Life Cycle Assessment of Greenhouse Gas Emissions in Hydrogen Production via Water Electrolysis in South Korea

Abstract

1. Introduction

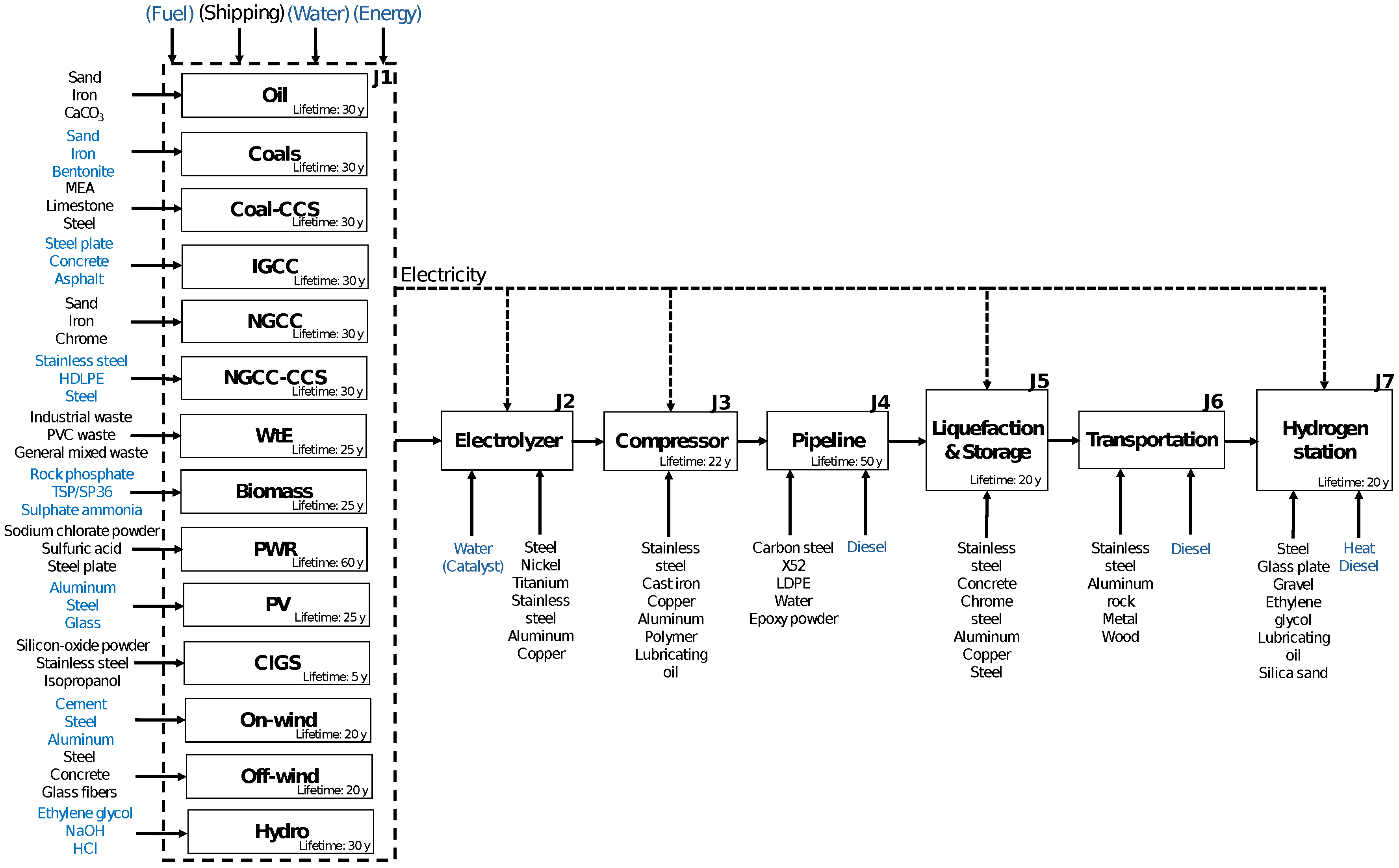

- To evaluate GHG emissions from well to pump, the hydrogen supply chain in Korea was divided into seven stages. These stages encompass everything from extracting raw materials for power plant construction to electricity generation, hydrogen production, liquefaction, storage, and distribution to hydrogen refueling stations. These stages are labeled J1 through J7. The total GHG emissions from J1 to J7 provide a comprehensive well-to-pump assessment. Additionally, if only the emissions from J1 and J2 are taken into account, a well-to-gate assessment can also be conducted.

- To conduct an LCA, we collected publicly available data regarding the services, materials, and energy consumed during the evaluation stage. Our primary focus was on diverse datasets that highlight how GHG emissions significantly depend on power sources, electrolyzer efficiency, and energy mixes, especially when using grid electricity. We gathered and compared data from sixteen power sources currently in operation or planned for operation in Korea, as well as three types of water electrolyzers from various sources.

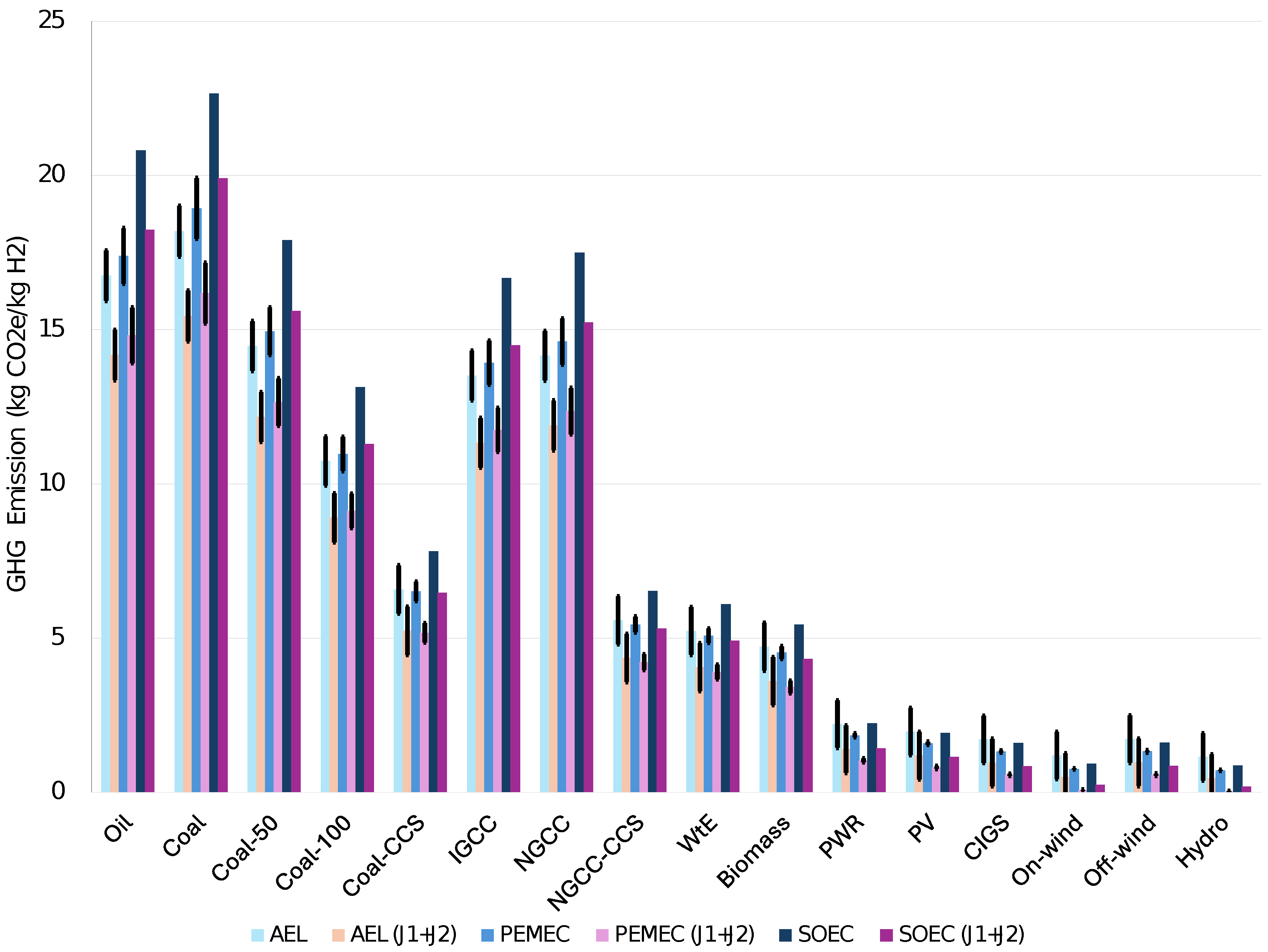

- We created a classification table (with the results of the LCA) that categorizes sixteen power sources according to Korea’s clean hydrogen certification standards. Hydroelectric dams and onshore wind turbines were considered the cleanest options, placed in Tier 2 when using the well-to-pump approach. However, they can be classified as Tier 1 if well-to-gate emissions are taken into account. Following hydroelectric and onshore wind sources, photovoltaics, nuclear energy, and offshore wind are next in line. Additionally, this study highlights that the results were highly sensitive to the methods of electrolysis used, specifically concerning their efficiency and the amount of non-energy inputs required during construction.

- Based on the future energy mixes projected by Korean energy and environmental authorities for the years 2036, 2040, and 2050, we predicted the position of hydrogen production using grid-connected water electrolysis. The results indicated that, with the expected energy mixes stemming from successful decarbonization in the Korean power sector, future grid electricity will qualify as a Tier 2 energy source for clean hydrogen production. Furthermore, when well-to-gate accounting is applied, this could reach Tier 1 status.

2. Related Studies

2.1. Related Works from Overseas Studies

2.2. Related Works for Korea

3. LCA Scope and Data

3.1. LCA System Boundary

- J1: This stage involves the construction and operation of power sources used to generate electricity for the subsequent stages (J2 to J7).

- J7: The final stage involves the supply of liquefied hydrogen to refueling stations. This includes the construction and operation of the refueling stations, as well as the balance of plant (BoP) equipment [54].

3.2. Power Plant Assumptions

3.3. Input Materials and Data

4. Results

4.1. GHG Emissions According to Power Generation Sources and Water Electrolyzers

4.2. GHG Emissions from Grid-Connected Hydrogen Production in Korea

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| K | Kelvin |

| kg e/kg | kilogram of equivalent per kilogram of |

| kg e/kWh | kilogram of equivalent per kilowatt-hour |

| CF | Capacity Factor |

| AUS | Australia |

| NOR | Norway |

| UAE | United Arab Emirates |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| GHG | Greenhouse Gas |

| Carbon Dioxide | |

| Hydrogen | |

| Liquid Hydrogen | |

| NOx | Nitrogen Oxides |

| SOx | Sulfur Oxides |

| AEL | Alkaline Electrolyzer |

| PEMEC | Proton Exchange Membrane Electrolyzer Cell |

| SOEC | Solid Oxide Electrolyzer Cell |

| CCS | Carbon Capture and Storage |

| IGCC | Integrated Gasification Combined Cycle |

| NGCC | Natural Gas Combined Cycle |

| WtE | Waste-to-Energy |

| LWR | Light Water Reactor |

| PWR | Pressurized Water Reactor |

| PV | Photovoltaic |

| CIGS | Copper Indium Gallium Selenide |

| CSP | Concentrated Solar Power |

| On-wind | Onshore Wind |

| Off-wind | Offshore Wind |

| BOS | Balance of System |

| BoP | Balance of Plant |

| MOTIE | Ministry of Trade, Industry and Energy |

| KEEI | Korea Energy Economics Institute |

| EEI | Energy Efficiency Improvement |

| EOE | Electrification of End-use |

References

- Park, W.; Korea Energy Economics Institute (KEEI). World Nuclear Power Market INSIGHT. Available online: https://www.keei.re.kr/pdfOpen.es?bid=0002&list_no=83629&seq=1 (accessed on 13 January 2023).

- Ministry of Trade, Industry and Energy (MOTIE). Hydrogen Economy Roadmap of Korea. 2021. Available online: https://www.korea.kr/briefing/pressReleaseView.do?newsId=156313631 (accessed on 15 January 2023).

- Korea Energy Agency. Current Status of Hydrogen Fuel Cell Deployment in Korea. 2022. Available online: https://www.h2hub.or.kr/main/stat/stat_use_supply_hCell.do (accessed on 3 February 2023).

- Oh, D.-S.; Park, J.S.; Kwon, C.S.; Oh, M.Y.; Choi, D.H. Notification on the Operation of Clean Hydrogen Certification System. 2023. Available online: https://www.kimchang.com/en/insights/detail.kc?sch_section=4&idx=28649 (accessed on 15 June 2024).

- GS Caltex. Energy Column] Trade Norms for Revitalizing the Hydrogen Economy, Global Trends in Clean Hydrogen Certification. Available online: https://gscaltexmediahub.com/energy/hydrogen/ (accessed on 24 May 2024).

- Jung, G. Three Strategies and Support Policies for the Development of Clean Hydrogen in the United States; Korea Energy Economics Institute (KEEI): Ulsan, Republic of Korea, 2023. [Google Scholar]

- Ryu, K. Overseas Clean Hydrogen Certification Systems and Domestic Implications; National Assembly Research Service (NARS): Seoul, Republic of Korea, 2021. [Google Scholar]

- Lee, H.; Korea Energy Economics Institute (KEEI). Clean Hydrogen Trade Initiative 2024—Korea’s Clean Hydrogen Certification Scheme. 2024. Available online: https://www.keei.re.kr/keei/download/seminar/240530/Presentation4.pdf (accessed on 18 June 2024).

- Sajawal, A.M. Life Cycle Sustainability Assessment of Green Hydrogen Production and Delivery-An Economic, Environmental, and Social Perspective. Ph.D. Thesis, Pukyong National University, Busan, Republic of Korea, 2023. Available online: https://repository.pknu.ac.kr:8443/handle/2021.oak/32949 (accessed on 4 August 2023).

- Yoo, E.; Kim, M.; Song, H. Well-to-wheel analysis of hydrogen fuel-cell electric vehicle in Korea. Int. J. Hydrogen Energy 2018, 43, 19267–19278. [Google Scholar] [CrossRef]

- Lee, B.; Cho, H.S.; Kim, H.; Lim, D.; Cho, W.; Kim, C.H.; Lim, H. Integrative techno-economic and environmental assessment for green H2 production by alkaline water electrolysis based on experimental data. J. Environ. Chem. Eng. 2021, 9, 106349. [Google Scholar] [CrossRef]

- Patel, G.H.; Havukainen, J.; Horttanainen, M.; Soukka, R.; Tuomaala, M. Climate change performance of hydrogen production based on life cycle assessment. Green Chem. 2024, 26, 992–1006. [Google Scholar] [CrossRef]

- Sphera, GaBi Software. Available online: https://sphera.com/solutions/product-stewardship/life-cycle-assessment-software-and-data/ (accessed on 18 July 2023).

- Jolaoso, L.A.; Duan, C.; Kazempoor, P. Life cycle analysis of a hydrogen production system based on solid oxide electrolysis cells integrated with different energy and wastewater sources. Int. J. Hydrogen Energy 2024, 52, 485–501. [Google Scholar] [CrossRef]

- Ecoinvent. Available online: https://ecoinvent.org/ (accessed on 20 July 2023).

- SimaPro. Available online: https://simapro.com/ (accessed on 21 July 2023).

- AspenTech. Aspen Plus. Available online: https://www.aspentech.com/en/products/engineering/aspen-plus (accessed on 21 July 2023).

- Yang, S.; Mao, D.; Yu, Z.; Ma, W.; Ma, L.; Li, X.; Xi, F. Comparison of life cycle assessment between hydrogen production from silicon waste and alkaline water electrolysis. Sci. Total Environ. 2024, 920, 171065. [Google Scholar] [CrossRef]

- Chinese Life Cycle Database (CLCD). Available online: https://ghgprotocol.org/Third-Party-Databases/CLCD (accessed on 4 December 2024).

- Pawłowski, A.; Żelazna, A.; Żak, J. Is the polish solar-to-hydrogen pathway green? A carbon footprint of AEM electrolysis hydrogen based on an LCA. Energies 2023, 16, 3702. [Google Scholar] [CrossRef]

- Hamed, A.M.; Kamaruddin, T.N.A.T.; Ramli, N.; Wahab, M.F.A. A review on blue and green hydrogen production process and their life cycle assessments. IOP Conf. Ser. Earth Environ. Sci. 2023, 1281, 012034. [Google Scholar] [CrossRef]

- Schropp, E.; Naumann, G.; Gaderer, M. Prospective life cycle assessment: A case study of hydrogen production with water electrolysis. Procedia CIRP 2022, 105, 92–97. [Google Scholar] [CrossRef]

- GitHub. LCA-ActivityBrowser/Activity-Browser: GUI for Brightway2. Available online: https://github.com/LCA-ActivityBrowser/activity-browser (accessed on 25 July 2023).

- Elgowainy, A.; Frank, E.D.; Vyawahare, P.; Ng, C.; Bafana, A.; Burnham, A.; Sun, P.; Cai, H.; Lee, U.; Reddi, K.; et al. Hydrogen Life-Cycle Analysis in Support of Clean Hydrogen Production; Argonne National Laboratory (ANL): Argonne, IL, USA, 2022. [Google Scholar] [CrossRef]

- Department of Energy (DOE). Program Records: Hydrogen Program. Available online: https://www.hydrogen.energy.gov/library/program-records (accessed on 27 July 2023).

- Argonne National Laboratory. GREET. Available online: https://www.anl.gov/topic/greet (accessed on 4 December 2024).

- Ozawa, A.; Kudoh, Y. Assessing uncertainties of life-cycle CO2 emissions using hydrogen energy for power generation. Energies 2021, 14, 6943. [Google Scholar] [CrossRef]

- Inventory Database for Environmental Analysis (IDEA). Available online: https://idea-lca.com/en/ (accessed on 23 July 2023).

- Gerloff, N. Comparative Life-Cycle-Assessment analysis of three major water electrolysis technologies while applying various energy scenarios for a greener hydrogen production. J. Energy Storage 2021, 43, 102759. [Google Scholar] [CrossRef]

- Sadeghi, S.; Ghandehariun, S.; Rosen, M. Comparative economic and life cycle assessment of solar-based hydrogen production for oil and gas industries. Energy 2020, 208, 118347. [Google Scholar] [CrossRef]

- Data for Environmental Analysis and Management (DEAM). Available online: https://ghgprotocol.org/Third-Party-Databases/DEAM (accessed on 4 December 2024).

- International Energy Agency-Photovoltaic Power Systems Programme (IEA-PVPS). Available online: https://iea-pvps.org/ (accessed on 23 July 2023).

- treeze.ch. Available online: https://treeze.ch/ (accessed on 1 August 2023).

- Bareiß, K.; de la Rua, C.; Möckl, M.; Hamacher, T. Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Appl. Energy 2019, 237, 862–872. [Google Scholar] [CrossRef]

- Federal Ministry of Education and Research. Kopernikus-Projekte. Available online: https://www.kopernikus-projekte.de/en/projects (accessed on 1 August 2023).

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life cycle assessment of hydrogen production via electrolysis—A review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Cetinkaya, E.; Dincer, I.; Naterer, G. Life cycle assessment of various hydrogen production methods. Int. J. Hydrogen Energy 2012, 37, 2071–2080. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). LCA Commons. Available online: https://www.lcacommons.gov/lca-collaboration/search/page=1&group=National_Renewable_Energy_Laboratory (accessed on 2 August 2023).

- Maack, M.H. Generation, of the Energy Carrier HYDROGEN in Context with Electricity Buffering Generation Through Fuel Cells; New Energy Externalities Developments for Sustainability (NEEDS): Brussels, Belgium, 2007. [Google Scholar]

- IEA. Energy System of China, 2021. 2021. Available online: https://www.iea.org/countries/china (accessed on 13 August 2023).

- United Nations Climate Change. National Economic, Environment and Development Study (NEEDS) for Climate Change. Available online: https://unfccc.int/topics/climate-finance/workstreams/determination-of-the-needs-of-developing-country-parties/national-economic-environment-and-development-study-needs-for-climate-change-project (accessed on 4 December 2024).

- Fuel Cell Electric Buses. HyFLEET-CUTE (2006–2009). Available online: https://www.fuelcellbuses.eu/wiki/history-fuel-cell-electric-buses/hyfleet-cute-2006-2009 (accessed on 4 December 2024).

- Mann, M.; Spath, P. Life Cycle Assessment of Renewable Hydrogen Production via Wind/Electrolysis: Milestone Completion Report; Technical Report NREL/MP-560-35404; National Renewable Energy Laboratory: Golden, CO, USA, 2004. Available online: https://www.nrel.gov/docs/fy04osti/35404.pdf (accessed on 12 March 2024).

- Edwards, R.; Mahieu, V.; Griesemann, J.C.; Larivé, J.F.; Rickeard, D.J. Well-to-wheels analysis of future automotive fuels and powertrains in the European context. SAE Trans. 2004, 103, 1072–1084. [Google Scholar]

- Ramsden, T.; Ruth, M.; Diakov, V.; Laffen, M.; Timbario, T.A. Hydrogen Pathways: Updated Cost, Well-to-Wheels Energy Use, and Emissions for the Current Technology Status of Ten Hydrogen Production, Delivery, and Distribution Scenarios; Technical Report NREL/TP-6A10-60528; National Renewable Energy Laboratory: Golden, CO, USA, 2013. [Google Scholar]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Wulf, C.; Kaltschmitt, M. Hydrogen Supply Chains for Mobility—Environmental and Economic Assessment. Sustainability 2018, 10, 1699. [Google Scholar] [CrossRef]

- Sundin, C. Environmental Assessment of Electrolyzers for Hydrogen Gas Production. 2019. Available online: https://www.diva-portal.org/smash/get/diva2:1354467/FULLTEXT01.pdf (accessed on 14 March 2024).

- Zhang, J.; Wang, Z.; He, Y.; Li, M.; Wang, X.; Wang, B.; Zhu, Y.; Cen, K. Comparison of onshore/offshore wind power hydrogen production through water electrolysis by life cycle assessment. Sustain. Energy Technol. Assess. 2023, 60, 103515. [Google Scholar] [CrossRef]

- Lundberg, S. Comparative LCA of Electrolyzers for Hydrogen Gas Production. 2019. Available online: http://www.diva-portal.org/smash/get/diva2:1331089/FULLTEXT01.pdf (accessed on 14 March 2024).

- Boo, K. Infrastructure Building for Materialization of a Future Hydrogen Economy: H2 Supply Infrastructure in the Transportation Sector; Korea Energy Economics Institute (KEEI): Ulsan, Republic of Korea, 2009; pp. 1–154. Available online: https://www.keei.re.kr/board.es?mid=a20102000000&bid=0028&act=view&list_no=118943&nPage=147 (accessed on 23 December 2023).

- Ghandehariun, S.; Amit, K. Life cycle assessment of wind-based hydrogen production in Western Canada. Int. J. Hydrogen Energy 2016, 41, 9696–9704. [Google Scholar] [CrossRef]

- Kanz, O.; Brüggemann, F.; Ding, K.; Bittkau, K.; Rau, U.; Reinders, A. Life-cycle global warming impact of hydrogen transport through pipelines from Africa to Germany. Sustain. Energy Fuels 2023, 7, 3014–3024. [Google Scholar] [CrossRef]

- Weiszflog, E.; Manan, A. Life Cycle Assessment of Hydrogen Storage Systems for Trucks An Assessment of Environmental Impacts and Recycling Flows of Carbon Fiber. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2022. Available online: https://odr.chalmers.se/server/api/core/bitstreams/2a16256f-2858-4f55-972f-a6889d05e252/content (accessed on 22 March 2024).

- Risk CSP; Ministry of Land, Infrastructure and Transport. Final Report on the Design, Safety Assessment, and Management Technology Development of a City-Scale Integrated Hydrogen Network for a Population of One Million: Final Report of the Land Transport Technology Promot; National Library of Korea: Seoul, Republic of Korea, 2019; pp. 1–82. [Google Scholar]

- Stripple, H.; Stefan, U. Life Cycle Assessment of Railways and Rail Transports-Application in Environmental Product Declarations (EPDs) for the Bothnia Line. 2010. Available online: https://www.ivl.se/download/18.694ca0617a1de98f473456/1628416183076/FULLTEXT01.pdf (accessed on 25 March 2024).

- ECOsquare, Korea Environmental Industry and Technology Institute (KEITI). 2021. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs3&menuSn=20018000&tabId2=3 (accessed on 28 July 2021).

- Park, W.Y.; Abhyankar, N.; Paliwal, U.; Kim, J.H.; Khanna, N.; Shiraishi, K.; Lin, J.; Phadke, A.; Song, Y.H.; Moon, H.S.; et al. A Clean Energy Korea by 2035; Technical Report; Lawrence Berkeley National Laboratory (LBNL): Berkeley, CA, USA, 2023; Available online: https://nextgroup.or.kr/nextkor/upfile/P230421105021.pdf (accessed on 26 March 2024).

- Renewable Energy Institute. South Korea: Low Renewable Energy Ambitions Result in High Nuclear and Fossil Power Dependencies. 2023. Available online: https://www.renewable-ei.org/pdfdownload/activities/REI_SKoreaReport_202311_EN.pdf (accessed on 11 May 2024).

- Absolute Clean Energy (ACE). Industry Overview and Growth Potential. 2018. Available online: https://www.ace-energy.co.th/storage/content/ir/home/industry-overview-and-growth-potential.pdf (accessed on 12 May 2024).

- Wu, Y.; Xu, Z.; Zheng, L. Lifecycle analysis of coal-fired power plants with CCS in China. Energy Procedia 2014, 63, 7444–7451. [Google Scholar] [CrossRef]

- Petrescu, L.; Cormos, C. Environmental assessment of IGCC power plants with pre-combustion CO2 capture by chemical & calcium looping methods. J. Clean. Prod. 2017, 158, 233–244. [Google Scholar] [CrossRef]

- Mohammed, R.K.; Hooman, F. Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design. Energies 2023, 16, 1545. [Google Scholar] [CrossRef]

- Ferronato, N.; Giaquinta, C.; Conti, F.; Torretta, V. When solid recovered fuel (SRF) production and consumption maximize environmental benefits? A life cycle assessment. Waste Manag. 2024, 178, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Ramos, A.; Rouboa, A. Renewable energy from solid waste: Life cycle analysis and social welfare. Environ. Impact Assess. Rev. 2020, 85, 106469. [Google Scholar] [CrossRef]

- Karunakaran, V.; Abd-Talib, N.; Yong, T.L.K. Lignin from oil palm empty fruit bunches (EFB) under subcritical phenol conditions as a precursor for carbon fiber production. Mater. Today Proc. 2020, 31, 100–105. [Google Scholar] [CrossRef]

- Siregar, K.; Sofyan, H.; Miharza, T.; Sofiah, I. Life cycle inventory of electricity production from biomass power plant system using life cycle assessment in Aceh Province, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2021, 749, 012061. [Google Scholar] [CrossRef]

- Gibon, T.; Menacho, Á.H.; Guiton, M. Life Cycle Assessment of Electricity Generation Options; Technical Report; United Nations Economic Commission for Europe (UNECE): Geneva, Switzerland, 2021; Available online: https://unece.org/sed/documents/2021/10/reports/life-cycle-assessment-electricity-generation-options (accessed on 15 May 2024).

- Na, W.C.; Kim, Y.; Kim, K.; Lee, K.Y. Analysis on the Water Footprint of Crystalline Silicon PV System. Clean Technol. 2014, 20, 449–456. [Google Scholar] [CrossRef][Green Version]

- Resalati, S.; Okoroafor, T.; Maalouf, A.; Saucedo, E.; Placidi, M. Life cycle assessment of different chalcogenide thin-film solar cells. Appl. Energy 2022, 313, 118888. [Google Scholar] [CrossRef]

- Korea Hydrographic and Oceanographic Agency (KHOA). Sea Distance. Available online: https://www.khoa.go.kr/kcom/cnt/selectContentsPage.do?cntId=31307000#tabs3 (accessed on 3 October 2024).

- SEA-DISTANCES.ORG. Available online: https://sea-distances.org/ (accessed on 17 October 2024).

- Huh, I.S. The Gasification & Melting Treatment Technology of Waste. In Proceedings of the KFMA Annual Meeting, Changwon, Republic of Korea, 15–16 December 2005; pp. 133–138. [Google Scholar]

- Kim, K.; Chang, N.; Kim, D. Life Cycle Assessment of Greenhouse Gas Emissions from Electrolytic Hydrogen Supply. In Proceedings of the The Korean Institute of Communications and Information Sciences (KICS) Proceedings of the Academic Conference, Gyeongju, Republic of Korea, 22–24 November 2023; pp. 979–980. Available online: https://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE11667614 (accessed on 4 December 2024).

- CarbonCloud. ClimateHub. Available online: https://apps.carboncloud.com/climatehub/ (accessed on 14 November 2023).

- City of Winnipeg. Emission Factors in kg CO2-Equivalent per Unit. Available online: https://legacy.winnipeg.ca/finance/findata/matmgt/documents/2012/682-2012/682-2012_appendix_h-wstp_south_end_plant_process_selection_report/appendix%207.pdf (accessed on 26 October 2024).

- Budsberg, E.; Morales-Vera, R.; Crawford, J.T.; Bura, R.; Gustafson, R. Production routes to bio-acetic acid: Life cycle assessment. Biotechnol. Biofuels 2020, 13, 154. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M. Life cycle assessment of metals: A scientific synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

- Poszmik, G.; Kim, H.S.; Choo, J. Estimating the Impact of Using Recycled PTFE on CO2 Emissions. 2020. Available online: https://shamrocktechnologies.com/co2-emissions/ (accessed on 5 October 2024).

- Sævarsdottir, G.; Halvor, K.; Thordur, M. Greenhouse gas emissions from silicon production-development of carbon footprint with changing energy systems. In Proceedings of the 16th International Ferro-Alloys Congress (INFACON XVI), Virtual, 27–29 September 2021. [Google Scholar] [CrossRef]

- GIT Information Center. Gem and Jewelry Industry Sets to Reduce Carbon Footprints. 2021. Available online: https://infocenter.git.or.th/en/article/article-20210324#:~:text=A%20ton%20of%20silver%20emits,77%2C000%20tons%20of%20carbon%20dioxide (accessed on 6 October 2024).

- Haque, N.; Norgate, T. Estimation of greenhouse gas emissions from ferroalloy production using life cycle assessment with particular reference to Australia. J. Clean. Prod. 2013, 39, 220–230. [Google Scholar] [CrossRef]

- Shacat, J.; Richard, W.; Ben, C. The Carbon Footprint of Asphalt Pavements. A Reference Document For Decarbonization; Technical Report; NAPA: Greenbelt, MD, USA, 2024; Available online: https://www.asphaltpavement.org/uploads/documents/Climate/NAPA-SIP109-TheCarbonFootprintOfAsphaltPavements-March2024.pdf (accessed on 8 October 2024).

- Stichnothe, H.; Morgan, A.; Gujba, H.; Azapagic, A. Estimating the carbon footprint of paints: Some important considerations. Surf. Coatings Int. 2011, 94, 108. Available online: https://www.researchgate.net/publication/359577531_Estimating_the_Carbon_Footprint_of_Paints_Some_Important_Considerations (accessed on 27 October 2024).

- Korea Energy Economics Institute (KEEI). Overview of the Clean Hydrogen Certification System. Available online: https://www.keei.re.kr/menu.es?mid=a10211010300 (accessed on 2 November 2024).

- Bui, T.; Kim, Y.S.; Lee, D.K.; Ahn, K.Y.; Bae, Y.; Lee, S.M. Economic Analysis and Comparison between Low-Power and High-Power SOEC Systems. J. Hydrogen New Energy 2022, 33, 707–714. [Google Scholar] [CrossRef]

- Ministry of Trade, Industry and Energy (MOTIE). 10th Basic Plan for Electricity Supply and Demand (2022 2036). 2023. Available online: https://www.kier.re.kr/resources/download/tpp/policy_230113_data.pdf (accessed on 5 November 2024).

- Korea Energy Economics Institute (KEEI). KEEI 2022 Long-Term Energy Outlook. 2023. Available online: https://www.kesis.net/FileDownloadAction.do?file=/admin/admin_RegList.jsp/20230322/7951679477342707_01.pdf&oldFile=2022_EnergyOutlook.pdf (accessed on 6 November 2024).

- Research Nester. Market Size, Share, and Growth Forecast for Thin-Film Solar Power by 2036. Available online: https://www.researchnester.com/kr/reports/thin-film-photovoltaic-market/5615 (accessed on 2 June 2024).

- Choo, H.; Kim, Y.G.; Kim, D. Power sector carbon reduction review for South Korea in 2030. Renew. Sustain. Energy Rev. 2024, 196, 114348. [Google Scholar] [CrossRef]

| No. | Author | Country | Scope 1 | Electrolyzer | Efficiency (%) | Electricity Sources | Emission | Datas |

|---|---|---|---|---|---|---|---|---|

| 1 | Patel (2024, [12]) | Finland | J2 | PEMEC | 71.6 | PV | 0.075 | [13] |

| Wind | 0.018 | |||||||

| PV 50, Wind 50 | 0.048 | |||||||

| 2 | Jolaoso (2024, [14]) | U.S. | J1–J2 | SOEC | 71.7 | PV 50, Coal 50 | 0.207 | [15,16,17] |

| 3 | Yang (2024, [18]) | China | J2 | AEL | 80.5 | Grid 2021 | 0.922 | [15,19] |

| Hydro | 0.019 | |||||||

| 4 | Pawlowski (2023, [20]) | Poland | J1–J2 | AEL | 70.0 | PV standing | 0.090–0.130 | [15,16] |

| PV tracker | 0.082–0.116 | |||||||

| 5 | Hamed (2023, [21]) | - | J2 | AEL | - | PV | 0.069–0.129 | - |

| - | PV | 0.060–0.210 | ||||||

| SOEC | PV | 0.006 | ||||||

| On-wind | 0.008 | |||||||

| 6 | Schropp (2022, [22]) | Germany | J2 | PEMEC | 71.0 | Grid 2022 | 0.006–0.007 | [15,23] |

| Grid 2030 | 0.002–0.003 | |||||||

| Grid 2050 | 0.0005–0.0006 | |||||||

| 7 | Elgowainy (2022, [24]) | U.S. | J2 | PEMEC SOEC | 70.6 93.5 | LWR | 0.009 | [25,26] |

| Renewables | 0 | |||||||

| LWR | 0.012 | |||||||

| 8 | Ozawa and Kudoh (2021, [27]) | Japan | J1–J2, J5, J7 | AEL/PEMEC | - | PV in AUS | 0.089–0.240 | [28] |

| Wind in AUS | 0.036–0.082 | |||||||

| Wind in NOR | 0.049–0.095 | |||||||

| PV in UAE | 0.091–0.244 | |||||||

| 9 | Gerloff (2021, [29]) | Germany | J2 | AEL | 76.2 | Grid | 0.523–0.806 | [15] |

| Renewables | 0.087 | |||||||

| PEMEC | 73.0 | Grid | 0.543–0.838 | |||||

| Renewables | 0.088 | |||||||

| SOEC | 93.2 | Grid | 0.472–0.705 | |||||

| Renewables | 0.115 | |||||||

| 10 | Sadeghi (2020, [30]) | U.S. | J1–J2 | AEL | 68.5 | CSP | 0.062 | [16,31,32,33] |

| PV | 0.092 | |||||||

| 11 | Bareiß (2019, [34]) | Germany | J2 | PEMEC 2 | 71.0 | Grid 2017 | 0.885 | [13,15,16,35] |

| Grid 2050 | 0.348 | |||||||

| Renewables | 0.009 | |||||||

| 12 | Bhandari (2014, [36]) | - | - | AEL/PEMEC /SOEC | 62–86 | PV | 0.147 | [31] |

| Nuclear | 0.069 | |||||||

| Wind | 0.024 | |||||||

| Biomass | 0.105 | |||||||

| Coal Gasification | 0.360 | |||||||

| Hydro | 0.060 | |||||||

| UCTE Grid 2010 | 0.975 | |||||||

| 13 | Cetinkaya (2012, [37]) | Canada | J1–J3 | PEMEC | 85.0 | Wind | 0.029 | [15,38] |

| J1–J2 | PV | 0.072 | ||||||

| 14 | Maack (2007, [39]) | Iceland | J1–J3, J7 | PEMEC | 70.0 | UCTE Grid 2020 | 0.852 | [13,40,41,42] |

| 15 | Spath and Mann (2004, [43]) | U.S. | J1–J3, J5 3 | PEMEC | 85 | Wind | 0.029 | [15,38] |

| No. | Author | Country | Scope | Electrolyzer | Efficiency (%) | Electricity Sources | Emission | Data |

|---|---|---|---|---|---|---|---|---|

| 1 | Malik (2023, [9]) | Korea | J1, J2, J5–J7 | AEL | 77.9 | Wind | 0.008 | [15] |

| 2 | Boreum (2021, [11]) | Korea | J1–J7 1 | AEL | 82 | Grid 2021 | 0.360–0.411 | [15,16] |

| Grid 2030 | 0.203–0.253 | |||||||

| Grid 2050 | 0.082–0.130 | |||||||

| Renewables | 0.040–0.088 | |||||||

| 3 | Eunji (2018, [10]) | Korea | J1–J2 | - | 65–80 56–71.5 | Grid | 0.578 | [26,44,45] |

| Electrolyzer | Reference | Lifetime | H2 Purity (%) | Efficiency (%) | H2 Production (kg H2/h) | Electricity (kWh/kg H2) |

|---|---|---|---|---|---|---|

| AEL | [47] | 20 y | - | 80.5 | 26 | 49 |

| [48] | 80,000 h | <99.5 | 72 | 130 | 50 | |

| [49] | 30 y | 99.5–99.9 | 70 | 90 | 49.5 | |

| [18] | 10 y | - | 85.6 | 26 | 49 | |

| PEMEC | [47] | 20 y | - | 78.9 | 48 | 50 |

| [50] | 40,000 h | 99.99 | 73.5 | 22.1 | 57.5 | |

| [49] | 30 y | 99.99 | 80 | 90 | 49 | |

| [34] 1 | 20 y | - | 71 | 18.75 | 55 | |

| [39] | 15 y | <99.99 | 87 | 5.38 | 53 | |

| SOEC | [50] | 10,000 h | 99.9 | 99 | 0.0297 2 | 65 |

| Transportation | Pressure (bar) | Temperature (K) | Storage Capacity (kg H2) | Lifetime (year) | Fuel Efficiency (km/L) |

|---|---|---|---|---|---|

| Truck | 6 | 20 | 4000 | 14 | 2.55 |

| Train (Rail) | 6 | 20 | 10,000 | 30 (60) | 4.25 |

| Power Plant | CF | Carbon Capture Rate (%) | Lifetime (y) | References |

|---|---|---|---|---|

| Oil | 0.90 | - | 30 | [57] |

| Coal | 0.59 | - | 30 | [57] |

| Coal-CCS | 0.59 | 90.7 | 30 | [57,61] |

| IGCC | 0.86 | - | 30 | [62] |

| NGCC | 0.50 | - | 30 | [57] |

| NGCC-CCS | 0.50 | 90 | 30 | [63] |

| WtE | 0.73 | - | 25 | [64,65] |

| Biomass | 0.88 | - | 25 | [66,67] |

| PWR | 0.85 | - | 60 | [57,59,68] |

| PV | 0.17 | - | 25 | [57,69] |

| CIGS | 0.17 | - | 5 | [57,70] |

| On-wind | 0.24 | - | 30 | [43,49] |

| Off-wind | 0.36 | - | 30 | [43,49] |

| Hydro | - | - | 30 | [57] |

| Power Source | Non-Energy Materials | Electricity (Operational) | Other Energy | Generation Fuel | Shipping (Fuel) | Emission |

|---|---|---|---|---|---|---|

| Oil | 0.006 | 0.051 | 0.003 | 0.215 | 0.003 | 0.278 |

| Coal | 0.004 | 0.022 | 2.95 | 0.275 | 0.003 | 0.303 |

| Coal-50 | 0.004 | 0.022 | 2.95 | 0.215 | 0.003 | 0.243 |

| Coal-100 | 0.004 | 0.022 | 2.95 | 0.142 | 0.003 | 0.171 |

| Coal-CCS | 0.046 | 0.022 | 2.95 | 0.026 | 0.003 | 0.097 |

| IGCC | 0.025 | 0.002 | 4.23 | 0.187 | 0.006 | 0.220 |

| NGCC | 0.050 | 0.017 | 1.03 | 0.165 | 1.15 | 0.232 |

| NGCC-CCS | 0.054 | 0.017 | 1.03 | 0.007 | 1.15 | 0.079 |

| WtE | 0.072 | 0.001 | 5.71 | 0 | 0 | 0.073 |

| Biomass | 0.051 | 0.011 | 0.001 | 0 | 0 | 0.064 |

| PWR | 0.003 | 0.001 | 0.002 | 0.013 | 2.36 | 0.019 |

| PV | 0.014 | 0.0009 | 1.14 | - | - | 0.015 |

| CIGS | 0.010 | 0.0002 | 1.14 | - | - | 0.010 |

| On-wind | 0.001 | 3.80 | 0 | - | - | 0.001 |

| Off-wind | 0.010 | 5.99 | 0 | - | - | 0.010 |

| Hydro | 5.35 | 1.71 | 5.52 | - | - | 5.37 |

| AEL | PEMEC | SOEC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| [47] | [48] | [49] | [18] | [47] | [50] | [49] | [34] 1 | [34] 2 | [39] | [50] | |

| Oil | 16.199 | 16.665 | 17.926 | 16.213 | 16.478 | 18.571 | 16.221 | 17.867 | 17.857 | 17.350 | 20.816 |

| Coal | 17.632 | 18.124 | 19.372 | 17.646 | 17.936 | 20.222 | 17.655 | 19.454 | 19.444 | 18.886 | 22.660 |

| Coal-50 | 13.933 | 14.359 | 15.639 | 13.946 | 14.171 | 15.960 | 13.954 | 15.357 | 15.347 | 14.921 | 17.900 |

| Coal-100 | 10.234 | 10.593 | 11.906 | 10.247 | 10.405 | 11.697 | 10.253 | 11.260 | 11.250 | 10.957 | 13.140 |

| Coal-CCS | 6.094 | 6.379 | 7.729 | 6.107 | 6.191 | 6.927 | 6.112 | 6.675 | 6.665 | 6.520 | 7.814 |

| IGCC | 12.983 | 13.392 | 14.681 | 12.997 | 13.204 | 14.865 | 13.004 | 14.305 | 14.295 | 13.903 | 16.678 |

| NGCC | 13.622 | 14.042 | 15.325 | 13.635 | 13.854 | 15.601 | 13.643 | 15.012 | 15.002 | 14.587 | 17.500 |

| NGCC-CCS | 5.098 | 5.365 | 6.723 | 5.111 | 5.177 | 5.779 | 5.116 | 5.572 | 5.562 | 5.453 | 6.532 |

| WtE | 4.759 | 5.020 | 6.381 | 4.772 | 4.832 | 5.388 | 4.776 | 5.196 | 5.186 | 5.089 | 6.096 |

| Biomass | 4.250 | 4.502 | 5.868 | 4.264 | 4.315 | 4.802 | 4.268 | 4.633 | 4.623 | 4.544 | 5.441 |

| PWR | 1.756 | 1.963 | 3.351 | 1.769 | 1.776 | 1.928 | 1.773 | 1.871 | 1.861 | 1.871 | 2.232 |

| PV | 1.518 | 1.721 | 3.111 | 1.531 | 1.533 | 1.654 | 1.534 | 1.607 | 1.597 | 1.616 | 1.926 |

| CIGS | 1.267 | 1.465 | 2.857 | 1.280 | 1.277 | 1.364 | 1.283 | 1.328 | 1.318 | 1.347 | 1.602 |

| On-wind | 0.742 | 0.931 | 2.328 | 0.755 | 0.744 | 0.760 | 0.758 | 0.748 | 0.738 | 0.785 | 0.927 |

| Off-wind | 1.273 | 1.471 | 2.863 | 1.286 | 1.283 | 1.371 | 1.289 | 1.335 | 1.325 | 1.353 | 1.610 |

| Hydro | 0.699 | 0.888 | 2.285 | 0.713 | 0.700 | 0.710 | 0.715 | 0.700 | 0.690 | 0.739 | 0.872 |

| Class | Range (kg CO2e/kg ) | Well-to-Pump (J1–J7) | Well-to-Gate (J1–J2) |

|---|---|---|---|

| Out of tiers | >4.00 | Oil, Coal, Coal-CCS, Coal-50 Coal-100, IGCC, NGCC NGCC-CCS, WtE, Biomass | Oil, Coal, Coal-CCS, Coal-50 Coal-100, IGCC, NGCC |

| Tier 4 | 2.01–4.00 | - | NGCC-CCS 7, WtE 8, Biomass 9 |

| Tier 3 | 1.01–2.00 | PWR 1, PV 4, CIGS 5, Off-wind 3 | - |

| Tier 2 | 0.11–1.00 | Hydro 6, On-wind 2 | PWR 10, Off-wind 11, PV 12, CIGS 13 |

| Tier 1 | 0.00–0.10 | - | On-wind 14, Hydro 15 |

| Electrolyzer | Ref. | Electricity for Water Electrolysis | Electricity (Operational) | Non-Energy Materials | Catalyst | Water | Other Energy | Emission |

|---|---|---|---|---|---|---|---|---|

| AEL | [47] | 0.003–14.871 | 0 | 0.007 | 0.002 | 0.005 | 0 | 0.017–14.885 |

| [48] | 0.003–15.175 | 0.0005 | 0.087 | 0.037 | 0.008 | 0.069 | 0.205–15.377 | |

| [49] | 0.003–15.026 | 0 | 1.568 | 0.028 | 0 | 0.002 | 1.601–16.624 | |

| [18] | 0.003–14.871 | 0 | 0.015 | 0.002 | 0.009 | 0 | 0.029–14.897 | |

| PEMEC | [47] | 0.003–15.175 | 0 | 0.008 | 0.0003 | 0.005 | 0 | 0.016–15.188 |

| [50] | 0.003–17.451 | 0.003 | 0.011 | 0.001 | 0.008 | 0 | 0.026–17.474 | |

| [49] | 0.003–14.877 | 0 | 0.028 | 0.001 | 0 | 0 | 0.032–14.906 | |

| [34] 1 | 0.003–16.692 | 0 | 0.008 | 0.003 | 0.002 | 0 | 0.016–16.705 | |

| [34] 2 | 0.003–16.692 | 0 | 0.001 | 0.0002 | 0.002 | 0 | 0.006–16.695 | |

| [39] | 0.003–16.085 | 0 | 0.049 | 0 | 0.002 | 0 | 0.054–16.136 | |

| SOEC | [50] | 0.003–19.727 | 0.083 | 0.095 | 0 | 0.007 | 0 | 0.188–19.912 |

| Stage | Electricity | Non-Energy Materials | Other Energy | Transportation (Manufacturing + Fuel) | Emission |

|---|---|---|---|---|---|

| J3 | 3.78 –0.0002 | 0.005 | 0 | 0 | 0.005 |

| J4 | 0 | 0.181 | 0.0006 | 0.0004 | 0.182 |

| J5 | 0.0004–2.052 | 0.141 | 0 | 3.48 | 0.141–2.160 |

| J6 | 0.035 | 0.008 | 0 | 0.0005 | 0.044 |

| J7 | 0.0009–0.014 | 0.274 | 0.017 | 0.020 | 0.312–0.325 |

| Power Source | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Oil | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 |

| Coal-50 | 15.5 | 9.9 | 7.7 | 0.2 | 0.3 |

| Coal-100 | - | 1.5 | 1.2 | 5.8 | 5.3 |

| IGCC | - | 1.5 | 1.2 | 5.8 | 5.3 |

| NGCC | 5.0 | - | - | - | - |

| NGCC-CCS | 5.0 | 25.8 | 22.9 | 18.5 | 13.8 |

| WtE | 4.0 | - | - | - | - |

| Biomass | - | 0.9 | 0.7 | 0.8 | 0.8 |

| PWR | 37.3 | 18.3 | 14.7 | 14.2 | 13.3 |

| PV | 5.8 | 7.4 | 9.1 | 9.7 | 10.9 |

| CIGS | 13.6 | 17.1 | 21.2 | 22.4 | 25.1 |

| On-wind | 5.0 | 6.4 | 7.9 | 8.4 | 9.4 |

| Off-wind | 8.0 | 10.1 | 12.5 | 13.2 | 14.8 |

| Hydro | 0.5 | 1.0 | 0.8 | 0.9 | 0.9 |

| Year | 2036 | 2040 EEI | 2040 EOE | 2050 EEI | 2050 EOE |

| Reference | [87] | [88] | |||

| AEL | PEMEC | SOEC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| [47] | [48] | [49] | [18] | [47] | [50] | [49] | [34] 1 | [34] 2 | [39] | [50] | |

| S1 | 0.733 (0.045) | 0.922 (0.234) | 2.319 (1.631) | 0.828 (0.058) | 0.734 (0.046) | 0.749 (0.061) | 0.753 (0.061) | 0.738 (0.050) | 0.728 (0.040) | 0.775 (0.087) | 0.916 (0.228) |

| S2 | 0.729 (0.041) | 0.917 (0.230) | 2.314 (1.627) | 0.823 (0.054) | 0.730 (0.042) | 0.744 (0.056) | 0.749 (0.057) | 0.749 (0.045) | 0.723 (0.035) | 0.770 (0.083) | 0.910 (0.222) |

| S3 | 0.724 (0.037) | 0.912 (0.225) | 2.309 (1.622) | 0.818 (0.050) | 0.725 (0.038) | 0.738 (0.051) | 0.744 (0.053) | 0.727 (0.040) | 0.717 (0.030) | 0.765 (0.078) | 0.904 (0.217) |

| S4 | 0.722 (0.035) | 0.910 (0.224) | 2.307 (1.621) | 0.816 (0.048) | 0.723 (0.036) | 0.736 (0.049) | 0.742 (0.051) | 0.725 (0.038) | 0.715 (0.028) | 0.763 (0.076) | 0.901 (0.214) |

| S5 | 0.719 (0.033) | 0.908 (0.221) | 2.305 (1.618) | 0.814 (0.046) | 0.720 (0.034) | 0.733 (0.047) | 0.739 (0.049) | 0.722 (0.036) | 0.712 (0.026) | 0.760 (0.074) | 0.898 (0.211) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.-M.; Kim, D. Life Cycle Assessment of Greenhouse Gas Emissions in Hydrogen Production via Water Electrolysis in South Korea. Sustainability 2024, 16, 11010. https://doi.org/10.3390/su162411010

Kim K-M, Kim D. Life Cycle Assessment of Greenhouse Gas Emissions in Hydrogen Production via Water Electrolysis in South Korea. Sustainability. 2024; 16(24):11010. https://doi.org/10.3390/su162411010

Chicago/Turabian StyleKim, Kyeong-Mi, and Dongwoo Kim. 2024. "Life Cycle Assessment of Greenhouse Gas Emissions in Hydrogen Production via Water Electrolysis in South Korea" Sustainability 16, no. 24: 11010. https://doi.org/10.3390/su162411010

APA StyleKim, K.-M., & Kim, D. (2024). Life Cycle Assessment of Greenhouse Gas Emissions in Hydrogen Production via Water Electrolysis in South Korea. Sustainability, 16(24), 11010. https://doi.org/10.3390/su162411010