Recycled Content for Metals with Refined Classification of Metal Scrap: Micro-Level Circularity Indicator in Accordance with Macro-Level System

Abstract

:1. Introduction

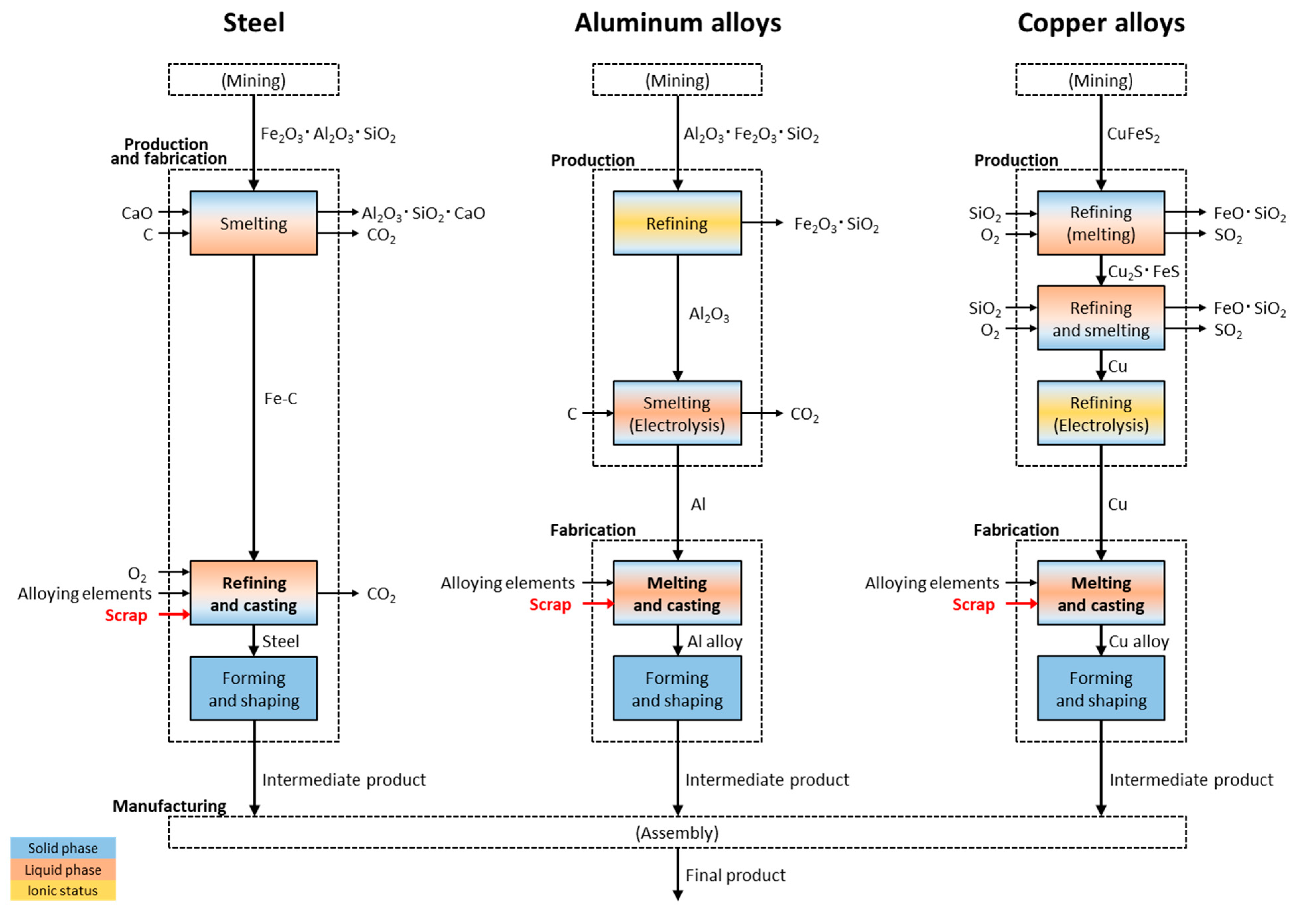

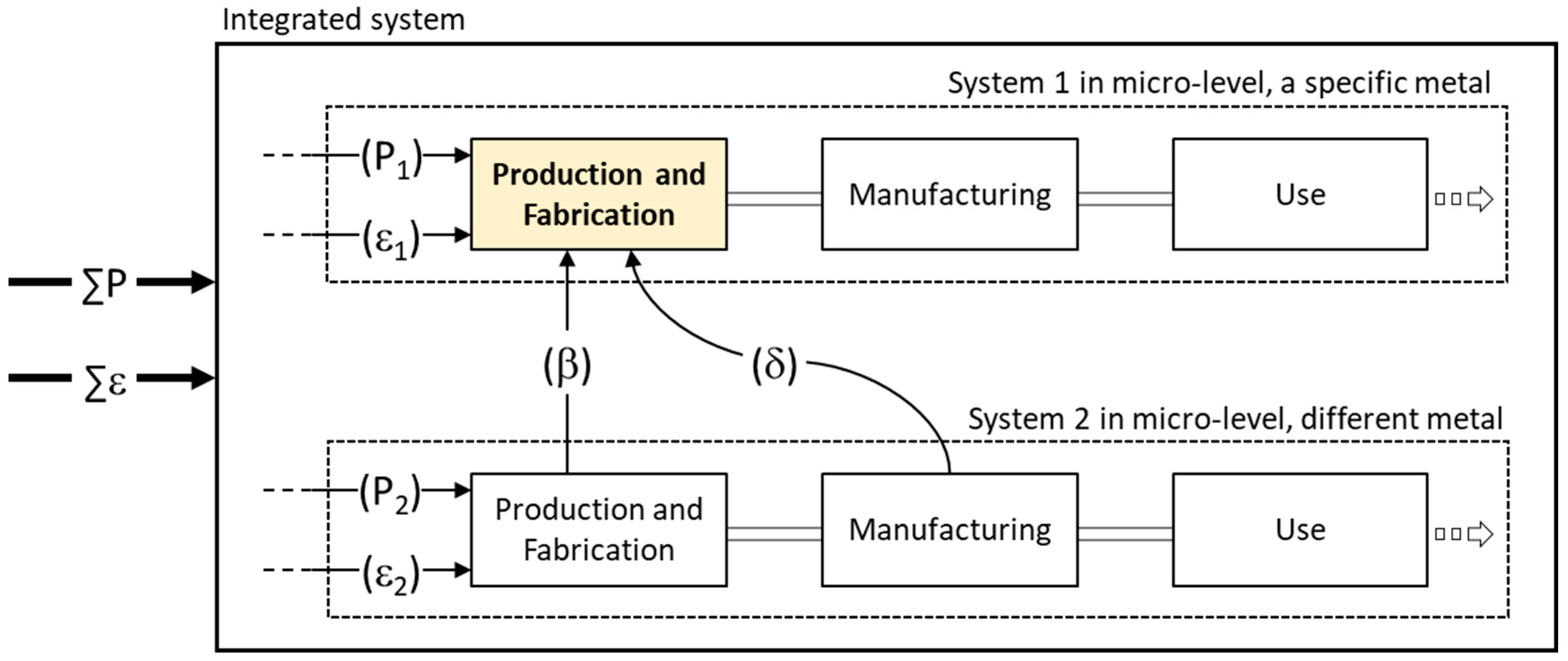

2. Methodological Framework

2.1. Classification of Metal Scrap

2.2. Determining Secondary Raw Material Status in Metal Scrap

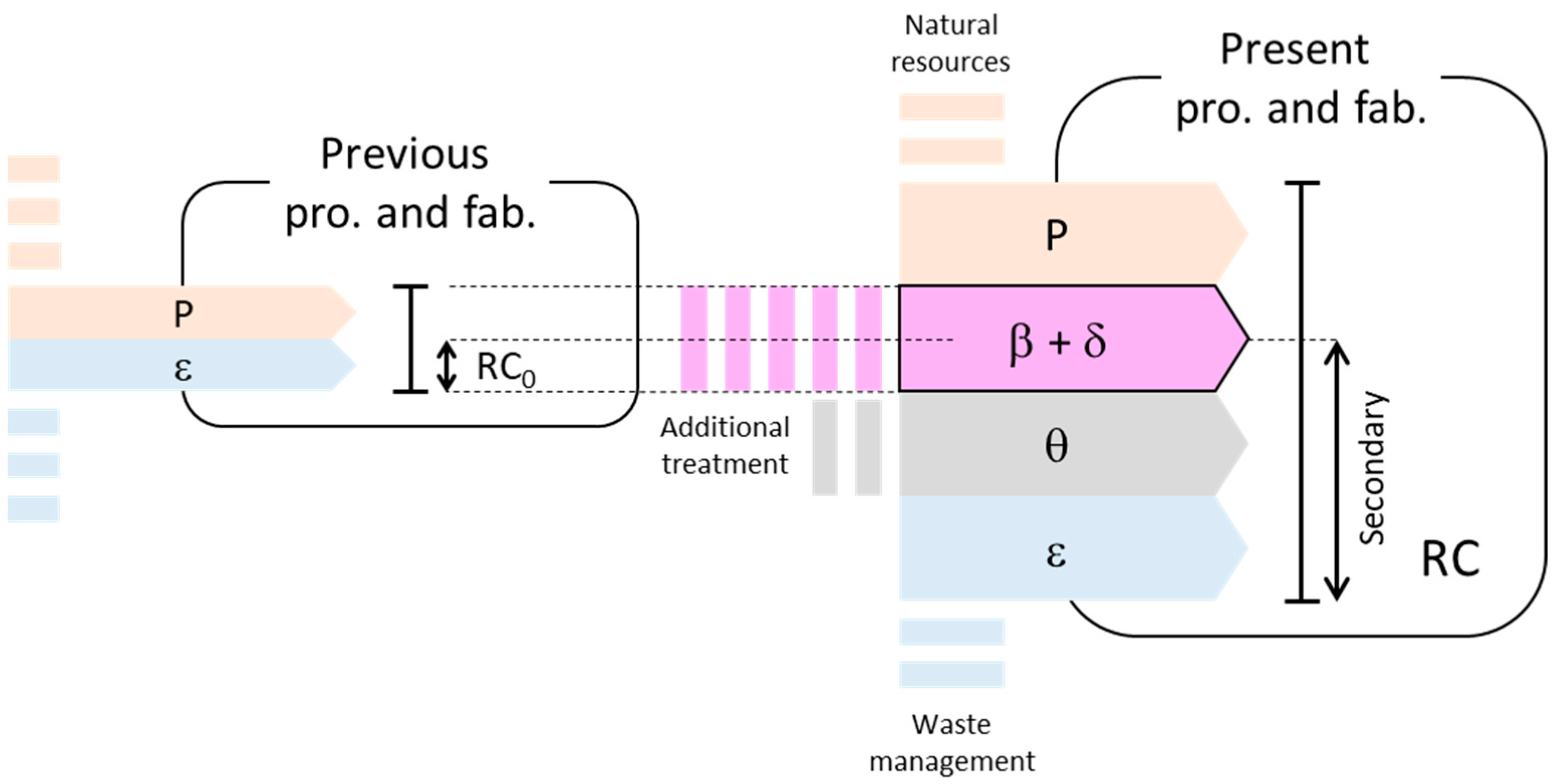

2.3. Formulation of Recycled Content

- RC is the recycled content of a specific metal.

- RC0 is the original recycled content of individual input of new scrap.

- is a weighted average of RC0.

- P is the mass of the primary raw material input.

- β is the mass of new scrap input generated from the production and fabrication of a different metal.

- δ is the mass of new scrap input generated from the manufacturing of a different product.

- ε is the mass of old scrap input.

3. Demonstration and Discussions

3.1. Is New Scrap Secondary Raw Material?

- θ is the mass of new scrap input after an additional treatment.

3.2. Evaluation of Recycled Content by Proposed Methodology

3.3. Comparison of Various Definitions of Recycled Content

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A Taxonomy of Circular Economy Indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A Review of Micro Level Indicators for a Circular Economy—Moving Away from the Three Dimensions of Sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical Appraisal of the Circular Economy Standard BS 8001:2017 and a Dashboard of Quantitative System Indicators for Its Implementation in Organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Nazzal, M.A.; Darras, B.M.; Deiab, I.M. A Comprehensive Multi-Level Circular Economy Assessment Framework. Sustain. Prod. Consum. 2022, 32, 700–717. [Google Scholar] [CrossRef]

- Graedel, T.E.; Allwood, J.; Birat, J.-P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. What Do We Know About Metal Recycling Rates? J. Ind. Ecol. 2011, 15, 355–366. [Google Scholar] [CrossRef]

- Reck, B.K.; Graedel, T.E. Challenges in Metal Recycling. Science 2012, 337, 690–695. [Google Scholar] [CrossRef]

- Daigo, I.; Iwata, K.; Ohkata, I.; Goto, Y. Macroscopic Evidence for the Hibernating Behavior of Materials Stock. Environ. Sci. Technol. 2015, 49, 8691–8696. [Google Scholar] [CrossRef]

- ISO 14021:2016(E); Environmental Labels and Declarations—Self-Declared Environmental Claims (Type II Environmental Labelling). ISO: Geneva, Switzerland, 2016.

- United Nations Environment Programme; International Resource Panel. Recycling Rates of Metals: A Status Report; Report of the Working Group on the Global Metal Flows to the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2011. [Google Scholar]

- Rombach, G.; Modaresi, R.; Müller, D.B. Aluminium Recycling—Raw Material Supply from a Volume and Quality Constraint System. World Metall. 2012, 7, 157–162. [Google Scholar]

- Norgate, T. Metal Recycling: The Need for a Life Cycle Approach; CSIRO: Canberra, Australia, 2013.

- Pauliuk, S.; Milford, R.L.; Müller, D.B.; Allwood, J.M. The Steel Scrap Age. Environ. Sci. Technol. 2013, 47, 3448–3454. [Google Scholar] [CrossRef] [PubMed]

- Daigo, I.; Hashimoto, S.; Matsuno, Y.; Adachi, Y. Material Stocks and Flows Accounting for Copper and Copper-Based Alloys in Japan. Resour. Conserv. Recycl. 2009, 53, 208–217. [Google Scholar] [CrossRef]

- Dubreuil, A.; Young, S.B.; Atherton, J.; Gloria, T.P. Metals Recycling Maps and Allocation Procedures in Life Cycle Assessment. Int. J. Life Cycle Assess. 2010, 15, 621–634. [Google Scholar] [CrossRef]

- Milford, R.L.; Allwood, J.M.; Cullen, J.M. Assessing the Potential of Yield Improvements, through Process Scrap Reduction, for Energy and CO2 Abatement in the Steel and Aluminium Sectors. Resour. Conserv. Recycl. 2011, 55, 1185–1195. [Google Scholar] [CrossRef]

- Flint, I.P.; Cabrera Serrenho, A.; Lupton, R.C.; Allwood, J.M. Material Flow Analysis with Multiple Material Characteristics to Assess the Potential for Flat Steel Prompt Scrap Prevention and Diversion without Remelting. Environ. Sci. Technol. 2020, 54, 2459–2466. [Google Scholar] [CrossRef] [PubMed]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Reck, B.K. On the Materials Basis of Modern Society. Proc. Natl. Acad. Sci. USA 2015, 112, 6295–6300. [Google Scholar] [CrossRef] [PubMed]

- Frees, N. Crediting Aluminium Recycling in LCA by Demand or by Disposal. Int. J. Life Cycle Assess. 2008, 13, 212–218. [Google Scholar] [CrossRef]

- Frischknecht, R. LCI Modelling Approaches Applied on Recycling of Materials in View of Environmental Sustainability, Risk Perception and Eco-Efficiency. Int. J. Life Cycle Assess. 2010, 15, 666–671. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular Economy Indicators: What Do They Measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 5th ed.; Butterworth-Heinemann: Oxford, UK; Boston, MA, USA, 2016; ISBN 978-0-08-100610-8. [Google Scholar]

- Forsén, O.; Aromaa, J.; Lundström, M. Primary Copper Smelter and Refinery as a Recycling Plant—A System Integrated Approach to Estimate Secondary Raw Material Tolerance. Recycling 2017, 2, 19. [Google Scholar] [CrossRef]

- Worrell, E.; Reuter, M.A. (Eds.) Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2014; ISBN 978-0-12-396459-5. [Google Scholar]

- Kevorkijan, V. The Recycle of Wrought Aluminum Alloys in Europe. JOM 2002, 54, 38–41. [Google Scholar] [CrossRef]

- Buchner, H.; Laner, D.; Rechberger, H.; Fellner, J. In-Depth Analysis of Aluminum Flows in Austria as a Basis to Increase Resource Efficiency. Resour. Conserv. Recycl. 2014, 93, 112–123. [Google Scholar] [CrossRef]

- Blomberg, J.; Söderholm, P. The Economics of Secondary Aluminium Supply: An Econometric Analysis Based on European Data. Resour. Conserv. Recycl. 2009, 53, 455–463. [Google Scholar] [CrossRef]

- Davis, J.; Geyer, R.; Ley, J.; He, J.; Clift, R.; Kwan, A.; Sansom, M.; Jackson, T. Time-Dependent Material Flow Analysis of Iron and Steel in the UK. Resour. Conserv. Recycl. 2007, 51, 118–140. [Google Scholar] [CrossRef]

- Strategy for Secondary Raw Materials. Available online: https://www.europarl.europa.eu/legislative-train/carriage/strategy-for-secondary-raw-materials/report?sid=6201 (accessed on 10 May 2024).

- Joint Research Center RMIS—Raw Materials Information System. Available online: https://rmis.jrc.ec.europa.eu/?page=policies-and-definitions-2d5b5e (accessed on 10 May 2024).

- Eurometaux. Product Environmental Footprint Category Rules (PEFCR) for Metal Sheets for Various Applications; Eurometaux: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Product Environmental Footprint Category Rules Guidance; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Van den Eynde, S.; Bracquené, E.; Diaz-Romero, D.; Zaplana, I.; Engelen, B.; Duflou, J.R.; Peeters, J.R. Forecasting Global Aluminium Flows to Demonstrate the Need for Improved Sorting and Recycling Methods. Waste Manag. 2022, 137, 231–240. [Google Scholar] [CrossRef]

- Tercero Espinoza, L.A.; Soulier, M. Defining Regional Recycling Indicators for Metals. Resour. Conserv. Recycl. 2018, 129, 120–128. [Google Scholar] [CrossRef]

- Chen, W.-Q. Recycling Rates of Aluminum in the United States: Recycling Rates of Aluminum in the United States. J. Ind. Ecol. 2013, 17, 926–938. [Google Scholar] [CrossRef]

- Ding, N. Substance Flow Analysis of Aluminum Industry in Mainland China. J. Clean. Prod. 2016, 133, 1167–1180. [Google Scholar] [CrossRef]

- Cooper, D.R.; Ryan, N.A.; Syndergaard, K.; Zhu, Y. The Potential for Material Circularity and Independence in the U.S. Steel Sector. J. Ind. Ecol. 2020, 24, 748–762. [Google Scholar] [CrossRef]

- Glöser, S.; Soulier, M.; Tercero Espinoza, L.A. Dynamic Analysis of Global Copper Flows. Global Stocks, Postconsumer Material Flows, Recycling Indicators, and Uncertainty Evaluation. Environ. Sci. Technol. 2013, 47, 6564–6572. [Google Scholar] [CrossRef]

- Broadbent, C. Steel’s Recyclability: Demonstrating the Benefits of Recycling Steel to Achieve a Circular Economy. Int. J. Life Cycle Assess. 2016, 21, 1658–1665. [Google Scholar] [CrossRef]

- Bailey, R.; Bras, B.; Allen, J.K. Measuring Material Cycling in Industrial Systems. Resour. Conserv. Recycl. 2008, 52, 643–652. [Google Scholar] [CrossRef]

- Rombach, G. Raw Material Supply by Aluminium Recycling—Efficiency Evaluation and Long-Term Availability. Acta Mater. 2013, 61, 1012–1020. [Google Scholar] [CrossRef]

- Andreasi Bassi, S.; Tonini, D.; Ekvall, T.; Astrup, T.F. A Life Cycle Assessment Framework for Large-Scale Changes in Material Circularity. Waste Manag. 2021, 135, 360–371. [Google Scholar] [CrossRef] [PubMed]

- Ardente, F.; Mathieux, F. Identification and Assessment of Product’s Measures to Improve Resource Efficiency: The Case-Study of an Energy Using Product. J. Clean. Prod. 2014, 83, 126–141. [Google Scholar] [CrossRef]

- Niero, M. Closing the Loop for Aluminum Cans: Life Cycle Assessment of Progression in Cradle-to-Cradle Certification Levels. J. Clean. Prod. 2016, 126, 352–362. [Google Scholar] [CrossRef]

- Apple Environment. Available online: https://www.apple.com/environment/ (accessed on 10 May 2024).

- Mercedes-Benz. On the Road to the Circular Economy. Available online: https://group.mercedes-benz.com/responsibility/sustainability/resources/circular-economy.html (accessed on 10 May 2024).

- SCS Global Services. Recycled Content Standard, V7.0, Environmental Certification Services; SCS Global Services: Emeryville, CA, USA, 2014. [Google Scholar]

- Underwriters Laboratories. Environmental Claim Validation Procedure (ECVP) for Recycled Content, UL2809; Underwriters Laboratories: Northbrook, IL, USA, 2020. [Google Scholar]

| Generated From | Conventional Classification | Expression in This Study | ||

|---|---|---|---|---|

| (α) | P&F of a specific metal in scope | Home scrap | Home scrap | |

| (β) | P&F of a different metal | from the same facility | Home scrap | New (different, P&F) scrap |

| from a different facility | New scrap | |||

| (γ) | M of the product | New scrap | New (same, M) scrap | |

| (δ) | M of a different product | New scrap | New (different, M) scrap | |

| (ε) | WM | Old scrap | Old scrap | |

| Case | Inputs | Calculation | |||||

|---|---|---|---|---|---|---|---|

| P | β + δ | γ | ε | RC | Conv-RCa | Conv-RCb | |

| 1 | 60 | 0 | 0 | 40 | 40% | 40% | 40% |

| 2 | 40 | 20 | 0 | 40 | 42% | 60% | 40% |

| 3 | 20 | 40 | 0 | 40 | 44% | 80% | 40% |

| 4 | 60 | 0 | 20 | 40 | 40% | 50% | 33% |

| 5 | 60 | 0 | 40 | 40 | 40% | 57% | 29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, T.; Daigo, I. Recycled Content for Metals with Refined Classification of Metal Scrap: Micro-Level Circularity Indicator in Accordance with Macro-Level System. Sustainability 2024, 16, 6933. https://doi.org/10.3390/su16166933

Suzuki T, Daigo I. Recycled Content for Metals with Refined Classification of Metal Scrap: Micro-Level Circularity Indicator in Accordance with Macro-Level System. Sustainability. 2024; 16(16):6933. https://doi.org/10.3390/su16166933

Chicago/Turabian StyleSuzuki, Taichi, and Ichiro Daigo. 2024. "Recycled Content for Metals with Refined Classification of Metal Scrap: Micro-Level Circularity Indicator in Accordance with Macro-Level System" Sustainability 16, no. 16: 6933. https://doi.org/10.3390/su16166933

APA StyleSuzuki, T., & Daigo, I. (2024). Recycled Content for Metals with Refined Classification of Metal Scrap: Micro-Level Circularity Indicator in Accordance with Macro-Level System. Sustainability, 16(16), 6933. https://doi.org/10.3390/su16166933