Two Decades of Advancements in Cold Supply Chain Logistics for Reducing Food Waste: A Review with Focus on the Meat Industry

Abstract

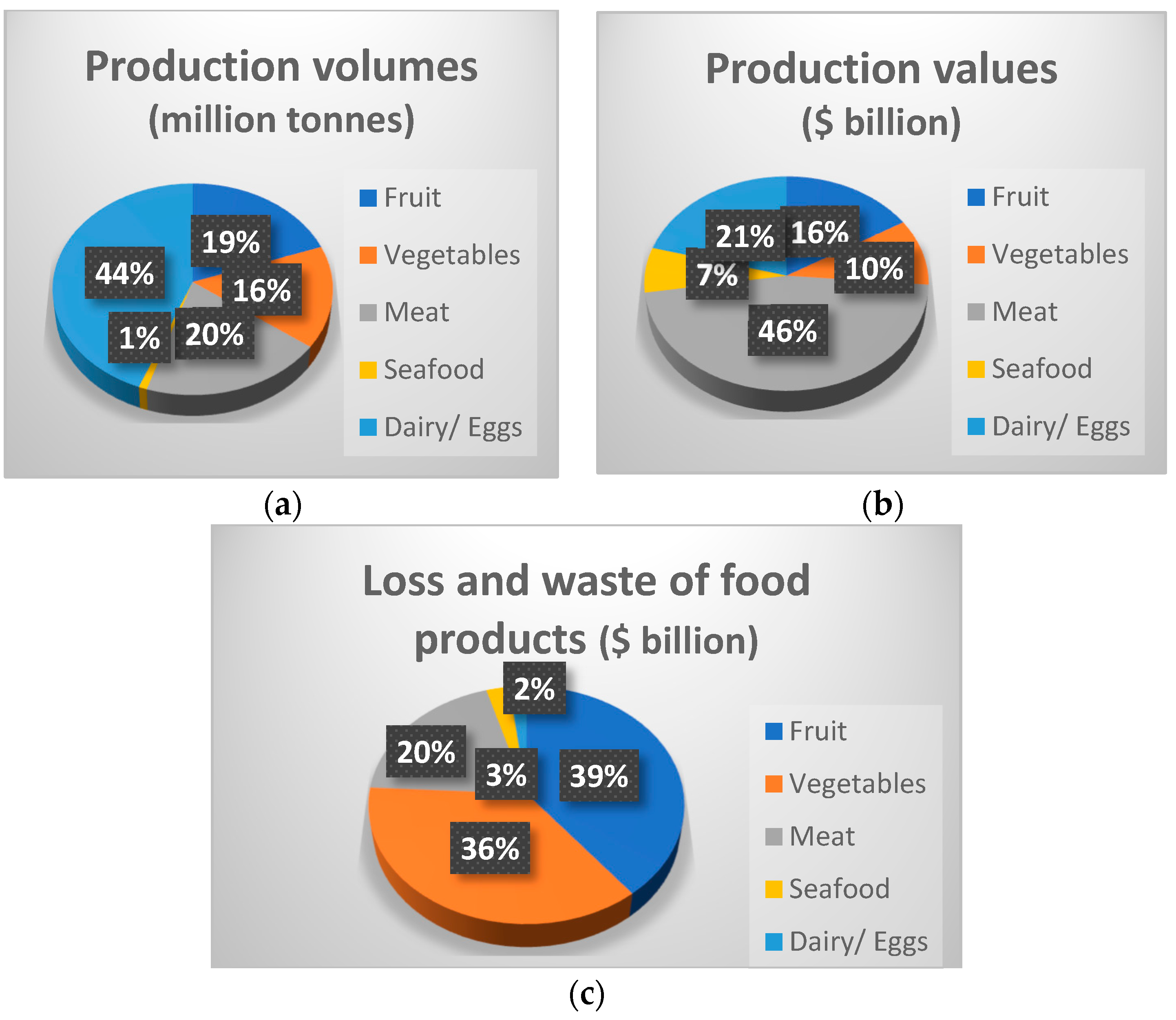

1. Introduction

Objective and Scope of Study

- What is the current state of the art on beef CSCL in terms of management, sustainability, network design, and the use of information technologies for red meat waste reduction?

- To provide an overview of the current state of the art and to identify the gaps and contemporary challenges to red meat waste reduction;

- To identify key research themes and their potential role and associated elements in mitigating red meat waste reduction, especially across the beef CSCL systems;

- To pinpoint the directions in each theme that warrant further research advancement.

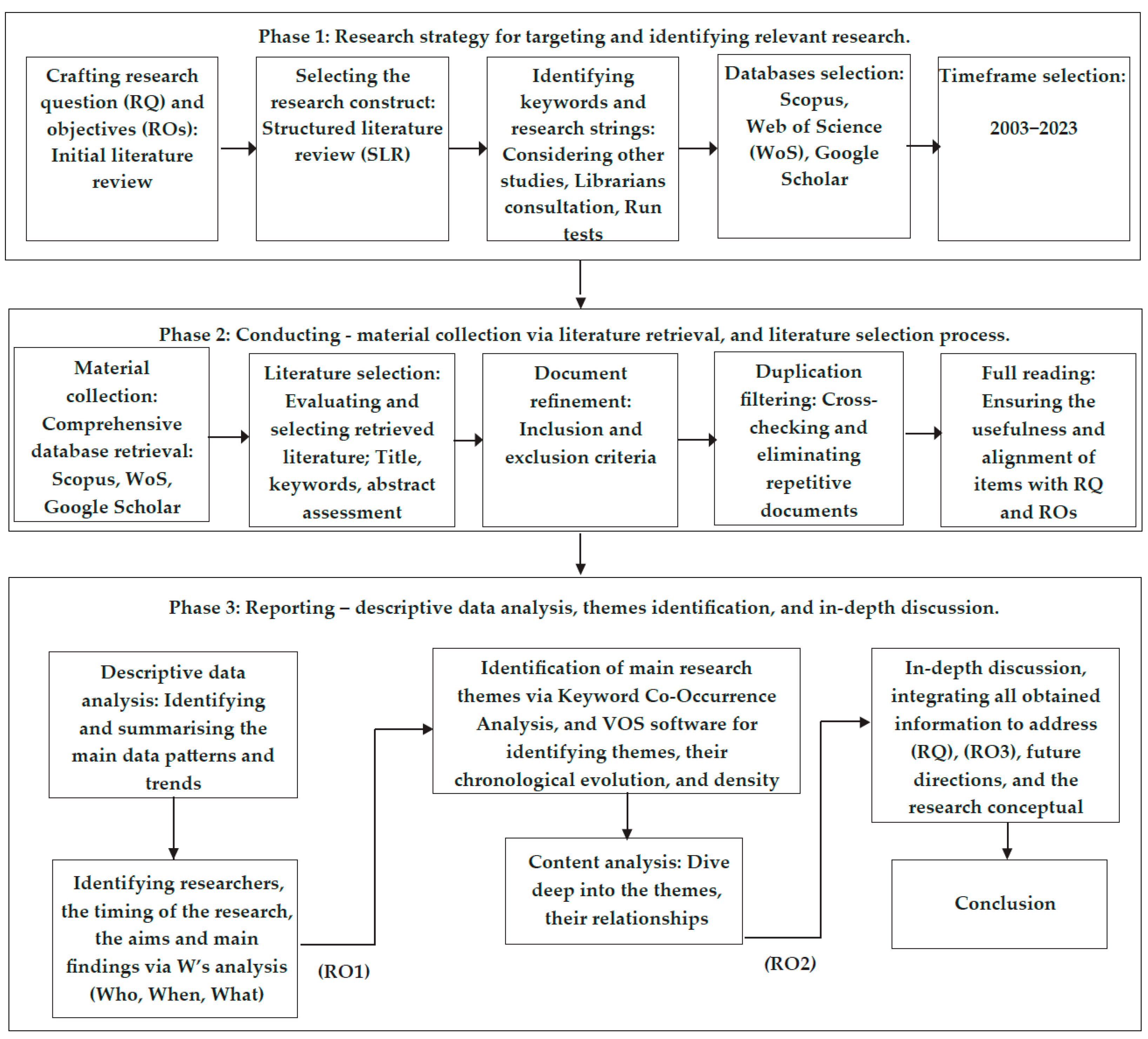

2. Materials and Methods

2.1. Literature Retrieval and Selection

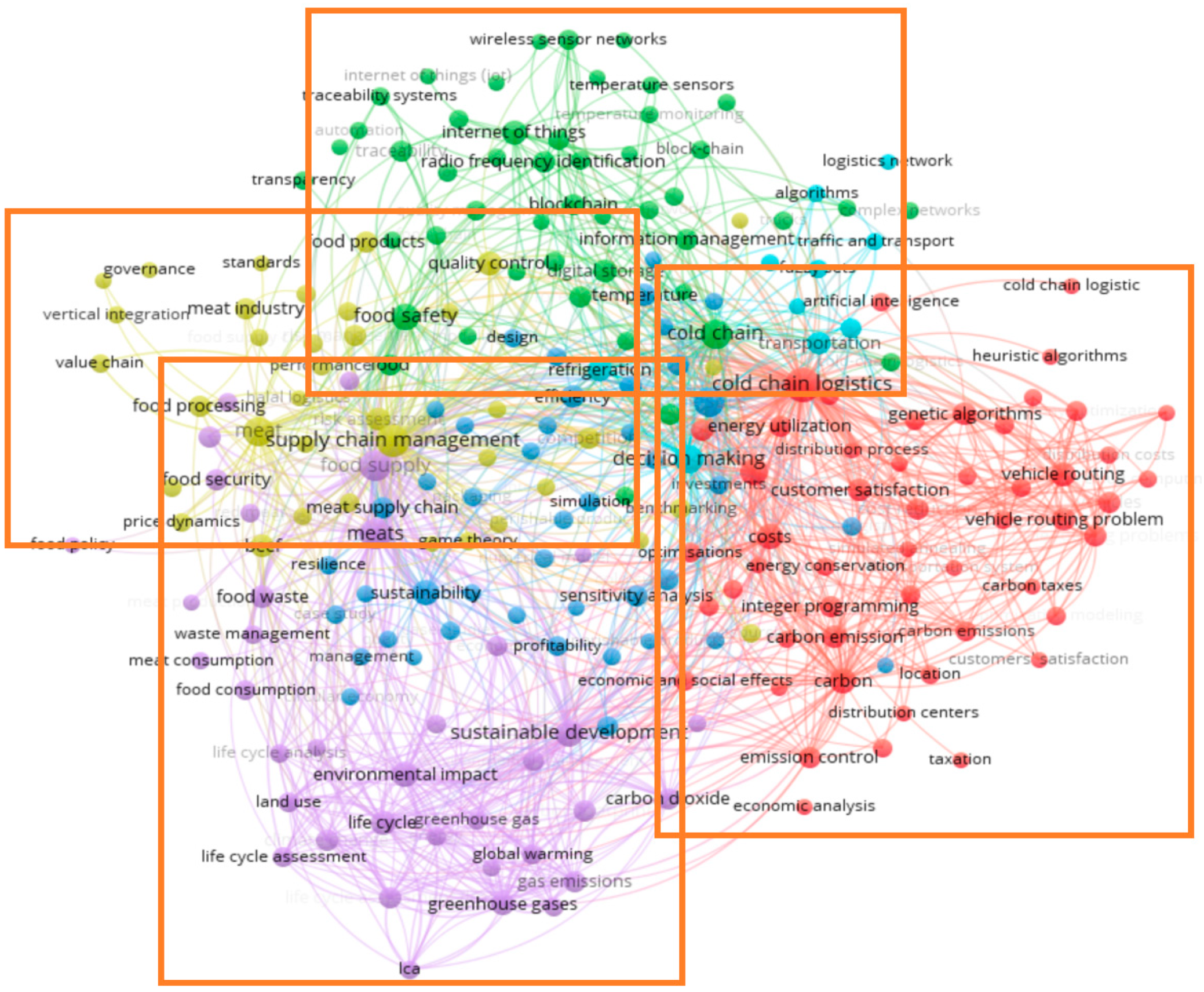

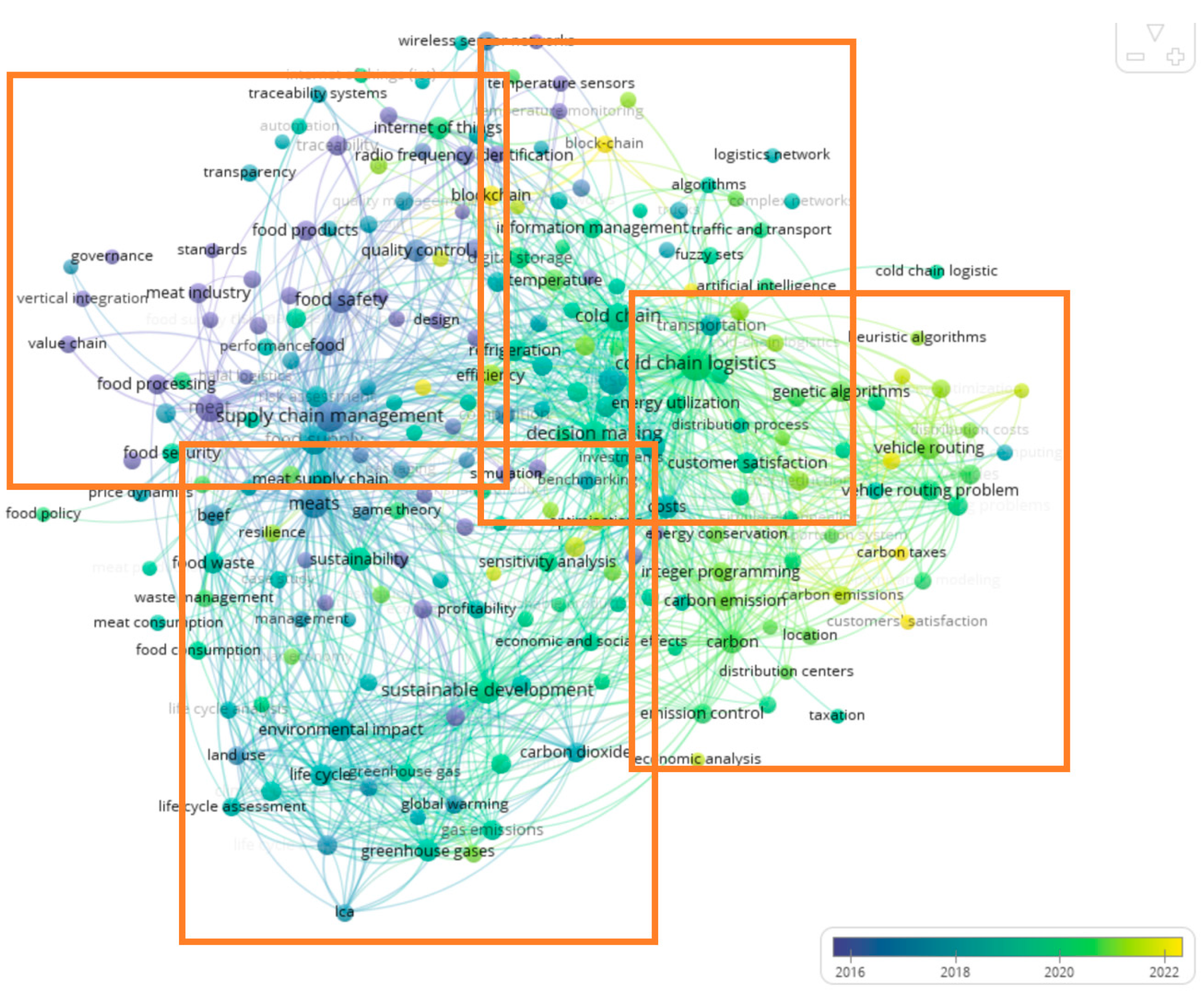

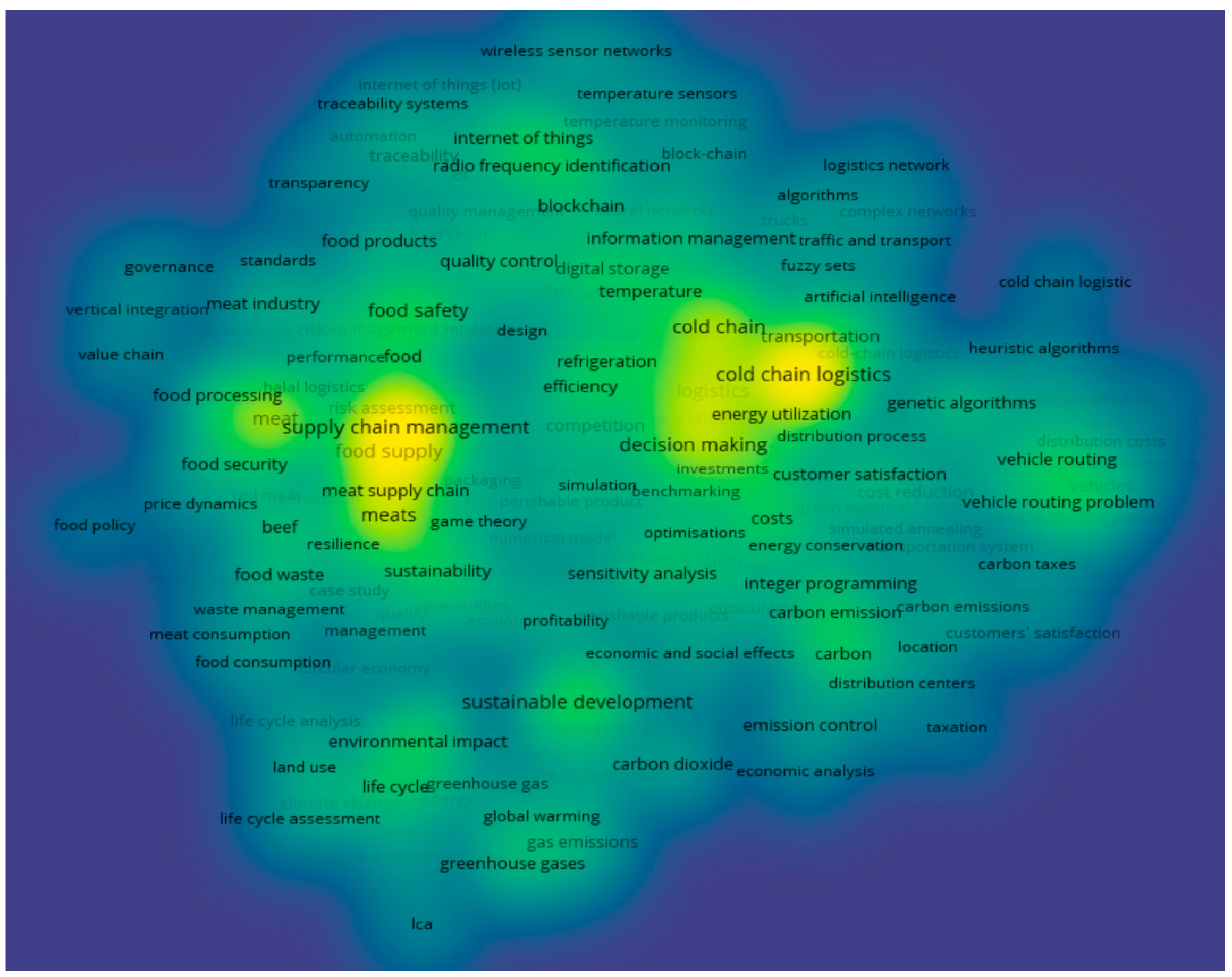

2.2. Extracting the Research Themes

3. Results

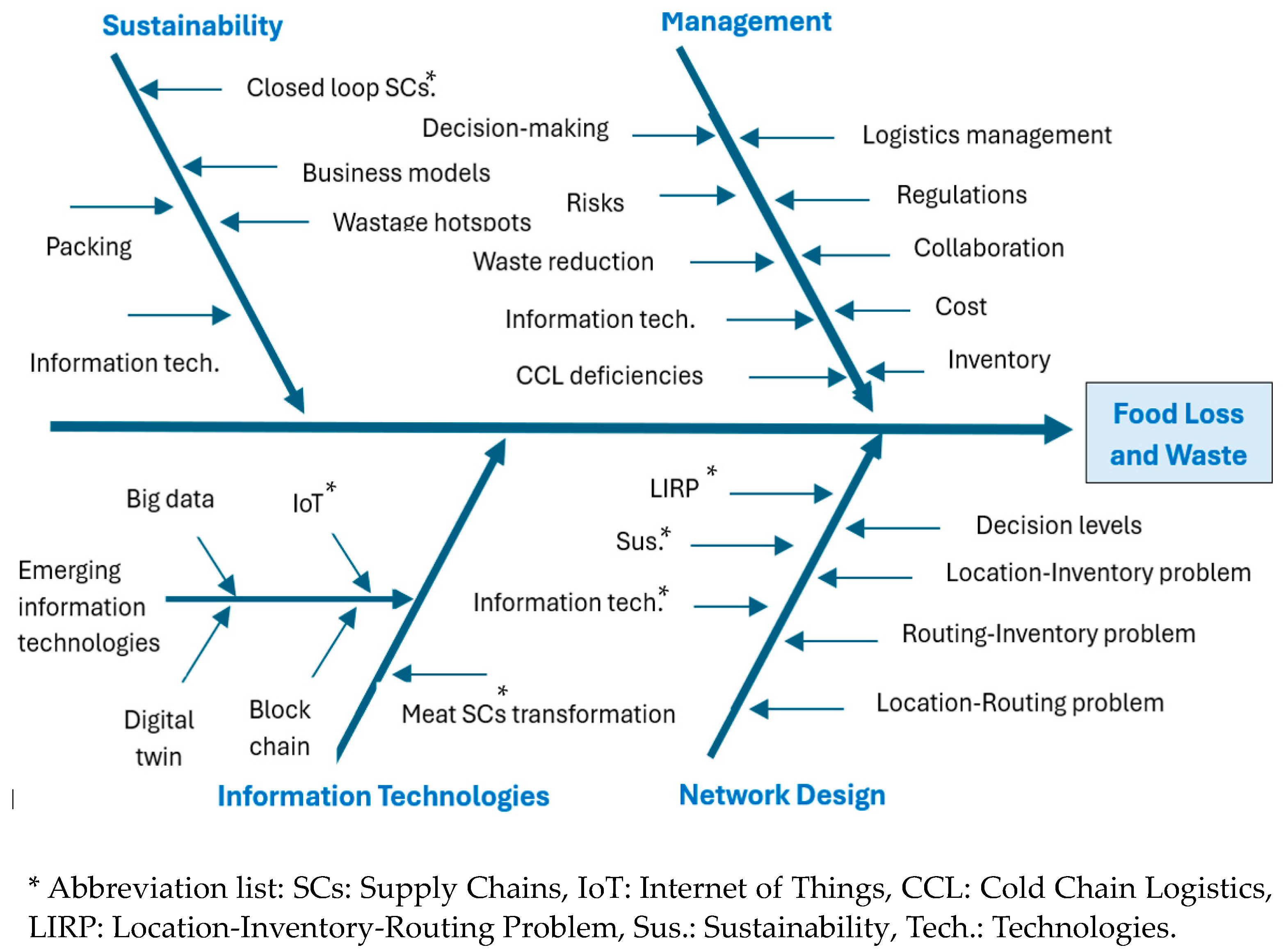

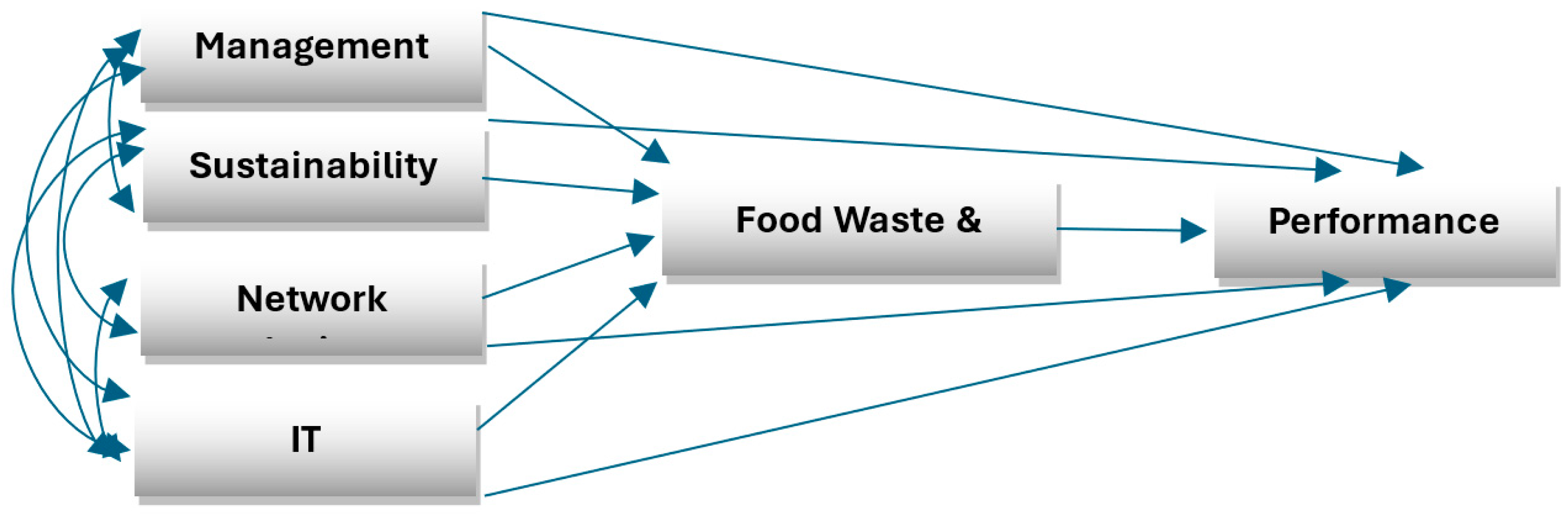

3.1. The Literature Review Identified Themes and Subjects

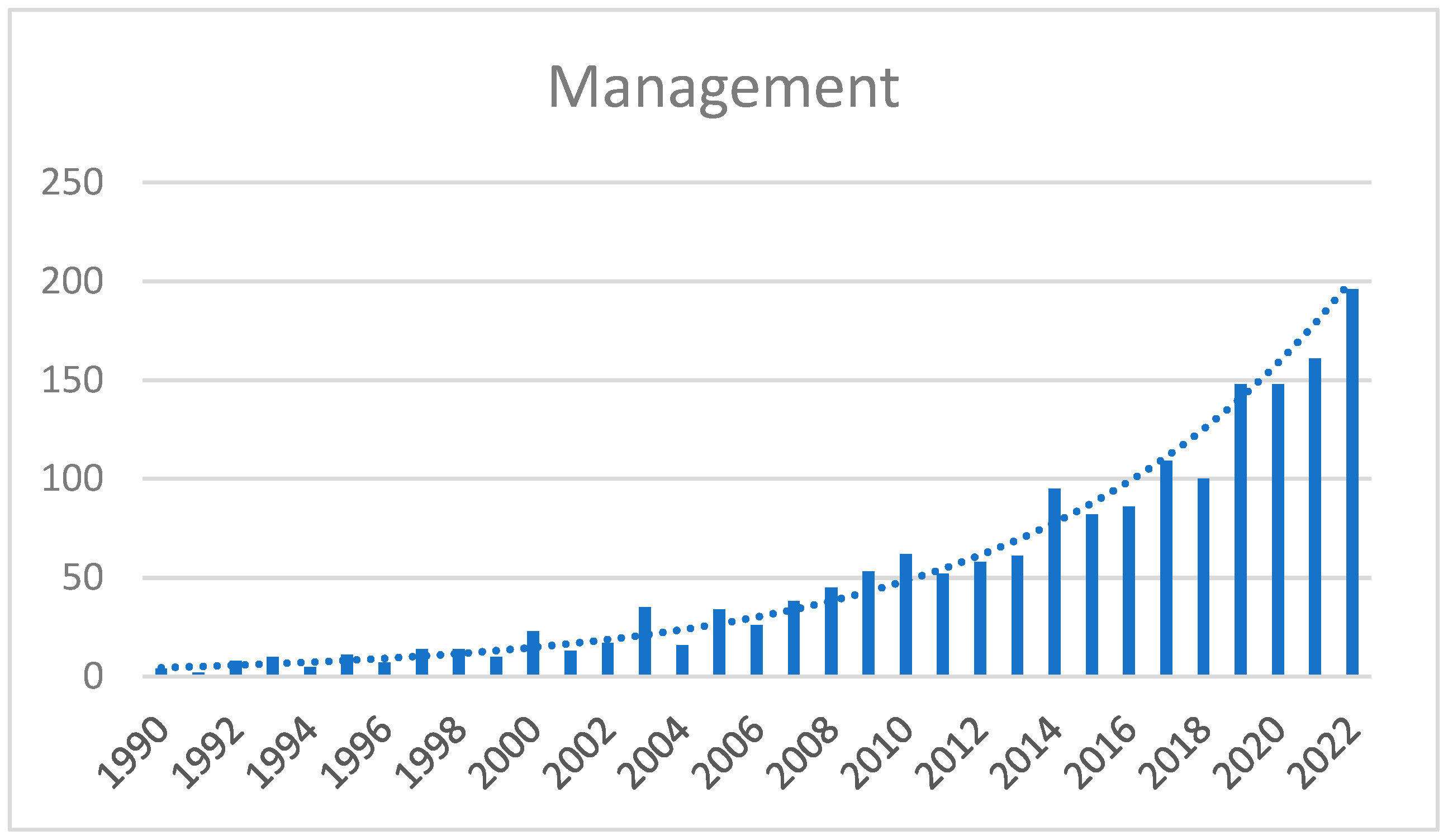

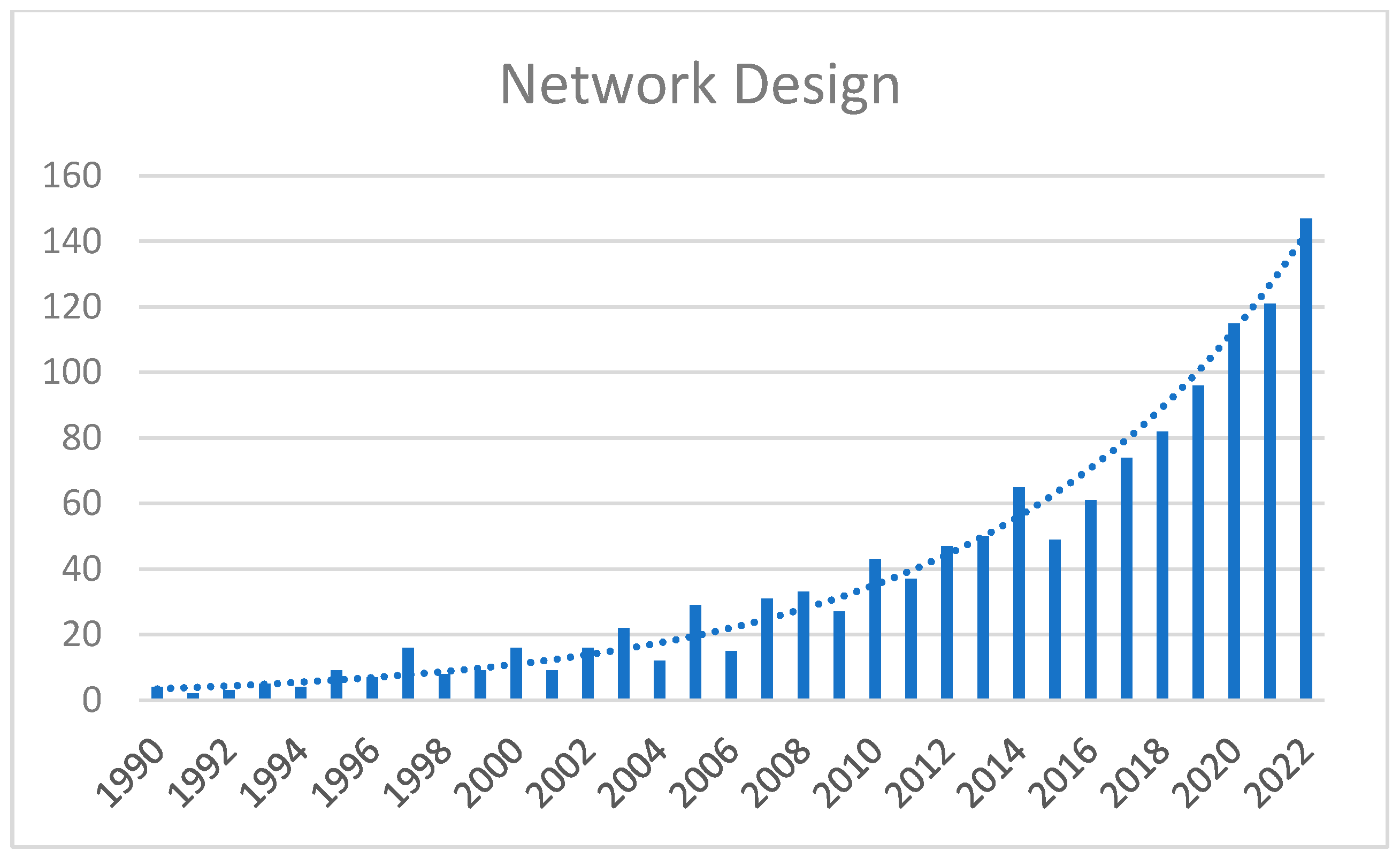

3.2. The Literature’s Evolution and Descriptive Results

3.3. Management

3.3.1. Logistics Management and Chronological Evolution

3.3.2. Management and Regulations

3.3.3. Management and Collaboration

3.3.4. Management and Costs

3.3.5. Management and Inventory

3.3.6. Management and Decision-Making

3.3.7. Management and Risks

3.3.8. Management and Waste Reduction

3.3.9. Management and Information

3.3.10. Management and Cold Chain Deficiencies

3.4. Sustainability

3.4.1. Sustainability and Closed-Loop SCs (CLSCs)

3.4.2. Sustainability and Business Models

3.4.3. Sustainability and Wastage Hotspots

3.4.4. Sustainability and Packing

3.4.5. Sustainability and Information Flow

3.5. Network Design Optimisation

3.5.1. Network Design and Decision Levels

3.5.2. Network Design and the Location–Inventory Problem

3.5.3. Network Design and Routing-Inventory Problem

3.5.4. Network Design and the Location Routing Problem

3.5.5. Network Design and the Integrated Location–Inventory Routing Problem

3.5.6. Network Design and Sustainability

3.5.7. Network Design and Information Flow

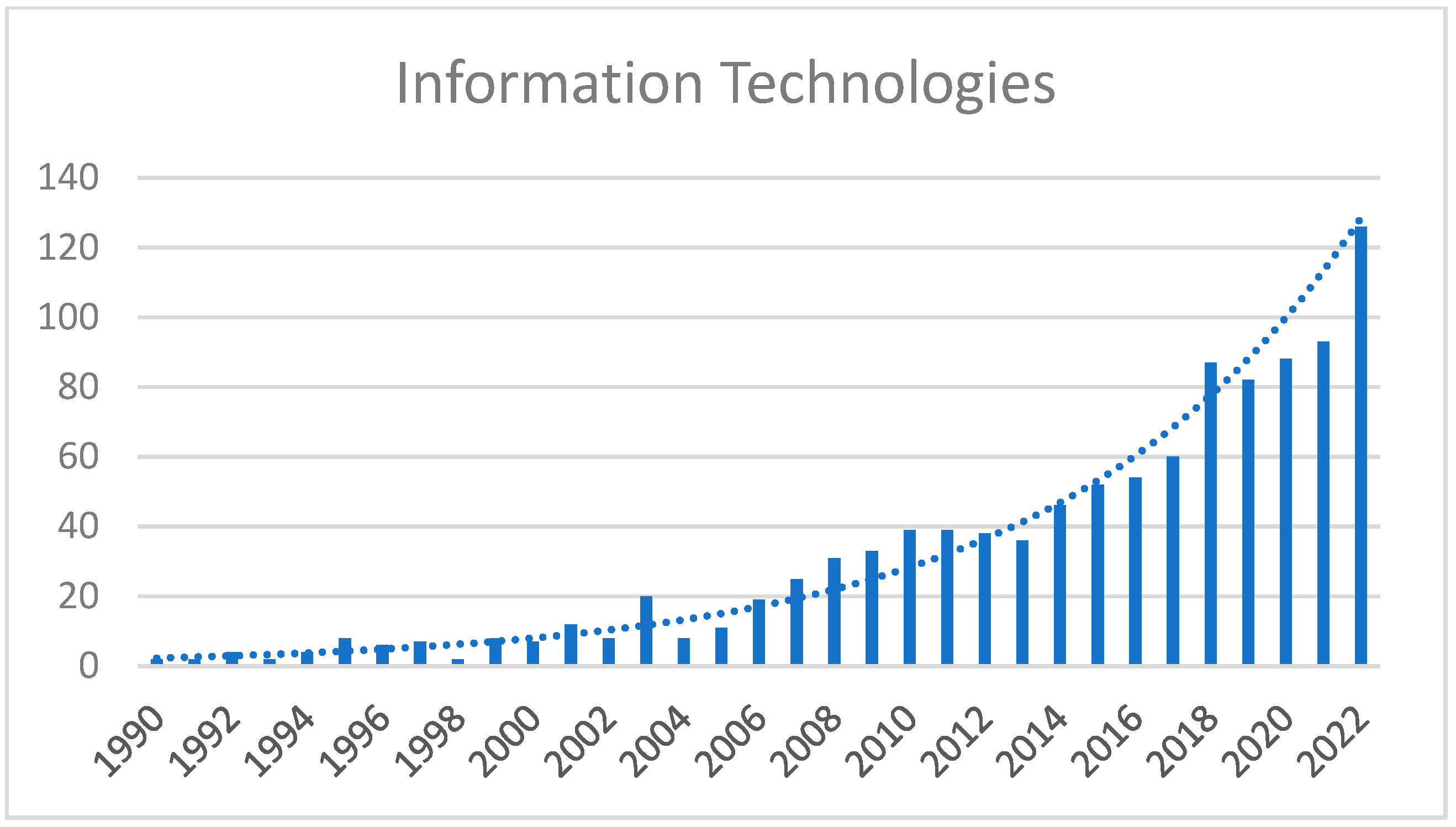

3.6. Information Technologies

3.6.1. IT and Meat SC Transformation

3.6.2. Emerging Information Technologies and Meat SCs

Technical Instruments

Technological Systems

4. Discussion

4.1. Management

4.2. Sustainability

4.3. Network Design

4.4. Information Technology

5. Conclusions

- Management:

- ◦

- Effective management practices are crucial for addressing FLW in beef CSCL systems.

- ◦

- There is a notable transition from LM to FLM and SFLM, with the potential for emerging technologies to create an “Intelligent Sustainable Food Logistics Management” phase.

- ◦

- Suboptimal management practices continue to contribute significantly to FLW, underscoring the need for enhanced strategies and adherence to regulations and standards.

- Sustainability:

- ◦

- Sustainability in beef CSCL involves addressing social, economic, and environmental benefits.

- ◦

- Reducing FLW can lead to increased profits, improved customer satisfaction, public health, equity, and environmental conservation by minimising resource use and emissions.

- ◦

- Comprehensive research integrating all sustainability dimensions is needed to fully understand and mitigate FLW. Current efforts often address only parts of sustainability. A more holistic approach is required to balance environmental, economic, and social dimensions effectively.

- Network Design:

- ◦

- Effective network design and optimisation are pivotal in reducing FLW within beef CSCL systems.

- ◦

- There is a necessity for integrating all three levels of management decisions in the logistics network design process. Decision levels in network design must be considered to understand trade-offs among sustainability components in this process.

- ◦

- Future research should focus on integrating management decisions and network design, CSCL uncertainties, sustainability dimensions, and advanced technologies to enhance efficiency and reduce waste in beef CSCL systems.

- Information Technologies:

- ◦

- Information technologies such as Digital Twins (DTs) and Blockchain (BC) play a significant role in improving efficiency and reducing FLW in beef CSCL.

- ◦

- The integration of these technologies can enhance understanding of fluid dynamics, thermal exchange, and meat quality variations, optimising the cooling process and reducing energy usage.

- ◦

- Challenges like data security and management efficiency need to be addressed to maximise the benefits of these technologies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Scholar, Ref. | Year | Subject | Objectives I | II | Methodology | Industry (Product) | Measures to Reduce FLW |

|---|---|---|---|---|---|---|---|

| Gunasekaran et al. [39] | 2008 | Logistics management | To improve the responsiveness of SCs | To increase the competitiveness of SCs | Group Process and Analytical Hierarchy Process | Multi-industry | - |

| Dabbene et al. [40] | 2008 | Food logistics management | To minimise logistic costs | To maintain food product quality | Stochastic optimisation | Fresh food | - |

| Lipinski et al. [42] | 2013 | Food logistics management | To minimise the costs associated with food waste | To reduce food waste | Qualitative analysis | Food products | Proposing appropriate strategies |

| van der Vorst et al. [43] | 2011 | Food logistics management | To improve the competitiveness level, maintaining the quality of products | To improve efficiency and reduce food waste levels | Qualitative analysis | Agrifood products | The development of a diagnostic instrument for quality-controlled logistics |

| Soysal et al. [45] | 2012 | Sustainable logistics management | To enhance the level of sustainability and efficiency in food supply chains | To reduce FLW levels | Qualitative analysis | Food supply chains | The analysis of existing quantitative models, contributing to their development |

| Bettley and Burnley [48] | 2008 | Sustainable logistics management (SLM) | To improving environmental and social sustainability | To reduce costs and food waste | Qualitative analysis | Multi-industry | application of a closed-loop supply chain concept to incorporate sustainability into operational strategies and practices |

| Zokaei and Simons, [322] | 2006 | SML, Collaboration, Regulation, Cost, Inventory, Waste reduction, Information sharing, | To introduce the food value chain analysis (FVCA) methodology for improving consumer focus in the agri-food sector | To present how the FVCA method enabled practitioners to identify the misalignments of both product attributes and supply chain activities with consumer needs | Statistical analysis/FVCA | Red meat | Suggesting the application of FVCA can improve the overall efficiency and reduce the waste level |

| Cox et al. [323] | 2007 | SML, Cost, Decision-making, Risks, Waste reduction, Sustainability | To demonstrate the proactive alignment of sourcing with marketing and branding strategies in the red meat industry | To showcase how this alignment can contribute to competitive advantage in the food industry | Qualitative | Beef and Red meat | Emphasising the role of the lean approach, identifying waste hotspots, and collaboration in reducing food loss and waste |

| Jie and Gengatharen, [324] | 2019 | SML, Regulation, Collaboration, Cost, Inventory, Waste reduction, Info. Sharing, IT, Sustainability, Sco | To empirically investigate the adoption of supply chain management practices on small and medium enterprises in the Australian food retail sector | To analyse the structure of food and beverage distribution in the Australian retail market | Statistical analysis | Food/Beef Meat Industry | Adopting lean thinking and improving information sharing in the supply chains |

| Knoll et al. [325] | 2017 | SML, Collaboration, Regulation, Cost, Inventory, Decision-making, Risks, Information sharing, Deficiencies, Network design | To characterise the supply chain structure | To identify its major fragilities | Qualitative | Beef meat | - |

| Schilling-Vacaflor, A., [326] | 2021 | Regulation, Sustainability | To analyse the institutional design of supply chain regulations | To integrate human rights and environmental concerns into these regulations | Qualitative | Beef and Soy Industries | - |

| Knoll et al. [327] | 2018 | Regulation, Collaboration, Cost, Risks, Deficiencies, Decision-making, Sustainability, Information sharing | To analyse the information flow within the Sino-Brazilian beef trade, considering the opportunities presented by the Chinese beef market and the vulnerabilities in the supply chain | To investigate the challenges and opportunities in the information exchange process between China and Brazil within the beef trade sector | Mixed method | Beef Industry | - |

| E-Fatima et al. [328] | 2022 | Regulation, Risks, Safety, Collaboration, Business model, Packing, information sharing | To critically examine the potential barriers to the implementation and adoption of Robotic Process Automation in beef supply chains | To investigate the financial risks and barriers to the adoption of RPA in beef supply chains | Mixed method | Beef supply chain | - |

| Jedermann et al. [52] | 2014 | Regulations and Food Safety | To reduce food loss and waste | To improve traceability | Qualitative analysis | Meat and Food products | Proposing appropriate strategies to improve quality monitoring |

| Kayikci et al. [51] | 2018 | Regulations, Sustainability, Waste reduction | To minimise food waste by investigating the role of regulations | To improve sustainability, social and environmental benefits | Grey prediction method | Red meat | Proposing circular and central slaughterhouse model and emphasising efficiency of regulations based on circular economy comparing with the linear economy model |

| Storer et al. [329] | 2014 | Regulation, Collaboration, Cost, Inventory, Decision-making, Risks, IT, Sustainability | To examine how forming strategic supply chain relationships and developing strategic supply chain capability influences beneficial supply chain outcomes | To understand the factors influencing the utilisation of industry-led innovation in the form of electronic business solutions | Mixed methods | Beef supply chain | - |

| Liljestrand, K., [63] | 2017 | Collaboration, FLW, Information sharing | To analyse sustainability practices adopted in collaboration, including vertical collaboration in the food supply chain | To explore the role of collaboration in tackling food loss and waste | Qualitative analysis | Meat and Food products | Investigating how Food Policy can foster collaborations to reduce FLW |

| Mangla et al. [330] | 2021 | Collaboration, food safety and traceability | To enhance food safety and traceability levels through collaboration lens | To examine traceability dimensions and decrease information hiding | Qualitative analysis | Meat and Food products | Offering a framework for collaboration role in reducing info hiding and FLW in the circular economy |

| Liljestrand, K. [63] | 2017 | Collaboration, FLW, Information sharing | To investigate the role of logistics management and relevant solutions in reducing FLW | To explore the role of collaboration in food supply chains | Qualitative analysis | Meat and Food products | Examining the role of collaborative forecasting in reducing food waste |

| Esmizadeh et al. [79] | 2021 | Cost and Network design | To investigate the relations among cost, freshness, travel time, and Hub facilities vs Distribution centres | To investigate the product perishability effect in the distribution phase under hierarchical hub network design | Deterministic optimisation | Meat and food products | - |

| Cristóbal et al. [304] | 2018 | Cost, FLW and Sustainability | To consider the cost factor in the planning to reduce FLW | To develop a method to reduce costs and FLW environmental effects and improve the sustainability level | Mixed method | Meat and Food products | Proposing novel methods and programmes for cost effective and sustainable FLW management |

| Esmizadeh et al. [79] | 2021 | Cost and Network design | To investigate the relations among cost, freshness, travel time, and Hub facilities vs Distribution centres | To investigate the product perishability effect in the distribution phase under hierarchical hub network design | Deterministic optimisation | Meat and food products | - |

| Faisal. M. N., [331] | 2015 | Cost, Risks, Regulations, Deficiencies, Collaboration, Decision-making, IT, Information sharing | To identify variables that act as inhibitors to transparency in a red meat supply chain | To contribute to making the supply chain more transparent | Mixed method | Red meat | - |

| Shanoyan et al. [332] | 2019 | Cost, Risks, Information sharing | To analyse the incentive structures at the producer–processor interface within the beef supply chain in Brazil | To assess the dynamics and effectiveness of incentive mechanisms between producers and processors in the Brazilian beef supply chain | Qualitative | Beef Industry | - |

| Nakandala et al. [333] | 2016 | Cost, Sustainability | To minimise transportation costs and CO2 emissions | To maximise product freshness and quality | Stochastic optimisation | Meat and food products | - |

| Ge et al. [334] | 2022 | Cost, Decision-making, | To develop an optimal network model for the beef supply chain in the Northeastern US | To optimize the operations within this supply chain | Mathematical modelling | Beef meat | - |

| Hsiao et al. [335] | 2017 | Cost, Inventory, Network design | To maximise distribution efficiency and customer satisfaction | ZTo minimise the quality drop of perishable food products/meat | Deterministic optimisation | Meat products | - |

| Shanoyan et al. [332] | 2019 | Cost, Risks, Information sharing | To analyse the incentive structures at the producer–processor interface within the beef supply chain in Brazil | To assess the dynamics and effectiveness of incentive mechanisms between producers and processors in the Brazilian beef supply chain | Qualitative | Beef Industry | - |

| Magalhães et al. [85] | 2020 | Inventory and FW | To identify FLW causes in the beef supply chain in Brazil and explore the role of inventory management strategies and demand forecasting in FLW issue | To investigate their interconnections | Mixed method | Beef meat industry | Providing a theoretical basis to implement appropriate FLW mitigation strategies |

| Jedermann et al. [52] | 2014 | Inventory and Food Safety | To reduce food loss and waste | To improve traceability | Qualitative analysis | Meat and Food products | Proposing appropriate strategies to improve quality monitoring |

| Meksavang et al. [336] | 2019 | Inventory, Cost, Decision-making, Information sharing, Sustainability | To develop an extended picture fuzzy VIKOR approach for sustainable supplier management | To apply the developed approach in the beef industry for sustainable supplier management | Mixed methods | Beef meat | - |

| Herron et al. [89] | 2022 | Inventory and Sustainability | To identify the minimum shelf life required to prevent food waste and develop FEFO models | To identify the risk of food products reaching the bacterial danger zone | Deterministic optimisation | Meat products | Building a decision-making model and incorporating quality and microbiological data |

| Rahbari et al. [95] | 2021 | Decision-making and Network design | To minimise distribution cost, variable cost | To reduce inventory costs, the total cost | Deterministic optimisation | Red meat | - |

| Taylor D.H., [337] | 2006 | Decision-making, Cost Risks, Inventory, Waste Reduction, Deficiencies, Sustainability, Env. | To examine the adoption and implementation of lean thinking in food supply chains, particularly in the UK pork sector | To assess the environmental and economic impact of lean practices in the agri-food supply chain | Qualitative | Red meat | Suggesting the combination of Value Chain Analysis and Lean principles |

| Erol and Saghaian, [338] | 2022 | Risks, Cost, Regulation | To investigate the dynamics of price adjustment in the US beef sector during the COVID-19 pandemic | To analyse the impact of the pandemic on price adjustments within the US beef sector | Mixed method | Beef Industry | - |

| Galuchi et al. [339] | 2019 | Risks, Regulations, Sustainability, Soc., Env. | To identify the main sources of reputational risks in Brazilian Amazon beef supply chains | To analyse the actions taken by slaughterhouses to manage these risks | Mixed method | Beef supply chain | Mitigating risks |

| Silvestre et al. [340] | 2018 | Risks, Collaboration, Regulation, Management, Sustainability | To examine the challenges associated with sustainable supply chain management | To propose strategies for addressing identified challenges | Qualitative | Beef Industry | - |

| Bogataj et al. [125] | 2020 | Risks, Cost, Sustainability, Inventory | To maximise the profit | To improve sustainability performance | Mixed method | Beef industry | Incorporating the remaining shelf life in the decision-making process |

| Nguyen et al. [126] | 2023 | Risks, Waste reduction, Sustainability, Cost, Inventory | To improve the operational efficiency | To reduce carbon footprint and food waste | Statistical analysis | Beef industry | Identifying the root causes of waste and proposing a framework composed of autonomous agents to minimise waste |

| Amani and Sarkodie, [129] | 2022 | Risks, Information technologies, Sustainability | To minimise overall cost and waste | To improve the sustainability performance | Stochastic optimisation | Meat products | Incorporating artificial intelligence in the management context |

| Klein et al. [130] | 2014 | Risks, Information Technologies | To analyse the use of mobile technology for management and risk control | To identify drivers and barriers to mobile technology adoption in risk reduction | - | Beef meat | Introducing a framework that connects the challenges associated with the utilisation of mobile technology in SCM and risk control |

| Gholami-Zanjani et al. [138] | 2021 | Risk, ND, Inventory, Wastage Hot Spots, Sustainability | To reduce the risk effect and improve the resiliency against disruptions | To minimise environmental implications | Stochastic optimisation | Meat products | - |

| Buisman et al. [87] | 2019 | Waste reduction | To reduce food loss and waste at the retailer level | To improve food safety level and maximise the profit | Stochastic optimisation | Meat and Food products | Employing a dynamically adjustable expiration date strategy and discounting policy |

| Verghese et al. [109] | 2015 | Waste reduction, Information Technologies and Sustainability | To reduce food waste in food supply chains and relevant costs | To improve the sustainability performance | Qualitative analysis | Meat and Food products | Applying of information technologies and improved packaging |

| Jedermann et al. [52] | 2014 | Waste reduction | To reduce food loss and waste | To improve traceability | Qualitative analysis | Meat and Food products | Introducing some initiatives and waste reduction action plans |

| Mohebi and Marquez, [131] | 2015 | Waste reduction and Information Technologies | To improve the customer satisfaction and the quality of food products | To reduce food waste and loss | Qualitative analysis | Meat products | Proposing strategies and technologies for meat quality monitoring during the transport and storage phases |

| Kowalski et al. [133] | 2021 | Waste reduction and Information Technologies | To reduce food waste | To create a zero-waste solution for handling dangerous meat waste | Mixed method | Meat products | Recovering meat waste and transforming it into raw, useful materials |

| Beheshti et al. [135] | 2022 | Waste reduction, Network design, and Information Technologies | To reduce food waste by optimising the initial rental capacity and pre-equipped capacity required for the maximisation of profit | To optimise CLSCs and to improve cooperation level among supply chain stakeholders | Stochastic optimisation | Meat products | Applying optimisation across reverse logistics and closed-loop supply chains |

| Albrecht et al. [140] | 2020 | Waste reduction, IT, Decision-making, Inventory | To examine the effectiveness of sourcing strategy in reducing food loss and waste and product quality | To validate the applicability of the TTI monitoring system for meat products | Mixed method | Meat products | Applying of new information technologies in order to monitor the quality of products |

| Eriksson et al. [341] | 2014 | Waste reduction and Sustainability | To compare the wastage of organic and conventional meats | To compare the wastage of organic and conventional food products | Mixed method | Meat and perishable food products | Providing hints to reduce the amount of food loss and waste based on research findings |

| Accorsi et al. [342] | 2019 | Waste reduction, Decision support, Sustainability (Eco., Soc., Env.) | To address sustainability and environmental concerns related to meat production and distribution | To maximise the profit | Deterministic optimisation | Beef and meat products | Providing a decision-support model for the optimal allocation flows across the supply chain and a system of valorisation for the network |

| Jo et al. [146] | 2015 | Information technologies, Sustainability | To reduce food loss and waste levels, improve food traceability and sustainability | To minimise CO2 emissions | Mixed method | Beef meat products | Incorporating blockchain technology |

| Ersoy et al. [343] | 2022 | Information technologies, Sustainability, Food loss and Waste | To improve collaboration among multi-tier suppliers through knowledge transfer and to provide green growth in the industry | To improve traceability in the circular economy context through information technology innovations | Statistical analysis | Meat products | Suggesting a validated conceptual framework expressing the role of information technologies in information sharing |

| Kler et al. [147] | 2022 | Information technologies, Sustainability | To minimise transport CO2 emission level and food waste level | To improve traceability and demand monitoring levels | Data Analytics | Meat products | Employing information technologies (IoT) and utilising data analytics for optimising the performance |

| Singh et al. [118] | 2018 | IT, Information sharing, Waste reduction, Decision-making, and Packing | To explore the application of social media data analytics in enhancing supply chain management within the food industry | To investigate how social media data analytics can be utilised to improve decision-making processes and operational efficiency | Mixed method | Beef and food supply chain | Highlighting the role of content analysis of Twitter data obtained from beef supply chains and retailers |

| Martinez et al. [23] | 2007 | Deficiencies, Regulation, Cost, Inventory | To improve food safety | To lower regulatory cost | Statistical analysis | Meat and food products | - |

| Kayikci et al. [51] | 2018 | Deficiencies, Regulations, Waste reduction, Sustainability | To minimise food waste by investigating the role of regulations | To improve sustainability, social and environmental benefits | Grey prediction method | Red meat | Proposing circular and central slaughterhouse model and emphasising efficiency of regulations based on circular economy comparing with the linear economy model |

| Nychas et al. [151] | 2008 | Deficiencies, Waste reduction, Information Technologies | To characterise the microbial spoilage of meat samples during distribution | To assess the factors contributing to meat spoilage | Mixed method | Meat products | Identifying and discussing factors contributing to meat spoilage |

| Sander et al. [161] | 2018 | Deficiencies, Risks, Information Technologies | To investigate meat traceability by outlining the different aspects of transparency | To understand the perspectives of various stakeholders regarding BCT | Qualitative analysis | Meat products | - |

| Scholar, Ref. | Year | Subject | Objectives I | II | Methodology | Industry (Product) | Measures to Reduce FLW |

|---|---|---|---|---|---|---|---|

| Mahbubi and Uchiyama, [344] | 2020 | Eco, Soc., Evn., Management, Collaboration, IT, Information sharing | To identify the Indonesian halal beef supply chain’s basic system | To assess the sustainability level in the Indonesian halal beef supply chain | Life cycle assessment | Beef Industry | Identifying waste in different actors’ sections |

| Bragaglio et al. [345] | 2018 | Env., Management, Inventory, Decision-making | To assess and compare the environmental impacts of different beef production systems in Italy | To provide a comprehensive analysis of the environmental implications | Life cycle assessment | Beef Industry | - |

| Zeidan et al. [346] | 2020 | Env., Management, Collaboration, Cost | To develop an existence inductive theory | To study coordination failures in sustainable beef production | Qualitative | Beef Industry | - |

| Santos and Costa, [347] | 2018 | Env., Packing, Management, Cost, Regulations | To assess the role of large slaughterhouses in promoting sustainable intensification of cattle ranching in the Amazon and the Cerrado | To evaluate the environmental and social impacts of large slaughterhouses | Statistical Analysis | Beef Industry | - |

| E-Fatima et al. [348] | 2023 | Business model, Packing, Eco., Socio., Env., Management, Waste reduction | To investigate the financial risks and barriers in the adoption of robotic process automation (RPA) in the beef supply chains | To examine the potential influence of RPA on sustainability in the beef industry | Simulation | Beef Industry | Adopting Robotic Process Automation |

| Huerta et al. [349] | 2015 | Env., Packing, Waste Management, Waste | To assess the environmental impact of beef production in Mexico | To conduct a life cycle assessment of the beef production process | Life cycle assessment | Beef Industry | Suggesting utilising generated organic waste to produce usable energy |

| Cox et al. [350] | 2007 | Env., Business model, Packing, Management, Waste reduction, Information sharing, Cost, Risk | To explore the creation of sustainable strategies within red meat supply chains | To investigate the development of sustainable practices and strategies in the context of red meat supply chains | Qualitative | Red meat Industry | Proposing the adoption of lean strategies in the red meat supply chain industry |

| Teresa et al. [351] | 2018 | Eco., Env., Business model, Management, Deficiencies, Regulation, Collaboration, Cost | To provide current perspectives on cooperation among Irish beef farmers | To explore the future prospects of cooperation within the context of new producer organisation legislation | Qualitative | Beef Industry | Highlighting the role of legislation in the joint management of waste |

| Kyayesimira et al. [352] | 2019 | Eco., Waste hotspots, Management, Regulations | To identify and analyse the causes of losses at various post-harvest handling points along the beef value chain in Uganda | To estimate the economic losses incurred due to those factors | Statistical analysis | Beef Industry | Providing insights into potential improvements in the beef value chain management |

| Ranaei et al. [353] | 2021 | Env., Eco., Wastage hotspots Management, deficiencies, Waste reduction, Regulation, Collaboration | To identify the causes of meat waste and meat value chain losses in Iran | To propose solutions to reduce meat value chain losses | Qualitative | Meat/Red Meat Industry | Identifying the causes and hotspots of wastage points and proposing solutions |

| Wiedemann et al. [354] | 2015 | Env., Eco., Waste hotspots, Manag., Inventory | To assess the environmental impacts and resource use associated with meat export | To determine the environmental footprint | Life Cycle Assessment | Red meat Industry | Providing insights into potential improvements |

| Pinto et al. [167] | 2022 | Sustainability (Eco., Evo., Soc.) Management | To explore the sustainable management and utilisation of animal by-products and food waste in the meat industry | To analyse the food loss and waste valorisation of animal by-products | Mixed method | Meat products and industry | Employing the CE concept in the context of the meat supply chain suggested the development of effective integrated logistics for wasted product collection |

| Chen et al. [195] | 2021 | Sustainability (Env.) and Management | To identify existing similarities among animal-based supply chains | To measure the reduction effect of interventions applied | Mixed method | Beef meat and food products | Applying the food waste reduction scenario known to be effective in emission reduction |

| Martínez and Poveda, [355] | 2022 | Sustainability (Env.), Management | To minimise environmental impacts by exploring refrigeration system characteristics | To develop refrigeration systems-based policies for improving food quality | Mixed method | Meat and food products | - |

| Peters et al. [202] | 2010 | Sustainability (Env.), Wastage hotspots | To assess the environmental impacts of red meat in a lifecycle scope | To compare the findings with similar cases across the world | Life Cycle Impact Assessment | Beef meat and red meat | - |

| Soysal et al. [251] | 2014 | Sustainability (Env.), Wastage hotspots, Network Design | To minimise inventory and transportation costs | To minimise CO2 emissions | Deterministic optimisation | Beef meat | - |

| Mohebalizadehgashti et al. [252] | 2020 | Sustainability (Env.), Wastage hotspots, Network Design | To maximise facility capacity, minimise total cost | To minimise CO2 emissions | Deterministic optimisation | Meat products | - |

| Fattahi et al. [356] | 2013 | Sustainability (Env.), Packing, Management | To develop a model for measuring the performance of meat SC | To analyse the operational efficiency of meat SC | Mixed method | Meat products | - |

| Florindo et al. [357] | 2018 | Sustainability (Env.), Wastage hotspots, Management | To reduce carbon footprint | To evaluate performance | Mixed method | Beef meat | - |

| Diaz et al. [358] | 2021 | Sustainability (Env.), Wastage hotspots | To conduct a lifecycle-based study to find the impact of energy efficiency measures | To evaluate environmental impacts and to optimise the energy performance | Life Cycle Impact Assessment | Beef meat | Reconversing of Energy from Food Waste through Anaerobic Processes |

| Schmidt et al. [359] | 2022 | Sustainability (Env.), Wastage hotspots, Management, Information Technologies | To optimise the supply chain by considering food traceability, economic, and environmental issues | To reduce the impact and cost of recalls in case of food safety issues | Deterministic optimisation | Meat products | - |

| Mohammed and Wang, [169] | 2017 | Sustainability (Eco.) Management, Decision-making, Network design | To minimise total cost, To maximise delivery rate | To minimise CO2 emissions and distribution time | Stochastic optimisation | Meat products | - |

| Asem-Hiablie et al. [203] | 2019 | Sustainability (Env.), energy consumption, greenhouse gas | To quantify the sustainability impacts associated with beef products | To identify opportunities for reducing its environmental impacts | Life cycle assessment | Beef industry | - |

| Bottani et al. [206] | 2019 | Sustainability (Eco., and Env.), Packaging, Waste management | To conduct an economic assessment of various reverse logistics scenarios for food waste recovery | To perform an environmental assessment for them | Life cycle assessment | Meat and food industry | Examining and employing different reverse logistics scenarios |

| Kayikci et al. [51] | 2018 | Sustainability (Eco., Soc., Env.) Management, Regulations, Waste reduction | To minimise food waste by investigating the role of regulations | To improve sustainability, social and environmental benefits | Grey prediction method | Red meat | Proposing circular and central slaughterhouse model and emphasising efficiency of regulations based on circular economy comparing with the linear economy model |

| Tsakiridis et al. [204] | 2020 | Sustainability (Env.), Information technologies | To compare the economic and environmental impact of aquatic and livestock products | To employ environmental impacts into the Bio-Economy model | Life cycle assessment | Beef and meat products | - |

| Jo et al. [146] | 2015 | Sustainability (Eco. and Env.), Management, Cost, Food Safety, Risks, Information Technologies | To reduce food loss and waste levels, improve food traceability and sustainability | To minimise CO2 emissions | Mixed method | Beef meat products | Incorporating blockchain technology |

| Jeswani et al. [224] | 2021 | Sustainability (Env.), Waste management | To assess the extent of food waste generation in the UK | To evaluate its environmental impacts | Life cycle assessment | Meat products | Quantifying the extent of FW and impact assessment |

| Accorsi et al. [210] | 2020 | Sustainability (Eco. and Env.), Waste Management, Decision-making, Network design (LIP) | To reduce waste and enhance sustainability performance | To assess the economic and environmental implications of the proposed FSC | Deterministic optimisation | Meat and food industry | Designing a closed-loop packaging network |

| Chen et al. [195] | 2021 | Sustainability (Env.) and Waste Management | To identify the environmental commonality among selected FSCs | To measure the reduction effect of novel interventions for market characteristics | Life cycle assessment | Beef meat and food products | Confirming the efficiency of food waste management and reduction scenario |

| Sgarbossa et al. [175] | 2017 | Sustainability (Eco., Evo., Soc.) Network design | To develop a sustainable model for CLSC | To incorporate all three dimensions of sustainability | Deterministic optimisation | Meat products | Converting food waste into an output of a new supply chain |

| Zhang et al. [176] | 2022 | Sustainability (Eco. and Env.), Packaging, Network design | To maximise total profit | To minimise environmental impact, carbon emissions | Stochastic optimisation | Meat and food products | Using Returnable transport items instead of one-way packaging |

| Irani and Sharif., [223] | 2016 | Sustainability (Soc.) Management, IT | To explore sustainable food security futures | To provide perspectives on FW and IT across the food supply chain | Qualitative analysis | Meat and food products | Discussing potential strategies for waste reduction |

| Martindale et al. [180] | 2020 | Sustainability (Eco. and Env.), Management, food safety, IT (BCT) | To develop CE theory application in FSCs by employing a large geographical database | To test the data platforms for improving sustainability | Mixed method | Meat and food products | - |

| Mundler, and Laughrea, [187] | 2016 | Sustainability (Eco., Env., Soc.) | To evaluate short food supply chains’ contributions to the territorial development | To characterise their economic, social, and environmental benefits | Mixed method | Meat and food products | - |

| Vittersø et al. [189] | 2019 | Sustainability (Eco., Env., Soc.) | To explore the contributions of short food supply chains to sustainability | To understand its impact on all sustainability dimensions | Mixed method | Meat and food products | - |

| Bernardi and Tirabeni, [193] | 2018 | Sustainability (Eco., Env., Soc.) | To explore alternative food networks as sustainable business models | To explore the potentiality of the sustainable business model proposed | Mixed method | Meat and food products | Emphasising the role of accurate demand forecast |

| Bonou et al. [197] | 2020 | Sustainability (Env.) | To evaluate the environmental impact of using six different cooling technologies | To conduct a comparative study of pork supply chain efficiency | Life cycle assessment | Pork products | - |

| Apaiah et al. [201] | 2006 | Sustainability (Env.), Energy consumption | To examine and measure the environmental sustainability of food supply chains using exergy analysis | To identify improvement areas to diminish their environmental implications | Exergy analysis | Meat products | - |

| Peters et al. [202] | 2010 | Sustainability (Env.), energy consumption, greenhouse gas | To assess greenhouse gas emissions and energy use levels of red meat products in Australia | To compare its environmental impacts with other countries | Life cycle assessment | Red meat products | - |

| Farooque et al. [21] | 2019 | Sustainability (Env., and Eco.) Management, Regulation, Collaboration | To identify barriers to employing the circular economy concept in food supply chains | To analyse the relationship of identified barriers | Mixed method | Food products | Employing the CE concept in the context of the food supply chain |

| Kaipia et al. [93] | 2013 | Sustainability (Eco. and Env.) Management, Inventory, Information Technologies | To improve sustainability performance via information sharing | To reduce FLW level | Qualitative analysis | Food products | Incorporating demand and shelf-life data information sharing effect |

| Majewski et al. [191] | 2020 | Sustainability (Env.) and Waste management | To determine the environmental impact of short and longfood supply chains | To compare the environmental sustainability of short and long-food supply chains | Life cycle assessment | Food products | - |

| Rijpkema et al. [139] | 2014 | Sustainability (Eco. and Env.) Management, Waste reduction, Information Technologies | To create effective sourcing strategies for supply chains dealing with perishable products | To provide a method to reduce food waste and loss amounts | Simulation model | Food products | Proposing effective sourcing strategies |

| Scholar, Ref. | Year | Modelling Stages: Single or Multi | Solving Approach | Objectives I | II/III | Model Type | Supply Chain Industry (Product) | Main Attributes |

|---|---|---|---|---|---|---|---|---|

| Domingues Zucchi et al. [360] | 2011 | M | Metaheuristic/GA and CPLEX | To minimise the cost of facility installation | To minimise costs for sea and road transportation | MIP | Beef meat | LP |

| Soysal et al. [251] | 2014 | S | ε-constraint method | To minimise inventory and transportation cost | To minimise CO2 emissions | LP | Beef meat | PIAP |

| Rahbari et al. [95] | 2021 | M | GAMS | To minimise total cost | To minimise inventory, transport, storage costs | MIP | Red meat | PLIRP |

| Rahbari et al. [249] | 2020 | S | GAMS | To minimise total cost | MIP | Red meat | PLIRP | |

| Neves-Moreira et al. [245] | 2019 | S | Metaheuristic | To minimise routing cost | To minimise inventory holding cost | MIP | Meat | PRP |

| Mohammadi et al. [241] | 2023 | S | Pre-emptive fuzzy goal programming | To maximise total profit | To minimise adverse environmental impacts | MINLP | Meat/Perishable food products | LIP |

| Mohebalizadehgashti et al. [252] | 2020 | S | ε-constraint method | To maximise facility capacity, minimise total cost | To minimise CO2 emissions | MILP | Meat | LAP |

| Mohammed and Wang, [247] | 2017a | S | LINGO | To minimise total cost | To minimise number of vehicles/delivery time | MOPP | Meat | LRP |

| Mohammed and Wang, [169] | 2017b | S | LINGO | To minimise otal cost, to maximise delivery rate | To minimise CO2 emissions and distribution time | FMOP | Meat | LRP |

| Gholami Zanjani et al. [138] | 2021 | M | Metaheuristic | To improve the resilience and sustainability | To minimise inventory holding cost | MP | Meat | IP |

| Tarantilis and Kiranoudis, [242] | 2002 | S | Metaheuristic | To minimise total cost | To maximise the efficiency of distribution | OMDVRP | Meat | LRP |

| Dorcheh and Rahbari, [361] | 2023 | M | GAMS | To minimise total cost | To minimise CO2 emissions | MP | Meat/Poultry | IRP |

| Al Theeb et al. [74] | 2020 | M | Heuristic CPLEX | To minimise total cost, holding costs, and penalty cost | To maximise the efficiency of transport and distribution phase | MILP | Meat/Perishable food products | IRP |

| Moreno et al. [231] | 2020 | S | Metaheuristic/hybrid approach | To maximise the profit | To minimise the costs, delivery times | MIP | Meat | LRP |

| Javanmard et al. [362] | 2014 | S | Metaheuristic/Imperialist competitive algorithm | To minimise inventory holding cost | To minimise total cost | NS | Food and Meat | IRP |

| Ge et al. [334] | 2022 | S | Heuristic algorithm | To develop an optimal network model for the beef supply chain in the Northeastern US | To optimize the operations within this supply chain | MILP | Beef meat | LRP |

| Hsiao et al. [335] | 2017 | S | Metaheuristic/GA | To maximise distribution efficiency and customer satisfaction | To minimise the quality drop of perishable food products/meat | MILP * | Meat/Perishable food products | LRP |

| Govindan et al. [246] | 2014 | M | Metaheuristic/MHPV | To minimise carbon footprint | To minimise of the cost of greenhouse gas emissions | MOMIP * | Perishable food products | LRP |

| Zhang et al. [243] | 2003 | S | Metaheuristic | To minimise cost, food safety risks | To maximise the distribution efficiency | MP * | Perishable food products | LRP |

| Wang and Ying, [244] | 2012 | S | Heuristic, Lagrange slack algorithm | To maximise the delivery efficiency | To minimise the total costs | MINLP * | Perishable food products | LRP |

| Liu et al. [234] | 2021 | S | YALMIP toolbox | To minimise cost and carbon emission | To maximise product freshness | MP/MINLP | Perishable food products | LIRP |

| Dia et al. [363] | 2018 | S | Metaheuristic/GA | To minimise total cost | To reduce greenhouse gas emissions/maximise facility capacity | MINLP | Perishable food products | LIP |

| Saragih et al. [364] | 2019 | S | Simulated annealing | To fix warehouse cost | To minimise nventory cost, holding cost, and total cost | MINLP | Food products | LIRP |

| Biuki et al. [230] | 2020 | M | GA and PSO | To incorporate the three dimensions of sustainability | To minimise total cost, maximise facility capacity | MIP * | Perishable products | LIRP |

| Hiassat et al. [365] | 2017 | S | Genetic algorithm | To implement facility and inventory storage cost | To minimise routing cost | MIP | Perishable products | LIRP |

| Le et al. [366] | 2013 | S | Heuristic- Column generation | To minimise transport cost | To minimise inventory cost | MP | Perishable products | IRP |

| Wang et al. [367] | 2016 | S | Two-phase Heuristic and Genetic algorithm | To minimise total cost | To maximise the freshness of product quality | MP | Perishable food products | RP |

| Rafie-Majd et al. [368] | 2018 | S | Lagrangian relaxation/GAMS | To minimise total cost | To minimise product wastage | MINLP * | Perishable products | LIRP |

| Scholar, Ref. | Year | Subject | Objectives I | II | Methodology | Industry (Product) | Measures to Reduce FLW |

|---|---|---|---|---|---|---|---|

| Singh et al. [267] | 2018 | Information technologies, Sustainability, Regulations, Management | To measure greenhouse emission levels and select green suppliers with top-quality products | To reduce carbon footprint and environmental implications | Mixed method | Beef supply chain | - |

| Singh et al. [369] | 2015 | Information technologies, Sus. (Env.), Inventory, Collaboration, Management | To reduce carbon footprint and carbon emissions | To propose an integrated system for beef supply chain via the application of IT | Simulation | Beef supply chain | - |

| Juan et al. [7] | 2014 | Information technologies, Management, Inventory, Collaboration, Management | To explore the role of supply chain practices, strategic alliance, customer focus, and information sharing on food quality | To explore the role of lean system and cooperation, trust, commitment, and information quality on food quality | Statistical analysis | Beef supply chain | By application of IT and Lean system strategy |

| Zhang et al. [370] | 2020 | Information technologies, Management, Inventory, Food quality and safety | To develop a performance-driven conceptual framework regarding product quality information in supply chains | To enhance the understanding of the impact of product quality information on performance | Statistical analysis | Red meat supply chain | - |

| Cao et al. [371] | 2021 | IT, Blockchain, Management, Regulation, Collaboration, Risks, Cost, Waste reduction | To enhance consumer trust in the beef supply chain traceability through the implementation of a blockchain-based human–machine reconciliation mechanism | To investigate the role of blockchain technology in improving transparency and trust within the beef supply chain | Mixed method | Beef products | By applying new information technologies |

| Kassahun et al. [372] | 2016 | IT and ICTs | To provide a systematic approach for designing and implementing chain-wide transparency systems | To design and implement a transparency system/software for beef supply chains | Simulation | Beef meat Industry | By improving the traceability |

| Ribeiro et al. [373] | 2011 | IT and ICTs | To present and discuss the application of RFID technology in Brazilian harvest facilities | To analyse the benefits and challenges of implementing RFID | Qualitative | Beef Industry | - |

| Jo et al. [146] | 2015 | IT (BCT) Sustainability (Eco. and Env.), Management, Cost, Food safety, Risks | To reduce food loss and waste levels, improve food traceability and sustainability | To minimise CO2 emissions | Mixed method | Beef meat products | By incorporating blockchain technology |

| Rejeb, A., [227] | 2018 | IT (IoT, BCT), Management, risks, food safety | To propose a traceability system for the Halal meat supply chain | To mitigate the centralised, opaque issues and the lack of transparency in traceability systems | Mixed method | Beef meat and meat products | - |

| Cao et al. [374] | 2022 | IT and blockchain, Management, Collaboration, Risk, Cost, Sustainability | To propose a blockchain-based multisignature approach for supply chain governance | To present a specific use case from the Australian beef industry | A novel blockchain-based multi-signature approach | Beef Industry | - |

| Kuffi et al. [291] | 2016 | Digital 3D geometry scanning | To develop a CFD model to predict the changes in temperature and pH distribution of a beef carcass during chilling | To improve the performance of industrial cooling of large beef carcasses | Simulations | Beef meat products | - |

| Powell et al. [289] | 2022 | Information technologies, (IoT and BCT) | To examine the link between IoT and BCT in FSC for traceability improvement | To propose solutions for data integrity and trust in the BCT and IoT-enabled food SCs | Mixed method | Beef meat products | - |

| Jedermann et al. [52] | 2014 | Management, Regulations and Food Safety, FW, Information sharing, RFID | To reduce food loss and waste | To improve traceability | Qualitative analysis | Meat and Food products | By proposing appropriate strategies to improve quality monitoring |

| Liljestrand, K., [63] | 2017 | Collaboration, FLW, Information sharing | To analyse sustainability practices adopted in collaboration, including vertical collaboration in the food supply chain | To explore the role of collaboration in tackling food loss and waste | Qualitative analysis | Meat and Food products | By investigating how Food Policy can foster collaborations to reduce FLW |

| Liljestrand, K., [63] | 2017 | Collaboration, FLW, Information sharing | To analyse sustainability practices adopted in collaboration, including vertical collaboration in the food supply chain | To explore the role of collaboration in tackling food loss and waste | Qualitative analysis | Meat and Food products | By investigating how Food Policy can foster collaborations to reduce FLW |

| Harvey, J. et al. [228] | 2020 | IT and ICTs, Sustainability (Env. and Sco.), waste reduction, Management, decision-making | To conduct social network analysis of food sharing, redistribution, and waste reduction | To reduce food waste via information sharing and IT application | Mixed method | Food products | By examining the potential of social media applications in reducing food waste through sharing and redistribution |

| Rijpkema et al. [139] | 2014 | IT (Sharing), Sustainability Management, Waste reduction | To create effective sourcing strategies for SCs dealing with perishable products | To provide a method to reduce food waste and loss amounts | Simulation model | Food products | By proposing effective sourcing strategies |

| Wu, and Hsiao., [375] | 2021 | Information technologies, Management, Inventory, Food quality and safety, Risks | To identify and evaluate high-risk factors | To mitigate risks and food safety accidents | Mixed method | Food supply chain | By reducing food quality and safety risks and employing improvement plans |

| Kaipia et al. [93] | 2013 | IT (Sharing), Sustainability (Eco. and Env.) Management, Inventory | To improve sustainability performance via information sharing | To reduce FLW level | Qualitative analysis | Food products | By incorporating demand and shelf-life data information sharing effect |

| Mishra, N., and Singh, A., [229] | 2018 | IT and ICTs, Sustainability (Env.), waste reduction, Management, decision-making | To utilise Twitter data for waste minimisation in the beef supply chain | To contribute to the reduction in food waste | Mixed method | Food products | By offering insights into potential strategies for reducing food waste via social media and IT |

| Parashar et al. [18] | 2020 | Information sharing (IT), Sustainability (Env.), FW Management (regulation, inventory, risks) | To model the enablers of the food supply chain and improve its sustainability performance | To address the reducing carbon footprints in the food supply chains | Mixed method | Food products | By facilitating the strategic decision-making regarding reducing food waste |

| Tseng et al. [58] | 2022 | Regulations, Sustainability, Information technologies, (IoT and BCT) | To conduct a data-driven comparison of halal and non-halal sustainable food supply chains | To explore the role of regulations and standards in ensuring the compliance of food products with Halal requirements and FW reduction | Mixed method | Food products | By highlighting the role of legislation in reducing food waste and promoting sustainable food management |

| Mejjaouli, and Babiceanu, [101] | 2018 | Information technologies (RFID-WSN), Management, Decision-making | To optimise logistics decisions based on actual transportation conditions and delivery locations | To develop a logistics decision model via an IT application | Stochastic optimisation | Food products | - |

| Wu et al. [292] | 2019 | IT (Information exchange), Sustainability (Eco., and Env.) | To analyse the trade-offs between maintaining fruit quality and reducing environmental impacts | To combine virtual cold chains with life cycle assessment to provide a holistic approach for evaluating the environmental trade-offs | Mixed method | Food/fruit products | By suggesting a more sustainability-driven cold chain scenario |

References

- Ren, Q.-S.; Fang, K.; Yang, X.-T.; Han, J.-W. Ensuring the quality of meat in cold chain logistics: A comprehensive review. Trends Food Sci. Technol. 2022, 119, 133–151. [Google Scholar] [CrossRef]

- Nastasijević, I.; Lakićević, B.; Petrović, Z. (Eds.) Cold chain management in meat storage, distribution and retail: A review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Brodribb, P. A Study of Waste in the Cold Food Chain and Opportunities for Improvement; Expert Group: Hefei, China, 2020. [Google Scholar]

- Castonguay, A.C.; Polasky, S.; Holden, M.H.; Herrero, M.; Mason-D’Croz, D.; Godde, C.; Chang, J.; Gerber, J.; Witt, G.B.; Game, E.T. Navigating sustainability trade-offs in global beef production. Nat. Sustain. 2023, 6, 284–294. [Google Scholar] [CrossRef]

- FAO. FAOSTAT Online Database. 2021. Available online: http://faostat.fao.org/ (accessed on 20 September 2023).

- Australia, M.L. Global Beef Industry and Trade Report; Meat & Livestock Australia: Sydney, NSW, Australia, 2022. [Google Scholar]

- Juan Ding, M.; Jie, F.; Parton, K.A.; Matanda, M.J. Relationships between quality of information sharing and supply chain food quality in the Australian beef processing industry. Int. J. Logist. Manag. 2014, 25, 85–108. [Google Scholar] [CrossRef]

- Li, H.; Pan, P. (Eds.) Food waste in developed countries and cold chain logistics. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021. [Google Scholar]

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding food loss and waste—Why are we losing and wasting food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- National Food Waste Strategy: Halving Australia’s Food Waste by 2030. Department of Climate Change, Energy, the Environment and Water, Canberra, Australia. 2024. Available online: https://www.dcceew.gov.au/environment/protection/waste/food-waste#:~:text=Australia’s%20National%20Food%20Waste%20Strategy,the%20National%20Food%20Waste%20Strategy (accessed on 8 February 2024).

- Keegan, E.; Breadsell, J.K. Food waste and social practices in Australian households. Sustainability 2021, 13, 3377. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; De Hooge, I.; Amani, P.; Bech-Larsen, T.; Oostindjer, M. Consumer-related food waste: Causes and potential for action. Sustainability 2015, 7, 6457–6477. [Google Scholar] [CrossRef]

- Gokarn, S.; Kuthambalayan, T.S. Analysis of challenges inhibiting the reduction of waste in food supply chain. J. Clean. Prod. 2017, 168, 595–604. [Google Scholar] [CrossRef]

- Yan, H.; Song, M.-J.; Lee, H.-Y. A Systematic Review of Factors Affecting Food Loss and Waste and Sustainable Mitigation Strategies: A Logistics Service Providers’ Perspective. Sustainability 2021, 13, 11374. [Google Scholar] [CrossRef]

- Brennan, A.; Browne, S. Food waste and nutrition quality in the context of public health: A scoping review. Int. J. Environ. Res. Public Health 2021, 18, 5379. [Google Scholar] [CrossRef]

- Neff, R.A.; Kanter, R.; Vandevijvere, S. Reducing food loss and waste while improving the public’s health. Health Aff. 2015, 34, 1821–1829. [Google Scholar] [CrossRef]

- Luo, N.; Olsen, T.; Liu, Y. A Conceptual Framework to Analyze Food Loss and Waste within Food Supply Chains: An Operations Management Perspective. Sustainability 2021, 13, 927. [Google Scholar] [CrossRef]

- Parashar, S.; Sood, G.; Agrawal, N. Modelling the enablers of food supply chain for reduction in carbon footprint. J. Clean. Prod. 2020, 275, 122932. [Google Scholar] [CrossRef]

- Ma, L.; Qin, W.; Garnett, T.; Zhang, F. Review on drivers, trends and emerging issues of the food wastage in China. Front. Agric. Sci. Eng. 2015, 2, 159–167. [Google Scholar] [CrossRef]

- Lan, S.; Tseng, M.-L.; Yang, C.; Huisingh, D. Trends in sustainable logistics in major cities in China. Sci. Total Environ. 2020, 712, 136381. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y. Barriers to circular food supply chains in China. Supply Chain Manag. Int. J. 2019, 24, 677–696. [Google Scholar] [CrossRef]

- Han, J.-W.; Zuo, M.; Zhu, W.-Y.; Zuo, J.-H.; Lü, E.-L.; Yang, X.-T. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Martinez, M.G.; Fearne, A.; Caswell, J.A.; Henson, S. Co-regulation as a possible model for food safety governance: Opportunities for public–private partnerships. Food Policy 2007, 32, 299–314. [Google Scholar] [CrossRef]

- Wang, K.Y.; Yip, T.L. Cold-chain systems in China and value-chain analysis. In Finance and Risk Management for International Logistics and the Supply Chain; Elsevier: Amsterdam, The Netherlands, 2018; pp. 217–241. [Google Scholar]

- Liu, M.; Dan, B.; Zhang, S.; Ma, S. Information sharing in an E-tailing supply chain for fresh produce with freshness-keeping effort and value-added service. Eur. J. Oper. Res. 2021, 290, 572–584. [Google Scholar] [CrossRef]

- An, J.; Wang, L.; Lv, X. Research on agri-food cold chain logistics management system: Connotation, structure and operational mechanism. J. Serv. Sci. Manag. 2015, 8, 894–902. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, W.; Park, M. Reliability analysis and optimization of cold chain distribution system for fresh agricultural products. Sustainability 2019, 11, 3618. [Google Scholar] [CrossRef]

- Zhang, H.; Qiu, B.; Zhang, K. A new risk assessment model for agricultural products cold chain logistics. Ind. Manag. Data Syst. 2017, 117, 1800–1816. [Google Scholar] [CrossRef]

- Chauhan, C.; Dhir, A.; Akram, M.U.; Salo, J. Food loss and waste in food supply chains. A systematic literature review and framework development approach. J. Clean. Prod. 2021, 295, 126438. [Google Scholar] [CrossRef]

- Luo, N.; Olsen, T.; Liu, Y.; Zhang, A. Reducing food loss and waste in supply chain operations. Transp. Res. Part E Logist. Transp. Rev. 2022, 162, 102730. [Google Scholar] [CrossRef]

- Broeze, J.; Guo, X.; Axmann, H. Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains. Sustainability 2023, 15, 8531. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Kumar, P. An integrated literature review on sustainable food supply chains: Exploring research themes and future directions. Sci. Total Environ. 2022, 821, 153411. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management-How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Cerchione, R.; Esposito, E. A systematic review of supply chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 182, 276–292. [Google Scholar] [CrossRef]

- Ali, I.; Gölgeci, I. Where is supply chain resilience research heading? A systematic and co-occurrence analysis. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 793–815. [Google Scholar] [CrossRef]

- VOSviewer. Available online: https://www.vosviewer.com/getting-started (accessed on 20 May 2023).

- Chopra, S. Designing the distribution network in a supply chain. Transp. Res. Part E Logist. Transp. Rev. 2003, 39, 123–140. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Lai, K.-h.; Cheng, T.E. Responsive supply chain: A competitive strategy in a networked economy. Omega 2008, 36, 549–564. [Google Scholar] [CrossRef]

- Dabbene, F.; Gay, P.; Sacco, N. Optimisation of fresh-food supply chains in uncertain environments, Part I: Background and methodology. Biosyst. Eng. 2008, 99, 348–359. [Google Scholar] [CrossRef]

- Trienekens, J.; Zuurbier, P. Quality and safety standards in the food industry, developments and challenges. Int. J. Prod. Econ. 2008, 113, 107–122. [Google Scholar] [CrossRef]

- Lipinski, B.; Hanson, C.; Lomax, J.; Kitinoja, L.; Waite, R.; Searchinger, T. Reducing Food Loss and Waste; World Resources Institute: Washington, DC, USA, 2013. [Google Scholar]

- van der Vorst, J.G.; van Kooten, O.; Luning, P.A. Towards a diagnostic instrument to identify improvement opportunities for quality controlled logistics in agrifood supply chain networks. Int. J. Food Syst. Dyn. 2011, 2, 94–105. [Google Scholar]

- Wognum, P.N.; Bremmers, H.; Trienekens, J.H.; Van Der Vorst, J.G.; Bloemhof, J.M. Systems for sustainability and transparency of food supply chains–Current status and challenges. Adv. Eng. Inform. 2011, 25, 65–76. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Meuwissen, M.P.; van der Vorst, J.G. A review on quantitative models for sustainable food logistics management. Int. J. Food Syst. Dyn. 2012, 3, 136–155. [Google Scholar]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Bettley, A.; Burnley, S. Towards sustainable operations management integrating sustainability management into operations management strategies and practices. In Handbook of Performability Engineering; Springer: Berlin/Heidelberg, Germany, 2008; pp. 875–904. [Google Scholar]

- Zhong, R.; Xu, X.; Wang, L. Food supply chain management: Systems, implementations, and future research. Ind. Manag. Data Syst. 2017, 117, 2085–2114. [Google Scholar] [CrossRef]

- Van der Meulen, B.M. The structure of European food law. Laws 2013, 2, 69–98. [Google Scholar] [CrossRef]

- Kayikci, Y.; Ozbiltekin, M.; Kazancoglu, Y. Minimizing losses at red meat supply chain with circular and central slaughterhouse model. J. Enterp. Inf. Manag. 2020, 33, 791–816. [Google Scholar] [CrossRef]

- Jedermann, R.; Nicometo, M.; Uysal, I.; Lang, W. Reducing food losses by intelligent food logistics. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130302. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Liu, Y.; Wang, Q.; Sun, L.; Sun, S. (Eds.) Research on food safety and security of cold chain logistics. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012176. [Google Scholar]

- Centobelli, P.; Cerchione, R.; Ertz, M. Food cold chain management: What we know and what we deserve. Supply Chain Manag. Int. J. 2021, 26, 102–135. [Google Scholar]

- Lee, J.C.; Daraba, A.; Voidarou, C.; Rozos, G.; Enshasy, H.A.E.; Varzakas, T. Implementation of food safety management systems along with other management tools (HAZOP, FMEA, Ishikawa, Pareto). The case study of Listeria monocytogenes and correlation with microbiological criteria. Foods 2021, 10, 2169. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.K.; Luthra, S.; Mangla, S.K.; Uniyal, S. Applications of information and communication technology for sustainable growth of SMEs in India food industry. Resour. Conserv. Recycl. 2019, 147, 10–18. [Google Scholar] [CrossRef]

- Nayak, R.; Waterson, P. Global food safety as a complex adaptive system: Key concepts and future prospects. Trends Food Sci. Technol. 2019, 91, 409–425. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Ha, H.M.; Tran, T.P.T.; Bui, T.-D.; Lim, M.K.; Lin, C.-W.; Helmi Ali, M. Data-driven on sustainable food supply chain: A comparison on Halal and non-Halal food system. J. Ind. Prod. Eng. 2022, 39, 430–457. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Chan, F.T.; Wang, Z.; Goswami, A.; Singhania, A.; Tiwari, M.K. Multi-objective particle swarm optimisation based integrated production inventory routing planning for efficient perishable food logistics operations. Int. J. Prod. Res. 2020, 58, 5155–5174. [Google Scholar] [CrossRef]

- Fikar, C. A decision support system to investigate food losses in e-grocery deliveries. Comput. Ind. Eng. 2018, 117, 282–290. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Haijema, R.; van der Vorst, J.G. Modeling a green inventory routing problem for perishable products with horizontal collaboration. Comput. Oper. Res. 2018, 89, 168–182. [Google Scholar] [CrossRef]

- Liljestrand, K. Logistics solutions for reducing food waste. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 318–339. [Google Scholar] [CrossRef]

- Halloran, A.; Clement, J.; Kornum, N.; Bucatariu, C.; Magid, J. Addressing food waste reduction in Denmark. Food Policy 2014, 49, 294–301. [Google Scholar] [CrossRef]

- Cattaneo, A.; Sánchez, M.V.; Torero, M.; Vos, R. Reducing food loss and waste: Five challenges for policy and research. Food Policy 2021, 98, 101974. [Google Scholar] [CrossRef] [PubMed]

- Wang, X. Research on Food Cold Chain Logistics System Collaboration. Carpathian J. Food Sci. Technol. 2016, 8, 131. [Google Scholar]

- Weng, X.; An, J.; Yang, H. The analysis of the development situation and trend of the city-oriented cold chain logistics system for fresh agricultural products. Open J. Soc. Sci. 2015, 3, 70–80. [Google Scholar] [CrossRef][Green Version]

- Dania, W.A.P.; Xing, K.; Amer, Y. Collaboration behavioural factors for sustainable agri-food supply chains: A systematic review. J. Clean. Prod. 2018, 186, 851–864. [Google Scholar] [CrossRef]

- Seuring, S.; Brix-Asala, C.; Khalid, R.U. Analyzing base-of-the-pyramid projects through sustainable supply chain management. J. Clean. Prod. 2019, 212, 1086–1097. [Google Scholar] [CrossRef]

- Yu, Y.; Jaenicke, E.C. Estimating food waste as household production inefficiency. Am. J. Agric. Econ. 2020, 102, 525–547. [Google Scholar] [CrossRef]

- Huang, H.; He, Y.; Li, D. Pricing and inventory decisions in the food supply chain with production disruption and controllable deterioration. J. Clean. Prod. 2018, 180, 280–296. [Google Scholar] [CrossRef]

- Li, X.; Zhou, K. Multi-objective cold chain logistic distribution center location based on carbon emission. Environ. Sci. Pollut. Res. 2021, 28, 32396–32404. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Che, W.; Lim, J.J.; Shou, Y. Service innovation of cold chain logistics service providers: A multiple-case study in China. Ind. Mark. Manag. 2020, 89, 143–156. [Google Scholar] [CrossRef]

- Al Theeb, N.; Smadi, H.J.; Al-Hawari, T.H.; Aljarrah, M.H. Optimization of vehicle routing with inventory allocation problems in Cold Supply Chain Logistics. Comput. Ind. Eng. 2020, 142, 106341. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, S.; Tian, C.; Yan, G.; Wang, D. An overview of current status of cold chain in China. Int. J. Refrig. 2018, 88, 483–495. [Google Scholar] [CrossRef]

- Tang, J.; Zou, Y.; Xie, R.; Tu, B.; Liu, G. Compact supervisory system for cold chain logistics. Food Control 2021, 126, 108025. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications-A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Liu, G.; Hu, J.; Yang, Y.; Xia, S.; Lim, M.K. Vehicle routing problem in cold Chain logistics: A joint distribution model with carbon trading mechanisms. Resour. Conserv. Recycl. 2020, 156, 104715. [Google Scholar] [CrossRef]

- Esmizadeh, Y.; Bashiri, M.; Jahani, H.; Almada-Lobo, B. Cold chain management in hierarchical operational hub networks. Transp. Res. Part E Logist. Transp. Rev. 2021, 147, 102202. [Google Scholar] [CrossRef]

- Chen, J.; Dan, B.; Shi, J. A variable neighborhood search approach for the multi-compartment vehicle routing problem with time windows considering carbon emission. J. Clean. Prod. 2020, 277, 123932. [Google Scholar] [CrossRef]

- Wu, J.; Haasis, H.-D. The freight village as a pathway to sustainable agricultural products logistics in China. J. Clean. Prod. 2018, 196, 1227–1238. [Google Scholar] [CrossRef]

- Tsamboulas, D.A.; Kapros, S. Freight village evaluation under uncertainty with public and private financing. Transp. Policy 2003, 10, 141–156. [Google Scholar] [CrossRef]

- Pekkaya, M.; Keleş, N. Determining criteria interaction and criteria priorities in the freight village location selection process: The experts’ perspective in Turkey. Asia Pac. J. Mark. Logist. 2022, 34, 1348–1367. [Google Scholar] [CrossRef]

- Shashi, S.; Cerchione, R.; Singh, R.; Centobelli, P.; Shabani, A. Food cold chain management: From a structured literature review to a conceptual framework and research agenda. Int. J. Logist. Manag. 2018, 29, 792–821. [Google Scholar] [CrossRef]

- Magalhães, V.S.; Ferreira, L.M.D.; da Silva César, A.; Bonfim, R.M.; Silva, C. Food loss and waste in the Brazilian beef supply chain: An empirical analysis. Int. J. Logist. Manag. 2020, 32, 214–236. [Google Scholar] [CrossRef]

- Hülsmann, M.; Brenner, V. Causes and Effects of Cold Chain Ruptures: Performance of Fragmented Versus Integrated Cold Chains; Jacobs University, School of Engineering and Science, Internat. Logistics, Systems Management: Bremen, Germany, 2011. [Google Scholar]

- Buisman, M.; Haijema, R.; Bloemhof-Ruwaard, J. Discounting and dynamic shelf life to reduce fresh food waste at retailers. Int. J. Prod. Econ. 2019, 209, 274–284. [Google Scholar] [CrossRef]

- Kibler, K.M.; Reinhart, D.; Hawkins, C.; Motlagh, A.M.; Wright, J. Food waste and the food-energy-water nexus: A review of food waste management alternatives. Waste Manag. 2018, 74, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Herron, C.B.; Garner, L.J.; Siddique, A.; Huang, T.-S.; Campbell, J.C.; Rao, S.; Morey, A. Building “First Expire, First Out” models to predict food losses at retail due to cold chain disruption in the last mile. Front. Sustain. Food Syst. 2022, 6, 1018807. [Google Scholar] [CrossRef]

- Mendes, A., Cruz, J., Saraiva, T., Lima, T.M., Gaspar, P.D., Eds.; Logistics strategy (FIFO, FEFO or LSFO) decision support system for perishable food products. In Proceedings of the 2020 International Conference on Decision Aid Sciences and Application (DASA), Sakheer, Bahrain, 8–9 November 2020; IEEE: New York, NY, USA, 2020; pp. 173–178. [Google Scholar]

- Plan, W.R.A. Reducing Food Waste through Retail Supply Chain Collaboration; WRAP: Banbury, UK, 2011. [Google Scholar]

- Nikolicic, S.; Kilibarda, M.; Maslaric, M.; Mircetic, D.; Bojic, S. Reducing food waste in the retail supply chains by improving efficiency of logistics operations. Sustainability 2021, 13, 6511. [Google Scholar] [CrossRef]

- Kaipia, R.; Dukovska-Popovska, I.; Loikkanen, L. Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 262–276. [Google Scholar] [CrossRef]

- Govindan, K.; Kadziński, M.; Sivakumar, R. Application of a novel PROMETHEE-based method for construction of a group compromise ranking to prioritization of green suppliers in food supply chain. Omega 2017, 71, 129–145. [Google Scholar] [CrossRef]

- Rahbari, M.; Hajiagha, S.H.R.; Mahdiraji, H.A.; Dorcheh, F.R.; Garza-Reyes, J.A. A novel location-inventory-routing problem in a two-stage red meat supply chain with logistic decisions: Evidence from an emerging economy. Kybernetes 2021, 51, 1498–1531. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Kieu, P.T.; Nguyen, V.T.; Nguyen, V.T.; Ho, T.P. A spherical fuzzy analytic hierarchy process (SF-AHP) and combined compromise solution (CoCoSo) algorithm in distribution center location selection: A case study in agricultural supply chain. Axioms 2021, 10, 53. [Google Scholar] [CrossRef]

- Mihajlović, J.; Rajković, P.; Petrović, G.; Ćirić, D. The selection of the logistics distribution center location based on MCDM methodology in southern and eastern region in Serbia. Oper. Res. Eng. Sci. Theory Appl. 2019, 2, 72–85. [Google Scholar] [CrossRef]

- Zanoni, S.; Zavanella, L. Chilled or frozen? Decision strategies for sustainable food supply chains. Int. J. Prod. Econ. 2012, 140, 731–736. [Google Scholar] [CrossRef]

- Aravendan, M.; Panneerselvam, R. Literature review on network design problems in closed loop and reverse supply chains. Intell. Inf. Manag. 2014, 6, 104–117. [Google Scholar] [CrossRef]

- Mejjaouli, S.; Babiceanu, R.F. Cold supply chain logistics: System optimization for real-time rerouting transportation solutions. Comput. Ind. 2018, 95, 68–80. [Google Scholar] [CrossRef]

- Titiyal, R.; Bhattacharya, S.; Thakkar, J.J. The distribution strategy selection for an e-tailer using a hybrid DANP VIKOR MCDM model. Benchmarking Int. J. 2019, 26, 395–433. [Google Scholar] [CrossRef]

- Gallo, A.; Accorsi, R.; Baruffaldi, G.; Manzini, R. Designing sustainable cold chains for long-range food distribution: Energy-effective corridors on the Silk Road Belt. Sustainability 2017, 9, 2044. [Google Scholar] [CrossRef]

- Yakavenka, V.; Mallidis, I.; Vlachos, D.; Iakovou, E.; Eleni, Z. Development of a multi-objective model for the design of sustainable supply chains: The case of perishable food products. Ann. Oper. Res. 2020, 294, 593–621. [Google Scholar] [CrossRef]

- Sel, Ç.; Pınarbaşı, M.; Soysal, M.; Çimen, M. A green model for the catering industry under demand uncertainty. J. Clean. Prod. 2017, 167, 459–472. [Google Scholar] [CrossRef]

- Van Der Vorst, J.G.; Tromp, S.-O.; Zee, D.-J.v.d. Simulation modelling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. Int. J. Prod. Res. 2009, 47, 6611–6631. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C.; Botti, L.; Rosano, M. Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers. J. Clean. Prod. 2018, 184, 375–388. [Google Scholar] [CrossRef]

- Li, Q.; Yu, P.; Wu, X. Shelf life extending packaging, inventory control and grocery retailing. Prod. Oper. Manag. 2017, 26, 1369–1382. [Google Scholar] [CrossRef]

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. Packaging’s role in minimizing food loss and waste across the supply chain. Packag. Technol. Sci. 2015, 28, 603–620. [Google Scholar] [CrossRef]

- Ghadge, A.; Kaklamanou, M.; Choudhary, S.; Bourlakis, M. Implementing environmental practices within the Greek dairy supply chain: Drivers and barriers for SMEs. Ind. Manag. Data Syst. 2017, 117, 1995–2014. [Google Scholar] [CrossRef]

- Sajjad, A.; Eweje, G.; Tappin, D. Managerial perspectives on drivers for and barriers to sustainable supply chain management implementation: Evidence from New Zealand. Bus. Strategy Environ. 2020, 29, 592–604. [Google Scholar] [CrossRef]

- Hien, D.N.; Thanh, N.V. Optimization of cold chain logistics with Fuzzy MCDM Model. Processes 2022, 10, 947. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Karanam, M.; Krishnanand, L.; Manupati, V.K.; Antosz, K.; Machado, J. Identification of the critical enablers for perishable food supply chain using deterministic assessment models. Appl. Sci. 2022, 12, 4503. [Google Scholar] [CrossRef]

- Kutlu Gündoğdu, F.; Kahraman, C. A novel VIKOR method using spherical fuzzy sets and its application to warehouse site selection. J. Intell. Fuzzy Syst. 2019, 37, 1197–1211. [Google Scholar] [CrossRef]

- Ali, S.M.; Rahman, M.H.; Tumpa, T.J.; Rifat, A.A.M.; Paul, S.K. Examining price and service competition among retailers in a supply chain under potential demand disruption. J. Retail. Consum. Serv. 2018, 40, 40–47. [Google Scholar] [CrossRef]

- Ali, S.M.; Nakade, K. Optimal ordering policies in a multi-sourcing supply chain with supply and demand disruptions-a CVaR approach. Int. J. Logist. Syst. Manag. 2017, 28, 180–199. [Google Scholar] [CrossRef]

- Singh, A.; Shukla, N.; Mishra, N. Social media data analytics to improve supply chain management in food industries. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 398–415. [Google Scholar] [CrossRef]

- Tang, C.S. Perspectives in supply chain risk management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Ali, S.M.; Moktadir, M.A.; Kabir, G.; Chakma, J.; Rumi, M.J.U.; Islam, M.T. Framework for evaluating risks in food supply chain: Implications in food wastage reduction. J. Clean. Prod. 2019, 228, 786–800. [Google Scholar]

- Govindan, K. Sustainable consumption and production in the food supply chain: A conceptual framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- de Oliveira, U.R.; Marins, F.A.S.; Rocha, H.M.; Salomon, V.A.P. The ISO 31000 standard in supply chain risk management. J. Clean. Prod. 2017, 151, 616–633. [Google Scholar] [CrossRef]

- Khan, O.; Burnes, B. Risk and supply chain management: Creating a research agenda. Int. J. Logist. Manag. 2007, 18, 197–216. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. An integrated methodology of FTA and fuzzy AHP for risk assessment in green supply chain. Int. J. Oper. Res. 2016, 25, 77–99. [Google Scholar] [CrossRef]

- Bogataj, D.; Hudoklin, D.; Bogataj, M.; Dimovski, V.; Colnar, S. Risk mitigation in a meat supply chain with options of redirection. Sustainability 2020, 12, 8690. [Google Scholar] [CrossRef]

- Nguyen, A.H.T.; Singh, A.; Kumari, S.; Choudhary, S. Multi-agent architecture for waste minimisation in beef supply chain. Prod. Plan. Control 2023, 34, 1082–1096. [Google Scholar] [CrossRef]

- Deng, X.; Yang, X.; Zhang, Y.; Li, Y.; Lu, Z. Risk propagation mechanisms and risk management strategies for a sustainable perishable products supply chain. Comput. Ind. Eng. 2019, 135, 1175–1187. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Chaudhuri, A.; Srivastava, R.K. Propagation of risks and their impact on performance in fresh food retail. Int. J. Logist. Manag. 2015, 26, 568–602. [Google Scholar] [CrossRef]

- Amani, M.A.; Sarkodie, S.A. Mitigating spread of contamination in meat supply chain management using deep learning. Sci. Rep. 2022, 12, 5037. [Google Scholar] [CrossRef] [PubMed]