Automated System for Transportation and Separation of Textile-Cutting Surpluses: A Case Study in a Portuguese Clothing Company

Abstract

1. Introduction

2. Literature Review

2.1. Recycling of Textile

2.2. Challenges in Textile Waste Management

2.3. Automation in Intralogistics

2.4. Textile Collection and Sorting

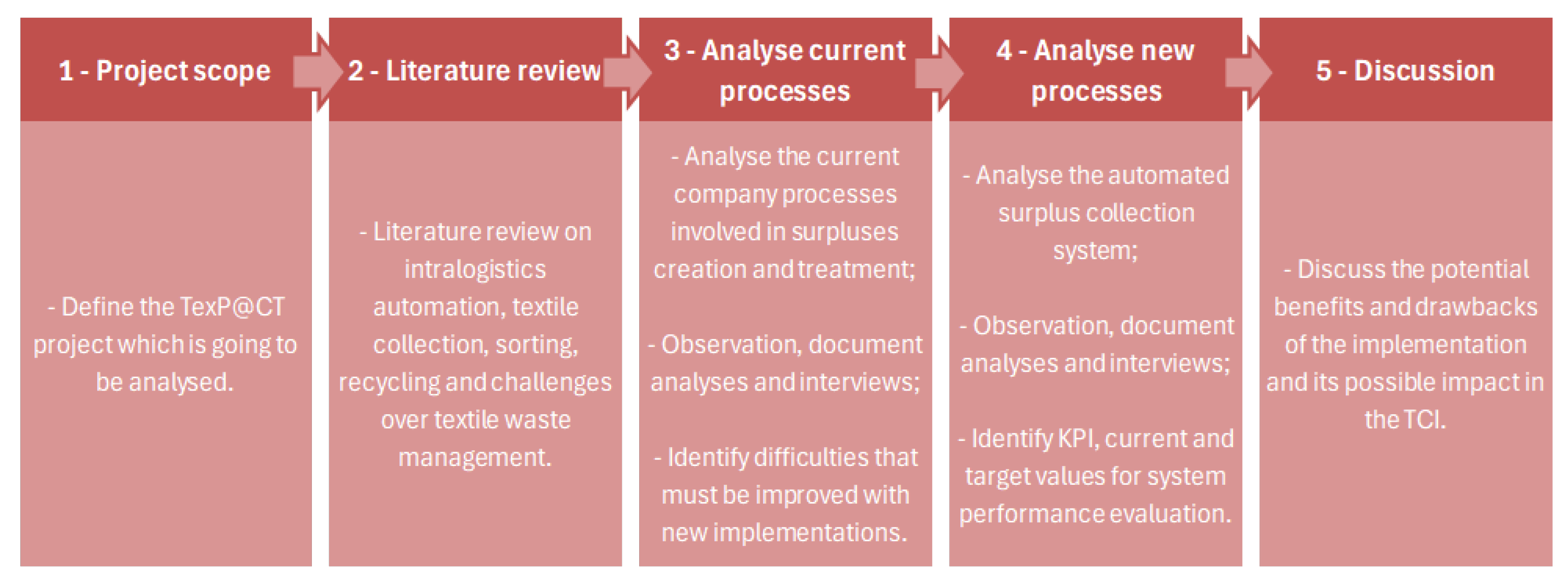

3. Research Objectives and Methodology

3.1. Research Objectives

- Describe the implementation of automated systems: Investigate the implications of adopting automated technologies for collecting textile-cutting surpluses, and assess their potential economic benefits.

- Promote adoption: Given the limited documentation and adoption of automated systems for collecting textile-cutting surpluses, developing an effective and efficient pilot can promote adoption by other garment manufacturers, enhancing textile recycling and sustainability.

- Identify barriers to adoption and propose solutions: Explore the challenges hindering the widespread adoption of automated textile sorting technologies, such as technical limitations, and propose strategies to overcome these obstacles.

3.2. Case Selection

3.3. Case Study Approach

4. Case Study

4.1. General Presentation of the Company

4.1.1. Textile Cutting

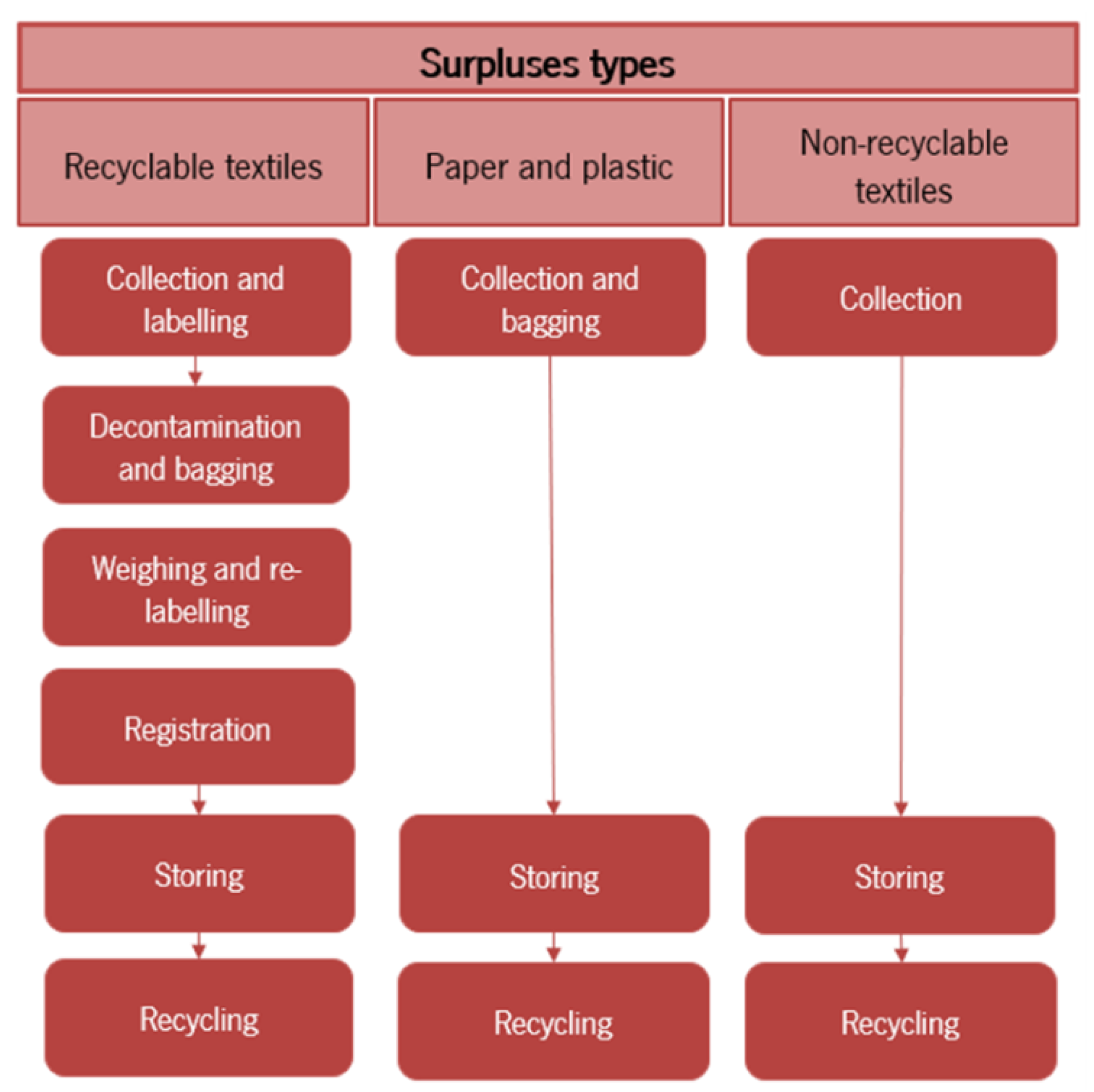

4.1.2. Collection and Separation of Surpluses

4.1.3. Processes Overview Before Implementation

- Lack of robustness in labelling and registration processes, leading to mistakes or missing information;

- High time spent by operators with no added value tasks, such as long transportation distances in manual transportations;

- High efforts in non-ergonomic tasks, which hinder the sector’s attractiveness;

- High need of available human resources to immediately collect and identify the surpluses generated, guaranteeing traceability losses do not occur, which is essential for the downstream recycling process.

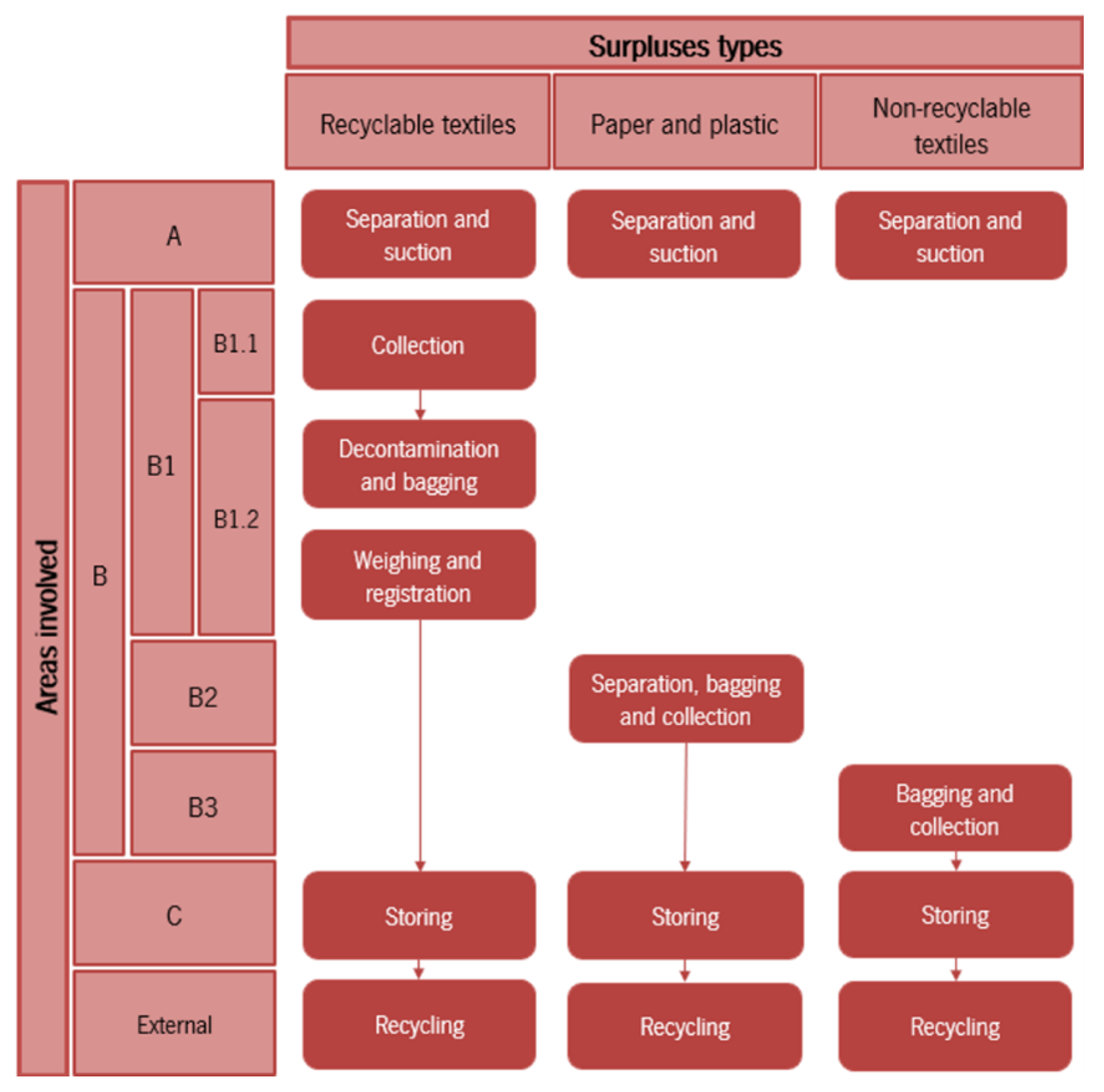

4.2. Implementation of the Automated Surplus Transportation and Separation System

4.2.1. System Introduction and Key Performance Indicators (KPI)

4.2.2. Purpose of Different Areas and Technologies Involved

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Job satisfaction: An explorative study on work characteristics changes of employees in Intralogistics 4.0. J. Bus. Logist. 2022, 43, 343–367. [Google Scholar] [CrossRef]

- Fottner, J.; Clauer, D.; Hormes, F.; Freitag, M.; Beinke, T.; Overmeyer, L.; Gottwald, S.N.; Elbert, R.; Sarnow, T.; Schmidt, T.; et al. Autonomous systems in intralogistics: State of the Art and future research challenges. Logist. Res. 2021, 14, 1–41. [Google Scholar] [CrossRef]

- Albrecht, T.; Baier, M.S.; Gimpel, H.; Meierhöfer, S.; Röglinger, M.; Schlüchtermann, J.; Will, L. Leveraging digital technologies in logistics 4.0: Insights on affordances from intralogistics processes. Inf. Syst. Front. 2024, 26, 755–774. [Google Scholar] [CrossRef]

- Dal Forno, A.J.; Bataglini, W.V.; Steffens, F.; Ulson de Souza, A.A. Industry 4.0 in textile and apparel sector: A systematic literature review. Res. J. Text. Appar. 2023, 27, 95–117. [Google Scholar] [CrossRef]

- Long, X.; Gui, L. Waste not want not? The environmental implications of quick response and upcycling. Manuf. Serv. Oper. Manag. 2024, 26, 612–631. [Google Scholar] [CrossRef]

- Yalcin-Enis, I.; Kucukali-Ozturk, M.; Sezgin, H. Risks and management of textile waste. In Nanoscience and Biotechnology for Environmental Applications; Springer: Cham, Switzerland, 2019; pp. 29–53. [Google Scholar] [CrossRef]

- Akter, M.M.K.; Haq, U.N.; Islam, M.M.; Uddin, M.A. Textile-apparel manufacturing and material waste management in the circular economy: A conceptual model to achieve sustainable development goal (SDG) 12 for Bangladesh. Clean. Environ. Syst. 2022, 4, 100070. [Google Scholar] [CrossRef]

- Abrishami, S.; Shirali, A.; Sharples, N.; Kartal, G.E.; Macintyre, L.; Doustdar, O. Textile recycling and recovery: An eco-friendly perspective on textile and garment industries challenges. Text. Res. J. 2024, 94, 2815–2834. [Google Scholar] [CrossRef]

- Akash, M.H.; Al Aziz, R.; Karmaker, C.L.; Md, A.R.; Islam, T. Investigating the attributes for implementing circular economy in the textile manufacturing supply chain: Implications for the triple bottom line of sustainability. Sustain. Horizons 2025, 14, 100129. [Google Scholar] [CrossRef]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A review on textile recycling practices and challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Bizuneh, B.; Omer, R. Lean waste prioritisation and reduction in the apparel industry: Application of waste assessment model and value stream mapping. Cogent Eng. 2024, 11, 2341538. [Google Scholar] [CrossRef]

- Hosen, M.I.; Tushar, S.R.; Alam, M.F.B.; Syduzzaman, M. Strategies for economic sustainability: An empirical study on Muri, Mura, and Muda in the readymade garment sector. Green Technol. Sustain. 2025, 3, 100115. [Google Scholar] [CrossRef]

- TEXP@CT. TEXP@CT Project Sheet. 2022. Available online: https://texpact.pt/sobre/artigos___sobre/texp_ct_project_sheet_4-00363557 (accessed on 24 April 2025).

- Zhang, A.; Seuring, S. Digital product passport for sustainable and circular supply chain management: A structured review of use cases. Int. J. Logist. Res. Appl. 2024, 27, 2513–2540. [Google Scholar] [CrossRef]

- Gardetti, M.A.; Muthu, S.S. Sustainable apparel? Is the innovation in the business model?—The case of IOU Project. Text. Cloth. Sustain. 2015, 1, 2. [Google Scholar] [CrossRef]

- Baloyi, R.B.; Gbadeyan, O.J.; Sithole, B.; Chunilall, V. Recent advances in recycling technologies for waste textile fabrics: A review. Text. Res. J. 2024, 94, 508–529. [Google Scholar] [CrossRef]

- Šimonová, T.; Malindzakova, M.; Malindzak, D. Integrating Management Strategy and Porter’s Five Forces Model for the Sustainable Recycling of Textile Waste. Sustainability 2024, 16, 9283. [Google Scholar] [CrossRef]

- Dissanayake, D.; Weerasinghe, D. Fabric waste recycling: A systematic review of methods, applications, and challenges. Mater. Circ. Econ. 2021, 3, 24. [Google Scholar] [CrossRef]

- Stubbe, B.; Van Vrekhem, S.; Huysman, S.; Tilkin, R.G.; De Schrijver, I.; Vanneste, M. White Paper on Textile Fibre Recycling Technologies. Sustainability 2024, 16, 618. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M.; Kulikowska, D. The growing problem of textile waste generation—The current state of textile waste management. Energies 2024, 17, 1528. [Google Scholar] [CrossRef]

- Cheng, T.; Kojima, D.; Hu, H.; Onoda, H.; Pandyaswargo, A.H. Optimizing Waste Sorting for Sustainability: An AI-Powered Robotic Solution for Beverage Container Recycling. Sustainability 2024, 16, 10155. [Google Scholar] [CrossRef]

- TERRA. Technical Monitoring of Optical Sorting, Recognition and Disassembly Technologies for Textiles at European Scale. 2023. Available online: https://pro.refashion.fr/sites/default/files/rapport-etude/240428_Synth%C3%A8se_Veille-technos-tri-d%C3%A9lissage_VF-EN.pdf (accessed on 7 May 2025).

- Tang, K.H.D. State of the art in textile waste management: A review. Textiles 2023, 3, 454–467. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.L.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Kumar, U.; Kaswan, M.S.; Kumar, R.; Chaudhary, R.; Garza-Reyes, J.A.; Rathi, R.; Joshi, R. A systematic review of Industry 5.0 from main aspects to the execution status. TQM J. 2023, 36, 1526–1549. [Google Scholar] [CrossRef]

- Hoque, M.A.; Rasiah, R.; Furuoka, F.; Kumar, S. Technology adoption in the apparel industry: Insight from literature review and research directions. Res. J. Text. Appar. 2021, 25, 292–307. [Google Scholar] [CrossRef]

- Reis, W.P.N.d.; Couto, G.E.; Junior, O.M. Automated guided vehicles position control: A systematic literature review. J. Intell. Manuf. 2023, 34, 1483–1545. [Google Scholar] [CrossRef]

- Fragapane, G.; De Koster, R.; Sgarbossa, F.; Strandhagen, J.O. Planning and control of autonomous mobile robots for intralogistics: Literature review and research agenda. Eur. J. Oper. Res. 2021, 294, 405–426. [Google Scholar] [CrossRef]

- Weiss, A.; Huber, A.; Minichberger, J.; Ikeda, M. First application of robot teaching in an existing industry 4.0 environment: Does it really work? Societies 2016, 6, 20. [Google Scholar] [CrossRef]

- Promkaew, N.; Thammawiset, S.; Srisan, P.; Sanitchon, P.; Tummawai, T.; Sukpancharoen, S. Development of metaheuristic algorithms for efficient path planning of autonomous mobile robots in indoor environments. Results Eng. 2024, 22, 102280. [Google Scholar] [CrossRef]

- Oladimeji, D.; Gupta, K.; Kose, N.A.; Gundogan, K.; Ge, L.; Liang, F. Smart transportation: An overview of technologies and applications. Sensors 2023, 23, 3880. [Google Scholar] [CrossRef]

- Tanimu, J.A.; Abada, W. Addressing cybersecurity challenges in robotics: A comprehensive overview. Cyber Secur. Appl. 2024, 3, 100074. [Google Scholar] [CrossRef]

- Kumar, N. Fundamentals of conveyors. In Transporting Operations of Food Materials Within Food Factories; Elsevier Inc.: Cambridge, MA, USA, 2023; pp. 221–251. [Google Scholar]

- Chinguwa, S.; Nyemba, W.R.; Boora, K.; Mbohwa, C. Feasibility study of the materials handling and development of a sustainable conveying system in plastics recycling and manufacture. Procedia Manuf. 2019, 33, 383–390. [Google Scholar] [CrossRef]

- Mills, D. Pneumatic Conveying Design Guide, 3rd ed.; Butterworth-Heinemann: Waltham, MA, USA, 2015. [Google Scholar]

- Shibani, W.; Zulkafli, M.; Basuno, B. Methods of transport technologies: A review on using tube/tunnel systems. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Melaka, Malaysia, 24–25 November 2016. [Google Scholar] [CrossRef]

- Jayaram, A. Lean six sigma approach for global supply chain management using industry 4.0 and IIoT. In Proceedings of the 2016 2nd International Conference on Contemporary Computing and Informatics (IC3I), Greater Noida, India, 14–17 December 2016; pp. 89–94. [Google Scholar] [CrossRef]

- Manglani, H.; Hodge, G.L.; Oxenham, W. Application of the internet of things in the textile industry. Text. Prog. 2019, 51, 225–297. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z. Research on green logistics scheduling system of textile vehicle automatic guided vehicle. J. Phy. Conf. Ser. 2020, 1549, 052071. [Google Scholar] [CrossRef]

- Marinelli, M.; Caggiani, L.; Ottomanelli, M.; Dell’Orco, M. En route truck–drone parcel delivery for optimal vehicle routing strategies. IET Intell. Transp. Syst. 2018, 12, 253–261. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Srai, J.S. Intelligent Autonomous Vehicles in digital supply chains: A framework for integrating innovations towards sustainable value networks. J. Clean. Prod. 2018, 181, 60–71. [Google Scholar] [CrossRef]

- Michalos, G.; Kousi, N.; Karagiannis, P.; Gkournelos, C.; Dimoulas, K.; Koukas, S.; Mparis, K.; Papavasileiou, A.; Makris, S. Seamless human robot collaborative assembly–An automotive case study. Mechatronics 2018, 55, 194–211. [Google Scholar] [CrossRef]

- Karabegović, I. The role of industrial and service robots in fourth industrial revolution with focus on China. J. Eng. Archit. 2017, 5, 110–117. [Google Scholar] [CrossRef]

- Guizzo, E. Your next t-shirt will be made by a robot. IEEE Spectr. 2018, 55, 50–57. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Tomme, B.; Goshayeshi, B.; Mynko, O.; Wang, Y.; Roy, S.; Kumar, R.; Baruah, B.; De Clerck, K.; De Meester, S.; et al. Advancing Textile Waste Recycling: Challenges and Opportunities Across Polymer and Non-Polymer Fiber Types. Polymers 2025, 17, 628. [Google Scholar] [CrossRef]

- Satav, A.G.; Kubade, S.; Amrutkar, C.; Arya, G.; Pawar, A. A state-of-the-art review on robotics in waste sorting: Scope and challenges. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 2789–2806. [Google Scholar] [CrossRef]

- Patton, M.Q. Qualitative Research & Evaluation Methods: Integrating Theory and Practice, 4th ed.; Sage Publications Inc.: Thousand Oaks, CA, USA, 2015. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage publications: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Kallmuenzer, A.; Mikhaylov, A.; Chelaru, M.; Czakon, W. Adoption and performance outcome of digitalization in small and medium-sized enterprises. Rev. Manag. Sci. 2024, 1–28. [Google Scholar] [CrossRef]

- Morgan, H. Conducting a qualitative document analysis. Qual. Rep. 2022, 27, 64–77. [Google Scholar] [CrossRef]

- Creswell, J.W.; Poth, C.N. Qualitative Inquiry and Research Design: Choosing Among Five Approaches, 4th ed.; Sage Publications Inc.: Thousand Oaks, CA, USA, 2018. [Google Scholar]

| # | KPI | KPI Extended Description | Unit | Pre-Project Value | Target Value |

|---|---|---|---|---|---|

| 1 | Collection time per Purchase Order (PO) | Total time consumed per average PO | Minute | 16 | 10 |

| 2 | Traceability management time at the cut exit | Time consumed in identifying surplus batches | Minute | 4 | 2 |

| 3 | Transport time to the decontamination area | Time consumed in transporting the surplus to the decontamination area | Minute | 18 | 0 |

| 4 | Post-decontamination traceability management time | Time consumed in quantifying the batches of surplus produced after decontamination | Minute | 6 | 5 |

| 5 | Searching for big bags to send for recycling | Time consumed searching for bags of a given reference | Minute | 5 | 2 |

| # | KPI | Pre-Project Value Per Event | Target Value Per Event | Events Per Shift | Expected Savings Per Shift |

|---|---|---|---|---|---|

| 1 | Collection time per PO | 16 min | 10 min | a | (16−10)∗a min |

| 2 | Traceability management time at the cut exit | 4 min | 2 min | b | (4−2)∗b min |

| 3 | Transport time to the decontamination area | 18 min | 0 min | c | (18−0)∗c min |

| 4 | Post-decontamination traceability management time | 6 min | 5 min | d | (6−5)∗d min |

| 5 | Searching for big bags to send for recycling | 5 min | 2 min | e | (5−2)∗e min |

| Total | 49 min | 19 min | a + b + c + d + e | 6a + 2b + 18c + d + 3e min | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, S.; Costa, H.; Fonseca, R.; Ribeiro, A.; Teixeira, S. Automated System for Transportation and Separation of Textile-Cutting Surpluses: A Case Study in a Portuguese Clothing Company. Sustainability 2025, 17, 4673. https://doi.org/10.3390/su17104673

Sousa S, Costa H, Fonseca R, Ribeiro A, Teixeira S. Automated System for Transportation and Separation of Textile-Cutting Surpluses: A Case Study in a Portuguese Clothing Company. Sustainability. 2025; 17(10):4673. https://doi.org/10.3390/su17104673

Chicago/Turabian StyleSousa, Sérgio, Hugo Costa, Rui Fonseca, Ana Ribeiro, and Senhorinha Teixeira. 2025. "Automated System for Transportation and Separation of Textile-Cutting Surpluses: A Case Study in a Portuguese Clothing Company" Sustainability 17, no. 10: 4673. https://doi.org/10.3390/su17104673

APA StyleSousa, S., Costa, H., Fonseca, R., Ribeiro, A., & Teixeira, S. (2025). Automated System for Transportation and Separation of Textile-Cutting Surpluses: A Case Study in a Portuguese Clothing Company. Sustainability, 17(10), 4673. https://doi.org/10.3390/su17104673