Eco-Innovation: Corn Stover as the Biomaterial in Packaging Designs

Abstract

1. Introduction

2. Biomaterials and Corn Stover

2.1. Biomaterials and Recycling

2.2. Corn Stover in the Context of Mainland China

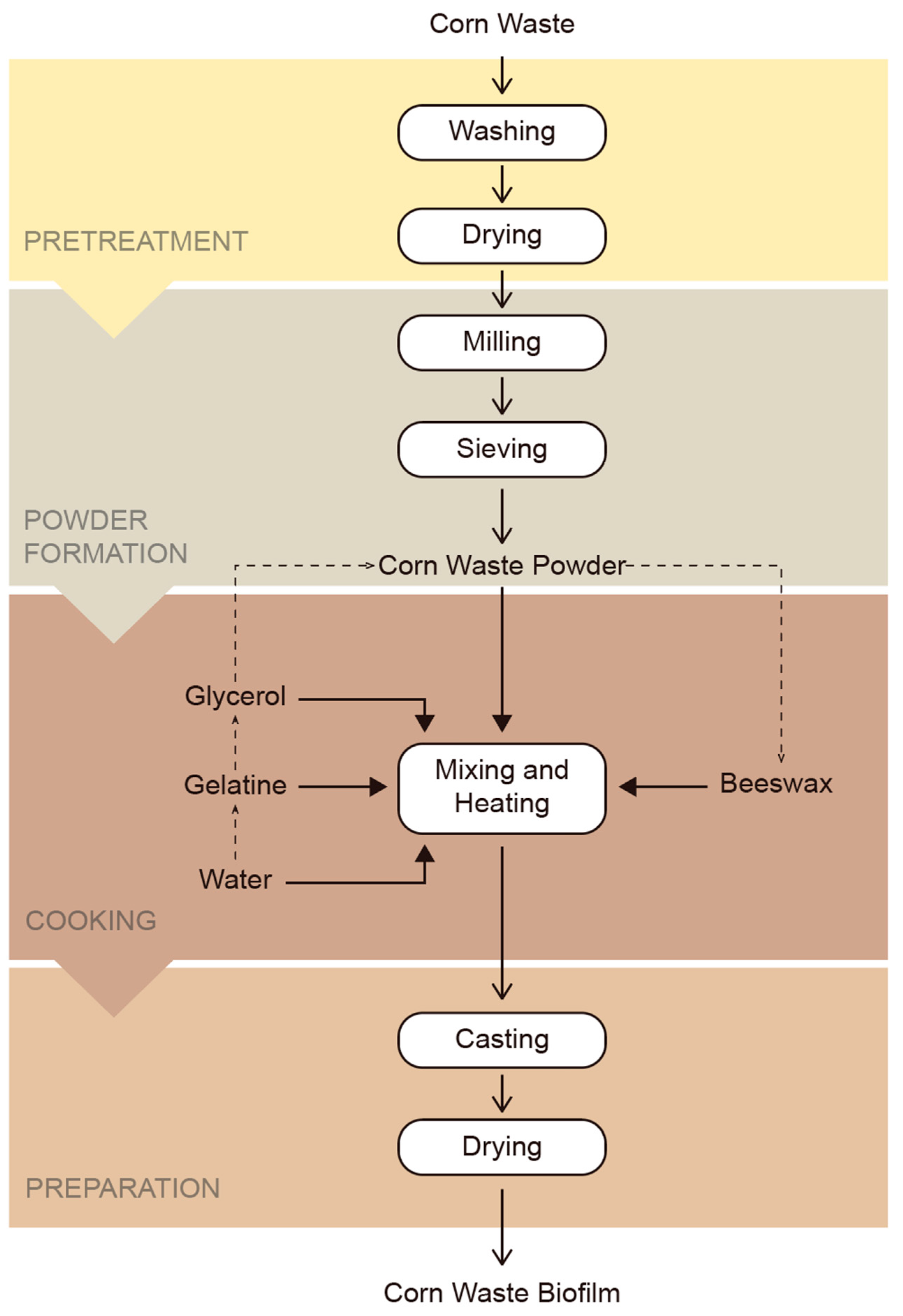

3. Methods

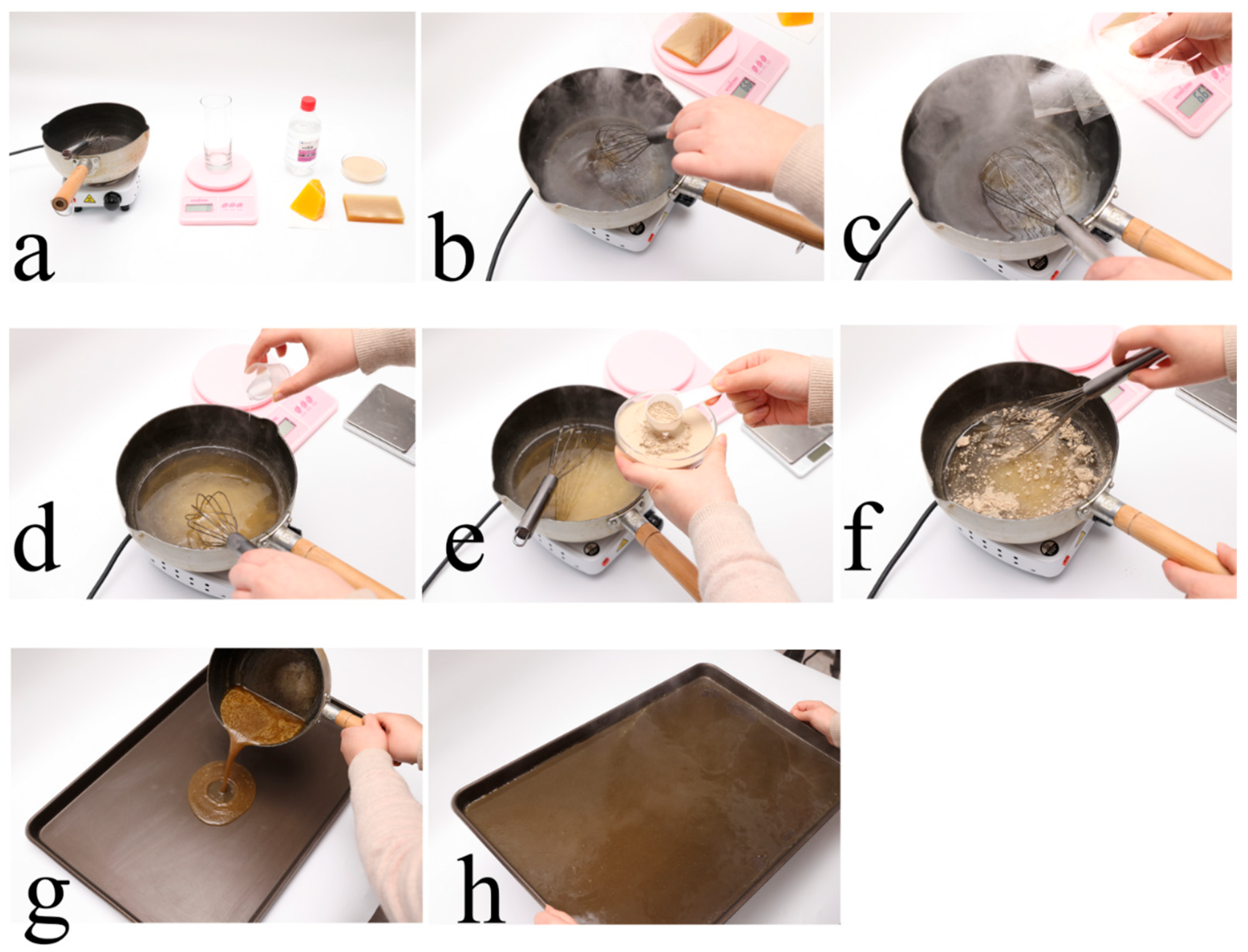

3.1. Confirmation of the Formula

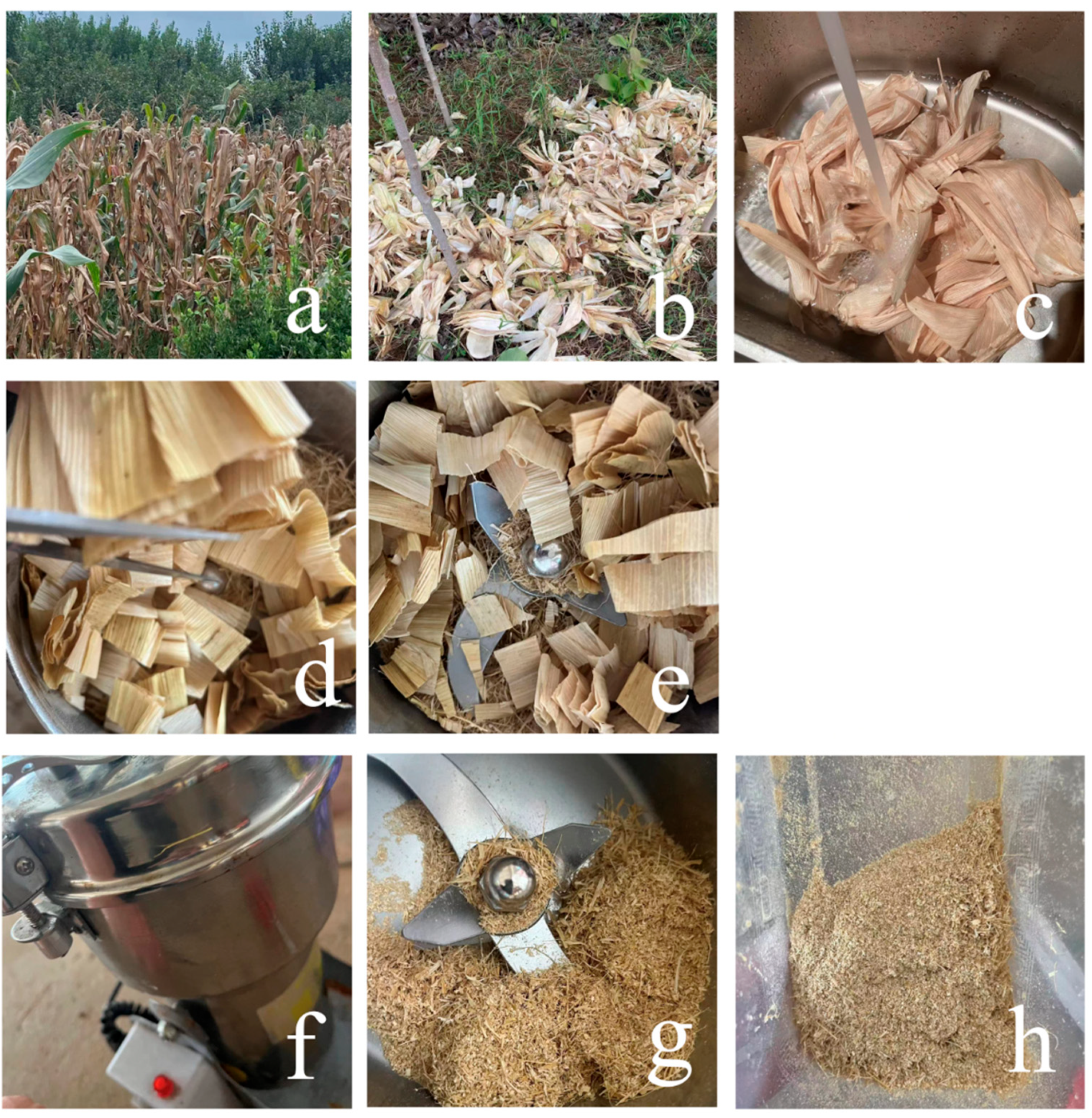

3.2. Material Processing

3.3. Primary Feature Test Methods

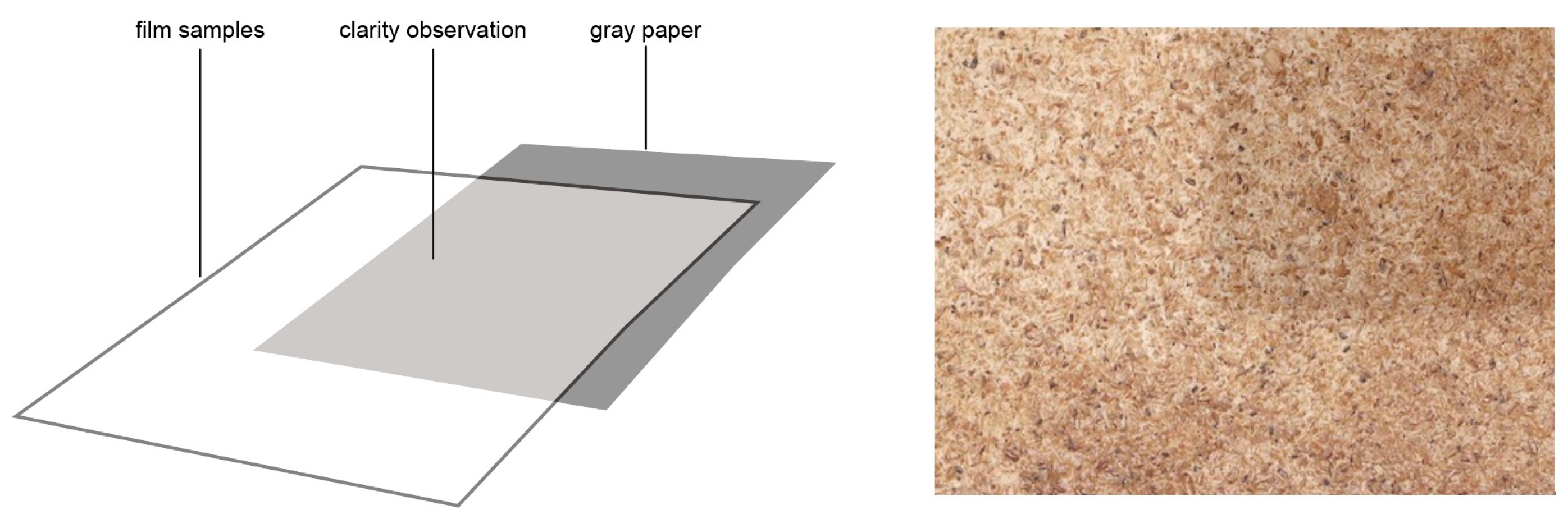

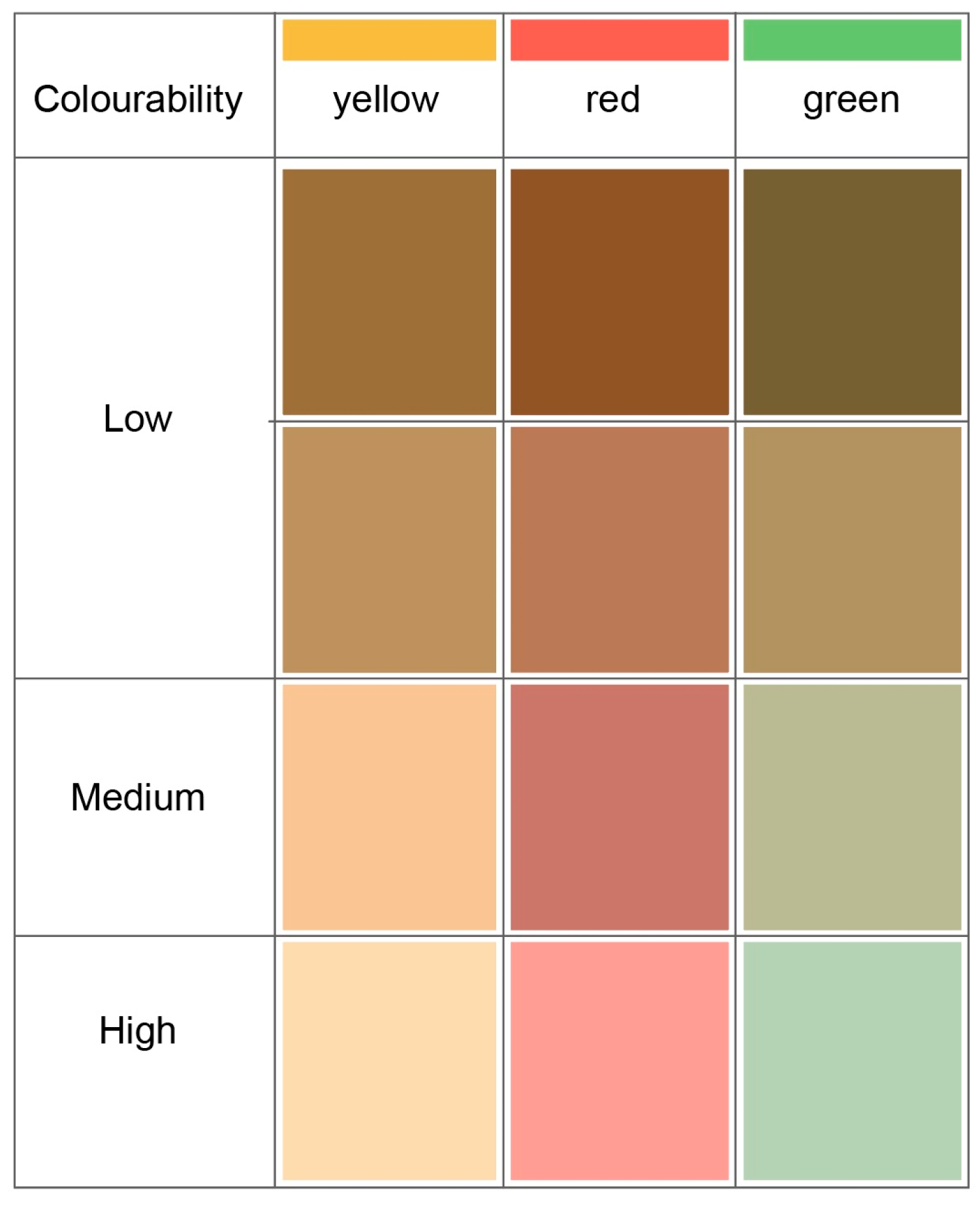

3.3.1. Transparency and Colourability

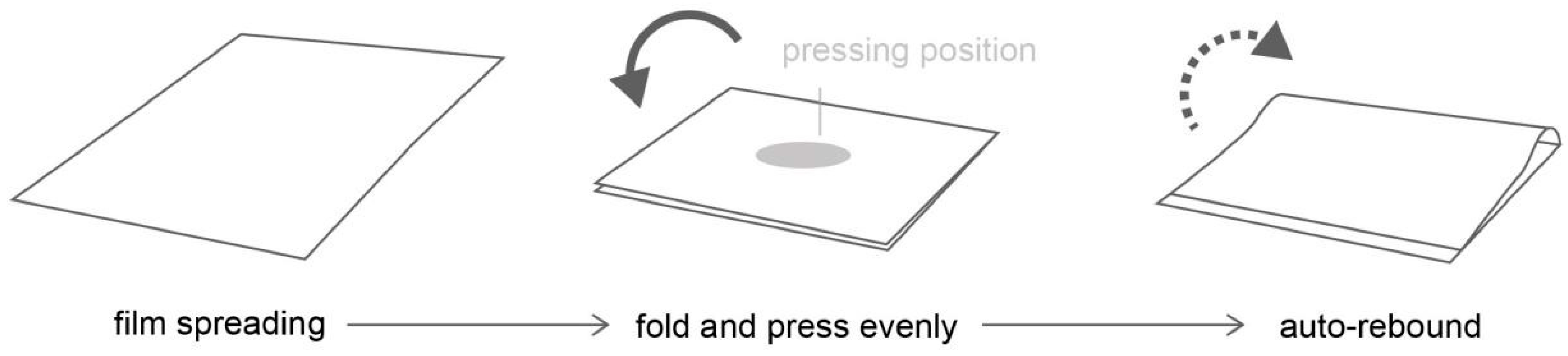

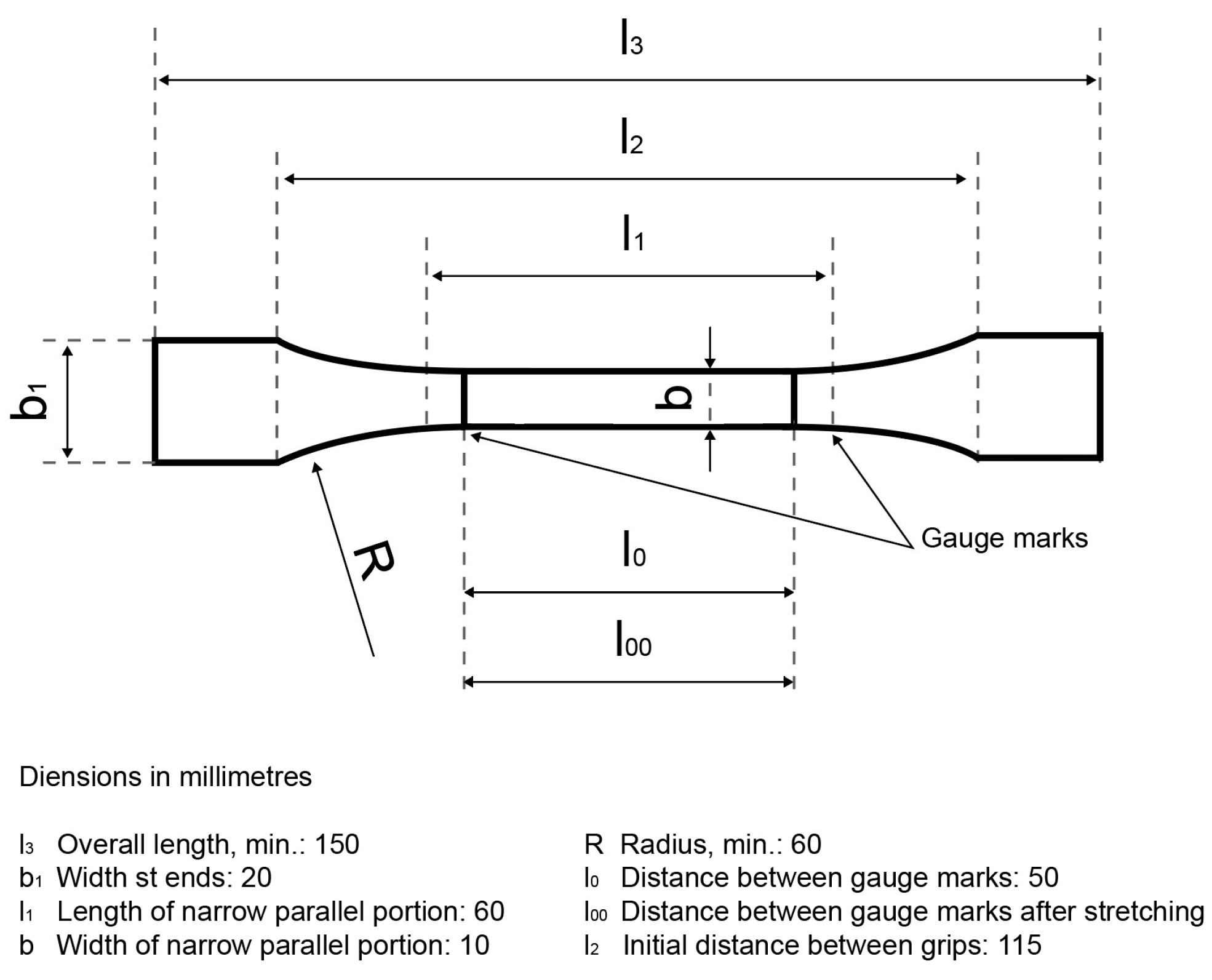

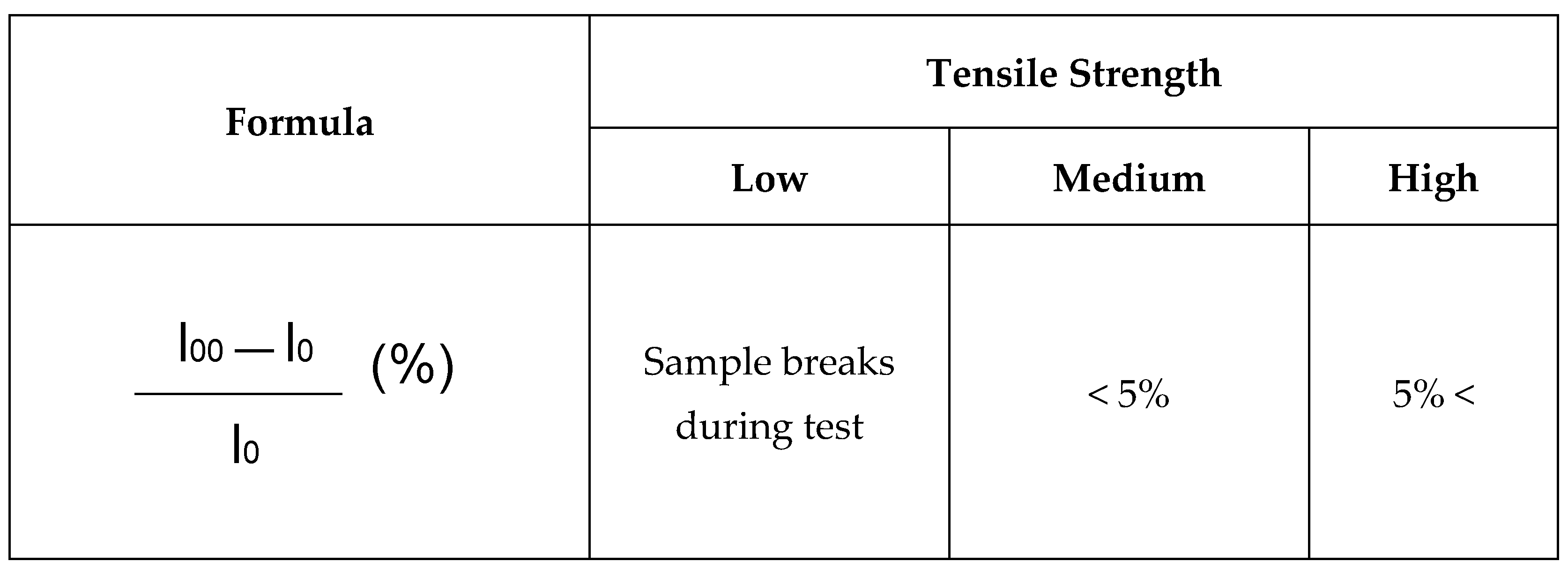

3.3.2. Strength and Elasticity

3.3.3. Smoothness and Waterproofing

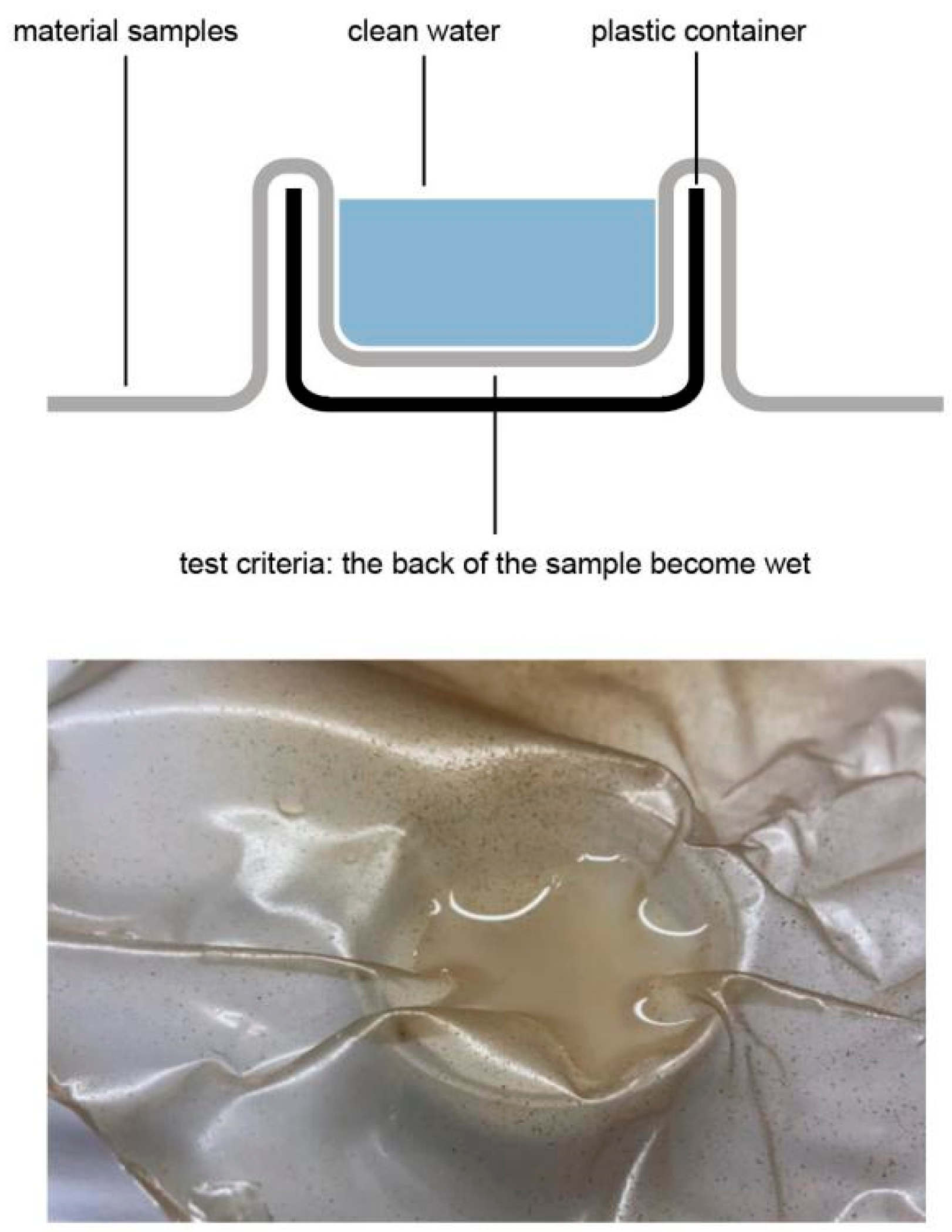

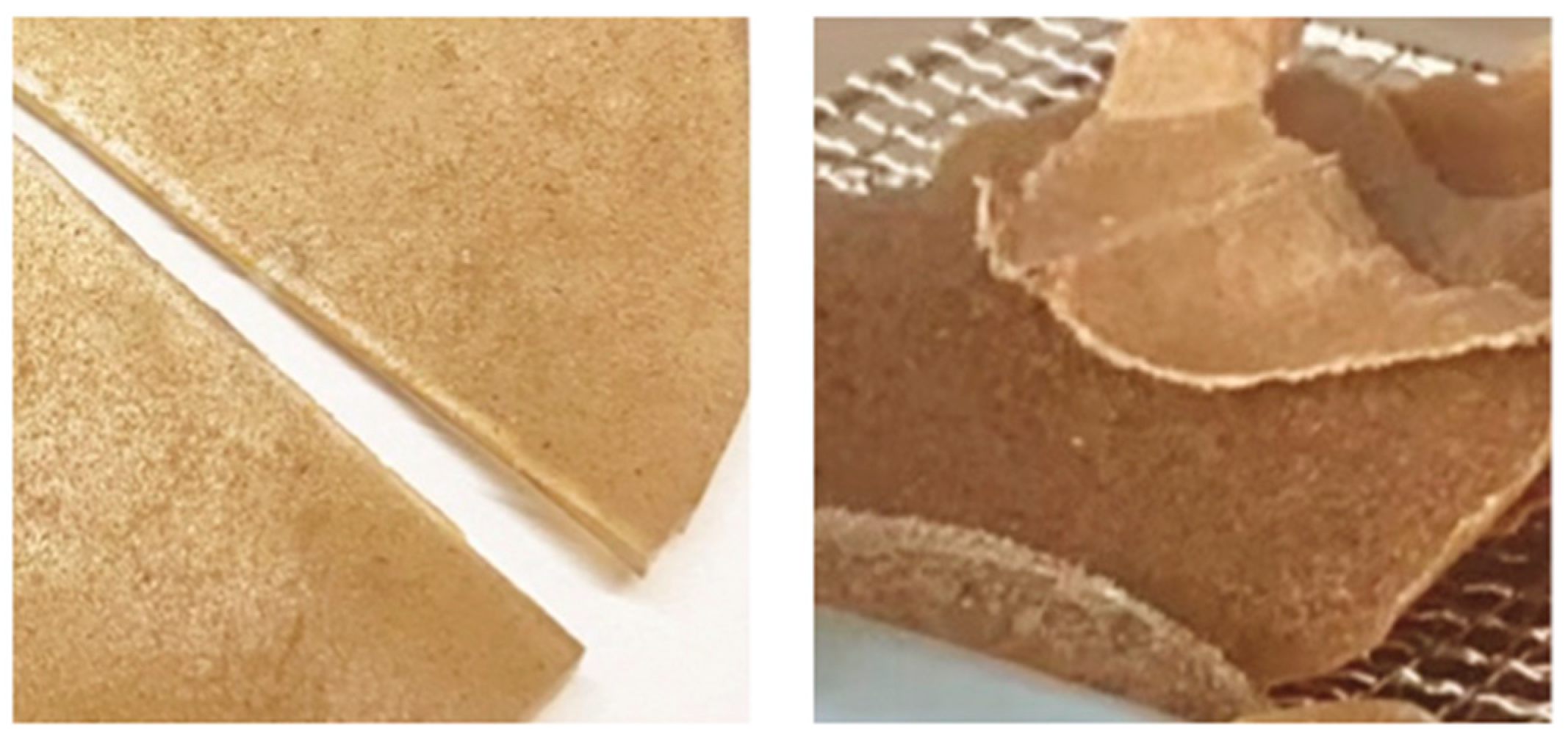

4. Results

4.1. Material Characteristics

4.1.1. Transparency and Colourability

4.1.2. Strength and Elasticity

4.1.3. Smoothness and Waterproofing

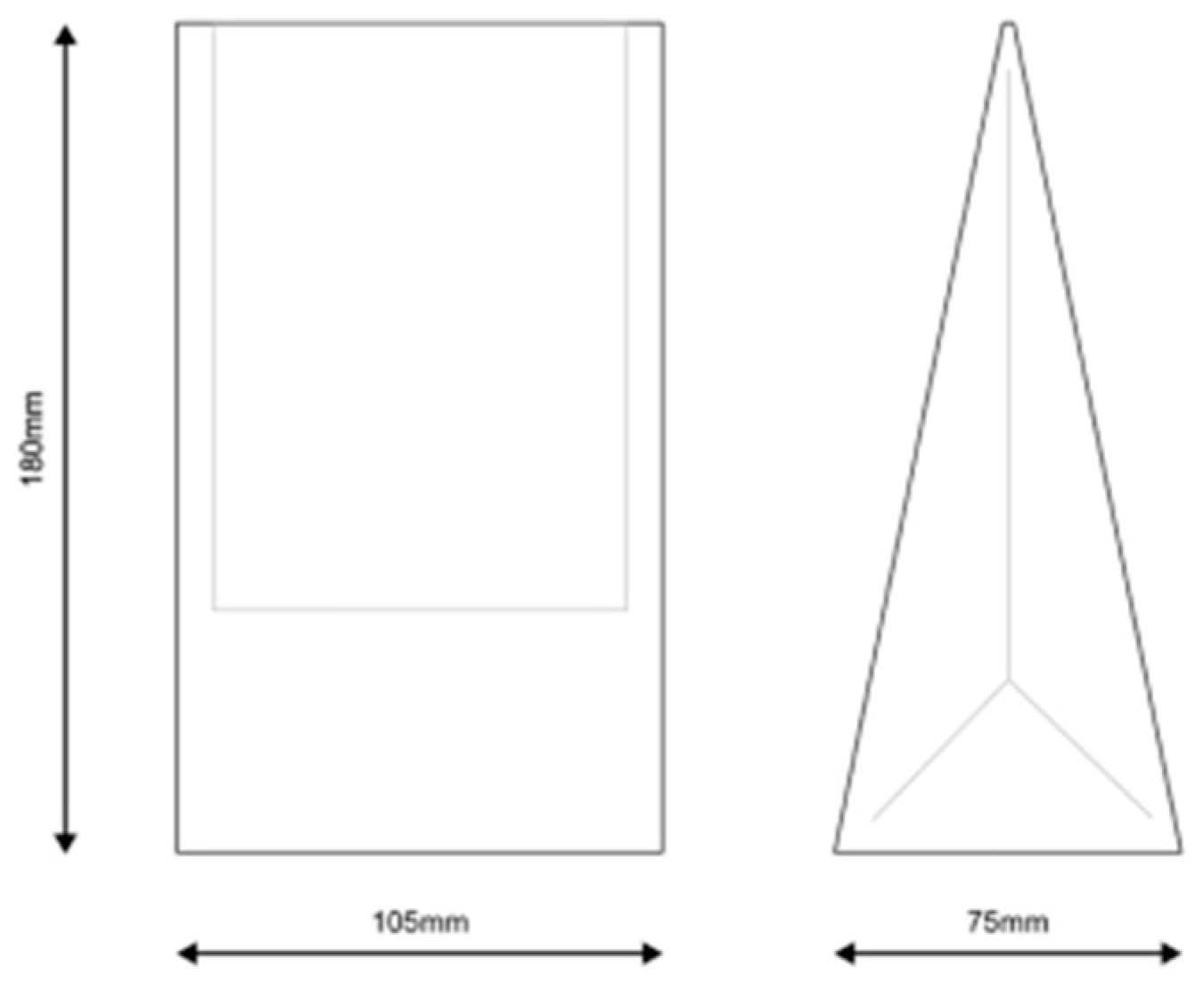

4.2. Packaging Design Applications

4.3. Recycling and Reuse

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Bank. Agriculture, Forestry, and Fishing, Value Added (% of GDP)—China; World Bank: Washington, DC, USA, 2022; Available online: https://data.worldbank.org/indicator/NV.AGR.TOTL.ZS?locations=CN (accessed on 30 December 2022).

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal insulation materials based on agricultural residual wheat straw and corn husk biomass, for application in sustainable buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Wang, P.; Chen, Y.M.; Wang, Y.; Lee, Y.Y.; Zong, W.; Taylor, S.; McDonald, T.; Wang, Y. Towards comprehensive lignocellulosic biomass utilization for bioenergy production: Efficient biobutanol production from acetic acid pretreated switchgrass with Clostridium saccharoperbutylacetonicum N1-4. Appl. Energy 2019, 236, 551–559. [Google Scholar] [CrossRef]

- Opoku-Kwanowaa, Y.; Wu, J.; Chen, X.; Sharaf, A.; Attipoe, S.G. Soil Physicochemical Properties Variation in Black Soil after the Long-term Application of Different Organic Amendments. Asian J. Adv. Agric. Res. 2020, 12, 24–34. [Google Scholar] [CrossRef][Green Version]

- Raheem, A.; Ding, L.; He, Q.; Mangi, F.H.; Khand, Z.H.; Sajid, M.; Ryzhkov, A.; Yu, G. Effective pretreatment of corn straw biomass using hydrothermal carbonization for co-gasification with coal: Response surface Methodology–Box Behnken design. Fuel 2022, 324, 124544. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Chong, T.Y.; Law, M.C.; Chan, Y.S. The Potentials of Corn Waste Lignocellulosic Fibre as an Improved Reinforced Bioplastic Composites. J. Polym. Environ. 2021, 29, 363–381. [Google Scholar] [CrossRef]

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste-Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- Meadowcroft, J. Who is in Charge here? Governance for Sustainable Development in a Complex World. J. Environ. Policy Plan. 2007, 9, 299–314. [Google Scholar] [CrossRef]

- El Haggar, S. Sustainable Industrial Design and Waste Management: Cradle-To-Cradle for Sustainable Development; Academic Press: Cambridge, MA, USA, 2007. [Google Scholar]

- Sharma, A.; Kumar, V.; Shahzad, B.; Tanveer, M.; Sidhu, G.P.S.; Handa, N.; Kohli, S.K.; Yadav, P.; Bali, A.S.; Parihar, R.D.; et al. Worldwide pesticide usage and its impacts on ecosystem. SN Appl. Sci. 2019, 1, 1446. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Madhavan, A.; Sindhu, R.; Pugazhendhi, A.; Binod, P.; Sirohi, R.; Awasthi, M.K.; Tarafdar, A.; Pandey, A. Advanced biomaterials for sustainable applications in the food industry: Updates and challenges. Environ. Pollut. 2021, 283, 117071. [Google Scholar]

- Østergaard, P.A.; Duic, N.; Noorollahi, Y.; Mikulcic, H.; Kalogirou, S. Sustainable development using renewable energy technology. Renew. Energy 2020, 146, 2430–2437. [Google Scholar] [CrossRef]

- Kumar Gupta, G.; De, S.; Franco, A.; Balu, A.M.; Luque, R. Sustainable biomaterials: Current trends, challenges and applications. Molecules 2015, 21, 48. [Google Scholar] [CrossRef] [PubMed]

- Milios, L. Advancing to a Circular Economy: Three essential ingredients for a comprehensive policy mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef] [PubMed]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef] [PubMed]

- LinkedIn Corporation. Biomaterials Market Growth Share 2022 with Industry Size, Business Opportunities, Key Drivers, Market Performance, Development and Dynamics, Major Key; LinkedIn Corporation: Sunnyvale, CA, USA, 2022. [Google Scholar]

- Wang, W.; Mo, T.; Wang, Y. Better self and better us: Exploring the individual and collective motivations for China’s Generation Z consumers to reduce plastic pollution. Resour. Conserv. Recycl. 2022, 179, 106111. [Google Scholar] [CrossRef]

- Precedence Research. Biomaterials Market Size, Share & Growth Analysis Report by Product (Metallic, Ceramics, Natural, and Polymers). Available online: https://www.precedenceresearch.com/biomaterials-market (accessed on 23 November 2023).

- Pascoli, D.U.; Dichiara, A.; Gustafson, R.; Bura, R. A Robust Process to Produce Lignocellulosic Nanofibers from Corn Stover, Reed Canary Grass, and Industrial Hemp. Polymers 2023, 15, 937. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, V.R.L.; Santos, F.K.G.; Leite, R.H.L.; Aroucha, E.M.M.; Silva, K.N.O. Use of biopolymeric coating hydrophobized with beeswax in post-harvest conservation of guavas. Food Chem. 2018, 259, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharian, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Hao, L. Contributions of open crop straw burning emissions to PM2.5 concentrations in China. Environ. Res. Lett. 2016, 11, 014014. [Google Scholar] [CrossRef]

- Dunne, M. Bioplastic Cook Book; FAB Textiles Inc.: Vaughan, ON, Canada, 2018. [Google Scholar]

- Wojcieszak, D.; Przybył, J.; Czajkowski, Ł.; Majka, J.; Pawłowski, A. Effects of Harvest Maturity on the Chemical and Energetic Properties of Corn Stover Biomass Combustion. Materials 2022, 15, 2831. [Google Scholar] [CrossRef]

- Rhim, J.W.; Ng, P.K. Natural biopolymer-based nanocomposite films for packaging applications. Crit. Rev. Food Sci. Nutr. 2007, 47, 411–433. [Google Scholar] [CrossRef]

- Gustafsson, J.; Landberg, M.; Bátori, V.; Åkesson, D.; Taherzadeh, M.J.; Zamani, A. Development of Bio-Based Films and 3D Objects from Apple Pomace. Polymers 2019, 11, 289. [Google Scholar] [CrossRef]

- Yaradoddi, J.S.; Banapurmath, N.R.; Ganachari, S.V.; Soudagar, M.E.M.; Sajjan, A.M.; Kamat, S.; Mujtaba, M.A.; Shettar, A.S.; Anqi, A.E.; Safaei, M.R.; et al. Bio-based material from fruit waste of orange peel for industrial applications. J. Mater. Res. Technol. 2022, 17, 3186–3197. [Google Scholar] [CrossRef]

- Kristo, E.; Biliaderis, C.G.; Zampraka, A. Water vapour barrier and tensile properties of composite caseinate-pullulan films: Biopolymer composition effects and impact of beeswax lamination. Food Chem. 2007, 101, 753–764. [Google Scholar] [CrossRef]

- Huang, E.; Zhang, X.; Rodriguez, L.; Khanna, M.; de Jong, S.; Ting, K.C.; Ying, Y.; Lin, T. Multi-objective optimization for sustainable renewable jet fuel production: A case study of corn stover based supply chain system in Midwestern U.S. Renew. Sustain. Energy Rev. 2019, 115, 109403. [Google Scholar] [CrossRef]

- Park, K.E.; Kang, G.H.; Kim, H.I.; Yu, G.J.; Kim, J.T. Analysis of thermal and electrical performance of semi-transparent photovoltaic (PV) module. Energy 2010, 35, 2681–2687. [Google Scholar] [CrossRef]

- International Standard ISO 1184:1983(E). Available online: https://cdn.standards.iteh.ai/samples/5774/89c3bab575284993a9801a5b9e2d2128/ISO-1184-1983.pdf (accessed on 1 February 2024).

- Calva-Estrada, S.J.; Jiménez-Fernández, M.; Lugo-Cervantes, E. Pro-tein-based films: Advances in the development of biomaterials applicable to food packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M.J.; et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2011.

- Reyes, L.F.; Cisneros-Zevallos, L. Degradation kinetics and colour of anthocyanins in aqueous extracts of purple-and red-flesh potatoes (Solanum tuberosum L.). Food Chem. 2007, 100, 885–894. [Google Scholar] [CrossRef]

- Amornraksa, S.; Subsaipin, I.; Simasatitkul, L.; Assabumrungrat, S. Systematic design of separation process for bioethanol production from corn stover. BMC Chem. Eng. 2020, 2, 10. [Google Scholar] [CrossRef]

- Hess, J.R.; Kenney, K.L.; Wright, C.T.; Perlack, R.; Turhollow, A. Corn stover availability for biomass conversion: Situation analysis. Cellulose 2009, 16, 599–619. [Google Scholar] [CrossRef]

- Martinez Hernandez, E.; Ng, K.S. Design of biorefinery systems for conversion of corn stover into biofuels using a biorefinery engineering framework. Clean Technol. Environ. Policy 2018, 20, 1501–1514. [Google Scholar] [CrossRef]

- Valdez-Vazquez, I.; Acevedo-Benítez, J.A.; Hernández-Santiago, C. Distribution and potential of bioenergy resources from agricultural activities in Mexico. Renew. Sustain. Energy Rev. 2010, 14, 2147–2153. [Google Scholar]

- Hamilton, L.A.; Feit, S. Plastic & Climate: The Hidden Costs of a Plastic Planet; Center for International Environmental Law CIEL: Genève, Switzerland, 2019. [Google Scholar]

- Markevičiūtė, Z.; Varžinskas, V. Smart Material Choice: The Importance of Circular Design Strategy Applications for Bio-Based Food Packaging Preproduction and End-of-Life Life Cycle Stages. Sustainability 2022, 14, 6366. [Google Scholar] [CrossRef]

- Moshood, T.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.; Abdul Ghani, A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability 2021, 13, 6170. [Google Scholar] [CrossRef]

- Astudillo, Á.; Rubilar, O.; Briceño, G.; Diez, M.C.; Schalchli, H. Advances in Agroindustrial Waste as a Substrate for Obtaining Eco-Friendly Microbial Products. Sustainability 2023, 15, 3467. [Google Scholar] [CrossRef]

- Bátori, V.; Jabbari, M.; Åkesson, D.; Lennartsson, P.R.; Taherzadeh, M.J.; Zamani, A. Production of Pectin-Cellulose Biofilms: A New Approach for Citrus Waste Recycling. Int. J. Polym. Sci. 2017, 2017, 9732329. [Google Scholar] [CrossRef]

- Power, D. Priority Sector Report: Creative and Cultural Industries; European Commission; Publications Office of the European Union: Brussels, Belgium, 2011. [Google Scholar]

- Hong, J.; Ren, L.; Hong, J.; Xu, C. Environmental impact assessment of corn straw utilization in China. J. Clean. Prod. 2016, 112, 1700–1708. [Google Scholar] [CrossRef]

| (a) | |

| Component | Mass % |

| Corn Waste Powder | 6.8% |

| Glycerol | 6.8% |

| Gelatin | 18.2% |

| Beeswax | 4.6% |

| Water | 63.6% |

| (b) | |

| Component | Mass Range (g) |

| Corn Waste Powder | 15~30 g |

| Glycerol | 10~20 g |

| Gelatin | 20~50 g |

| Beeswax | 0~20 g |

| Water | 140 g |

| Sample | Corn Waste Powder | Glycerol | Gelatin | Beeswax | Water | |

|---|---|---|---|---|---|---|

| Weight (in Grams) | ||||||

| Group1 | S1.1 | 15 | 15 | 40 | 10 | 140 |

| S1.2 | 30 | 15 | 40 | 10 | 140 | |

| S1.3 | 45 | 15 | 40 | 10 | 140 | |

| S1.4 | 60 | 15 | 40 | 10 | 140 | |

| Group2 | S2.1 | 15 | 5 | 40 | 10 | 140 |

| S2.2 | 15 | 10 | 40 | 10 | 140 | |

| S2.3 | 15 | 15 | 40 | 10 | 140 | |

| S2.4 | 15 | 20 | 40 | 10 | 140 | |

| S2.5 | 15 | 25 | 40 | 10 | 140 | |

| Group3 | S3.1 | 15 | 15 | 10 | 10 | 140 |

| S3.2 | 15 | 15 | 20 | 10 | 140 | |

| S3.3 | 15 | 15 | 30 | 10 | 140 | |

| S3.4 | 15 | 15 | 40 | 10 | 140 | |

| S3.5 | 15 | 15 | 50 | 10 | 140 | |

| Group4 | S4.1 | 15 | 15 | 40 | 5 | 140 |

| S4.2 | 15 | 15 | 40 | 10 | 140 | |

| S4.3 | 15 | 15 | 40 | 15 | 140 | |

| S4.4 | 15 | 15 | 40 | 20 | 140 | |

| S4.5 | 15 | 15 | 40 | 25 | 140 | |

| Sample | (%) | Tensile Strength |

|---|---|---|

| S2.2 | 3.2% | Medium |

| S2.3 | 4.5% | Medium |

| S2.4 | 9.2% | High |

| S2.5 | N/A | Low |

| S3.2 | N/A | Low |

| S3.3 | 7.8% | High |

| S3.4 | 4.5% | Medium |

| S3.5 | 3.7% | Medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Zhang, L.; Su, H.; Yang, D.; Xu, J. Eco-Innovation: Corn Stover as the Biomaterial in Packaging Designs. Sustainability 2024, 16, 1381. https://doi.org/10.3390/su16041381

Duan Y, Zhang L, Su H, Yang D, Xu J. Eco-Innovation: Corn Stover as the Biomaterial in Packaging Designs. Sustainability. 2024; 16(4):1381. https://doi.org/10.3390/su16041381

Chicago/Turabian StyleDuan, Yu, Linli Zhang, Hang Su, Dongfang Yang, and Jinhui Xu. 2024. "Eco-Innovation: Corn Stover as the Biomaterial in Packaging Designs" Sustainability 16, no. 4: 1381. https://doi.org/10.3390/su16041381

APA StyleDuan, Y., Zhang, L., Su, H., Yang, D., & Xu, J. (2024). Eco-Innovation: Corn Stover as the Biomaterial in Packaging Designs. Sustainability, 16(4), 1381. https://doi.org/10.3390/su16041381