Pathways to Improve Energy Conservation and Emission Reduction Efficiency During the Low-Carbon Transformation of the Logistics Industry

Abstract

1. Introduction

- (1)

- Considering the varying energy use and consumption characteristics of logistics, this paper proposes an efficiency evaluation model that incorporates different energy proportions.

- (2)

- This study examines how the alignment between energy conservation and emission reduction affects logistics efficiency, contributing to the development of sustainable strategies in the sector.

- (3)

- Based on fs-QCA, we reveal multiple pathways for energy conservation and emission reduction, clarifying how different transformation strategies can lead to divergent outcomes.

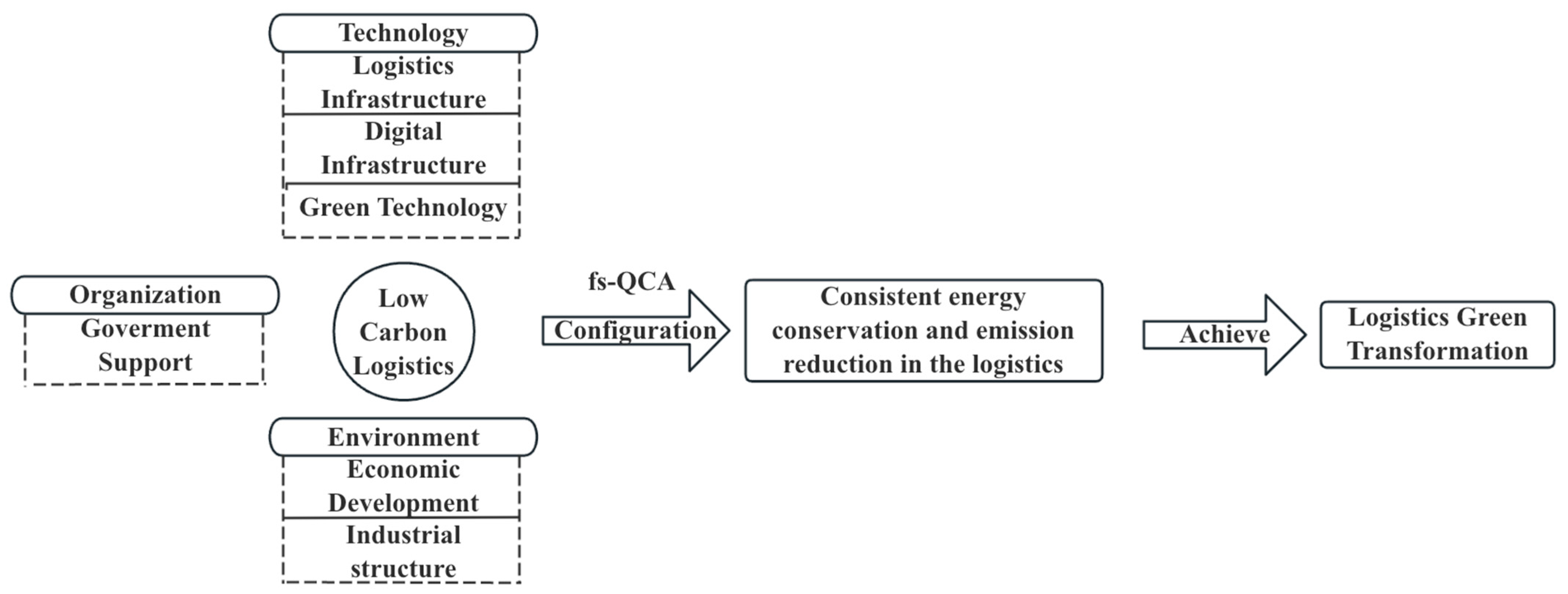

2. Theoretical Framework

2.1. Technological Condition

2.2. Organizational Condition

2.3. Environmental Condition

3. Methodology

3.1. Theorems

3.2. Data Source

3.3. Efficiency Measurement Model

4. Results

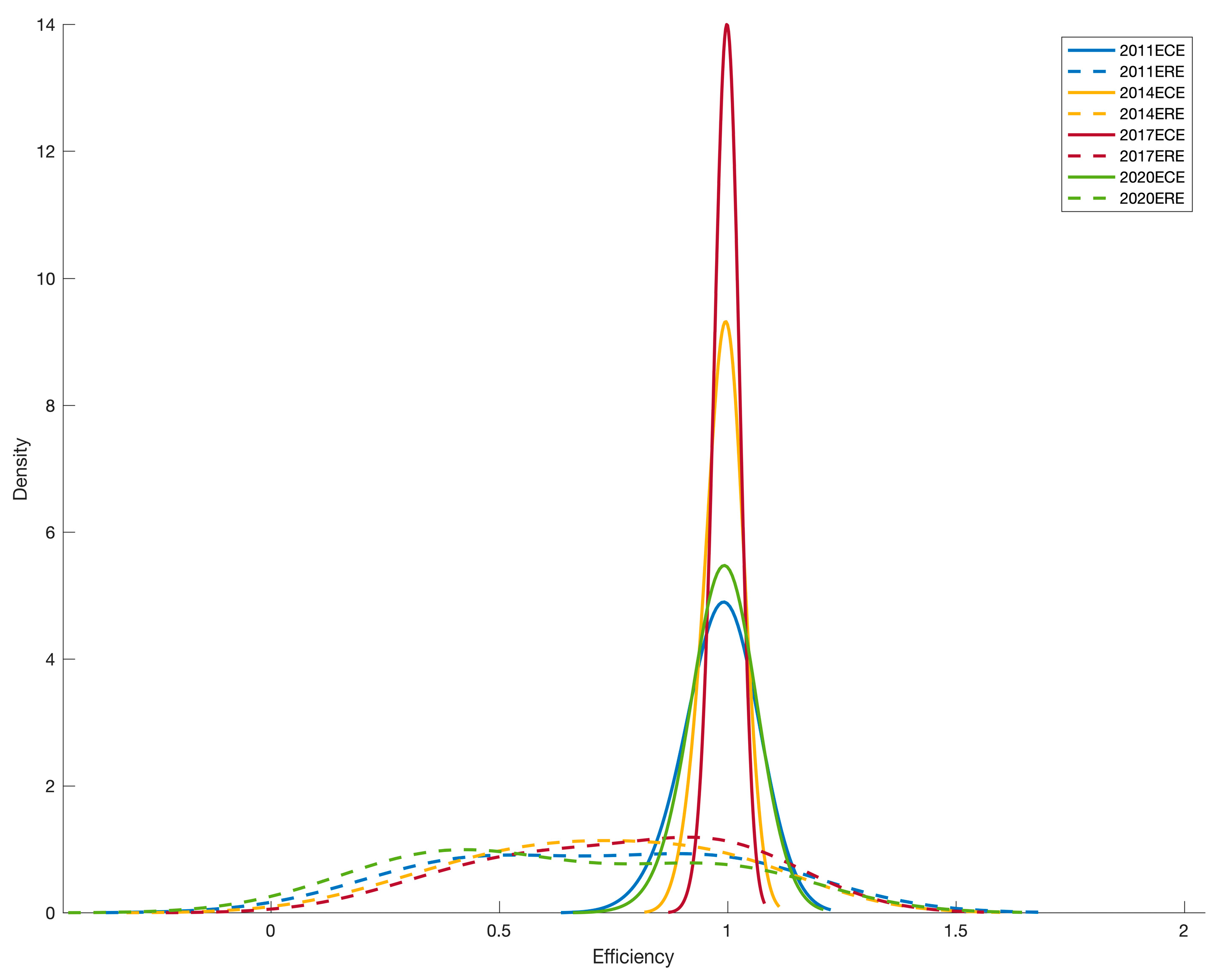

4.1. Comparison of Efficiency Measurement Models

4.2. Measurement and Analysis of the ECE and ERE

5. fs-QCA

5.1. Sample Selection

5.2. Calibration

5.3. Analysis of Necessary Conditions

5.4. Configuration Paths

5.5. Robust Analysis

6. Conclusions

6.1. Discussion of Results

- (1)

- The logistics industry exhibits distinctive characteristics in terms of energy conservation and emission reduction. From 2011 to 2021, the average M2 in the national logistics industry ranged between 0.624 and 0.777. Consistent with previous studies on provincial logistics efficiency in China, this paper finds that the eastern regions performed better than the central and western regions. Earlier studies integrated energy conservation and emission reduction into logistics efficiency as a single concept. In contrast, this paper differentiates between ECE and ERE. The ECE and ERE are expected to be consistent. However, calculations reveal a discrepancy between them. In general, the ECE was higher than the ERE. The ECE and ERE were aligned in only 129 of the 330 DMUs. The findings suggest that logistics efficiency reaches its optimal level when ECE and ERE are consistent.

- (2)

- Based on the fs-QCA analysis, this study identifies four distinct development pathways leading to consistent energy conservation and emission reduction in the logistics industry. The four high Cons configuration paths covered 36.6% of the cases. These high Cons configurations reflect the joint effects of key conditions such as transportation infrastructure, government support, green technology innovation, and digital development.

- (3)

- Two low Cons configuration paths were identified, covering 29.2% of the cases, predominantly located in the western regions. The NH1 suggests that even with technological advancement, the lack of basic infrastructure significantly constrains the efficiency and sustainability of logistics operations. NH2 shows that multiple core conditions are absent, and the development of sustainable logistics is severely hampered, regardless of the status of logistics infrastructure. Therefore, building a consistent development system for the ECE and the ERE in the logistics industry requires the coordinated promotion of multiple factors.

- (4)

- Despite the valuable insights provided by this study, several limitations remain. First, while it analyzes the impact of energy structure changes on logistics efficiency from a macro perspective, it does not provide precise quantitative values for specific energy structure adjustments. Second, although the fs-QCA provides valuable insights into different pathways for improving green logistics efficiency, its results are highly dependent on the selection of conditions and thresholds.

6.2. Managerial Implications

- (1)

- Regions classified as H1 refer to those with well-developed logistics infrastructure and digital capabilities. To achieve sustainable development, it is imperative for these regions to deepen the integration between digital ecosystems and physical infrastructure systems. Cloud computing, artificial intelligence, and blockchain technologies should be applied to develop collaborative platforms that strengthen the coordination between digital infrastructure and logistics operations. By coupling virtual and physical systems, digital twin models can be formed to enhance real-time supervision, improve energy efficiency, and reduce carbon emissions.

- (2)

- Regions classified as H2 and H4 refer to those with strong digital capabilities and high levels of economic development. These regions are at the forefront of the digital economy and could drive the large-scale application of green and low-carbon technologies in the logistics sector. By embedding green technologies into digital platforms and strengthening data connectivity across logistics nodes, they can enhance supply chain transparency and coordination. This facilitates the integration of upstream and downstream industries, laying the groundwork for a collaborative and low-carbon logistics ecosystem.

- (3)

- Regions classified as H3a and H3b refer to those driven by secondary industry. In these areas, accelerating the use of clean energy to replace fossil fuels in industrial production and transportation is key to reducing carbon emissions. As energy structures shift, logistics activities such as procurement, distribution, and delivery also become greener. Meanwhile, the integration of production-oriented services enables more precise supply chain coordination and resource efficiency, gradually forming a sustainable development model through the synergy of the secondary and tertiary sectors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ECE | Energy Conservation Efficiency |

| ERE | Emission Reduction Efficiency |

| ECERE | Energy Conservation and Emission Reduction Efficiency |

| NDDF | Non-radial Directional Distance Function |

| fs-QCA | Fuzzy-set Qualitative Comparative Analysis |

| DEA | Data Envelopment Analysis |

| TOE | Technology-Organization-Environment |

| LI | Logistics Infrastructure |

| DI | Digital Infrastructure |

| GT | Green Technology |

| GS | Government Support |

| ED | Economic Development |

| IS | Industrial Structure |

| DMU | Decision-Making Unit |

| Cons | Consistency between energy conservation and emission reduction |

References

- LogClub. China Green Logistics Development Report. [EB/OL]. Available online: https://www.logclub.com/front/lc_report/get_report_info/3977 (accessed on 12 March 2023).

- CEIC China Energy: Final Consumption: Transport, Storage, Postal & Telecom Service. [EB/OL]. Available online: https://www.ceicdata.com.cn/zh-hans/china/energy-balance-sheet/cn-energy-final-consumption-transport-storage-postal--telecom-service (accessed on 5 September 2024).

- Zeng, S.; Su, B.; Zhang, M.; Gao, Y.; Liu, J.; Luo, S.; Tao, Q. Analysis and forecast of China’s energy consumption structure. Energy Policy 2021, 159, 112630. [Google Scholar] [CrossRef]

- Liang, H.; Lin, S.; Wang, J. Impact of technological innovation on carbon emissions in China’s logistics industry: Based on the rebound effect. J. Clean. Prod. 2022, 377, 134371. [Google Scholar] [CrossRef]

- Wang, Q.; Su, B.; Sun, J.; Zhou, P.; Zhou, D. Measurement and decomposition of energy-saving and emissions reduction performance in Chinese cities. Appl. Energy 2015, 151, 85–92. [Google Scholar] [CrossRef]

- Barma, M.C.; Saidur, R.; Rahman, S.M.A.; Allouhi, A.; Akash, B.A.; Sait, S.M. A review on boilers energy use, energy savings, and emissions reductions. Renew. Sustain. Energy Rev. 2017, 79, 970–983. [Google Scholar] [CrossRef]

- Jimenez, V.J.; Kim, H.; Munim, Z.H. A review of ship energy efficiency research and directions towards emission reduction in the maritime industry. J. Clean. Prod. 2022, 366, 132888. [Google Scholar] [CrossRef]

- Li, X.; Xu, H. The energy-conservation and emission-reduction paths of industrial sectors: Evidence from Chinas 35 industrial sectors. Energy Econ. 2020, 86, 104628. [Google Scholar] [CrossRef]

- Markovits-Somogyi, R.; Bokor, Z. Assessing the logistics efficiency of European countries by using the DEA-PC methodology. Transport 2014, 29, 137–145. [Google Scholar] [CrossRef]

- Zheng, W.; Xu, X.; Wang, H. Regional logistics efficiency and performance in China along the Belt and Road Initiative: The analysis of integrated DEA and hierarchical regression with carbon constraint. J. Clean. Prod. 2020, 276, 123649. [Google Scholar] [CrossRef]

- Yang, W.; Liu, D.; Sui, X.; Li, F. Does logistics efficiency matter? Evidence from green economic efficiency side. Res. Int. Bus. Financ. 2022, 61, 101650. [Google Scholar]

- Khan, S.A.R.; Qianli, D. Does national scale economic and environmental indicators spur logistics performance? Evidence from UK. Environ. Sci. Pollut. Res. 2017, 24, 26692–26705. [Google Scholar] [CrossRef]

- Park, Y.S.; Lim, S.H.; Egilmez, G.; Szmerekovsky, J. Environmental efficiency assessment of US transport sector: A slack-based data envelopment analysis approach. Transp. Res. Part D Transp. Environ. 2018, 61, 152–164. [Google Scholar] [CrossRef]

- Lo Storto, C.; Evangelista, P. Infrastructure efficiency, logistics quality and environmental impact of land logistics systems in the EU: A DEA-based dynamic mapping. Res. Transp. Bus. Manag. 2023, 46, 100814. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635. [Google Scholar] [CrossRef]

- Dakpo, K.H.; Jeanneaux, P.; Latruffe, L. Modelling pollution-generating technologies in performance benchmarking: Recent developments, limits and future prospects in the nonparametric framework. Eur. J. Oper. Res. 2016, 250, 347–359. [Google Scholar] [CrossRef]

- Yao, X.; Cheng, Y.; Zhou, L.; Song, M. Green efficiency performance analysis of the logistics industry in China: Based on a kind of machine learning methods. Ann. Oper. Res. 2020, 308, 727–752. [Google Scholar] [CrossRef]

- Qin, W.; Qi, X. Evaluation of Green Logistics Efficiency in Northwest China. Sustainability 2022, 14, 6848. [Google Scholar] [CrossRef]

- Liang, Z.J.; Chiu, Y.H.; Guo, Q.; Liang, Z. Low-carbon logistics efficiency: Analysis on the statistical data of the logistics industry of 13 cities in Jiangsu Province, China. Res. Transp. Bus. Manag. 2022, 43, 100740. [Google Scholar] [CrossRef]

- Lu, M.; Lei, W.; Gao, Y.; Wan, Q. If There Appears a Path to Improve Chinese Logistics Industry Efficiency in Low-Carbon Perspective? A Qualitative Comparative Analysis of Provincial Data. Math. Probl. Eng. 2021, 2021, 9977497. [Google Scholar] [CrossRef]

- Chen, B.; Liu, F.; Gao, Y.; Ye, C. Spatial and temporal evolution of green logistics efficiency in China and analysis of its motivation. Environ. Dev. Sustain. 2024, 26, 2743–2774. [Google Scholar] [CrossRef]

- Xin, Y.; Zheng, K.; Zhou, Y.; Han, Y.; Tadikamalla, P.R.; Fan, Q. Logistics efficiency under carbon constraints based on a super SBM model with undesirable output: Empirical evidence from China’s logistics industry. Sustainability 2022, 14, 5142. [Google Scholar] [CrossRef]

- Zhang, J.; Chang, Y.; Wang, C.; Zhang, L. The green efficiency of industrial sectors in China: A comparative analysis based on sectoral and supply-chain quantifications. Resour. Conserv. Recycl. 2018, 132, 269–277. [Google Scholar] [CrossRef]

- Guo, X.; Li, B. Efficiency evaluation of regional logistics industry and its influencing factors under low-carbon constraints. Environ. Dev. Sustain. 2024, 26, 15667–15679. [Google Scholar] [CrossRef]

- Lu, M.; Xie, R.; Chen, P.; Zou, Y.; Tang, J. Green transportation and logistics performance: An improved composite index. Sustainability 2019, 11, 2976. [Google Scholar] [CrossRef]

- Ye, C.; Huang, Z.X.; Wei, J.; Wang, X. Spatial-Temporal Evolutionary Characteristics and Its Driving Mechanisms of China’s Logistics Industry Efficiency under Low Carbon Constraints. Pol. J. Environ. Stud. 2022, 31, 5405–5417. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Huang, K.; Xie, X.; Chen, Y. Dynamic evolution, regional differences and influencing factors of high-quality development of China’s logistics industry. Ecol. Indic. 2024, 159, 111728. [Google Scholar] [CrossRef]

- Qin, W. Spatial-temporal Evolution and Improvement Path of Logistics Industry Efficiency in Guangdong-Hong Kong-Macao Greater Bay Area. China Bus. Mark. 2020, 34, 31–40. [Google Scholar] [CrossRef]

- Gong, X. Measurement of regional logistics efficiency and analysis of influencing factors. Stat. Decis. 2022, 38, 112–116. [Google Scholar] [CrossRef]

- Fiss, P.C. Building better causal theories: A fuzzy set approach to typologies in organization research. Acad. Manag. J. 2011, 54, 393–420. [Google Scholar] [CrossRef]

- Greckhamer, T.; Furnari, S.; Fiss, P.C.; Aguilera, R.V. Studying configurations with qualitative comparative analysis: Best practices in strategy and organization research. Strateg. Organ. 2018, 16, 482–495. [Google Scholar] [CrossRef]

- Grossman, G.M.; Krueger, A.B. Economic growth and the environment. Q. J. Econ. 1995, 110, 353–377. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Pasurka, C.A. Enviromental production functions and enviromental Directional Distance Functions. Energy 2007, 32, 1055–1066. [Google Scholar] [CrossRef]

- D’Inverno, G.; Carosi, L.; Romano, G.; Guerrini, A. Water pollution in wastewater treatment plants: An efficiency analysis with undesirable output. Eur. J. Oper. Res. 2018, 269, 24–34. [Google Scholar] [CrossRef]

- Gramacki, A. Nonparametric Kernel Density Estimation and Its Computational Aspects; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Zhang, H.; You, J.; Haiyirete, X.; Zhang, T. Measuring logistics efficiency in China considering technology heterogeneity and carbon emission through a meta-frontier model. Sustainability 2020, 12, 8157. [Google Scholar] [CrossRef]

- Shan, Y.; Guan, D.; Liu, J.; Mi, Z.; Liu, Z.; Liu, J.; Schroeder, H.; Cai, B.; Chen, Y.; Shao, S.; et al. Methodology and applications of city level CO2 emission accounts in China. J. Clean. Prod. 2017, 161, 1215–1225. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, Y.; Guo, X.; He, Z. Research on measurement and application of China’s regional logistics development level under low carbon environment. Processes 2021, 9, 2273. [Google Scholar] [CrossRef]

- Pappas, I.O.; Woodside, A.G. Fuzzy-set Qualitative Comparative Analysis (fsQCA): Guidelines for research practice in Information Systems and marketing. Int. J. Inf. Manag. 2021, 58, 102310. [Google Scholar] [CrossRef]

- Khan, A.; Rezaei, S.; Valaei, N. Social commerce advertising avoidance and shopping cart abandonment: A fs/QCA analysis of German consumers. J. Retail. Consum. Serv. 2022, 67, 102976. [Google Scholar] [CrossRef]

| Type of Energy Input | DEA Model Type | Carbon Emissions | Analysis Method of Influencing Factors | Efficiency Level | Regional Differences | Efficiency Trends | |

|---|---|---|---|---|---|---|---|

| Storto and Evangelista [14] | One type | Radial | As output | ||||

| Park et al. [13] | One type | As output | |||||

| Zhou et al. [15], Dakpo et al. [16] | One type | Non-radial | As output | ||||

| Yao et al. [17] | One type | Non-radial | As output | Machine learning models | Overall low | High in the East and low in the West | |

| Qin and Qi [18], Liang et al. [19] | One type | Radial | As input | Stochastic frontier analysis | |||

| Lu et al. [20] | One type | Radial | As output | Fs-QCA | Overall low | High in the East and low in the West | Slowly rising |

| Chen et al. [21] | One type | Radial | As output | Pearson correlation analysis | Overall low | High in the East and low in the West | Fluctuation rise |

| Xin et al. [22] | One type | Radial | As output | Efficiency decomposition | Comprehensive efficiency not high | High in the East and low in the West | Slowly rising |

| Zhang et al. [23] | Many type | As output | Tobit model |

| Energy | Discount Factor for Standard Coal | Unit | Carbon Emission Factor | Unit |

|---|---|---|---|---|

| Raw coal | 0.7143 | Million tons of standard coal/million tons | 0.7558 | Tons of carbon/ton of standard coal |

| Gasoline | 1.4714 | 0.5538 | ||

| Kerosene | 1.4714 | 0.5714 | ||

| Diesel | 1.4517 | 0.5821 | ||

| Fuel oil | 1.4286 | 0.6185 | ||

| Liquefied petroleum gas | 1.7143 | 0.5042 | ||

| Natural gas | 13.3 | Million tons of standard coal/billion cubic meters | 0.4483 | |

| Power | 1.229 | Million tons of standard coal/million kilowatt hours | 2.2132 |

| Indicator/Unit | OBS | Max | Min | Mean | |

|---|---|---|---|---|---|

| Input | Fixed asset investment/100 million yuan | 330 | 5386.95 | 100.3 | 5286.65 |

| Number of employees/10 thousand people | 330 | 64.17 | 2.78 | 61.39 | |

| Energy consumption /ten thousand tons of standard coal | 330 | 3549.37 | 122.57 | 3426.8 | |

| Output | Industrial output value/100 million yuan | 330 | 4166.8 | 67.53 | 4099.27 |

| Freight volume /ten thousand tons | 330 | 434,298 | 12,586 | 421,712 | |

| Carbon emissions /ten thousand tons | 330 | 2357.05 | 78.3 | 2278.75 |

| Region | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M1 | M2 | M1 | M2 | M1 | M2 | M1 | M2 | M1 | M2 | |

| Beijing | 0.46 | 0.47 | 0.37 | 0.35 | 0.55 | 0.55 | 0.49 | 0.43 | 1 | 1 | 1 | 1 |

| Tianjin | 1 | 1 | 1 | 1 | 1 | 1 | 0.7 | 0.65 | 0.73 | 0.68 | 0.76 | 0.75 |

| Hebei | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Shanxi | 0.46 | 0.52 | 0.49 | 0.56 | 0.47 | 0.53 | 0.47 | 0.52 | 0.62 | 0.75 | 0.71 | 0.86 |

| Inner Mongolia | 0.45 | 0.45 | 0.5 | 0.48 | 0.63 | 0.69 | 0.59 | 0.71 | 0.56 | 0.72 | 1 | 1 |

| Liaoning | 1 | 1 | 1 | 1 | 0.68 | 0.71 | 0.64 | 0.54 | 1 | 1 | 1 | 1 |

| Jilin | 0.39 | 0.44 | 0.42 | 0.44 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Heilongjiang | 0.37 | 0.36 | 0.38 | 0.33 | 0.39 | 0.33 | 0.32 | 0.28 | 0.33 | 0.29 | 0.37 | 0.37 |

| Shanghai | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Jiangsu | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Zhejiang | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Anhui | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Fujian | 0.79 | 0.78 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Jiangxi | 0.78 | 0.84 | 0.88 | 0.93 | 1 | 1 | 0.91 | 0.88 | 0.77 | 0.68 | 0.84 | 0.79 |

| Shandong | 1 | 1 | 1 | 1 | 0.83 | 0.76 | 0.86 | 0.79 | 0.77 | 0.68 | 0.82 | 0.74 |

| Henan | 0.67 | 0.64 | 0.75 | 0.73 | 0.66 | 0.72 | 0.71 | 0.72 | 0.6 | 0.57 | 0.62 | 0.64 |

| Hubei | 0.29 | 0.35 | 0.32 | 0.37 | 0.45 | 0.42 | 0.43 | 0.4 | 0.46 | 0.44 | 0.45 | 0.41 |

| Hunan | 0.9 | 0.92 | 1 | 1 | 0.69 | 0.66 | 0.64 | 0.59 | 0.65 | 0.61 | 0.67 | 0.65 |

| Guangdong | 0.57 | 0.49 | 0.6 | 0.53 | 0.72 | 0.66 | 0.78 | 0.7 | 0.9 | 0.86 | 1 | 1 |

| Guangxi | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Hainan | 1 | 1 | 0.5 | 0.43 | 0.47 | 0.41 | 1 | 1 | 0.56 | 0.5 | 0.54 | 0.49 |

| Chongqing | 0.53 | 0.5 | 0.44 | 0.45 | 0.47 | 0.46 | 0.6 | 0.6 | 0.59 | 0.58 | 0.6 | 0.6 |

| Sichuan | 0.58 | 0.53 | 0.61 | 0.57 | 0.7 | 0.7 | 0.66 | 0.66 | 0.75 | 0.79 | 0.67 | 0.67 |

| Guizhou | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Yunnan | 0.37 | 0.42 | 0.42 | 0.47 | 0.73 | 0.8 | 0.66 | 0.73 | 0.68 | 0.76 | 0.68 | 0.74 |

| Shaanxi | 0.35 | 0.36 | 0.4 | 0.43 | 0.52 | 0.53 | 0.54 | 0.53 | 0.57 | 0.59 | 0.69 | 0.72 |

| Gansu | 0.35 | 0.4 | 0.4 | 0.42 | 0.31 | 0.3 | 0.3 | 0.3 | 0.33 | 0.36 | 0.34 | 0.4 |

| Qinghai | 0.32 | 0.34 | 0.32 | 0.36 | 0.31 | 0.34 | 0.32 | 0.33 | 0.34 | 0.38 | 0.34 | 0.37 |

| Ningxia | 1 | 1 | 1 | 1 | 1 | 1 | 0.61 | 0.66 | 0.68 | 0.75 | 0.72 | 0.77 |

| Xinjiang | 0.31 | 0.32 | 0.34 | 0.36 | 0.3 | 0.32 | 0.31 | 0.33 | 0.29 | 0.31 | 0.32 | 0.34 |

| Region | 2017 | 2018 | 2019 | 2020 | 2021 | |||||||

| M1 | M2 | M1 | M2 | M1 | M2 | M1 | M2 | M1 | M2 | |||

| Beijing | 0.72 | 0.61 | 0.44 | 0.33 | 0.44 | 0.72 | 0.61 | 0.44 | 0.33 | 0.44 | ||

| Tianjin | 1 | 1 | 1 | 1 | 0.8 | 1 | 1 | 1 | 1 | 0.8 | ||

| Hebei | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Shanxi | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Inner Mongolia | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Liaoning | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Jilin | 0.58 | 0.61 | 0.47 | 0.44 | 0.45 | 0.58 | 0.61 | 0.47 | 0.44 | 0.45 | ||

| Heilongjiang | 0.35 | 0.35 | 0.25 | 0.24 | 0.22 | 0.35 | 0.35 | 0.25 | 0.24 | 0.22 | ||

| Shanghai | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Jiangsu | 1 | 1 | 0.74 | 0.71 | 0.73 | 1 | 1 | 0.74 | 0.71 | 0.73 | ||

| Zhejiang | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Anhui | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Fujian | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Jiangxi | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Shandong | 0.85 | 0.79 | 0.88 | 0.82 | 1 | 0.85 | 0.79 | 0.88 | 0.82 | 1 | ||

| Henan | 0.56 | 0.57 | 0.94 | 0.96 | 0.99 | 0.56 | 0.57 | 0.94 | 0.96 | 0.99 | ||

| Hubei | 0.46 | 0.41 | 0.59 | 0.5 | 0.63 | 0.46 | 0.41 | 0.59 | 0.5 | 0.63 | ||

| Hunan | 0.66 | 0.67 | 0.52 | 0.51 | 0.54 | 0.66 | 0.67 | 0.52 | 0.51 | 0.54 | ||

| Guangdong | 0.91 | 0.87 | 0.61 | 0.49 | 0.65 | 0.91 | 0.87 | 0.61 | 0.49 | 0.65 | ||

| Guangxi | 1 | 1 | 0.48 | 0.5 | 0.54 | 1 | 1 | 0.48 | 0.5 | 0.54 | ||

| Hainan | 0.56 | 0.5 | 0.59 | 0.45 | 0.75 | 0.56 | 0.5 | 0.59 | 0.45 | 0.75 | ||

| Chongqing | 0.6 | 0.57 | 0.57 | 0.52 | 0.57 | 0.6 | 0.57 | 0.57 | 0.52 | 0.57 | ||

| Sichuan | 0.65 | 0.64 | 0.56 | 0.47 | 0.58 | 0.65 | 0.64 | 0.56 | 0.47 | 0.58 | ||

| Guizhou | 1 | 1 | 0.6 | 0.5 | 0.57 | 1 | 1 | 0.6 | 0.5 | 0.57 | ||

| Yunnan | 0.7 | 0.74 | 0.66 | 0.7 | 0.6 | 0.7 | 0.74 | 0.66 | 0.7 | 0.6 | ||

| Shaanxi | 0.69 | 0.72 | 0.61 | 0.65 | 0.62 | 0.69 | 0.72 | 0.61 | 0.65 | 0.62 | ||

| Gansu | 0.33 | 0.39 | 0.35 | 0.42 | 0.35 | 0.33 | 0.39 | 0.35 | 0.42 | 0.35 | ||

| Qinghai | 0.31 | 0.32 | 0.28 | 0.29 | 0.26 | 0.31 | 0.32 | 0.28 | 0.29 | 0.26 | ||

| Ningxia | 0.65 | 0.64 | 0.52 | 0.61 | 1 | 0.65 | 0.64 | 0.52 | 0.61 | 1 | ||

| Xinjiang | 0.34 | 0.33 | 0.35 | 0.34 | 0.45 | 0.34 | 0.33 | 0.35 | 0.34 | 0.45 | ||

| Sets | Calibration Anchors | Descriptive Analysis | ||||

|---|---|---|---|---|---|---|

| Fully In (75%) | Crossover (50%) | Fully Out (25%) | Min | Max | Mean | |

| Cons | 1 | 0.69 | 0.453 | 0.24 | 1 | 0.70 |

| LI | 13,957.44 | 11,638.82 | 7349.88 | 1247.23 | 24,030.33 | 11,218.92 |

| DI | 0.841 | 0.735 | 0.657 | 0.51 | 1.07 | 0.75 |

| GT | 5189 | 2650 | 1198 | 256 | 24,072 | 5092.36 |

| GS | 213.695 | 161.525 | 98.178 | 47.13 | 493.55 | 174.13 |

| ED | 86,763.25 | 65,592.5 | 58,117 | 41,046 | 183,980 | 80,537.3 |

| IS | 0.529 | 0.511 | 0.491 | 0.435 | 0.833 | 0.529 |

| Conditions | Results | |||

|---|---|---|---|---|

| High Cons | Low Cons | |||

| Consistency | Coverage | Consistency | Coverage | |

| LI | 0.602007 | 0.579151 | 0.520266 | 0.503861 |

| ~LI | 0.484281 | 0.500692 | 0.565448 | 0.58852 |

| DI | 0.551839 | 0.566621 | 0.505648 | 0.522665 |

| ~DI | 0.535117 | 0.518135 | 0.580731 | 0.566062 |

| GT | 0.606154 | 0.581568 | 0.513621 | 0.496085 |

| ~GT | 0.474783 | 0.492301 | 0.566777 | 0.591622 |

| GS | 0.553846 | 0.545455 | 0.569435 | 0.564559 |

| ~GS | 0.55786 | 0.562753 | 0.541528 | 0.549932 |

| ED | 0.480334 | 0.474526 | 0.591495 | 0.588251 |

| ~ED | 0.583211 | 0.586467 | 0.471628 | 0.477433 |

| IS | 0.58796 | 0.583665 | 0.487043 | 0.48672 |

| ~IS | 0.482943 | 0.483266 | 0.583389 | 0.587684 |

| Antecedent Condition | High Cons | Low Cons | |||||

|---|---|---|---|---|---|---|---|

| H1 | H2 | H3a | H3b | H4 | NH1 | NH2 | |

| LI | O | x | x | O | X | ||

| DI | O | o | x | x | x | o | X |

| GT | x | o | X | X | o | O | x |

| GS | x | X | o | O | o | X | |

| ED | X | O | O | O | x | x | X |

| IS | o | X | X | X | X | O | X |

| Consistency | 1 | 0.992958 | 0.915085 | 0.912664 | 0.859922 | 0.967033 | 0.94471 |

| Raw coverage | 0.0668896 | 0.0943144 | 0.122542 | 0.125819 | 0.147826 | 0.0584718 | 0.249767 |

| Unique coverage | 0.0474916 | 0.0548495 | 0.0234782 | 0.0214047 | 0.10301 | 0.0431894 | 0.234485 |

| Over solution consistency | 0.933583 | 0.946341 | |||||

| Over solution coverage | 0.366689 | 0.292957 | |||||

| Antecedent Condition | High Cons | Low Cons | |||

|---|---|---|---|---|---|

| H1 | H2 | H3a | NH1 | NH2 | |

| LI | x | X | O | X | |

| DI | o | x | x | o | x |

| GT | o | x | o | O | x |

| GS | X | O | o | X | |

| ED | O | O | x | x | X |

| IS | X | x | X | O | X |

| Consistency | 0.891213 | 0.84326 | 0.806201 | 0.901709 | 0.802594 |

| Raw coverage | 0.139856 | 0.176625 | 0.204859 | 0.153232 | 0.404502 |

| Unique coverage | 0.0216678 | 0.0630336 | 0.133946 | 0.0341322 | 0.289034 |

| Over solution consistency | 0.828756 | 0.779176 | |||

| Over solution coverage | 0.336835 | 0.494553 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, L.; Zhao, Y.; Zheng, X.; Ma, S. Pathways to Improve Energy Conservation and Emission Reduction Efficiency During the Low-Carbon Transformation of the Logistics Industry. Sustainability 2025, 17, 4629. https://doi.org/10.3390/su17104629

Tang L, Zhao Y, Zheng X, Ma S. Pathways to Improve Energy Conservation and Emission Reduction Efficiency During the Low-Carbon Transformation of the Logistics Industry. Sustainability. 2025; 17(10):4629. https://doi.org/10.3390/su17104629

Chicago/Turabian StyleTang, Lianjie, Yabin Zhao, Xiaojie Zheng, and Shiang Ma. 2025. "Pathways to Improve Energy Conservation and Emission Reduction Efficiency During the Low-Carbon Transformation of the Logistics Industry" Sustainability 17, no. 10: 4629. https://doi.org/10.3390/su17104629

APA StyleTang, L., Zhao, Y., Zheng, X., & Ma, S. (2025). Pathways to Improve Energy Conservation and Emission Reduction Efficiency During the Low-Carbon Transformation of the Logistics Industry. Sustainability, 17(10), 4629. https://doi.org/10.3390/su17104629