Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector

Abstract

1. Introduction

2. Materials and Methods

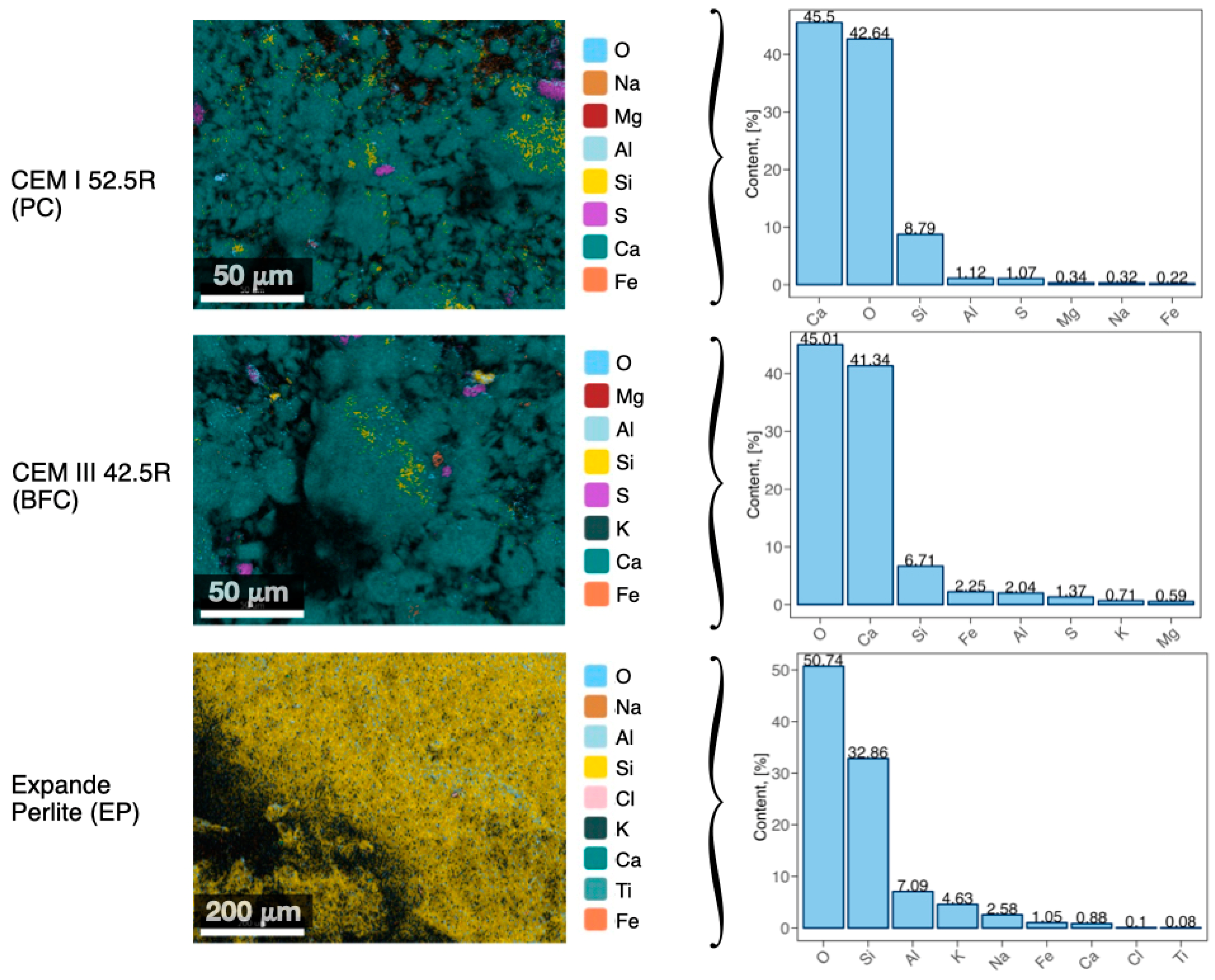

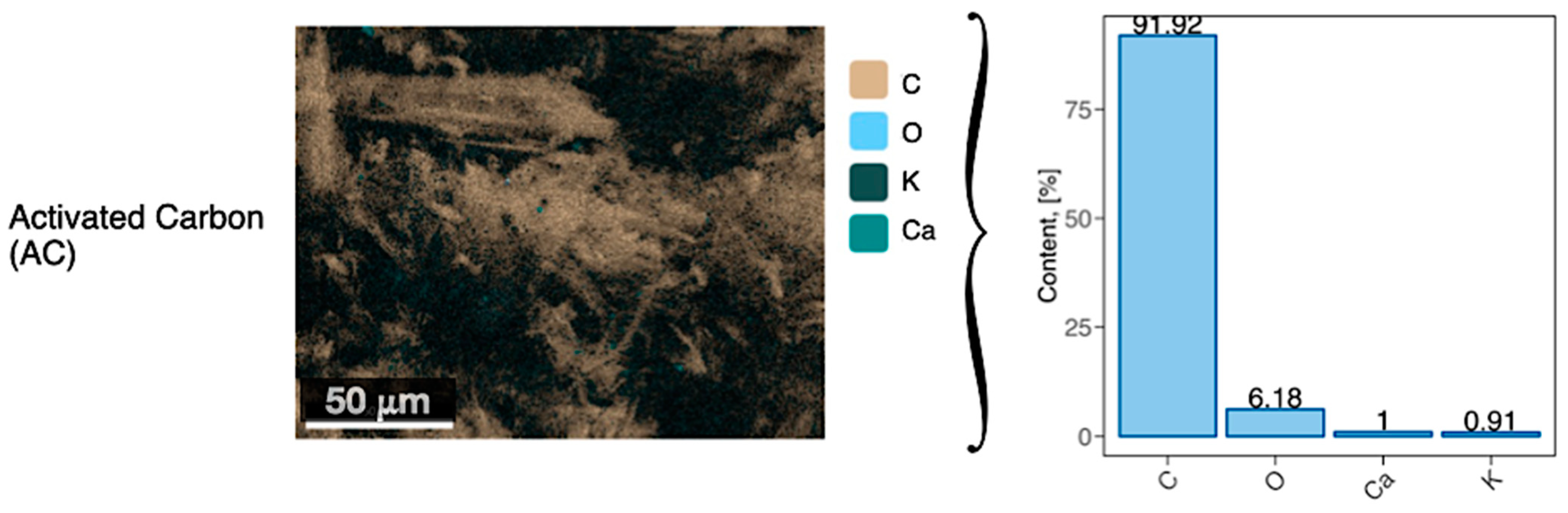

2.1. Material

2.1.1. Perlite Concrete

2.1.2. Activated Carbon’s Characteristics

2.1.3. Experimental Soil

2.1.4. Tested Samples

2.2. Methods

2.2.1. Research Methodology of Plant Material and Soil

2.2.2. Statistical Analysis

3. Results

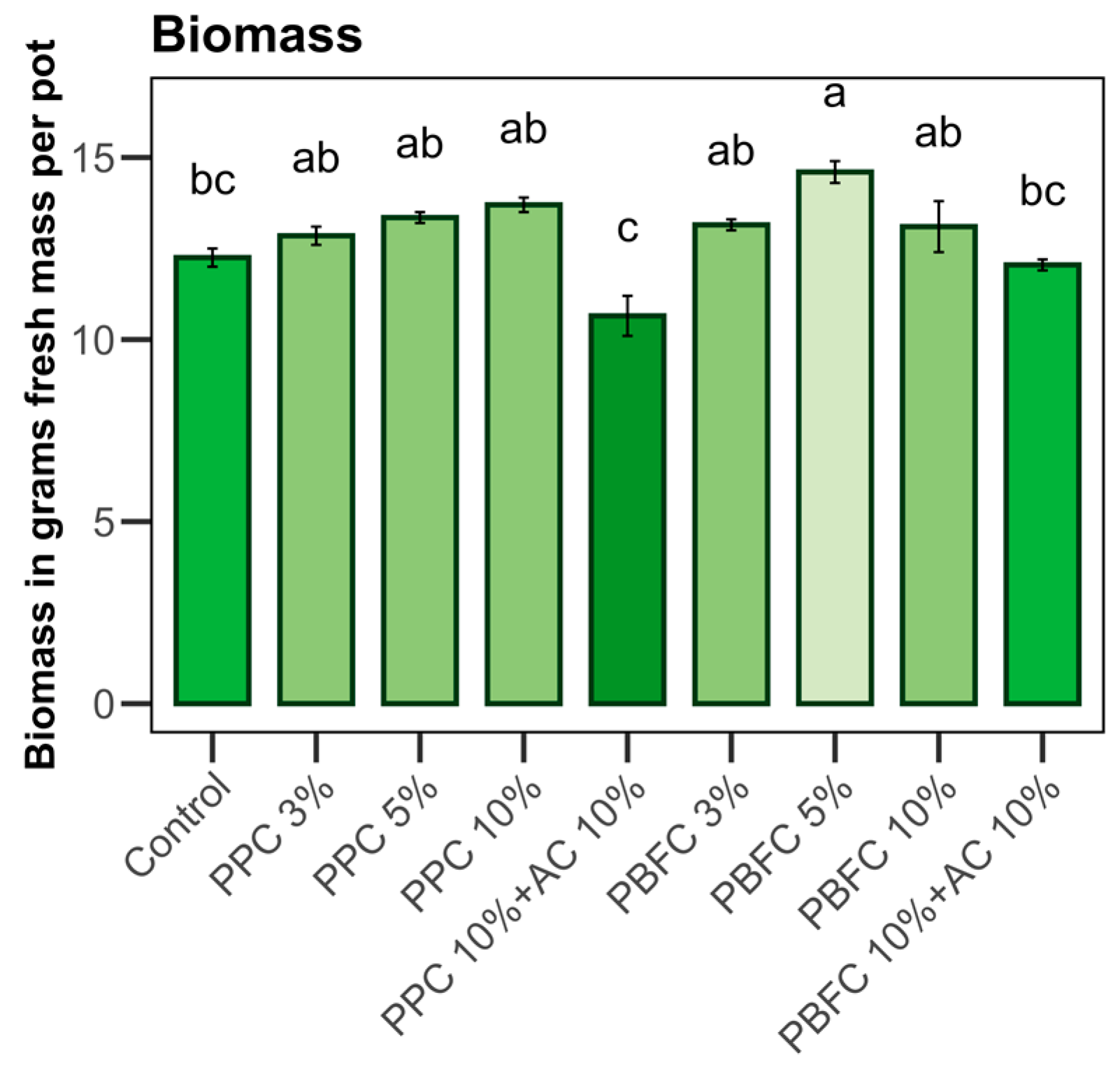

3.1. Effect of Various Concentrations of Perlite Concrete Rubble (PPC and PBFC) and Activated Carbon on the Biomass of Festuca rubra L.

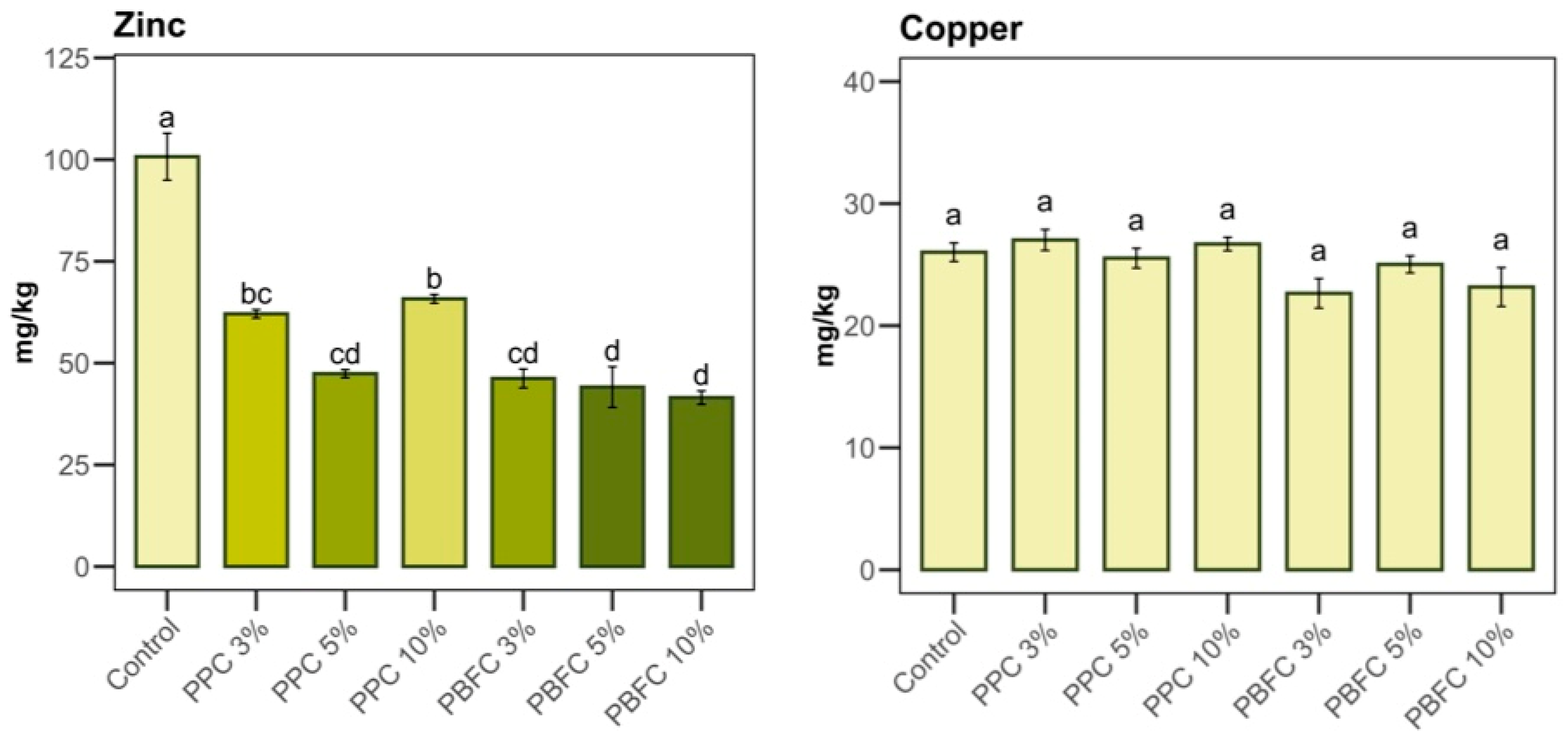

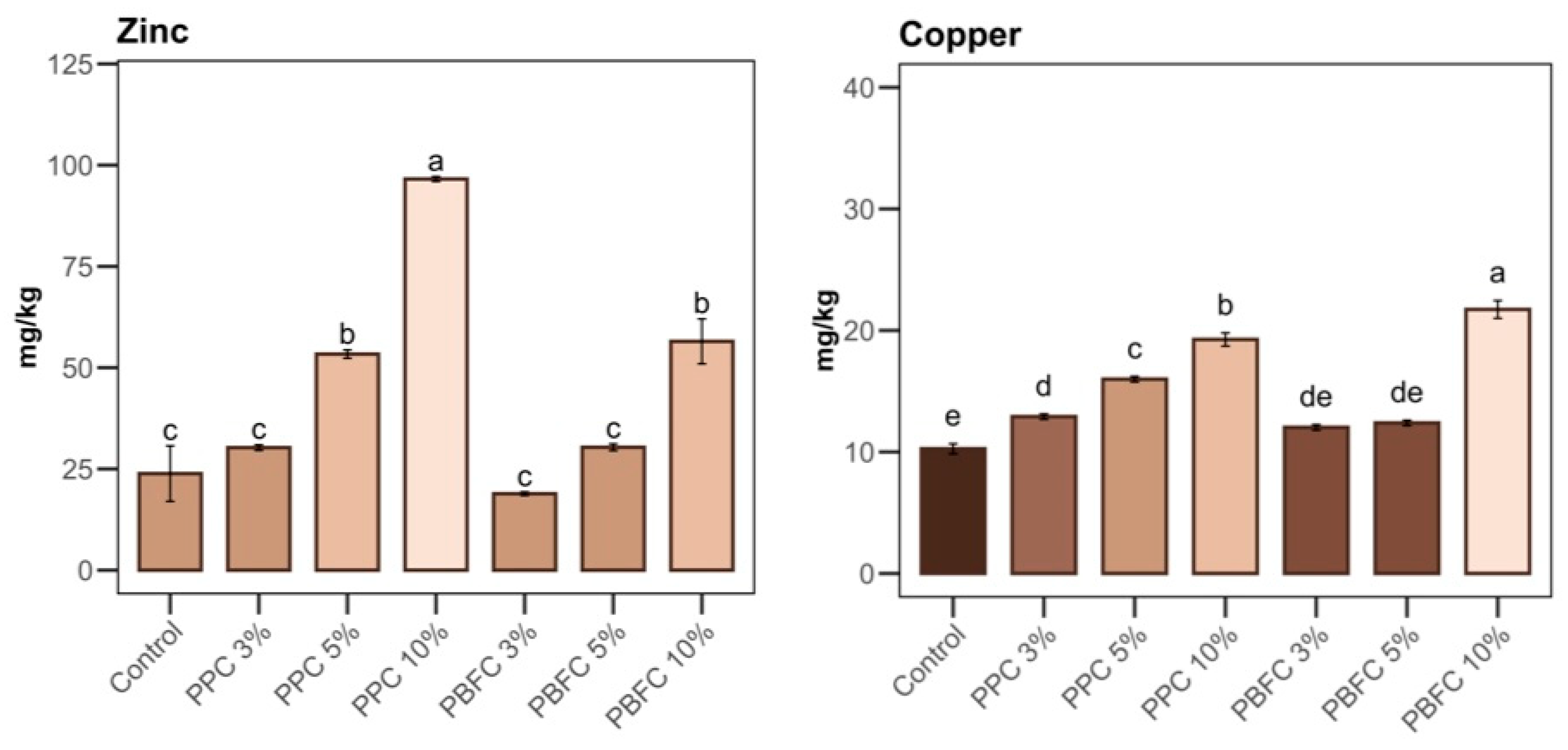

3.2. Immobilization Properties of PTEs in Plants and Soil for Various Concentrations of Perlite Concrete Rubble (PPC and PBFC)

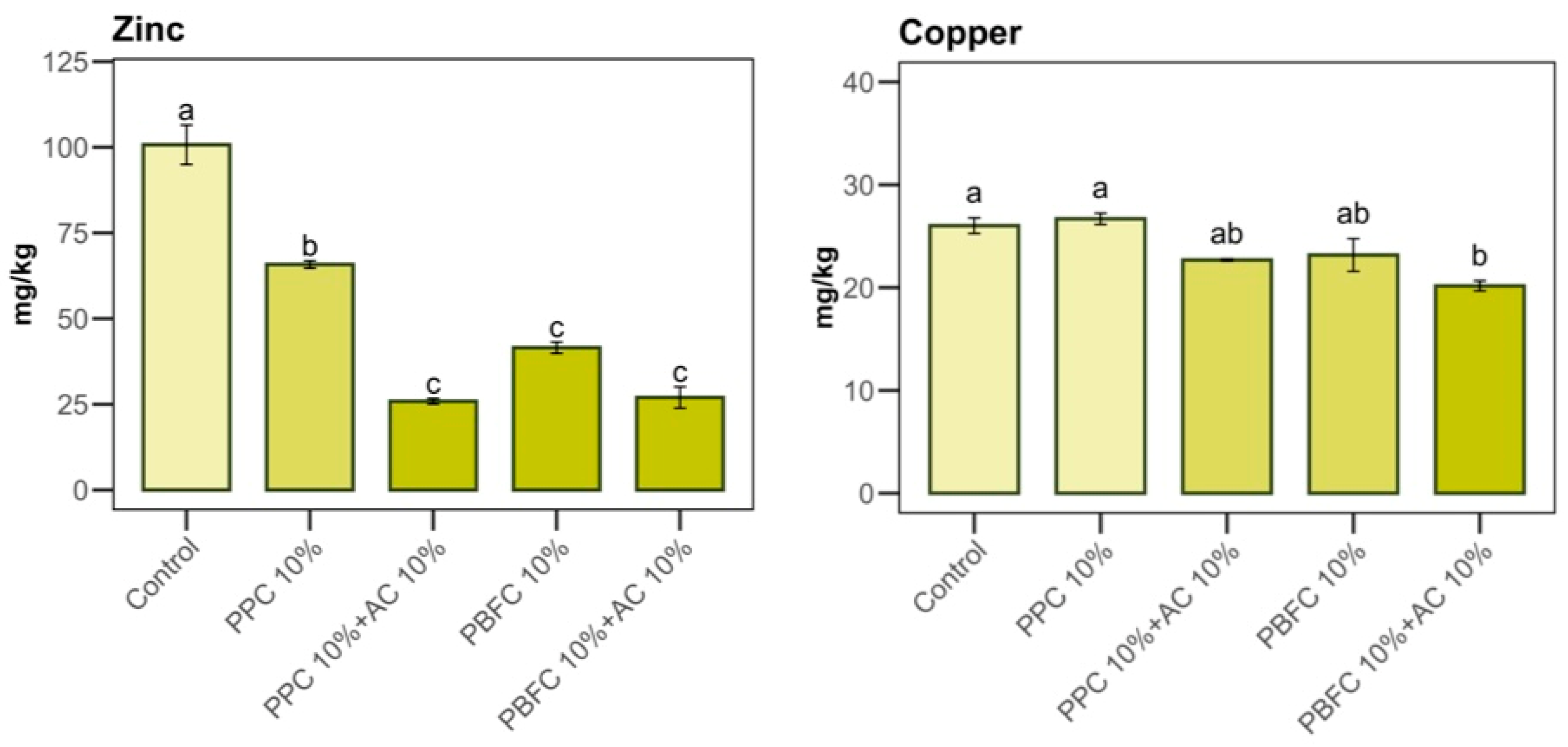

3.3. Immobilization Properties of PTEs in Plants and Soil for Various Concentrations of Perlite Concrete Rubble (PPC and PBFC) and Activated Carbon (AC)

4. Discussion

5. Conclusions

- The addition of PPC at various concentrations did not significantly impact plant biomass, indicating that PPC alone is neutral in its effect on plant growth. However, combining PPC 10% with AC 10% reduced biomass, suggesting that activated carbon, while effective in adsorbing PTEs, may also hinder plant growth by adsorbing essential nutrients. In contrast, PBFC at 3% and 5% concentrations enhanced plant biomass, implying beneficial properties for soil and plant growth.

- The addition of PPC reduced zinc levels in aboveground parts, with the most significant decrease observed with PPC 5%, reducing the zinc content by 50% compared to the control. Similarly, PBFC also reduced the zinc contents, with the largest reduction observed for PBFC 10%, decreasing the zinc level by 67%. In plant roots, adding PPC increased the zinc content by 48% for PPC 10%, while PBFC decreased the zinc level by 44% for PBFC 10%.

- In the soil, zinc contents increased significantly with the PPC addition, peaking at a 304% increase with PPC 10%. PBFC also raised soil zinc contents, with the highest level for PBFC 10%, increasing by 136%. These results suggest that PPC is more effective at immobilizing zinc in soil.

- Adding PPC increased the copper content in the soil by 88% for PPC 10%. PBFC also elevated the soil copper levels, with an increase of 112% for PBFC 10%. In plant roots, the control group’s copper content was 20.9 mg/kg. PPC increased the copper content by 48% for PPC 10%, whereas PBFC reduced it by 20% with PBFC 10%.

- The addition of activated carbon to perlite concrete rubble offers a potent method for improving the immobilization of toxic elements in soil. The integration of activated carbon into perlite concrete formulations for soil stabilization presents a promising approach for enhancing the immobilization of PTEs. However, it is crucial to balance the benefits of contaminant immobilization with the potential negative impacts on plant growth. Further research is needed to optimize the concentrations and application methods of AC to maximize its benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aziz, A.; Benzaouak, A.; Bellil, A.; Alomayri, T.; Ni el Hassani, I.E.E.; Achab, M.; El Azhari, H.; Et-Tayea, Y.; Shaikh, F.U.A. Effect of Acidic Volcanic Perlite Rock on Physio-Mechanical Properties and Microstructure of Natural Pozzolan Based Geopolymers. Case Stud. Constr. Mater. 2021, 15, e00712. [Google Scholar] [CrossRef]

- Różycka, A.; Pichór, W. Effect of Perlite Waste Addition on the Properties of Autoclaved Aerated Concrete. Constr. Build. Mater. 2016, 120, 65–71. [Google Scholar] [CrossRef]

- Burriesci, N.; Arcoraci, C.; Antonucci, P.L.; Polizzotti, G. Physico-Chemical Characterization of Perlite of Various Origins. Mater. Lett. 1985, 3, 103–110. [Google Scholar] [CrossRef]

- Khanna, P.; Mukulam, A.M.; Teja, K.V.; Meena, T. Study on Durability Properties of Perlite Incorporated Concrete. Int. J. Civ. Eng. Technol. 2018, 9, 1545–1553. [Google Scholar]

- Doǧan, M.; Alkan, M.; Çakir, Ü. Electrokinetic Properties of Perlite. J. Colloid Interface Sci. 1997, 192, 114–118. [Google Scholar] [CrossRef]

- Erdem, T.K.; Meral, C.; Tokyay, M.; Erdoǧan, T.Y. Use of Perlite as a Pozzolanic Addition in Producing Blended Cements. Cem. Concr. Compos. 2007, 29, 13–21. [Google Scholar] [CrossRef]

- Szabó, R.; Dolgos, F.; Debreczeni, Á.; Mucsi, G. Characterization of Mechanically Activated Fly Ash-Based Lightweight Geopolymer Composite Prepared with Ultrahigh Expanded Perlite Content. Ceram. Int. 2022, 48, 218. [Google Scholar] [CrossRef]

- Ilahi, W.F.F.; Ahmad, D. A Study on the Physical and Hydraulic Characteristics of Cocopeat Perlite Mixture as a Growing Media in Containerized Plant Production. Sains Malays. 2017, 46, 975–980. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of Expanded Perlite on the Mechanical Properties and Thermal Conductivity of Lightweight Concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Jia, G.; Li, Z.; Liu, P.; Jing, Q. Preparation and Characterization of Aerogel/Expanded Perlite Composite as Building Thermal Insulation Material. J. Non Cryst. Solids 2018, 482, 47. [Google Scholar] [CrossRef]

- Markoska, V.; Spalevic, V.; Lisichkov, K.; Atkovska, K.; Gulaboski, R. Determination of Water Retention Characteristics of Perlite and Peat. J. Agric. For. 2018, 64, 113. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Mohamed Suhoothi, A.C. Durability of Structural Lightweight Concrete Containing Expanded Perlite Aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 50. [Google Scholar] [CrossRef]

- Saǧlik, A.U.; Erdoǧan, S.T. Chemical and Thermal Activation of Perlite-Containing Cementitious Mixtures. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 1517–1527. [Google Scholar]

- Dacić, A.; Fenyvesi, O.; Kopecskó, K. Investigation of Waste Perlite and Recycled Concrete Powders as Supplementary Cementitious Materials. Period. Polytech. Civ. Eng. 2023, 67, 683–694. [Google Scholar] [CrossRef]

- Karein, S.M.M.; Balapour, M.; Karakouzian, M. Improving the Hardened and Transport Properties of Perlite Incorporated Mixture through Different Solutions: Surface Area Increase, Nanosilica Incorporation or Both. Constr. Build. Mater. 2019, 209, 187–194. [Google Scholar] [CrossRef]

- Yanjun, X.; Rui, L.; Haiping, S.; Ran, J.; Jiayu, Z. The Characteristics of Perlite Sound Absorption Board Formed by Vibration Molding. Open Mater. Sci. J. 2015, 9, 10039. [Google Scholar] [CrossRef]

- Pawluk, K.; Lendo-Siwicka, M.; Trach, R.; Wrzesiński, G.; Kowalski, J.; Ogrodnik, P.; Jasztal, M.; Omen, Ł.; Skrypchuk, P. Sustainable Design and Construction Cost of Warehouse in the Light of Applicable Fire Regulations. Sustainability 2024, 16, 3002. [Google Scholar] [CrossRef]

- Wolfthaler, A.; Harsányi, P.; Schneider, M. Development and Performance of High Strength Lightweight Concrete with Perlites. In Modern Building Materials, Structures and Techniques; Springer: Cham, Switherland, 2024; pp. 126–133. [Google Scholar]

- Al-Jadiri, R.S.F.; Al-Wahab Ali, M.A.; Frayyeh, Q.J. Study Some Mechanical and Thermal Properties of Reinforced Perlite Concrete. Key Eng. Mater. 2022, 924, 233–242. [Google Scholar] [CrossRef]

- Nastac, S.; Nechita, P.; Debeleac, C.; Simionescu, C.; Seciureanu, M. The Acoustic Performance of Expanded Perlite Composites Reinforced with Rapeseed Waste and Natural Polymers. Sustainability 2022, 14, 103. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Alengaram, U.J.; Kaliyavaradhan, S.K.; Ling, T.C. Study on the Use of Lightweight Expanded Perlite and Vermiculite Aggregates in Blended Cement Mortars. Eur. J. Environ. Civ. Eng. 2022, 26, 6934. [Google Scholar] [CrossRef]

- Cojocaru, A.; Isopescu, D.N.; Maxineasa, S.G. Perlite Concrete: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1283, 012003. [Google Scholar] [CrossRef]

- Ahmad, S.A.; Rafiq, S.K.; Hilmi, H.D.M.; Ahmed, H.U. Mathematical Modeling Techniques to Predict the Compressive Strength of Pervious Concrete Modified with Waste Glass Powders. Asian J. Civ. Eng. 2024, 25, 773–785. [Google Scholar] [CrossRef]

- Witkowska-Dobrev, J.; Szlachetka, O.; Malarski, M.; Czajkowska, J.; Miturski, M.; Nowak, P.; Dohojda, M. Effect of Sewage on Compressive Strength and Geometric Texture of the Surface of Concrete Elements. Struct. Concr. 2023, 24, 468–484. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Radziemska, M. Blast Furnace Slag, Post-Industrial Waste or Valuable Building Materials with Remediation Potential? Minerals 2022, 12, 478. [Google Scholar] [CrossRef]

- Sas, W.; Dzięcioł, J.; Radzevičius, A.; Radziemska, M.; Dapkienė, M.; Šadzevičius, R.; Skominas, R.; Głuchowski, A. Geotechnical and Environmental Assessment of Blast Furnace Slag for Engineering Applications. Materials 2021, 14, 6029. [Google Scholar] [CrossRef] [PubMed]

- El Mir, A.; Nehme, S.G.; Assaad, J.J. Durability of Self-Consolidating Concrete Containing Natural Waste Perlite Powders. Heliyon 2020, 6, e03165. [Google Scholar] [CrossRef] [PubMed]

- Ragul, P.; Naga Theera Hari, M.; Arunachelam, N.; Chellapandian, M. An Experimental Study on the Partial Replacement of Fine Aggregate with Perlite in Cement Concrete. Mater. Today Proc. 2022, 68, 1219–1224. [Google Scholar] [CrossRef]

- Guo, X.-P.; Li, Y.-X.; Zuo, X.-Y.; Xu, Y.-Q.; Miao, J.-H.; Zhang, H.-Y.; Yao, J.-B.; Xu, Z.-L.; Fu, R.-B. The Field-Scale Stabilization Remediation and Assessment of Potential Toxic Elements Based on the Multi-Source Information from a Chinese Pb/Zn Smelter Contaminated Site. J. Cent. South Univ. 2024, 31, 1207–1216. [Google Scholar] [CrossRef]

- Boaja, I.P.; Radu, V.M.; Dinca, G.; Szabo, R.; Anghel, M.A. Spatial Distribution and Mobility of Potentially Toxic Elements in the Soils of Romania; Springer: Cham, Switherland, 2024; ISBN 9783031439216. [Google Scholar]

- Ramezanianpour, A.A.; Motahari Karein, S.M.; Vosoughi, P.; Pilvar, A.; Isapour, S.; Moodi, F. Effects of Calcined Perlite Powder as a SCM on the Strength and Permeability of Concrete. Constr. Build. Mater. 2014, 66, 222–228. [Google Scholar] [CrossRef]

- Vijayaraghavan, K.; Raja, F.D. Experimental Characterisation and Evaluation of Perlite as a Sorbent for Heavy Metal Ions in Single and Quaternary Solutions. J. Water Process Eng. 2014, 4, 179–184. [Google Scholar] [CrossRef]

- Palansooriya, K.N.; Shaheen, S.M.; Chen, S.S.; Tsang, D.C.W.; Hashimoto, Y.; Hou, D.; Bolan, N.S.; Rinklebe, J.; Ok, Y.S. Soil Amendments for Immobilization of Potentially Toxic Elements in Contaminated Soils: A Critical Review. Environ. Int. 2020, 134, 105046. [Google Scholar] [CrossRef]

- Rajput, V.D.; Kumari, A.; Minkina, T.; Barakhov, A.; Singh, S.; Mandzhieva, S.S.; Sushkova, S.; Ranjan, A.; Rajput, P.; Garg, M.C. A Practical Evaluation on Integrated Role of Biochar and Nanomaterials in Soil Remediation Processes. Environ. Geochem. Health 2023, 45, 9435–9449. [Google Scholar] [CrossRef] [PubMed]

- Tica, D.; Udovic, M.; Lestan, D. Immobilization of Potentially Toxic Metals Using Different Soil Amendments. Chemosphere 2011, 85, 577–583. [Google Scholar] [CrossRef] [PubMed]

- Bolan, N.; Srivastava, P.; Kirkham, M.B. Microbial Responses to Immobilization of Potentially Toxic Elements in Soils; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 9780323856218. [Google Scholar]

- Patthanavarit, J.; Kitiwan, M.; Keawprak, N.; Tunthawiroon, P. Effect of Expanded Perlite on Physical and Mechanical Properties of Cement Mortar. AIP Conf. Proc. 2021, 2397, 070001. [Google Scholar]

- Łagosz, A.; Olszowski, D.; Pichór, W.; Kotwica, Ł. Quantitative Determination of Processed Waste Expanded Perlite Performance as a Supplementary Cementitious Material in Low Emission Blended Cement Composites. J. Build. Eng. 2021, 40, 102335. [Google Scholar] [CrossRef]

- Akyuncu, V.; Sanliturk, F. Investigation of Physical and Mechanical Properties of Mortars Produced by Polymer Coated Perlite Aggregate. J. Build. Eng. 2021, 38, 102182. [Google Scholar] [CrossRef]

- Calik, U.; Sadoglu, E. Engineering Properties of Expansive Clayey Soil Stabilized with Lime and Perlite. Geomech. Eng. 2014, 6, 403–418. [Google Scholar] [CrossRef]

- Şadoğlu, E.; Çalik, Ü. Permeability of High Plasticity Clayey Soil Stabilized with Lime and Perlite | Kireç ve Perlitle Stabilize Edilen Yüksek Plastisiteli Kil Zeminin Geçirimliliği. J. Fac. Eng. Archit. Gazi Univ. 2020, 35, 551–561. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzięcioł, J.; Szlachetka, O. Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector. Sustainability 2024, 16, 6818. https://doi.org/10.3390/su16166818

Dzięcioł J, Szlachetka O. Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector. Sustainability. 2024; 16(16):6818. https://doi.org/10.3390/su16166818

Chicago/Turabian StyleDzięcioł, Justyna, and Olga Szlachetka. 2024. "Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector" Sustainability 16, no. 16: 6818. https://doi.org/10.3390/su16166818

APA StyleDzięcioł, J., & Szlachetka, O. (2024). Waste or Raw Material? Perlite Concrete as Part of a Sustainable Materials Management Process in the Construction Sector. Sustainability, 16(16), 6818. https://doi.org/10.3390/su16166818