The Adhesion Performance in Green-Glued Finger Joints Using Different Wood Ring Orientations

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection, Preparation, and Characterization of Wood

2.2. Measurement of Moisture

2.3. Drying Protocol

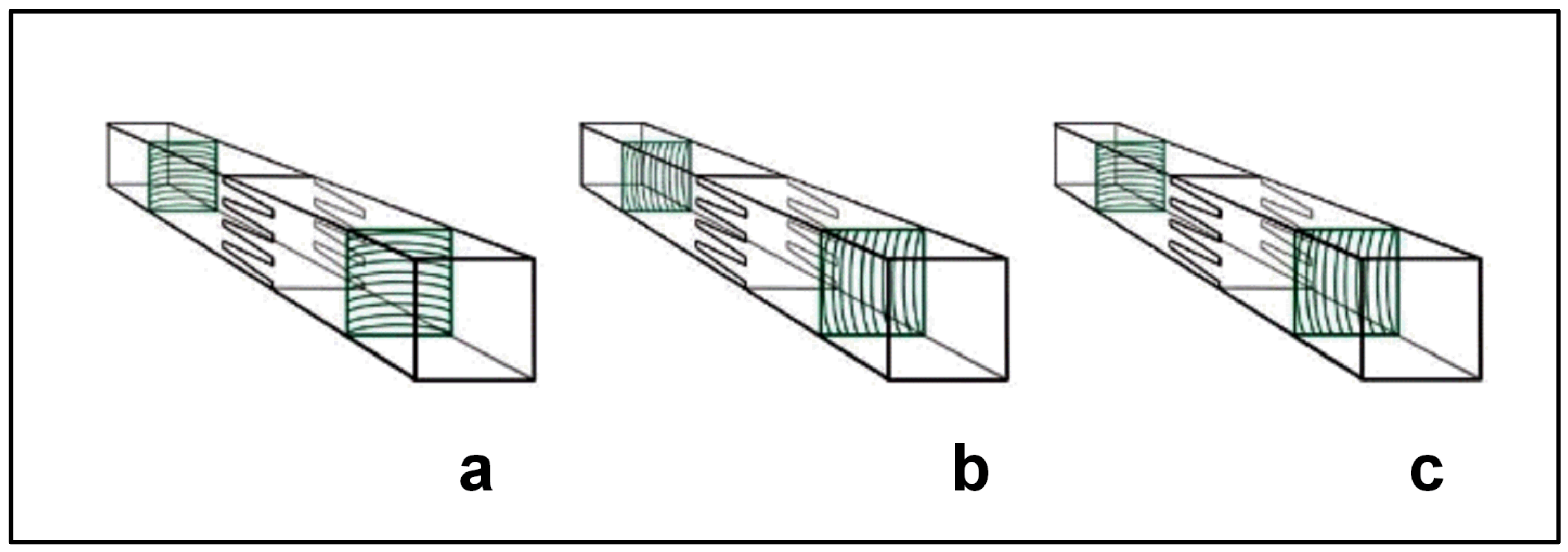

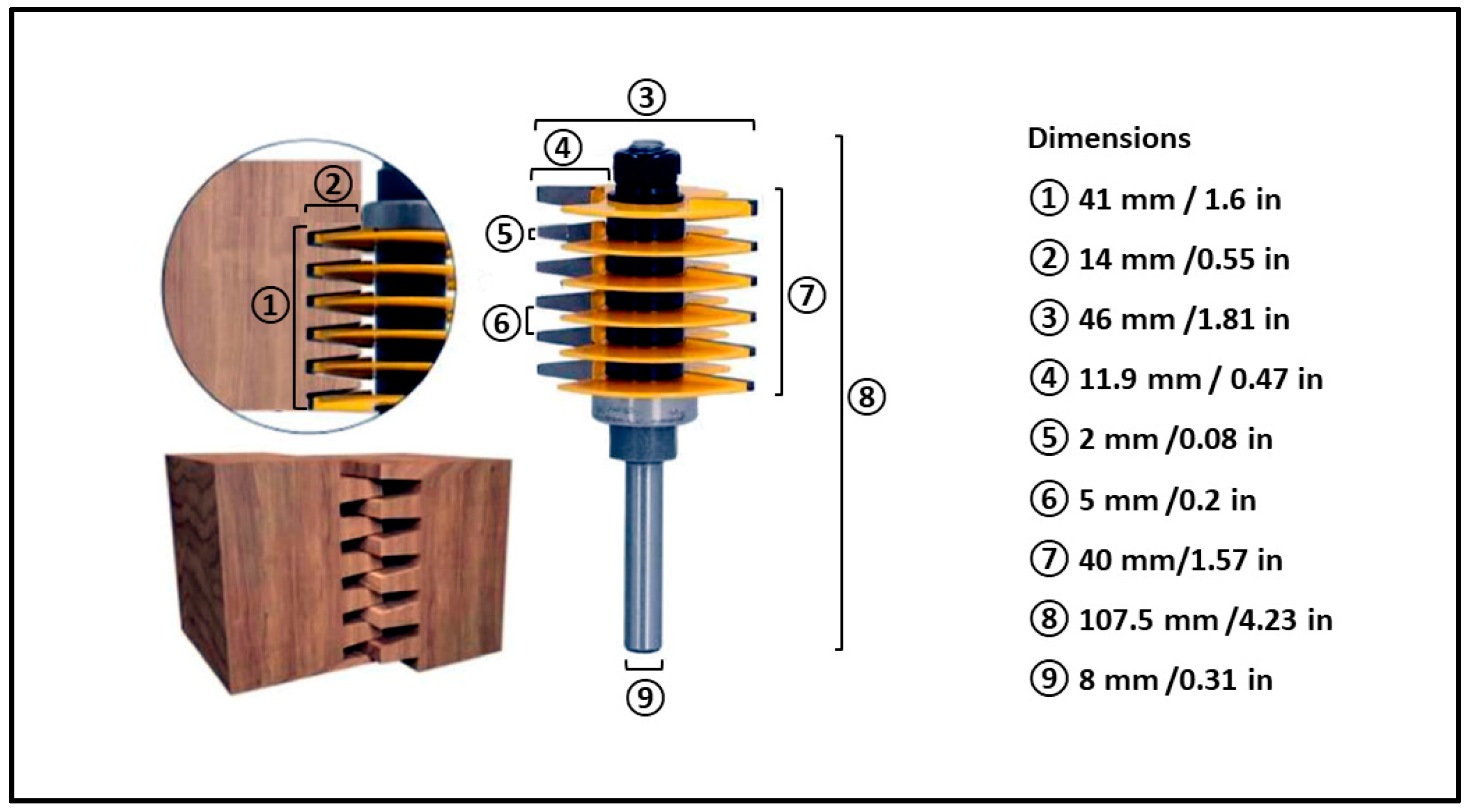

2.4. Finger Joint Profile Cutting Protocol

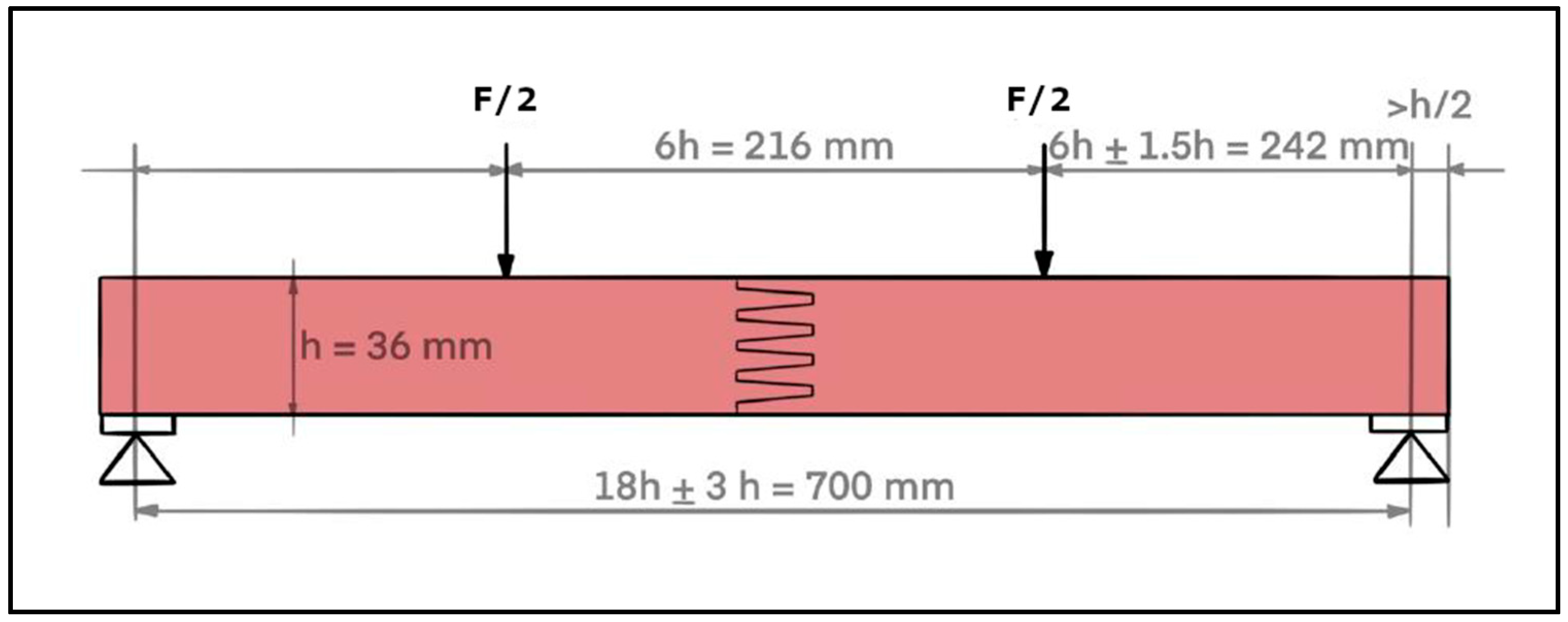

2.5. Mechanical Tests

- P: applied load (N);

- a: distance from one of the supports to the applied load (mm). In this case, 242 mm;

- L: span of the tested element (mm). In this case, 700 mm;

- b: width of the section of the part (mm);

- h: height of the section of the part (mm);

- α: coefficient of elastic deformation;

- δ: deformation at span center.

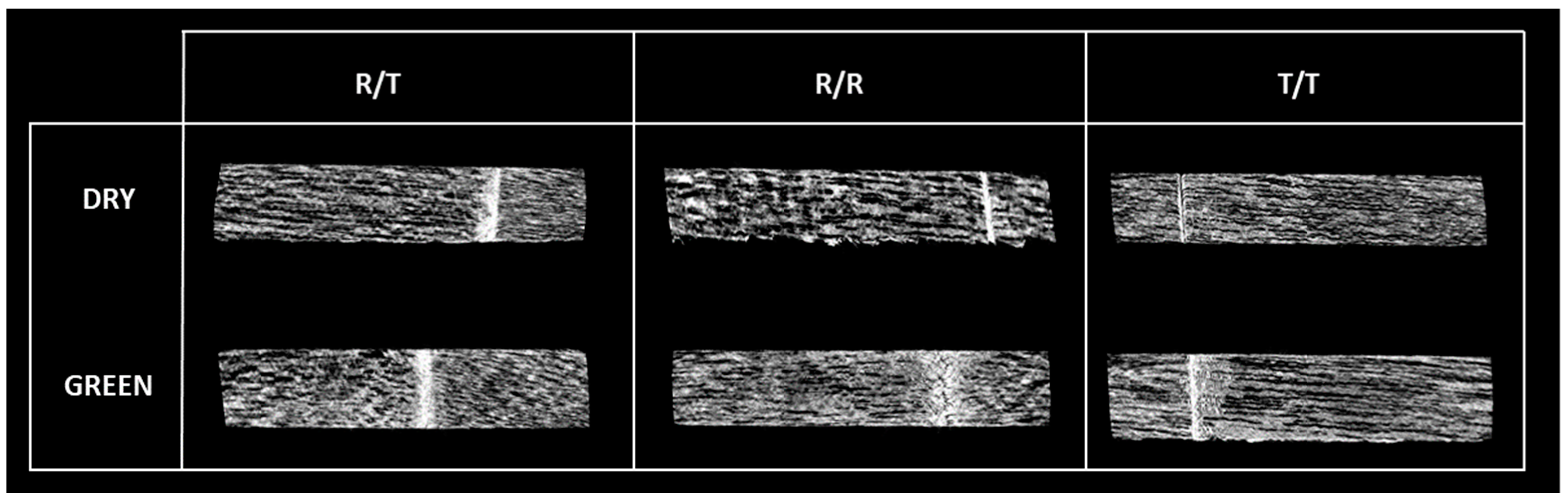

2.6. Micro-Computed Tomography (Micro-CT)

2.7. Roughness Measurement

2.8. Statistical Analysis

3. Results

3.1. Wood Characterizations

3.2. Mechanical Test

3.3. Characterization by Microcomputed Tomography (Micro-CT)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cuadrado, J.; Zubizarreta, M.; Pelaz, B.; Marcos, I. Methodology to Assess the Environmental Sustainability of Timber Structures. Constr. Build. Mater. 2015, 86, 149–158. [Google Scholar] [CrossRef]

- Gilbert, B.P.; Davies, T.E.; McGavin, R.L.; Dowse, C.J. Towards Reducing the Capital Cost of Manufacturing Laminated Veneer Lumbers: Investigating Finger Jointing Solutions. Constr. Build. Mater. 2024, 411, 134158. [Google Scholar] [CrossRef]

- Hou, J.; Taoum, A.; Kotlarewski, N.; Nolan, G. Study on the Effect of Finger-Joints on the Strengths of Laminations from Fiber-Managed Eucalyptus Nitens. Forests 2023, 14, 1192. [Google Scholar] [CrossRef]

- Clouet, B. Comportement Hydromécanique d’assemblages Bois Collés à l’état Vert: Approches Expérimentale et Numérique. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2014. [Google Scholar]

- Romero, A.; Odenbreit, C. Experimental Investigation on Strength and Stiffness Properties of Laminated Veneer Lumber (LVL). Materials 2023, 16, 7194. [Google Scholar] [CrossRef] [PubMed]

- De Araujo, V.; Aguiar, F.; Jardim, P.; Mascarenhas, F.; Marini, L.; Aquino, V.; Santos, H.; Panzera, T.; Lahr, F.; Christoforo, A. Is Cross-Laminated Timber (CLT) a Wood Panel, a Building, or a Construction System? A Systematic Review on Its Functions, Characteristics, Performances, and Applications. Forests 2023, 14, 264. [Google Scholar] [CrossRef]

- Hermawan, A.; Mohammad Sofi, A.Z.; Roszalli, M.N. Performance of Glued Laminated Timber (Glulam) Made from Rubberwood with Different Lamina Assembly Patterns and Adhesive Spreads Rates. In Proceedings of the IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2023; Volume 1145. [Google Scholar]

- Rodríguez-Grau, G.; Marín-Uribe, C.; Cortés-Rodríguez, P.; Montero, C.; Rosales, V.; Galarce, C. Bibliometric Analysis of the Green Gluing Technique (2000–2020): Trends and Perspectives. Forests 2022, 13, 1714. [Google Scholar] [CrossRef]

- Sterley, M. Green Gluing of Wood; KTH—Royal Institute of Technology: Stockolm, Sweden, 2004. [Google Scholar]

- Lissouck, R.O.; Pommier, R.; Castéra, P.; Ayina Ohandja, M.L. Timber Engineering as a Tool for Species in Tropical Rain Forests: The Case of Congo Basin Forest. In Proceedings of the World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012. [Google Scholar]

- Bidzo, C.H.N.; Nziengui, C.F.P.; Ikogou, S.; Kaiser, B.; Pitti, R.M. Mechanical Behavior of Tropical Glued Laminated Timber Beams with Fingers Joints. Procedia Struct. Integr. 2022, 37, 447–452. [Google Scholar] [CrossRef]

- Morin-Bernard, A.; Blanchet, P.; Dagenais, C.; Achim, A. Glued-Laminated Timber from Northern Hardwoods: Effect of Finger-Joint Profile on Lamellae Tensile Strength. Constr. Build. Mater. 2021, 271, 121591. [Google Scholar] [CrossRef]

- Ahmad, Z.; Lum, W.C.; Lee, S.H.; Razlan, M.A.; Mohamad, W.H.W. Mechanical Properties of Finger Jointed Beams Fabricated from Eight Malaysian Hardwood Species. Constr. Build. Mater. 2017, 145, 464–473. [Google Scholar] [CrossRef]

- Rosales, V.; Rodríguez-Grau, G.; Galarce, C.; Montero, C.; Alvarado, C.; Muñoz, L.; Pommier, R. Feasibility of Bonding High-Moisture-Content Wood Using Nothofagus Chilean Species. Forests 2023, 14, 2386. [Google Scholar] [CrossRef]

- Sterley, M.; Gustafsson, P.J. Shear Fracture Characterization of Green-Glued Polyurethane Wood Adhesive Bonds at Various Moisture and Gluing Conditions. Wood Mater. Sci. Eng. 2012, 7, 93–100. [Google Scholar] [CrossRef]

- Pommier, R.; Elbez, G. Finger-Jointing Green Softwood: Evaluation of the Interaction between Polyurethane Adhesive and Wood. Wood Mater. Sci. Eng. 2006, 1, 127–137. [Google Scholar] [CrossRef]

- Ayarkwa, J.; Hirashima, Y.; Sasaki, Y.; Yamasaki, M. Influence of Finger-Joint Geometry and End Pressure on Tensile Properties of Three Finger-Jointed Tropical African Hardwoods. S. Afr. For. J. 2000, 188, 37–49. [Google Scholar] [CrossRef]

- Tsalagkas, D.; Börcsök, Z.; Pásztory, Z. The Effect of Finger Length and Adhesive Type on the Curing Time of Finger-Jointed Black Pine (Pinus nigra L.) Lumber. Wood Mater. Sci. Eng. 2021, 16, 312–320. [Google Scholar] [CrossRef]

- Bustos, C.; Hernández, R.E.; Beauregard, R.; Mohammad, M. Effects of End-Pressure on the Finger-Joint Quality of Black Spruce Lumber: A Microscopic Analysis. Maderas. Cienc. Tecnol. 2011, 13, 319–328. [Google Scholar] [CrossRef]

- Groom, L.H.; Leichti, R.J. Effect of Adhesive Stiffness and Thickness on Stress Distributions in Structural Finger Joints. J. Adhes. 1994, 44, 69–83. [Google Scholar] [CrossRef][Green Version]

- Faircloth, A.; Kumar, C.; McGavin, R.; Gilbert, B.; Leggate, W. Mechanical Performance and Bond Integrity of Finger Jointed High-Density Sub-Tropical Hardwoods for Residential Decking. Forests 2023, 14, 956. [Google Scholar] [CrossRef]

- NCh2245:2015; Hoja de Datos de Seguridad para Productos Químicos—Contenido y Orden de las Secciones. Instituto Nacional de Normalización: Santiago, Chile, 2015.

- Grabianowski, M.; Manley, B.; Walker, J.C.F. Acoustic Measurements on Standing Trees, Logs and Green Lumber. Wood Sci. Technol. 2006, 40, 205–216. [Google Scholar] [CrossRef]

- Balmori Roiz, J.A.; Acuña Rello, L.B.; Otero, L.A. Estudio de La Influencia de La Dirección de La Fibra En La Velocidad de Propagación de Ultrasonidos (FAKOPP) En Madera Estructural de “Pinus sylvestris L.” y “Pinus radiata D. Don.”. In Proceedings of the 6th Rehabend Congress, Burgos, Spain, 24–27 May 2016. [Google Scholar]

- NCh176/1; Madera-Parte 1: Determinación Del Contenido de Humedad. Instituto Nacional de Normalización: Santiago, Chile, 2019.

- NCh176/2; Madera-Parte 2: Determinación de Densidad. Instituto Nacional de Normalización: Santiago, Chile, 1988.

- He, S.; Lin, L.; Wu, Z.; Chen, Z. Application of Finite Element Analysis in Properties Test of Finger-Jointed Lumber. J. Bioresour. Bioprod. 2020, 5, 124–133. [Google Scholar] [CrossRef]

- NCh 2148; Madera Laminada Encolada Estructural—Requisitos, Métodos de Muestreo e Inspección. Instituto Nacional de Normalización: Santiago, Chile, 2013.

- EN 408:2010+A1:2012; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. European Committee for Standardization: Brussels, Belgium, 2010.

- Meseguer, A.G. Hormigon Armado (Vol. II): Calculos en Estados Limite; Fundación Escuela de la Edificación: Madrid, Spain, 2001. [Google Scholar]

- Kazup, Á.; Fegyverneki, G.; Gácsi, Z. Evaluation of the Applicability of Computer-Aided Porosity Testing Methods for Different Pore Structures. Metallogr. Microstruct. Anal. 2022, 11, 774–789. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The Strength and Stiffness of Oriented Wood and Cellulose-Fibre Materials: A Review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Pizzi, A.; Raftery, G.M.; Hashemi, A. One-Component Polyurethane Adhesives in Timber Engineering Applications: A Review. Int. J. Adhes. Adhes. 2023, 123, 103358. [Google Scholar] [CrossRef]

- Clerc, G.; Brülisauer, M.; Affolter, S.; Volkmer, T.; Pichelin, F.; Niemz, P. Characterization of the Ageing Process of One-Component Polyurethane Moisture Curing Wood Adhesive. Int. J. Adhes. Adhes. 2017, 72, 130–138. [Google Scholar] [CrossRef]

- Yang, G.; Gong, Z.; Luo, X.; Chen, L.; Shuai, L. Bonding Wood with Uncondensed Lignins as Adhesives. Nature 2023, 621, 511–515. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Jeong, B.; Park, B.-D. A Comparison of Adhesion Behavior of Urea-Formaldehyde Resins with Melamine-Urea-Formaldehyde Resins in Bonding Wood. Forests 2021, 12, 1037. [Google Scholar] [CrossRef]

- Iždinský, J.; Reinprecht, L.; Sedliačik, J.; Kúdela, J.; Kučerová, V. Bonding of Selected Hardwoods with PVAc Adhesive. Appl. Sci. 2020, 11, 67. [Google Scholar] [CrossRef]

- Yue, K.; Wang, F.; Lu, W.; Tang, Z.; Chen, Z.; Liu, W. Tensile Properties of Finger-Jointed Lumber under High-Temperature and Oxygen-Free Conditions. Holzforschung 2021, 75, 838–846. [Google Scholar] [CrossRef]

- Hill, S.J.; Kirby, N.M.; Mudie, S.T.; Hawley, A.M.; Ingham, B.; Franich, R.A.; Newman, R.H. Effect of Drying and Rewetting of Wood on Cellulose Molecular Packing. Holzforschung 2010, 64, 421–427. [Google Scholar] [CrossRef]

- Tomad, J.; Leelatanon, S.; Jantawee, S.; Srisuchart, K.; Matan, N. Internal Stress Development within Wood during Drying: Regime and Kinetics. Dry. Technol. 2023, 41, 77–88. [Google Scholar] [CrossRef]

- González-Prieto, O.; Casas Mirás, J.M.; Torres, L.O. Finger-Jointing of Green Eucalyptus Globulus L. Wood with One-Component Polyurethane Adhesives. Eur. J. Wood Wood Prod. 2022, 80, 429–437. [Google Scholar] [CrossRef]

- Alia-Syahirah, Y.; Paridah, M.T.; Hamdan, H.; Anwar, U.M.K.; Nordahlia, A.S.; Lee, S.H. Effects of Anatomical Characteristics and Wood Density on Surface Roughness and Their Relation to Surface Wettability of Hardwood. J. Trop. For. Sci. 2019, 31, 269–277. [Google Scholar] [CrossRef]

- Yu, Q.; Pan, X.; Yang, Z.; Zhang, L.; Cao, J. Effects of the Surface Roughness of Six Wood Species for Furniture Production on the Wettability and Bonding Quality of Coating. Forests 2023, 14, 996. [Google Scholar] [CrossRef]

- Báder, M.; Németh, R. Moisture-Dependent Mechanical Properties of Longitudinally Compressed Wood. Eur. J. Wood Prod. 2019, 77, 1009–1019. [Google Scholar] [CrossRef]

| Physical Parameter | Statistical Tests | Finger Joint of Green Gluing | Wet Wood | Finger Joint of Dry Wood | Dry Wood |

|---|---|---|---|---|---|

| Oven-dry density (kg/m3) | Average | 0.511 | 0.534 | 0.541 | 0.548 |

| Standard deviation | 0.046 | 0.045 | 0.039 | 0.037 | |

| Size sample | 14 | 14 | 16 | 16 |

| Statistical Tests | Finger Joint of Green Gluing | Wet Wood | Finger Joint of Dry Wood | Dry Wood |

|---|---|---|---|---|

| Average | 12.345 | 8.707 | 9.650 | 10.497 |

| Standard deviation | 2.900 | 1.727 | 2.475 | 2.709 |

| Size sample | 69 | 70 | 80 | 80 |

| Factors | Degrees of Freedom | Sum of Squares | Mean Square | F-Value | Probability | F Critical |

|---|---|---|---|---|---|---|

| Between groups | 3 | 502.765 | 167.588 | 26.847 | 2.2169 × 10−15 * | 2.635 |

| Within groups | 295 | 1841.500 | 6.242 | |||

| Total | 298 | 2344.265 |

| Finger Joint of Green Gluing | Wet Wood | Finger Joint of Dry Wood | Dry Wood | |

|---|---|---|---|---|

| Finger-joint of green gluing | - | <0.001 * | <0.001 * | <0.001 * |

| Wet wood | - | 0.0988 NS | <0.001 * | |

| Finger-joint of dry wood | - | 0.1421 NS | ||

| Dry wood | - |

| Condition | Orientation | |||||

|---|---|---|---|---|---|---|

| R/T | R/R | T/T | ||||

| Dry | Mean MOR (MPa) | 23.09 | Mean MOR (MPa) | 20.10 | Mean MOR (MPa) | 18.02 |

| COV | 0.175 | COV | 0.396 | COV | 0.398 | |

| Type of failure | c (100%) | Type of failure | b (20%) c (80%) | Type of failure | c (100%) | |

| Mean MOE (Mpa) | 10,665.4 | Mean MOE (Mpa) | 10,319.97 | Mean MOE (Mpa) | 9842.91 | |

| COV | 0.99 | COV | 0.056 | COV | 0.148 | |

| Green | Mean MOR (MPa) | 51.32 | Mean MOR (MPa) | 50.42 | Mean MOR (MPa) | 45.80 |

| COV | 0.158 | COV | 0.074 | COV | 0.109 | |

| Type of failure | a (25%) b (60%) c (15%) | Type of failure | a (30%) b (40%) c (30%) | Type of failure | a (50%); b (50%) | |

| Mean MOE (Mpa) | 11,151.88 | Mean MOE (Mpa) | 11,813.25 | Mean MOE (Mpa) | 11,771.55 | |

| COV | 0.126 | COV | 0.092 | COV | 0.182 | |

| Sample | Thickness of the Glued Line (µm) | Average Porosity (%) | Average Porosity in Glue Line (%) |

|---|---|---|---|

| Dry R/T | 340 ± 72.1 | 56.7 ± 0.79 | 13.7 |

| Green R/T | 341.3 ± 120.7 | 59.6 ± 0.33 | 11.3 |

| Dry R/R | 229 ± 63.7 | 70.7 ± 0.29 | 9.4 |

| Green R/R | 350 ± 55.7 | 50.2 ± 0.48 | 1.49 |

| Dry T/T | 187.7 ± 51.9 | 66.3 ± 0.23 | 6.07 |

| Green T/T | 247 ± 61.4 | 52.5 ± 1.41 | 7.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Grau, G.; Cordonnier, P.-L.; Navarrete, B.; Montero, C.; Alvarado, C.; Pommier, R.; Rosales, V.; Galarce, C. The Adhesion Performance in Green-Glued Finger Joints Using Different Wood Ring Orientations. Sustainability 2024, 16, 7158. https://doi.org/10.3390/su16167158

Rodríguez-Grau G, Cordonnier P-L, Navarrete B, Montero C, Alvarado C, Pommier R, Rosales V, Galarce C. The Adhesion Performance in Green-Glued Finger Joints Using Different Wood Ring Orientations. Sustainability. 2024; 16(16):7158. https://doi.org/10.3390/su16167158

Chicago/Turabian StyleRodríguez-Grau, Gonzalo, Pierre-Louis Cordonnier, Benjamín Navarrete, Claudio Montero, Claudia Alvarado, Régis Pommier, Víctor Rosales, and Carlos Galarce. 2024. "The Adhesion Performance in Green-Glued Finger Joints Using Different Wood Ring Orientations" Sustainability 16, no. 16: 7158. https://doi.org/10.3390/su16167158

APA StyleRodríguez-Grau, G., Cordonnier, P.-L., Navarrete, B., Montero, C., Alvarado, C., Pommier, R., Rosales, V., & Galarce, C. (2024). The Adhesion Performance in Green-Glued Finger Joints Using Different Wood Ring Orientations. Sustainability, 16(16), 7158. https://doi.org/10.3390/su16167158