Abstract

The intensification of agricultural production due to high global demand has led to uncontrolled waste production from this industry, creating an environmental imbalance due to inadequate waste management. In developing regions, the lack of access to electricity has become a critical problem, affecting people’s health, education, and economy. To address this issue, alternative and sustainable ways of generating electricity have been explored. This research focuses on the potential of using asparagus waste in single-chamber microbial fuel cells (MFCs) at different pH levels (4, 4.7—target, 7, and 9) to achieve optimal performance. It has been demonstrated that using this substrate, the MFC at pH 7 obtained the best results on the seventh day, generating an electric current of 4.859 mA and a maximum voltage of 0.965 V. The substrate showed an oxidation-reduction potential of 312.821 mV, a chemical oxygen demand reduction of 76.47%, and an electrical conductivity of 254.854 mS/cm. Additionally, it managed to generate a power density of 2.149 mW/cm2 at a current density of 5.979 mA/cm2. MFCs at different pH levels (4, 4.7—target, 7, and 9) demonstrated their potential to generate electrical energy by powering an LED light when connected in series. This research holds promise in promoting sustainable energy solutions for the future.

1. Introduction

Agro-industrial waste has become a serious economic and social problem for companies and governments because many countries lack an adequate management system for its collection, resulting in its disposal in informal landfills or on streets near where it originates [1,2]. Although the waste of fruits, vegetables, tubers, and others depends on several factors, it has been estimated that the waste (peels and residues) of fruits and vegetables varies between 30 and 50% during the harvesting and consumption process [3]. Regarding cereals, it has been estimated that for each ton of harvested grain, about 2 tons of waste is produced, and for each ton of olive and palm, about 800 kg of waste is produced [4]. The Food and Agriculture Organization (FAO) has estimated that agricultural waste amounts to about 5 billion tons per year, with Asia, Africa, and South America being the most significant contributors to this type of waste generation due to the reliance of many of their countries on the agricultural sector [5,6].

Peru stands out for producing grapes, asparagus, and avocados, with asparagus being the most produced in the last year [7]. It has also become one of the leading exporters of asparagus (canned, frozen, and fresh) in the region, mainly white asparagus, which has a higher demand in Asian and European markets [8,9]. It has been reported that in 2023, Peru exported about 97,969 tons of fresh asparagus, generating approximately USD 393 million, each kilogram of the product being sold for USD 4.02 [10]. This boom in asparagus production has contributed to the generation of large quantities of asparagus waste, creating a problem for agro-exporting companies [8]. Asparagus waste is a rich source of bioactive compounds and fiber, making it an interesting option for producing value-added products in the food and health industries [10]. Similarly, other vegetable residues can be used to produce microbial fuel cells (MFCs) due to their chemical and mechanical properties. For example, carrot waste contains carotenoids and potent antioxidants, and its high fiber content makes it a good substrate for fermentation in MFCs [11]. Likewise, beet waste is rich in vitamins, minerals, and antioxidants, making it useful as a raw material for fermentation in MFCs [12]. Additionally, pepper extracts contain capsaicin and other beneficial compounds, making them ideal for producing extracts in fermentation processes [6]. Asparagus waste is rich in bioactive compounds, including fiber, antioxidants, and carbohydrates, which make it an ideal substrate for microbial metabolism in microbial fuel cells (MFCs) [10,12]. These components promote organic degradation and oxidation, thereby enhancing electron transfer and facilitating bioelectricity generation [9,11].

Over the past few decades, economic growth has significantly increased electricity demand. Although efforts have been made to expand generation and distribution capacity, this growth has not always kept pace with demand, resulting in some areas experiencing power outages or insufficient supply [13]. Electric energy consumption has significantly increased in the last decade due to various factors such as urbanization, economic development, and industry expansion [14]. Energy prices derived from natural gas, coal, and oil increase due to limited supply, and they are highly susceptible to external factors. These sources are estimated to be exhausted in 50 years, making a vital energy transition necessary [15,16]. This situation has led people and companies to seek sustainable alternatives for electricity generation to meet basic needs. In Peru, the price of electricity is currently USD 0.186 per kilowatt-hour (kWh), which is very high compared to the price in China, which is USD 0.08 per kWh. For this reason, installing new power plants in remote locations in Peru remains virtually impossible [15,16]. Despite investments in the energy sector, the electrical infrastructure remains limited or inadequate in several areas, particularly in rural and hard-to-reach regions [16]. This is mainly due to insufficient distribution networks and a lack of investment in the maintenance and expansion of the electrical grid [17,18]. Consequently, individuals and businesses seek alternative and sustainable ways to generate electricity to meet the population’s basic needs, which still lack access to this service.

In this context, scientists have explored new alternatives for sustainable electricity generation. Microbial fuel cells (MFCs) offer a sustainable alternative for the treatment of agricultural waste by harnessing microbial activity to degrade organic matter while simultaneously generating electricity. These systems not only reduce pollutant loads and improve waste management but also provide decentralized energy solutions for rural communities with limited access to electricity, contributing to both environmental and energy sustainability [19,20]. MFCs convert the chemical energy of various wastes into electricity through biochemical processes [20]. In these processes, microorganisms in the substrates used as fuel break down organic matter (such as fatty acids, lactose, and glucose), releasing electrons. These electrons are captured by the anode electrode and transported through an external circuit to the cathode electrode, generating electricity. Standardizing various parameters, including pH, is essential to ensure the optimal functioning of MFCs. The optimal pH value directly influences the behavior of biochemical reactions, microbial activity, and electron transfer between the anode and cathode chambers [21]. For example, He et al. (2021) used fruit waste in their MFCs, generating 0.75 V and a power density of 0.197 W/m2 at a pH of 6.8 ± 0.1 [22]. Similarly, Yaqoob et al. (2022) used rambutan, langsat, and mango waste as substrates in their MFCs, operating at a pH of 7.04, generating a current density of 87.71 mA/m2 and a maximum voltage of 0.4 V [23]. Fruits significantly contribute to waste in agribusiness. Reducing waste levels by harnessing this waste to generate energy through MFCs can be beneficial [24]. For the proper acclimatization of microbes in asparagus waste, specific bacterial cultures are typically used to decompose organic matter and facilitate bacterial cellulose production [25]. A typical example is using Komagataeibacter xylinus, a bacterium known for producing bacterial cellulose from agro-industrial residues, including asparagus waste [25]. During the fermentation process, Komagataeibacter xylinus converts these sugars into bacterial cellulose. Additionally, Lactobacillus spp. is lactic acid bacteria that can be used in the fermentation of vegetable residues, promoting the production of lactic acid and improving the preservation and organoleptic properties of the products [26]. Each substrate tends to have different optimal pH values, so a pH optimization study is necessary to achieve optimal values for electrical energy generation in MFCs.

The primary purpose of this research is to observe the values generated by single-chamber microbial fuel cells with asparagus waste, in which the pH was varied to obtain the best electrical energy values over 14 days. The values of chemical oxygen demand, electric current, internal resistance, power density, voltage, electrical conductivity, and current density were obtained from the monitoring carried out on the MFCs. This research will determine the optimal pH value of asparagus waste to be used as a substrate in single-chamber microbial fuel cells for later large-scale use, benefiting agro-exporting companies and society. MFCs that utilize fruit waste can provide a localized and decentralized energy solution for small communities or rural industries, particularly where fruit production is a significant activity. These communities could generate electricity from crop waste, reducing costs and dependence on external energy sources.

2. Materials and Methods

- Construction of Microbial Fuel Cells (MFCs)

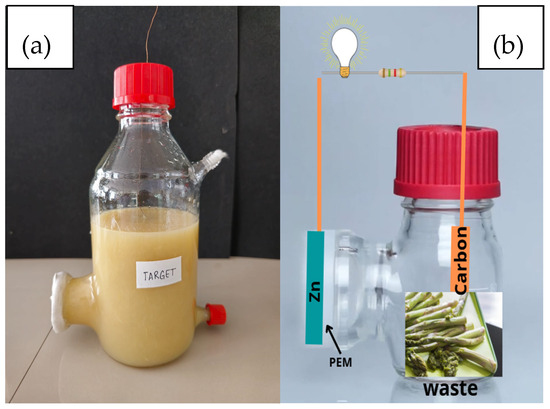

The single-chamber microbial fuel cells (MFCs) constructed for this study were designed with a capacity of one liter, utilizing borosilicate glass (Boron 3.3) for enhanced durability and chemical resistance. Each MFC was equipped with carbon anode electrodes, which had a surface area of 45 cm2, and a zinc cathode electrode with a smaller surface area of 12.27 cm2. These electrodes were externally connected via an electrical circuit with an internal resistance of 100 Ω. Internally, they were separated by a Nafion 117 proton exchange membrane (PEM), known for its high proton conductivity and chemical stability. The zinc cathode electrode, which was circular with a radius of 1.976 cm and a thickness of 0.01 mm (sourced from China Tisco, Liaocheng, China), was secured to one end of the MFC using white silicone adhesive (Sikasil AC, Lima, Peru). This ensured a watertight seal while maintaining the electrode’s integrity. Figure 1a,b illustrate the actual MFC used in the experiment as well as its schematic representation, offering a visual understanding of the setup.

Figure 1.

(a) Actual photo and (b) schematic diagram of the MFC.

- b.

- Preparation of Substrate

The substrate for the MFCs was derived from asparagus waste, which was generously provided by the company CUC SAC. A total of 8 kg of asparagus waste was collected and processed to obtain a liquid substrate. This was achieved using an industrial extractor (Labtron, Grand Rapids, MI, USA, LDO-B10-USA), which yielded approximately three liters of liquid asparagus waste. This substrate was subsequently used as the primary fuel for microbial activity within the MFCs. The pH levels of the substrate were adjusted to explore their impact on the MFCs’ performance. Specifically, pH values of 4, 7, and 9 were prepared. For the MFC with a target pH of 4, 12 mL of 0.1 N hydrochloric acid (HCl) was added to the substrate. Similarly, for the MFCs with pH values of 7 and 9, 9 mL and 13 mL of 0.1 N sodium hydroxide (NaOH) were added, respectively. An MFC control was also established using the raw asparagus waste without pH adjustment, which had a natural pH of 4.7.

- c.

- MFC Configuration and Operation

Each MFC was filled with 800 mL of the prepared asparagus residue, ensuring consistency across the experimental setup. This volume was optimized to provide adequate substrate for microbial activity while maintaining an appropriate reaction chamber size. The configuration aimed to maximize electrical performance and investigate the influence of substrate pH on energy generation and microbial efficiency.

- d.

- Acquisition of physicochemical values of MFCs

To obtain the monitoring values of the single-chamber microbial fuel cell, voltage and current were measured using a Prasek Premium brand multimeter (PR-85, FL, USA). Observations of the oxidation-reduction potential (ORP), pH, conductivity, and chemical oxygen consumption values were performed and measured using a BioMars multiparameter device (HI98194, MI, USA). The power density (PD) and current density (CD) values were obtained applying the formulas PD = V2cell/(Rext.A) and CD = Vcell/(Rext.A), where Vcell represents the MFC voltage and A is the area using external resistors of 0.2 (±0.05), 5 (±0.50), 20 (±2.4), 50 (±6.52), 120 (±10.55), 240 (±15.62), 480 (±20.64), 520 (±30.88), 780 (±50.75) and 1000 (±60.55) Ω [27]. Additionally, the potential for electricity generation through single-chamber microbial fuel cells, for which the MFCs were connected in series, is presented.

3. Result and Analysis

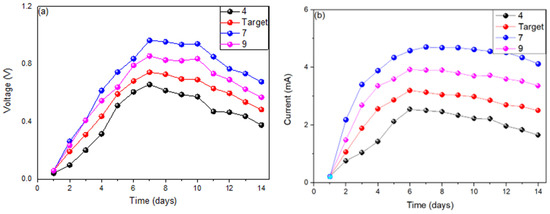

Figure 2a displays the voltage values of the MFCs at different pH levels. The MFCs showed an increase in values from the second to the seventh day. The MFC at pH 7 recorded the highest value of 0.965 V, while the MFC at pH 4 had the lowest value at 0.658 V. The MFC used as the target, operating at pH 9, recorded voltage values of 0.743 V and 0.856 V, respectively. All MFCs, after reaching their maximum voltage, exhibited a decline in their output. pH plays a crucial role in voltage generation within MFCs due to its impact on the electrochemical reactions occurring in the anodic and cathodic chambers. This is attributed to the oxidation processes carried out by microorganisms on the organic substrate [28,29]. The influence of pH on microbial activity within microbial fuel cells (MFCs) has been extensively studied. It has been reported that acidic pH levels can inhibit microbial activity, reducing the efficiency of organic substrate oxidation [30]. However, recent studies have demonstrated that alkaline conditions can also enhance bioelectricity generation under certain experimental configurations. Li et al. (2021) [31] evaluated MFCs using wastewater as a substrate, adjusting the pH to 8.5, 9.5, and 10.5. Their findings revealed that the MFC at pH 10.5 achieved the highest output voltage (820 mV), surpassing the values recorded for the other configurations [31]. This suggests that certain microorganisms can adapt and optimize their metabolism under alkaline conditions, promoting electrochemical reactions within the system. The relationship between pH, microbial metabolism, and electrochemical efficiency must be considered in an integrated manner to assess the feasibility of MFCs in different environments and substrates [31]. Bagchi S. and Behera M. (2021) [32] similarly used wastewater as a substrate, varying the pH levels to 5 and 9. Their results showed that the MFC at pH 5 produced 801 mV, while the one at pH 9 generated 685 mV. These results reinforce the notion that neutral pH levels promote the growth of electrogenic bacteria [32]. Figure 2b presents the electric current values recorded by the MFCs. On the seventh day, the MFC at pH 7 recorded 4.859 mA, while the MFC at pH 4 reached 2.617 mA. In comparison, the target MFC at pH 9 achieved 3.154 mA and 3.592 mA before a decline in current was observed toward the final day. The generation of electric current in MFCs is attributed to microbial metabolism, electrode reactions, and electron transfer processes, all of which are directly influenced by pH. Microbial activity operates most efficiently within an optimal pH range, which facilitates substrate oxidation and, consequently, electron generation [33,34]. Akinwumi et al. (2024) [35] used pharmaceutical wastewater as a substrate in their MFCs, varying the pH from 4.5 to 7.5. They recorded an electric current of 2.56 mA, with the optimal performance observed at a pH of 7.3 [35]. Meanwhile, Sigalingging R. and Sitorus Y. (2024) used starfruit, mango, and strawberry as substrates, achieving a maximum electric current of 3.65 mA with MFCs operating at a pH of 4 [36].

Figure 2.

Reports of (a) voltage and (b) electric current values obtained from the MFCs.

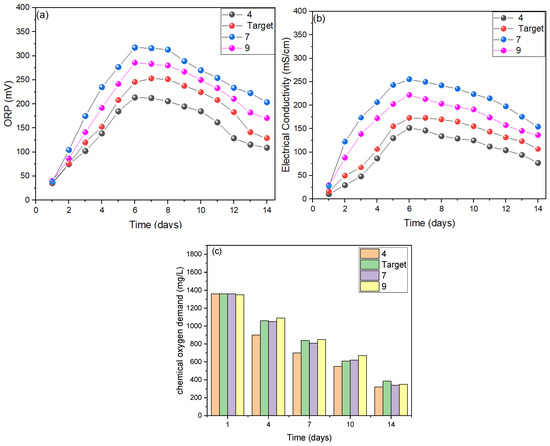

The values obtained from the redox potential of the MFCs are presented in Figure 3a. A progressive increase is observed from the first to the sixth day, with the MFC-pH 7 reaching a maximum value of 312.821 mV. The MFC-pH 4 recorded the lowest value (213.472 mV), while the MFC-target and the MFC-pH 9 showed 252.872 mV and 282.762 mV, respectively, before decreasing. The values of the substrates used as fuels in MFCs can accept or donate electrons during redox reactions, depending on the electrochemical stability of the medium. An acidic, neutral, or alkaline pH directly influences this process [37,38]. In his research, Teng P. (2023) highlighted that the decrease in pH values causes the oxidation potential of the microbes present in the substrate to vary due to the change in the concentration of protons in acidic environments [38]. Hsu et al. (2022) used sediments as a substrate in MFC, managing to generate an ORP of 236 mV operating at pH values of 7.9–8.2, mentioning that the efficiency of oxygen reduction in the cathodic chamber depends on the pH because the availability of protons directly influences the oxygen reduction potential [39]. The monitored electrical conductivity values can be observed in Figure 3b, where all the MFCs show similar values around 10.514 ± 22.231 mS/cm in the first days and then increase until day six, where the MFC-pH 7 shows an electrical conductivity of 254.854 mS/cm and the MFC-pH 4 shows the lowest value (151.599 mS/cm). A substrate with good conductivity is crucial for maintaining a consistent flow of ions (such as protons) and electrons within the cell, facilitating redox reactions. Oxidation occurs at the anode, while reduction takes place at the cathode [40]. Electrogenic bacteria are capable of efficiently metabolizing sugars like glucose and fructose. However, the impact of these sugars on conductivity depends on the bacteria’s ability to extract electrons effectively [41]. Although sugars themselves are poor conductors of electricity, their decomposition produces protons and electrons, which improve the system’s overall conductivity [42]. In comparison, the MFC-target was 154.571 mS/cm, and the MFC-pH 9 obtained a 202.207 mS/cm value. The values gradually decreased until the last day of monitoring. In previous studies, it has been observed that electrical conductivity depends on the ionic concentration of the substrate, and in acidic solutions, protons are the charge carriers, while in alkaline range solutions, hydroxide ions have an essential role as carriers [43,44]. Pineapple, potato, and tomato wastes have been used as substrates in MFC, showing an electrical conductivity of 69.47 ± 0.91 mS/cm on the twenty-third day of cell operation, mentioning that neutral pH values tend to stabilize the electrical conductivity values [45].

Figure 3.

Reported values of (a) ORP, (b) electrical conductivity and (c) COD.

Figure 3c shows the values of the chemical oxygen demand obtained from the monitoring carried out on the MFCs, observing that the MFC-pH 4 is the one that reduced the COD the most by 76.47% (1360 to 320 mg/L) during the monitoring period. The MFC-pH target was the one that reduced the least (70.69%); the MFC- pH 9 reduced it by 74.07 and the MFC-pH 7 by 75%. The influence of pH values on COD values is fundamental, mainly due to the metabolic activity of microbes, electrochemical reactions, and solubility of the compounds [46]. In their research, Yang et al. (2022) mentioned that Ph values in the neutral range favor generating maximum microbial activity, which enhances the effective degradation of organic compounds, increasing conversion efficiency and reducing COD values [47]. The relationship between COD reduction and energy production in MFCs is a key aspect that demonstrates how bioelectrochemical processes are interconnected. COD reduction reflects the efficiency with which electrogenic microorganisms metabolize the organic substrate, releasing electrons and protons that drive energy generation [32,41]. In MFCs, COD reduction serves as an indicator of organic matter degradation at the anode [37]. Microorganisms such as Komagataeibacter xylinus break down carbohydrates and other compounds present in asparagus residues, releasing electrons that are captured by the anode and transferred to the external circuit [43]. This process is directly influenced by the pH of the medium: Neutral conditions (pH 7) favor optimal microbial activity, contributing both to a higher COD reduction (75%, according to reported data) and to the generation of electrical energy (4.859 mA current and 0.965 V voltage). In contrast, extreme pH levels (acidic or alkaline) partially inhibit microbial activity, which limits the microorganisms’ ability to break down the substrate, thereby reducing energy production [27,35]. For instance, while pH 4 achieves a 76.47% COD reduction, the generated voltage and current are lower due to decreased efficiency in electron transfer under such conditions [40].

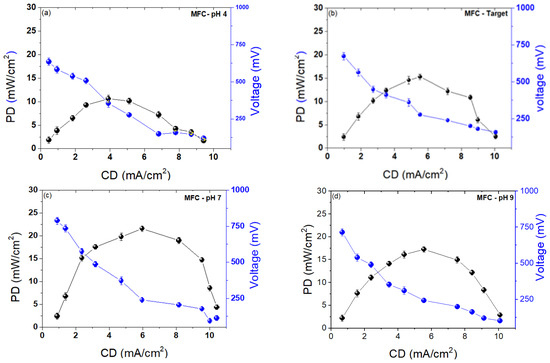

The power density (PD) values as a function of the current density (CD) of the microbial fuel cells (MFCs) are shown in Figure 4. The MFCs with pH levels of 4, target, 7, and 9 obtained maximum PDs of 10.92, 15.23, 21.49, and 17.31 mW/cm2, respectively, with corresponding CDs of 3.933, 5.572, 5.979, and 5.571 mA/cm2 and voltages of 638.082, 666.353, 790.637, and 715.089 V. The pH values at which an MFC operates significantly influence the power density values because the microbes responsible for degrading organic matter and generating electricity are sensitive to changes in the pH values of the medium. Variations in this parameter affect microbial activity and the efficiency of the MFC [48]. The studies by Li et al. (2021) and Bagchi and Behera (2021) present contrasting results regarding the optimal pH for microbial fuel cells (MFCs) using wastewater as a substrate [31,32]. While Li et al. [31] observed higher energy production at pH 10.5, Bagchi and Behera reported better performance at pH 5. This variability can be attributed to differences in substrate composition, microbial diversity, and experiment duration. Although neutral pH is widely recognized for its stability in microbial activity, certain experimental configurations may enhance bioelectricity generation under more extreme conditions. Further studies are needed to better understand the influence of pH on different systems and its impact on the electrochemical performance of MFCs. Previous reports indicate that various fruit wastes, such as peels and pulps, contain organic acids like citric and malic acid, which bacteria can utilize in MFCs. However, organic acids typically generate fewer electrons than sugars. As a result, their presence may limit power density unless balanced with other, more easily metabolizable compounds [49,50].

Figure 4.

Power density values as a function of the current densities of the MFCs at different pH values.

The table N° 01 emphasizes the performance of microbial fuel cells (MFCs) powered by organic waste, highlighting the critical influence of pH on electrochemical efficiency. Across varying pH levels (4, 4.7, 7, and 9), the results demonstrate that pH significantly impacts microbial metabolism, electron transfer, and substrate degradation, all of which play a vital role in energy generation within MFCs. Neutral pH conditions (pH 7) proved to be the most effective, showing superior performance across several electrochemical parameters. The asparagus waste MFC operating at pH 7 achieved a peak voltage of 0.965 V, a current of 4.859 mA, and the highest oxidation-reduction potential (ORP) of 312.821 mV. These results suggest that a neutral pH environment supports optimal microbial activity, enhances redox reactions, and facilitates efficient electron transfer between electrodes. Furthermore, electrical conductivity reached its highest value of 254.854 mS/cm at pH 7, indicating improved ion flow and effective substrate breakdown under these conditions. Despite a modest power density of 2.149 mW/cm2, these findings align with studies that highlight the benefits of neutral pH conditions in maximizing microbial efficiency and energy production. In contrast, acidic conditions (pH 4) inhibited microbial activity, yielding lower voltages (0.658 V), currents (2.617 mA), and ORP values (213.472 mV). Similarly, slightly alkaline conditions (pH 9) resulted in moderate performance, with a voltage of 0.856 V and a current of 3.592 mA. However, prolonged exposure to alkaline stress caused a gradual decline in microbial viability and systemic efficiency. Overall, the comparative analysis highlights the importance of maintaining a balanced pH environment within MFCs to optimize energy production. While asparagus waste demonstrates promise as an MFC substrate, further improvements in electrode materials and microbial adaptation could enhance power density and overall system performance.

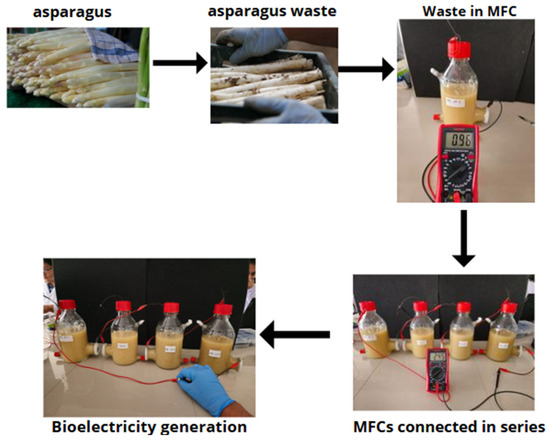

The process of generating electricity sustainably is shown in Figure 5, where the microbial fuel cells at pH 4, 4.7 (Target), 7, and 9 were connected in series, managing to generate a voltage of 2.45 V, which was sufficient to light an LED light for the operating period of all the MFCs. Advancements in biotechnology will enable the creation of more efficient and specialized bacterial strains capable of effectively breaking down compounds found in fruit waste, such as sugars, organic acids, and other components. These bacteria could enhance electricity production in microbial fuel cells (MFCs), improving their performance [51]. See Table 1 for details.

Figure 5.

Bioelectricity generation process.

Table 1.

Evaluation of electrochemical parameters in microbial fuel cells (MFCs) fed with different organic waste.

4. Conclusions

In this research, we observed the potential of asparagus waste at different pHs (4, 4.7—target, 7, and 9), successfully showing how the parameters vary. It was revealed that the optimal pH of operation was neutral (pH = 7) because the MFC-pH 7 showed a maximum voltage and electric current of 0.965 V and 4.859 mA on the seventh day; in addition, the oxidation-reduction power of said MFC was 312.821 mV with an electrical conductivity of 254.854 mS/cm and also managed to reduce the chemical oxygen demand from 1360 to 320 mg/L (76.47%). The MFC-pH 7 also showed a power density of 2.149 mW/cm2 for a current density of 5.979 mA/cm2. Finally, all the microbial fuel cells were connected in series, achieving the potential for bioelectricity generation by turning on a 2.45 V LED light.

Future work is recommended to use pH 7 in single-layer microbial fuel cells with asparagus waste and the inclusion of catalytic microbes to enhance the values obtained in this research. The compatibility of the electrodes with the substrate at different temperatures should also be studied to study the electrodes’ capacity for conducting electrons, their durability, and their cost. Microbial fuel cells are anticipated to advance in efficiency, cost-effectiveness, and ease of integration into large-scale industrial processes. Materials engineering developments, such as using more conductive electrodes and more efficient membranes, will enhance energy production from fruit waste. Future studies should incorporate metagenomic analysis to precisely characterize microbial dynamics and their impact on the efficiency of microbial fuel cells, optimizing bioelectricity generation and substrate degradation.

Author Contributions

Conceptualization, R.-F.S.; methodology, C.-C.L.; validation, N.M.O.; formal analysis, R.-F.S. and M.D.L.C.-N.; investigation, R.-F.S. and M.D.L.C.-N.; data curation, M.D.L.C.-N.; writing—original draft preparation, R.-F-S.; writing—review and editing, R.-F.S.; project administration, R.-F.S. and C.-C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financed by the Universidad Cesar Vallejo, project code No. P-2024-172.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hernandez, D.; Pasha, L.; Yusuf, D.A.; Nurfaizi, R.; Julianingsih, D. The role of artificial intelligence in sustainable agriculture and waste management: Towards a green future. Int. Trans. Artif. Intell. 2024, 2, 150–157. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Phiri, R.; Rangappa, S.M.; Siengchin, S. Agro-waste for renewable and sustainable green production: A review. J. Clean. Prod. 2024, 434, 139989. [Google Scholar] [CrossRef]

- Alola, A.A.; Adebayo, T.S. Analyzing the waste management, industrial and agricultural greenhouse gas emissions of biomass, fossil fuel, and metallic ores utilization in Iceland. Sci. Total Environ. 2023, 887, 164115. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Rojas-Villacorta, W.; Rojas-Flores, S.; Benites, S.M.; Delfín-Narciso, D.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Rodríguez-Serin, H.; Rebaza-Araujo, S. Potential use of pepper waste and microalgae Spirulina sp. for bioelectricity generation. Energy Rep. 2023, 9, 253–261. [Google Scholar] [CrossRef]

- Esteve-Llorens, X.; Ita-Nagy, D.; Parodi, E.; González-García, S.; Moreira, M.T.; Feijoo, G.; Vázquez-Rowe, I. Environmental footprint of critical agro-export products in the Peruvian hyper-arid coast: A case study for green asparagus and avocado. Sci. Total Environ. 2022, 818, 151686. [Google Scholar] [CrossRef]

- Casas, A.; Rioja, R.; Chavez, D. Production of seven asparagus cultivars in the Peruvian central coast. Acta Hortic. 2022, 1376, 71–74. [Google Scholar] [CrossRef]

- Shimizu, T. The Growth of the Fruit and Vegetable Export Industry in Peru; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Aryaningsih, N.N.; Irianto, I.K. The Assessment of Capital Flow and Technology Transfer in Asparagus Production. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 291. [Google Scholar] [CrossRef]

- Šeregelj, V.; Vulić, J.; Ćetković, G.; Čanadanovć-Brunet, J.; Šaponjac, V.T.; Stajčić, S. Natural bioactive compounds in carrot waste for food applications and health benefits. Stud. Nat. Prod. Chem. 2020, 67, 307–344. [Google Scholar] [CrossRef]

- Suffo, M.; De La Mata, M.; Molina, S.I. A sugar-beet waste based thermoplastic agro-composite as substitute for raw materials. J. Clean. Prod. 2020, 257, 120382. [Google Scholar] [CrossRef]

- Fernandez-Fuentes, M.H.; Eras-Almeida, A.A.; Egido-Aguilera, M.A. Characterization of technological innovations in photovoltaic rural electrification, based on the experiences of Bolivia, Peru, and Argentina: Third generation solar home systems. Sustainability 2021, 13, 3032. [Google Scholar] [CrossRef]

- Rios, R.; Duarte, S. Selection of ideal sites for the development of large-scale solar photovoltaic projects through Analytical Hierarchical Process–Geographic information systems (AHP-GIS) in Peru. Renew. Sustain. Energy Rev. 2021, 149, 111310. [Google Scholar] [CrossRef]

- Navarro, C.E.B.; Álvarez-Quiroz, V.J.; Sampi, J.; Sánchez, A.A.A. Does economic growth promote electric power consumption? Implications for electricity conservation, expansive, and security policies. Electr. J. 2023, 36, 107235. [Google Scholar] [CrossRef]

- Rinaldi, F.; Moghaddampoor, F.; Najafi, B.; Marchesi, R. Economic feasibility analysis and optimization of hybrid renewable energy systems for rural electrification in Peru. Clean Technol. Environ. Policy 2021, 23, 731–748. [Google Scholar] [CrossRef]

- Segura, R.D.R. Organizational structure and administrative management in the electric power supply service in Peru, 2019. Cienc. Tecnol. J. 2024, 20, 75–87. [Google Scholar] [CrossRef]

- Alca-Cruz, M.; Alvarez-Rozas, K. Behavior of financial profitability in electricity generating companies in Peru: 2008-2018. Gest. J. Bus. Gov. 2024, 4, 41–55. [Google Scholar] [CrossRef]

- Boas, J.V.; Oliveira, V.B.; Simões, M.; Pinto, A.M. Review on microbial fuel cells applications, developments and costs. J. Environ. Manag. 2022, 307, 114525. [Google Scholar] [CrossRef]

- Obileke, K.; Onyeaka, H.; Meyer, E.L.; Nwokolo, N. Microbial fuel cells, a renewable energy technology for bio-electricity generation: A mini-review. Electrochem. Commun. 2021, 125, 107003. [Google Scholar] [CrossRef]

- Mohyudin, S.; Farooq, R.; Jubeen, F.; Rasheed, T.; Fatima, M.; Sher, F. Microbial fuel cells a state-of-the-art technology for wastewater treatment and bioelectricity generation. Environ. Res. 2022, 204, 112387. [Google Scholar] [CrossRef]

- He, J.; Xin, X.; Pei, Z.; Chen, L.; Chu, Z.; Zhao, M.; Wu, X.; Li, B.; Tang, X.; Xiao, X. Microbial profiles associated improving bioelectricity generation from sludge fermentation liquid via microbial fuel cells with adding fruit waste extracts. Bioresour. Technol. 2021, 337, 125452. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, A.A.; Guerrero–Barajas, C.; Ibrahim, M.N.M.; Umar, K.; Yaakop, A.S. Local fruit wastes driven benthic microbial fuel cell: A sustainable approach to toxic metal removal and bioelectricity generation. Environ. Sci. Pollut. Res. 2022, 29, 32913–32928. [Google Scholar] [CrossRef] [PubMed]

- Quiñones-Cerna, C.; Rodríguez-Soto, J.C.; Barraza-Jáuregui, G.; Huanes-Carranza, J.; Cruz-Monzón, J.A.; Ugarte-López, W.; Hurtado-Butrón, F.; Samanamud-Moreno, F.; Haro-Carranza, D.; Valdivieso-Moreno, S.; et al. Bioconversion of agroindustrial asparagus waste into bacterial cellulose by Komagataeibacter rhaeticus. Sustainability 2024, 16, 736. [Google Scholar] [CrossRef]

- Redondo-Cuenca, A.; García-Alonso, A.; Rodríguez-Arcos, R.; Castro, I.; Alba, C.; Rodríguez, J.M.; Goni, I. Nutritional composition of green asparagus (Asparagus officinalis L.), edible part and by-products, and assessment of their effect on the growth of human gut-associated bacteria. Food Res. Int. 2023, 163, 112284. [Google Scholar] [CrossRef]

- Godain, A.; Vogel, T.M.; Fongarland, P.; Haddour, N. Influence of shear stress on electroactive biofilm characteristics and performance in microbial fuel cells. Biosens. Bioelectron. 2024, 244, 115806. [Google Scholar] [CrossRef]

- Segundo, R.F.; Magaly, D.L.C.N.; Luis, C.C.; Otiniano, N.M.; Soto-Deza, N.; Terrones-Rodríguez, N. Reducing Plastic Waste and Generating Bioelectricity Simultaneously through Fuel Cells Using the Fungus Pleurotus ostreatus. Sustainability 2024, 16, 7909. [Google Scholar] [CrossRef]

- López, A.C.C.; Marín, A.A.L.; De las Heras Pérez, M.Á.; Stepanovic, M.B. The concept of pH and its logarithmic scale: A Micro Bit experience through inquiry, modeling, and computational thinking. Eurasia J. Math. Sci. Technol. Educ. 2024, 20, em2424. [Google Scholar] [CrossRef]

- Genç, N.; Pişkin, E.D. Evaluation of simultaneous energy production and biotic and abiotic nitrate removal in microbial fuel cells (MFCs): Selection of the most suitable MFC by a multi-criteria decision methodology. Process Saf. Environ. Prot. 2025, 194, 807–815. [Google Scholar] [CrossRef]

- Avci, K. Development of a wearable activity tracker based on BBC micro: Bit and its performance analysis for detecting bachata dance steps. Sci. Rep. 2024, 14, 30700. [Google Scholar] [CrossRef]

- Li, X.; Lu, Y.; Luo, H.; Liu, G.; Torres, C.I.; Zhang, R. Effect of pH on bacterial distributions within cathodic biofilm of the microbial fuel cell with maltodextrin as the substrate. Chemosphere 2021, 265, 129088. [Google Scholar] [CrossRef]

- Bagchi, S.; Behera, M. Evaluation of the effect of anolyte recirculation and anolyte pH on the performance of a microbial fuel cell employing ceramic separator. Process Biochem. 2021, 102, 207–212. [Google Scholar] [CrossRef]

- Tan, W.H.; Chong, S.; Fang, H.W.; Pan, K.L.; Mohamad, M.; Lim, J.W.; Tiong, T.J.; Chan, Y.J.; Huang, C.M.; Yang, T.C.K. Microbial fuel cell technology—A critical review on scale-up issues. Processes 2021, 9, 985. [Google Scholar] [CrossRef]

- Karuppiah, T.; Uthirakrishnan, U.; Sivakumar, S.V.; Authilingam, S.; Arun, J.; Sivaramakrishnan, R.; Pugazhendhi, A. Processing of electroplating industry wastewater through dual chambered microbial fuel cells (MFC) for simultaneous treatment of wastewater and green fuel production. Int. J. Hydrogen Energy 2022, 47, 37569–37576. [Google Scholar] [CrossRef]

- Akinwumi, O.D.; Dada, E.O.; Agarry, S.E.; Aremu, M.O.; Agbede, O.O.; Alade, A.O.; Aworanti, O.A.; Alao, A.I. Effects of retention time, pH, temperature and type of fruit wastes on the bioelectricity generation performance of microbial fuel cell during the biotreatment of pharmaceutical wastewater: Experimental study, optimization and modelling. Environ. Process. 2024, 11, 51. [Google Scholar] [CrossRef]

- Sigalingging, R.; Sitorus, Y. Study of Fruit Waste as Bio-battery Materials for Alternative Electricity. J. Sustain. Agric. Biosyst. Eng. 2024, 2, 1–10. [Google Scholar] [CrossRef]

- Zha, Z.; Zhang, Z.; Xiang, P.; Zhu, H.; Shi, X.; Chen, S. Porous graphitic carbon from mangosteen peel as efficient electrocatalyst in microbial fuel cells. Sci. Total Environ. 2021, 764, 142918. [Google Scholar] [CrossRef]

- Teng, P. A Novel Portable Oxidation-Reduction Potential and Microbial Fuel Cell-Based Sensor to Monitor Microbial Growth. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2023. [Google Scholar]

- Hsu, J.Y.; Lee, C.C.; Jian, Z.R.; Chen, J.C.; Lin, C.H. The Potential of Using Microbial Fuel Cells as a “Quality” Monitor for Ornamental Seawater Aquarium. J. Appl. Biotechnol. Rep. 2022, 9, 799–806. [Google Scholar] [CrossRef]

- Jiang, D.; Chen, Y.; Xie, K.; Li, S.; Wang, Y. Carbon-coated Fe3O4@ cotton fiber biomass carbon for the oxygen reduction reaction in air cathode microbial fuel cells. J. Alloys Compd. 2024, 982, 173843. [Google Scholar] [CrossRef]

- Erenler, S.A.; Unver, T.; Ozaslan, B.F.; Koytepe, S.; Sezer, S. Development of microbial chondroitin sulfate-based proton exchange membranes for microbial fuel cells. Fuel 2024, 363, 130976. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, Y.; Li, Y.; Chen, P.; Ma, H.; Han, P.; Wang, C.; Liu, W.; Wang, Y.; Qing, R.; et al. Investigating the effect of anode materials on the performance and microbial community in an integrated chamber-free microbial fuel cell. Fuel 2024, 357, 129648. [Google Scholar] [CrossRef]

- Li, C.; Luo, M.; Zhou, S.; He, H.; Cao, J.; Luo, J. Comparison analysis on simultaneous decolorization of Congo red and electricity generation in microbial fuel cell (MFC) with l-threonine-/conductive polymer-modified anodes. Environ. Sci. Pollut. Res. 2021, 28, 4262–4275. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Duan, C.; Duan, W.; Sun, F.; Cui, H.; Zhang, S.; Chen, X. Role of electrode materials on performance and microbial characteristics in the constructed wetland coupled microbial fuel cell (CW-MFC): A review. J. Clean. Prod. 2021, 301, 126951. [Google Scholar] [CrossRef]

- Flores, S.R.; Nazario-Naveda, R.; Delfín-Narciso, D.; Cardenas, M.G.; Diaz, N.D.; Ravelo, K.V. Generation of bioelectricity from organic fruit waste. Environ. Res. Eng. Manag. 2021, 77, 6–14. [Google Scholar] [CrossRef]

- Shadman, P.; Shakeri, A.; Zinadini, S. Improving MFC efficiency in power generation and COD removal by using protic ionic liquid in MWCNT-CS-2-aminothiazole-SO3H nanoparticle-infused sulfonated PES. Energy Convers. Manag. 2024, 301, 118049. [Google Scholar] [CrossRef]

- Yang, J.; Cao, X.; Sun, Y.; Yang, G.; Yi, W. Recovery of microbial fuel cells with high COD molasses wastewater and analysis of the microbial community. Biomass Bioenergy 2022, 161, 106450. [Google Scholar] [CrossRef]

- Liu, T.; Nadaraja, A.V.; Friesen, J.; Gill, K.; Lam, M.I.; Roberts, D.J. Narrow pH tolerance found for a microbial fuel cell treating winery wastewater. J. Appl. Microbiol. 2021, 131, 2280–2293. [Google Scholar] [CrossRef]

- Hassan, M.; Kanwal, S.; Singh, R.S.; SA, M.A.; Anwar, M.; Zhao, C. Current challenges and future perspectives associated with configuration of microbial fuel cell for simultaneous energy generation and wastewater treatment. Int. J. Hydrogen Energy 2024, 50, 323–350. [Google Scholar] [CrossRef]

- Ng, C.A.; Chew, S.N.; Bashir, M.J.; Abunada, Z.; Wong, J.W.; Habila, M.A.; Khoo, K.S. Enhancing microbial fuel cell performance for sustainable treatment of palm oil mill wastewater using carbon cloth anode coated with activated carbon. Int. J. Hydrogen Energy 2024, 52, 1092–1104. [Google Scholar] [CrossRef]

- Apollon, W.; Rusyn, I.; Kuleshova, T.; Luna-Maldonado, A.I.; Pierre, J.F.; Gwenzi, W.; Kumar, V. An overview of agro-industrial wastewater treatment using microbial fuel cells: Recent advancements. J. Water Process Eng. 2024, 58, 104783. [Google Scholar] [CrossRef]

- Mulyono, T.; Misto, M.; Cahyono, B.E.; Fahmidia, N.H. The impact of adding vegetable waste on the functioning of microbial fuel cell. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2022; Volume 2663, No. 1. [Google Scholar] [CrossRef]

- Rojas-Villacorta, W.; Rojas-Flores, S.; Benites, S.M.; Nazario-Naveda, R.; Romero, C.V.; Gallozzo-Cardenas, M.; Delfín-Narciso, D.; Díaz, F.; Murga-Torres, E. Preliminary study of bioelectricity generation using lettuce waste as substrate by microbial fuel cells. Sustainability 2023, 15, 10339. [Google Scholar] [CrossRef]

- Latuihamallo, Y.; Mahulette, F.; Watuguly, T.W. Potential of vegetable waste as alternative production bioelectricity. BIOEDUPAT Pattimura J. Biol. Learn. 2023, 3, 90–94. [Google Scholar] [CrossRef]

- Rokhim, D.A.; Vitarisma, I.Y.; Sumari, S.; Utomo, Y.; Asrori, M.R. Optimizing Household Wastes (Rice, Vegetables, and Fruit) as an Environmentally Friendly Electricity Generator. J. Renew. Mater. 2024, 12, 275–284. [Google Scholar] [CrossRef]

- Din, M.I.; Iqbal, M.; Hussain, Z.; Khalid, R. Bioelectricity generation from waste potatoes using single chambered microbial fuel cell. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 12596–12606. [Google Scholar] [CrossRef]

- Rathinavel, N.; Veleeswaran, A.; Rathinam, Y.; Alagarsamy, A. Turning Waste into Watt: Usage of natural biomass activated carbon-based anode and septic tank wastewater for Microbial Fuel Cell (MFC) based electricity generation. Carbon Trends 2025, 19, 100461. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).