined, which allows the automated creation of inventory models in openLCA based on the modeled life cycle within the system model.

The focus of this research is to provide product-specific data from development to automatically create an LCI model within an LCA tool using known processes and specifying the LCI model according to the products’ specification. This contribution provides a proof of concept of the developed approach on the example of an exemplary joining process of metal and plastic using laser-structured metal surfaces.

2. State of Research

In this section, an overview of the most relevant research fields, methodologies and tools for this contribution is provided. First, an introduction to life cycle assessment is provided. After this, MBSE is introduced, focusing on the usage of SysML system models. Finally, the state of research in combining LCAs with MBSE is presented.

2.1. Life Cycle Assessment

LCA is a method, standardized by ISO 14040 and ISO 14044, for assessing the environmental impacts of products and services throughout their entire life cycle [

26,

27]. According to ISO 14040 [

26], an LCA study is structured into the four phases goal and scope definition, inventory analysis, impact assessment and interpretation, which are conducted iteratively.

The goal and scope definition phase of an LCA is very important since it strongly influences the following phases. In this phase, it is defined what purpose the study is conducted for (e.g., comparison of products) and what scope is considered by the study. Based on the set scope, the system boundary for the LCI model set up in the inventory analysis phase is defined. In this phase, also the functional unit is defined, which quantifiably describes the performance of the system under consideration and which is used to enable comparability between two systems if they have the same functional unit. Based on the functional unit, a reference flow is defined, which describes the amount of product needed to deliver the performance set by the functional unit [

26,

28]

Within the inventory analysis phase, the LCI model is created, which collects all material and energy flows (e.g., raw material and ancillary inputs, products and waste, emissions, energy in the form of electricity or fuels, etc.) relevant during the products’ life cycle. The created LCI model is then used to calculate the overall material extractions and emissions related to the product, as well as relating data to single processes within the products’ life cycle [

26,

29].

In the impact assessment phase, potential environmental impacts are evaluated based on the results of the inventory analysis by associating all calculated material extractions and emissions with specific indicators and categories resembling different environmental impacts. A prominent example is the impact global warming potential (GWP), which summarizes the impacts of all greenhouse gases within a single characteristic described by CO

2-equivalents. To calculate impacts such as the GWP, different methods exist. Two exemplary and widespread examples for such life cycle impact assessment (LCIA) methods are IMPACT World+ [

30] and ReCiPe2016 [

26,

31].

During the interpretation phase, the results of the inventory analysis and the impact assessment are used to draw conclusions and formulate recommendations in the context of the defined goals and scope of the study [

26].

Since this paper focuses on the collection and provision of product- and life cycle-specific data for performing LCA studies, the LCI model created in the inventory analysis phase is introduced in more detail. For detailed information on the other phases, please refer to ISO 14040 [

26].

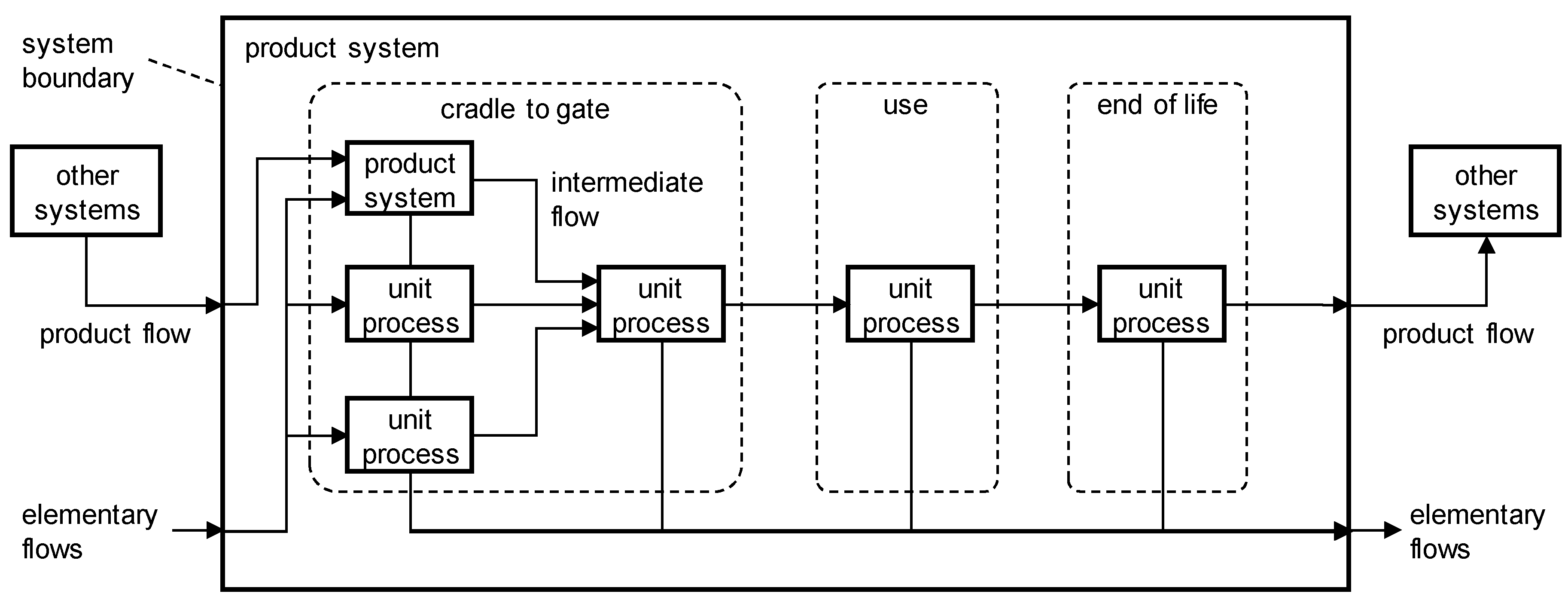

In

Figure 1, a schematic example of an LCI model according to ISO 14040 [

26] is provided. There are three main elements relevant for modeling an LCI, the

product system,

unit processes and

flows. A

product system describes the life cycle of a product. It is characterized by its system boundary and the input and output flows. To model the life cycle within the

product system, a set of

unit processes or other

product systems is used. A

unit process describes a single process within the inventory model, which is not decomposed any further. The

unit processes and

product systems are linked by different

material and

energy flows. On a top level, the used flows can be divided into three different types.

Product flows describe all flows entering from or leaving to another

unit process or

product system.

Intermediate flows are all flows linking

unit processes with each other (e.g., lubricant, cooling medium, etc.).

Elementary flows are all flows that are crossing the

system boundary and that are not used in other

unit processes or

product systems. As input for the LCI model, the

elementary flows describe all material extractions from the environment (e.g., crude oil, groundwater, etc.), and as output, they describe all emissions into the environment (e.g., emissions to air, discharges to water, disposal to landfill, etc.). The sum of all

elementary flows is used in the impact assessment phase to calculate environmental impacts like GWP.

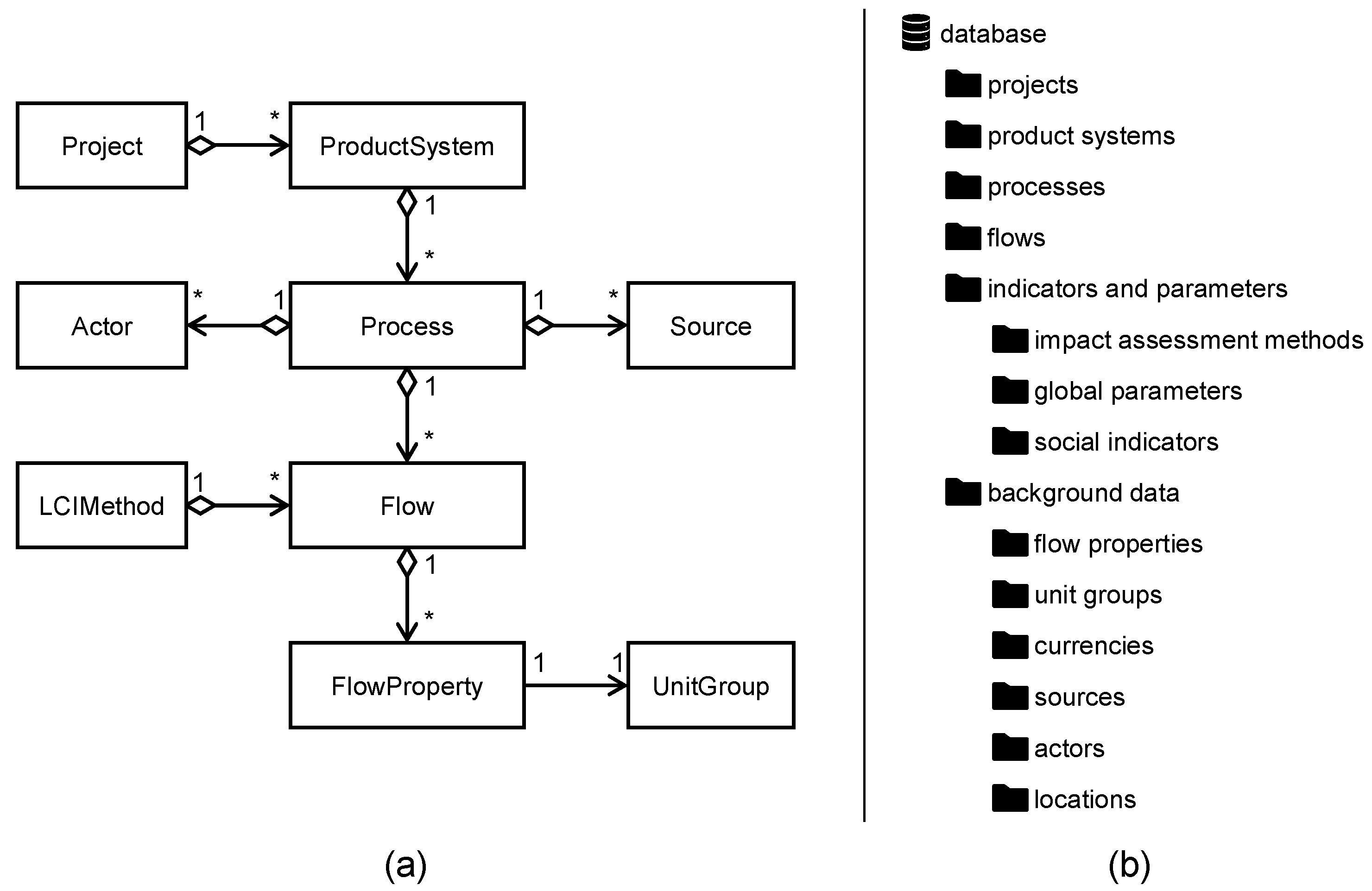

To further understand the data-need for setting up LCI models, the data structure of LCA tools is introduced in this section using openLCA as an example. The modeling elements of LCI models relevant for this work are product systems, processes, flows and impact assessment methods. Product systems refer to the product systems of ISO 14040 and contain sets of multiple interconnected processes, which are linked by flows. Processes refer to the unit processes of ISO 14040 and are used to describe all activities within the products’ life cycle that transform inputs into outputs. Flows contain all material and energy flows that are input and/or output of any process or product system. Impact assessment methods contain the different impact assessment methods, including all relevant information, like the algorithms for quantifying and assessing the product’s environmental impact.

Most LCA Tools utilize databases as their modeling core. Within such a database, the above-described elements are stored and organized. In

Figure 2, the data model [

32], as well as the structure of the database of openLCA, is shown [

33].

To be able to import and export data or exchange data between LCA models, different standardized exchange formats are available. Two examples for these LCA exchange formats are ILCD [

22] and openLCA schema [

23]. ILCD is a standardized exchange format for LCA databases developed, maintained and promoted by the European Commission. It contains a ZIP file containing folders for all elements of the database (e.g.,

product systems,

unit processes,

flows, etc.). Within these folders, for every element of this type, a single XML file is stored, defining this element. The openLCA schema is structured quite similar to ILCD and adopts many of its concepts. The main differences are that the single files for the different elements are JSON files instead of XML files and that the format is extended to support all modeling features of openLCA. In both exchange formats, every file is named by its elements’ individual UUID (Universally Unique Identifier). UUIDs are assumed to be unique due to the probability of generating duplicates being very close to zero [

34]. Therefore, there is no need for a central registration. In both exchange formats, UUIDs are used to identify every element within the database and to refer to each other.

Even though LCAs are standardized and established, there are multiple challenges to face when conducting an LCA. One of the biggest problems is the availability and quality of data needed for a study [

9,

35]. To support users in setting up LCI models, databases are available that provide datasets containing processes, including their input and output flows. Prominent examples for databases are the Managed LCA Content database from sphera [

36] and ecoinvent [

37]. However, there are many other databases available; many of them focus on specific fields of industry, like construction, chemistry or agriculture. The openLCA nexus provides an overview of many different databases available [

38].

Although the databases available contain datasets for many products and processes, there are still many processes that cannot be found in databases. Another issue is that available datasets oftentimes do not represent the specific process within a company. This can be due to an either too specific or a too general representation of the process. Therefore, to set up LCI models that represent real products and processes within a company, the product-related data need to be collected in a digitalized and formalized manner and then be linked with the LCA data within an LCI model. However, this is not yet done systematically. MBSE is a promising approach to tackle this challenge. In MBSE, all data regarding the system under development are stored in a digitalized and formalized manner. Therefore, this data can be used in other domain-specific models, which allows a high level of data consistency.

2.2. Model-Based Systems Engineering

For the development of complex technical systems, MBSE offers a structured methodology supporting the analysis, design, specification and verification of a system [

39,

40]. In many MBSE approaches, a central system model is used, which allows the modeling of the systems’ architecture, structure and behavior, as well as the linkage of models and simulations of all involved disciplines [

11,

39,

40]. In the system model, engineering information, system properties and technical relationships are captured in a digital manner instead of document-centric, improving data consistency and availability.

For modeling MBSE system models, an often used language is SysML, a graphical modeling language developed by the Object Modeling Group [

11,

12,

39]. In this paper, SysML v1 [

12] is used since SysML v2 is not yet finalized [

41] and tool support is limited. SysML v1 is an extension of a subset of the Unified Modeling Language with the goal to address the specific needs of systems engineering [

11]. Additionally, to a modeling language like SysML, which defines the model elements and their linkage, a modeling method is needed, which guides the engineers in the process of creating a system model [

11].

The method this work is based on is Motego [

42]. Motego is a function-oriented modeling method developed by Jacobs et al. [

43] that aims at improving the practicality of MBSE in developing technical systems. The Motego method structures the development process into the four pillars requirements, functions, solutions and product according to the RFLP approach [

43,

44]. Based on requirements, functions are derived, which are realized by solutions [

45]. Within the solutions, first geometric properties are defined, which create the link to the product pillar. To be able to simulate the system behavior and validate the system design, Motego allows the structured integration and linkage of domain-specific models [

46].

Additionally, to the modeling method, Motego offers its own SysML profile, supporting the engineer in the modeling process. The profile introduces new stereotypes for different development artifacts along all four pillars of RFLP. For this paper, especially the stereotypes StructureElement and Module are important. A StructureElement represents a single physical component within a system, while a Module represents an assembly.

Currently, Motego, as well as other MBSE modeling languages, primarily focuses on system specification and design during the product development phase rather than modeling a product’s life cycle. Motego’s SysML profile therefore predominantly includes artifacts and elements related to product development and will need to be extended to be more encompassing of the entire product life cycle, thereby providing a more holistic framework for comprehensive life cycle assessment.

In the following, relevant SysML elements used in this work are briefly described, according to [

11]:

block: Basic element for structuring SysML models. It can be used to model any type of entity within a system.

constraint block: Element to perform calculations.

full port: Part property of a block, serving as an interface to other blocks. A full port is typed by a block and can therefore have a structure and behavior in itself.

proxy port: Element representing an interface between blocks without its own structure and behavior. A proxy port only allows the transfer of information.

generalization: Relationship between two elements, allowing the inheritance of properties from one element (supertype) to another (subtype).

block definition diagram: Diagram used to model the systems’ structure and relations.

internal block diagram: Diagram to model the internal structure of a single block.

parametric diagram: Diagram used to model constraints and connect the constraints with other model elements (e.g., other constraints, value properties, etc.).

2.3. Sustainability Assessment in Model-Based Systems Engineering

There are multiple approaches utilizing MBSE for sustainability assessment [

13,

14,

15,

16,

18,

19,

20]. Azevedo et al. [

13] present an approach for modeling the sustainability of complex systems with the example of the transport system of Atlanta, Georgia. In the approach, a SysML model is used as the central model defining the system boundary and the hierarchical structure of the system. Then, for each vehicle type and the total traveling distance for each vehicle, a model element is created, calculating the CO

2 emissions. Due to computational reasons, the calculation of the overall CO

2 emissions is outsourced to an external tool like MATLAB, Mathematica or Excel. This approach does not consider an integration of LCA since it only focuses on CO

2 emissions based on fuel consumption. All calculations are defined within the SysML model, which leads to high modeling effort. There is also no relation to product development.

Another approach is presented by Bougain and Gerhard [

14] for integrating the calculation of the greenhouse gas potential, as well as the cumulative energy demand, over the products’ life cycle. The approach considers a very simplified modeling of the life cycle. For every part and every relevant life cycle phase of the part, two value properties are added within the block of the part representing the CO

2 emissions and the energy consumption. It is claimed that the values for these parameters can be extracted by external tools or databases, like the enterprise resource planning system, however it is not shown how this linkage can be achieved. This approach is more related to product development, starting from defining environment-related requirements and modeling use scenarios using behavior diagrams. The whole products’ life cycle is considered; however, LCAs are not considered, and the calculation is limited to CO

2-equivalents and the cumulated energy demand.

A similar approach is presented by Eigner et al. [

15,

16], with the focus on the use phase in the example of an excavator, by modeling different use scenarios like idling, traveling and lifting in the form of activities including parameters for their specific fuel consumption, usage time and emissions. Depending on an overall use scenario, the overall fuel consumption, and therefore the overall CO

2 emissions, is calculated. Due to the focus on calculating the CO

2 emissions based on fuel consumption, the consideration of environmental impacts is very simplified.

Dammann et al. [

18] present an approach for a sustainability-oriented development process using SysML. The created process model represents a stage gate process, where each stage is represented by a block. A central element of this approach is the so-called

document, containing the needed and generated information and data in the process.

Documents are represented by predefined blocks. They can be standards, CAD-Models, simulation or LCA-reports. For each stage in the process, the needed or generated

documents are linked to the process via proxy ports. This approach is primarily focusing on the modeling of the development process as a stage gate process. Since the process is modeled in SysML, therefore the process model is machine-readable; linkage to a system model, as well as other models like LCAs, is theoretically possible but not described.

Lipšinić and Pavković [

19] present an approach for modeling and executing LCAs within a SysML system model. To do so, they define an LCA general object library in SysML, defining the relevant elements needed for an LCA. Additionally, they model the four phases of LCA as activities and link these activities to the defined packages and their blocks. For modeling the inventory model, first all processes are modeled as activity diagrams, and for each activity, a block is allocated containing all needed LCA-related information. This information has to be inserted either manually or can be calculated by parametric diagrams. The inventory model itself is then modeled using parametric diagrams. To reduce the modeling effort, some elements, like the constraints needed in the parametric diagrams, can be imported from the LCA general object library. However, the overall modeling effort of this approach is much higher than the modeling effort in established LCA tools, since not only the life cycle itself has to be modeled, including the processes and their flows, but the calculations for determining the environmental impacts have to be modeled as well via parametric diagrams. In LCA tools, this calculation is performed automatically. Additionally, the computing capabilities of system modeling tools like the cameo systems modeler are limited, which makes it very error-prone and inefficient to perform large calculations within these tools.

Bassam et al. [

20] present another approach for the integration of LCA into MBSE. Similar to Lipšinić and Pavković [

19], Bassam et al. [

20] have modeled the life cycle inventory within a SysML model and calculate the overall CO

2 emissions within this model. However, the modeling approach has significant differences. Within a block definition diagram, a so-called context analysis is modeled for each phase of the life cycle, showing the relations of all involved entities, like actors, the environment and facilities. The specific material and energy flows within a life cycle phase are modeled within an internal block diagram of the block representing this life cycle phase. Each process within the modeled phase is represented by a block, and the flows in-between the processes are modeled by connecting the corresponding blocks with each other. Within the blocks, the inputs and outputs are quantified using value properties. The data needed to perform the LCI calculation (e.g., the CO

2 emissions of the process) are collected from secondary databases and inserted manually into the model. The environmental impact of a process and a life cycle phase is calculated within a parametric diagram. Additionally, on the inventory model, a traceability scheme is modeled, which allows tracing each component along the life cycle back to a single requirement. This allows an identification of components, processes, machines, etc. with potential for improvement. Since all environmental-related data need to be gathered externally and integrated manually into the model, and the parametric diagrams needed for the calculation of the overall environmental impact need to be modeled specifically for the considered product, the modeling effort is very high, and the reusability is limited. Additionally, the calculation of the environmental impacts of large LCI models within SysML modeling tools is error-prone and inefficient.

Ghanjaoui et al. [

21] present an approach for evaluating the sustainability of production systems with SysML using the example of a pre-assembly station used in aircraft production. In their approach, they first perform a context analysis to identify all elements associated with it. For each identified element, additional sustainability attributes are defined, like the sustainability type, impact type, impact and indicator. Then, a scope analysis is performed by modeling the functional use cases. For each identified use case, a representation of a unit process is modeled within an internal block diagram. The SysML model of the production process is digitally linked to the physical production line, allowing the integration of real production data like energy consumption, temperatures, noise emissions and so on. These data are used to validate the sustainability targets of the production process. The presented approach is limited to the production phase and requires an integration of live production data, since no calculations of required process data are included. Another shortcoming is that no established LCI methods are used for the impact assessment. Instead, the impact categories and related indicators are defined by the authors themselves.

3. Research Need

As the state of the research shows, there are multiple approaches integrating sustainability into MBSE. Most of the approaches are focused on specific aspects of sustainability, like a specific subject of assessment or a specific life cycle phase. Only two approaches consider a complete LCA [

19,

20]. All presented approaches have in common that they integrate all data needed for the assessment into the SysML model and that the calculation of the environmental impacts is performed within the SysML model, as well. This leads to high modeling effort due to a missing interface for integrating the data needed and because the parametric diagrams needed for the calculation must be specifically modeled for each system that is developed. Another problem with integrating the calculation into the SysML model is that the available modeling tools are not designed for large, complex calculations, which leads to inefficiency and a high susceptibility to errors.

To counter the above-mentioned disadvantages, an approach that can utilize the benefits of SysML system models, as well as the established LCA tools, is needed. Therefore, the authors suggest an approach in which the system model is used as the data provider for product-specific data related to the products’ life cycle, and to use this data to set up a product-specific LCI model within an LCA tool. A similar research need is derived by Inkermann [

17], who suggest developing an LCA-specific SysML profile and to integrate needed LCA data as preparation for executing an LCA. Also Bassam et al. [

20] state that it is advisable to use “a SysML profile tailored for LCA and build an interface between the SysML and LCA tool [

20]”. In order to do so, three research questions are identified.

What is the minimum information needed to automatically set up an LCI model within an LCA tool?

How can the Motego method and profile be extended to integrate this information?

How can the linkage between the SysML model and an LCA tool be realized?

4. Methodology

The goal of this research is to develop a SysML modeling framework that allows the integration of all information needed to set up LCI models within LCA tools and to implement an interface between the SysML model and the LCA tool to automatically set up the LCI model, execute an inventory analysis and return the results back into the SysML model.

To achieve the stated goal and answer the research questions, three major tasks are performed and presented in this section. In

Section 4.1, existing LCA exchange formats are analyzed to identify the minimum information needed for setting up an LCI model. Then, it is compared which of the identified data are already contained in Motego and for which data an extension of the modeling methodology is required. Based on the findings, in

Section 4.2, an LCA-specific SysML profile is implemented, which extends the Motego method and contains all information required to set up LCI models. In

Section 4.3, an interface between the cameo systems modeler and openLCA is developed, which allows the extraction of LCA-specific data from the SysML model and automatically creates a corresponding LCI model in openLCA. This model is then executed in openLCA, and the results are returned to the system model.

In this paper, the basic functionality of the developed approach for linking SysML models with LCA tools is shown. The focus is on the development of a methodology for modeling a SysML LCI model and linking it with openLCA. It is assumed that all required

unit processes are already contained within the openLCA database. The authors are aware that the lack of datasets for certain products and processes is a big problem in conducting LCAs; however, it is explicitly not part of this research to create new datasets for missing processes. In case new datasets are needed to model the life cycle of a product, these datasets first must be created, for example, manually by appropriate experts. In

Section 7, it is also discussed how the developed approach might be used in the future to generate new product-specific datasets.

4.1. Identification of the Minimum Information Needed to Set Up LCI Models

Since the modeling effort within the SysML model shall be minimized, only the minimum data necessary for setting up an LCI model shall be integrated into the SysML model. To identify this minimum data-need, the authors differentiate between two types of data needed for LCAs. On the one hand, there are data related to the product and its life cycle. This includes the materials within the product and the processes within the life cycle (e.g., the production processes, processes describing the use or the end of life). Regarding the LCI model, these data are represented by the product system and its internal structure containing the unit processes, as well as the product and intermediate flows. On the other hand, environment-related data are needed. This includes all data describing the material extractions and emissions of a single process, which are used to calculate the environmental impacts of this process. Regarding the LCI model, these data are represented by the elementary flows within unit processes. Due to the assumption that all required unit processes are contained within the openLCA database, only the product system and its internal structure defining the contained unit processes, product and intermediate flows need to be transferred to the LCA model.

With this assumption in mind, a generic product system is modeled in openLCA, containing generic unit processes. The unit processes are linked via generic flows. Since it is assumed that the unit processes are already defined within the database, only the product and intermediate flows need to be considered, and the elementary flows can be neglected.

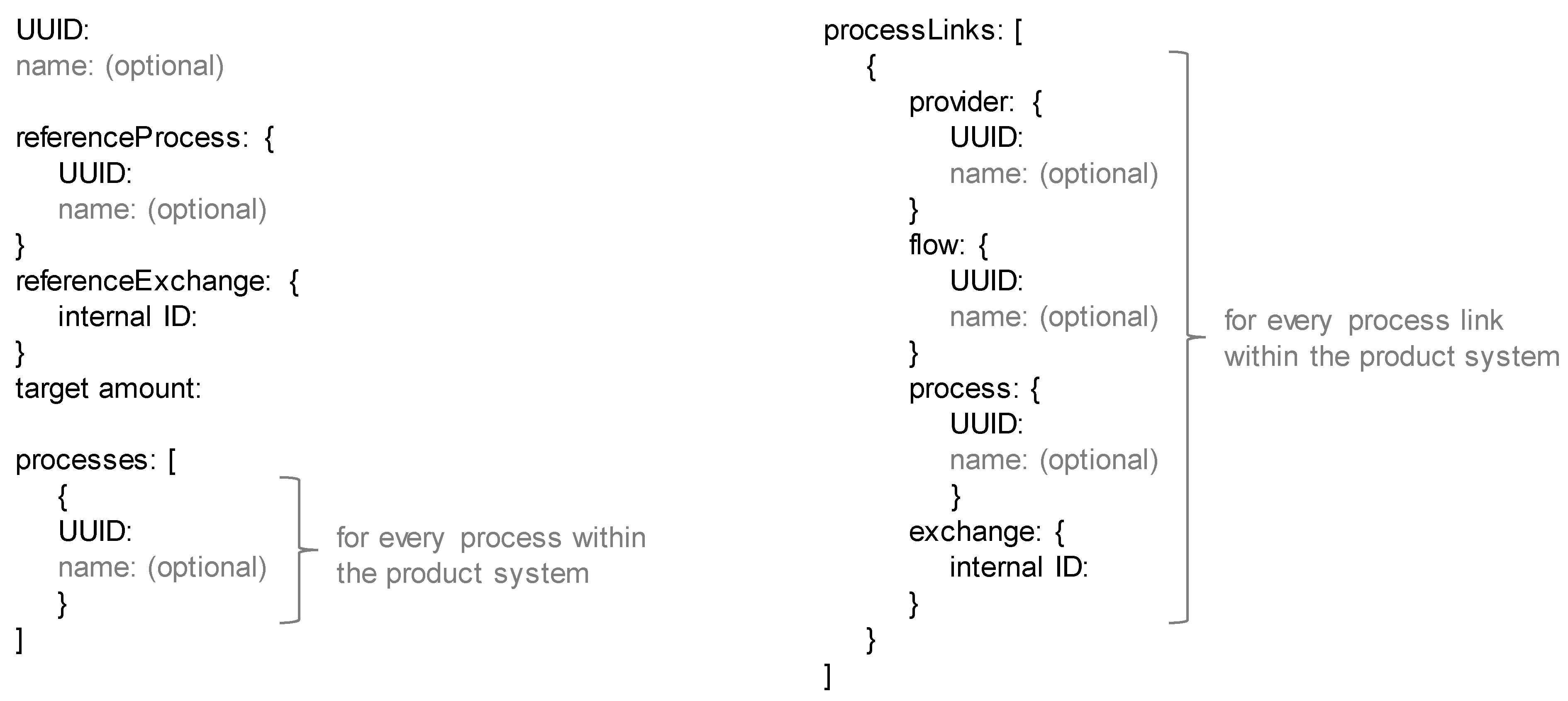

To identify the minimum data needed to set up an LCI model, the generic product system is exported from openLCA into the exchange formats openLCA schema and ILCD. Then, both exchange files are manipulated by deleting information from the file and reimporting it to openLCA. This procedure is repeated iteratively until the minimum information content within the files is identified, which still rebuilds the same generic product system in openLCA. The identified information contains the

UUID and the

name of the product system, the

reference process and the

reference exchange with its

target amount, all

processes within the product system, as well as all

process links between the different processes. The

reference process, as well as the other

processes, are defined by their

UUID. The

reference exchange is defined by its internal ID, which is an internal parameter within a

product system or

unit process that identifies all inputs and outputs of this element. To define the

process links, the

flow, as well as the

provider process and the receiving

process, are defined by their

UUID. For the

process, receiving the

flow the

exchange is defined by the

internal ID of its input. In

Figure 3, a simplified structure of a JSON file of a product system, containing the identified minimum information, is shown.

4.2. Extension of the Modeling Methodology and SysML Profile

To answer the second research question, the identified information needs to be integrated into a SysML system model. It is proposed to define a modeling framework for a product life cycle within SysML that inherits all the identified information and that can be integrated into existing system models and linked to the other relevant elements of the system model. There are two major aspects that this life cycle model must address. Firstly, the structure of the LCI model must be defined containing all processes and the flows between them. Secondly, the defined processes and flows must be quantified. This is accomplished by linking the elements of the life cycle model with elements of the existing system model of the product.

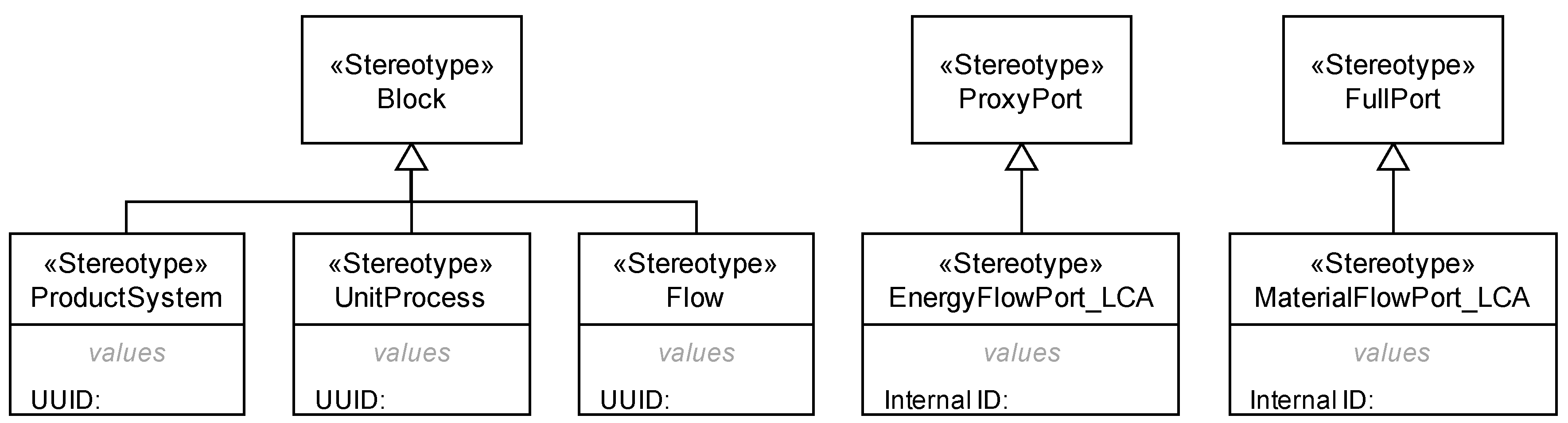

The concept of the life cycle model is based on the modeling of functional architectures in Motego, since it already allows a modeling of material, energy and signal flows [

43]. To allow a distinction between the function model and the life cycle model, and to allow an automated identification of the relevant model elements, a SysML LCA-profile with its own stereotypes is created. New defined stereotypes are the

ProductSystem,

UnitProcess and

Flow, as generalizations of the SysML block. Within the function model of Motego, for each flow type, a specific port is defined as a generalization of the SysML proxy port. Since there are no signal flows within the life cycle model, no specific port stereotype is defined. For the energy flows, the

EnergyFlowPort_LCA as a generalization of the SysML proxy port is defined, allowing the usage of the same energy flows used within the function model. Since the material flows within the life cycle model represent not only general materials but also specific products, proxy ports are not sufficient. Therefore, the

MaterialFlowPort_LCA as generalization of the SysML full port is introduced, allowing the port to be typed by

StructureElements or

Modules.

Figure 4 shows the defined stereotypes and their relation to the original SysML stereotypes.

The created SysML_LCA profile allows the modeling of a life cycle within a system model. Within the internal block diagram of a

ProductSystem, the life cycle, or just a life cycle phase, can be modeled by inserting all needed

ProductSystems and

UnitProcesses. The material and energy flows can be modeled by linking the corresponding ports using connectors. In

Figure 5, a generic product system is shown, modeled in SysML using the developed SysML-LCA profile.

A ProductSystem modeled this way provides all structural information and all parameters needed for setting up the inventory models within an LCA tool. To be able to refer to the elements of the SysML model with the elements of the LCA database, the SysML elements ProductSystem, UnitProcess and Flow contain a value property with the respective UUID of the referred element within the LCA database. Each MaterialFlowPort_LCA and EnergyFlowPort_LCA contains a value property with their respective internal ID within the unit process or product system. Now the SysML life cycle model contains all information identified in the analysis of the exchange formats ILCD and openLCA schema.

4.3. Linkage Between the SysML Model and the LCA Tool

To answer the third research question and automatically generate an LCI model in openLCA based on the SysML life cycle model from the cameo systems modeler, an interface is needed, which allows the transfer of all relevant information. For this, a plugin for the cameo systems modeler is programmed, using the provided API. The basic functionality of the interface can be summarized in four steps:

System identification and Data location;

Data collection and extraction;

External Processing and Communication with openLCA;

Calculation Results Integration.

System identification and Data location: The interface is configured to export all information belonging to a single product system. As a result, upon initiating the interface from a product, it locates the relevant product system through the previously described stereotype known as ProductSystem. Once the specific product system is located, essential details about the system itself, its internal processes, their links and the nature of flows between these processes are gathered. For each element, their UUIDs and parameters are identified.

Data collection and extraction: For each element identified by the plugin, a JSON file is created, which is named by the element’s UUID. Within the JSON file, all relevant information of this process is stored according to the structure defined by the openLCA schema, and then the created JSON files are zipped into one ZIP file. Since the data crucial for establishing life cycle inventory models remain largely consistent across various LCA tools, specific file structures for other tools can be effortlessly derived by simply reconfiguring the analyzed data. This can be accomplished without altering the process of analyzing the SysML model itself.

External Processing and Communication with openLCA: Once all relevant information is extracted from the SysML model and saved in an openLCA schema ZIP file, subsequent steps external to the Cameo Systems Modeler environment are executed. To access openLCA externally, the Python package olca-ipc offers inter-process communication (IPC) with openLCA, enabling the invocation of openLCA functions and subsequent processing of their outcomes using Python. For this publication openLCA 2.0 and Python 3.11 are used.

The setup of the LCI model and its computation involves a Python script. Initially, this script retrieves essential information from the JSON files generated in the prior step and reconstructs the product system accordingly within openLCA. Configuration parameters for the calculation (e.g., selection of an LCIA method), specified via a graphical user interface in Cameo Systems Modeler, are employed to configure the calculation process.

The outcomes of the calculation conducted in openLCA are extracted and then re-saved into another JSON file, which acts as a means of communication between openLCA and the Cameo Systems Modeler.

Calculation Results Integration: In a last step, the JSON file containing the LCIA results is processed, so that the calculation results for the CO2-equivalent are stored within the respective value property of the StructureElement within the SysML model.

In conclusion, the minimum data needed for creating LCI models in an LCA tool were identified by analyzing standardized exchange formats for LCAs. To be able to integrate the identified data into a SysML system model, an LCA-specific SysML profile was created, allowing the modeling of the products’ life cycle in SysML. To automatically execute an impact assessment within openLCA based on the LCI model modeled in SysML, a plugin for the cameo systems modeler was developed. This plugin allows the extraction of the before-identified data and creates a new database entry of the product system in openLCA, where an impact assessment is triggered. The results are then transferred back into the SysML model.

For validating the functionality of the developed approach, the tools cameo systems modeler and openLCA are used, since they are both established tools. The modeling approach can also be applied using other tools, since SysML is a standardized modeling Language, and for identifying the data needed to automatically create LCI models, the openLCA schema, as well as the tool-independent ILCD format, is used. However, the interface, of course, is tool-dependent and must be programmed again if a different tool combination is used. To show the applicability of the developed approach, in the following section, it is applied to a use case.

5. Case Study

As an example to show the applicability of the developed approach, a laser-based plastic–metal hybrid joining is presented. The technology for producing such metal–plastic joints, including relevant process and material data, is known to the authors from a finalized research project [

47,

48]. First, the use case of a laser-based plastic–metal hybrid joining is described. Then, an LCI model for the case is modeled within openLCA as a reference. In the next step, an equivalent model is modeled in SysML using the before-developed modeling framework. Finally, the developed plugin is used to show that the automatically created openLCA model is identical to the manually modeled model and that the developed approach is suitable to perform impact assessments based on the SysML-LCA model.

In laser-based metal–plastic hybrid joints, the surface of the metal part is micro-structured by a laser, and the plastic part is directly molded onto the metal part, creating a form fit between both parts. For further details on the technology, see [

47,

49,

50]. In

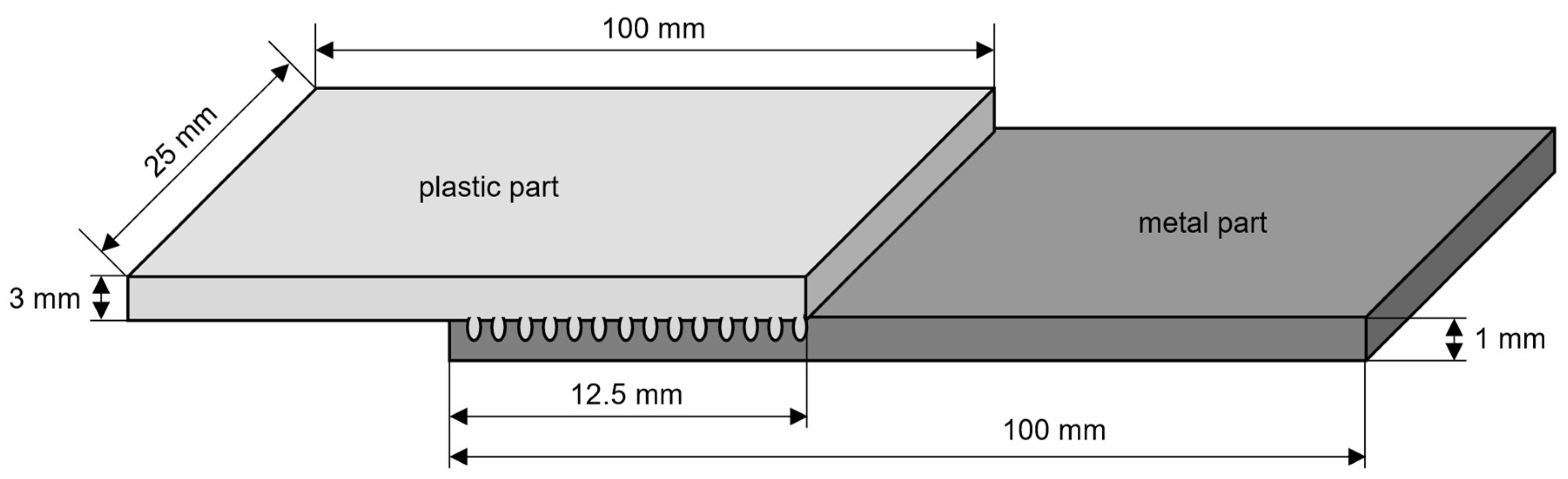

Figure 6, the use case example and its dimensions are shown.

To provide a proof of concept of the developed approach presented in

Section 4, the cradle-to-gate phase of the metal part is presented in more detail. It contains four unit processes and one production model calculating the electrical energy for laser structuring the metal part, based on the specific product parameters, and thereby offers all aspects relevant to be considered to validate the functionality of the developed approach. The other life cycle phases are not considered since the use phase of the joining has no impact itself, and for considering the end of life, no sufficient data are available regarding the recycling of this joining since it is a technology still under development. However, the limitation to the cradle-to-gate phase has no implication for the validation of the developed approach since all life cycle phases are modeled using the same elements and modeling guidelines [

26].

In

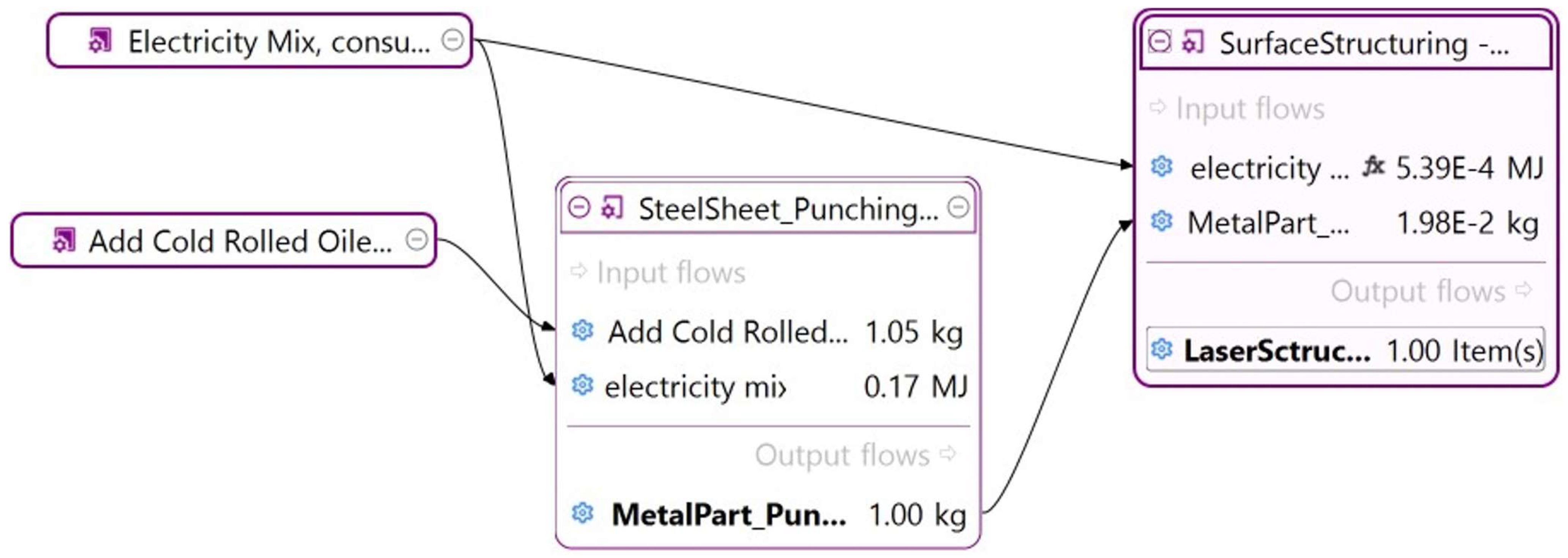

Figure 7, the product system of the laser-structured metal part, containing its cradle-to-gate life cycle, is shown. The model contains four unit processes. The unit process

SurfaceStructuring is selected as the reference process with the reference flow

LaserStructuredMetalPart. An upstream unit process is

SteelSheet_Punching&Bending, which represents the production of the unstructured metal part. Both unit processes are created by the authors since no appropriate unit processes from databases were accessible to the authors. The two remaining unit processes are the process

Add Cold Rolled Oiled Steel Structural Sections 98%PCR—AU from the OzLCI2019 database, for providing the raw material, and the process

Electricity Mix,

consumption mix,

at consumer,

AC, 1 kV–60 kV from the ELCD database 2.0, for providing the needed electrical energy. These processes can be downloaded via the openLCA nexus [

38]. The dimensions of the metal part are shown in

Figure 6 and the result in a weight of 0.0198 kg. The electricity consumption of the structuring processes is independent of the parts’ weight and calculated based on design parameters of the structured surface and process parameters. For the modeled cradle-to-gate life cycle, an LCIA is conducted using the ReCiPe 2016 Midpint (E) method [

31], resulting in a GWP of 0.04750 kg CO

2-equivalent.

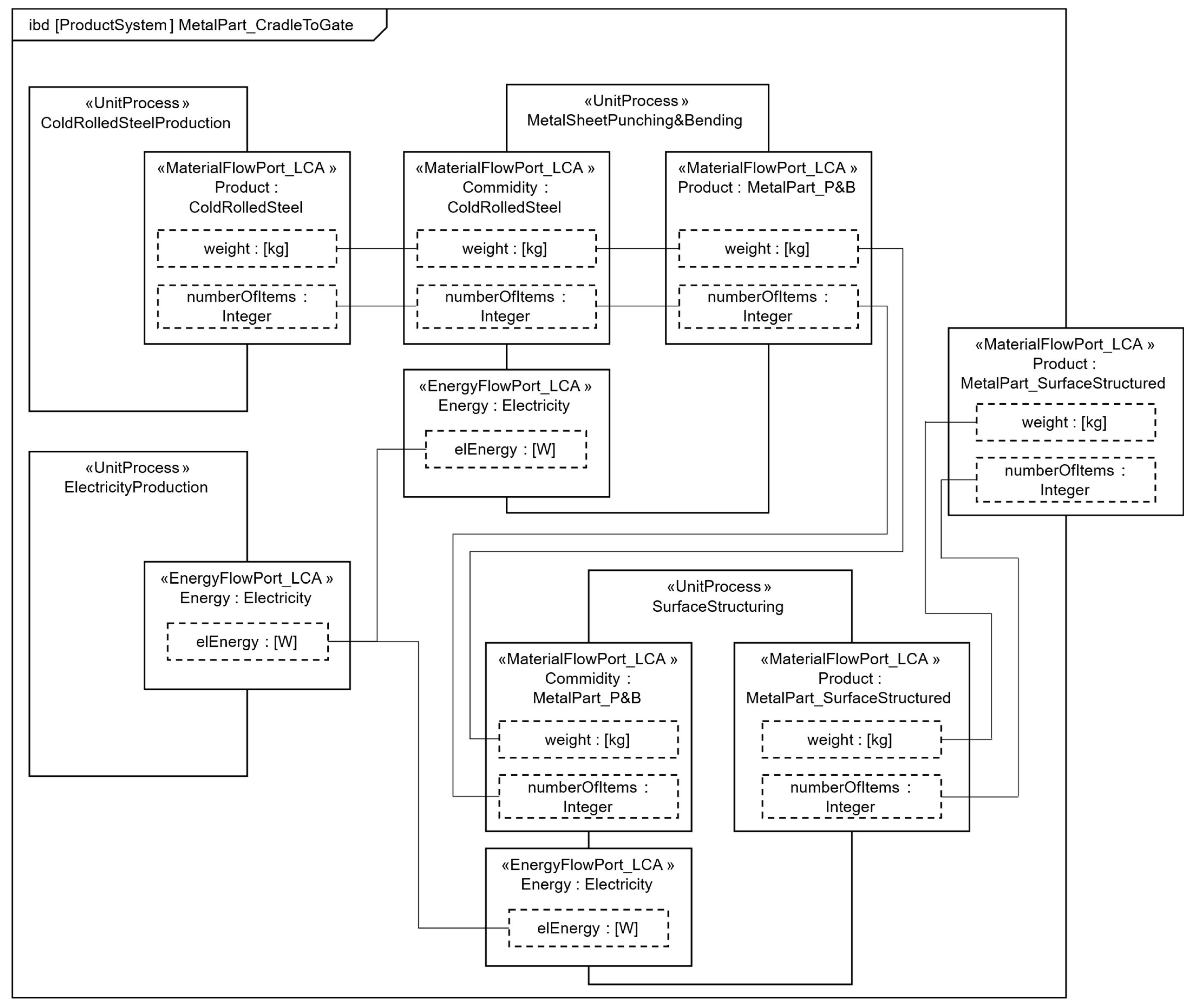

Based on the modeling approach developed in

Section 3, an equivalent LCI model was modeled in SysML, shown in

Figure 8. For modeling the cradle-to gate life cycle phase of the metal part, the

ProductSystem element is used. Within the internal block diagram of this

ProductSystem, the LCI model can be modeled in a similar manner as it was accomplished before in the openLCA model. For each process, a

UnitProcess element is inserted. To link the process and model, the material and energy flows for each input and output of each

UnitProcess must have a corresponding port be modeled. Within these ports, the parameters describing the flow, like the mass, number of items or amount of energy, are modeled as flow properties of the port. The flow properties are then directly linked using connectors.

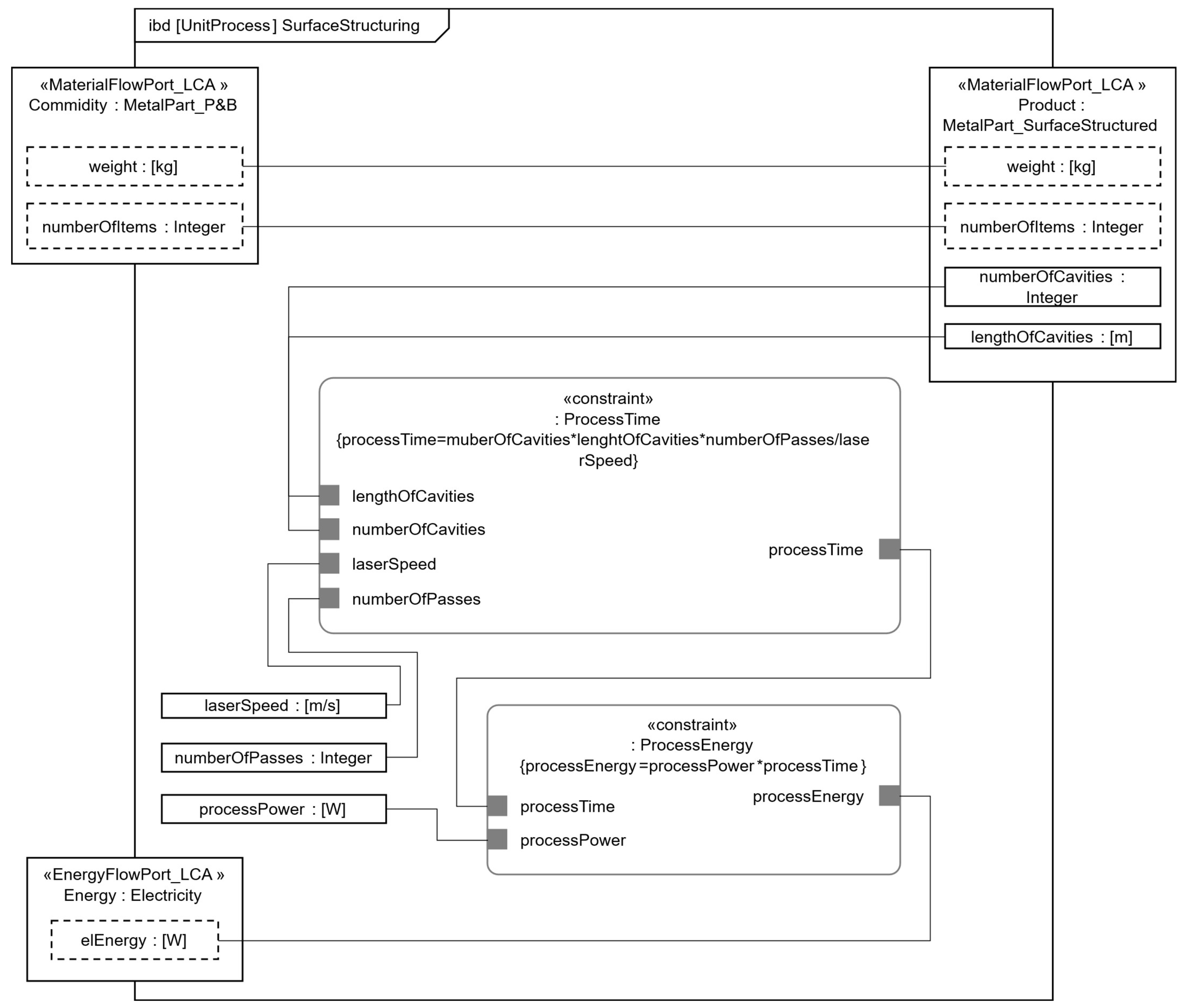

This model contains the whole structure of the LCI model. In a next step, the elements, which need further specification, have to be detailed. The unit processes ColdRolledSteelProduction, ElectricityProduction and MetalSheetPunching&Bending do not need any further specification since they are fully defined within the database of openLCA. The UnitProcess SurfaceStructuring needs further specification, since the energy consumption of this process does not depend on the weight of the metal part but is solely dependent on the specification of the structured surface.

The structuring energy is the product of the laser power and the process time. The process time, on the other hand, depends on the number and length of cavities, the number of times the laser passes over each cavity and the laser speed. The parameters

laserPpower,

numberOfPasses and

laserSpeed are parameters of the machine or process and are modeled as value properties of the unit process surface structuring. The parameters

numberOfCavities and

lengthOfCavities are parameters of the surface of the metal part and are therefore contained within the

StructureElement MetalPart_SurfaceStructured. To enable the linkage of the life cycle model to the product, the types of the

MaterialFlowPort_LCA of the

UnitProcess SurfaceStructuring and

ProductSystem MetalPart_CradleToGate are assigned to the

StructureElement MetalPart_SurfaceStructured. This way, they inherit all relevant properties of the

StructureElement MetalPart_SurfaceStructured, which can then be used within the life cycle model to define all needed flow properties. In

Figure 9, the internal block diagram of the

UnitProcess SurfacStructuring is depicted. For calculating the process time and process energy, two constraints are added. The two value properties

numberOfCavities and

lengthOfCavities can be linked via the

Product port, since it is typed by the

StructureElement MetalPart_SurfaceStructured.

The created life cycle model of the laser-structured metal part within the SysML system model contains all information needed to set up the LCI model in openLCA. Using the programmed plugin for cameo systems modeler, the modeled ProductSystem of the cradle-to-gate life cycle phase of the surface structured metal part is automatically created within openLCA, an impact assessment is performed (using the ReCiPe 2016 Midpoint (E) method), and the results of the assessment (e.g., the CO2-eqivalent) are returned back into the system model and written into the corresponding value properties of the StructureElement of the laser-structured metal part.

The LCI model automatically generated in openLCA based on the life cycle model created within the SysML model is identical to the initially manually modeled openLCA model. Since both the automatically generated model and the manually created model are identical, containing the same unit processes, the results of both assessments are identical, as well, resulting both in a GWP of 0.04750 kg CO2-equivalent.

6. Discussion

The goal of this research was to provide a proof of concept for the presented approach of utilizing a SysML system model for automatically creating an LCI model within an LCA tool to allow the execution of product-specific LCIAs already during product development. As a case, the manufacturing of a laser-structured metal part used for a metal plastic joining was considered. By comparing the LCIA results of the automatically generated LCI model with the manually created LCI model of the metal part, it could be shown that both results are identical (GWP of 0.04750 CO

2-equivalent). Therefore, the goal is reached, and the presented approach is working. Compared to other existing approaches combining SysML system models and sustainability assessment [

13,

14,

15,

16], the methodology supports the consideration of all environmental impacts and is not just limited to the GWP; since an LCA tool is used to perform the LCIA, established LCIA methods can be used to calculate any impact supported by the LCIA method. Compared to the existing methods using a SysML model to perform an LCA within the SysML model [

19,

20], the modeling effort of the presented approach is reduced, since the calculation of the environmental impacts takes place in the LCA tool, and thus, no effort is required for modeling the calculation in SysML.

The presented approach can help to provide product-specific data for creating product-specific inventory models and to assess the products’ sustainability already during product development. Once the inventory model is created in SysML, an LCIA can directly be executed from within the system model without any further user interaction, allowing for a calculation of differently parameterized product variants or the quick validation of changes made to design parameters of the product. Another benefit of the presented approach is the possibility to integrate production models, allowing the calculation of product-specific material and energy flows, which has the potential to contribute to a higher data quality for the performed LCA.

Despite these benefits, there are still some shortcomings in the presented approach. The modeling of the LCI model is shifted from the LCA tool to SysML, and the interface is programmed in a way that there needs to be no manual work performed within the LCA tool. However, the initial modeling effort for creating an inventory model within SysML compared to the direct modeling within an LCA tool is higher, since all needed processes and flows must be modeled in SysML, and linking of all model elements requires more steps. But the potential for reducing this modeling effort is high, since the plugin can probably be extended to also import processes and flows from the LCA tools’ database into the SysML model. This might help, as well, to keep data synchronized between the SysML model and the LCA tool. Also, SysML is suitable for creating reusable model elements, which can be especially beneficial for similar products with different specifications, like standardized machine elements, electric motors, gearboxes, etc., for which predefined life cycle models could be created. This way, companies can create libraries for their internal production processes and parts they produce. It could also be possible to create open-source repositories for standardized processes and parts.

Another shortcoming is the very simplified and reduced use case. It is sufficient to show that the approach is principally working, and it can be expected that the approach is scalable to larger systems. Since the approach was developed using SysML as a standardized modeling language and ISO 14040 and the tool-independent ILCD format to identify the data-need and derive the functionalities for the automated LCI creation, the approach should be generally applicable to any product. Regarding the scale of the LCI model, since the modeling methodology, and therefore the structure of the LCI model of product systems, is independent of the size of the product system (number of unit processes and sub-product systems), the developed approach should work for large systems, as well. However, the modeling of large LCI models in SysML might become complex and elaborate since the modeling effort is higher than in an LCA tool. If the concept of reusable life cycle models can be implemented, this disadvantage can be overcome. Also, the presented example only considered the cradle-to-gate phase. Since the inventory models of all life phases are modeled identically, the SysML LCI model, as well as the developed interface, can be applied to other life phases, as well. However, the integration of product-specific information regarding other life phases might look different. For example, use scenarios might be modeled using activity diagrams like in Eigner et al. [

15,

16].

The assumption made that all unit processes needed within the LCI model are already available within the LCA tools database was made to focus this paper on proving the functionality of the developed approach. However, the availability of general datasets representing certain products or processes is oftentimes not provided. If the developed approach is to be used in product development, it has to be made sure that all needed datasets are available within the LCA database. If certain unit processes are missing, they have to be added, for example, manually, by importing datasets from other databases or creating new datasets based on research. In the future, however, the approach developed could also be extended to create new datasets, for example, of production processes, if the corresponding models of these production processes are available and integrated in the SysML model.

Overall, the developed approach has the potential to enable the efficient implementation of LCAs during product development, allowing engineers to take sustainability into account in their design decisions with quantified assessment results and even use it for product optimization.

7. Conclusions and Outlook

LCAs are an essential tool to assess products’ environmental footprint. However, due to their high data demand, they are mostly performed after product development is already finished, and therefore, the results have no direct influence on design decisions during development. MBSE allows the efficient structuring and reusability of all development artifacts and their data and is promising to tackle the issue of data availability for performing LCAs during product development. Existing approaches combining MBSE and LCAs are trying to integrate the assessment, including the calculation of impacts, into the SysML system model. Since the modeling of system models is already complex, and performing large calculations directly within a system model is inefficient, the authors developed an approach that uses the already established LCA tools for the impact calculation, and the system model serves only as the provider for the needed data related to the product and its life cycle. The goal of this work was to present a proof of concept of this approach by developing a framework for modeling a products’ life cycle within a SysML system model that inherits all information needed to automatically set up an LCI model within an LCA tool. Additionally, to be able to automatically create a model within the LCA tool and to transfer the results back into the system model, an interface between the SysML modeling tool (cameo systems modeler) and the LCA tool (openLCA) was developed.

To reach the stated goal, first, the minimum data-need for setting up LCI models in LCA tools was identified by analyzing the standardized exchange formats for the LCA models ILCD and openLCA schema. This analysis led to a data structure containing the minimum information to define a product system in an LCA database. This information is the reference process and the reference flow, including the target amount of the product system, as well as all unit processes contained within the product system and the process links between the unit process. To be able to include these elements into a SysML system model, an LCA-specific SysML profile was created defining the new stereotypes ProductSystem, UnitProcess, Flow, EnergyFlowPort_LCA and MaterialFlowPort_LCA for the needed elements. Then, a modeling approach for modeling a product’s life cycle was shown, using the LCA-specific elements and defining the structure of the inventory model of the product system. The created SysML life cycle model can directly be linked to the existing system model of the product by using the block representing the product as a flow property within the reference process of the life cycle model. Additionally, it is possible to include models defining needed process parameters, like the energy consumption of a production process.

To be able to automatically conduct an impact assessment within openLCA and return the results to the system model, a plugin for the cameo systems modeler is implemented. The plugin reads out the structure of the modeled SysML life cycle model and writes the data into a JSON file according to the openLCA schema. Then, a Python script is triggered, which automatically executes openLCA in the background, imports the defined JSON file and triggers an impact assessment within openLCA. The results of the assessment are then returned to the SysML model and written into the corresponding value property of the StructureElement or Module.

The applicability of the developed approach was demonstrated using the example of a laser-structured metal part for laser-based metal–plastic hybrid joints. In a first step, the cradle-to-gate life cycle phase (

Figure 7) was modeled in openLCA. An equivalent life cycle model was then modeled in SysML based on the developed modeling framework (

Figure 8). In the example of the laser structuring process, it is shown how models can be integrated by specifying the inputs and outputs of a process specifically for the considered Product (

Figure 9). Finally, the developed plugin for the cameo systems modeler is used to automatically transfer the inventory data from the SysML model to openLCA, perform the impact assessment and return the CO

2-equivalent back into the system model. The automatically created inventory model is identical to the previously manually modeled inventory model. Also, the results of the impact assessments of both models are identical, with a GWP of 0.04750 CO

2-equivalent, showing that the goal of this work is achieved.

Summarized, the major contributions and benefits of the developed approach are as follows:

an LCA-specific language profile for SysML allows the modeling of life cycles within SysML;

automatic creation of LCI models in an LCA tool based on the life cycle model in SysML, allowing the execution of LCAs already during product development;

direct linkage with product-specific data and production models with the SysML life cycle model, resulting in product-specific LCI models allowing for easy validation of changes and different product variants.

However, there is still further research needed to allow a robust and easy to use application of the developed approach. A next step following this research can be the transfer of the developed approach to more complex and larger systems to prove its applicability and scalability. Another aspect is the extension of the developed interface between the SysML tool and the LCA tool to allow the automated import of all processes and flows from an LCA database into a system model. To further reduce the modeling effort, it should be investigated whether for often used components, like standardized machine elements (e.g., screws, bearings, gear wheels, etc.), predefined life cycle models can be created in SysML and stored in a library, which allows their reuse in different system configurations. It can also be investigated how the developed framework for a life cycle model can be utilized to assess other aspects of the products’ life cycle, like costs. To enable better reusability of the modeled production processes and the integrated models, the authors suggest developing a modeling framework for integrating production models in a more systematical manner. Since the developed approach allows an easy and quick assessment of a system under development, it should be investigated how the approach can be utilized for the optimization of the system architecture towards a minimized environmental impact. A further research topic that might be of interest is the linkage of the SysML model to digital twin platforms. The cameo systems modeler used as a SysMl modeling tool, for example, is already integrated into the 3D experience platform by Dassault systems, one of the largest digital twin platforms available. Also, the linkage of manufacturing execution platforms could be of interest in integrating real-time data, which is especially of interest regarding digital product passports. An approach for using live production data to perform an LCA with SysML was presented by Ghanjaoui et al. [

21]. Another aspect that can be investigated is how the method of production of the materials used within the LCI model can be included in the modeling approach and how this affects the quality of the data provided by the SysML model for the LCA. This includes, for example, the share of recycled material.