4.1. The 6-Bus Power System Case Study

(1) Case I: First, the energy problem for the three islands was solved without considering the ships. Assuming a deterministic load, the operational cost was USD 87,154.47, and the load demand was fully met. Then, the MESC-IS model was solved with PGSs considered stationary, and the problem was solved again. The new cost for the system was USD 79,133.80. This represented a significant cost reduction even when the ships were considered stationary during the operational horizon.

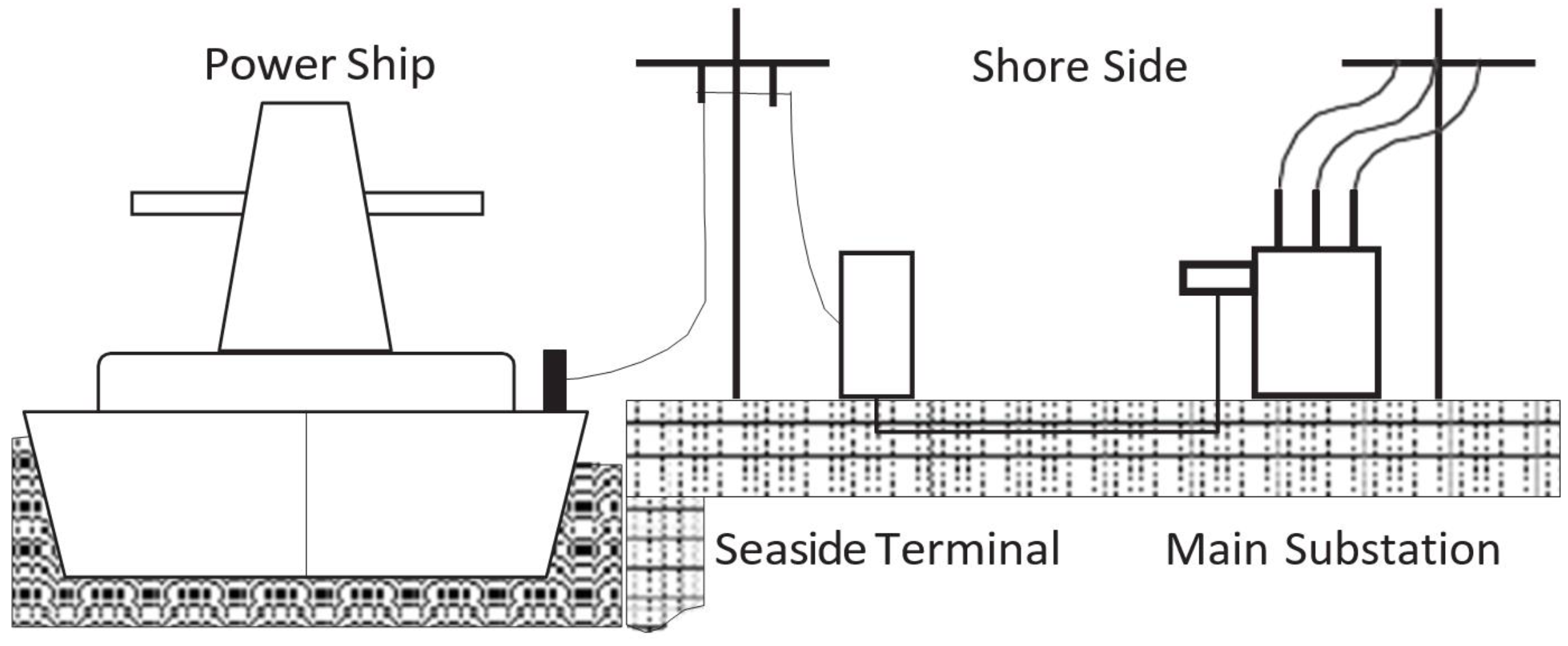

Figure 5 and

Figure 6 show the generation units and PGS output in both cases. PS-1 operated for 15 h, from hour 8 to the end of the operational horizon, supplying electricity from the same bus at which it was initially located (bus-3). The potential for further savings was examined by considering the other two solution approaches. To conclude, the integration of PGSs into power grid operations demonstrates significant economic benefits. The model shows that even when considering the ships as stationary assets, a considerable cost reduction of USD 8020.67 was achieved. This indicates that PGSs can effectively reduce operational costs, making them viable options for enhancing grid efficiency. To display the statistical details of the model, solver summary, and solver details,

Table 2,

Table 3 and

Table 4 are provided to indicate the complexity of the models.

In

Figure 5, under the GCUC case (where no ships were utilized), all conventional power plants were operational, leading to a higher overall cost. This increase in cost was primarily due to the operation of G2, which had the highest generation cost among the units; generation costs are provided in

Table 5.

However, in the MESC-IS case, where ships were considered but remained stationary, G2 was deactivated due to its high cost, thereby reducing overall system expenses. Additionally, G3 decreased its power output, as the ships contributed to electricity generation. Since the ships produced electricity at a lower cost compared to G2 and G3, their integration helped optimize generation dispatch, ultimately improving cost efficiency.

Since the unit status had already been obtained from the solution of the original model (GCUC), the sequential model (MESC-Sq) was considered first. This approach coordinates ship movements only after the UC has been determined. In this case, a total operational cost of USD 85,583.39 was achieved. As the UC decisions were fixed beforehand, the status of all generation units remained unchanged. However, cost reductions were still realized due to the mobility of the ships.

For example, in the MESC-Sq approach, ship PS-1 traveled from bus 2 to bus 4, departing at hour 6 and arriving at hour 10. Since the ships’ ability to operate immediately upon arrival was restricted, power generation started at hour 10. Despite this limitation, cost reductions were observed by allowing the mobility of the ships.

It can be concluded that the application of the maritime-based energy scheduling and coordination–sequential approach, known as MESC-Sq, resulted in significant cost savings. The ability of the PGS to move and supply power to different locations was found to be essential for optimizing the economic operation of the power system.

The most efficient solution was provided by the fully integrated model, known as MESC-I, where all decisions, including generation UC, dispatch, and ship mobility, were optimized simultaneously. This approach led to a total cost of USD 78,463.17, which was significantly lower than the MESC-Sq model.

In this case, ship PS-1 followed the same route from bus 2 to bus 4, but with key differences:

The ship departed one hour earlier (hour 5) and arrived at hour 9, instead of departing at hour 6.

This optimized scheduling allowed for a more efficient distribution of energy, which resulted in further cost reductions.

A significant reduction in costs was achieved by optimizing both power generation and ship mobility simultaneously. While the sequential approach (MESC-Sq) already demonstrated benefits from ship mobility, the fully integrated model (MESC-I) provided greater savings by jointly optimizing these factors.

The findings indicate that PGSs remain economically viable even if their daily operational costs (including sailing, entry, and departure costs) are USD 9000 higher. This suggests that the mobility of ships is a valuable asset in the optimization of power system operations.

However, for real-world implementation, larger case studies should be conducted. A more comprehensive analysis, incorporating additional constraints and uncertainties, is expected to provide deeper insights and potentially lead to even greater cost reductions. Future studies should focus on expanding the model to better reflect the actual conditions of energy markets and real-world maritime constraints.

Table 6 summarizes the cost comparisons between the different approaches.

4.2. 118-Bus Power System Case Study

The adopted 118-bus power system was used to simulate a larger case using the same ships from the previously studied case. Two different loading scenarios were considered, classified as high and low loading levels. The high loading level had an hourly average load of 1366.83 MW, while the low loading had an average load of 1354.04 MW.

(2) Case II: In this case, the GCUC was solved for the system, providing a total cost of USD 2,052,910.22 with 4.276 MW load shedding. Similar to the previous case, three solution approaches were obtained.

Table 6 shows the total cost of the three approaches.

After that, MESC-IS was modeled, resulting in 3.86 MW shedding, a slight improvement compared to the original case. The cost reduction achieved through this approach highlights the benefit of integrating power ships even without their mobility being fully utilized.

The solutions obtained using the MESC-I and MESC-Sq approaches resulted in no load shedding and achieved significant cost reductions of USD 10,696.6 and USD 15,906.12, respectively. The MESC-I (fully integrated) approach proved to be the most effective in cost savings. The mobility of the ships contributed more to cost savings in this case compared to case I. As shown in

Figure 7, PS-1 made one trip and generated 1570 MWh during the operational horizon. The ship traveled from its initial port to port 7. Additionally, the MESC-I suggested the deployment of PS-2, which made more trips than PS-1. Specifically, PS-2 sailed from bus 97 at the beginning of hour 3, arriving at bus 10 at hour 5. It operated for only one hour and waited for 4 h before sailing to bus 7.

Table 6 shows the complete coordination plan of the ships for the MESC-I and MESC-Sq approaches.

(3) Case III: To further illustrate the potential of integrating the PGS, a different load demand was considered in this case. The GCUC resulted in a total cost of USD 2,011,241.41 with no load shedding.

First, the integrated solution (MESC-I) approach resulted in system savings of USD 6971.68. Both ships sailed once during the operational horizon. As shown in

Figure 8, the total energy produced by the ships during this period was 1860.7 MWh. The total operational cost of the ships was USD 35,328.263.

The sequential solution (MESC-Sq) approach provided USD 3964.8 in savings. The total operational cost of the ships in this approach was USD 27,605.086. In this case, the stationary solution approach (MESC-IS) resulted in a better solution than the sequential one. The MESC-IS total cost was USD 2,005,790.52.

Table 6 shows the costs of all solution approaches. Despite the relatively low demand and no shedding penalties, the ships were still able to show potential for economic improvements.

The generation scheduling problem has long been recognized as computationally challenging to solve in real-time. The generation scheduling problem—which includes UC and ED—is classified as a non-deterministic polynomial-time hardness (NP-hard) problem. This means that as the problem size increases, the time required to solve it grows exponentially, making it computationally infeasible to obtain an optimal solution for large-scale systems in real-time. Therefore, it is critical to test the computational performance of any changes made to the problem. A significant computational burden was observed with the integrated solution approach, MESC-I. A running time of 2500 s was considered for all case studies. In case II, the solver achieved a global optimum solution for GCUC in 327.04 s and 1,059,585 iterations. However, in the integrated approach, MESC-I, the solver was unable to reach the global optimum and terminated after 2500 s and 2,449,504 iterations. In case III, GCUC required 410.6 s and 1,007,838 iterations, while MESC-IS and MESC-Sq needed just 61.51 s and 24 s, respectively, to reach a global optimum solution. Similar to the previous case, the MESC-I approach could not achieve the global optimum within the allotted 2500 s, which is more than 104 times the time required for the sequential approach to find a solution. Although the results of the integrated approach are unsatisfactory, they provide insight into the exponential growth in the complexity of the problem.

Table 7 presents a comparative analysis of Case II and Case III in terms of energy output, PGS total cost, and system savings. Case II consistently demonstrates higher energy production and incurs greater generation costs, yet it also delivers significantly higher system savings, indicating a positive return on investment. In contrast, Case III shows reduced energy generation and lower costs, but with notably diminished savings. The results reveal a positive correlation between energy output and economic benefit, suggesting that increased energy production—despite its higher cost—leads to proportionally greater system savings.

The approximate approaches performed computationally well, as shown in

Table 8, indicating potential time-accuracy trade-offs between different solution approaches. It is important to note that the MESC-Sq solution time in

Table 8 only includes the maritime-based problem. The first sub-problem must be solved even without the existence of PGS. The total or wall time can be obtained with a high degree of accuracy by adding the times together. Since the availability of the energy scheduling solution is assumed, the two times are provided independently.

Despite this complexity, the work marks a pioneering effort in exploring the incorporation of maritime energy transportation into power systems. There is substantial potential for future research to enhance the model’s computational performance. By introducing valid inequalities and cuts, the solution process can be made more efficient, reducing the computational burden. These techniques can streamline the problem-solving process, making it feasible to handle larger and more complex scenarios without compromising accuracy or efficiency. The development and implementation of such improvements could significantly advance the practical application of this innovative integration model.

Table 8 presents a comparative analysis of four computational approaches—GCUC, MESC-IS, MESC-Sq, and MESC-I—based on four key performance indicators: objective function, computation time, number of iterations, and relative gap percentage (R-Gap%). The MESC-I with a cost value of 2,004,269.73, making it the most effective in terms of solution quality. On the other hand, GCUC yields the highest objective value at USD 2,011,241.41, indicating it is the least effective. The slight variations in objective values across the methods suggest that all approaches provide relatively similar solutions, albeit with minor cost differences.

When it comes to computation time, the results show significant variation. MESC-Sq is the fastest, completing the solution in just 24.12 s, while MESC-I takes the longest at 2500 s. MESC-IS also performs efficiently, solving the problem in 61.51 s, whereas GCUC requires 410.62 s, making it significantly slower than the MESC-based approaches. The number of iterations further highlights the efficiency of each method. MESC-Sq stands out with only 27,709 iterations, indicating a highly efficient convergence process. In contrast, MESC-I requires 1,814,246 iterations, which aligns with its high computational time. GCUC has a high iteration count of 1,007,838, while MESC-IS reduces this number significantly to 118,964, demonstrating its efficiency.

The relative gap (R-Gap%) measures the difference between the computed objective value and the optimal solution, with lower values indicating better accuracy. All methods achieve near-optimal solutions, with R-Gap values close to zero. MESC-I exhibits a slight gap of 0.000076, but this is negligible in practical applications. The results demonstrate a clear trade-off between speed and solution quality. MESC-Sq is the fastest and requires the fewest iterations, but achieves a slightly higher objective value compared to MESC-I. Conversely, MESC-I achieves the best objective value but at the cost of significantly higher computational time and iterations. MESC-IS strikes a balance, offering near-optimal performance with reasonable computational effort, while GCUC is the least efficient in terms of both computational time and iteration count.

In conclusion, MESC-Sq emerges as the most efficient method for this problem, offering a strong balance between computational speed, iteration count, and solution quality. MESC-IS is a viable alternative, providing a good compromise between efficiency and performance. While MESC-I achieves the best solution quality, its high computational cost makes it less practical for large-scale or time-sensitive applications. GCUC, on the other hand, is the least effective and may not be suitable for problems requiring high efficiency or accuracy. The choice of method ultimately depends on the specific requirements of the problem: if speed is critical, MESC-Sq is the best choice; if solution quality is the top priority, MESC-I is preferable despite its computational cost; and MESC-IS offers a balanced middle ground.