Opportunities and Challenges in the Implementation of Modular Construction Methods for Urban Revitalization

Abstract

1. Introduction

1.1. Background

1.2. Current Studies in Modular Construction for Urban Settings

1.3. Motivation of the Study

2. Methodology

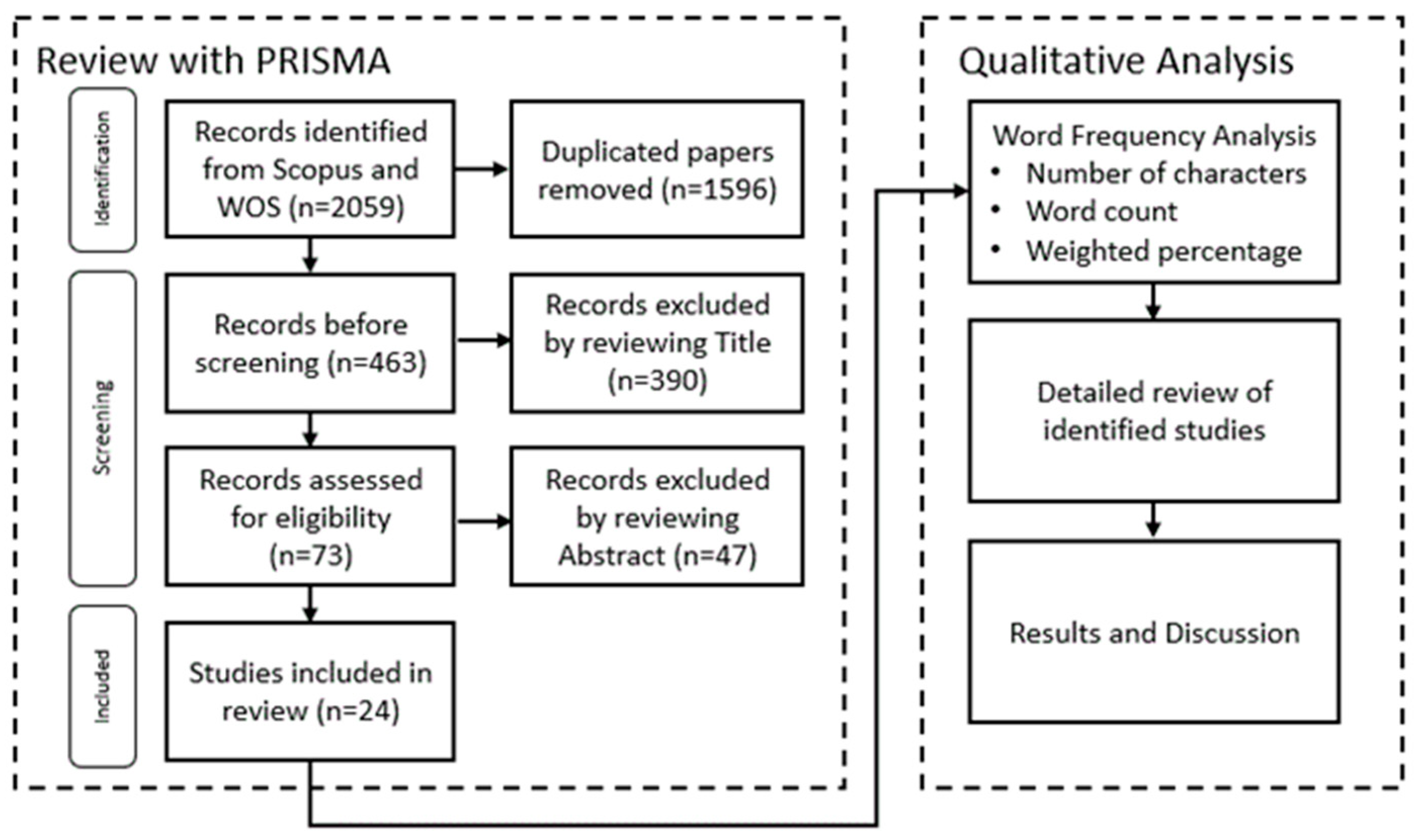

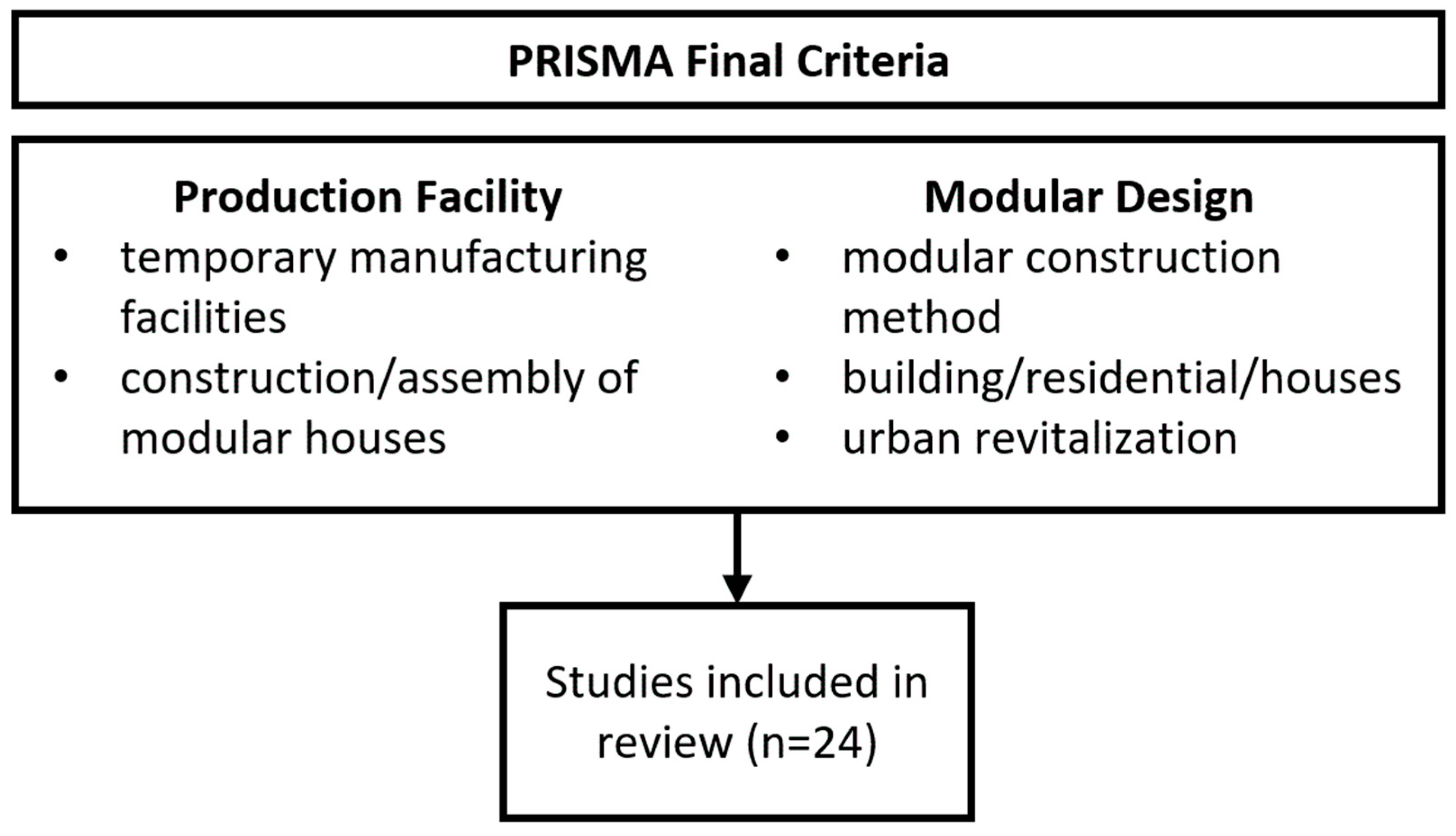

2.1. Systematic Review with PRISMA

2.2. Mixed Methods Research

3. Results

3.1. Review with PRISMA

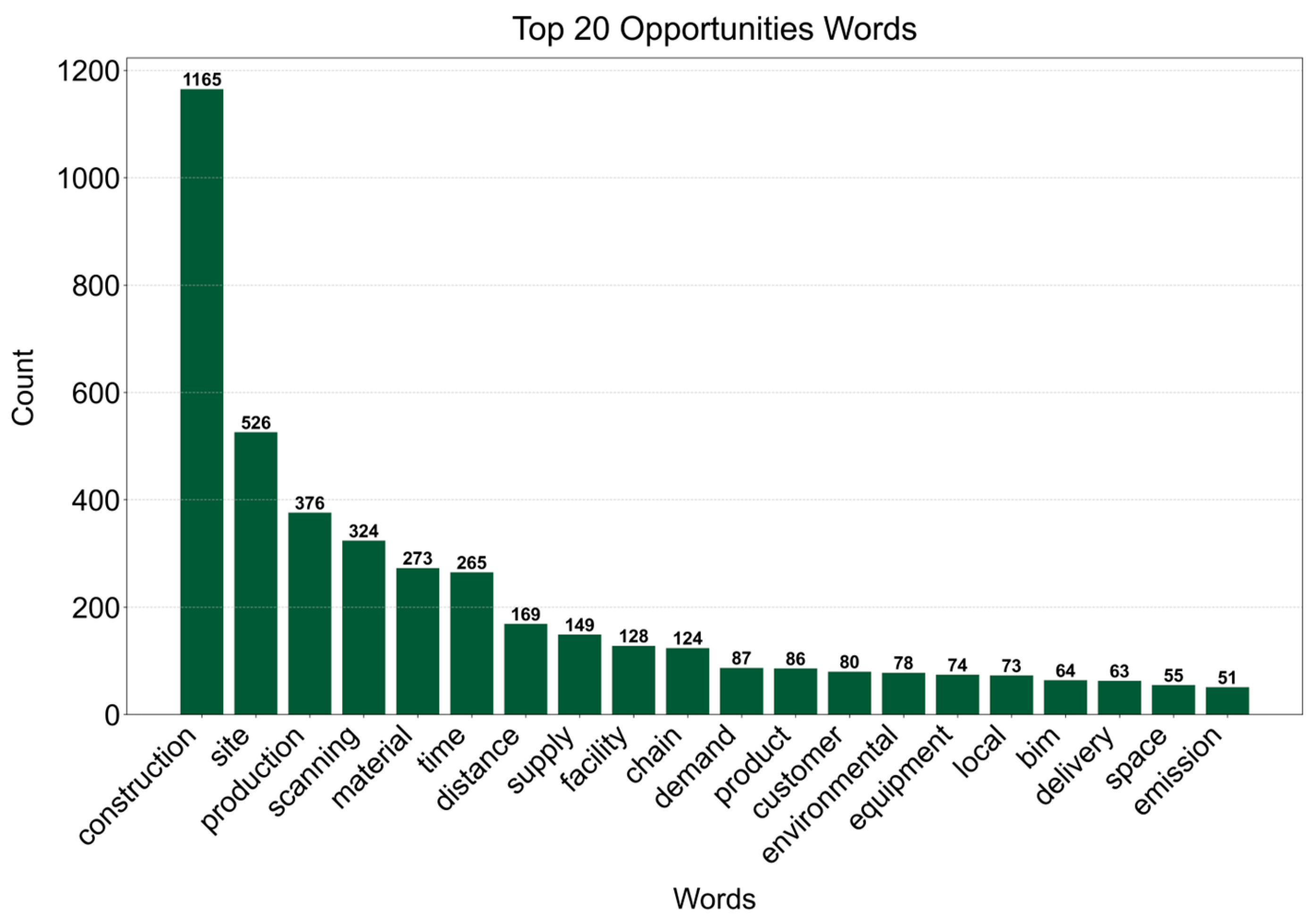

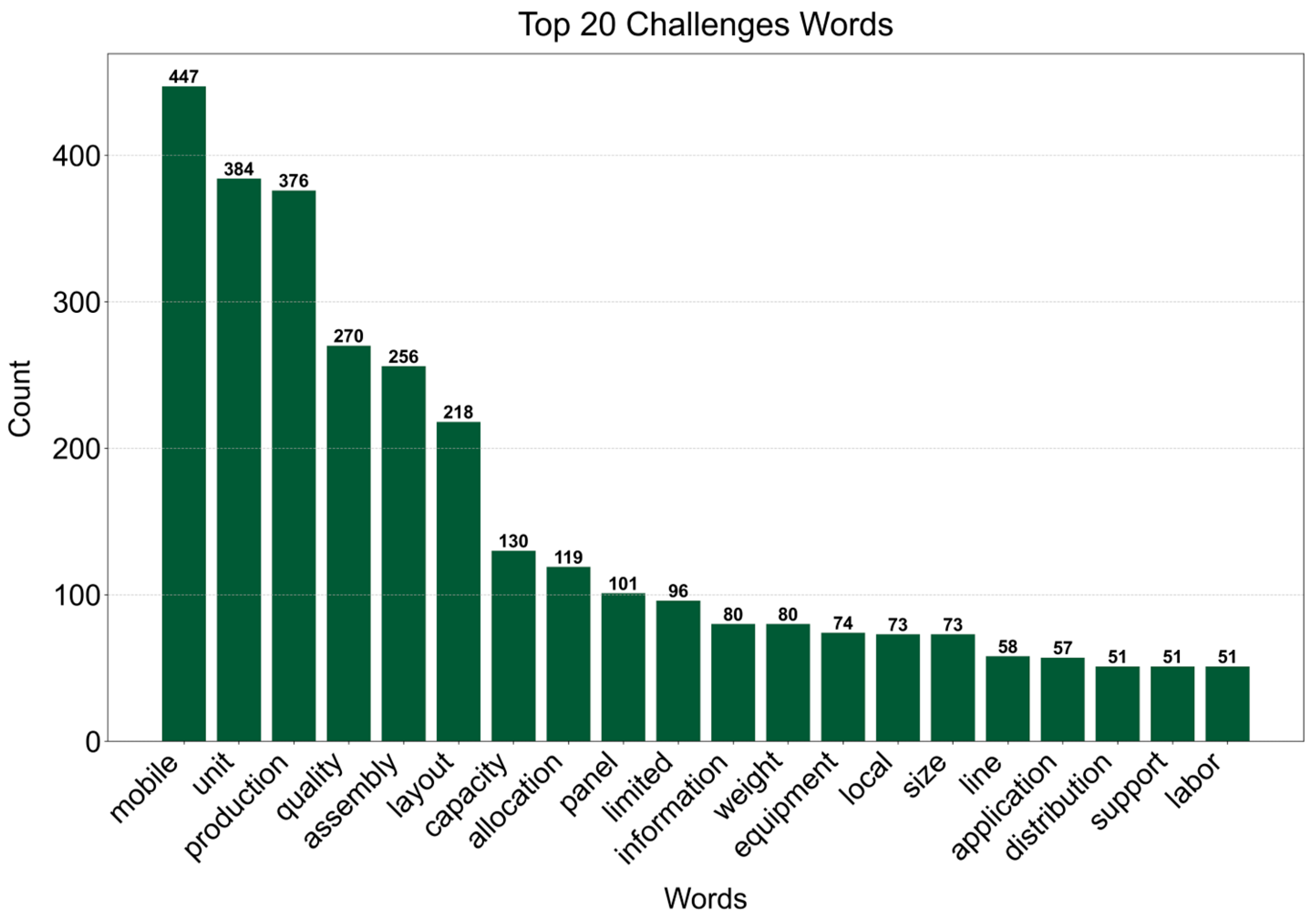

3.2. Mixed Methods Analysis

4. Discussion

4.1. Opportunities in Implementing Modular Construction Methods for Production Facility

4.2. Opportunities in Implementing Modular Methods with Respect to Modular Design

4.3. Challenges in Implementing Modular Methods for Production Facility

4.4. Challenges in Implementing Modular Methods for Modular Design

4.5. Identified Research Gaps

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Opportunities | Insights | [34] | [35] | [36] | [37] | [38] | [39] | [39] | [40] | [41] | [43] | [56] | [57] |

| Production facility layout and location | Agility | * | * | ||||||||||

| Mobility | |||||||||||||

| Less infrastructure and minimal site space for setting up | |||||||||||||

| Labor condition and efficiency | Labor safety | * | * | * | * | * | * | * | * | * | |||

| Reduced physical demand on skilled labor | |||||||||||||

| Enhanced product and production quality | |||||||||||||

| Controlled weather conditions for on-site construction | |||||||||||||

| Efficient storage solution | Addressing storage problems on site | * | * | ||||||||||

| Space for material inventory | |||||||||||||

| Transportation costs and delivery times | Short distance to customer | * | * | * | |||||||||

| Reduced transportation time | |||||||||||||

| Sustainability | |||||||||||||

| Better procurement | Shortening the supply chain uncertainty in material delivery | * | |||||||||||

| Local resources | |||||||||||||

| Just-in-time (JIT) delivery | |||||||||||||

| Resource leveling | Shared capacity and equipment among different stakeholders | * | * | * | * | * | * | * | * | * | * | ||

| Installing production capacity wherever it is needed | |||||||||||||

| Reduced construction schedule | |||||||||||||

| Sustainability | Reduced waste | * | * | * | * | * | |||||||

| Reduced environmental impact (carbon emission) | |||||||||||||

| Technology | Opportunity to use new technologies (e.g., BIM, 3D Scanning, IoT, etc.) | * | |||||||||||

| Challenges | Insights | [34] | [35] | [36] | [37] | [38] | [39] | [40] | [41] | [42] | [43] | [44] | [45] |

| Production facility design and planning | Maneuver capability due to the weight mobile unit | * | * | * | * | * | * | * | |||||

| Stability of the mobile unit | |||||||||||||

| Available space for the circulation | |||||||||||||

| Equipment size | |||||||||||||

| Storage space | |||||||||||||

| Setup and dismantling | |||||||||||||

| layout design (assembly line) | |||||||||||||

| Capacity | Low production capacity | * | * | * | * | ||||||||

| Manufacturing and assembly workforce | Travelling workforce | * | * | * | |||||||||

| Culture | |||||||||||||

| Training | |||||||||||||

| Finding qualified labor, availability of skilled labor | |||||||||||||

| Logistics and site | Support from off-site | * | * | * | * | * | |||||||

| Changing the location of the production units | |||||||||||||

| Path assignment and traffic allocation and distribution | |||||||||||||

| Quality assurance | Production of defective panels | * | * | ||||||||||

| Permits and regulations | Taxes | * | * | * | |||||||||

| Local people | |||||||||||||

| Legal permits | |||||||||||||

| Health and labor regulations in each region or country | |||||||||||||

| Technology integration | Limited information and application of new technologies (e.g., BIM, 3D scanning, IoT, etc.) | * |

| Opportunities | Insights | [46] | [47] | [48] | [49] | [50] | [51] | [52] | [53] | [54] | [55] | [56] | [57] |

| Design enhancements | Mass customization | * | * | * | * | * | * | ||||||

| Flexible and free-form structures | |||||||||||||

| Lightweight structures | |||||||||||||

| Aesthetics and versatile structural forms | |||||||||||||

| Increased structural redundancy | |||||||||||||

| Durability and stability | |||||||||||||

| Allowing for integration of technology | |||||||||||||

| Quality of the end product | Enhanced productivity and quality | * | * | * | * | ||||||||

| Cost optimization | Reduced construction cost and time | * | * | * | * | * | |||||||

| Safe working environment | Safe working space | * | * | * | * | ||||||||

| Site and space utilization | Relocatability | * | * | * | |||||||||

| Limited space in urban areas | |||||||||||||

| Efficient use of idle land | |||||||||||||

| Sustainability | Reduced embodied energy | * | * | * | * | * | * | * | * | * | |||

| Recycling and reuse of the materials | |||||||||||||

| Ease of dismantling and deconstruction | |||||||||||||

| Minimized environmental impacts in waste, pollution, resource, and energy | |||||||||||||

| Affordable housing | |||||||||||||

| Challenges | Insights | [46] | [47] | [48] | [49] | [50] | [51] | [52] | [53] | [54] | [55] | [56] | [57] |

| Design Limitation | Size and height of the units | * | * | ||||||||||

| Economic | High initial costs | * | * | * | |||||||||

| Initial investments in training of personnel | |||||||||||||

| Legal approvals and building permits | Legal requirements and building permits | * | |||||||||||

| Logistics and transportation | Transport limitations | * | * | * | |||||||||

| factory setup | |||||||||||||

| supply chain issues |

References

- Sutton, S.A. Urban Revitalization in the United States: Policies and Practices; 2008. Available online: https://www.columbia.edu/cu/c2arl/pdf_files/USURRP_Phase_I_Final_Report.pdf (accessed on 18 July 2024).

- Center for Sustainable Systems U.S. Cities Factsheet. Available online: https://css.umich.edu/publications/factsheets/built-environment/us-cities-factsheet (accessed on 10 July 2024).

- Galster, G. Driving Detroit: The Quest for Respect in the Motor City; University of Pennsylvania Press: Philadelphia, PA, USA, 2012; ISBN 9780812206463. [Google Scholar]

- Hirner, K. Fear and Awe: Social Construction of Fear in Detroit; 2019. Available online: https://core.ac.uk/download/pdf/216484419.pdf (accessed on 18 July 2024).

- Hartig, J.; Wallace, M. Creating World-Class Gathering Places for People and Wildlife along the Detroit Riverfront, Michigan, USA. Sustainability 2015, 7, 15073–15098. [Google Scholar] [CrossRef]

- Price, C. Michigan Central Station Historic Revitalization. Available online: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=2441&context=researchweek (accessed on 10 July 2024).

- Florida, R.; King, K. America’s Evolving Geography of Innovation: How the Heartland Region Can Lead the Way on Industry Transforming Technology. Available online: https://heartlandforward.org/case-study/americas-evolving-geography-of-innovation-how-the-heartland-region-can-lead-the-way-on-industry-transforming-technology/ (accessed on 10 July 2024).

- Goldbeck, H. Diverse Seattle Economy Built on Sky’s the Limit Innovation. Available online: https://goldbeck.com/blog/diverse-seattle-economy-built-on-skys-the-limit-innovation/ (accessed on 10 July 2024).

- Grodach, C.; Loukaitou-Sideris, A. Cultural development strategies and urban revitalization. Int. J. Cult. Policy 2007, 13, 349–370. [Google Scholar] [CrossRef]

- Purwantiasning, A.W.; Whittingham, N.; Schneider, V. Urban Planning Policies and Strategies for Revitalization: An Overview and Comparison of Experiences; 2015. Available online: https://repositorio.unne.edu.ar/handle/123456789/28346 (accessed on 12 August 2024).

- Anjaneyulu, L.; Syal, M.; Supanich-Goldner, F. The Built Environment Factor Based on Building Rehabilitation: A Critical Aspect of Urban Revitalization. Hous. Soc. 2004, 31, 73–88. [Google Scholar] [CrossRef]

- Choi, J.O.; Chen, X.B.; Kim, T.W. Opportunities and Challenges of Modular Methods in Dense Urban Environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- Hylton, O. City’s First Micro-Apartment Project “MY Micro NY” Ready for Stacking. 6spft 2015. Available online: https://www.6sqft.com/citys-first-micro-apartment-project-my-micro-ny-ready-for-stacking/ (accessed on 12 July 2024).

- Lubell, S. New York’s Modular Building Revolution Is Here. New York Post 2018. Available online: https://nypost.com/2018/09/13/new-yorks-modular-building-revolution-is-here/ (accessed on 12 July 2024).

- Boyd, N.; Khalfan, M.M.A.; Maqsood, T. Off-Site Construction of Apartment Buildings. J. Archit. Eng. 2013, 19, 51–57. [Google Scholar] [CrossRef]

- Baldea, M.; Edgar, T.F.; Stanley, B.L.; Kiss, A.A. Modular manufacturing processes: Status, challenges, and opportunities. AIChE J. 2017, 63, 4262–4272. [Google Scholar] [CrossRef]

- Sajid, Z.W.; Ullah, F.; Qayyum, S.; Masood, R. Climate Change Mitigation through Modular Construction. Smart Cities 2024, 7, 566–596. [Google Scholar] [CrossRef]

- Shahzad, W.M.; Reddy, S.M.; Kahandawa, R.; Rotimi, J.O.B. Benefits, Constraints and Enablers of Modular Offsite Construction (MOSC) in New Zealand High-Rise Buildings. Eng. Constr. Archit. Manag. 2023. [Google Scholar] [CrossRef]

- Thai, H.-T.; Ngo, T.; Uy, B. A Review on Modular Construction for High-Rise Buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Modular Construction: Determining Decision-Making Factors and Future Research Needs. J. Manag. Eng. 2020, 36, 04020085. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New Advancements, Challenges and Opportunities of Multi-Storey Modular Buildings—A State-of-the-Art Review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Gutiérrez, N.; Negrão, J.; Dias, A.; Guindos, P. Bibliometric Review of Prefabricated and Modular Timber Construction from 1990 to 2023: Evolution, Trends, and Current Challenges. Sustainability 2024, 16, 2134. [Google Scholar] [CrossRef]

- Wei, Y.; Choi, H.; Lei, Z. A Generative Design Approach for Modular Construction in Congested Urban Areas. Smart Sustain. Built Environ. 2022, 11, 1163–1181. [Google Scholar] [CrossRef]

- Sing, M.; Chan, J.; Liu, H.; Ngai, N.N.H. Developing an Analytic Hierarchy Process-Based Decision Model for Modular Construction in Urban Areas. J. Eng. Des. Technol. 2023, 21, 1212–1229. [Google Scholar] [CrossRef]

- Hyun, H.; Lee, Y.-M.; Kim, H.-G.; Kim, J.-S. Framework for Long-Term Public Housing Supply Plan Focusing on Small-Scale Offsite Construction in Seoul. Sustainability 2021, 13, 5361. [Google Scholar] [CrossRef]

- Airgood-Obrycki, W.; McCue, D. The Housing Shortage Is Still Out There. Hous. Policy Debate 2024, 1–5. [Google Scholar] [CrossRef]

- Detroit Land Bank Authority VACANT LAND. Available online: https://buildingdetroit.org/land-reuse-programs (accessed on 11 July 2024).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Plano Clark, V.L. Mixed Methods Research. J. Posit. Psychol. 2017, 12, 305–306. [Google Scholar] [CrossRef]

- Chadegani, A.A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ebrahim, N.A. A Comparison between Two Main Academic Literature Collections: Web of Science and Scopus Databases. arXiv 2013, arXiv:1305.0377. [Google Scholar] [CrossRef]

- Ashton, P.; Christophers, B. Remaking Mortgage Markets by Remaking Mortgages: U.S. Housing Finance after the Crisis. Econ. Geogr. 2018, 94, 238–258. [Google Scholar] [CrossRef]

- Christophers, B. Putting Financialisation in Its Financial Context: Transformations in Local Government-led Urban Development in Post-financial Crisis England. Trans. Inst. Br. Geogr. 2019, 44, 571–586. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, W. Facility Layout Design for Modular Construction Manufacturing: A Comparison Based on Simulation and Optimization. Autom. Constr. 2023, 147, 104713. [Google Scholar] [CrossRef]

- Peiris, A.; Hui, F.K.P.; Duffield, C.; Wang, J.; Gil Garcia, M.; Chen, Y.; Ngo, T. Digitalising Modular Construction: Enhancement of off-Site Manufacturing Productivity via a Manufacturing Execution & Control (MEC) System. Comput. Ind. Eng. 2023, 178, 109117. [Google Scholar] [CrossRef]

- Son, R.H.; Han, K. Automated Model-Based 3D Scan Planning for Prefabricated Building Components. J. Comput. Civ. Eng. 2023, 37, 04022058. [Google Scholar] [CrossRef]

- Huang, R.; Li, K.; Liu, G.; Shrestha, A.; Chang, R.; Tang, X. A Bi-Level Model and Hybrid Heuristic Algorithm for the Optimal Location of Prefabricated Building Industrial Park. Eng. Appl. Artif. Intell. 2022, 116, 105393. [Google Scholar] [CrossRef]

- O’Neill, S.; Wrigley, P.; Bagdasar, O. A Mixed-Integer Linear Programming Formulation for the Modular Layout of Three-Dimensional Connected Systems. Math. Comput. Simul. 2022, 201, 739–754. [Google Scholar] [CrossRef]

- Nam, S.; Yoon, J.; Kim, K.; Choi, B. Optimization of Prefabricated Components in Housing Modular Construction. Sustainability 2020, 12, 10269. [Google Scholar] [CrossRef]

- Ahn, S.; Han, S.; Al-Hussein, M. 2D Drawing Visualization Framework for Applying Projection-Based Augmented Reality in a Panelized Construction Manufacturing Facility: Proof of Concept. J. Comput. Civ. Eng. 2019, 33, 04019032. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Process Discovery and Conformance Checking in Modular Construction Using RFID and Process Mining. In Construction Research Congress; American Society of Civil Engineers: Reston, VA, USA, 2020; Volume 2020, pp. 640–648. [Google Scholar]

- Gee, S.; Brown, A. A Mobile System for the On-Site Assembly of Timber Frame Components: The Development of an Agile, Low-Cost Alternative to Offsite Prefabrication. Sustainability 2022, 14, 651. [Google Scholar] [CrossRef]

- Rauch, E.; Matt, D.T.; Dallasega, P. Mobile On-Site Factories—Scalable and Distributed Manufacturing Systems for the Construction Industry. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–10. [Google Scholar]

- Kazemi, Z.; Rask, J.K.; Gomes, C.; Yildiz, E.; Larsen, P.G. Movable Factory—A Systematic Literature Review of Concepts, Requirements, Applications, and Gaps. J. Manuf. Syst. 2023, 69, 189–207. [Google Scholar] [CrossRef]

- Alarcon-Gerbier, E.; Buscher, U. Modular and Mobile Facility Location Problems: A Systematic Review. Comput. Ind. Eng. 2022, 173, 108734. [Google Scholar] [CrossRef]

- Maalek, R.; Maalek, S. Repurposing Existing Skeletal Spatial Structure (SkS) System Designs Using the Field Information Modeling (FIM) Framework for Generative Decision-Support in Future Construction Projects. Sci. Rep. 2023, 13, 19591. [Google Scholar] [CrossRef] [PubMed]

- Pan, W.; Zhang, Z. Benchmarking the Sustainability of Concrete and Steel Modular Construction for Buildings in Urban Development. Sustain. Cities Soc. 2023, 90, 104400. [Google Scholar] [CrossRef]

- Glumac, B. Tiny Portable Home: Measuring the Rental Preferences. Cities 2021, 116, 103279. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, M.J. Affordable Modular Housing for College Students Emphasizing Habitability. J. Asian Archit. Build. Eng. 2016, 15, 49–56. [Google Scholar] [CrossRef]

- Herrera-Limones, R.; Hernández-Valencia, M.; Roa-Fernández, J. Urban Regeneration through Retrofitting Social Housing: The AURA 3.1 Prototype. J. Hous. Built Environ. 2023, 38, 837–859. [Google Scholar] [CrossRef]

- Woo, S.J.; Hwang, E.K. A Comparative Analysis of the Industrialization of Residential Building Performance Standards—Based on South Korea, Japan and Canada. Adv. Civ. Archit. Struct. Constr. Eng. 2016, 111–115. [Google Scholar]

- Yoo, H.Y.; Park, J.D. A Planning Direction of the Prefab Public Housing in Deteriorated Residential Area. Int. J. Appl. Eng. Res. 2015, 10, 26995–27003. [Google Scholar] [CrossRef]

- Zhou, J.; He, P.; Qin, Y.; Ren, D. A Selection Model Based on SWOT Analysis for Determining a Suitable Strategy of Prefabrication Implementation in Rural Areas. Sustain. Cities Soc. 2019, 50, 101715. [Google Scholar] [CrossRef]

- Ali, A.H.; Kineber, A.F.; Elyamany, A.; Ibrahim, A.H.; Daoud, A.O. Identifying and Assessing Modular Construction Implementation Barriers in Developing Nations for Sustainable Building Development. Sustain. Dev. 2023, 31, 3346–3364. [Google Scholar] [CrossRef]

- Tofiluk, A. Problems and Challenges of the Built Environment and the Potential of Prefabricated Architecture. Arch. Civ. Eng. 2023, 69, 405–424. [Google Scholar] [CrossRef]

- Hassan Ali, A.; Farouk Kineber, A.; Elshaboury, N.; Arashpour, M.; Osama Daoud, A. Analysing Multifaceted Barriers to Modular Construction in Sustainable Building Projects: A Comprehensive Evaluation Using Multi-Criteria Decision Making. Int. J. Constr. Manag. 2023. [Google Scholar] [CrossRef]

- Munmulla, T.; Hidallana-Gamage, H.D.; Navaratnam, S.; Ponnampalam, T.; Zhang, G.; Jayasinghe, T. Suitability of Modular Technology for House Construction in Sri Lanka: A Survey and a Case Study. Buildings 2023, 13, 2592. [Google Scholar] [CrossRef]

| Level | Objective | Scope | Method |

|---|---|---|---|

| Urban | Rehabilitation | Residential building | Modular construction |

| City | Regeneration | Housing | Off-site construction |

| Neighborhood | Renewal | Prefabricated construction | |

| Revitalization | Modular design |

| Objective | Scope | Method |

|---|---|---|

| Modular | Modular facilities | Modular construction |

| Temporary | Industrialized construction | |

| Facility | Off-site construction |

| Opportunities | Challenges | |

|---|---|---|

| Production Facility | Production facility layout and locations | Production facility design and planning |

| Labor condition and efficiency | Capacity of the production facility | |

| Efficient storage solution | Manufacturing and assembly workforce | |

| Transportation costs and delivery times | Logistics and site | |

| Procurement | Quality assurance | |

| Resource leveling | Permits and regulations | |

| Sustainability and technology | Technology integration | |

| Modular Design | Design enhancements | Design limitations |

| Quality of the end product | Economic | |

| Cost optimization | Legal approvals and building permits | |

| Safe working environment | Logistics and transportation | |

| Site and space utilization | ||

| Sustainability |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coskun, C.; Lee, J.; Xiao, J.; Graff, G.; Kang, K.; Besiktepe, D. Opportunities and Challenges in the Implementation of Modular Construction Methods for Urban Revitalization. Sustainability 2024, 16, 7242. https://doi.org/10.3390/su16167242

Coskun C, Lee J, Xiao J, Graff G, Kang K, Besiktepe D. Opportunities and Challenges in the Implementation of Modular Construction Methods for Urban Revitalization. Sustainability. 2024; 16(16):7242. https://doi.org/10.3390/su16167242

Chicago/Turabian StyleCoskun, Cansu, Jinwoong Lee, Jinwu Xiao, Geoffrey Graff, Kyubyung Kang, and Deniz Besiktepe. 2024. "Opportunities and Challenges in the Implementation of Modular Construction Methods for Urban Revitalization" Sustainability 16, no. 16: 7242. https://doi.org/10.3390/su16167242

APA StyleCoskun, C., Lee, J., Xiao, J., Graff, G., Kang, K., & Besiktepe, D. (2024). Opportunities and Challenges in the Implementation of Modular Construction Methods for Urban Revitalization. Sustainability, 16(16), 7242. https://doi.org/10.3390/su16167242