Bioleaching of Printed Circuit Board Waste to Obtain Metallic Nanoparticles

Abstract

1. Introduction

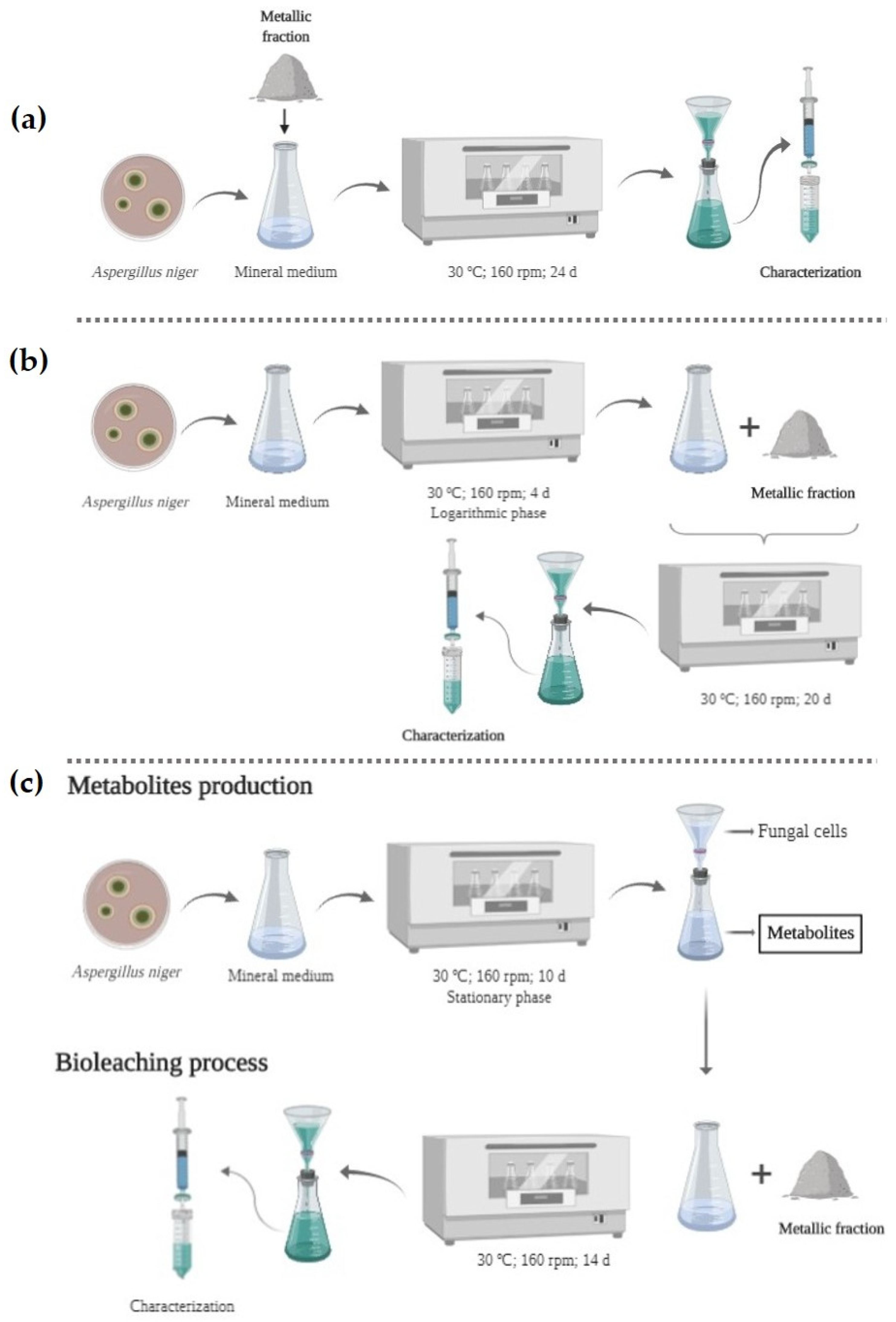

2. Materials and Methods

2.1. PCB Preparation and Metals Quantification

2.2. Production and Characterization of Metabolites

2.3. Bioleaching Procedure

- C0: Concentration of metal (Cu or Au) in the solution before bioleaching;

- C1: Concentration of metal (Cu or Au) in the solution after bioleaching.

2.4. Bioleaching in a Stirred Tank Reactor

2.5. Characterization of Bioleached Products

3. Results

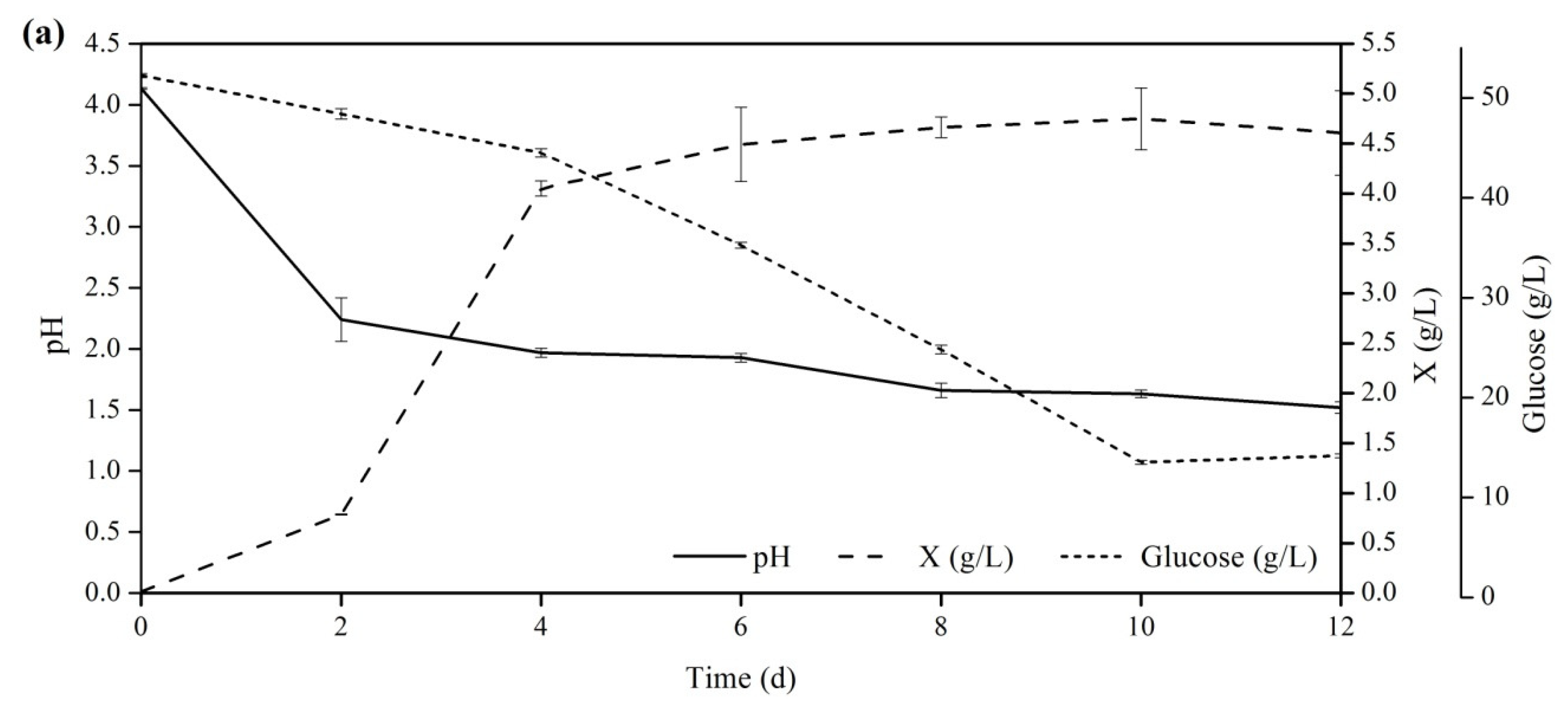

3.1. Metabolites Production by Aspergillus niger

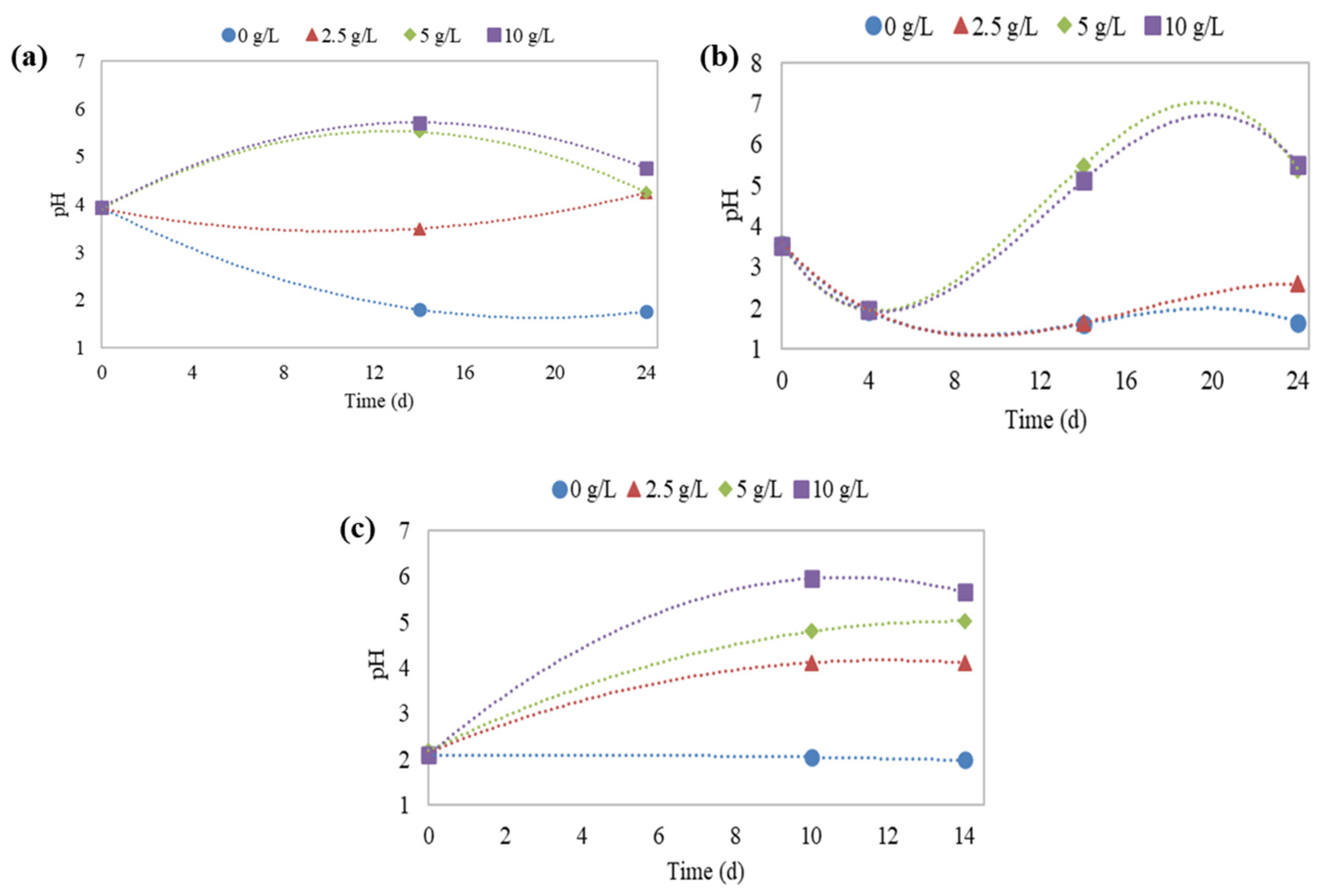

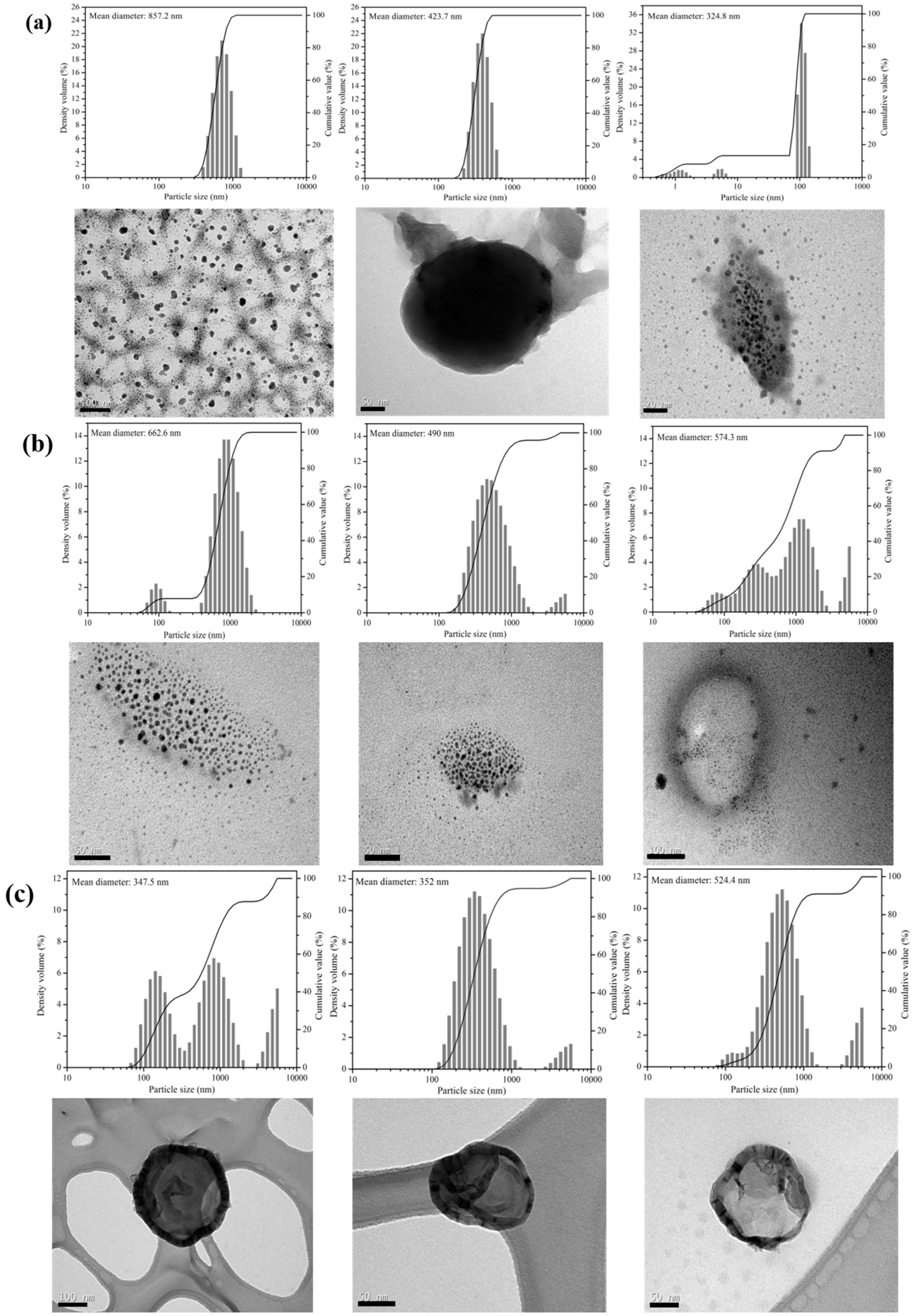

3.2. Copper and Gold Bioleaching

3.3. Bioleaching in a Stirred Tank Reactor

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Zhang, S.; Li, B.; Pan, D.; Wu, Y.; Zuo, T. Recovery of Waste Printed Circuit Boards through Pyrometallurgical Processing: A Review. Resour. Conserv. Recycl. 2017, 126, 209–218. [Google Scholar] [CrossRef]

- Baldé, C.P.; Kuehr, R.; Yamamoto, T.; McDonald, R.; D’Angelo, E.; Althaf, S.; Bel, G.; Deubzer, O.; Fernandez-Cubillo, E.; Forti, V.; et al. The Global Ewaste Monitor 2024; United Nations Institute for Training and Research (UNITAR): Bonn, Germany; International Telecommunication Union: Geneva, Switzerland, 2024. [Google Scholar]

- Canal Marques, A.; Cabrera, J.; de Fraga Malfatti, C. Printed Circuit Boards: A Review on the Perspective of Sustainability. J. Environ. Manag. 2013, 131, 298–306. [Google Scholar] [CrossRef]

- Ghosh, B.; Ghosh, M.K.; Parhi, P.; Mukherjee, P.S.; Mishra, B.K. Waste Printed Circuit Boards Recycling: An Extensive Assessment of Current Status. J. Clean. Prod. 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of Metals and Nonmetals from Electronic Waste by Physical and Chemical Recycling Processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef] [PubMed]

- Duan, C.; Wen, X.; Shi, C.; Zhao, Y.; Wen, B.; He, Y. Recovery of Metals from Waste Printed Circuit Boards by a Mechanical Method Using a Water Medium. J. Hazard. Mater. 2009, 166, 478–482. [Google Scholar] [CrossRef]

- Moosakazemi, F.; Ghassa, S.; Mohammadi, M.R.T. Environmentally Friendly Hydrometallurgical Recovery of Tin and Lead from Waste Printed Circuit Boards: Thermodynamic and Kinetics Studies. J. Clean. Prod. 2019, 228, 185–196. [Google Scholar] [CrossRef]

- Lambert, F.; Gaydardzhiev, S.; Léonard, G.; Lewis, G.; Bareel, P.F.; Bastin, D. Copper Leaching from Waste Electric Cables by Biohydrometallurgy. Miner. Eng. 2015, 76, 38–46. [Google Scholar] [CrossRef]

- Marra, A.; Cesaro, A.; Rene, E.R.; Belgiorno, V.; Lens, P.N.L. Bioleaching of Metals from WEEE Shredding Dust. J. Environ. Manag. 2018, 210, 180–190. [Google Scholar] [CrossRef]

- Cui, J.; Forssberg, E. Mechanical Recycling of Waste Electric and Electronic Equipment: A Review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Priya, A.; Hait, S. Comparative Assessment of Metallurgical Recovery of Metals from Electronic Waste with Special Emphasis on Bioleaching. Environ. Sci. Pollut. Res. 2017, 24, 6989–7008. [Google Scholar] [CrossRef]

- Maluleke, M.D.; Kotsiopoulos, A.; Govender-Opitz, E.; Harrison, S.T.L. Bioleaching of Printed Circuit Boards in a Two-Stage Reactor System with Enhanced Ferric Iron Regeneration in a Re-Circulating Packed-Bed Reactor from PCB Leaching. Miner. Eng. 2024, 218, 109000. [Google Scholar] [CrossRef]

- Nie, C.; Li, X.; Sun, Q.; Gao, Q.; Zhu, X.; Lyu, X.; Li, L.; You, X. Clean and Efficient Process for the Recycling of All Components from Waste Printed Circuit Boards: Pre-Treatment, Bio-Metallurgy, and Deep Utilization. J. Clean. Prod. 2024, 466, 142810. [Google Scholar] [CrossRef]

- Vakilchap, F.; Mohammad Mousavi, S. Exploring the Untapped Practices in Bacterial-Fungal Mixed-Based Cultures for Acidic Treatment of Metal-Enriched Printed Circuit Board Waste. Waste Manag. 2024, 179, 245–261. [Google Scholar] [CrossRef]

- Oh, C.J.; Lee, S.O.; Yang, H.S.; Ha, T.J.; Kim, M.J. Selective Leaching of Valuable Metals from Waste Printed Circuit Boards. J. Air Waste Manag. Assoc. 2003, 53, 897–902. [Google Scholar] [CrossRef] [PubMed]

- Kaksonen, A.H.; Boxall, N.J.; Gumulya, Y.; Khaleque, H.N.; Morris, C.; Bohu, T.; Cheng, K.Y.; Usher, K.M.; Lakaniemi, A. Recent Progress in Biohydrometallurgy and Microbial Characterisation. Hydrometallurgy 2018, 180, 7–25. [Google Scholar] [CrossRef]

- Johnson, D.B. Biomining—Biotechnologies for Extracting and Recovering Metals from Ores and Waste Materials. Curr. Opin. Biotechnol. 2014, 30, 24–31. [Google Scholar] [CrossRef]

- Yu, Z.; Han, H.; Feng, P.; Zhao, S.; Zhou, T.; Kakade, A.; Kulshrestha, S.; Majeed, S.; Li, X. Recent Advances in the Recovery of Metals from Waste through Biological Processes. Bioresour. Technol. 2020, 297, 122416. [Google Scholar] [CrossRef]

- Yang, L.; Lübeck, M.; Lübeck, P.S. Aspergillus as a Versatile Cell Factory for Organic Acid Production. Fungal Biol. Rev. 2017, 31, 33–49. [Google Scholar] [CrossRef]

- Argumedo-Delira, R.; Gómez-Martínez, M.J.; Soto, B.J. Gold Bioleaching from Printed Circuit Boards of Mobile Phones by Aspergillus Niger in a Culture without Agitation and with Glucose as a Carbon Source. Metals 2019, 9, 521. [Google Scholar] [CrossRef]

- Nikfar, S.; Parsa, A.; Bahaloo-Horeh, N.; Mousavi, S.M. Enhanced Bioleaching of Cr and Ni from a Chromium-Rich Electroplating Sludge Using the Filtrated Culture of Aspergillus Niger. J. Clean. Prod. 2020, 264, 121622. [Google Scholar] [CrossRef]

- Patel, F.; Lakshmi, B. Bioleaching of Copper and Nickel from Mobile Phone Printed Circuit Board Using Aspergillus Fumigatus A2DS. Braz. J. Microbiol. 2021, 52, 1475–1487. [Google Scholar] [CrossRef] [PubMed]

- Narayanasamy, M.; Dhanasekaran, D.; Vinothini, G.; Thajuddin, N. Extraction and Recovery of Precious Metals from Electronic Waste Printed Circuit Boards by Bioleaching Acidophilic Fungi. Int. J. Environ. Sci. Technol. 2018, 15, 119–132. [Google Scholar] [CrossRef]

- Faraji, F.; Golmohammadzadeh, R.; Rashchi, F.; Alimardani, N. Fungal Bioleaching of WPCBs Using Aspergillus Niger: Observation, Optimization and Kinetics. J. Environ. Manag. 2018, 217, 775–787. [Google Scholar] [CrossRef] [PubMed]

- Abhilash; Tabassum, S.; Ghosh, A.; Meshram, P.; van Hullebusch, E.D. Microbial Processing of Waste Shredded PCBs for Copper Extraction Cum Separation—Comparing the Efficacy of Bacterial and Fungal Leaching Kinetics and Yields. Metals 2021, 11, 317. [Google Scholar] [CrossRef]

- Sikander, A.; Kelly, S.; Kuchta, K.; Sievers, A.; Willner, T.; Hursthouse, A.S. Chemical and Microbial Leaching of Valuable Metals from PCBs and Tantalum Capacitors of Spent Mobile Phones. Int. J. Environ. Res. Public Health 2022, 19, 10006. [Google Scholar] [CrossRef]

- Díaz-Martínez, M.E.; Argumedo-Delira, R.; Sánchez-Viveros, G.; Alarcón, A.; Mendoza-López, M.R. Microbial Bioleaching of Ag, Au and Cu from Printed Circuit Boards of Mobile Phones. Curr. Microbiol. 2019, 76, 536–544. [Google Scholar] [CrossRef]

- Rodrigues, É.F.; De Rossi, A.; Rovaris, B.; Valério, A.; de Oliveira, D.; Hotza, D. Cleaner Pre-Concentration of Metals from Printed Circuit Board Waste Using Novel Dense Liquid Medium Based on Sodium Silicate. Waste Biomass Valorization 2020, 12, 4081–4087. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Lenore, S.C.; Arnold, E.G.; Andrew, D.E. APHA-AWWA-WEF Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1998; p. 2310. [Google Scholar]

- Treichel, H.; Sbardelotto, M.; Venturin, B.; Agnol, A.D.; Mulinari, J.; Golunski, S.M.; Baldoni, D.B.; Bevilacqua, C.B.; Seminoti Jacques, R.J.; Vargas, G.D.L.P.; et al. Lipase Production from a Newly Isolated Aspergillus Niger by Solid State Fermentation Using Canola Cake as Substrate. Curr. Biotechnol. 2016, 6, 295–300. [Google Scholar] [CrossRef]

- Rodrigues, É.F.; Ficanha, A.M.M.; Dallago, R.M.; Treichel, H.; Reinehr, C.O.; Machado, T.P.; Nunes, G.B.; Colla, L.M. Production and Purification of Amylolytic Enzymes for Saccharification of Microalgal Biomass. Bioresour. Technol. 2017, 225, 134–141. [Google Scholar] [CrossRef]

- Madrigal-Arias, J.E.; Argumedo-Delira, R.; Alarcón, A.; Mendoza-López, M.R.; García-Barradas, O.; Cruz-Sánchez, J.S.; Ferrera-Cerrato, R.; Jiménez-Fernández, M. Bioleaching of Gold, Copper and Nickel from Waste Cellular Phone PCBs and Computer Goldfinger Motherboards by Two Aspergillus Niger Strains. Braz. J. Microbiol. 2015, 46, 707–713. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Chai, L.; Yang, Z.; Tang, C.; Wang, Y.; Shi, Y. Bioleaching Mechanism of Heavy Metals in the Mixture of Contaminated Soil and Slag by Using Indigenous Penicillium Chrysogenum Strain F1. J. Hazard. Mater. 2013, 248–249, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Biswal, B.K.; Jadhav, U.U.; Madhaiyan, M.; Ji, L.; Yang, E.-H.; Cao, B. Biological Leaching and Chemical Precipitation Methods for Recovery of Co and Li from Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 12343–12352. [Google Scholar] [CrossRef]

- Gadd, G.M. Fungal Production of Citric and Oxalic Acid: Importance in Metal Speciation, Physiology and Biogeochemical Processes. In Advances in Microbial Physiology; Academic Press: Cambridge, MA, USA, 1999; Volume 41, pp. 47–92. ISBN 0120277417. [Google Scholar]

- Bullen, H.A.; Oehrle, S.A.; Bennett, A.F.; Taylor, N.M.; Barton, H.A. Use of Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy To Identify Microbial Metabolic Products on Carbonate Mineral Surfaces. Appl. Environ. Microbiol. 2008, 74, 4553–4559. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, K.B.; Sakthivel, N. Biological Synthesis of Metal Nanoparticles by Microbes. Adv. Colloid. Interface Sci. 2010, 156, 1–13. [Google Scholar] [CrossRef]

- Magdum, P.A.; Gundapalli, B.S.; Kurubar, M.M.; Nandibewoor, S.T. Kinetics And Mechanistic Investigation of Oxidation of D-Mannitol By Periodate In Aqueous Alkaline Medium. J. Appl. Chem. 2014, 4, 1744–1755. [Google Scholar] [CrossRef]

- Mehta, K.D.; Das, C.; Pandey, B.D. Leaching of Copper, Nickel and Cobalt from Indian Ocean Manganese Nodules by Aspergillus Niger. Hydrometallurgy 2010, 105, 89–95. [Google Scholar] [CrossRef]

- Bahaloo-horeh, N.; Mousavi, S.M.; Baniasadi, M. Use of Adapted Metal Tolerant Aspergillus Niger to Enhance Bioleaching Ef Fi Ciency of Valuable Metals from Spent Lithium-Ion Mobile Phone Batteries. J. Clean. Prod. 2018, 197, 1546–1557. [Google Scholar] [CrossRef]

- Işildar, A. Metal Recovery from Electronic Waste: Biological Versus Chemical Leaching for Recovery of Copper and Gold; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9780429023903. [Google Scholar]

- Amiri, F.; Yaghmaei, S.; Mousavi, S.M. Bioleaching of Tungsten-Rich Spent Hydrocracking Catalyst Using Penicillium Simplicissimum. Bioresour. Technol. 2011, 102, 1567–1573. [Google Scholar] [CrossRef]

- Horeh, N.B.; Mousavi, S.M.; Shojaosadati, S.A. Bioleaching of Valuable Metals from Spent Lithium-Ion Mobile Phone Batteries Using Aspergillus Niger. J. Power Sources 2016, 320, 257–266. [Google Scholar] [CrossRef]

- Muddanna, M.H.; Baral, S.S. A Comparative Study of the Extraction of Metals from the Spent Fluid Catalytic Cracking Catalyst Using Chemical Leaching and Bioleaching by Aspergillus Niger. J. Environ. Chem. Eng. 2019, 7, 103335. [Google Scholar] [CrossRef]

- Brandl, H.; Bosshard, R.; Wegmann, M. Computer-munching microbes: Metal leaching from electronic scrap by bacteria and fungi. Hydrometallurgy 2001, 59, 319–326. [Google Scholar] [CrossRef]

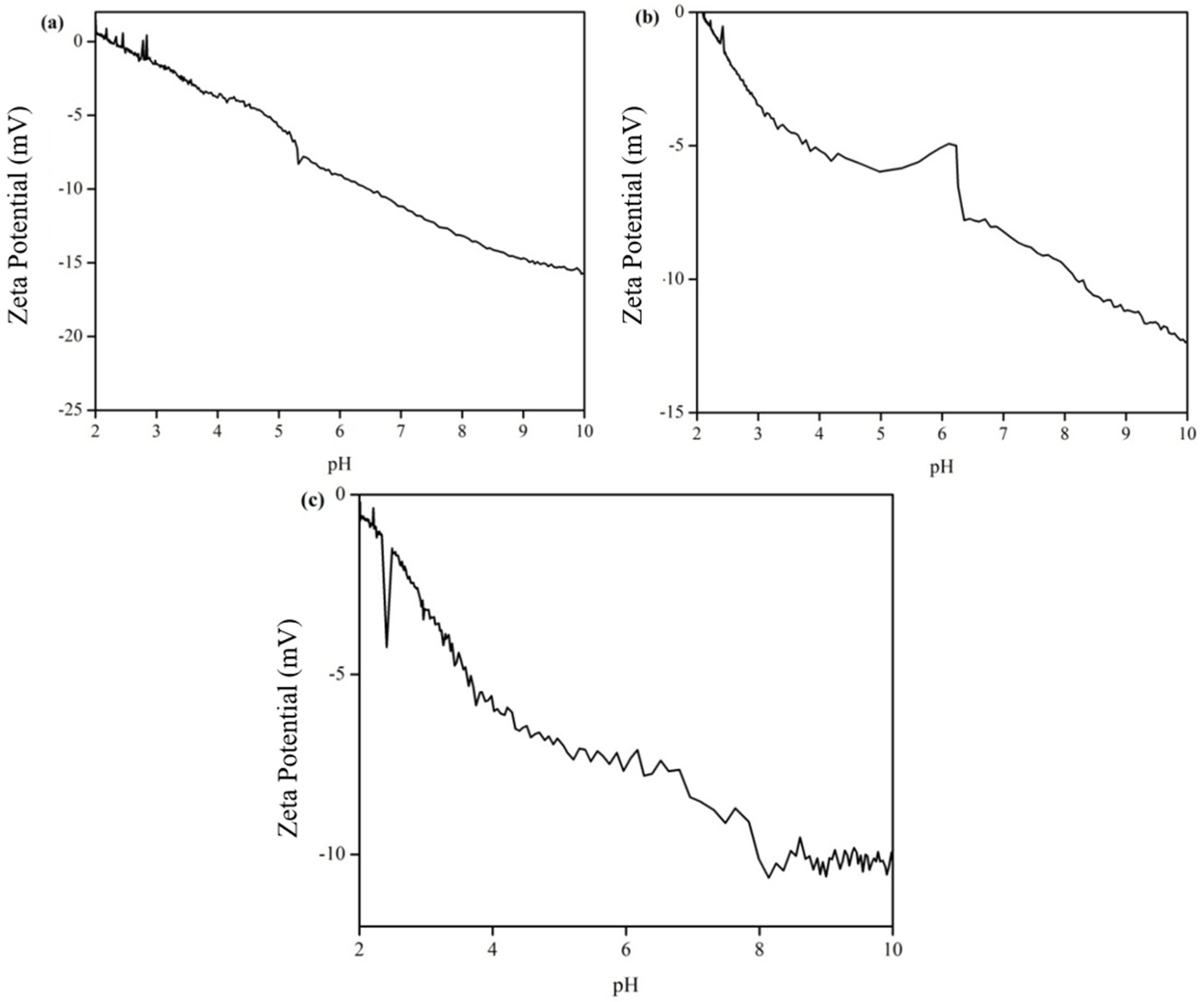

- Wang, N.; Hsu, C.; Zhu, L.; Tseng, S.; Hsu, J.-P. Influence of Metal Oxide Nanoparticles Concentration on Their Zeta Potential. J. Colloid. Interface Sci. 2013, 407, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Szűcs, R.; Balogh-Weiser, D.; Sánta-Bell, E.; Tóth-Szeles, E.; Varga, T.; Kónya, Z.; Poppe, L.; Lagzi, I. Green Synthesis and in Situ Immobilization of Gold Nanoparticles and Their Application for the Reduction of p -Nitrophenol in Continuous-Flow Mode. RSC Adv. 2019, 9, 9193–9197. [Google Scholar] [CrossRef]

- Vayssieres, L. On the Thermodynamic Stability of Metal Oxide Nanoparticles in Aqueous Solutions. Int. J. Nanotechnol. 2005, 2, 411. [Google Scholar] [CrossRef]

- Moore, T.L.; Rodriguez-Lorenzo, L.; Hirsch, V.; Balog, S.; Urban, D.; Jud, C.; Rothen-Rutishauser, B.; Lattuada, M.; Petri-Fink, A. Nanoparticle Colloidal Stability in Cell Culture Media and Impact on Cellular Interactions. Chem. Soc. Rev. 2015, 44, 6287–6305. [Google Scholar] [CrossRef]

- Wu, W.; Shevchenko, E.V. The Surface Science of Nanoparticles for Catalysis: Electronic and Steric Effects of Organic Ligands. J. Nanopart. Res. 2018, 20, 255. [Google Scholar] [CrossRef]

- Suárez-Cerda, J.; Espinoza-Gómez, H.; Alonso-Núñez, G.; Rivero, I.A.; Gochi-Ponce, Y.; Flores-López, L.Z. A Green Synthesis of Copper Nanoparticles Using Native Cyclodextrins as Stabilizing Agents. J. Saudi Chem. Soc. 2017, 21, 341–348. [Google Scholar] [CrossRef]

- Roto, R.; Izza, A.; Kunarti, E.S.; Suherman, S. Effect of Stabilizing Agent of Sodium Citrate and Polyethylene Glycol on Structure of Fe3O4 Nanoparticles. Key Eng. Mater. 2020, 840, 466–471. [Google Scholar] [CrossRef]

- Chen, S.-F.; Zhang, H. Aggregation Kinetics of Nanosilver in Different Water Conditions. Adv. Nat. Sci. Nanosci. Nanotechnol. 2012, 3, 035006. [Google Scholar] [CrossRef]

- Olad, A.; Alipour, M.; Nosrati, R. The Use of Biodegradable Polymers for the Stabilization of Copper Nanoparticles Synthesized by Chemical Reduction Method. Bull. Mater. Sci. 2017, 40, 1013–1020. [Google Scholar] [CrossRef]

- Lohse, S.E.; Murphy, C.J. The Quest for Shape Control: A History of Gold Nanorod Synthesis. Chem. Mater. 2013, 25, 1250–1261. [Google Scholar] [CrossRef]

- Begletsova, N.N.; Shinkarenko, O.A.; Chumakov, A.S.; Al-Alwani, A.J.K.; Selifonov, A.A.; Selifonova, E.I.; Pozharov, M.V.; Zakharevich, A.M.; Chernova, R.K.; Kolesnikova, A.S.; et al. Copper Nanoparticles Obtained by Chemical Reduction Stabilized by Micelles of Various Surfactants. J. Phys. Conf. Ser. 2017, 917, 092014. [Google Scholar] [CrossRef]

- Saidan, M.; Brown, B.; Valix, M. Leaching of Electronic Waste Using Biometabolised Acids. Chin. J. Chem. Eng. 2012, 20, 530–534. [Google Scholar] [CrossRef]

- Steer, J.M.; Griffiths, A.J. Investigation of Carboxylic Acids and Non-Aqueous Solvents for the Selective Leaching of Zinc from Blast Furnace Dust Slurry. Hydrometallurgy 2013, 140, 34–41. [Google Scholar] [CrossRef]

- Jadhav, U.; Su, C.; Hocheng, H. Leaching of Metals from Printed Circuit Board Powder by an Aspergillus Niger Culture Supernatant and Hydrogen Peroxide. RSC Adv. 2016, 6, 43442–43452. [Google Scholar] [CrossRef]

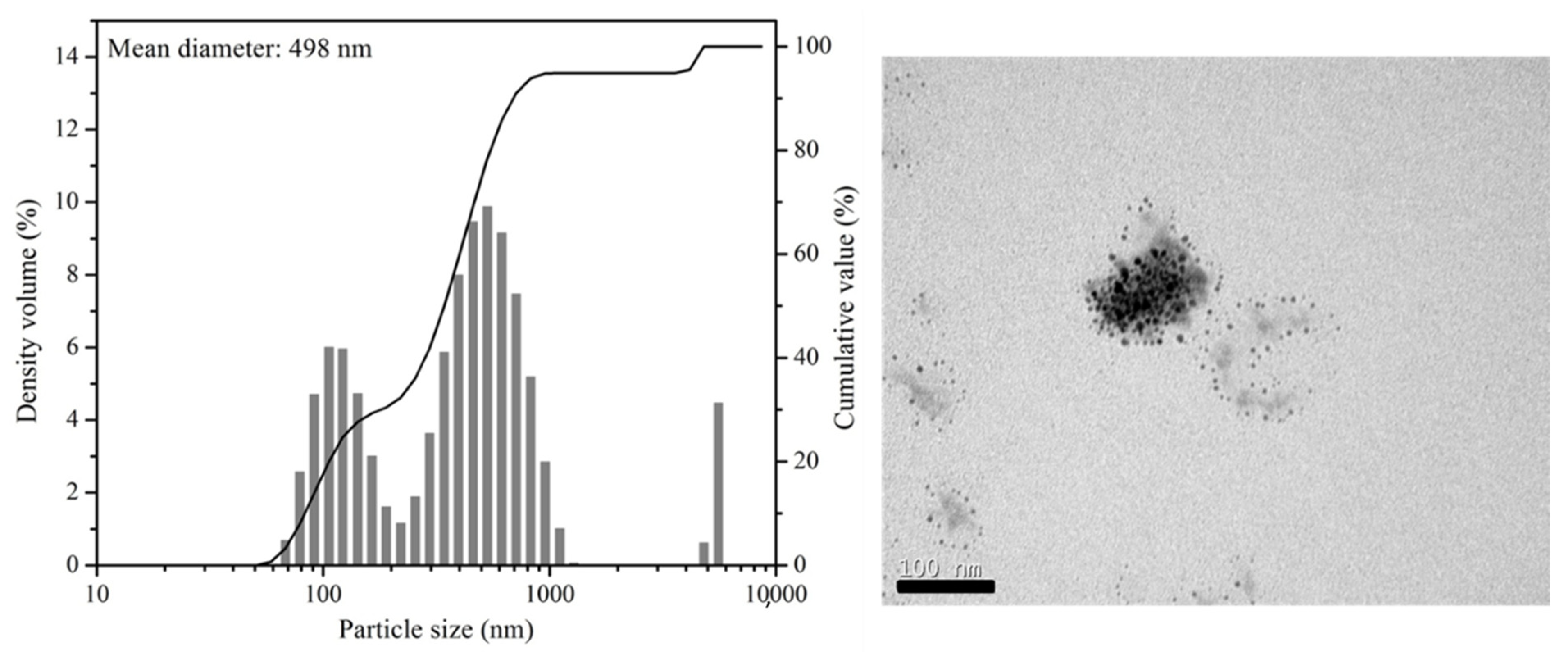

- Zheng, T.; Bott, S.; Huo, Q. Techniques for Accurate Sizing of Gold Nanoparticles Using Dynamic Light Scattering with Particular Application to Chemical and Biological Sensing Based on Aggregate Formation. ACS Appl. Mater. Interfaces 2016, 8, 21585–21594. [Google Scholar] [CrossRef]

- Eaton, P.; Quaresma, P.; Soares, C.; Neves, C.; de Almeida, M.P.; Pereira, E.; West, P. A Direct Comparison of Experimental Methods to Measure Dimensions of Synthetic Nanoparticles. Ultramicroscopy 2017, 182, 179–190. [Google Scholar] [CrossRef]

- Srivastava, S.; Bhargava, A.; Pathak, N.; Srivastava, P. Production, Characterization and Antibacterial Activity of Silver Nanoparticles Produced by Fusarium Oxysporum and Monitoring of Protein-Ligand Interaction through in-Silico Approaches. Microb. Pathog. 2019, 129, 136–145. [Google Scholar] [CrossRef]

| Metal | Concentration (wt.%) |

|---|---|

| Cu | 15.25 ± 0.35 |

| Fe | 1.40 ± 0.06 |

| Al | 0.960 ± 0.009 |

| Zn | 0.760 ± 0.011 |

| Ni | 0.210 ± 0.004 |

| Ag | 0.740 ± 0.015 |

| Au | 0.02400 ± 0.00001 |

| Pd | 0.00100 ± 0.00001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, É.F.; Cesa Rovaris, B.; Valerio, A.; de Oliveira, D.; Hotza, D. Bioleaching of Printed Circuit Board Waste to Obtain Metallic Nanoparticles. Sustainability 2024, 16, 9837. https://doi.org/10.3390/su16229837

Rodrigues ÉF, Cesa Rovaris B, Valerio A, de Oliveira D, Hotza D. Bioleaching of Printed Circuit Board Waste to Obtain Metallic Nanoparticles. Sustainability. 2024; 16(22):9837. https://doi.org/10.3390/su16229837

Chicago/Turabian StyleRodrigues, Éllen F., Beatriz Cesa Rovaris, Alexsandra Valerio, Débora de Oliveira, and Dachamir Hotza. 2024. "Bioleaching of Printed Circuit Board Waste to Obtain Metallic Nanoparticles" Sustainability 16, no. 22: 9837. https://doi.org/10.3390/su16229837

APA StyleRodrigues, É. F., Cesa Rovaris, B., Valerio, A., de Oliveira, D., & Hotza, D. (2024). Bioleaching of Printed Circuit Board Waste to Obtain Metallic Nanoparticles. Sustainability, 16(22), 9837. https://doi.org/10.3390/su16229837