Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition

Abstract

1. Introduction

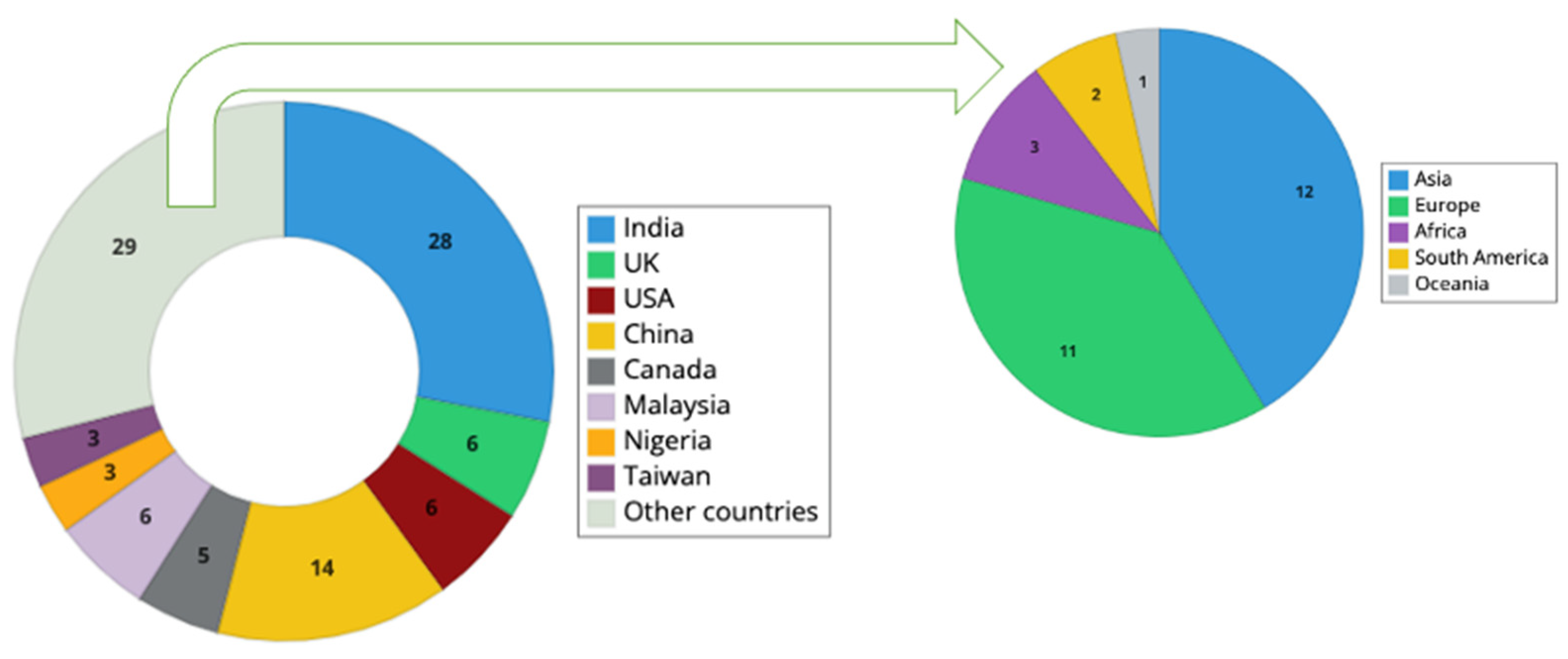

2. Methodology

3. Results

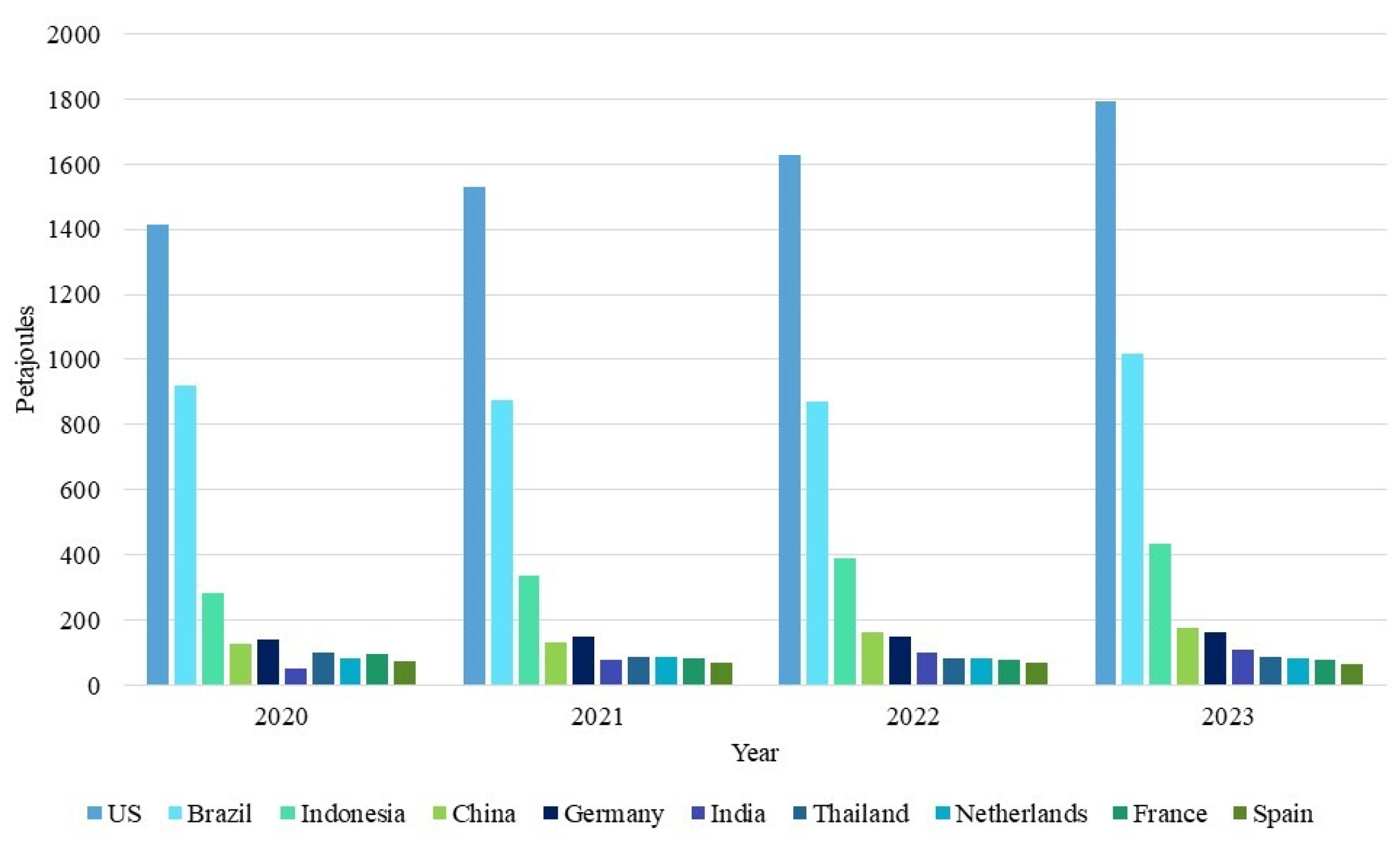

3.1. Current Status of Renewable Energy Sources

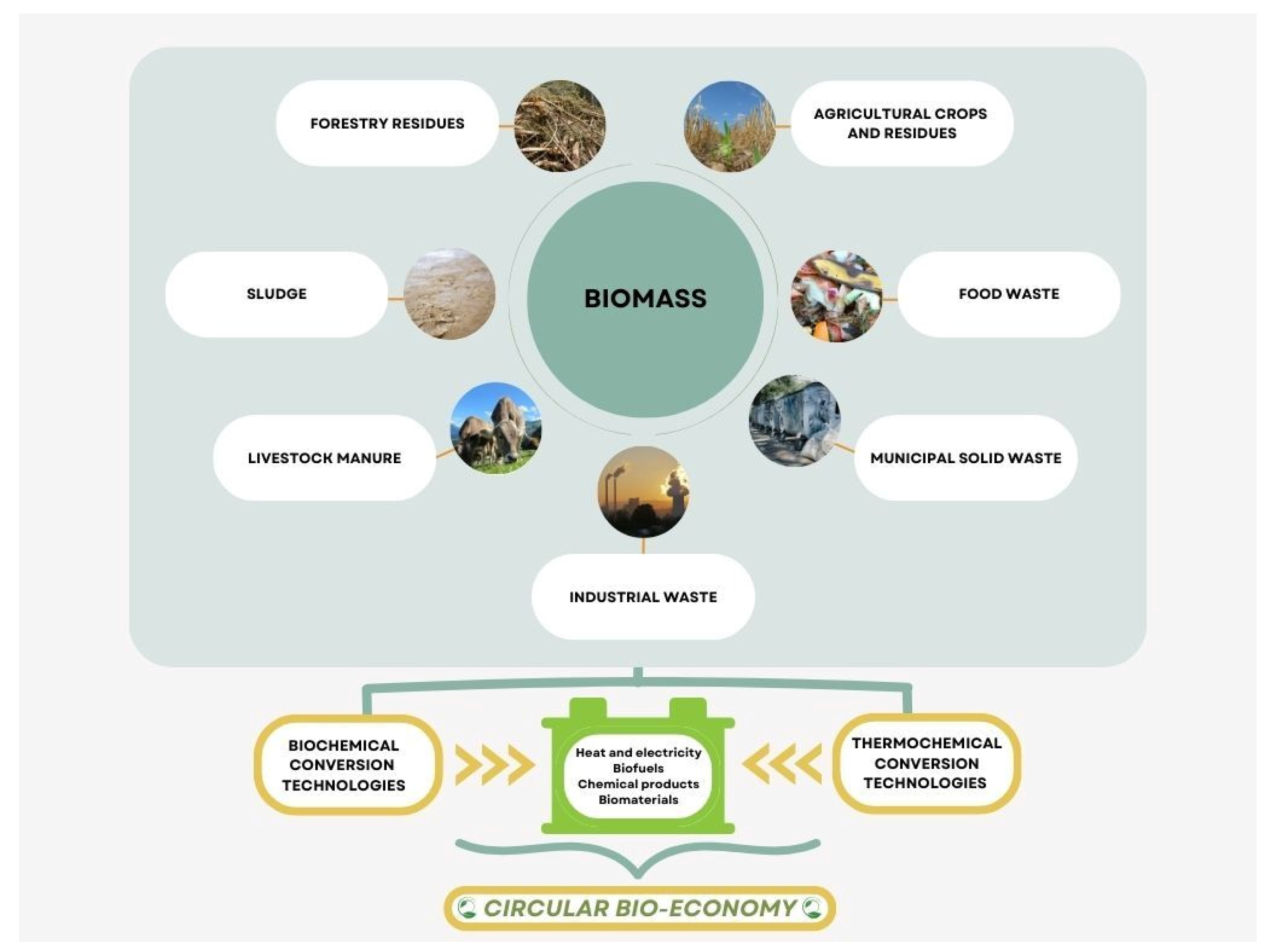

3.2. Recovery of Products from Biomass

4. Biofuels: Alternative to Conventional Energy Sources

4.1. First Generation Biofuels

4.2. Second Generation Biofuels

4.3. Third Generation Biofuels

4.4. Fourth Generation Biofuels

4.5. Impact and Prospects of Biofuels

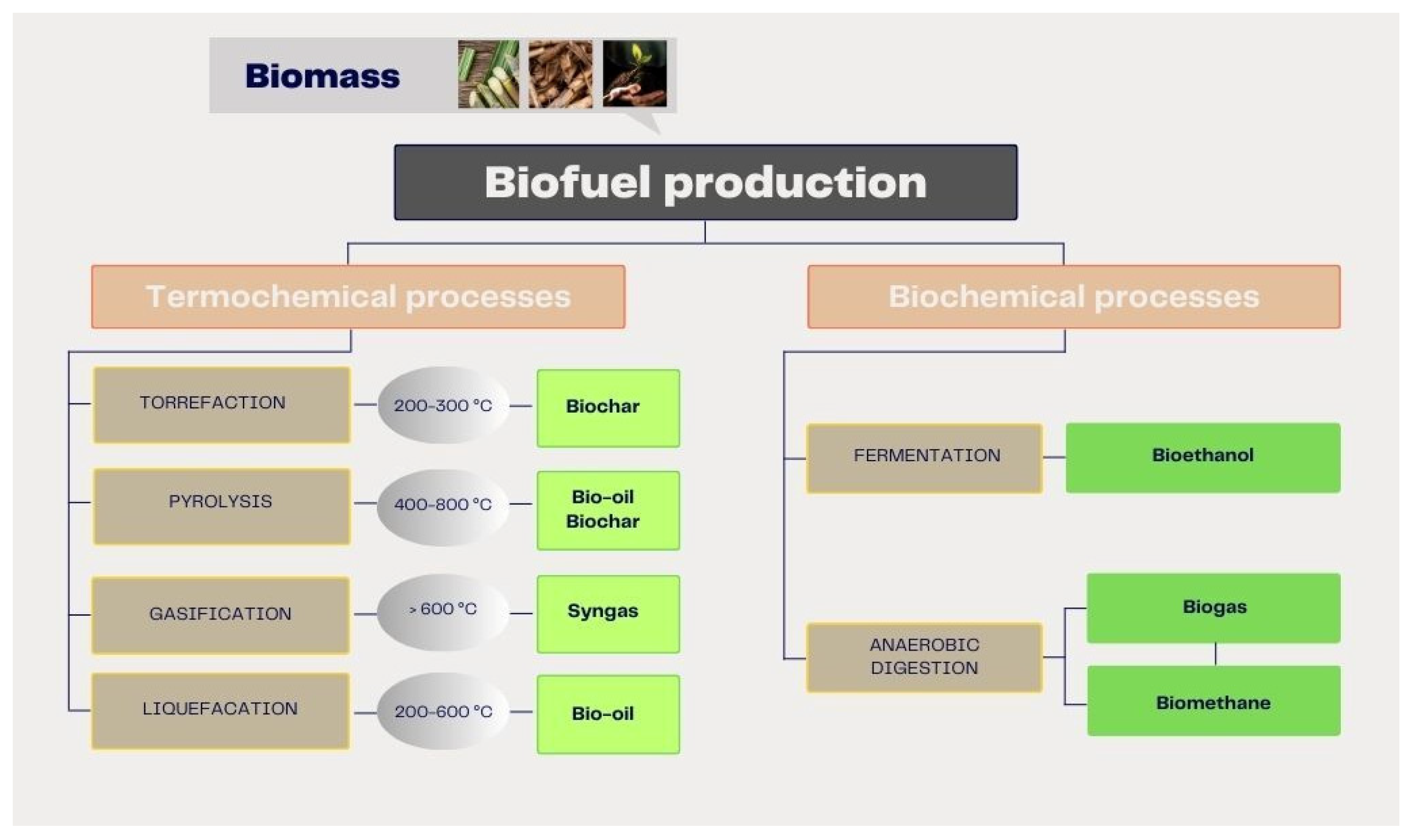

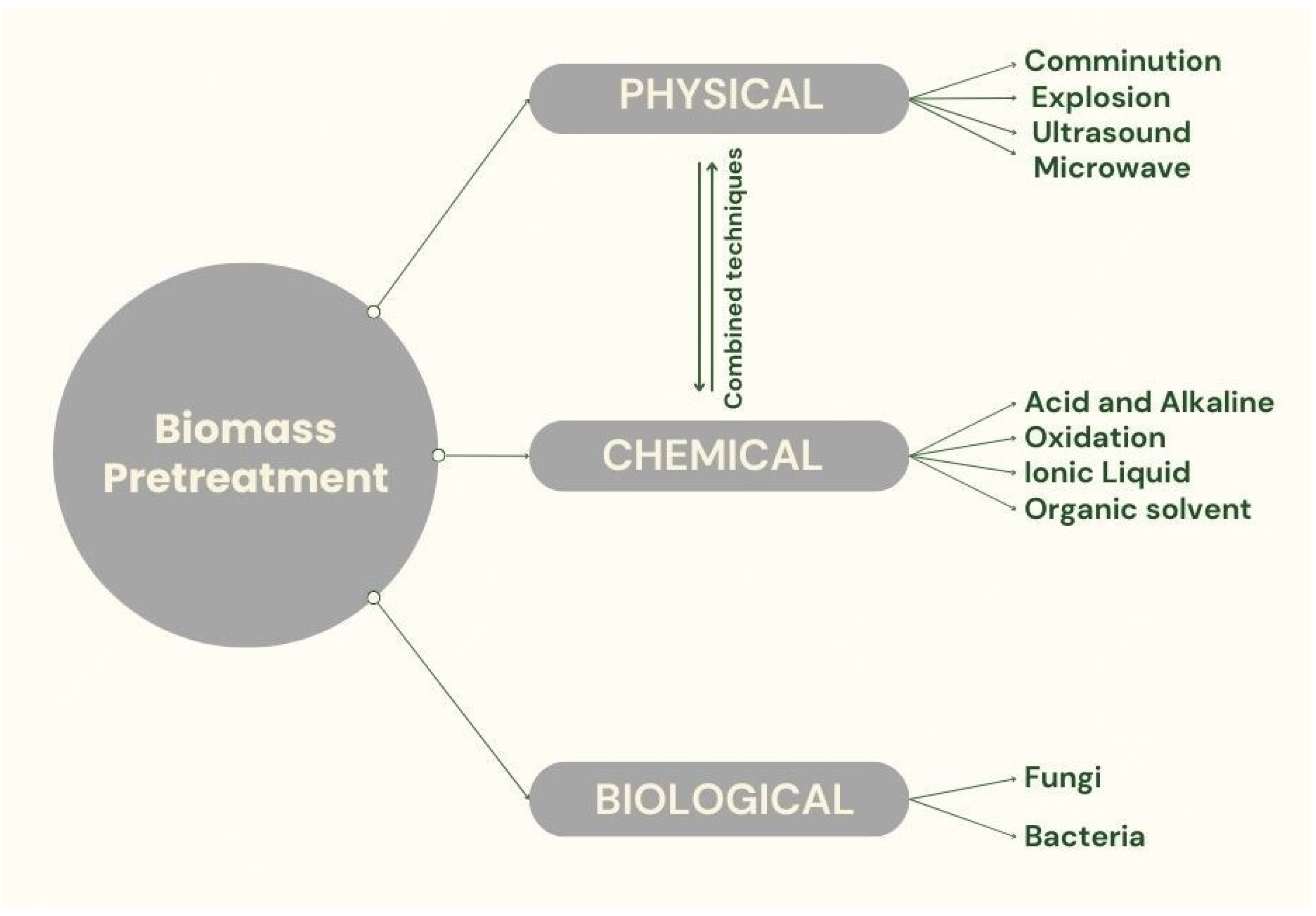

5. Biofuel Production Processes

5.1. Thermochemical Conversion Processes

5.1.1. Torrefaction

5.1.2. Pyrolysis

5.1.3. Hydrothermal Liquefaction

5.1.4. Gasification

5.2. Biochemical Conversion Processes

5.2.1. Fermentation

5.2.2. Anaerobic Digestion

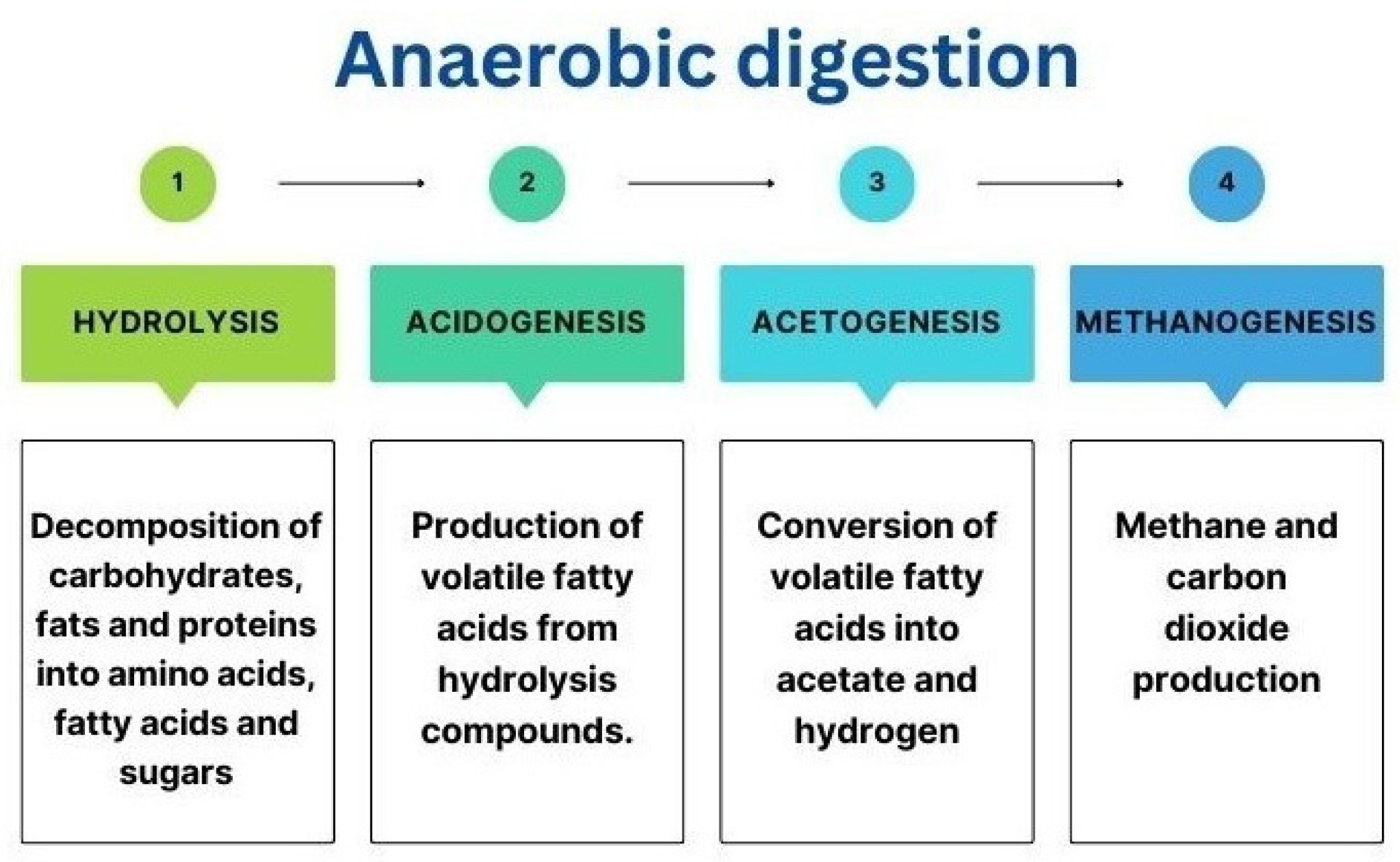

5.2.3. Economic and Sustainability Future Perspectives

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaloudas, D.; Pavlova, N.; Penchovsky, R. Lignocellulose, Algal Biomass, Biofuels and Biohydrogen: A Review. Environ. Chem. Lett. 2021, 19, 2809–2824. [Google Scholar] [CrossRef]

- Bhanuprakasha, P.; Babua, T.H.; Ramakrishnab, S.; Ramesha, A. Need to Shift towards Clean, Reliable, Accessible and Affordable Renewable Energy Resources for a Sustainable Future. In Proceedings of the Pollution Control and Sustainable Environment, New Delhi, India, 27 November 2023; pp. 24–25. [Google Scholar]

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Stančin, H.; Mikulčić, H.; Wang, X.; Duić, N. A Review on Alternative Fuels in Future Energy System. Renew. Sustain. Energy Rev. 2020, 128, 109927. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E.; Akincza, M. Bioenergy Technologies and Biomass Potential Vary in Northern European Countries. Renew. Sustain. Energy Rev. 2020, 133, 110238. [Google Scholar] [CrossRef]

- Igwebuike, C.M.; Awad, S.; Andrès, Y. Renewable Energy Potential: Second-Generation Biomass as Feedstock for Bioethanol Production. Molecules 2024, 29, 1619. [Google Scholar] [CrossRef] [PubMed]

- Alper, K.; Tekin, K.; Karagöz, S.; Ragauskas, A.J. Sustainable Energy and Fuels from Biomass: A Review Focusing on Hydrothermal Biomass Processing. Sustain. Energy Fuels 2020, 4, 4390–4414. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Saini, A.K.; Saini, V.; Pareek, B.; Gaidukovs, S.; Thakur, V.K. Recovery Processes of Sustainable Energy Using Different Biomass and Wastes. TIDEE TERI Inf. Dig. Energy Environ. 2022, 21, 162–163. [Google Scholar] [CrossRef]

- Sertolli, A.; Gabnai, Z.; Lengyel, P.; Bai, A. Biomass Potential and Utilization in Worldwide Research Trends—A Bibliometric Analysis. Sustainability 2022, 14, 5515. [Google Scholar] [CrossRef]

- Shahbaz, M.; AlNouss, A.; Ghiat, I.; Mckay, G.; Mackey, H.; Elkhalifa, S.; Al-Ansari, T. A Comprehensive Review of Biomass Based Thermochemical Conversion Technologies Integrated with CO2 Capture and Utilisation within BECCS Networks. Resour. Conserv. Recycl. 2021, 173, 105734. [Google Scholar] [CrossRef]

- Moodley, P. Sustainable Biofuels: Opportunities and Challenges. Sustain. Biofuels 2021, 1–20. [Google Scholar] [CrossRef]

- Candra, O.; Chammam, A.; Alvarez, J.R.N.; Muda, I.; Aybar, H.Ş. The Impact of Renewable Energy Sources on the Sustainable Development of the Economy and Greenhouse Gas Emissions. Sustainability 2023, 15, 2104. [Google Scholar] [CrossRef]

- Fushimi, C. Valorization of Biomass Power Generation System: Noble Use of Combustion and Integration with Energy Storage. Energy Fuels 2021, 35, 3715–3730. [Google Scholar] [CrossRef]

- Ahmad, L.; Khordehgah, N.; Malinauskaite, J.; Jouhara, H. Recent Advances and Applications of Solar Photovoltaics and Thermal Technologies. Energy 2020, 207, 118254. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental Impact of Renewable Energy Source Based Electrical Power Plants: Solar, Wind, Hydroelectric, Biomass, Geothermal, Tidal, Ocean, and Osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Waste-to-Energy Nexus for Circular Economy and Environmental Protection: Recent Trends in Hydrogen Energy. Sci. Total Environ. 2020, 713, 136633. [Google Scholar] [CrossRef] [PubMed]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable Energy and Energy Storage Systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Naveen, S.; Aravind, S.; Yamini, B.; Vasudhareni, R.; Gopinath, K.P.; Arun, J.; Pugazhendhi, A. A Review on Solar Energy Intensified Biomass Valorization and Value-Added Products Production: Practicability, Challenges, Techno Economic and Lifecycle Assessment. J. Clean. Prod. 2023, 405, 137028. [Google Scholar] [CrossRef]

- Freires, F.J.; Damasceno, V.d.N.; Machado, A.L.S.; Martins, G.B.; Silva, L.M.d.; Pio, M.C.d.S.; Júnior, L.H.C.; Sales, D.C.; Reis, A.G.; Nascimento-e-Silva, D. Advantages and Disadvantages of Renewable Energy: A Review of the Scientific Literature. Rev. Gestão Secr. 2023, 14, 20221–20240. [Google Scholar] [CrossRef]

- Gayen, D.; Chatterjee, R.; Roy, S. A Review on Environmental Impacts of Renewable Energy for Sustainable Development. Int. J. Environ. Sci. Technol. 2024, 21, 5285–5310. [Google Scholar] [CrossRef]

- Majeed, Y.; Khan, M.U.; Waseem, M.; Zahid, U.; Mahmood, F.; Majeed, F.; Sultan, M.; Raza, A. Renewable Energy as an Alternative Source for Energy Management in Agriculture. Energy Rep. 2023, 10, 344–359. [Google Scholar] [CrossRef]

- Electricity—Renewables 2023—Analysis. Available online: https://www.iea.org/reports/renewables-2023/electricity (accessed on 16 June 2024).

- Jain, D. Renewable Energy: Powering a Safer Future. Renew. Energy 2020, 1, 429–434. [Google Scholar]

- Dogan, M.S.; Medellin-Azuara, J.; Lund, J.R. Hydropower Reservoir Optimization with Solar Generation-Changed Energy Prices in California. Water Resour. Manag. 2024, 38, 2135–2153. [Google Scholar] [CrossRef]

- Premalatha, N.; Saranya, S.R. Global Research Trends in Biomass as Renewable Energy. In Biomass Energy for Sustainable Development; CRC Press: Boca Raton, FL, USA, 2024; pp. 355–374. ISBN 978-1-00-340650-1. [Google Scholar]

- Zafar, M.W.; Sinha, A.; Ahmed, Z.; Qin, Q.; Zaidi, S.A.H. Effects of Biomass Energy Consumption on Environmental Quality: The Role of Education and Technology in Asia-Pacific Economic Cooperation Countries. Renew. Sustain. Energy Rev. 2021, 142, 110868. [Google Scholar] [CrossRef]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Berruti, F.; Kozinski, J.A. A Review on Subcritical and Supercritical Water Gasification of Biogenic, Polymeric and Petroleum Wastes to Hydrogen-Rich Synthesis Gas. Renew. Sustain. Energy Rev. 2020, 119, 109546. [Google Scholar] [CrossRef]

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemeš, J.J. Torrefied Biomass Fuels as a Renewable Alternative to Coal in Co-Firing for Power Generation. Energy 2020, 209, 118444. [Google Scholar] [CrossRef]

- Farghali, M.; Osman, A.I.; Chen, Z.; Abdelhaleem, A.; Ihara, I.; Mohamed, I.M.A.; Yap, P.-S.; Rooney, D.W. Social, Environmental, and Economic Consequences of Integrating Renewable Energies in the Electricity Sector: A Review. Environ. Chem. Lett. 2023, 21, 1381–1418. [Google Scholar] [CrossRef]

- Mohaghegh, M.R.; Heidari, M.; Tasnim, S.; Dutta, A.; Mahmud, S. Latest Advances on Hybrid Solar–Biomass Power Plants. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–24. [Google Scholar] [CrossRef]

- Hassan, Q.; Al-Musawi, T.J.; Algburi, S.; Al-Razgan, M.; Awwad, E.M.; Viktor, P.; Ahsan, M.; Ali, B.M.; Jaszczur, M.; Kalaf, G.A. Evaluating Energy, Economic, and Environmental Aspects of Solar-Wind-Biomass Systems to Identify Optimal Locations in Iraq: A GIS-Based Case Study. Energy Sustain. Dev. 2024, 79, 101386. [Google Scholar] [CrossRef]

- Modu, B.; Abdullah, M.P.; Bukar, A.L.; Hamza, M.F.; Adewolu, M.S. Operational Strategy and Capacity Optimization of Standalone Solar-Wind-Biomass-Fuel Cell Energy System Using Hybrid LF-SSA Algorithms. Int. J. Hydrogen Energy 2024, 50, 92–106. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Paraschiv, S. Contribution of Renewable Energy (Hydro, Wind, Solar and Biomass) to Decarbonization and Transformation of the Electricity Generation Sector for Sustainable Development. Energy Rep. 2023, 9, 535–544. [Google Scholar] [CrossRef]

- Li, J.; Liu, P.; Li, Z. Optimal Design and Techno-Economic Analysis of a Solar-Wind-Biomass off-Grid Hybrid Power System for Remote Rural Electrification: A Case Study of West China. Energy 2020, 208, 118387. [Google Scholar] [CrossRef]

- Wieruszewski, M.; Mydlarz, K. The Potential of the Bioenergy Market in the European Union—An Overview of Energy Biomass Resources. Energies 2022, 15, 9601. [Google Scholar] [CrossRef]

- Qian, X.; Xue, J.; Yang, Y.; Lee, S.W. Thermal Properties and Combustion-Related Problems Prediction of Agricultural Crop Residues. Energies 2021, 14, 4619. [Google Scholar] [CrossRef]

- Prasad, S.; Yadav, K.K.; Kumar, S.; Pandita, P.; Bhutto, J.K.; Alreshidi, M.A.; Ravindran, B.; Yaseen, Z.M.; Osman, S.M.; Cabral-Pinto, M.M.S. Review on Biofuel Production: Sustainable Development Scenario, Environment, and Climate Change Perspectives − A Sustainable Approach. J. Environ. Chem. Eng. 2024, 12, 111996. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A.; Bassyouni, M.; Abdel-Hamid, S.M.S.; Ahmed, H.S.; Abdel-Aziz, M.H.; Zoromba, M.S.; Elhenawy, Y. Theoretical Investigation of Vapor Transport Mechanism Using Tubular Membrane Distillation Module. Membranes 2021, 11, 560. [Google Scholar] [CrossRef]

- Kumar, B.; Verma, P. Biomass-Based Biorefineries: An Important Architype towards a Circular Economy. Fuel 2021, 288, 119622. [Google Scholar] [CrossRef]

- Yu, S.; Sun, J.; Shi, Y.; Wang, Q.; Wu, J.; Liu, J. Nanocellulose from Various Biomass Wastes: Its Preparation and Potential Usages towards the High Value-Added Products. Environ. Sci. Ecotechnol. 2021, 5, 100077. [Google Scholar] [CrossRef]

- Parvez, A.M.; Lewis, J.D.; Afzal, M.T. Potential of Industrial Hemp (Cannabis sativa L.) for Bioenergy Production in Canada: Status, Challenges and Outlook. Renew. Sustain. Energy Rev. 2021, 141, 110784. [Google Scholar] [CrossRef]

- Ren, X.; Shanb Ghazani, M.; Zhu, H.; Ao, W.; Zhang, H.; Moreside, E.; Zhu, J.; Yang, P.; Zhong, N.; Bi, X. Challenges and Opportunities in Microwave-Assisted Catalytic Pyrolysis of Biomass: A Review. Appl. Energy 2022, 315, 118970. [Google Scholar] [CrossRef]

- Almagro-Herrera, N.; Lozano-Calvo, S.; Palma, A.; García, J.C.; Díaz, M.J. Assessing the Influence of Biomass Origin and Fractionation Methods on Pyrolysis of Primary Biomass Fractions. Fuel 2024, 367, 131501. [Google Scholar] [CrossRef]

- Rozzi, E.; Minuto, F.D.; Lanzini, A.; Leone, P. Green Synthetic Fuels: Renewable Routes for the Conversion of Non-Fossil Feedstocks into Gaseous Fuels and Their End Uses. Energies 2020, 13, 420. [Google Scholar] [CrossRef]

- Yana, S.; Nizar, M.; Irhamni; Mulyati, D. Biomass Waste as a Renewable Energy in Developing Bio-Based Economies in Indonesia: A Review. Renew. Sustain. Energy Rev. 2022, 160, 112268. [Google Scholar] [CrossRef]

- Arpia, A.A.; Chen, W.H.; Lam, S.S.; Rousset, P.; de Luna, M.D.G. Sustainable Biofuel and Bioenergy Production from Biomass Waste Residues Using Microwave-Assisted Heating: A Comprehensive Review. Chem. Eng. J. 2021, 403, 126233. [Google Scholar] [CrossRef]

- Karthik, A.; Asha, V.; Nijhawan, G.; Stephan, M.; Pahwa, S.; Al-Jawahry, H.M.; Khan, I. Biomass and Operational Initiatives for Sustainable Bioenergy Generation. E3S Web Conf. 2024, 529, 02014. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Patel, A.K.; Pant, D.; Rajesh Banu, J.; Rao, C.V.; Kim, Y.-G.; Yang, Y.-H. Recent Developments in Pretreatment Technologies on Lignocellulosic Biomass: Effect of Key Parameters, Technological Improvements, and Challenges. Bioresour. Technol. 2020, 300, 122724. [Google Scholar] [CrossRef]

- Roy, S.; Dikshit, P.K.; Sherpa, K.C.; Singh, A.; Jacob, S.; Chandra Rajak, R. Recent Nanobiotechnological Advancements in Lignocellulosic Biomass Valorization: A Review. J. Environ. Manag. 2021, 297, 113422. [Google Scholar] [CrossRef] [PubMed]

- Taymaz, E.R.; Uslu, M.E.; Deniz, I. Introduction to Biomass to Biofuels Technologies. In Liquid Biofuels; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 1–38. ISBN 978-1-119-79303-8. [Google Scholar]

- Karimi, S.; Karri, R.R.; Yaraki, M.T.; Koduru, J.R. Processes and Separation Technologies for the Production of Fuel-Grade Bioethanol: A Review. Environ. Chem. Lett. 2021, 19, 2873–2890. [Google Scholar] [CrossRef]

- Jain, S.; Kumar, S. A Comprehensive Review of Bioethanol Production from Diverse Feedstocks: Current Advancements and Economic Perspectives. Energy 2024, 296, 131130. [Google Scholar] [CrossRef]

- Maity, S.; Mallick, N. Trends and Advances in Sustainable Bioethanol Production by Marine Microalgae: A Critical Review. J. Clean. Prod. 2022, 345, 131153. [Google Scholar] [CrossRef]

- Cho, E.J.; Trinh, L.T.P.; Song, Y.; Lee, Y.G.; Bae, H.-J. Bioconversion of Biomass Waste into High Value Chemicals. Bioresour. Technol. 2020, 298, 122386. [Google Scholar] [CrossRef]

- Tsai, T.-Y.; Lo, Y.-C.; Dong, C.-D.; Nagarajan, D.; Chang, J.-S.; Lee, D.-J. Biobutanol Production from Lignocellulosic Biomass Using Immobilized Clostridium acetobutylicum. Appl. Energy 2020, 277, 115531. [Google Scholar] [CrossRef]

- Dharmaraja, J.; Shobana, S.; Arvindnarayan, S.; Vadivel, M.; Atabani, A.E.; Pugazhendhi, A.; Kumar, G. Chapter 5—Biobutanol from Lignocellulosic Biomass: Bioprocess Strategies. In Lignocellulosic Biomass to Liquid Biofuels; Yousuf, A., Pirozzi, D., Sannino, F., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 169–193. ISBN 978-0-12-815936-1. [Google Scholar]

- Liu, Y.; Yuan, Y.; Ramya, G.; Mohan Singh, S.; Thuy Lan Chi, N.; Pugazhendhi, A.; Xia, C.; Mathimani, T. A Review on the Promising Fuel of the Future—Biobutanol; the Hindrances and Future Perspectives. Fuel 2022, 327, 125166. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Mariod, A.A.; Aroua, M.K.; Rahman, S.M.A.; Soudagar, M.E.M.; Fattah, I.M.R. Current State and Perspectives on Transesterification of Triglycerides for Biodiesel Production. Catalysts 2021, 11, 1121. [Google Scholar] [CrossRef]

- Mathew, G.M.; Raina, D.; Narisetty, V.; Kumar, V.; Saran, S.; Pugazhendi, A.; Sindhu, R.; Pandey, A.; Binod, P. Recent Advances in Biodiesel Production: Challenges and Solutions. Sci. Total Environ. 2021, 794, 148751. [Google Scholar] [CrossRef] [PubMed]

- Pydimalla, M.; Husaini, S.; Kadire, A.; Kumar Verma, R. Sustainable Biodiesel: A Comprehensive Review on Feedstock, Production Methods, Applications, Challenges and Opportunities. Mater. Today Proc. 2023, 92, 458–464. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas Production and Applications in the Sustainable Energy Transition. J. Energy 2022, 2022, 8750221. [Google Scholar] [CrossRef]

- Ardolino, F.; Cardamone, G.F.; Parrillo, F.; Arena, U. Biogas-to-Biomethane Upgrading: A Comparative Review and Assessment in a Life Cycle Perspective. Renew. Sustain. Energy Rev. 2021, 139, 110588. [Google Scholar] [CrossRef]

- Francisco López, A.; Lago Rodríguez, T.; Faraji Abdolmaleki, S.; Galera Martínez, M.; Bello Bugallo, P.M. From Biogas to Biomethane: An In-Depth Review of Upgrading Technologies That Enhance Sustainability and Reduce Greenhouse Gas Emissions. Appl. Sci. 2024, 14, 2342. [Google Scholar] [CrossRef]

- Parkhey, P. Biomethanol: Possibilities towards a Bio-Based Economy. Biomass Conv. Bioref. 2022, 12, 1877–1887. [Google Scholar] [CrossRef]

- Galusnyak, S.C.; Petrescu, L.; Chisalita, D.A.; Cormos, C.-C.; Ugolini, M. From Secondary Biomass to Bio-Methanol through CONVERGE Technology: An Environmental Analysis. Energies 2023, 16, 2726. [Google Scholar] [CrossRef]

- Senthil Rathi, B.; Senthil Kumar, P.; Rangasamy, G.; Rajendran, S. A Critical Review on Biohydrogen Generation from Biomass. Int. J. Hydrogen Energy 2024, 52, 115–138. [Google Scholar] [CrossRef]

- Badawi, E.Y.; Elkharsa, R.A.; Abdelfattah, E.A. Value Proposition of Bio-Hydrogen Production from Different Biomass Sources. Energy Nexus 2023, 10, 100194. [Google Scholar] [CrossRef]

- Ramprakash, B.; Lindblad, P.; Eaton-Rye, J.J.; Incharoensakdi, A. Current Strategies and Future Perspectives in Biological Hydrogen Production: A Review. Renew. Sustain. Energy Rev. 2022, 168, 112773. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, Q.; Yu, D. The Future of Hydrogen Energy: Bio-Hydrogen Production Technology. Int. J. Hydrogen Energy 2022, 47, 33677–33698. [Google Scholar] [CrossRef]

- Chopra, J.; Rangarajan, V.; Rathnasamy, S.; Dey, P. Life Cycle Assessment as a Key Decision Tool for Emerging Pretreatment Technologies of Biomass-to-Biofuel: Unveiling Challenges, Advances, and Future Potential. Bioenerg. Res. 2024, 17, 857–876. [Google Scholar] [CrossRef]

- Malode, S.J.; Prabhu, K.K.; Mascarenhas, R.J.; Shetti, N.P.; Aminabhavi, T.M. Recent Advances and Viability in Biofuel Production. Energy Convers. Manag. X 2021, 10, 100070. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging Technologies for Biofuel Production: A Critical Review on Recent Progress, Challenges and Perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef] [PubMed]

- Malode, S.J.; Gaddi, S.A.M.; Kamble, P.J.; Nalwad, A.A.; Muddapur, U.M.; Shetti, N.P. Recent Evolutionary Trends in the Production of Biofuels. Mater. Sci. Energy Technol. 2022, 5, 262–277. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Z.; Ding, D.; Liu, C. Research and Prospect of Food Fuels Issues. J. Energy Biosci. 2023, 14, 1–7. [Google Scholar] [CrossRef]

- Cavelius, P.; Engelhart-Straub, S.; Mehlmer, N.; Lercher, J.; Awad, D.; Brück, T. The Potential of Biofuels from First to Fourth Generation. PLoS Biol. 2023, 21, e3002063. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An Overview of Integration Opportunities for Sustainable Bioethanol Production from First- and Second-Generation Sugar-Based Feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Bautista-Herrera, A.; Ortiz-Arango, F.; Álvarez-García, J. Profitability Using Second-Generation Bioethanol in Gasoline Produced in Mexico. Energies 2021, 14, 2294. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus Climate Change: Exploring Potentials and Challenges in the Energy Transition. Renew. Sustain. Energy Rev. 2024, 196, 114369. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.-H.; Nguyen, T.H.P. Sustainability of the Four Generations of Biofuels—A Review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Ganguly, P.; Sarkhel, R.; Das, P. 2—The Second- and Third-Generation Biofuel Technologies: Comparative Perspectives. In Sustainable Fuel Technologies Handbook; Dutta, S., Mustansar Hussain, C., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 29–50. ISBN 978-0-12-822989-7. [Google Scholar]

- Liang, G.; Li, Y.; Yang, C.; Zi, C.; Zhang, Y.; Zhang, D.; Wang, M.; Zhao, W. Ash Properties Correlated with Diverse Types of Biomass Derived from Power Plants: An Overview. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–12. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Jeevanantham, S.; Karishma, S.; Vo, D.-V.N. Recent Advances and Sustainable Development of Biofuels Production from Lignocellulosic Biomass. Bioresour. Technol. 2022, 344, 126203. [Google Scholar] [CrossRef] [PubMed]

- Ananthi, V.; Raja, R.; Carvalho, I.S.; Brindhadevi, K.; Pugazhendhi, A.; Arun, A. A Realistic Scenario on Microalgae Based Biodiesel Production: Third Generation Biofuel. Fuel 2021, 284, 118965. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, Z.; Heidarrezaei, M.; Ong, H.C.; Rahimian Koloor, S.S.; Petrů, M.; Lau, W.J.; Ismail, A.F. Fourth Generation Biofuel from Genetically Modified Algal Biomass: Challenges and Future Directions. Chemosphere 2021, 285, 131535. [Google Scholar] [CrossRef] [PubMed]

- Bibi, F.; Jamal, A.; Huang, Z.; Urynowicz, M.; Ishtiaq Ali, M. Advancement and Role of Abiotic Stresses in Microalgae Biorefinery with a Focus on Lipid Production. Fuel 2022, 316, 123192. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Yang, M.; Singh, S.; Cheng, G. Transforming Lignocellulosic Biomass into Biofuels Enabled by Ionic Liquid Pretreatment. Bioresour. Technol. 2021, 322, 124522. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Iyyappan, J.; Gopinath, M.; Jayamuthunagai, J.; PraveenKumar, R. Transgenicism in Algae: Challenges in Compatibility, Global Scenario and Future Prospects for next Generation Biofuel Production. Renew. Sustain. Energy Rev. 2022, 154, 111829. [Google Scholar] [CrossRef]

- Sun, Y. Technology Research and Development Prospects of Biofuels. J. Educ. Educ. Res. 2024, 7, 11–15. [Google Scholar] [CrossRef]

- Singh, P.; FNU, K.; Encarnação, T. Genetic Modification: A Gateway to Stimulate the Industrial Production of Biofuels. In Marine Organisms: A Solution to Environmental Pollution? Uses in Bioremediation and in Biorefinery; Encarnação, T., Canelas Pais, A., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 237–260. ISBN 978-3-031-17226-7. [Google Scholar]

- Zhu, Z.; Sun, J.; Fa, Y.; Liu, X.; Lindblad, P. Enhancing Microalgal Lipid Accumulation for Biofuel Production. Front. Microbiol. 2022, 13, 1024441. [Google Scholar] [CrossRef]

- Srinivas, G.L.K.; Singh, D.; Kumar, S. Transition of Biofuels from the First to the Fourth Generation: The Journey So Far. In Biofuels; CRC Press: Boca Raton, FL, USA, 2023; ISBN 978-1-00-319773-7. [Google Scholar]

- Yaashikaa, P.R.; Keerthana Devi, M.; Senthil Kumar, P. Algal Biofuels: Technological Perspective on Cultivation, Fuel Extraction and Engineering Genetic Pathway for Enhancing Productivity. Fuel 2022, 320, 123814. [Google Scholar] [CrossRef]

- Mousdale, D.M. Past, Present and Future: A Role for Liquid Biofuels in Transitioning to Net Zero? Nat. Resour. 2024, 15, 107–124. [Google Scholar] [CrossRef]

- Energy Institute. Statistical Review of World Energy. 2024. Available online: https://www.energyinst.org/statistical-review (accessed on 26 July 2024).

- Rodoshi Khan, N.; Bin Rashid, A. Carbon-Based Nanomaterials: A Paradigm Shift in Biofuel Synthesis and Processing for a Sustainable Energy Future. Energy Convers. Manag. X 2024, 22, 100590. [Google Scholar] [CrossRef]

- Roick, C.; Otun, K.O.; Diankanua, N.; Joshua, G. Non-Edible Feedstock for Biodiesel Production. In Biodiesel Technology and Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 285–309. ISBN 978-1-119-72495-7. [Google Scholar]

- Khawaja, A.S.; Zaheer, M.A.; Ahmad, A.; Mirani, A.A.; Ali, Z. Advances in Limitations and Opportunities of Clean Biofuel Production to Promote Decarbonization. Fuel 2023, 342, 127662. [Google Scholar] [CrossRef]

- Beig, B.; Riaz, M.; Raza Naqvi, S.; Hassan, M.; Zheng, Z.; Karimi, K.; Pugazhendhi, A.; Atabani, A.E.; Thuy Lan Chi, N. Current Challenges and Innovative Developments in Pretreatment of Lignocellulosic Residues for Biofuel Production: A Review. Fuel 2021, 287, 119670. [Google Scholar] [CrossRef]

- Barry, T.; Crisby, C.; LaBossiere, M.; Luft, R.; Peterson, D.; Thompson, D.; Yeske, R. Biofuels: The Potential Opportunities and the Realistic Limitations; University of Victoria: Victoria, BC, Canada, 2020. [Google Scholar]

- Lin, C.-Y.; Lu, C. Development Perspectives of Promising Lignocellulose Feedstocks for Production of Advanced Generation Biofuels: A Review. Renew. Sustain. Energy Rev. 2021, 136, 110445. [Google Scholar] [CrossRef]

- Das, S.; Goswami, T.; Ghosh, A.; Bhat, M.; Hait, M.; Jalgham, R.T.T.; Vidya, L.; Das, R.; Goswami, J.; Roymahapatra, G. Biodiesel from Algal Biomass: Renewable, and Environment-Friendly Solutions to Global Energy Needs and Its Current Status. ES Gen. 2024, 4, 1133. [Google Scholar] [CrossRef]

- Ahmad, I.; Yuzir, A.; Mohamad, S.E.; Iwamoto, K.; Abdullah, N. Role of Microalgae in Sustainable Energy and Environment. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012059. [Google Scholar] [CrossRef]

- Semalty, S.; Bhardwaj, A.; Karn, S.K. Global Status of Microbial Engineering for Biofuel Production—Advances, Challenges, and Roadmap. In Emerging Sustainable Technologies for Biofuel Production; Shah, M., Deka, D., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 633–644. ISBN 978-3-031-52167-6. [Google Scholar]

- Rajesh Banu, J.; Preethi; Kavitha, S.; Gunasekaran, M.; Kumar, G. Microalgae Based Biorefinery Promoting Circular Bioeconomy-Techno Economic and Life-Cycle Analysis. Bioresour. Technol. 2020, 302, 122822. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Lin, X.; Yang, M.; He, Z.; Bao, E.; Zhang, H.; Tian, Z. Progress in the Application of Machine Learning in Combustion Studies. ES Energy Environ. 2020, 9, 1–14. [Google Scholar] [CrossRef]

- Ong, H.C.; Yu, K.L.; Chen, W.-H.; Pillejera, M.K.; Bi, X.; Tran, K.-Q.; Pétrissans, A.; Pétrissans, M. Variation of Lignocellulosic Biomass Structure from Torrefaction: A Critical Review. Renew. Sustain. Energy Rev. 2021, 152, 111698. [Google Scholar] [CrossRef]

- Güleç, F.; Parthiban, A.; Umenweke, G.C.; Musa, U.; Williams, O.; Mortezaei, Y.; Suk-Oh, H.; Lester, E.; Ogbaga, C.C.; Gunes, B.; et al. Progress in Lignocellulosic Biomass Valorization for Biofuels and Value-Added Chemical Production in the EU: A Focus on Thermochemical Conversion Processes. Biofuels Bioprod. Biorefining 2024, 18, 755–781. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.J. Thermochemical Conversion of Biomass: Potential Future Prospects. Renew. Sustain. Energy Rev. 2023, 187, 113754. [Google Scholar] [CrossRef]

- Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable Environmental Management and Related Biofuel Technologies. J. Environ. Manag. 2020, 273, 111096. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Lin, Y.-L.; Chiueh, P.-T.; Den, W. Environmental and Energy Assessment of Biomass Residues to Biochar as Fuel: A Brief Review with Recommendations for Future Bioenergy Systems. J. Clean. Prod. 2020, 251, 119714. [Google Scholar] [CrossRef]

- Kwoczynski, Z.; Čmelík, J. Characterization of Biomass Wastes and Its Possibility of Agriculture Utilization Due to Biochar Production by Torrefaction Process. J. Clean. Prod. 2021, 280, 124302. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Kikas, T. Biomass Torrefaction: An Overview on Process Parameters, Economic and Environmental Aspects and Recent Advancements. Bioresour. Technol. 2020, 301, 122737. [Google Scholar] [CrossRef]

- Wyn, H.K.; Zárate, S.; Carrascal, J.; Yermán, L. A Novel Approach to the Production of Biochar with Improved Fuel Characteristics from Biomass Waste. Waste Biomass Valor. 2020, 11, 6467–6481. [Google Scholar] [CrossRef]

- Eling, J.; Okot, D.K.; Menya, E.; Atim, M.R. Densification of Raw and Torrefied Biomass: A Review. Biomass Bioenergy 2024, 184, 107210. [Google Scholar] [CrossRef]

- Doddapaneni, T.R.K.C.; Kikas, T. Advanced Applications of Torrefied Biomass: A Perspective View. Energies 2023, 16, 1635. [Google Scholar] [CrossRef]

- Anshu, K.; Lee, J.S.; Mohan, V.; Kung, K.S.; Sokhansanj, S.; Cao, Y.; Thengane, S.K. Torrefaction Severity Influence on the Nutrient Composition of Biomass. Biomass Conv. Bioref. 2023. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Chen, H.; Yang, H. Pyrolysis Chemistry and Mechanisms: Interactions of Primary Components. In Production of Biofuels and Chemicals with Pyrolysis; Fang, Z., Smith Jr, R.L., Xu, L., Eds.; Springer: Singapore, 2020; pp. 113–137. ISBN 9789811527326. [Google Scholar]

- Yang, X.; Zhao, Z.; Zhao, Y.; Xu, L.; Feng, S.; Wang, Z.; Zhang, L.; Shen, B. Effects of Torrefaction Pretreatment on Fuel Quality and Combustion Characteristics of Biomass: A Review. Fuel 2024, 358, 130314. [Google Scholar] [CrossRef]

- Abdulyekeen, K.A.; Umar, A.A.; Patah, M.F.A.; Daud, W.M.A.W. Torrefaction of Biomass: Production of Enhanced Solid Biofuel from Municipal Solid Waste and Other Types of Biomass. Renew. Sustain. Energy Rev. 2021, 150, 111436. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Ojo, O.T. Biomass Torrefaction for the Production of High-Grade Solid Biofuels: A Review. Bioenerg. Res. 2020, 13, 999–1015. [Google Scholar] [CrossRef]

- Lee, J.-P.; Lee, J.-S.; Lee, J.-W.; Lee, H.-W.; Jeong, S.; Min, K. Waste to Energy: Steam Explosion-Based Torrefaction Process to Produce Solid Biofuel for Power Generation Utilizing Various Waste Biomasses. Bioresour. Technol. 2024, 394, 130185. [Google Scholar] [CrossRef]

- Barontini, F.; Biagini, E.; Tognotti, L. Influence of Torrefaction on Biomass Devolatilization. ACS Omega 2021, 6, 20264–20278. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in Biomass Torrefaction: Principles, Applications and Challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Thengane, S.K.; Kung, K.S.; Gomez-Barea, A.; Ghoniem, A.F. Advances in Biomass Torrefaction: Parameters, Models, Reactors, Applications, Deployment, and Market. Prog. Energy Combust. Sci. 2022, 93, 101040. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of Biomass to Biofuels and Life Cycle Assessment: A Review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Hasan, M.F.; Abdul Rahman, M.R.; Nyakuma, B.B.; Muhamad Said, M.F. Alternatives for Inert Torrefaction to Produce High-Quality Solid Fuel: Review of Available Techniques, Parameters, Potentials and Challenges. Biomass Bioenergy 2024, 182, 107108. [Google Scholar] [CrossRef]

- Bello, R.S.; Olorunnisola, A.O.; Omoniyi, T.E.; Onilude, M.A. A Review of Technoeconomic Benefits of Torrefaction Pretreatment Technology and Application in Torrefying Sawdust. Sustain. Econ. 2024, 2, 104. [Google Scholar] [CrossRef]

- Kaczor, Z.; Buliński, Z.; Werle, S. Modelling Approaches to Waste Biomass Pyrolysis: A Review. Renew. Energy 2020, 159, 427–443. [Google Scholar] [CrossRef]

- Patel, A.; Agrawal, B.; Rawal, B.R. Pyrolysis of Biomass for Efficient Extraction of Biofuel. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1649–1661. [Google Scholar] [CrossRef]

- Moya, R.; Tenorio, C.; Quesada-Kimzey, J. Charcoal Production from Four Tropical Woods through Slow Pyrolysis under Different Temperatures: Yield of Different Products and Condition of Pyrolysis into the Reactor. Biomass Conv. Bioref. 2024. [Google Scholar] [CrossRef]

- Aboelela, D.; Saleh, H.; Attia, A.M.; Elhenawy, Y.; Majozi, T.; Bassyouni, M. Recent Advances in Biomass Pyrolysis Processes for Bioenergy Production: Optimization of Operating Conditions. Sustainability 2023, 15, 11238. [Google Scholar] [CrossRef]

- Adelawon, B.O.; Latinwo, G.K.; Eboibi, B.E.; Agbede, O.O.; Agarry, S.E. Comparison of the Slow, Fast, and Flash Pyrolysis of Recycled Maize-Cob Biomass Waste, Box-Benhken Process Optimization and Characterization Studies for the Thermal Fast Pyrolysis Production of Bio-Energy. Chem. Eng. Commun. 2022, 209, 1246–1276. [Google Scholar] [CrossRef]

- Maqsood, T.; Dai, J.; Zhang, Y.; Guang, M.; Li, B. Pyrolysis of Plastic Species: A Review of Resources and Products. J. Anal. Appl. Pyrolysis 2021, 159, 105295. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the Lignocellulosic Biomass Pyrolysis for Biofuel Production toward Environmental Sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Raza, M.; Inayat, A.; Ahmed, A.; Jamil, F.; Ghenai, C.; Naqvi, S.R.; Shanableh, A.; Ayoub, M.; Waris, A.; Park, Y.-K. Progress of the Pyrolyzer Reactors and Advanced Technologies for Biomass Pyrolysis Processing. Sustainability 2021, 13, 11061. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass Pyrolysis Technologies for Value-Added Products: A State-of-the-Art Review. Environ. Dev. Sustain. 2021, 23, 14324–14378. [Google Scholar] [CrossRef]

- Yogalakshmi, K.N.; Poornima Devi, T.; Sivashanmugam, P.; Kavitha, S.; Yukesh Kannah, R.; Varjani, S.; AdishKumar, S.; Gopalakrishnan, K.; Rajesh Banu, J. Lignocellulosic Biomass-Based Pyrolysis: A Comprehensive Review. Chemosphere 2022, 286, 131824. [Google Scholar] [CrossRef]

- Konur, O. Biomass Pyrolysis and Pyrolysis Oils: A Review of the Research. In Biodiesel Fuels; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-0-367-45623-8. [Google Scholar]

- Kumar, G.; Eswari, A.P.; Kavitha, S.; Kumar, M.D.; Kannah, R.Y.; How, L.C.; Muthukaruppan, G.; Banu, J.R. Thermochemical Conversion Routes of Hydrogen Production from Organic Biomass: Processes, Challenges and Limitations. Biomass Conv. Bioref. 2023, 13, 8509–8534. [Google Scholar] [CrossRef]

- Soni, B.; Karmee, S.K. Towards a Continuous Pilot Scale Pyrolysis Based Biorefinery for Production of Biooil and Biochar from Sawdust. Fuel 2020, 271, 117570. [Google Scholar] [CrossRef]

- Edeh, I.G.; Mašek, O.; Buss, W. A Meta-Analysis on Biochar’s Effects on Soil Water Properties—New Insights and Future Research Challenges. Sci. Total Environ. 2020, 714, 136857. [Google Scholar] [CrossRef] [PubMed]

- Wan Mahari, W.A.; Azwar, E.; Foong, S.Y.; Ahmed, A.; Peng, W.; Tabatabaei, M.; Aghbashlo, M.; Park, Y.-K.; Sonne, C.; Lam, S.S. Valorization of Municipal Wastes Using Co-Pyrolysis for Green Energy Production, Energy Security, and Environmental Sustainability: A Review. Chem. Eng. J. 2021, 421, 129749. [Google Scholar] [CrossRef]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste Biomass Valorization for the Production of Biofuels and Value-Added Products: A Comprehensive Review of Thermochemical, Biological and Integrated Processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Aparecida da Silveira Rossi, R.; Barbosa, J.M.; Antonio de Souza Barrozo, M.; Martins Vieira, L.G. Solar Assisted Catalytic Thermochemical Processes: Pyrolysis and Hydropyrolysis of Chlamydomonas reinhardtii Microalgae. Renew. Energy 2021, 170, 669–682. [Google Scholar] [CrossRef]

- Fakayode, O.A.; Aboagarib, E.A.A.; Zhou, C.; Ma, H. Co-Pyrolysis of Lignocellulosic and Macroalgae Biomasses for the Production of Biochar—A Review. Bioresour. Technol. 2020, 297, 122408. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, X.; Gan, Z.; Cen, K.; Ba, Y.; Chen, F.; Chen, D. Upgrading Biochar by Co-Pyrolysis of Heavy Bio-Oil and Apricot Shell Using Response Surface Methodology. Fuel 2022, 310, 122447. [Google Scholar] [CrossRef]

- Rao, G.; Shao, J.; Chen, X.; Fu, L.; Zhang, X.; Zhang, J.; Wang, Q.; Krivoshapkin, P.; Krivoshapkina, E.; Chen, H. A New Strategy of Preparing High-Value Products by Co-Pyrolysis of Bamboo and ZIF-8. Fuel Process. Technol. 2023, 243, 107669. [Google Scholar] [CrossRef]

- Bai, J.; Huang, G.; Qiu, C.; Shang, X.; Sun, Z.; Hu, J.; Chang, C. Preparation of Low-Nitrogen Bio-Oil from Co-Pyrolysis of Waste Tobacco Stem and Corn Stalk: Product Characteristics and Denitrogenation Mechanism. Energy 2024, 301, 131653. [Google Scholar] [CrossRef]

- Rawat, S.; Singh, A.K.; Chakraborty, J.P.; Kumar, S. Characterization and Mechanism Elucidation of High-Quality Bio-Oil Production from Co-Pyrolysis of Waste Low-Rank Coal Fines and de-Oiled Microalgae Biomass Using Bimetallic (Cu-Cr) ZSM-5 Catalyst. J. Environ. Chem. Eng. 2024, 12, 113046. [Google Scholar] [CrossRef]

- SundarRajan, P.; Gopinath, K.P.; Arun, J.; GracePavithra, K.; Adithya Joseph, A.; Manasa, S. Insights into Valuing the Aqueous Phase Derived from Hydrothermal Liquefaction. Renew. Sustain. Energy Rev. 2021, 144, 111019. [Google Scholar] [CrossRef]

- Singh, A.; Prajapati, P.; Vyas, S.; Gaur, V.K.; Sindhu, R.; Binod, P.; Kumar, V.; Singhania, R.R.; Awasthi, M.K.; Zhang, Z.; et al. A Comprehensive Review of Feedstocks as Sustainable Substrates for Next-Generation Biofuels. Bioenerg. Res. 2023, 16, 105–122. [Google Scholar] [CrossRef]

- Li, Q.; Yuan, X.; Hu, X.; Meers, E.; Ong, H.C.; Chen, W.-H.; Duan, P.; Zhang, S.; Lee, K.B.; Ok, Y.S. Co-Liquefaction of Mixed Biomass Feedstocks for Bio-Oil Production: A Critical Review. Renew. Sustain. Energy Rev. 2022, 154, 111814. [Google Scholar] [CrossRef]

- Grande, L.; Pedroarena, I.; Korili, S.A.; Gil, A. Hydrothermal Liquefaction of Biomass as One of the Most Promising Alternatives for the Synthesis of Advanced Liquid Biofuels: A Review. Materials 2021, 14, 5286. [Google Scholar] [CrossRef]

- Ahmad, S.F.K.; Ali, U.F.M.; Isa, K.M. Compilation of Liquefaction and Pyrolysis Method Used for Bio-Oil Production from Various Biomass: A Review. Environ. Eng. Res. 2020, 25, 18–28. [Google Scholar] [CrossRef]

- Teoh, R.H.; Mahajan, A.S.; Moharir, S.R.; Abdul Manaf, N.; Shi, S.; Thangalazhy-Gopakumar, S. A Review on Hydrothermal Treatments for Solid, Liquid and Gaseous Fuel Production from Biomass. Energy Nexus 2024, 14, 100301. [Google Scholar] [CrossRef]

- Singh, S.; Pant, K.K.; Krishania, M. Current Perspective for Bio-Oil Production from Agricultural Residues in Commercialization Aspect: A Review. J. Anal. Appl. Pyrolysis 2023, 175, 106160. [Google Scholar] [CrossRef]

- Ming, H.; Yang, X.; Zheng, P.; Zhang, Y.; Jiang, H.; Zhang, L. Recent Advances of Solvent Effects in Biomass Liquefaction Conversion. Energies 2024, 17, 2814. [Google Scholar] [CrossRef]

- Bassoli, S.C.; Sanson, A.L.; Naves, F.L.; Amaral, M.d.S. Hydrothermal Co-Liquefaction of Microalgae, Sugarcane Bagasse, Brewer’s Spent Grain, and Sludge from a Paper Recycling Mill: Modeling and Evaluation of Biocrude and Biochar Yield. J. Environ. Manag. 2024, 356, 120626. [Google Scholar] [CrossRef]

- Dandamudi, K.P.R.; Murdock, T.; Lammers, P.J.; Deng, S.; Fini, E.H. Production of Functionalized Carbon from Synergistic Hydrothermal Liquefaction of Microalgae and Swine Manure. Resour. Conserv. Recycl. 2021, 170, 105564. [Google Scholar] [CrossRef]

- Ali Shah, A.; Sohail Toor, S.; Hussain Seehar, T.; Sadetmahaleh, K.K.; Helmer Pedersen, T.; Haaning Nielsen, A.; Aistrup Rosendahl, L. Bio-Crude Production through Co-Hydrothermal Processing of Swine Manure with Sewage Sludge to Enhance Pumpability. Fuel 2021, 288, 119407. [Google Scholar] [CrossRef]

- Chan, Y.H.; Lock, S.S.M.; Chin, B.L.F.; Wong, M.K.; Loy, A.C.M.; Foong, S.Y.; Yiin, C.L.; Lam, S.S. Progress in Thermochemical Co-Processing of Biomass and Sludge for Sustainable Energy, Value-Added Products and Circular Economy. Bioresour. Technol. 2023, 380, 129061. [Google Scholar] [CrossRef]

- Hu, Y.; Hu, M.; Jiang, H.; Yu, P.; Yang, W. Co-Liquefaction of Livestock Manure and Food Waste: Synergistic Effects and Product Combustion Performance. Appl. Energy 2023, 341, 121073. [Google Scholar] [CrossRef]

- Luo, Z.; Xiong, J.; Jiang, M.; Li, L.; Wang, G.; Huang, H. Co-Treatment of Swine Manure and Lignocellulosic Biomass by Liquefaction: Parameter Optimization, Product Characterization, Reaction Mechanism. J. Supercrit. Fluids 2024, 205, 106138. [Google Scholar] [CrossRef]

- He, S.; Wang, J.; Cheng, Z.; Dong, H.; Yan, B.; Chen, G. Synergetic Effect and Primary Reaction Network of Corn Cob and Cattle Manure in Single and Mixed Hydrothermal Liquefaction. J. Anal. Appl. Pyrolysis 2021, 155, 105076. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on Biomass Gasification: Gasifiers, Gasifying Mediums, and Operational Parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Fang, Y.; Paul, M.C.; Varjani, S.; Li, X.; Park, Y.-K.; You, S. Concentrated Solar Thermochemical Gasification of Biomass: Principles, Applications, and Development. Renew. Sustain. Energy Rev. 2021, 150, 111484. [Google Scholar] [CrossRef]

- Suryawanshi, S.J.; Shewale, V.C.; Thakare, R.S.; Yarasu, R.B. Parametric Study of Different Biomass Feedstocks Used for Gasification Process of Gasifier—A Literature Review. Biomass Conv. Bioref. 2023, 13, 7689–7700. [Google Scholar] [CrossRef]

- Alabi, O.O.; Gbadeyan, O.J.; Towoju, O.A.; Deenadayalu, N. Enhancing Sustainable Energy Production through Biomass Gasification Gas Technology: A Review. F1000Research 2024, 13, 511. [Google Scholar] [CrossRef]

- Havilah, P.R.; Sharma, A.K.; Govindasamy, G.; Matsakas, L.; Patel, A. Biomass Gasification in Downdraft Gasifiers: A Technical Review on Production, Up-Gradation and Application of Synthesis Gas. Energies 2022, 15, 3938. [Google Scholar] [CrossRef]

- Narnaware, S.L.; Panwar, N.L. Biomass Gasification for Climate Change Mitigation and Policy Framework in India: A Review. Bioresour. Technol. Rep. 2022, 17, 100892. [Google Scholar] [CrossRef]

- Tripathi, K.; Gupta, V.; Awasthi, V.; Pant, K.K.; Upadhyayula, S. Design Framework for Dimethyl Ether (DME) Production from Coal and Biomass-Derived Syngas via Simulation Approach. Can. J. Chem. Eng. 2023, 101, 3213–3225. [Google Scholar] [CrossRef]

- Jenčík, J.; Hönig, V.; Obergruber, M.; Hájek, J.; Vráblík, A.; Černý, R.; Schlehöfer, D.; Herink, T. Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Diesel Engines. Materials 2021, 14, 3077. [Google Scholar] [CrossRef]

- Li, J.; Pan, L.; Suvarna, M.; Wang, X. Machine Learning Aided Supercritical Water Gasification for H2-Rich Syngas Production with Process Optimization and Catalyst Screening. Chem. Eng. J. 2021, 426, 131285. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, L.; Han, Z.; He, P.; Cao, Y.; Li, J.; Li, H. Efficient Hydrogenation of Ethylene Carbonate Derived from CO2 to Synthesize Methanol and Ethylene Glycol over Core-Shell Cu@GO Catalyst. Green Chem. Eng. 2022, 3, 228–239. [Google Scholar] [CrossRef]

- Glushkov, D.; Nyashina, G.; Shvets, A.; Pereira, A.; Ramanathan, A. Current Status of the Pyrolysis and Gasification Mechanism of Biomass. Energies 2021, 14, 7541. [Google Scholar] [CrossRef]

- Erdiwansyah; Gani, A.; Zaki, M.; Mamat, R.; Nizar, M.; Rosdi, S.M.; Yana, S.; Sarjono, R.E. Analysis of Technological Developments and Potential of Biomass Gasification as a Viable Industrial Process: A Review. Case Stud. Chem. Environ. Eng. 2023, 8, 100439. [Google Scholar] [CrossRef]

- Li, T.; Wang, J.; Chen, H.; Li, W.; Pan, P.; Wu, L.; Xu, G.; Chen, H. Performance Analysis of an Integrated Biomass-to-Energy System Based on Gasification and Pyrolysis. Energy Convers. Manag. 2023, 287, 117085. [Google Scholar] [CrossRef]

- Lanjekar, P.R.; Panwar, N.L.; Agrawal, C. A Comprehensive Review on Hydrogen Production through Thermochemical Conversion of Biomass for Energy Security. Bioresour. Technol. Rep. 2023, 21, 101293. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sar, T.; Gowd, S.C.; Rajendran, K.; Kumar, V.; Sarsaiya, S.; Li, Y.; Sindhu, R.; Binod, P.; Zhang, Z.; et al. A Comprehensive Review on Thermochemical, and Biochemical Conversion Methods of Lignocellulosic Biomass into Valuable End Product. Fuel 2023, 342, 127790. [Google Scholar] [CrossRef]

- Roncancio, R.; Gore, J.P. CO2 Char Gasification: A Systematic Review from 2014 to 2020. Energy Convers. Manag. X 2021, 10, 100060. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.-L.; Zhao, X.-Y.; Cao, J.-P. Biomass Thermochemical Conversion: A Review on Tar Elimination from Biomass Catalytic Gasification. J. Energy Inst. 2020, 93, 1083–1098. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Zhang, L.; Wang, R.; Bi, X.; Olazar, M. A Comprehensive Review of Primary Strategies for Tar Removal in Biomass Gasification. Energy Convers. Manag. 2023, 276, 116496. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.-L.; Zhao, X.-Y.; Cao, J.-P. Methanation of Syngas from Biomass Gasification: An Overview. Int. J. Hydrogen Energy 2020, 45, 4223–4243. [Google Scholar] [CrossRef]

- Faizan, M.; Song, H. Critical Review on Catalytic Biomass Gasification: State-of-Art Progress, Technical Challenges, and Perspectives in Future Development. J. Clean. Prod. 2023, 408, 137224. [Google Scholar] [CrossRef]

- Ashokkumar, V.; Chandramughi, V.P.; Kumar, G.; Ngamcharussrivichai, C.; Piechota, G.; Igliński, B.; Kothari, R.; Chen, W.-H. Advancements in Lignocellulosic Biomass: A Critical Appraisal of Fourth-Generation Biofuels and Value-Added Bioproduct. Fuel 2024, 365, 130751. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Nanda, S. Biohydrogen Production Through Dark Fermentation. Chem. Eng. Technol. 2020, 43, 601–612. [Google Scholar] [CrossRef]

- Taqvi, S.A.A.; Kazmi, B.; Naqvi, S.R.; Juchelková, D.; Bokhari, A. State-of-the-Art Review of Biomass Gasification: Raw to Energy Generation. ChemBioEng Rev. 2024, 11, e202400003. [Google Scholar] [CrossRef]

- Dutta, N.; Usman, M.; Ashraf, M.A.; Luo, G.; Gamal El-Din, M.; Zhang, S. Methods to Convert Lignocellulosic Waste into Biohydrogen, Biogas, Bioethanol, Biodiesel and Value-Added Chemicals: A Review. Environ. Chem. Lett. 2023, 21, 803–820. [Google Scholar] [CrossRef]

- Azeez, R.A.; Al-Zuhairi, F.K. Biofuels (Bioethanol, Biodiesel, and Biogas) from Lignocellulosic Biomass: A Review. J. Univ. Babylon. Eng. Sci. 2020, 28, 202–215. [Google Scholar]

- Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Rupani, P.F.; Mohammadi, A.A. Different Pretreatment Technologies of Lignocellulosic Biomass for Bioethanol Production: An Overview. Energy 2020, 199, 117457. [Google Scholar] [CrossRef]

- Sai Bharadwaj, A.V.S.L.; Dev, S.; Zhuang, J.; Wang, Y.; Yoo, C.G.; Jeon, B.-H.; Aggarwal, S.; Park, S.H.; Kim, T.H. Review of Chemical Pretreatment of Lignocellulosic Biomass Using Low-Liquid and Low-Chemical Catalysts for Effective Bioconversion. Bioresour. Technol. 2023, 368, 128339. [Google Scholar] [CrossRef]

- Hakeem, I.G.; Sharma, A.; Sharma, T.; Sharma, A.; Joshi, J.B.; Shah, K.; Ball, A.S.; Surapaneni, A. Techno-Economic Analysis of Biochemical Conversion of Biomass to Biofuels and Platform Chemicals. Biofuels Bioprod. Biorefining 2023, 17, 718–750. [Google Scholar] [CrossRef]

- Dharmaraja, J.; Shobana, S.; Arvindnarayan, S.; Francis, R.R.; Jeyakumar, R.B.; Saratale, R.G.; Ashokkumar, V.; Bhatia, S.K.; Kumar, V.; Kumar, G. Lignocellulosic Biomass Conversion via Greener Pretreatment Methods towards Biorefinery Applications. Bioresour. Technol. 2023, 369, 128328. [Google Scholar] [CrossRef]

- Zhou, M.; Tian, X. Development of Different Pretreatments and Related Technologies for Efficient Biomass Conversion of Lignocellulose. Int. J. Biol. Macromol. 2022, 202, 256–268. [Google Scholar] [CrossRef]

- Broda, M.; Yelle, D.J.; Serwańska, K. Bioethanol Production from Lignocellulosic Biomass—Challenges and Solutions. Molecules 2022, 27, 8717. [Google Scholar] [CrossRef]

- Robak, K.; Balcerek, M. Current State-of-the-Art in Ethanol Production from Lignocellulosic Feedstocks. Microbiol. Res. 2020, 240, 126534. [Google Scholar] [CrossRef]

- Jayakumar, M.; Gindaba, G.T.; Gebeyehu, K.B.; Periyasamy, S.; Jabesa, A.; Baskar, G.; John, B.I.; Pugazhendhi, A. Bioethanol Production from Agricultural Residues as Lignocellulosic Biomass Feedstock’s Waste Valorization Approach: A Comprehensive Review. Sci. Total Environ. 2023, 879, 163158. [Google Scholar] [CrossRef]

- Afedzi, A.E.K.; Parakulsuksatid, P. Recent Advances in Process Modifications of Simultaneous Saccharification and Fermentation (SSF) of Lignocellulosic Biomass for Bioethanol Production. Biocatal. Agric. Biotechnol. 2023, 54, 102961. [Google Scholar] [CrossRef]

- Devos, R.J.B.; Colla, L.M. Simultaneous Saccharification and Fermentation to Obtain Bioethanol: A Bibliometric and Systematic Study. Bioresour. Technol. Rep. 2022, 17, 100924. [Google Scholar] [CrossRef]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Verma, P. Bioethanol Production: Generation-Based Comparative Status Measurements. In Biofuel Production Technologies: Critical Analysis for Sustainability; Srivastava, N., Srivastava, M., Mishra, P.K., Gupta, V.K., Eds.; Springer: Singapore, 2020; pp. 155–201. ISBN 9789811386374. [Google Scholar]

- Tse, T.J.; Wiens, D.J.; Chicilo, F.; Purdy, S.K.; Reaney, M.J.T. Value-Added Products from Ethanol Fermentation—A Review. Fermentation 2021, 7, 267. [Google Scholar] [CrossRef]

- Feng, Y.; Rosa, L. Global Biomethane and Carbon Dioxide Removal Potential through Anaerobic Digestion of Waste Biomass. Environ. Res. Lett. 2024, 19, 024024. [Google Scholar] [CrossRef]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in Biogas Production: Pretreatment and Codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar] [CrossRef]

- Dhull, P.; Lohchab, R.K.; Kumar, S.; Kumari, M.; Shaloo; Bhankhar, A.K. Anaerobic Digestion: Advance Techniques for Enhanced Biomethane/Biogas Production as a Source of Renewable Energy. Bioenerg. Res. 2024, 17, 1228–1249. [Google Scholar] [CrossRef]

- Keerthana Devi, M.; Manikandan, S.; Oviyapriya, M.; Selvaraj, M.; Assiri, M.A.; Vickram, S.; Subbaiya, R.; Karmegam, N.; Ravindran, B.; Chang, S.W.; et al. Recent Advances in Biogas Production Using Agro-Industrial Waste: A Comprehensive Review Outlook of Techno-Economic Analysis. Bioresour. Technol. 2022, 363, 127871. [Google Scholar] [CrossRef] [PubMed]

- Leung, D.Y.C.; Wang, J. An overview on biogas generation from anaerobic digestion of food waste. Int. J. Green Energ. 2016, 13, 119–131. [Google Scholar] [CrossRef]

- Harirchi, S.; Wainaina, S.; Sar, T.; Nojoumi, S.A.; Parchami, M.; Parchami, M.; Varjani, S.; Khanal, S.K.; Wong, J.; Awasthi, M.K.; et al. Microbiological Insights into Anaerobic Digestion for Biogas, Hydrogen or Volatile Fatty Acids (VFAs): A Review. Bioengineered 2022, 13, 6521–6557. [Google Scholar] [CrossRef]

- Tavera-Ruiz, C.; Martí-Herrero, J.; Mendieta, O.; Jaimes-Estévez, J.; Gauthier-Maradei, P.; Azimov, U.; Escalante, H.; Castro, L. Current Understanding and Perspectives on Anaerobic Digestion in Developing Countries: Colombia Case Study. Renew. Sustain. Energy Rev. 2023, 173, 113097. [Google Scholar] [CrossRef]

- Nwokolo, N.; Mukumba, P.; Obileke, K.; Enebe, M. Waste to Energy: A Focus on the Impact of Substrate Type in Biogas Production. Processes 2020, 8, 1224. [Google Scholar] [CrossRef]

- Kamperidou, V.; Terzopoulou, P. Anaerobic Digestion of Lignocellulosic Waste Materials. Sustainability 2021, 13, 12810. [Google Scholar] [CrossRef]

- Mariana, O.-S.; Camilo, S.-T.J.; Ariel, C.-A.C. A Comprehensive Approach for Biorefineries Design Based on Experimental Data, Conceptual and Optimization Methodologies: The Orange Peel Waste Case. Bioresour. Technol. 2021, 325, 124682. [Google Scholar] [CrossRef]

- Kiani Deh Kiani, M.; Parsaee, M.; Safieddin Ardebili, S.M.; Reyes, I.P.; Fuess, L.T.; Karimi, K. Different Bioreactor Configurations for Biogas Production from Sugarcane Vinasse: A Comprehensive Review. Biomass Bioenergy 2022, 161, 106446. [Google Scholar] [CrossRef]

- Rathore, A.S.; Singh, A. Biomass to Fuels and Chemicals: A Review of Enabling Processes and Technologies. J. Chem. Technol. Biotechnol. 2022, 97, 597–607. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Kumar Khanal, S. Anaerobic Co-Digestion: Current Status and Perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Technologies for Biogas to Electricity Conversion. Energy Rep. 2022, 8, 774–786. [Google Scholar] [CrossRef]

- Bijarchiyan, M.; Sahebi, H.; Mirzamohammadi, S. A Sustainable Biomass Network Design Model for Bioenergy Production by Anaerobic Digestion Technology: Using Agricultural Residues and Livestock Manure. Energy Sustain. Soc. 2020, 10, 19. [Google Scholar] [CrossRef]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Zhang, Y.; Qi, X. Biogas from Microalgae: Technologies, Challenges and Opportunities. Renew. Sustain. Energy Rev. 2020, 117, 109503. [Google Scholar] [CrossRef]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas Upgrading Technologies–Recent Advances in Membrane-Based Processes. Int. J. Hydrogen Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current Status of Biogas Upgrading for Direct Biomethane Use: A Review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of Biogas and Biomethane as Renewable Energy Sources: A Review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Karthigadevi, G.; Bharathiraja, B.; Praveen Kumar, R.; Abo, L.D.; Venkatesa Prabhu, S.; Balachandar, R.; Jayakumar, M. Current and Prognostic Overview on the Strategic Exploitation of Anaerobic Digestion and Digestate: A Review. Environ. Res. 2023, 216, 114526. [Google Scholar] [CrossRef]

- Singh, A.K.; Pal, P.; Rathore, S.S.; Sahoo, U.K.; Sarangi, P.K.; Prus, P.; Dziekański, P. Sustainable Utilization of Biowaste Resources for Biogas Production to Meet Rural Bioenergy Requirements. Energies 2023, 16, 5409. [Google Scholar] [CrossRef]

- Nogueira, L.A.H.; Souza, G.M.; Cortez, L.A.B.; de Brito Cruz, C.H. Biofuels for transport. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 173–197. [Google Scholar] [CrossRef]

| Renewable Energy | Different Uses |

|---|---|

| Solar | Electrical, thermal or mechanical energy |

| Wind | Electricity generation |

| Biomass | Heat, electricity generation, synthesis of fuels and bioproducts |

| Geothermal | Power generation, heating buildings, hot water and agricultural drying |

| Hydroelectric | Power generation |

| Biomass Sources | Products |

|---|---|

| Sugarcane bagasse, rice husks, corn stalks, wheat straw, pulp, peel, stubble, cereals |

| Household waste, paper, food, garden waste |

| Sawdust, wood waste and shavings, timber, leaves and bark, bamboo |

| Animal excrement, slurry, animal manure |

| Sewage waste |

| Pre-consumer food waste, production waste, post-consumer food waste (e.g., food, rice, vegetables, fruits) |

| Waste from the petrochemical, pharmaceutical, agricultural and food industries. |

| Microalgae and macroalgae |

| Different Agricultural Energy Crops | Products Used |

|---|---|

| Sugar-based crops | Sugarcane, sugar beet, sorghum |

| Starch-based crops | Corn, barley, wheat |

| Oil-based crops | Rapeseed, sunflower, palm |

| Process | Advantages | Disadvantages |

|---|---|---|

| Separate hydrolysis and fermentation (SHF) | Easy monitoring of pH, temperature, enzyme concentration, sugar accumulation, and inhibitor concentration | Long working times, increased inhibitory effects and use of additional equipment and processing steps |

| Simultaneous saccharification and fermentation (SSF) | Low risk of contamination and reduction in inhibitory effects, reduced times | Incompatibility of optimal temperature (50–55 °C) and pH (4.5–5.5) |

| AD Steps | Microbial Community | Enzymes |

|---|---|---|

| Hydrolysis | Bacteroides, Actinobacteria, Firmicutes, Espiroquetas, Proteobacteria, Eubacterium, Chloroflexi | Cellulase, amylase, protease, lipase, and xylanse |

| Acidogenesis | Enterobacter, Bacteroidetes, Firmicutes, Clostridium | Acetate kinase, C-acetyl transferase, acetaldehyde dehydrogenase, and hydrogen lyase |

| Acetogenesis | Acetobacterium, Holophaga Clostridium, Ruminococcus Sporomusa, Desulfotignum, Eubacterium, Moorella | Hydrogenase |

| Methanogenesis | Methanobacterium, Methanobrevibacter, Methanococcus Methanosarcina, Methanospirillum, Methanothermobacter, Methanosaeta | Methyl-coenzyme, methyltransferase, formylmethano furan dehydrogenase, methyltransferase, and methyl-coenzyme reductase |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mignogna, D.; Szabó, M.; Ceci, P.; Avino, P. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability 2024, 16, 7036. https://doi.org/10.3390/su16167036

Mignogna D, Szabó M, Ceci P, Avino P. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability. 2024; 16(16):7036. https://doi.org/10.3390/su16167036

Chicago/Turabian StyleMignogna, Debora, Márta Szabó, Paolo Ceci, and Pasquale Avino. 2024. "Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition" Sustainability 16, no. 16: 7036. https://doi.org/10.3390/su16167036

APA StyleMignogna, D., Szabó, M., Ceci, P., & Avino, P. (2024). Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability, 16(16), 7036. https://doi.org/10.3390/su16167036