Integrating Artificial Intelligence into the Supply Chain in Order to Enhance Sustainable Production—A Systematic Literature Review

Abstract

1. Introduction

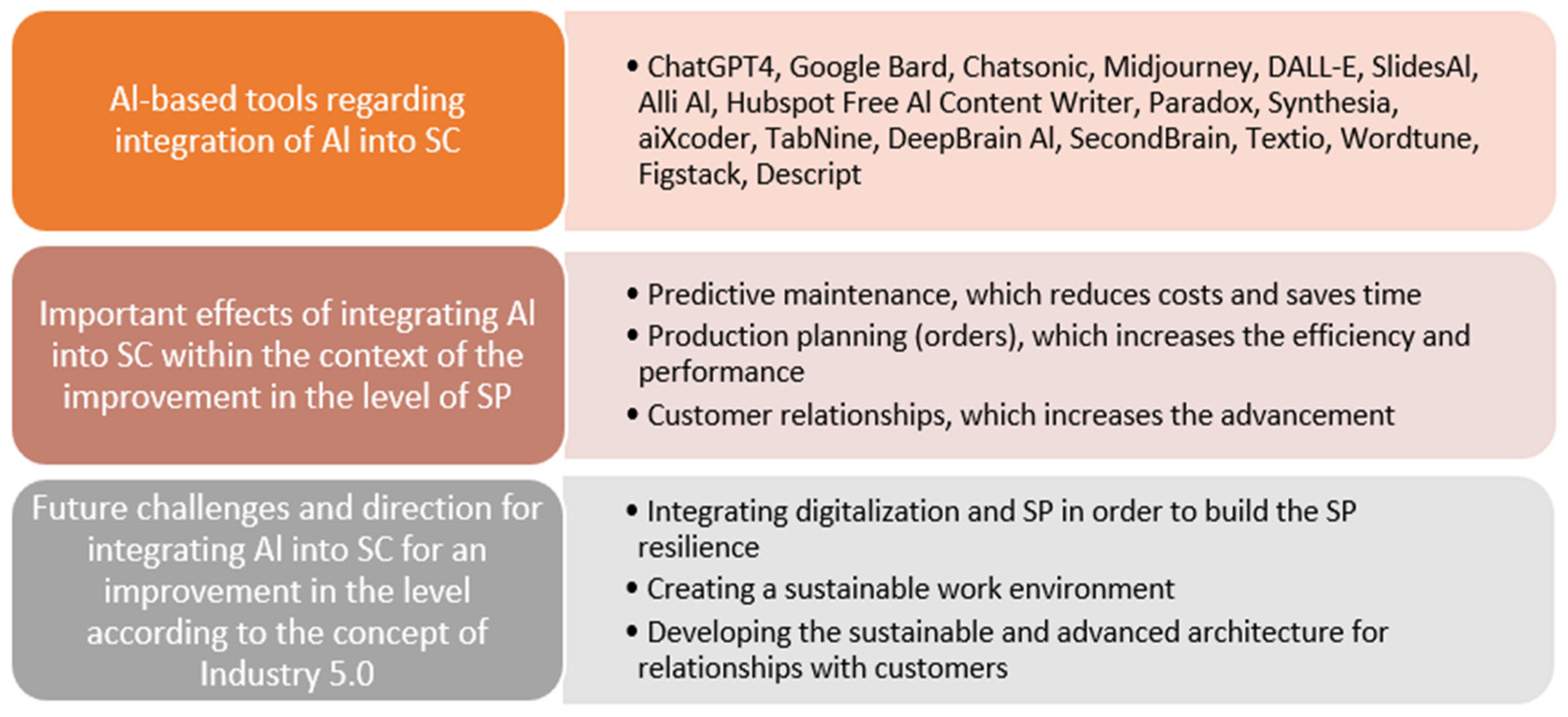

- RQ1: What type of AI-based methods and tools, according to the concept of Industry 5.0, were dominant in literature regarding the integration of AI into the SC?

- RQ2: When do the most important effects of integrating the AI into the SC in the context of the improvement of the level of SP occur?

- RQ3: What are the future challenges and direction for integrating AI into the SC for an improvement in the level of SP according to the concept of Industry 5.0?

2. Materials and Methods

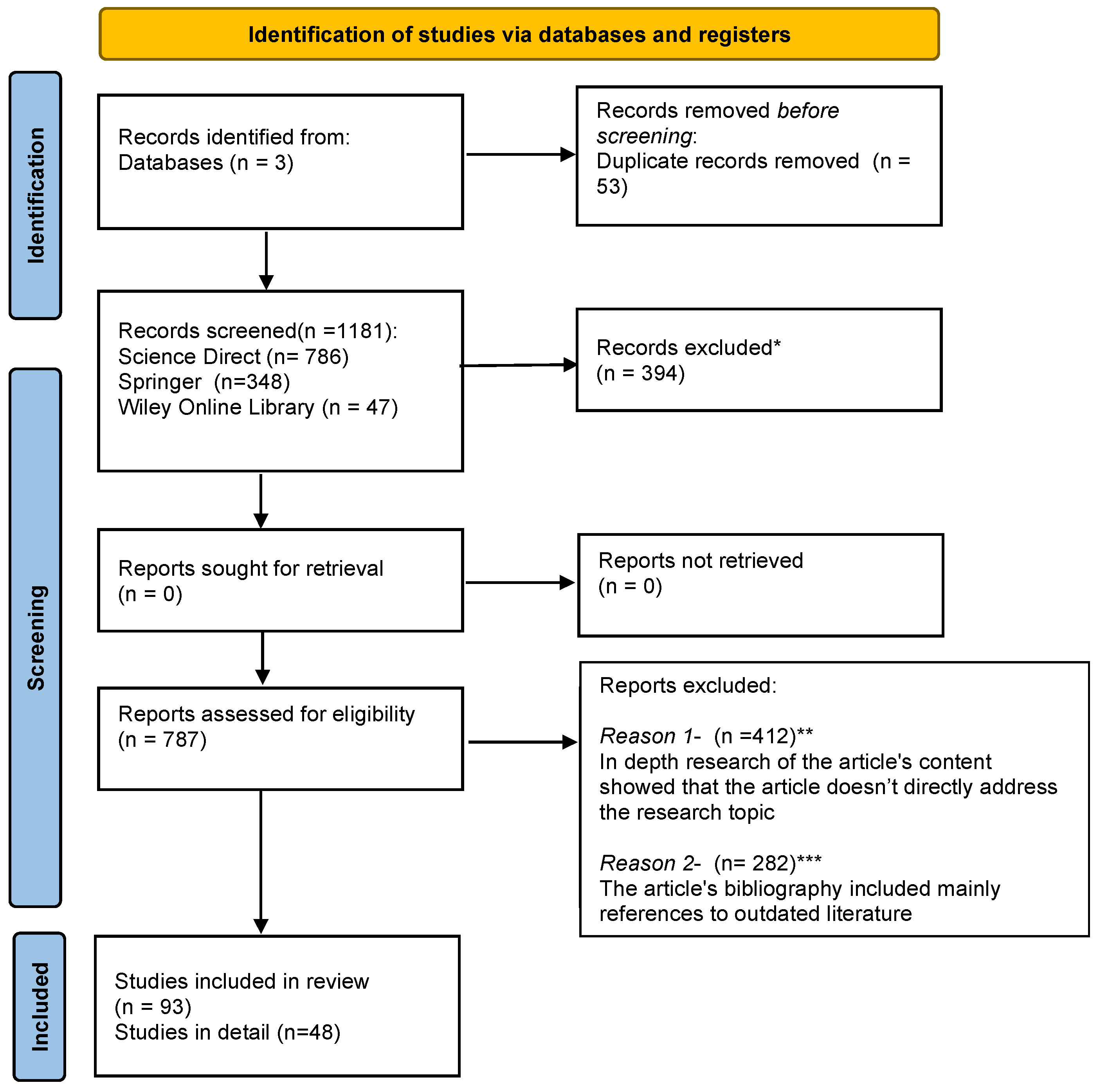

2.1. PRISMA Study Characteristics

- Step 1: Defining the research objective.

- Step 2: Carrying out the search process using identified databases, ultimately defining the final search strings and exclusion criteria.

- Step 3: Conducting the analysis, after a comprehensive process of the analysis of the content of selected literature items.

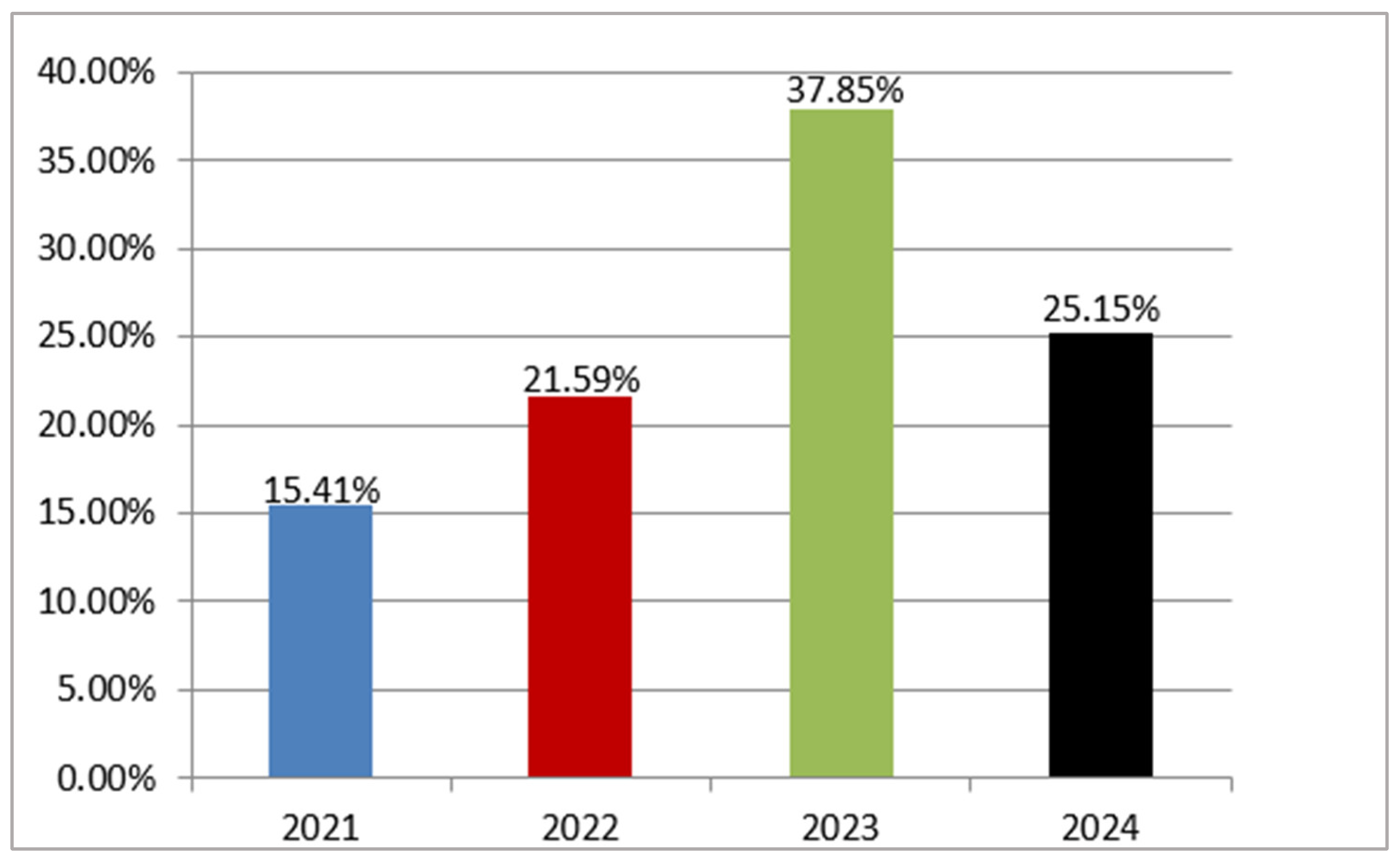

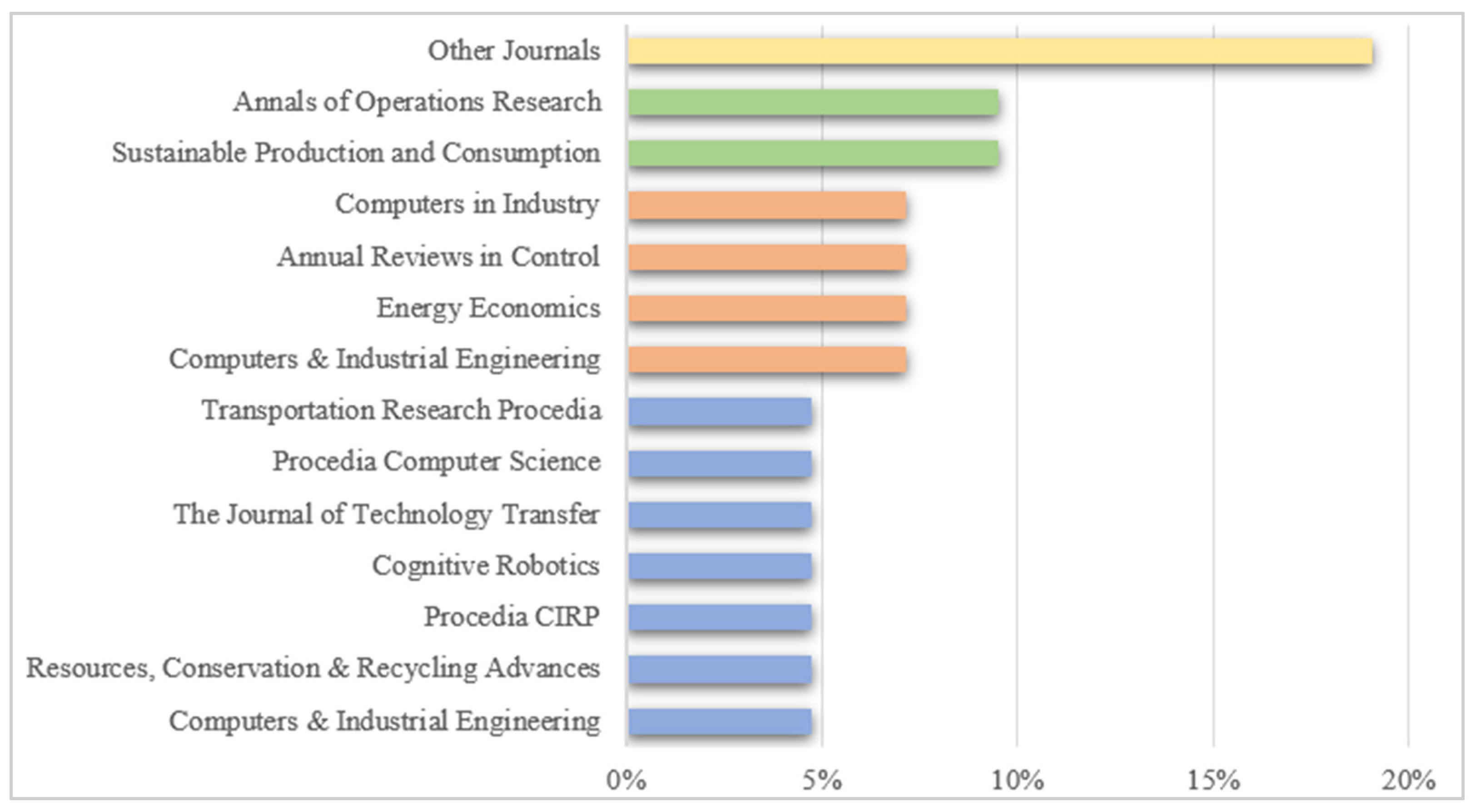

2.2. Quantitative Analysis of Selected Literature Items

- to QR1: AI in SC, AI-based methods and SC, AI-based tools and SC;

- to QR2: effects of integrating AI in SC, integrating AI in SC;

- to QR3: AI in SC, the impact of AI in SC on the level of SP.

2.3. Assessment of the Full Version of Texts in Terms of Quality

3. Results

- predictive maintenance, which reduces costs and saves time,

- production planning (orders), which increases efficiency and performance,

- customer relationships, which increases advancement.

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Literature Research Results

- Abirami Raja Santhi & Padmakumar Muthuswamy (2023), Industry 5.0 or industry 4.0S? Introduction to industry 4.0 and a peek into the prospective industry 5.0 technologies, International Journal on Interactive Design and Manufacturing (IJIDeM) Volume 17, pp. 947–979.

- Susana Garrido, Jorge Muniz Jr. Vagner Batista Ribeiro (2024), Operations Management, Sustainability & Industry 5.0: A critical analysis and future agenda, Cleaner Logistics and Supply Chain.

- Moin Khan, Abid Haleem, Mohd Javaid (2023), Changes and improvements in Industry 5.0: A strategic approach to overcome the challenges of Industry 4.0, Green Technologies and Sustainability, Volume 1, Issue 2.

- Morteza Ghobakhloo, Mohammad Iranmanesh, Muhammad Faraz Mubarak (2022), Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values, Sustainable Production and Consumption, Volume 33.

- Joaquín Ordieres-Meré, Miguel Gutierrez, Javier Villalba-Díez (2023), Toward the industry 5.0 paradigm: Increasing value creation through the robust integration of humans and machines, Computers in Industry, Volume 150.

- Weihua Liu, Yang He, Jingxin Dong &Yuenan Cao (2023), Disruptive technologies for advancing supply chain resilience, Frontiers of Engineering Management, Volume 10, pp. 360–366.

- Ying Li, Dakun Li, Yuyang Liu &Yongyi Shou (2023), Digitalization for supply chain resilience and robustness: The roles of collaboration and formal contracts, Frontiers of Engineering Management, Volume 10, pp. 5–19.

- Özge Albayrak Ünal, Burak Erkayman, Bilal Usanmaz (2023), Applications of Artificial Intelligence in Inventory Management: A Systematic Review of the Literature, Archives of Computational Methods in Engineering, Volume 30, pp. 2605–2625.

- Stefan Walter (2023), AI impacts on supply chain performance: a manufacturing use case study, Discover Artificial Intelligence, Volume 3, 18.

- Bill Cope, Mary Kalantzis, (2022), Artificial intelligence in the long view: from mechanical intelligence to cyber-social systems, Discover Artificial Intelligence, Volume 2,13.

- Bukhoree Sahoh, Anant Choksuriwong (2023), The role of explainable Artificial Intelligence in high-stakes decision-making systems: a systematic review, Volume 14, pages 7827–7843, Journal of Ambient Intelligence and Humanized Computing.

- Alim Al Ayub Ahmed, Arumugam Mahalakshmi, K. Arul Rajan, Joel Alanya-Beltran & Mohd (2023), Naved Integrated artificial intelligence effect on crisis management and lean production: structural equation modelling frame work, International Journal of System Assurance Engineering and Management, Volume 14, pp. 220–227.

- Anthony D. Scaife (2024), Improve predictive maintenance through the application of artificial intelligence: A systematic review, Results in Engineering, Volume 21.

- Mario Angos Mediavilla, Fabian Dietrich, Daniel Palm (2022), Review and analysis of artificial intelligence methods for demand forecasting in supply chain management, Procedia CIRP, Volume 107, pp. 1126–1131.

- Basim Aljabhan (2023), Economic strategic plans with supply chain risk management (SCRM) for organizational growth and development, Alexandria Engineering Journal, Volume 79, pp. 411–426.

- Mohsen Soori, Behrooz Arezoo, Roza Dastres (2023), Artificial intelligence, machine learning and deep learning in advanced robotics, a review, Cognitive Robotics, Volume 3, 2023, pp. 54–70.

- Subhajit Saha, Adel Fahad Alrasheedi, Md. Al-Amin Khan, Amalesh Kumar Manna (2023), Optimal strategies for green investment, sharing contract and advertisement effort in a supply chain coordination problem, Ain Shams Engineering Journal.

- Marek Pawlicki, Aleksandra Pawlicka, Rafał Kozik, Michał Choraś, Advanced insights through systematic analysis: Mapping future research directions and opportunities for xAI in deep learning and artificial intelligence used in cybersecurity, Neurocomputing, Volume 590, 2024, 127759, ISSN 0925-2312.

- István Mezgár, József Váncza (2022), From ethics to standards—A path via responsible AI to cyber-physical production systems, Annual Reviews in Control, Volume 53, pp. 391–404.

- Andrea Szalavetz (2022), The digitalisation of manufacturing and blurring industry boundaries, CIRP Journal of Manufacturing Science and Technology, Volume 37.

- Khlood Ahmad, Mohamed Abdelrazek, Chetan Arora, Arbind Agrahari Baniya, Muneera Bano, John Grundy (2023), Requirements engineering framework for human-centered artificial intelligence software systems, Applied Soft Computing, Volume 143.

- Gianclaudio Malgieri, Frank Pasquale (2024), Licensing high-risk artificial intelligence: Toward ex ante justification for a disruptive technology, Computer Law & Security Review, Volume 52.

- Juha Sipola, Minna Saunila, Juhani Ukko (2023), Adopting artificial intelligence in sustainable business, Journal of Cleaner Production, Volume 426.

- Kabita Das, Manaswini Pattanaik, SmitimayeeBasantia, Radhashyam Mishra, Debashreemayee Das, Kanhucharan Sahoo, BiswaranjanPaital (2023), Informatics on a social view and need of ethical interventions for wellbeing via interference of artificial intelligence, Telematics and Informatics Reports, Volume 11.

- Kiarash Sadeghi R., Divesh Ojha, Puneet Kaur, Raj V. Mahto, Amandeep Dhir (2024), Explainable artificial intelligence and agile decision-making in supply chain cyber resilience, Decision Support Systems, Volume 180.

- Morteza Ghobakhloo, Hannan AmoozadMahdiraji, Mohammad Iranmanesh& Vahid Jafari-Sadeghi, (2024), From Industry 4.0 Digital Manufacturing to Industry 5.0 Digital Society: a Roadmap Toward Human-Centric, Sustainable, and Resilient Production, Information Systems Frontiers.

- Sachin Modgil, Rohit Kumar Singh & Soni Agrawal (2023), Developing human capabilities for supply chains: an industry 5.0 perspective, Annals of Operations Research, 2023.

- Rahardjo, B., Wang, FK., Lo, SC. et al. (2023), A Sustainable Innovation Framework Based on Lean Six Sigma and Industry 5.0. Arabian Journal for Science and Engineering.

- Jiménez-Partearroyo, M., Medina-López, A. & Juárez-Varón, D. (2023), Towards industry 5.0: evolving the product-process matrix in the new paradigm. The Journal of Technology Transfer.

- Agrawal, S., Agrawal, R., Kumar, A. et al. (2023), Can industry 5.0 technologies overcome supply chain disruptions?—a perspective study on pandemics, war, and climate change issues, Operations Management Research.

- Kazancoglu, Y., Mangla, S.K., Berberoglu, Y. et al. (2023), Towards Industry 5.0 Challenges for The Textile and Apparel Supply Chain for The Smart, Sustainable, and Collaborative Industry in Emerging Economies. Information Systems Frontiers.

- Rana, J., Daultani, Y. (2023), Mapping the Role and Impact of Artificial Intelligence and Machine Learning Applications in Supply Chain Digital Transformation: A Bibliometric Analysis. Operations Management Research 16, pp. 1641–1666.

- Jiewu Leng, Xiaofeng Zhu, Zhiqiang Huang, Xingyu Li, Pai Zheng, Xueliang Zhou, Dimitris Mourtzis, Baicun Wang, Qinglin Qi, Haidong Shao, Jiafu Wan, Xin Chen, Lihui Wang, Qiang Liu (2024), Unlocking the power of industrial artificial intelligence towards Industry 5.0: Insights, pathways, and challenges, Journal of Manufacturing Systems, Volume 73, pp. 349–363.

- Xiaowen Wang, Mingyue Chen, Nanxu Chen (2024), How artificial intelligence affects the labour force employment structure from the perspective of industrial structure optimisation, Heliyon, Volume 10, Issue 5.

- Marta Daroń, Monika Górska (2023) Enterprises development in context of artificial intelligence usage in main processes, Procedia Computer Science, Volume 225, pp. 2214–2223.

- Stefan Walter (2023), Impacts of AI driven manufacturing processes on supply chains: the contributions of the knowlEdge project, Transportation Research Procedia, Volume 72, pp. 3443–3449.

- Tazim Ahmed, Chitra Lekha Karmaker, Sumaiya Benta Nasir, Md. Abdul Moktadir, Sanjoy Kumar Paul (2023), Modeling the artificial intelligence-based imperatives of industry 5.0 towards resilient supply chains: A post-COVID-19 pandemic perspective, Computers & Industrial Engineering, Volume 177.

- Hassan Alimam, Giovanni Mazzuto, Nicola Tozzi, Filippo Emanuele Ciarapica, Maurizio Bevilacqua (2023), The resurrection of digital triplet: A cognitive pillar of human-machine integration at the dawn of industry 5.0, Journal of King Saud University—Computer and Information Sciences, Volume 35, Issue 10.

- Mariia Golovianko, VaganTerziyan, Vladyslav Branytskyi, Diana Malyk (2023), Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid, Procedia Computer Science, Volume 217, pp. 102–113.

- Giovanni Francesco Massari, Raffaele Nacchiero, Ilaria Giannoccaro (2023), Digital technologies for resource loop redesign in circular supply chains: A systematic literature review, Resources, Conservation & Recycling Advances, Volume 20.

- Yufei Zhong, Xuesheng Chen, Zhixian Wang, Regina Fang-Ying Lin (2024), The nexus among artificial intelligence, supply chain and energy sustainability: A time-varying analysis, Energy Economics, Volume 132.

- Martijn Koot, Martijn R.K. Mes, Maria E. Lacob (2021), A systematic literature review of supply chain decision making supported by the Internet of Things and Big Data Analytics, Computers & Industrial Engineering, Volume 154.

- SospeterOlewe, Melina Finke, Julia Belke, Florian Dyck, Christian Kürpick (2023), Use Case Catalog and Assessment for AI Applications in Intralogistics of Manufacturing Companies, Procedia CIRP, Volume 118, pp. 74–79.

- Raj, R., Kumar, V. & Verma, P. (2023), Big data analytics in mitigating challenges of sustainable manufacturing supply chain. Operations Management Research 16, pp. 1886–1900.

- Alsolbi, I., Shavaki, F.H., Agarwal, R. et al. (2023), Big data optimisation and management in supply chain management: A systematic literature review. Artificial Intelligence Review, (Suppl 1), pp. 253–284.

- Alahmadi, D.H., Jamjoom, A.A. (2022), Decision support system for handling control decisions and decision-maker related to supply chain. Journal of Big Data 9, 114.

- Akbari, M., Hopkins, J.L. (2022), Digital technologies as enablers of supply chain sustainability in an emerging economy. Operations Management Research 15, pp. 689–710.

- Durugbo, C.M., Al-Balushi, Z. (2023), Supply chain management in times of crisis: A systematic review. Management Review Quarterly 73, pp. 1179–1235.

Appendix B

| Science Direct | Number of Articles |

| Ain Shams Engineering Journal | 1 |

| Alexandria Engineering Journal, Volume | 1 |

| Annual Reviews in Control | 1 |

| Applied Soft Computing | 1 |

| CIRP Journal of Manufacturing Science and Technology | 1 |

| Cleaner Logistics and Supply Chain | 1 |

| Computer Law & Security Review | 1 |

| Computers in Industry | 1 |

| Decision Support Systems | 1 |

| Energy Economics | 1 |

| Green Technologies and Sustainability | 1 |

| Heliyon | 1 |

| Journal of King Saud University—Computer and Information Sciences | 1 |

| Journal of Manufacturing Systems | 1 |

| Operations Management Research | 1 |

| Procedia CIRP | 1 |

| Procedia Computer Science | 1 |

| Resources, Conservation & Recycling Advances | 1 |

| Results in Engineering | 1 |

| Sustainable Production and Consumption | 1 |

| Telematics and Informatics Reports | 1 |

| Transportation Research Procedia | 1 |

| Cognitive Robotics | 2 |

| Computers & Industrial Engineering | 2 |

| Journal of Cleaner Production | 2 |

| Total | 28 |

| Springer | Number of articles |

| Annals of Operations Research | 1 |

| Arabian Journal for Science and Engineering | 1 |

| Archives of Computational Methods in Engineering | 1 |

| Artificial Intelligence Review springer | 1 |

| Computers & Industrial Engineering | 1 |

| International Journal of System Assurance Engineering and Management | 1 |

| International Journal on Interactive Design and Manufacturing | 1 |

| Journal of Ambient Intelligence and Humanized Computing | 1 |

| Procedia CIRP | 1 |

| The Journal of Technology Transfer | 1 |

| Discover Artificial Intelligence | 2 |

| Frontiers of Engineering Management | 2 |

| Information Systems Frontiers | 2 |

| Journal of Big Data | 2 |

| Operations Management Research | 2 |

| Total | 20 |

References

- Darko, E.O.; Vlachos, I. Creating Valuable Relationships with Third-Party Logistics (3PL) Providers: A Multiple-Case Study. Logistics 2022, 6, 38. [Google Scholar] [CrossRef]

- European Commission, Publication Office of European Union, Brussel. Industry 5.0. Towards a Sustainable, Humancentric and Resilient European Industry; European Commission: Brussels, Belgium, 2021; pp. 8–9. [Google Scholar]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: Anemerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; Min, H.; Munim, Z.H. The role of artificial intelligence in supply chain management: Mapping the territory. Int. J. Prod. Res. 2022, 60, 7527–7550. [Google Scholar] [CrossRef]

- Jung, D.; Choi, Y. Systematic review of machine learning applications in mining: Exploration, exploitation, and reclamation. Minerals 2021, 1, 148. [Google Scholar] [CrossRef]

- Narkhede, P.; Walambe, R.; Mandaokar, S.; Chandel, P.; Kotecha, K.; Ghinea, G. Gas detection and identification using multimodal artificial intelligence based sensor fusion. Appl. Syst. Innov. 2021, 4, 3. [Google Scholar] [CrossRef]

- Diaz, R.; Ungoa, R.; Smithb, K.; Haghnegahdara, L.; Singha, B.; Phuonga, T. 5th International Conference on Industry 4.0 and Smart Manufacturing Applications of AI /ML in Maritime Cyber Supply Chains. Procedia Comput. Sci. 2024, 232, 3247–3325. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Z.; Zhao, R. From Fiction to Fact: The Growing Role of Generative AI in Business and Finance. J. Chin. Econ. Bus. Stud. 2023, 21, 471–496. [Google Scholar] [CrossRef]

- Topuz, K.; Zengul, F.D.; Dag, A.; Almehmi, A.; Yildirim, M.B. Predicting graft survival among kidney transplant recipients: A Bayesian decision support model. Decis. Support. Syst. 2018, 106, 97–109. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Choi, T.M.; Kumar, A.; Antony, J. Influences of artificial intelligence and blockchain technology on financial resilience of supply chains. Int. J. Prod. Econ. 2023, 261, 108868. [Google Scholar] [CrossRef]

- Akram, M.W.; Akram, N.; Shahzad, F.; Rehman, K.U.; Andleeb, S. Blockchain technology in a crisis: Advantages, challenges, and lessons learned for enhancing food supply chains during the COVID-19 pandemic. J. Clean. Prod. 2024, 434, 140034. [Google Scholar] [CrossRef]

- Zechiel, F.; Blaurock, M.; Weber, E.; Büttgen, M.; Coussement, K. How tech companies advance sustainability through artificial intelligence: Developing and evaluating an AI x Sustainability strategy framework. Ind. Mark. Manag. 2024, 119, 75–89. [Google Scholar] [CrossRef]

- Mehmood, M.U.; Chun, D.; Han, H.; Jeon, G.; Chen, K. A review of the applications of artificial intelligence and big data to buildings for energy-efficiency and a comfortable indoor living environment. Energy Build. 2019, 202, 109383. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Łosyk, H. Changes in Sustainable Development in Manufacturing in Cases of Unexpected Occurrences—A Systematic Review. Sustainability 2024, 16, 717. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.; Dulebenets, M. Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef] [PubMed]

- Raj, A.; Mukherjee, A.; Lopes de Sousa Jabbour, A.; Srivastava, S. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef]

- Kühner, C.; Stein, M.; Zacher, H. A person-environment fit approach to environmental sustainability in the workplace. J. Environ. Psychol. 2024, 95, 102270. [Google Scholar] [CrossRef]

- Li, F.; Xu, G. AI-driven customer relationship management for sustainable enterprise performance. Sustain. Energy Technol. Assess. 2022, 52 Pt B, 102103. [Google Scholar] [CrossRef]

- Barmer, H.; Dzombak, R.; Gaston, M.; Palat, V.; Redner, F.; Smith, C.; Smith, T. Human-Centered AI. SEI White Paper. 2021. Available online: https://kilthub.cmu.edu/articles/report/Human-Centered_AI/16560183/1?file=30632667 (accessed on 11 July 2024).

- Maternowska, M. Nowe technologie i ich wpływ Na łańcuchy dostaw. Sztuczna inteligencja. In Studia Ekonomiczne; Zeszyty Naukowe Uniwersytetu Ekonomicznego w Katowicach: Katowice, Poland, 2019; Volume 388. [Google Scholar]

- Raman, R.; Sreenivasan, A.; Ma, S.; Patwardhan, A.; Nedungadi, P. Green Supply Chain Management Research Trends and Linkages to UN Sustainable Development Goals. Sustainability 2023, 15, 15848. [Google Scholar] [CrossRef]

- Walter, S. Impacts of AI driven manufacturing processes on supply chains: The contributions of the knowledge project. Transp. Res. Procedia 2023, 72, 3443–3449, ISSN 2352-1465. [Google Scholar] [CrossRef]

- Nikolakis, N.; Sipsas, K.; Makris, K. A cyber-physicalcontext-aware system for coordinating human-robot collaboration.51st CIRP Conference on Manufacturing Systems. Procedia CIRP 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Wang, L.; Gao, R.; Vancza, J.; Kruger, J.; Wang, X.V.; Makris, S.; Chryssolouris, G. Symbiotichuman-robot collaborative assembly. CIRP Ann. 2019, 68, 701–726. [Google Scholar] [CrossRef]

- Almusaed, A.; Yitmen, I.; Almssad, A. Reviewing and Integrating AEC Practices into Industry 6.0: Strategies for Smart and Sustainable Future-Built Environments. Sustainability 2023, 15, 13464. [Google Scholar] [CrossRef]

- Ivanov, D. Structural Dynamics and Resilience in Supply Chain Risk Management; Springer: New York, NY, USA, 2018. [Google Scholar]

- Ivanov, D. Two views of supply chain resilience. Int. J. Prod. Res. 2023, 62, 4031–4045. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B. Control and system-theoretic identification of the supply chain dynamics domain for planning, analysis and adaptation of performance under uncertainty. Eur. J. Oper. Res. 2013, 224, 313–323. [Google Scholar] [CrossRef]

- Fabbe-Costes, N.; Ziad, Y. Improving Supply Chain Robustness & Resilience. Lessons from a case study in the automotive industry during the first wave of COVID-19. In Proceedings of the 28th EurOMA Conference, University of Sussex, Sussex, UK; Berlin, Germany, 5–7 July 2021. [Google Scholar]

| No. | Thematic Scope | Yes | No |

|---|---|---|---|

| 1 | Impact of AI in SC on the level of SP | ||

| 2 | Optimal AI solutions in SC | ||

| 3 | A resilient SC and the effects of AI solutions | ||

| 4 | Benefits and opportunities of AI | ||

| 5 | AI-based methods and SC |

| Source (Appendix A) | Tools and Methods | The Impact of AI in SC on the Level of SP |

|---|---|---|

| 1 | review | Yes |

| 2 | review | Yes |

| 3 | review | Yes |

| 4 | interpretive structural modelling technique | Yes |

| 5 | integrated system for traceability of operations over time, semantic network of things, IoT, intelligent CPS, LAsim Smart FActor Plus reference framework | Yes |

| 6 | IoT, blockchain | Yes |

| 7 | blockchain, digitalisation, convenience sampling method, standardised mean square root residual | No |

| 8 | review | Yes |

| 9 | distributed data analytics, embedded computing, IoT, CPS, software engineering, edge and Cloud technologies | Yes |

| 10 | - | No |

| 11 | review | No |

| 12 | lean maintenance, lean manufacturing | No |

| 13 | review | No |

| 14 | review | Yes |

| 15 | ML (ALRC) | Yes |

| 16 | review | Yes |

| 17 | mathematical formulation for own model | Yes |

| 18 | review | Yes |

| 19 | CPPS | Yes |

| 20 | digitization, IoT | No |

| 21 | review | No |

| 22 | ChatGPT | No |

| 23 | HR systems support, NN | No |

| 24 | intelligent identification, ANAFIS, genetic algorithms, hidden Markov models | No |

| 25 | digitisation, XAI | Yes |

| 26 | HRM, Cloud manufacturing, IoT, predictive analytics, DT | Yes |

| 27 | - | Yes |

| 28 | IoE, Cobots, Smart sensors, 3Dprinting | Yes |

| 29 | DT, IoT | No |

| 30 | ML, DL, Collaborative Robots, tracking technology, blockchain, DT | No |

| 31 | IoS, CPS, Big Data Analytics, DM, Blockchain, AR, Cobots | Yes |

| 32 | ML, bibliometric, IoT | Yes |

| 33 | Cobots, ML, intelligent algorithms | Yes |

| 34 | Cloud computing | No |

| 35 | statistical methods, data | |

| 36 | distributed data analytics, embedded computing, IoT, CPS | |

| 37 | Bayesian Best Worst Method | No |

| 38 | review | Yes |

| 39 | Digital cognitive clones | Yes |

| 40 | review | Yes |

| 41 | TVP-SV-VAR methodology | No |

| 42 | IoT | No |

| 43 | questionnaire, OMEGA method | No |

| 44 | Big Data Analytics, AHP, GRA methodology | Yes |

| 45 | review | No |

| 46 | ontological model, MATLAB, JAVA, IoT | Yes |

| 47 | survey | Yes |

| 48 | review | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patalas-Maliszewska, J.; Szmołda, M.; Łosyk, H. Integrating Artificial Intelligence into the Supply Chain in Order to Enhance Sustainable Production—A Systematic Literature Review. Sustainability 2024, 16, 7110. https://doi.org/10.3390/su16167110

Patalas-Maliszewska J, Szmołda M, Łosyk H. Integrating Artificial Intelligence into the Supply Chain in Order to Enhance Sustainable Production—A Systematic Literature Review. Sustainability. 2024; 16(16):7110. https://doi.org/10.3390/su16167110

Chicago/Turabian StylePatalas-Maliszewska, Justyna, Małgorzata Szmołda, and Hanna Łosyk. 2024. "Integrating Artificial Intelligence into the Supply Chain in Order to Enhance Sustainable Production—A Systematic Literature Review" Sustainability 16, no. 16: 7110. https://doi.org/10.3390/su16167110

APA StylePatalas-Maliszewska, J., Szmołda, M., & Łosyk, H. (2024). Integrating Artificial Intelligence into the Supply Chain in Order to Enhance Sustainable Production—A Systematic Literature Review. Sustainability, 16(16), 7110. https://doi.org/10.3390/su16167110