Applying Material Flow Analysis for Sustainable Waste Management of Single-Use Plastics and Packaging Materials in the Republic of Korea

Abstract

1. Introduction

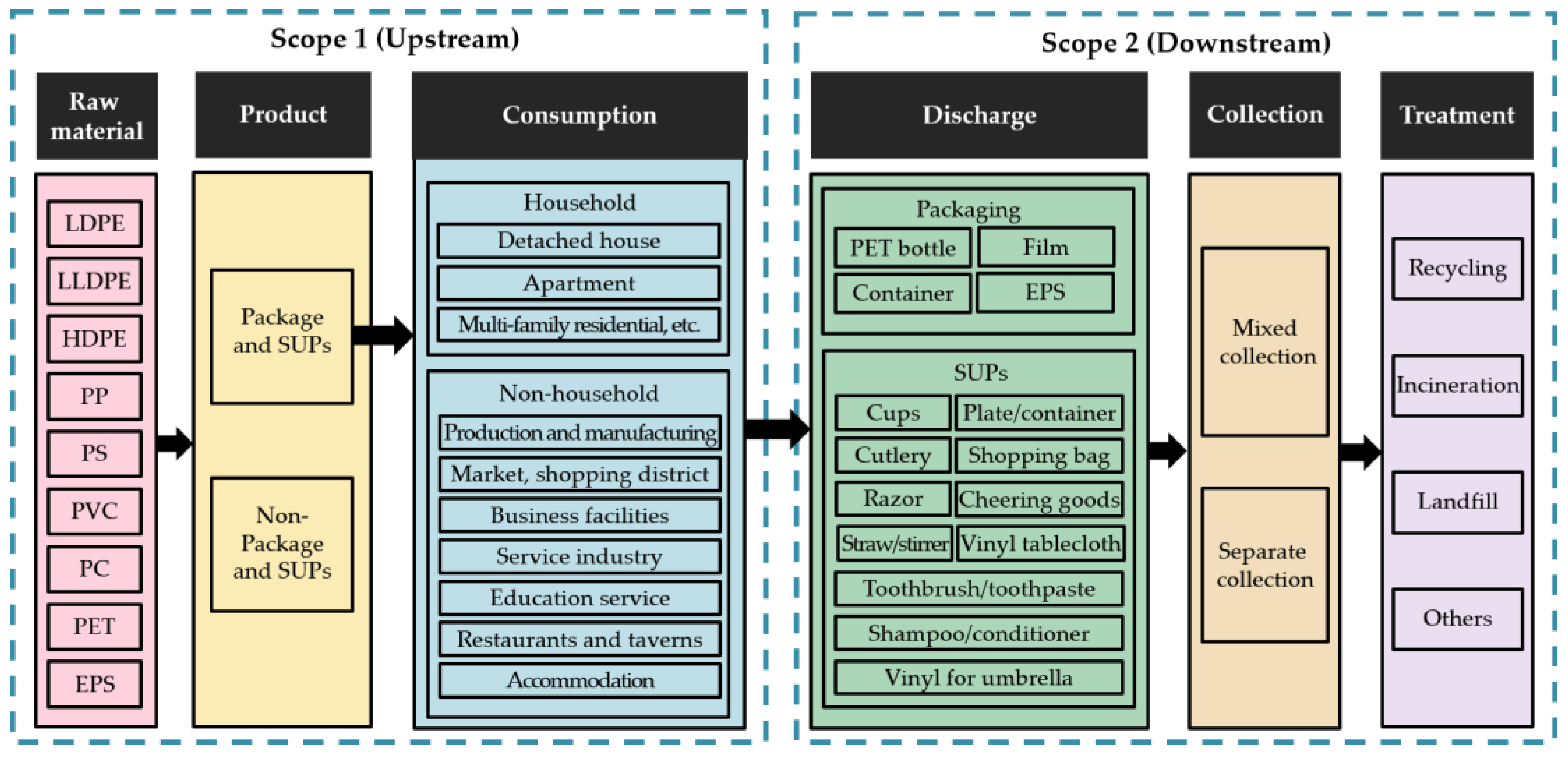

2. Materials and Methods

2.1. Data Sources and Method for Material Flow Analysis (MFA)

2.2. Reliability Assessment

3. Results and Discussion

3.1. Policies for Packaging Materials and Single-Use Plastics (SUPs) in the Republic of Korea

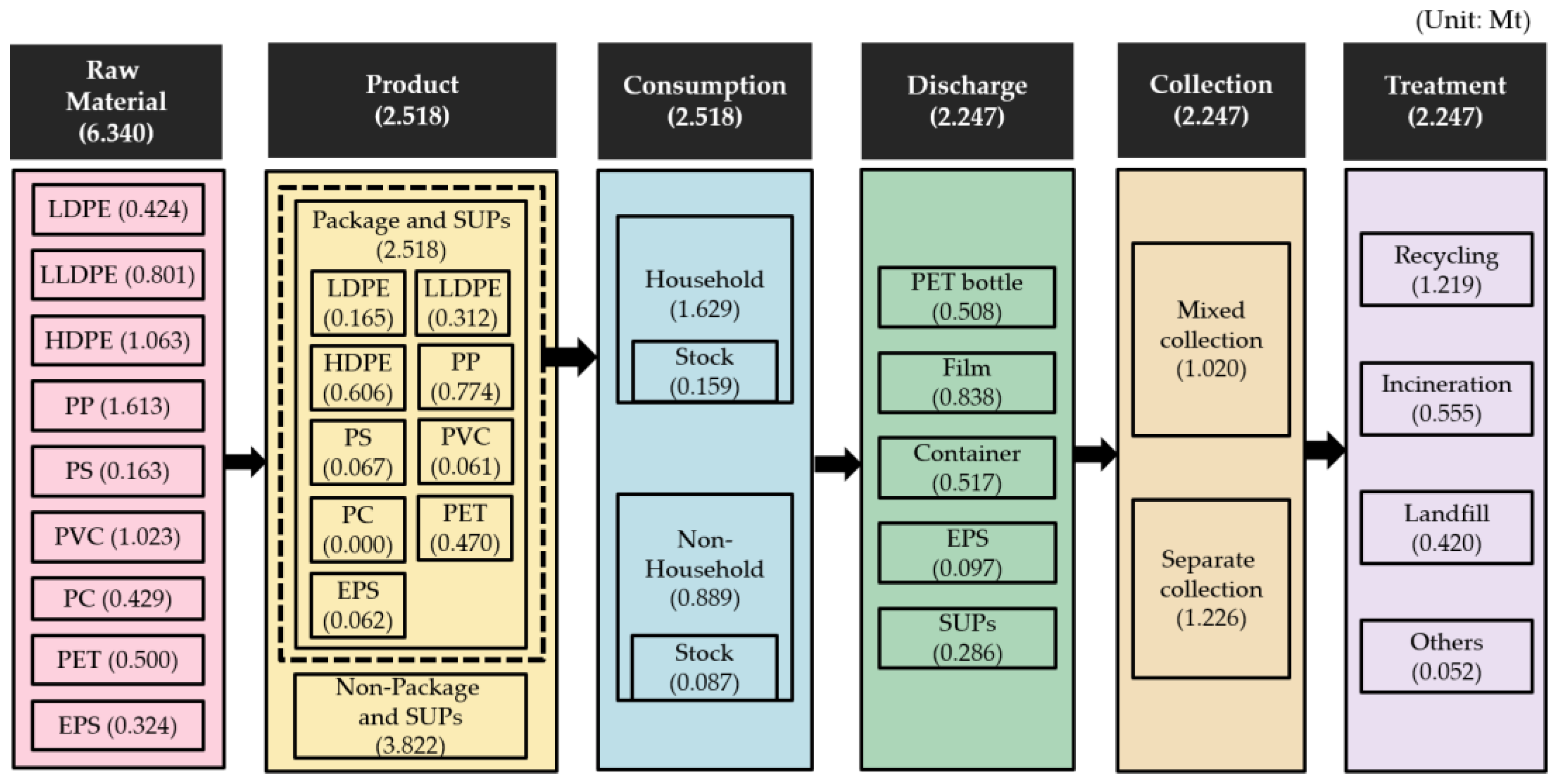

3.2. Material Flow MFA of Packaging Materials and SUPs

3.2.1. Scope 1: Raw-Materials Stage

3.2.2. Scope 1: Product Stage

3.2.3. Scope 1: Consumption Stage

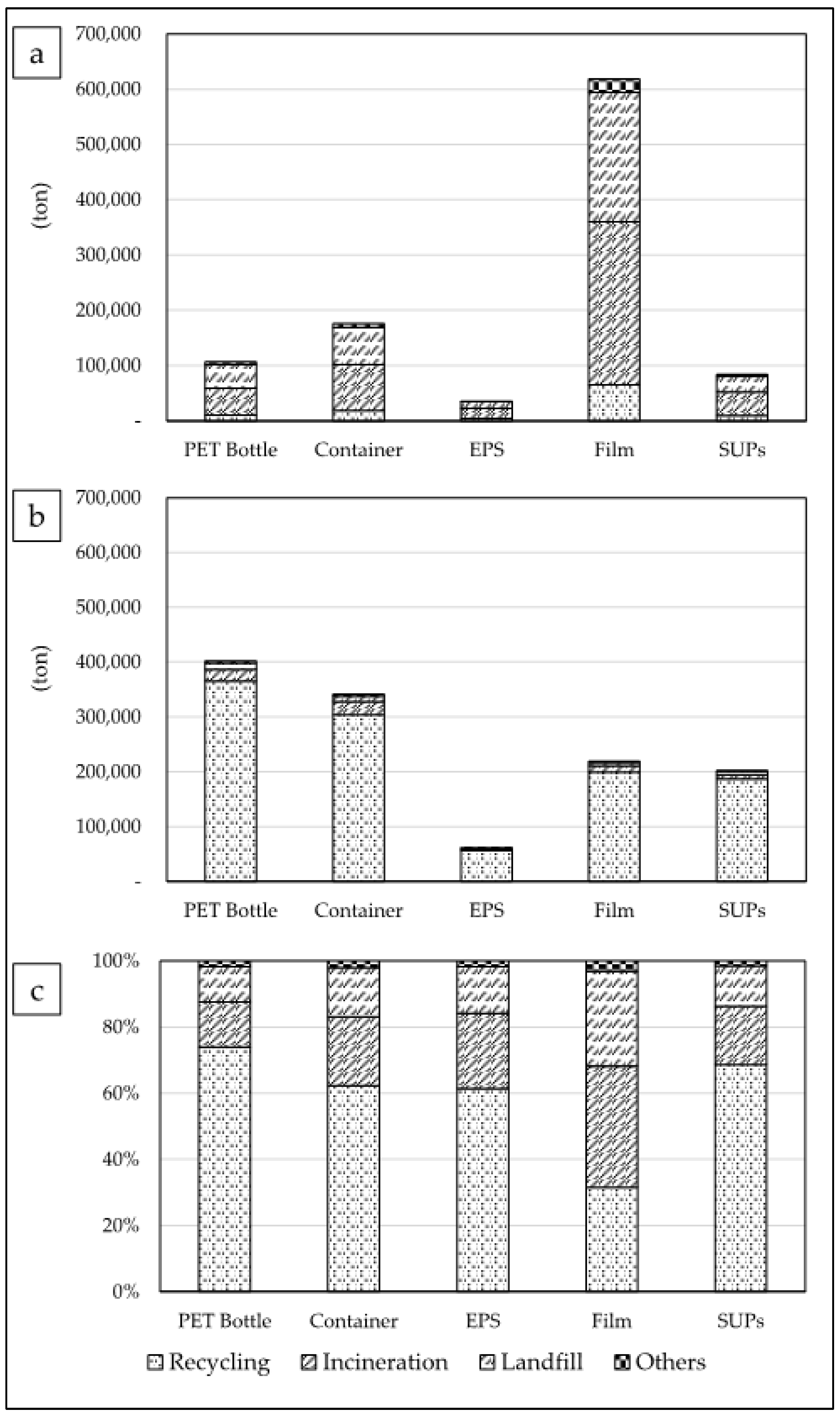

3.2.4. Scope 2: Collection Stage

3.2.5. Scope 2: Treatment Stage

3.3. Limitations and Reliability of the Material Flow Analysis (MFA) Results

3.4. Future Perspectives for the Management of Waste from Packaging Materials and SUPs

3.4.1. Policy Recommendations and Implementation

3.4.2. Future Research Directions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gilbert, M. Plastics materials: Introduction and historical development. In Brydson’s Plastics Materials, 8th ed.; Gilber, M., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 1–18. ISBN 978-03-23-35824-8. [Google Scholar]

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022; ISBN 978-92-64-58406-8. [Google Scholar] [CrossRef]

- OECD. Plastic Waste by Region and End-of-Life Fate; OECD Environment Statistics: Paris, France, 2023; ISSN 18169465. [Google Scholar] [CrossRef]

- OECD. Plastic waste projections to 2060. In Global Plastics Outlook: Policy Scenarios to 2060; OECD Publishing: Paris, France, 2022; pp. 83–108. ISBN 978-92-64-89881-3. [Google Scholar] [CrossRef]

- Nnorom, I.C.; Osibanjo, O. Sound management of brominated flame retarded (BFR) plastics from electronic wastes: State of the art and options in Nigeria. Resour. Conserv. Recycl. 2008, 52, 1362–1372. [Google Scholar] [CrossRef]

- Necibi, M.C.; Dhiba, D.; El Hajjaji, S. Contaminants of emerging concern in African wastewater effluents: Occurrence, impact and removal technologies. Sustainability 2021, 13, 1125. [Google Scholar] [CrossRef]

- UNEP. Terms of reference for the Basel Convention Partnership on Plastic Waste and workplan for the working group of the Partnership on Plastic Waste for the biennium 2020–2021. In Proceedings of the Conference of the Parties to the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal Fourteenth Meeting, Geneva, Switzerland, 29 April–10 May 2019. [Google Scholar]

- UNEP. Resolution Adopted by the United Nations Environment Assembly on 2 March 2022, UNEP/EA.5/Res.14. 2022. Available online: https://digitallibrary.un.org/record/3999257?v=pdf (accessed on 10 May 2024).

- Korea Ministry of Environment. National Waste Generation and Treatment Status. 2013, 2014. Available online: https://library.me.go.kr/#/search/detail/5586116 (accessed on 1 August 2024).

- Korea Ministry of Environment. National Waste Generation and Treatment Status. 2022, 2023. Available online: https://library.me.go.kr/#/search/detail/5912624 (accessed on 11 May 2024).

- Korea Ministry of Environment. Master Plan for Recyclable Waste Management. 2018. Available online: http://www.kwaste.or.kr/bbs/board.php?bo_table=board16&wr_id=277 (accessed on 10 May 2024).

- Korea Ministry of Environment. Reduction and Recycling Measures for the Lifecycle of Plastics. 2020. Available online: https://me.go.kr/home/web/board/read.do?menuId=&boardId=1420640&boardMasterId=1 (accessed on 10 May 2024).

- Korea Ministry of Environment. The 5th Comprehensive National Environmental Plan (2020–2040). 2019. Available online: https://me.go.kr/home/web/policy_data/read.do?menuId=10259&seq=7448 (accessed on 10 May 2024).

- Korea Government. De-Plastic Measures for the Entire Cycle. 2022. Available online: http://www.kwaste.or.kr/bbs/board.php?bo_table=board17&wr_id=185&page=1 (accessed on 10 May 2024).

- Choi, H.J.; Rhee, S.W. Material flow analysis of the recycling process for linear type spent fluorescent lamp. J. Korean Soc. Waste Manag. 2016, 33, 537–546. [Google Scholar] [CrossRef]

- Meherishi, L.; Narayana, S.A.; Ranjani, K.S. Integrated product and packaging decisions with secondary packaging returns and protective packaging management. Eur. J. Oper. Res. 2021, 292, 930–952. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Lombardi, M.; Rana, R.; Fellner, J. Material flow analysis and sustainability of the Italian plastic packaging management. J. Clean. Prod. 2021, 287, 125573. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Passel, S.; Alaerts, L.; Dewulf, J. Retrospective and prospective material flow analysis of the post-consumer plastic packaging waste management system in Flanders. Waste Manag. 2022, 147, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Madden, B.; Jazbec, M.; Florin, N. Increasing packaging grade recovery rates of plastic milk bottles in Australia: A material flow analysis approach. Sustain. Prod. Consum. 2023, 37, 65–77. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Jang, Y.C.; Son, M.; Pack, J.Y. Plastics Flow Analysis for Korea, 2017–2019. J. Korean Soc. Waste Manag. 2022, 39, 194–206. [Google Scholar] [CrossRef]

- Lee, S.R.; Jo, J.H.; Shin, D.W.; Jung, D.W.; Go, I.C.; Lee, C.H.; Hwang, Y.W.; Hong, S.Y. Analysis of the life cycle status and outlook of plastics. In A Study on Plastic Management Strategies for Transitioning to a Circular Economy; Korea Environment Institute: Sejong, Republic of Korea, 2019; pp. 33–61. ISBN 979-11-5980-363-5. [Google Scholar]

- Lopez-Aguilar, J.F.; Sevigné-Itoiz, E.; Maspoch, M.L.; Peña, J. A realistic material flow analysis for end-of-life plastic packaging management in Spain: Data gaps and suggestions for improvements towards effective recyclability. Sustain. Prod. Consum. 2022, 31, 209–219. [Google Scholar] [CrossRef]

- Jang, Y.C. Strategies for the construction of a circular economy for plastics and to stimulate the use of regenerated materials in the Republic of Korea. In Proceedings of the Forum for the 20th Anniversary of the Extended Producer Responsibility (EPR) System: EPR 2.0, Seoul, Republic of Korea, 1 June 2023. [Google Scholar]

- Korea Petrochemical Industry Association. Product Statistics: Synthetic Resin. 2023. Available online: https://www.kpia.or.kr/petrochemical-industry/statistics (accessed on 10 May 2024).

- Korea Petrochemical Industry Association. Domestic Sales Status of Synthetic Resin by Usage (Internal Data); Korea Petrochemical Industry Association: Seoul, Republic of Korea, 2014. [Google Scholar]

- Statistics Korea. Number of Businesses and Employees by City/Industry/Business Category. 2023. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_1K52D01&vw_cd=MT_ZTITLE&list_id=J2_17_001_001&scrId=&seqNo=&lang_mode=ko&obj_var_id=&itm_id=&conn_path=K2&path=%252Fcommon%252Fmeta_onedepth.jsp (accessed on 16 May 2024).

- Statistics Korea. 2021 Population and Housing Census (Register-Based Census). 2022. Available online: https://kostat.go.kr/board.es?mid=a20108070000&bid=11747&act=view&list_no=419981 (accessed on 10 May 2024).

- Korea Ministry of Environment. The 6th National Waste Statistics Survey; Korea Ministry of Environment: Seoul, Republic of Korea, 2022.

- Korea Ministry of Environment. National Waste Generation and Treatment Status 2021, 2022. Available online: https://library.me.go.kr/#/search/detail/5882048 (accessed on 11 May 2024).

- Meylan, G.; Reck, B.K.; Rechberger, H.; Graedel, T.E.; Schwab, O. Assessing the reliability of material flow analysis results: The cases of rhenium, gallium, and germanium in the United States economy. Environ. Sci. Technol. 2017, 51, 11839–11847. [Google Scholar] [CrossRef] [PubMed]

- Klinglmair, M.; Zoboli, O.; Laner, D.; Rechberger, H.; Astrup, T.F.; Scheutz, C. The effect of data structure and model choices on MFA results: A comparison of phosphorus balances for Denmark and Austria. Resour. Conserv. Recycl. 2016, 109, 166–175. [Google Scholar] [CrossRef]

- Zoboli, O.; Kaner, D.; Zessner, M.; Rechberger, H. Added values of time series in MFA: The Austrian phosphorus budget from 1990 to 2011. J. Ind. Ecol. 2015, 20, 1334–1348. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.J. Establishment of a Plastic Waste Inventory to Promote the Circular Economy: Focusing on Packaging and Single-Use Plastics. Ph.D. Thesis, Kyonggi University, Suwon-si, Republic of Korea, 2023. Available online: https://dl.nanet.go.kr/view/callViewer.do?controlNo=KDMT12023000053413&orgId=dl&linkSysId=NADL (accessed on 25 March 2024).

- Plastics Europe. Plastics—The Facts; Plastics Europe: Brussels, Belgium, 2022; Volume 2022, pp. 16–23. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/ (accessed on 10 May 2024).

- Plastic Waste Management Institute. Plastic Products, Plastic Waste and Resource Recovery [2021]. 2023, pp. 4–7. Available online: https://www.pwmi.or.jp/ei/siryo/ei/ei_pdf/ei52.pdf (accessed on 16 May 2024).

- World Bank. GDP Per Capita (Current US$). 2023. Available online: https://data.worldbank.org/indicator/NY.GDP.PCAP.CD (accessed on 26 May 2024).

- Grigore, M.E. Methods of recycling, properties and applications of recycled thermoplastic polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Imam, S.H.; Glenn, G.M.; Chiellini, E. Utilization of biobased polymers in food packaging: Assessment of materials, production and commercialization. In Emerging Food Packaging Technologies: Principles and Practice; Yam, K.L., Lee, D.S., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2012; pp. 435–468. ISBN 978-1-84569-809-6. [Google Scholar]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An overview of plastic waste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality assessment and circularity potential of recovery systems for household plastic waste. J. Ind. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef]

- Um, N.; Kang, Y.Y.; Kim, K.H.; Shin, S.K.; Lee, Y. Strategic environmental assessment for effective waste management in Korea: A review of the new policy framework. Waste Manag. 2018, 82, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Nizzetto, L.; Futter, M.; Langaas, S. Are agricultural soils dumps for microplastics of urban origin? Environ. Sci. Technol. 2016, 50, 10777–10779. [Google Scholar] [CrossRef]

- Pojar, I.; Dobre, O.; Lazăr, C.; Baboș, T.; Ristea, O.; Constantin, A.; Cristoiu, N. Microplastic Evaluation in Water and Sediments of a Dam Reservoir–Riverine System in the Eastern Carpathians, Romania. Sustainability 2024, 16, 4541. [Google Scholar] [CrossRef]

- Kumar, M.; Xiong, X.; He, M.; Tsang, D.C.; Gupta, J.; Khan, E.; Harrad, S.; Hou, D.; Ok, Y.S.; Bolan, N.S. Microplastics as pollutants in agricultural soils. Environ. Pollut. 2020, 265, 114980. [Google Scholar] [CrossRef] [PubMed]

- Pincelli, I.P.; de Castilhos Júnior, A.B.; Matias, M.S.; Rutkowski, E.W. Post-consumer plastic packaging waste flow analysis for Brazil: The challenges moving towards a circular economy. Waste Manag. 2021, 126, 781–790. [Google Scholar] [CrossRef]

- Tang, Y.; Mao, J.; Yu, G.; Li, J.; Wang, J. Material flow analysis and statistical entropy evaluation of plastic packaging for express delivery in China. Environ. Sci. Pollut. Res. 2024, 31, 28939–28949. [Google Scholar] [CrossRef] [PubMed]

- Hsu, W.T.; Domenech, T.; McDowall, W. How circular are plastics in the EU? MFA of plastics in the EU and pathways to circularity. Clean. Environ. Syst. 2021, 2, 100004. [Google Scholar] [CrossRef]

- Heller, M.C.; Mazor, M.H.; Keoleian, G.A. Plastics in the US: Toward a material flow characterization of production, markets and end of life. Environ. Res. Lett. 2020, 15, 094034. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G. Waste hierarchy index for circular economy in waste management. Waste Manag. 2019, 95, 298–305. [Google Scholar] [CrossRef]

- Duan, C.; Wang, Z.; Zhou, B.; Yao, X. Global Polyethylene Terephthalate (PET) Plastic Supply Chain Resource Metabolism Efficiency and Carbon Emissions Co-Reduction Strategies. Sustainability 2024, 16, 3926. [Google Scholar] [CrossRef]

- Choi, H.J.; Choi, Y.; Rhee, S.W. The strategy for management of plastic waste in Korea through the recycling policy in developed countries. J. Korean Soc. Waste Manag. 2018, 35, 709–720. [Google Scholar] [CrossRef]

- Siracusa, V.; Ingrao, C.; Giudice, A.L.; Mbohwa, C.; Dalla Rosa, M. Environmental assessment of a multilayer polymer bag for food packaging and preservation: An LCA approach. Food Res. Int. 2014, 62, 151–161. [Google Scholar] [CrossRef]

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Phil. Trans. R. Soc. B 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- Rohr, J.R.; Martin, L.B. Reduce, reuse, recycle scientific reviews. Trends Ecol. Evol. 2012, 27, 192–193. [Google Scholar] [CrossRef] [PubMed]

- Knickmeyer, D. Social factors influencing household waste separation: A literature review on good practices to improve the recycling performance of urban areas. J. Clean. Prod. 2020, 245, 118605. [Google Scholar] [CrossRef]

- Ittiravivongs, A. Factors influence household solid waste recycling behaviour in Thailand: An integrated perspective. In Sustainability Today; Brebbia, C.A., Ed.; WIT Press: Southampton, UK, 2012; pp. 437–448. ISBN 978-1-84564-652-3. [Google Scholar]

- Zaikova, A.; Deviatkin, I.; Havukainen, J.; Horttanainen, M.; Astrup, T.F.; Saunila, M.; Happonen, A. Factors influencing household waste separation behavior: Cases of Russia and Finland. Recycling 2022, 7, 52. [Google Scholar] [CrossRef]

- Tayebi, S.T.; Sambucci, M.; Valente, M. Waste Management of Wind Turbine Blades: A Comprehensive Review on Available Recycling Technologies with A Focus on Overcoming Potential Environmental Hazards Caused by Microplastic Production. Sustainability 2024, 16, 4517. [Google Scholar] [CrossRef]

- Qi, R.; Jones, D.L.; Li, Z.; Liu, Q.; Yan, C. Behavior of microplastics and plastic film residues in the soil environment: A critical review. Sci. Total Environ. 2020, 703, 134722. [Google Scholar] [CrossRef]

- European Environnment Agency. Demand for Common Plastics in Packaging and Non-Packaging Applications as a Percentage of Total Demand, by Plastic Type (EU27+3). 2022. Available online: https://www.eea.europa.eu/data-and-maps/figures/demand-for-common-plastics-in (accessed on 5 May 2024).

- Nakatani, J.; Maruyama, T.; Moriguchi, Y. Revealing the intersectoral material flow of plastic containers and packaging in Japan. Proc. Nati. Acad. Sci. USA 2020, 117, 19844–19853. [Google Scholar] [CrossRef]

- Korea Resource Recirculation Information System. Amount of Packaging Waste Generated and Recycled. 2023. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020208&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC013&nttId=1328&searchBgnDe=&searchEndDe= (accessed on 5 May 2024).

| Scope | Stage | Data | Data Source | |

|---|---|---|---|---|

| Scope 1 (Upstream) | Raw material | Raw-materials statistics | PET | Jang et al. [25] |

| Others | KPIA 1 [26] | |||

| Production /consumption | Distribution coefficient by type of synthetic resin | KPIA [27] | ||

| Scope 2 (Downstream) | Discharge /collection | Number of people working by area | Statistics Korea [28] | |

| Number of people residing by area | Statistics Korea [29] | |||

| Basic unit waste collection | Korea Ministry of Environment [30] | |||

| Treatment | Residue-generation factor by waste type | |||

| Percentage of treatment by residue | ||||

| Ratio by waste-treatment method | Korea Ministry of Environment [31] | |||

| Major Policy (Year) | Major Contents | ||

|---|---|---|---|

| Raw Material-Product | Consumption-Discharge | Collection-Treatment | |

| Master Plan for Recyclable Waste Management (2018) |

|

|

|

| 1st Master Plan for Resource Circulation (2018) |

|

|

|

| 2050 Carbon Neutral Strategy of the Republic of Korea (2020) |

|

|

|

| Reduction and Recycling Measures for the Life Cycle of Plastics (2020) |

|

|

|

| Raising the 2030 national greenhouse gas reduction target (2021) | - | - |

|

| Plan to Implement Korean-style Circular Economy for Carbon Neutrality (2021) | - |

|

|

| Performance management strategic plan (2022) |

|

|

|

| Plastic-removal measures for the entire cycle (2022) |

|

| - |

| Type | PET Bottle (Mt) | Container (Mt) | EPS (Mt) | Film (Mt) | SUPs (Mt) | Total (Mt) | |

|---|---|---|---|---|---|---|---|

| Household | Detached house | 0.033 | 0.053 | 0.012 | 0.094 | 0.029 | 0.221 |

| Apartment | 0.281 | 0.296 | 0.064 | 0.403 | 0.218 | 1.262 | |

| Multi-family residential, etc. | 0.017 | 0.033 | 0.006 | 0.067 | 0.017 | 0.139 | |

| Sub-total | 0.330 | 0.382 | 0.082 | 0.564 | 0.264 | 1.622 | |

| Non-household | Production and manufacturing | 0.031 | 0.053 | 0.006 | 0.145 | 0.013 | 0.250 |

| Market, shopping district | 0.029 | 0.050 | 0.008 | 0.080 | 0.014 | 0.181 | |

| Business facilities | 0.019 | 0.030 | 0.004 | 0.050 | 0.009 | 0.113 | |

| Service industry | 0.023 | 0.038 | 0.005 | 0.057 | 0.014 | 0.137 | |

| Education services | 0.009 | 0.010 | 0.001 | 0.015 | 0.004 | 0.040 | |

| Restaurants and taverns | 0.024 | 0.044 | 0.006 | 0.067 | 0.015 | 0.156 | |

| Accommodation | 0.005 | 0.004 | 0.001 | 0.007 | 0.004 | 0.020 | |

| Sub-total | 0.140 | 0.228 | 0.032 | 0.423 | 0.073 | 0.896 | |

| Total | 0.470 | 0.610 | 0.114 | 0.987 | 0.337 | 2.518 | |

| Type of Waste | PET Bottle | Container | EPS | Film | SUPs | Total | |

|---|---|---|---|---|---|---|---|

| Household (%) | Detached house | 76 | 51.2 | 53.7 | 18 | 45.7 | 41.5 |

| Apartment | 89.8 | 79.3 | 70.4 | 42.5 | 83.9 | 71.4 | |

| Multi-family residential, etc. | 81 | 60.5 | 60 | 25.4 | 48.7 | 45.8 | |

| Sub-total | 88 | 73.8 | 67.2 | 36.4 | 77.5 | 65.2 | |

| Non-household (%) | Production and manufacturing | 21.6 | 19.1 | 24.4 | 2.9 | 20.8 | 10.6 |

| Market, shopping district | 69.7 | 69 | 64.1 | 23.3 | 64 | 49.2 | |

| Business facilities | 56.5 | 48 | 53.1 | 11.4 | 41.9 | 33.9 | |

| Service industry | 71.7 | 64.9 | 68.4 | 16.6 | 53.7 | 45.9 | |

| Education services | 77.2 | 52.6 | 51.7 | 12.7 | 48.3 | 44.7 | |

| Restaurants and taverns | 68.2 | 68.7 | 61.7 | 17.7 | 50.8 | 45.6 | |

| Accommodation | 73.6 | 33.6 | 39.5 | 17.5 | 30 | 41.8 | |

| Sub-total | 57.9 | 52.8 | 53.9 | 12.6 | 46.1 | 35.1 | |

| Total (%) | 79.1 | 66 | 63.4 | 26.2 | 70.7 | 54.6 | |

| Type | Recycling Code | Mixed Collection (ton) | Separate Collction (ton) |

|---|---|---|---|

| Recycling to original form | R-1 | - | 10,798 |

| Recycling by simple repair, drying, or washing | R-2 | - | 671 |

| Recycling by recovering solid resources or reproducing the raw materials | R-3 | - | 231,731 |

| Recycling by reproducing the product | R-4 | - | 49,612 |

| Recycling of organic/inorganic materials for the purpose of aiding agricultural production | R-5 | 811 | 170 |

| Recycling of organic materials for the purpose of soil improvement | R-6 | - | - |

| Recycling to produce embankment materials, cover material, road-layer material, or filling material for soil or public water | R-7 | - | - |

| Recycling to a form that allows direct recovery of energy | R-8 | - | 106,974 |

| Recycling to a form that enables recovery of energy | R-9 | 106,793 | 63,551 |

| Recycling to make intermediate processed waste for manufacturing | R-10 | - | 641,090 |

| Total | 107,604 | 1,111,599 | |

| Type | Country | Time | Target Items | ) | Reference |

|---|---|---|---|---|---|

| This study | Republic of Korea | 2022 | Packaging materials and SUPs | 83.1% | - |

| Priror study | Brazil | 2017 | Packaging materials | 33.8% | Pincelli et al. [47] |

| China | 2020 | Packaging materials | 63.2% | Tang et al. [48] | |

| EU | 2016 | Packaging materials | 82.8% | Hsu et al. [49] | |

| Reuplic of Korea | 2017–2019 | Packaging materials and SUPs | 79.5% | Jang et al. [22] | |

| 2017 | Packaging materials and SUPs | 74.8% | Lee et al. [23] | ||

| US | 2017 | Packaging materials and SUPs | 82.6% | Heller et al. [50] |

| Management Strategies | Contents | |

|---|---|---|

| Reduction | Manufacting stage |

|

| Consumption stage |

| |

| Improvement in separation collection | Expansion of infrastructure |

|

| Awareness improvement |

| |

| Implementation of regulations |

| |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, H.-J.; Hwang, D.; Yoon, Y.-S.; Jeon, T.-W.; Rhee, S.-W. Applying Material Flow Analysis for Sustainable Waste Management of Single-Use Plastics and Packaging Materials in the Republic of Korea. Sustainability 2024, 16, 6926. https://doi.org/10.3390/su16166926

Choi H-J, Hwang D, Yoon Y-S, Jeon T-W, Rhee S-W. Applying Material Flow Analysis for Sustainable Waste Management of Single-Use Plastics and Packaging Materials in the Republic of Korea. Sustainability. 2024; 16(16):6926. https://doi.org/10.3390/su16166926

Chicago/Turabian StyleChoi, Hyeong-Jin, Donggun Hwang, Young-Sam Yoon, Tae-Wan Jeon, and Seung-Whee Rhee. 2024. "Applying Material Flow Analysis for Sustainable Waste Management of Single-Use Plastics and Packaging Materials in the Republic of Korea" Sustainability 16, no. 16: 6926. https://doi.org/10.3390/su16166926

APA StyleChoi, H.-J., Hwang, D., Yoon, Y.-S., Jeon, T.-W., & Rhee, S.-W. (2024). Applying Material Flow Analysis for Sustainable Waste Management of Single-Use Plastics and Packaging Materials in the Republic of Korea. Sustainability, 16(16), 6926. https://doi.org/10.3390/su16166926