1. Introduction

Additive building manufacturing is a process of building parts based on creating a physical object from an electronic model by adding material, typically layer by layer. Additive technologies are widely used to construct buildings and structures [

1].

A significant part of the world’s energy consumption is spent on building maintenance. Therefore, the energy efficiency of the buildings has become a key priority for solving energy-saving issues. Additive technology improves the quality and reliability of a construction structure by excluding human errors, significantly reducing the cost of constructing buildings with unique architecture [

2,

3]. The thermal properties of 3D printing enclosed structures have a significant impact on the energy efficiency of buildings. The research of thermal behavior and the development of solutions for increasing the energy efficiency of enclosing structures created using additive technologies are necessary to reduce energy costs consumed for heating and cooling buildings and improve the quality of the building’s internal environment [

4].

The building envelope constructed by additive technology is classified according to the purpose, the character of static work, the homogeneity of the material, the placement of insulation in the cavities of the structure, the sequence of insulation placement, the material, reinforcement, and the presence of a rigidity diaphragm [

5].

According to the purpose, structures are divided into external ones that protect the premises from natural climatic conditions, and internal ones that meet the objective’s constructive and ecological, sanitary, and hygienic operational, aesthetic, and economic requirements. According to the character of static work, the structures can be classified as load-bearing, self-supporting, and non-load-bearing, performing the role of partitions in the room. The additive building structure can be classified as homogeneous (made of one material) and non-homogeneous (composed of several materials). Non-homogeneous walls can have partial filling and consist, not only of one material, but also can have closed air cavities. The enclosing structure can be divided into a frame and an inner filling.

The thermal insulation materials used for the additive exterior wall are polystyrene foam, extruded polystyrene foam, urethane foam, mineral wool, liquid thermal insulation, and aerogel materials. The aerogel is rarely used as a thermal insulation material in additive building constructions [

6].

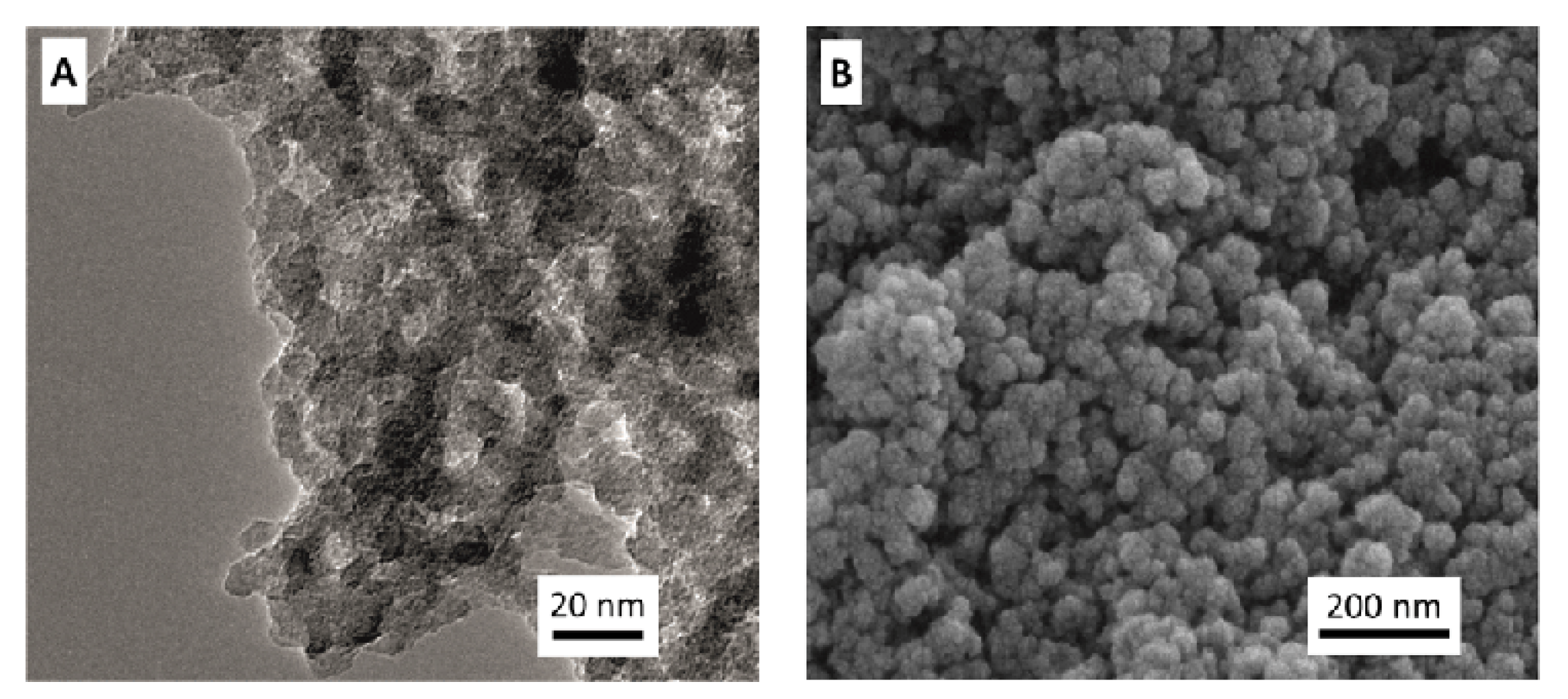

An aerogel is a nano-porous insulation material with unique properties such as extremely low thermal conductivity, superior flexibility, compression resistance, and the most promising superinsulation systems. The thermal conductivity of thermal insulation materials is one of the most important parameters for increasing the energy efficiency of buildings. Aerogels consist of globules, several nanometers in size, interconnected by an extensive mesoporous network filled with air [

7]. The pore size exceeds the size of the clusters themselves by ten or more times (

Figure 1). The aerogel is a nanostructured material with high porosity and excellent thermal insulation properties [

8,

9]. A significant disadvantage is the high cost of manufacturing and application.

Nevertheless, studies of thermophysical properties and properties of aerogel materials have been relevant research topics in the last few years. Testing and developing these insulation materials are very important for manufacturers and designers. Therefore, studies of thermal properties are extremely important [

8].

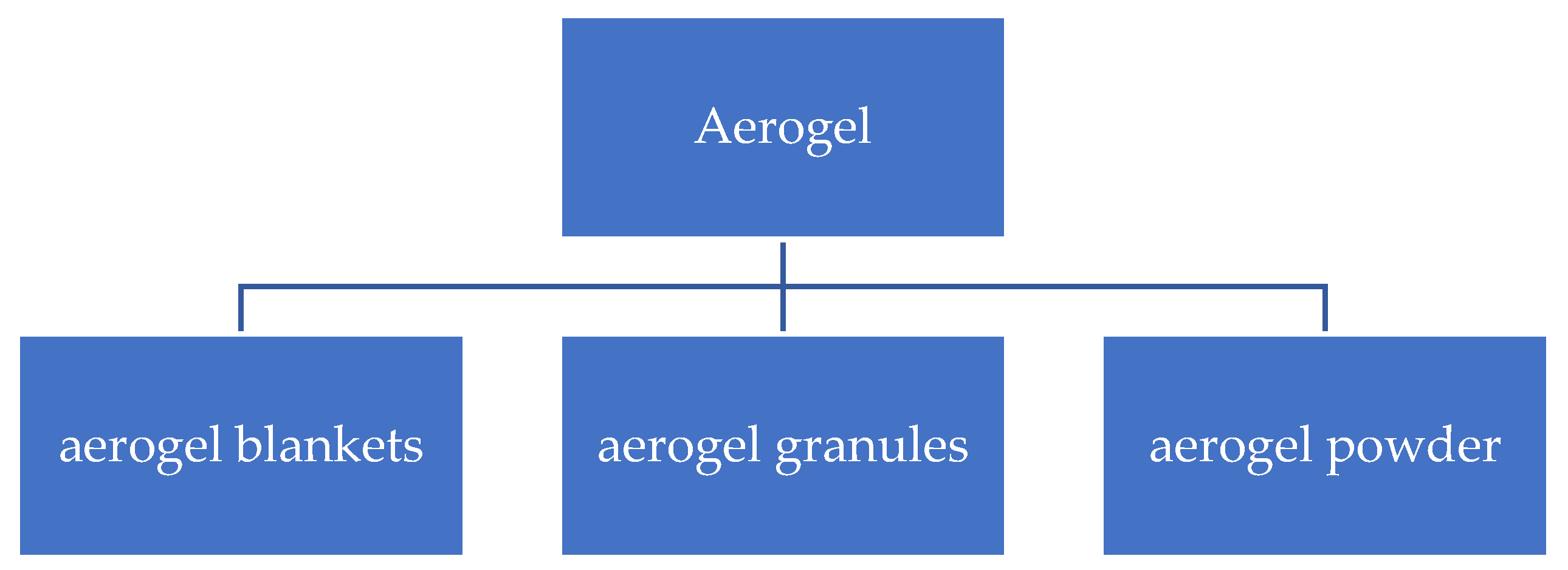

The applications of aerogels can be used as aerogel granules, powder, and aerogel blankets (

Figure 2).

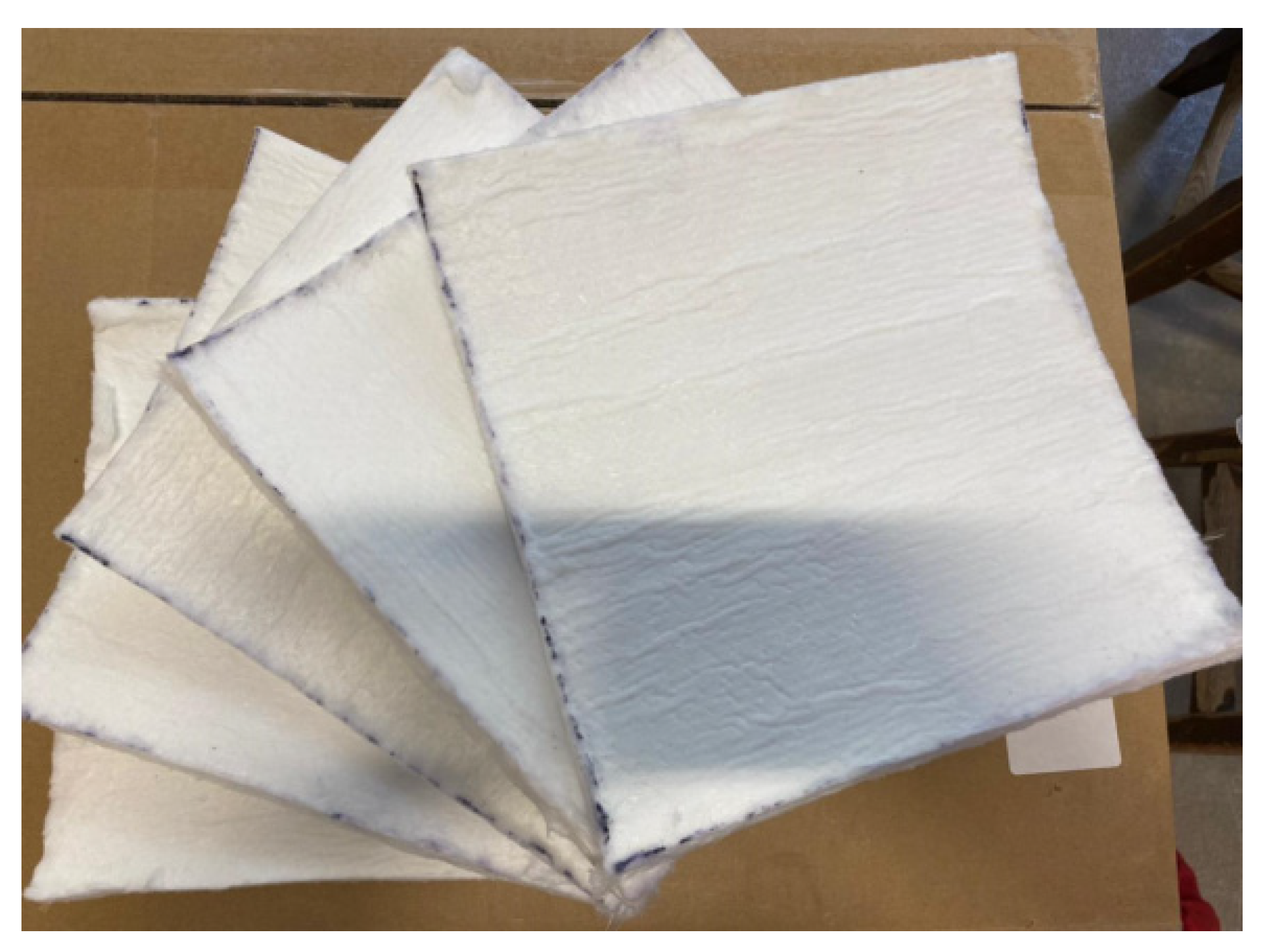

Aerogel blankets are a based innovative insulation material based on silica aerogel produced from fiberglass (

Figure 3).

The study [

12] investigated the thermal properties of aerogel blankets. The paper obtained the temperature dependence of the thermal conductivity of aerogel blanket samples in the range from 0 to 65 °C and established a change of about 18%. The thermal conductivity and temperature effect were investigated on the change in specific heat from 0 to 65 °C. Thermal conductivity and heat transfer are obtained based on the measured thermal conductivity and specific heat capacity. The study’s results showed that the thickness could have a negligible effect on thermal conductivity.

The paper [

13] presents a theoretical and experimental study of the thermal conductivity of aerogel blankets. The authors presented a model that considers all the heat transfer mechanisms. The authors carried out an analytical calculation of the change in thermal conductivity depending on temperature; the model was verified with experimental data. The parametric studies used the proposed model to evaluate the effect of the total porosity and thermal conductivity of fibers on the effective thermal conductivity of an aerogel blanket.

The research [

14,

15,

16] reported the results of thermal conductivity behavior of aerogel-enhanced blankets. The research [

14,

15,

16] presented comparative thermal characterization results of aerogel blankets and established the thermal conductivity as 0.013 W/(m K). The research [

14,

15,

16] developed and presented some new aerogel-enhanced blankets.

The study [

17] presents research of two types of aerogel blanket: with a fiberglass web and with a polyethylene terephthalate fiber web. The calculations showed that aerogel coatings have low thermal conductivity (0.015 W m

−1 K

−1) and hydrophobic properties [

17].

The aerogel blanket has a wide range of applications in construction [

18]:

Insulation of building facades to reduce cold bridge and energy costs;

Noise insulation of internal walls. The speed is up to 70 m/s (the minimum speed of sound propagation through the material), so it acts as a sound insulation system, and its minimum thickness allows for increasing the saleable area;

Insulation of internal walls. Due to the small thickness of the material, it is suitable for cladding any internal walls, partitions, and corners, for local elimination of freezing, and for preventing condensation and the appearance of mold;

Thermal insulation of the floors;

Insulation of window and door openings;

Thermal insulation of saunas and baths;

Thermal insulation of pipes, etc.

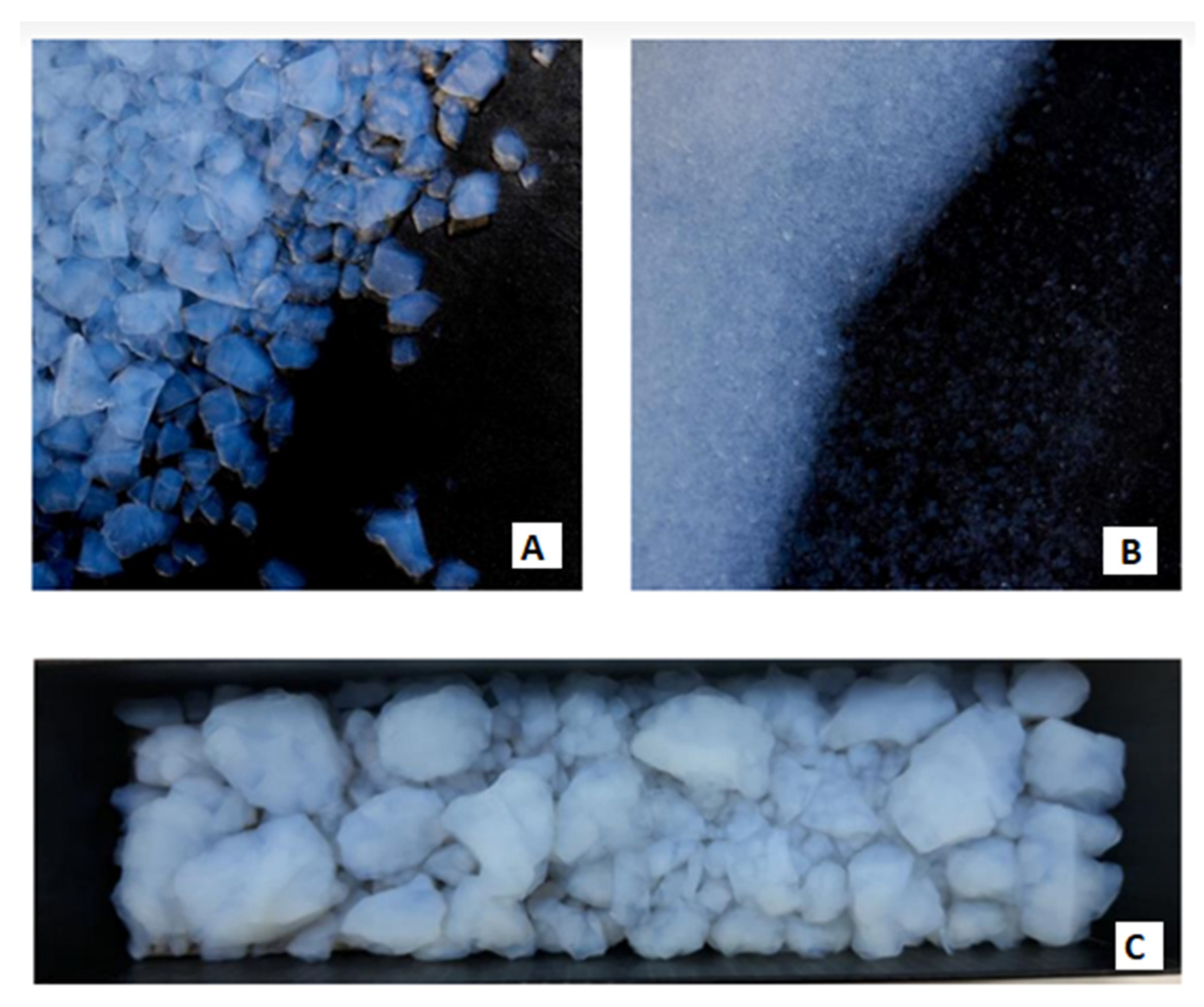

Aerogel powder and granules are also used as components of insulation solutions and building materials (

Figure 4). Concrete has a high thermal conductivity ranging from 1.7 to 2.5 W/(m·K). Therefore, it requires insulation layers for standard insulating properties. Hence, building mixtures and concrete with aerogel powder or granules are being developed, which ensure sufficient compressive strength and good thermal insulation. As the amount of aerogel in the mixture increases, the thermal conductivity decreases linearly [

19].

The study [

19] presented the experimental results of the thermal performance of aerogel granules in the cavity of double-glazing units. The results indicate that the aerogel granules’ particle size influences the glazing unit’s optical and thermal properties. Compared to standard double-glazing, double-glazed windows with large aerogel granules (particle size 3–5 mm) achieve a 58% reduction in heat loss and a 38% decrease in light transmittance. For a glazing unit with aerogel granules (particle size < 0.5 mm), the reduction amounts to 63% in heat loss but as much as 81% in light transmittance.

This study has developed a synthesis method for silica powders and granules. The process involves the direct hydrophobization of silica aerogel in a diluted organic solution of trimethylchlorosilane, which acts as the phase separation inducer, followed by subsequent drying at atmospheric pressure. This approach allows for the collection and drying of gels at atmospheric pressure without the need for the solvent replacement phase typical in traditional methods. The silica aerogel in the form of powder and granules, obtained by the above method, has a specific surface area of up to 756.0 m

2/g, thermal conductivity of up to 0.0164 W/(m·K), and a variable density from 47.6 to 120.0 mg/cm

3. Overall, the proposed method represents a simple and economical technique to produce high-quality silica aerogel powders and granules. The obtained aerogels could be applicable in thermal insulation, environmental restoration, adsorption, and other areas [

20,

21].

In study [

22] the impact of aerogel granule size on the solar light transmittance coefficient was investigated. The energy characteristics of the glazing system with different sizes of aerogel granules and different filler thicknesses were evaluated under various climatic conditions. The study [

22] revealed that using aerogel granules with a diameter of 1 mm and a layer thickness of 16 mm can reduce heat losses by 22% when facing the horizon and 10% when facing east or west in hot summer and cold winter conditions. The results also showed that using aerogel granules can reduce the increase in heat by 17.36% throughout the year in climatic conditions with a hot summer and warm winter. It was also noted that changing the size of aerogel granules and the filler’s thickness does not significantly change the energy characteristics of the aerogel glazing system when facing north.

The research [

23] studied the thermal properties of paraffin-impregnated burnt clay aggregate (PIA) concrete. Paraffin was used as a phase change material (PCM) carrier and was incorporated into the burnt clay aggregates using heat and pressure. The compressive and flexural strengths of the concretes and the thermal insulation of the concrete panels were tested. The results of these tests revealed that the strengths and thermal insulation of the standard burnt clay aggregate concrete were improved using PIA. The panels with PIA required more time to reach peak temperature and exhibited a larger drop in peak temperature relative to the control panel without PIA.

The paper [

24] examines experimentally and numerically the effectiveness of Phase Change Materials (PCMs) and a new type of hybrid sandwich insulated panel (SIP) at improving the thermal comfort of four case study houses built in Thailand.

The research [

25] presents an experimental thermal study of a new PCM-concrete thermal storage block (PCM-CTSB). The experimental results show that PCM-CLSC aggregate has good absorption and compatibility. The thermal conductivity and compressive strength of PCM-concrete thermal storage blocks decreased with the increase of PCM weight percentage.

A literature review showed insufficient experimental and numerical data and research on the aerogel application for the additive manufacturing of energy-efficient buildings. In this paper an experimental and numerical assessment of the thermal performance of aerogel-enhanced building structure is presented. The granules can be used as backfill insulation in additive wall cavities. They can be used to make a powder. Due to the fact that the use of granules is not economically feasible, this option is not considered in this article.

This study aimed to assess the aerogel application in additive construction of energy-efficient buildings. The objectives of the study are as follows:

Experimentally estimate the thermal conductivity properties of aerogel-enhanced materials;

Evaluate the impact of aerogel blanket materials on energy consumption in additives;

Experimental assessment of the aerogel application as a mixture powder component and the thermal conductivity assessment of the concrete samples with and without aerogel application.

2. Materials and Methods

2.1. The Aerogel-Enhanced Blanket Applications for Thermal Insulation Building Envelope

2.1.1. The Experimental Assessment of Thermal Conductivity of a Aerogel-Enhanced Blanket

This study provides determination of the thermal conductivity of the aerogel-based material and comparison of the obtained value with the value provided by the manufacturer.

Figure 1 shows the samples of the aerogel-enhanced blanket.

Aerogel has similar mechanical properties (flexibility, etc.) to other blanket heat-insulating materials. And the aerogel has the same scope of application as the mineral wool blanket.

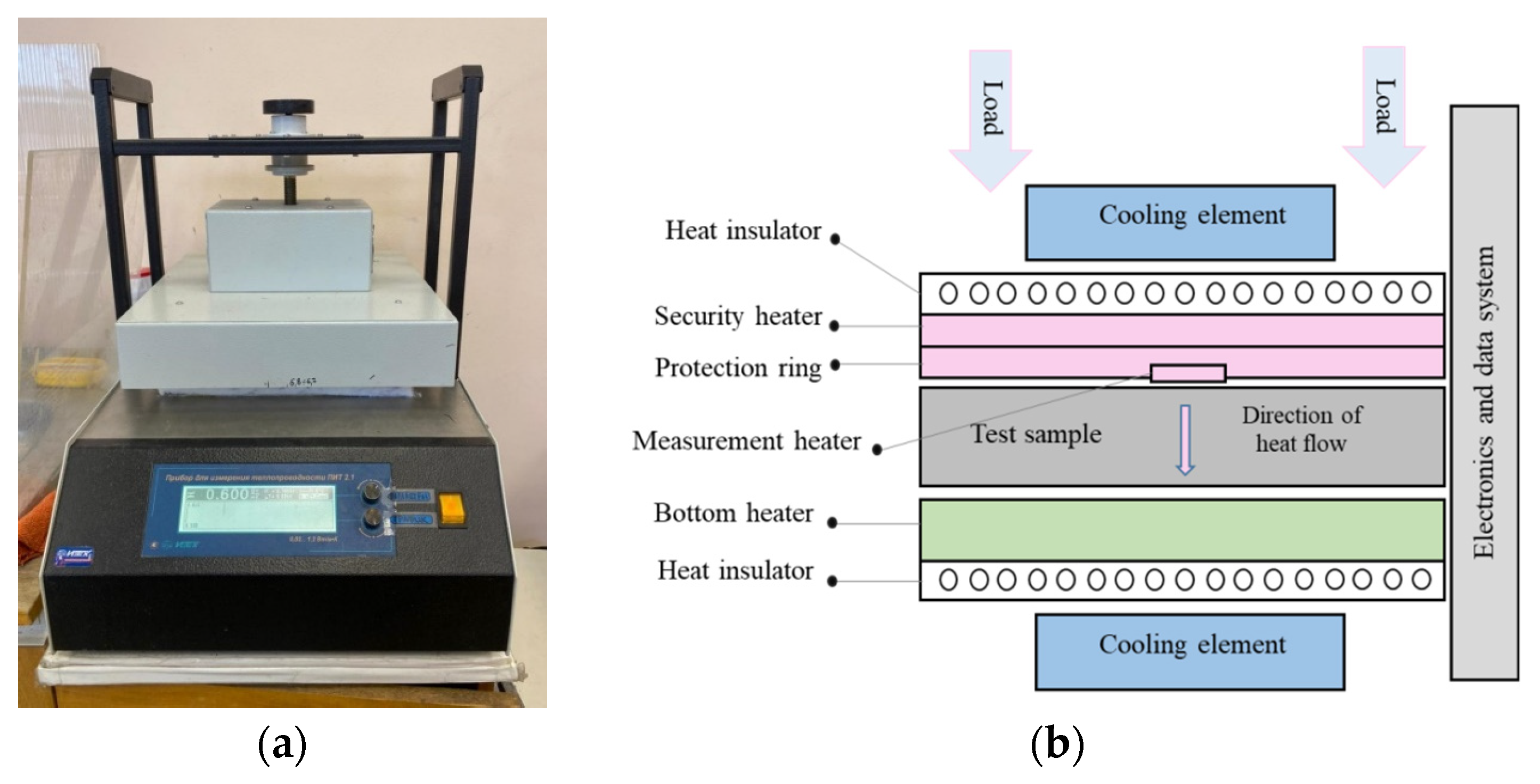

The thermal conductivity of the aerogel samples was measured by the heat flow meter equipment PIT-2.1 (LLC “IzTech”, Moscow, Russia) (

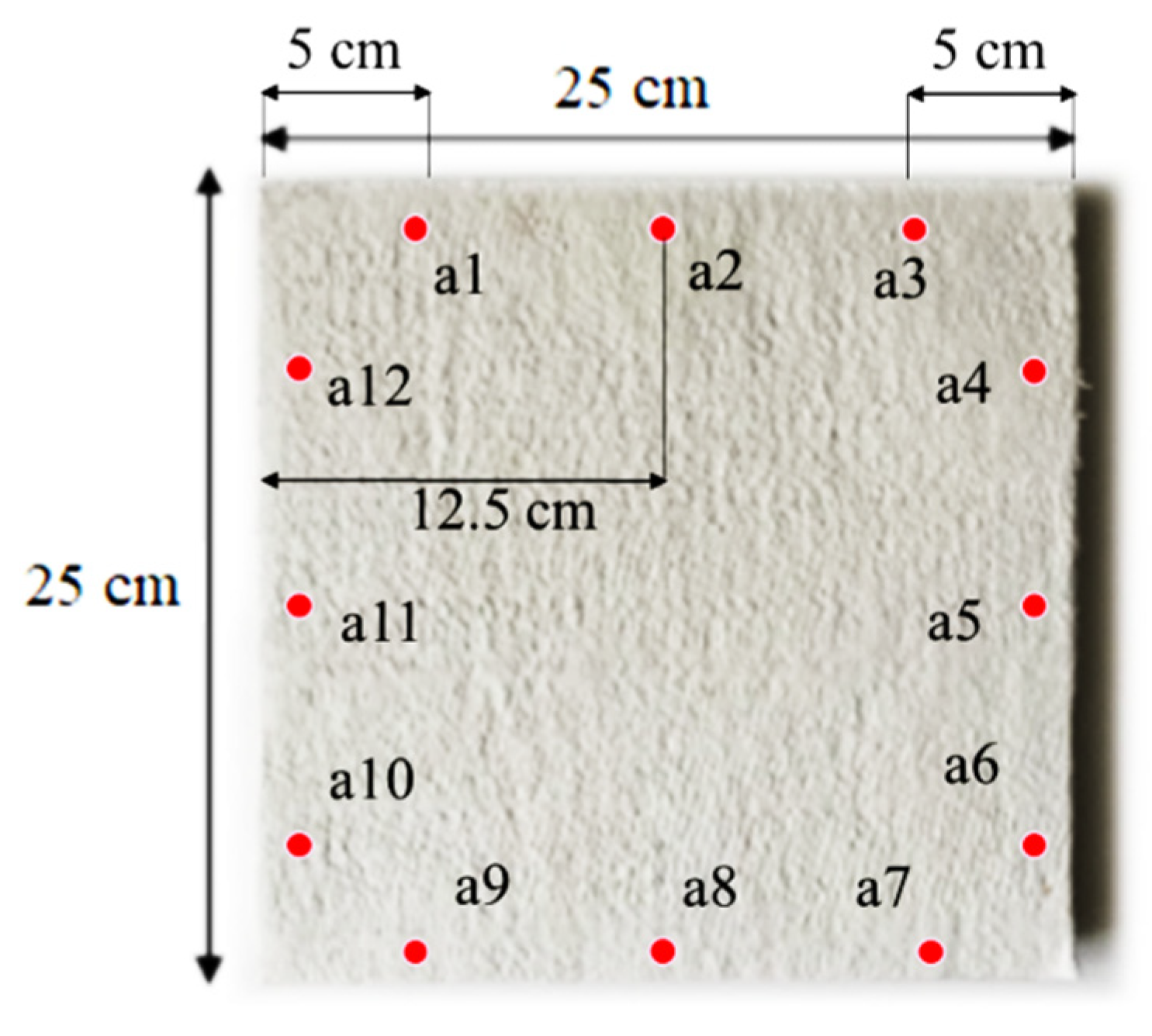

Figure 5). The Alison Aerogel Blanket of the DRT06 series (TIM Company, St. Petersburg, Russia) material was applied to the experimental assessment of thermal conductivity. The technical thermal conductivity of the material is λ = 0.0220 W/(m·K). The dimensions of the sample are 250 mm × 250 mm. The technical thickness of material is 10 mm.

The samples’ actual thickness differs from the manufacturer’s declared information. The actual thickness of the aerogel blanket was measured.

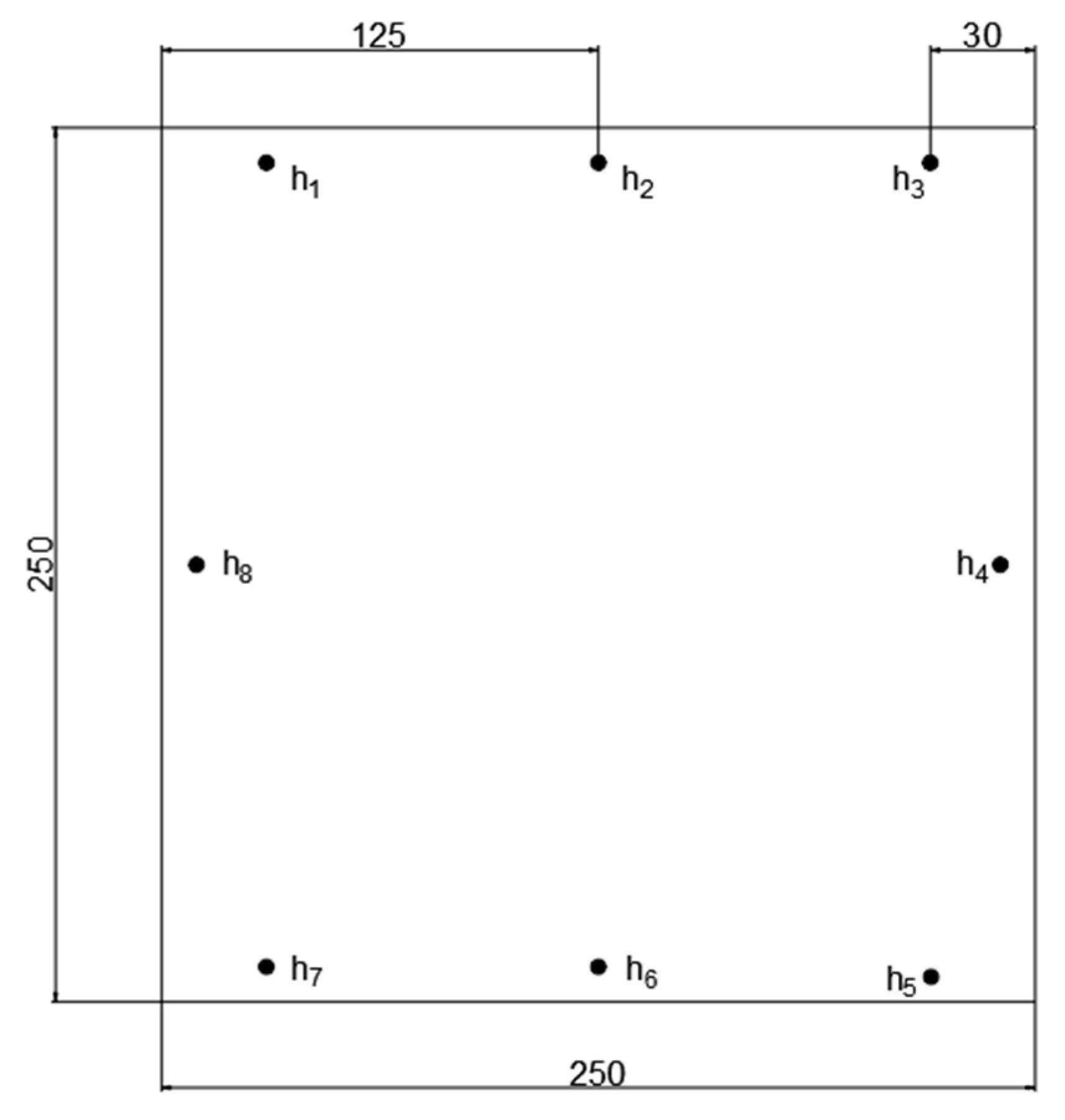

Figure 6 shows the aerogel sample scheme of the thickness measuring points.

The estimation results of aerogel-blanket sample thickness are presented at

Table 1.

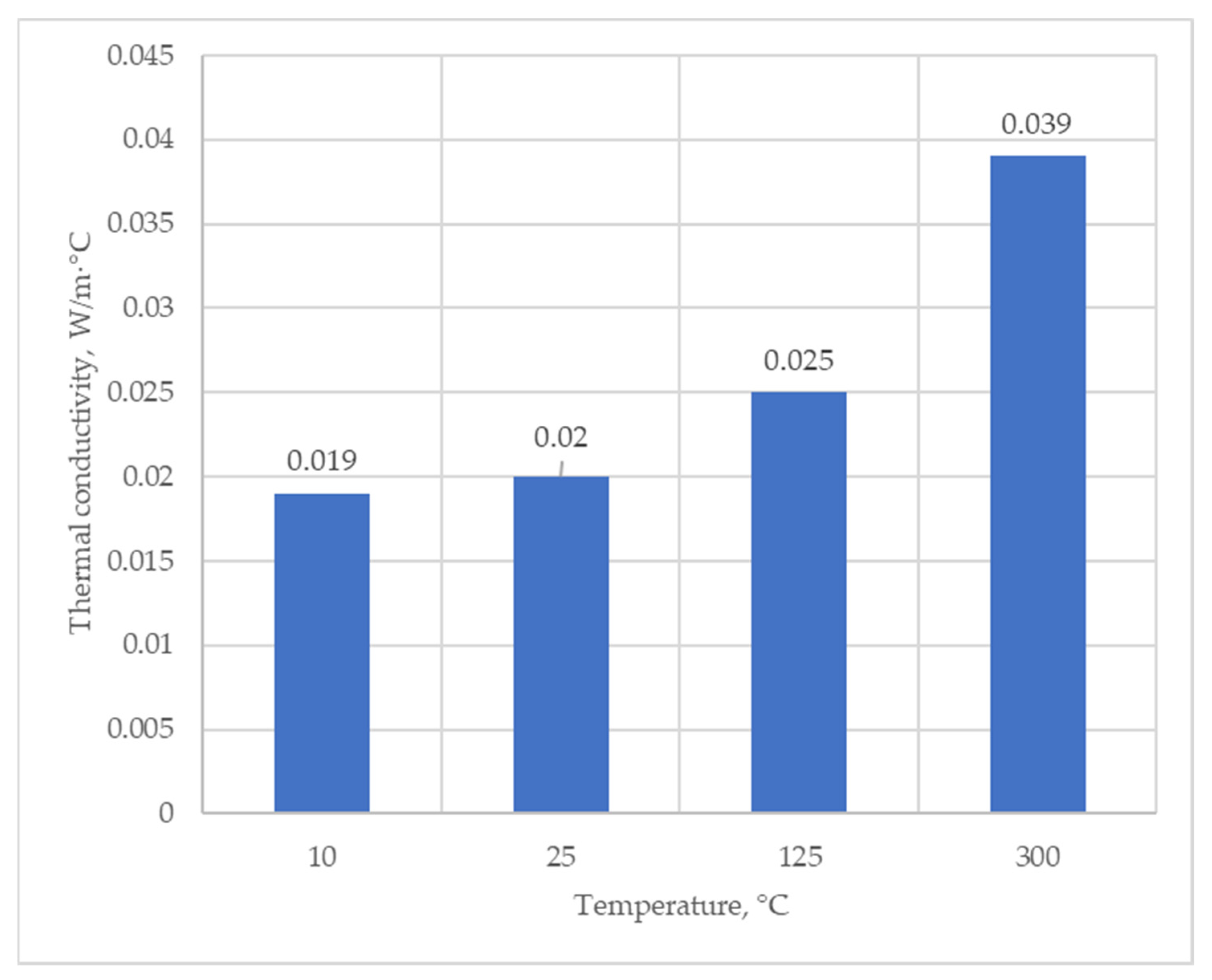

To experimentally assess the thermal conductivity of the aerogel-blanket sample, the thermal conductivity meter ITP-MG4 “250” (Manufacturer: STROYPRIBOR, Moscow, Russia) is applied. The average inside temperatures of the aerogel-blanket samples is equal to 10 °C and 25 °C.

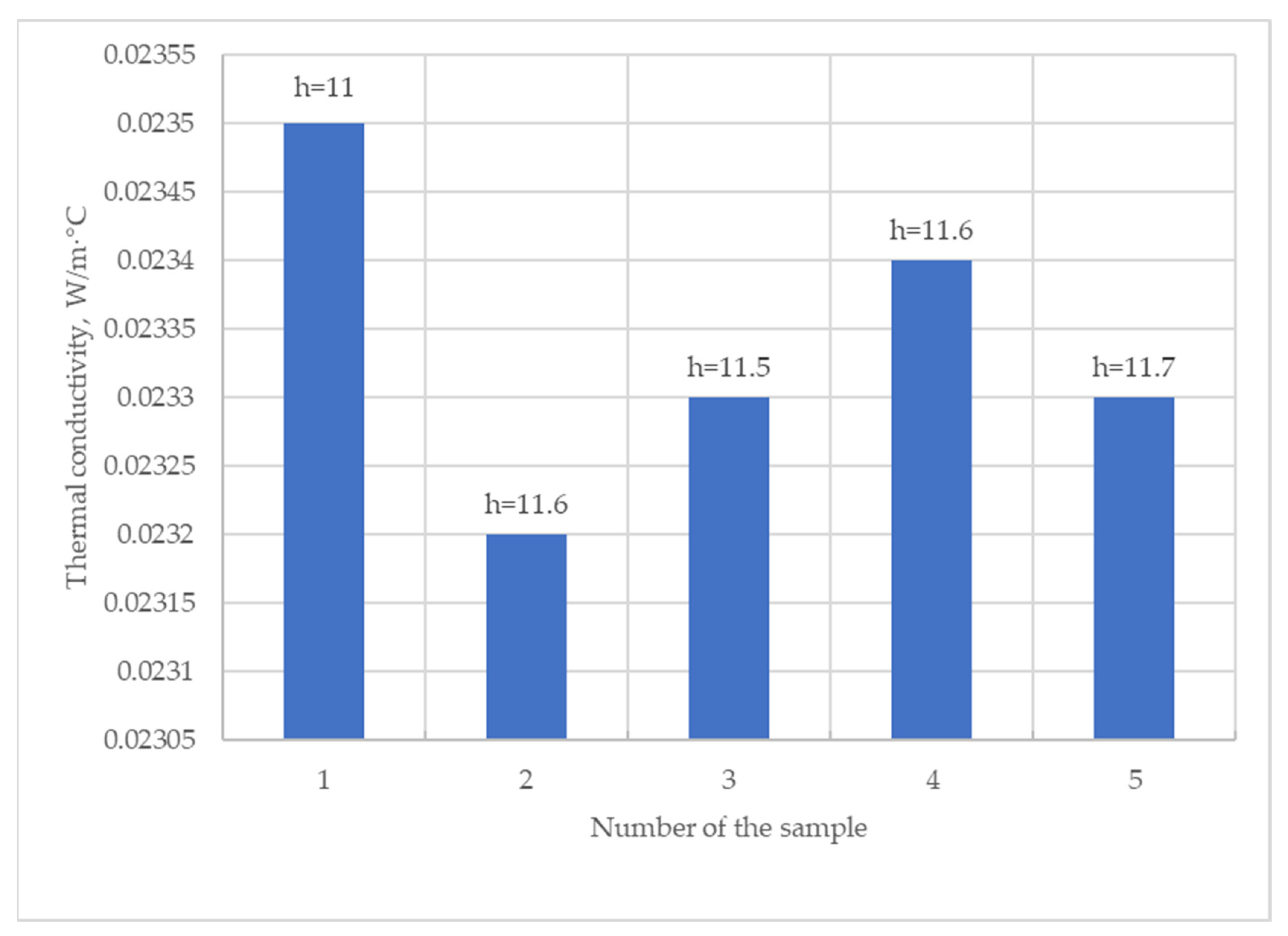

Figure 7 presents the experimental assessment results of the thermal conductivity of the aerogel-blanket sample.

According to the experimental results, the average thermal conductivity is equal to 0.0227 W/(m·K). The thermal conductivity differs from the manufacturing value (λ = 0.0220 W/(m·K)) by 3%.

Table 2 contains the average thermal conductivity values from the tests’ results.

Figure 8 presents the thermal conductivity dependence on temperature.

2.1.2. Experimental Assessment of the Thermal Performance of Aerogel Blanket Application in Additive Construction of Energy-Efficient Buildings

Aerogel blankets are promising materials for construction applications as insulation for walls, ceilings and floors, and ventilation systems. Aerogel blankets are also used for insulation of pipelines at industrial facilities, where, in addition to high thermal insulation, they are also required to resist chemical influences and humidity.

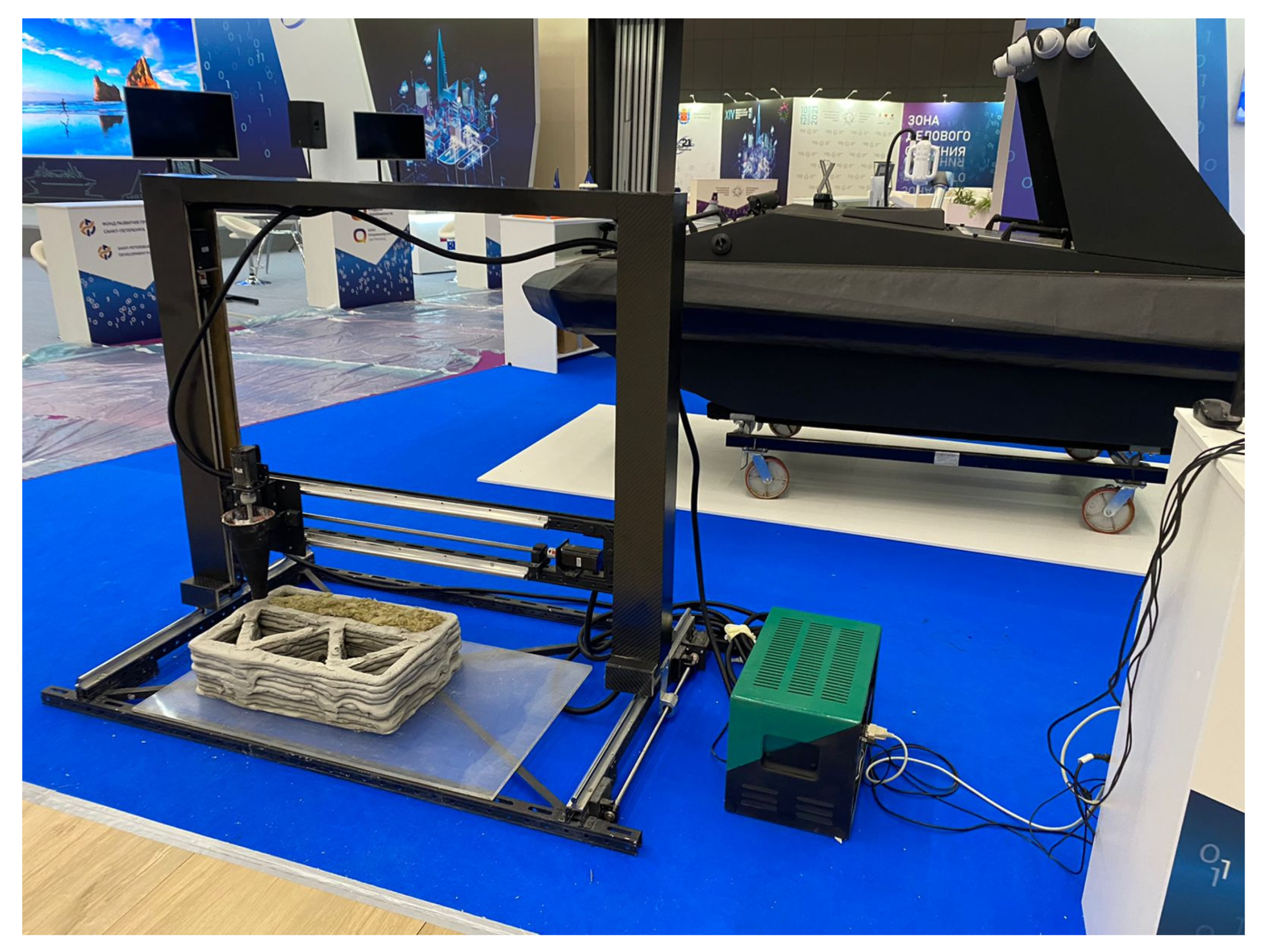

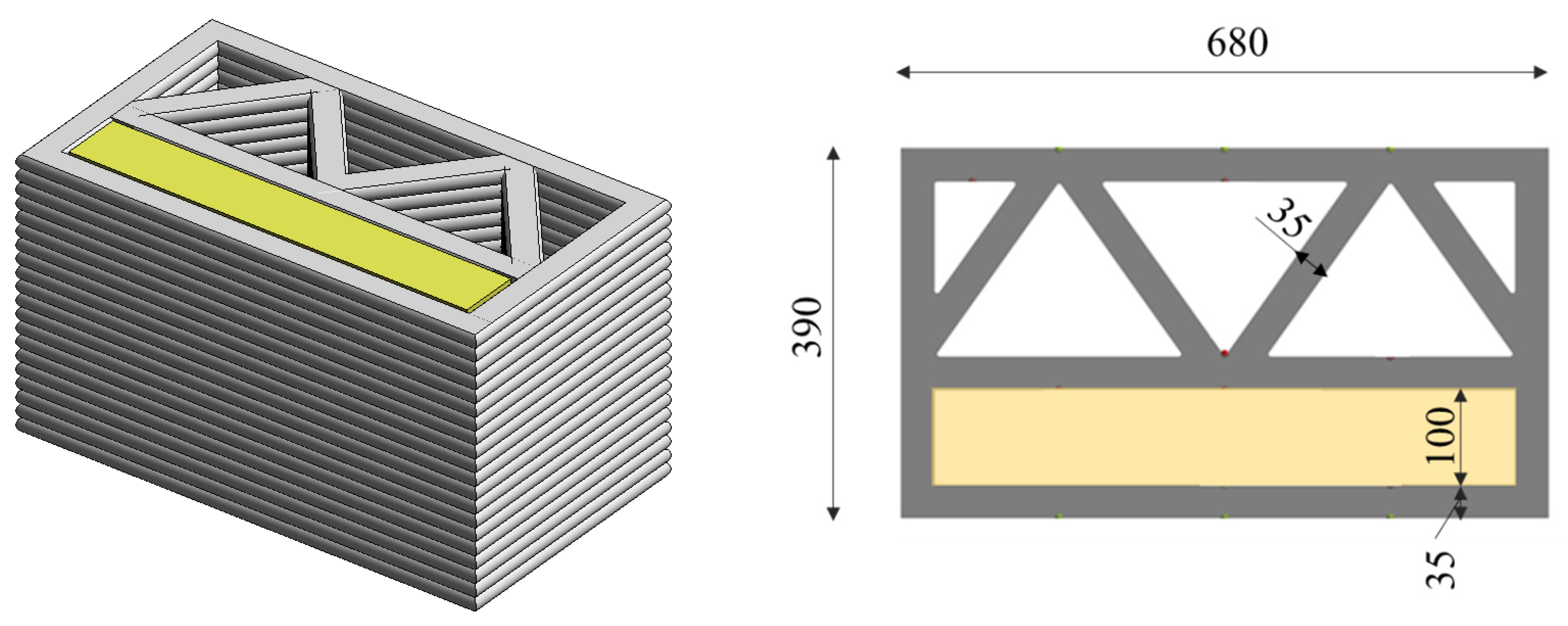

For the experimental assessment of the thermal performance of aerogel-enhanced building structures, samples are produced using additive technologies (

Figure 9).

The sample measures are equal to 390 mm × 680 mm × 310 mm. For experimental assessment the rolled heat-insulating aerogel (Alison Aerogel Blanket of the DRT06-Z series) is applied. The rolled heat-insulating aerogel has a technical characteristic: the temperature range application is −170–1000 °C; the thermal conductivity is 0.020 W/(m·K); the thickness is 10 mm.

Figure 10 shows the aerogel-blanket thermal insulation material located inside of the additive structure.

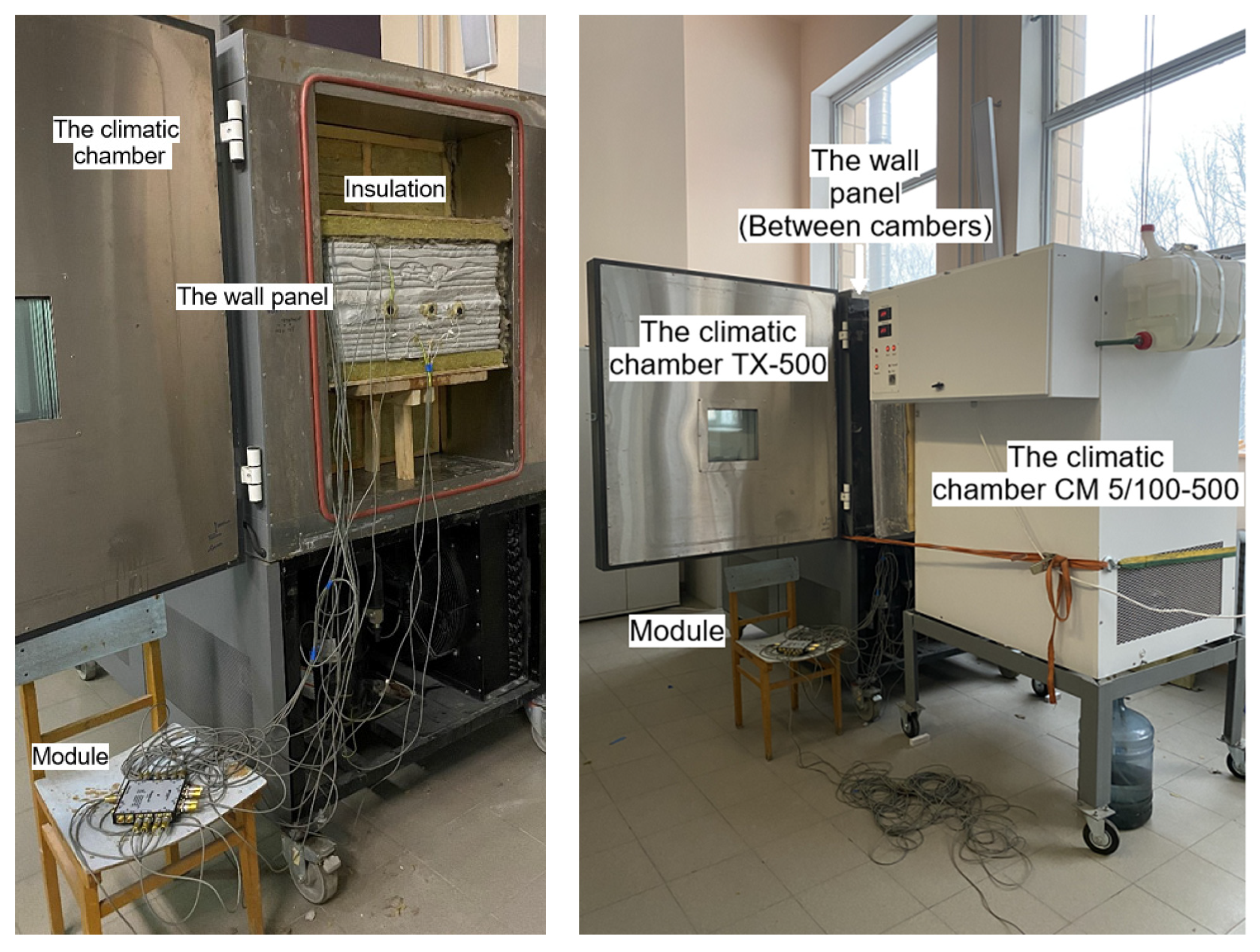

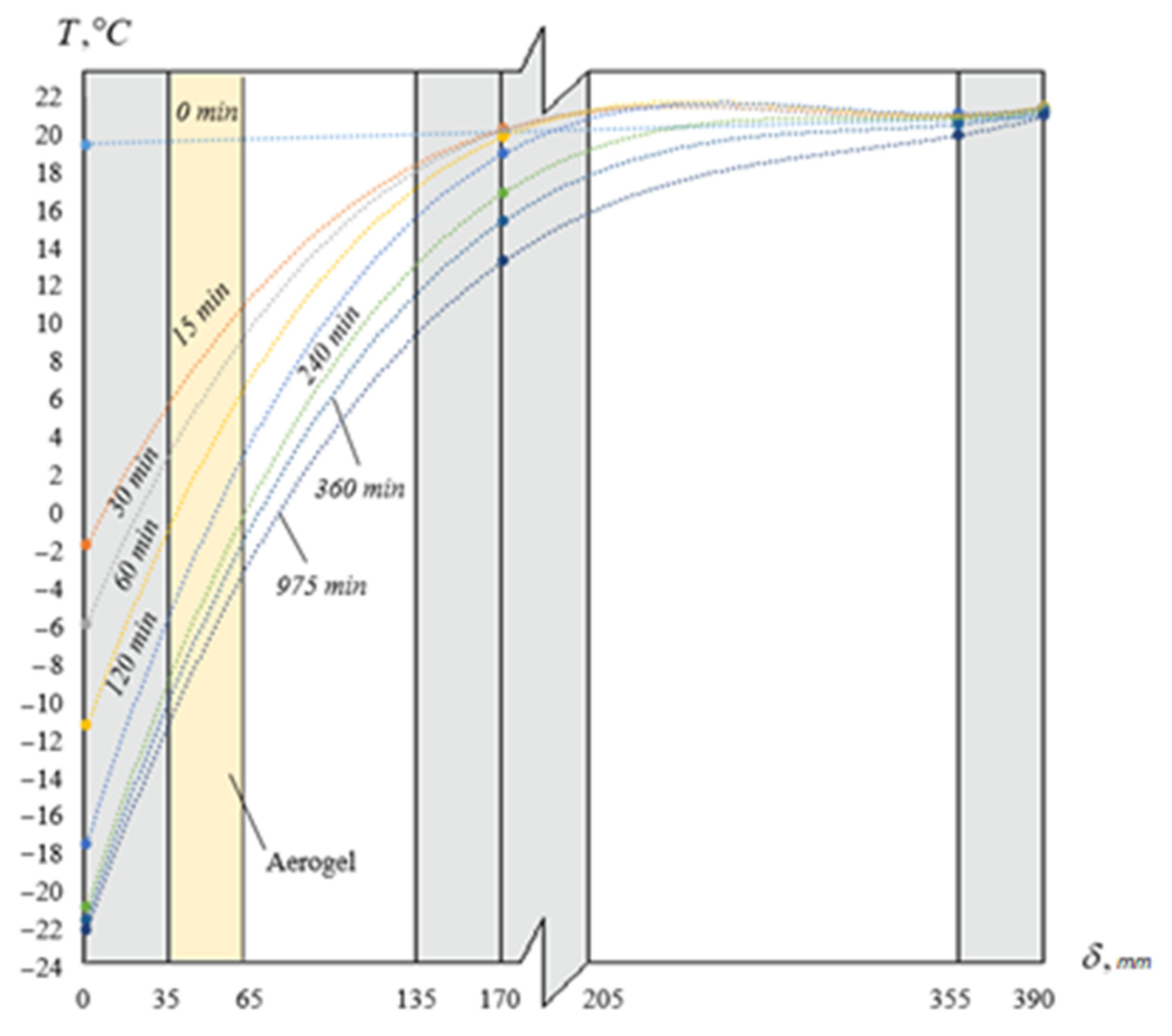

The temperature difference on the two sides of the test wall fragment was created using two climate chambers. The sample was placed between the chambers. One camera simulated the outside temperature. The second chamber simulated the inside temperature. The temperature in both chambers was constant and did not depend on the temperature of the surrounding laboratory room. The outdoor temperature produced by climatic chamber TX-500 was equal to −24 °C. The internal temperature produced by climatic chamber SM 5/100-500 was equal to +22 °C. The internal space size of the climatic chamber TX-500 was equal to 700 mm × 1000 mm × 700 mm. The inner space size of the climatic chamber CM 5/100-500 is equal to 700 mm × 895 mm × 800 mm. The negative outside space of the additive structure is additionally insulated (

Figure 11).

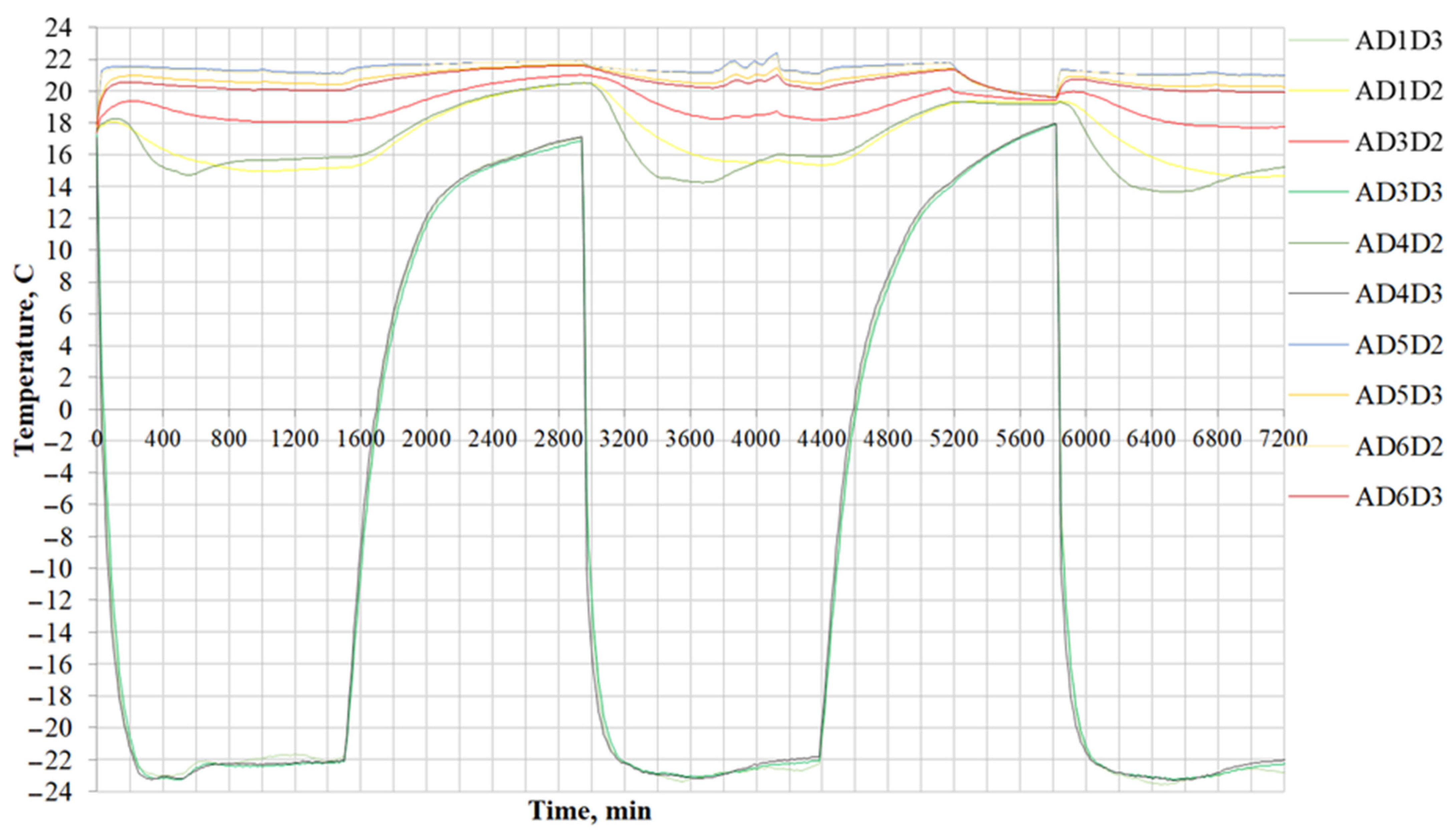

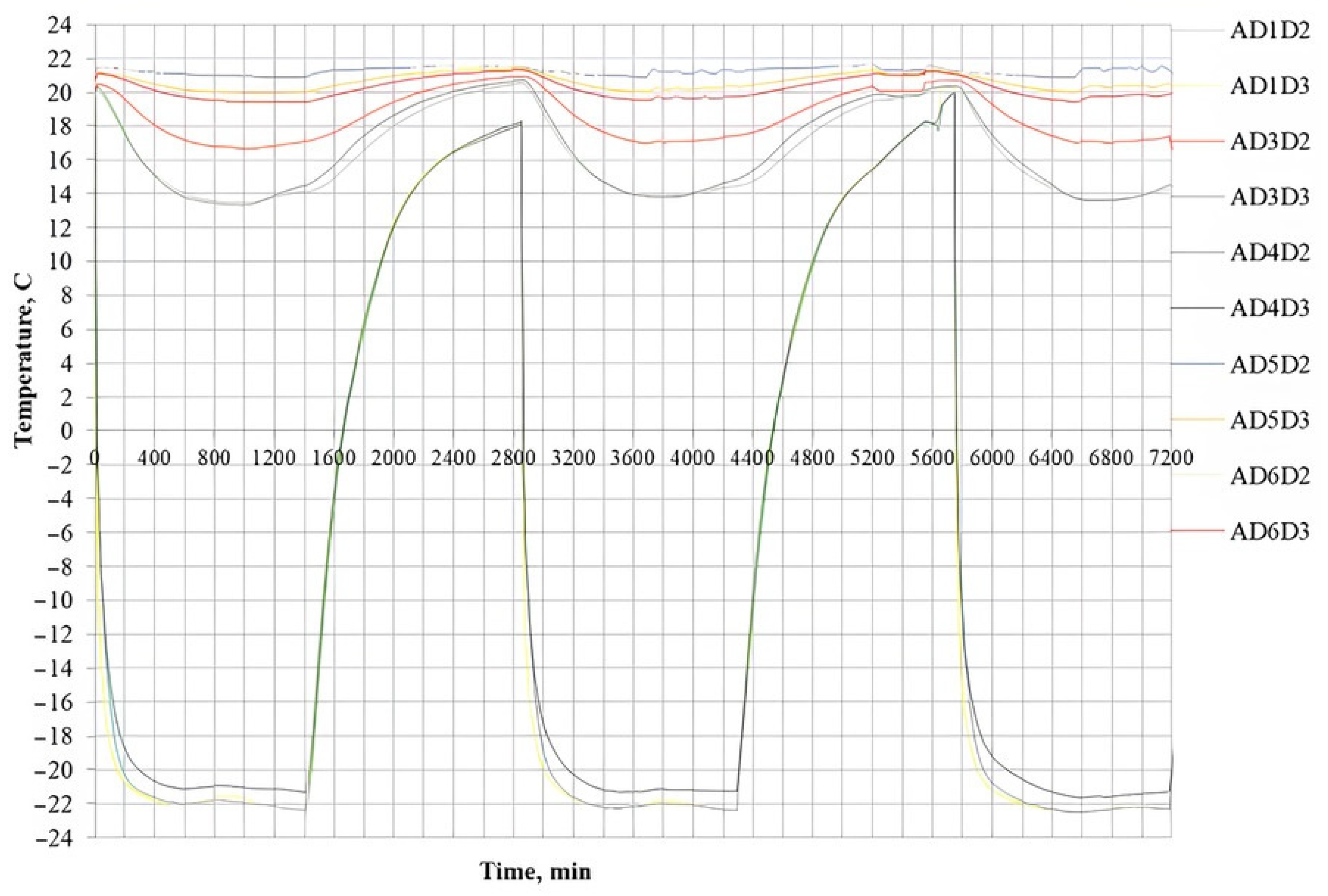

The dimensional parameters of the aerogel-enhanced additive structure sample are equal to 390 mm × 680 mm × 310 mm. The sample has a position between climate chambers. The hot climate chamber temperature is installed at +22 °C, the cold climate chamber temperature is installed at −24 °C. The chamber temperature varied for 120 h (7200 min).

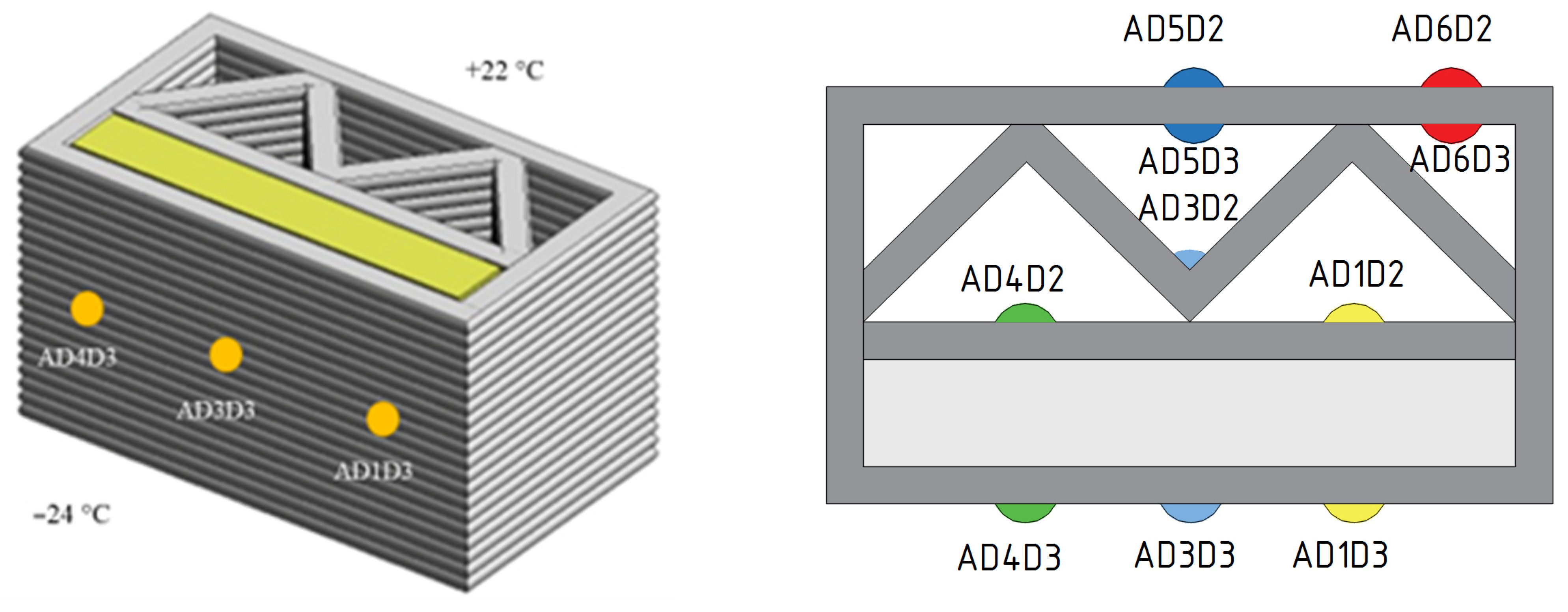

Figure 12 shows the temperature sensor’s points location:

Temperature sensor’s points AD1D3, AD3D3, AD4D3 have a position at the outer surface sample from the cold chamber side;

Temperature sensor’s points AD1D2, AD3D2, AD4D2 have a position at the triangular cavities inside sample on the insulated surface;

Temperature sensor’s points AD5D2, AD6D2 have a position at the outer surface sample from the hot chamber side;

Temperature sensor’s points AD5D3, AD6D3 have a position at the triangular cavities inside sample on the not insulated surface.

2.2. The Aerogel-Enhanced Application as Mixture Powder Component of the Concrete Mixture for Printing Building

Aerogel powder is usually used as an additive to various mixtures and materials to enhance their thermal insulation properties. For example, aerogel powder can be added to concrete, plasters, and composite materials, providing a high level of thermal insulation without a significant increase in mass. It is also widely used in research to create new materials with improved properties.

This subsection produced an experimental assessment of the aerogel application as a mixture powder component of the concrete mixture to the insulating concrete properties.

For the experimental assessment of the aerogel application as a mixture powder component, the thermal conductivity assessment of the concrete samples with and without aerogel application was provided.

To concretize the samples, formwork with dimensions 25 × 25 ×3 cm was applied. The volume of the sample V is equal (0.25)2 × 0.03 = 0.001875 m3 = 1.875 L. The following parameters were used to create the concrete mix: 1 kg mixture consumption per 0.14 L equals 140 mL (g) water, and the volumetric flow rate of the mixture is assumed to be 19.5 kg per 0.01 m3 equals 10 L.

Table 3 presents the mixture parameters of concrete samples without aerogel.

Table 4 presents the mixture parameters of concrete samples with an aerogel of 15%.

The concrete samples were produced by plexiglass formwork to measure the thermal resistance coefficient of materials. The samples had been made in a plate form with dimensions 250 × 250 × 30 mm.

Measurements of the thermal resistance coefficient were conducted using a thermal conductivity meter. The requirements of surface quality and thickness are achieving high measurement accuracy. The sample surface was flat and smooth, without irregularities, shells, cavities, and fractures.

Figure 13 shows the concreting sample processes.

Concrete plate samples were kept in a humid environment for 7 days to achieve 80% strength gain. The samples were dried for 48 h at a temperature of 105 °C.

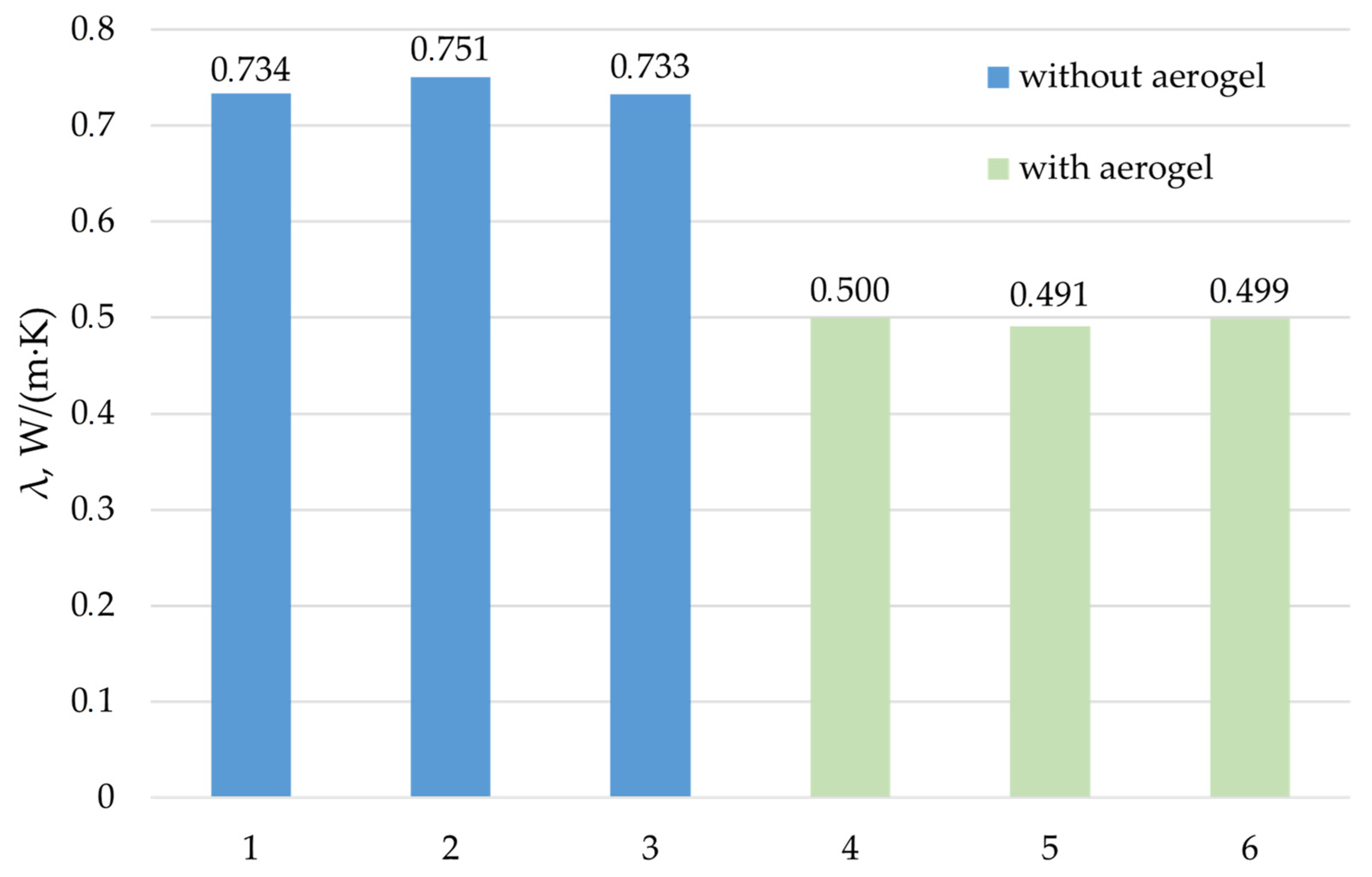

Table 5 presents the thermal conductivity measurement results.

The sample thickness was measured by a caliper.

Table 6 shows the measurement thickness results.

The effect of aerogel application as a parget powder component on the thermal conductivity of the structure is investigated.

Six samples were produced with the size 250 × 250 × 20 mm to study the effect of aerogel application as a parget powder component on the thermal conductivity of the structure. Aerogel-blanket material had been added to the 3 gypsum plaster samples. Gypsum plaster had been produced with a constant volumetric water-binding ratio.

Table 7 shows information about the components’ proportions of the samples.

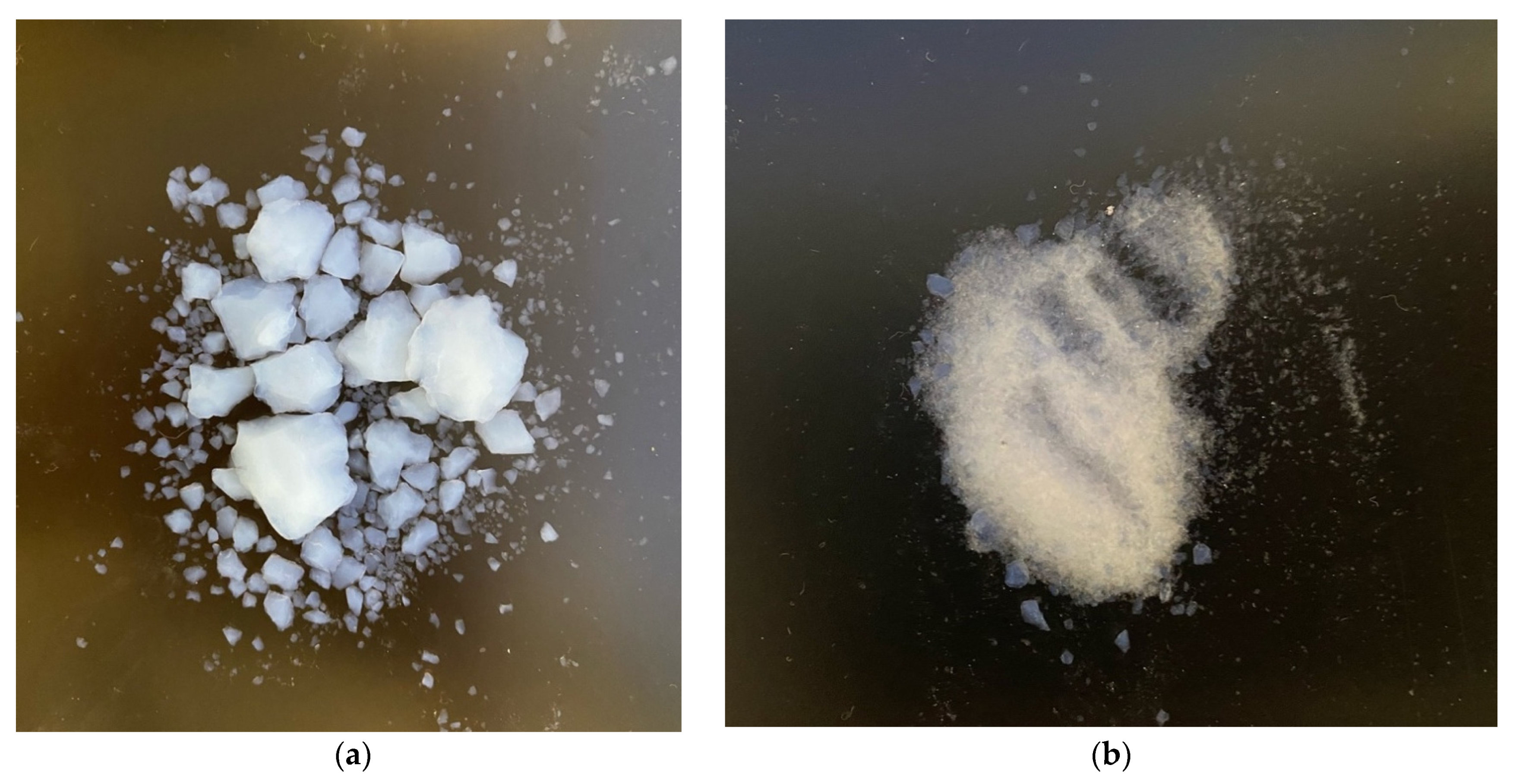

Aerogel granules were produced into powders of 10–200 microns.

Figure 14a shows aerogel in the granules state, and

Figure 14b shows aerogel in the powder state.

There is a dry mixing process of aerogel powder and dry plaster mixture. The mixture is poured into six plastic forms and vibrated for 3–5 min to ensure sealing and avoid delamination. The thermal conductivity characteristics of the samples were measured by thermal conductivity equipment (PIT 2.1) at a temperature of 25 °C.

Figure 15 shows the samples’ thicknesses determined at eight points.

The samples thicknesses measurement is presented at

Table 8.

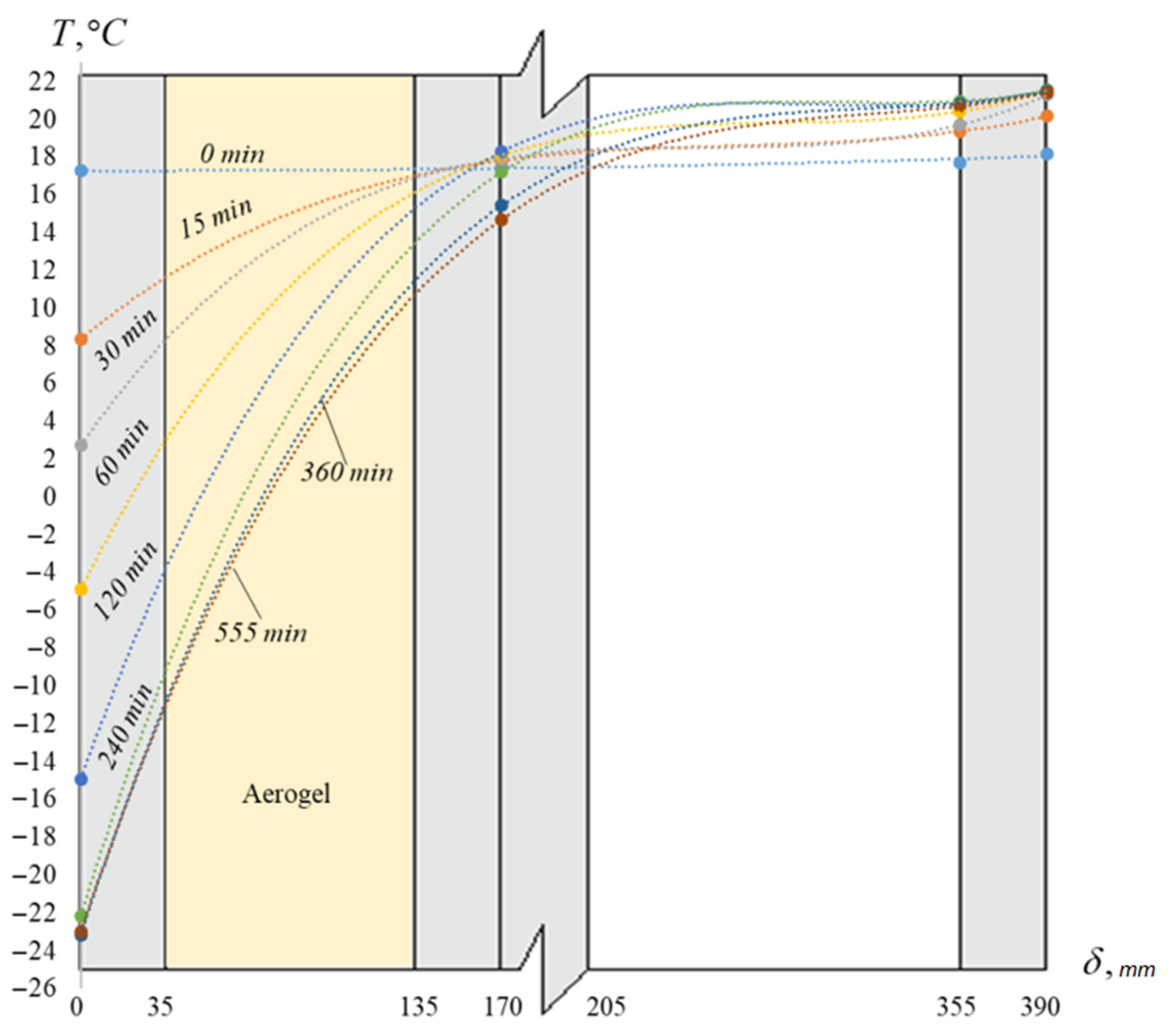

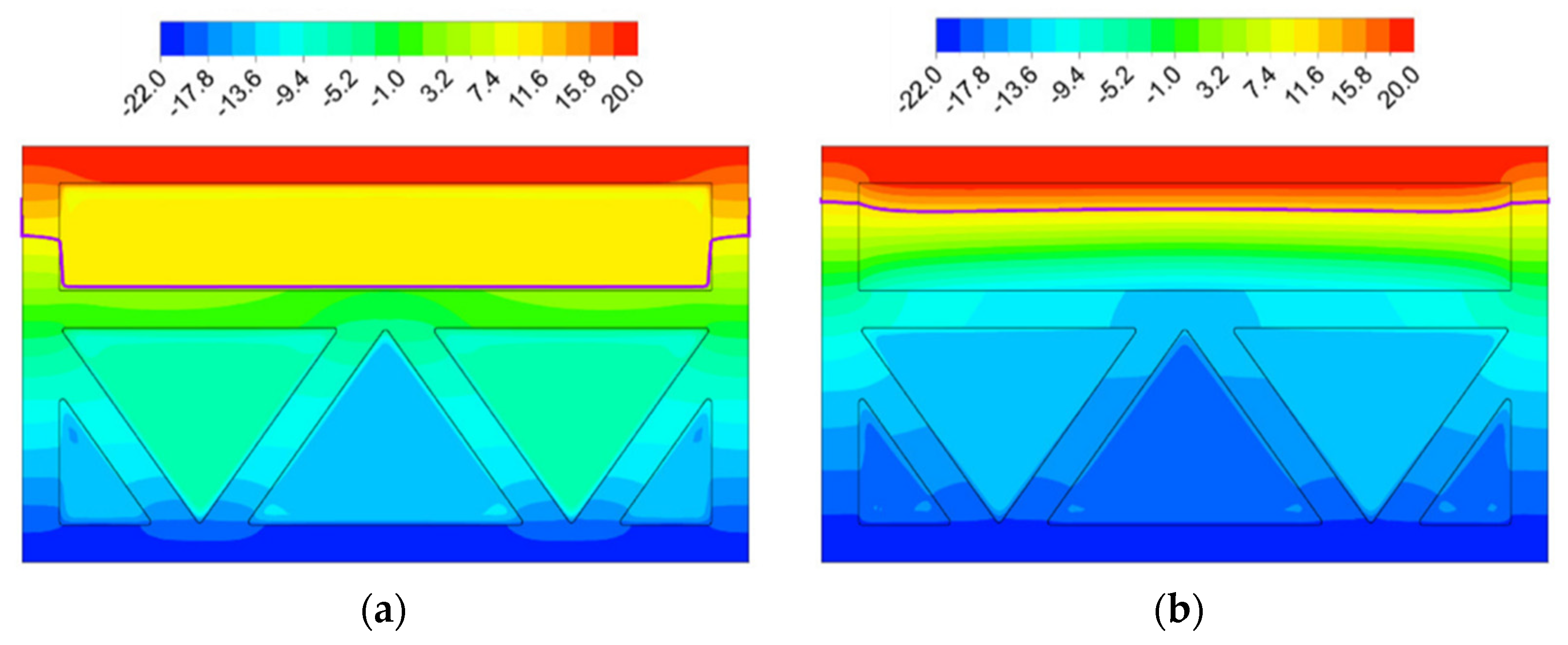

2.3. Numerical Approach

Computational fluid dynamics methods are employed for numerical work. Both Navier–Stokes equations for convective heat transfer and Fourier heat equation for conductive heat transfer are solved conjugately with the finite volume method. A hybrid mesh for both solid and fluid computational domains is constructed, and the mesh size is approximately 4.95 M nodes and 4.5 M elements. The mesh is mostly hexahedral (99.2% of elements, 0.8% of elements degenerate into wedges).

Convection is assumed to be laminar and modelled by Boussinesq approximation with a standard g value of 9.81 m/s

2. Other material properties are presented in

Table 9.

There are several boundary conditions: firstly, adiabatic wall boundary conditions for side walls (

Figure 16, purple lines), external (blue line) and internal (red line) convective heat transfer, and fluid-solid heat transfer (thin black lines). The concrete area is painted grey, and air/aerogel area is painted light blue colors.

The internal heat transfer temperature is 22 °C, and the external heat transfer temperature is −24 °C. Heat transfer coefficients for both of the zones are 3 W/(m2 ∗ K). Heat transfer coefficients are conducted with Churchill and Chu approximation for natural convection on vertical plate.

ANSYS CFX finite-volume solver is employed to get the solution for different cases.