Research Trends on Valorisation of Agricultural Waste Discharged from Production of Distilled Beverages and Their Implications for a “Three-Level Valorisation System”

Abstract

1. Introduction

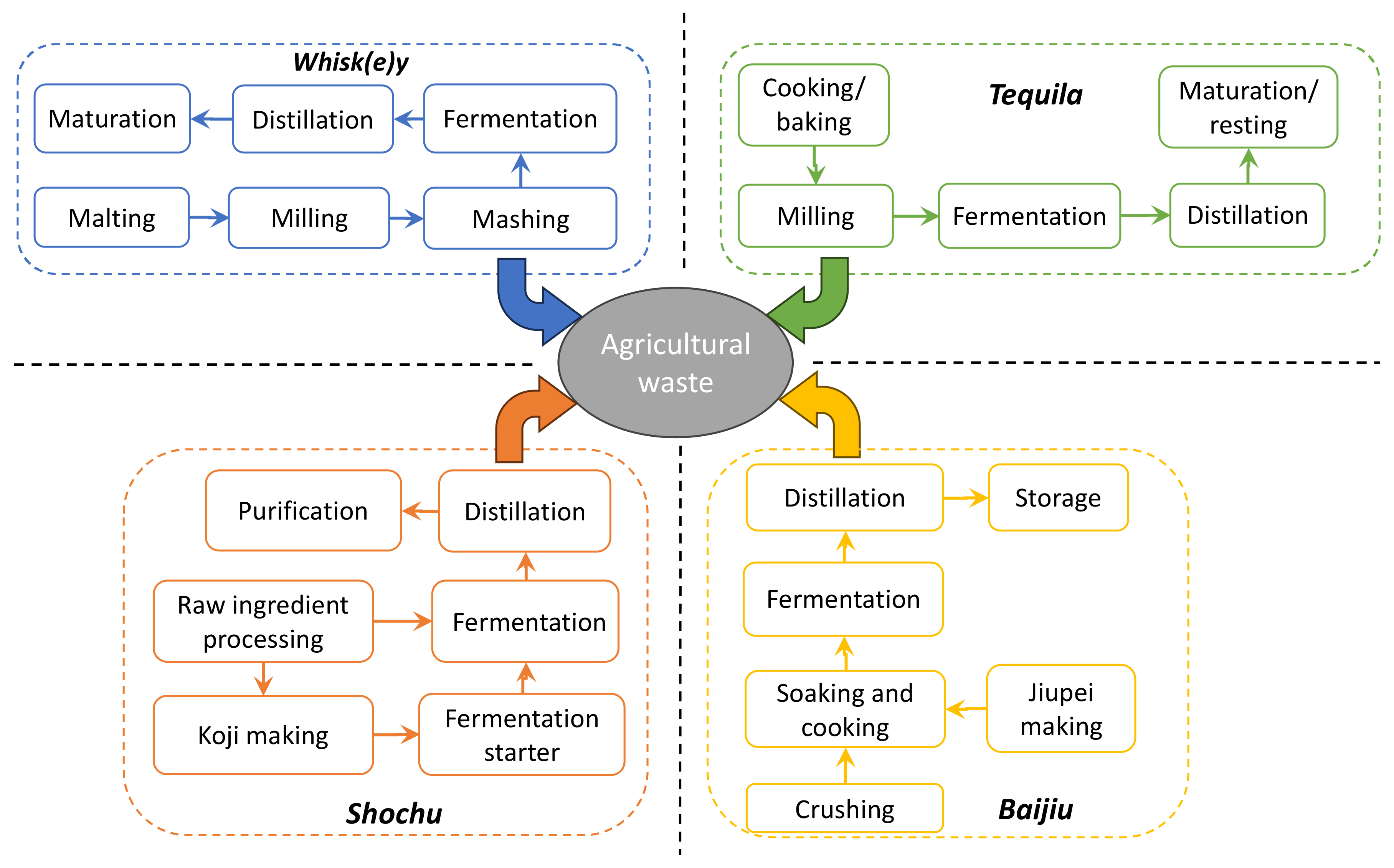

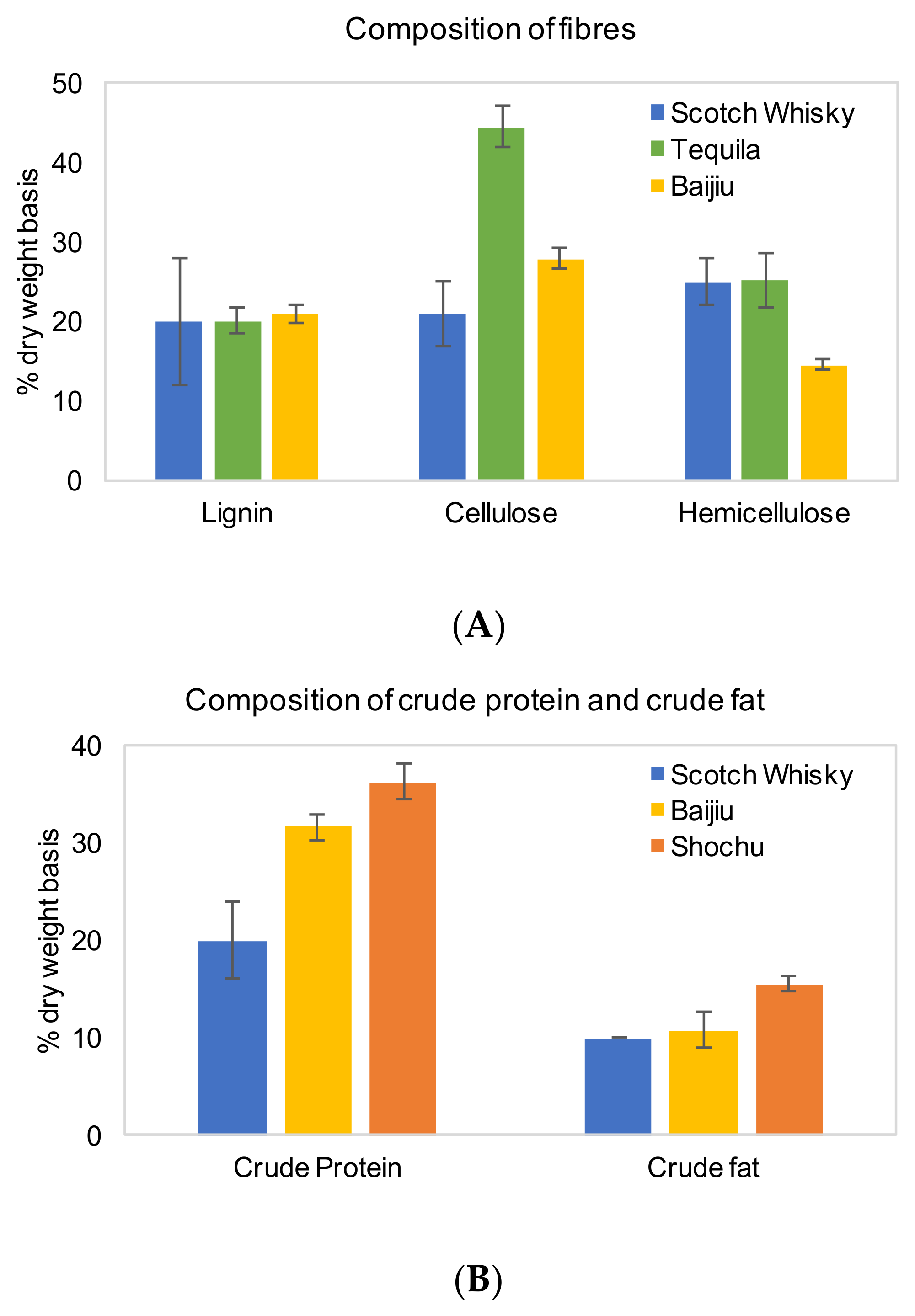

2. Whisk(e)y

2.1. Bioenergy Production from Combined Draff and Pot Ale

2.2. Pretreatment to Optimise Renewable Energy Production from Draff and Pot Ale

2.3. Bioenergy Production from Draff Alone

2.4. Feed/Food

3. Tequila

3.1. Bioenergy—Pretreatment of Agave Bagasse for Increased Productivity

3.2. Optimisation of Production Systems for Renewable Energy Production from Agave Bagasse

3.3. Nanofibres and Green Composites

3.4. Chemical Production

4. Baijiu

4.1. Functional Peptides

4.2. Glutelin

4.3. Xylooligosaccharides (XOS)

4.4. Biochar

4.5. Chemical Production

5. Shochu

5.1. Bacterial Culture Medium

5.2. Electricity Generation

5.3. Functional Feed

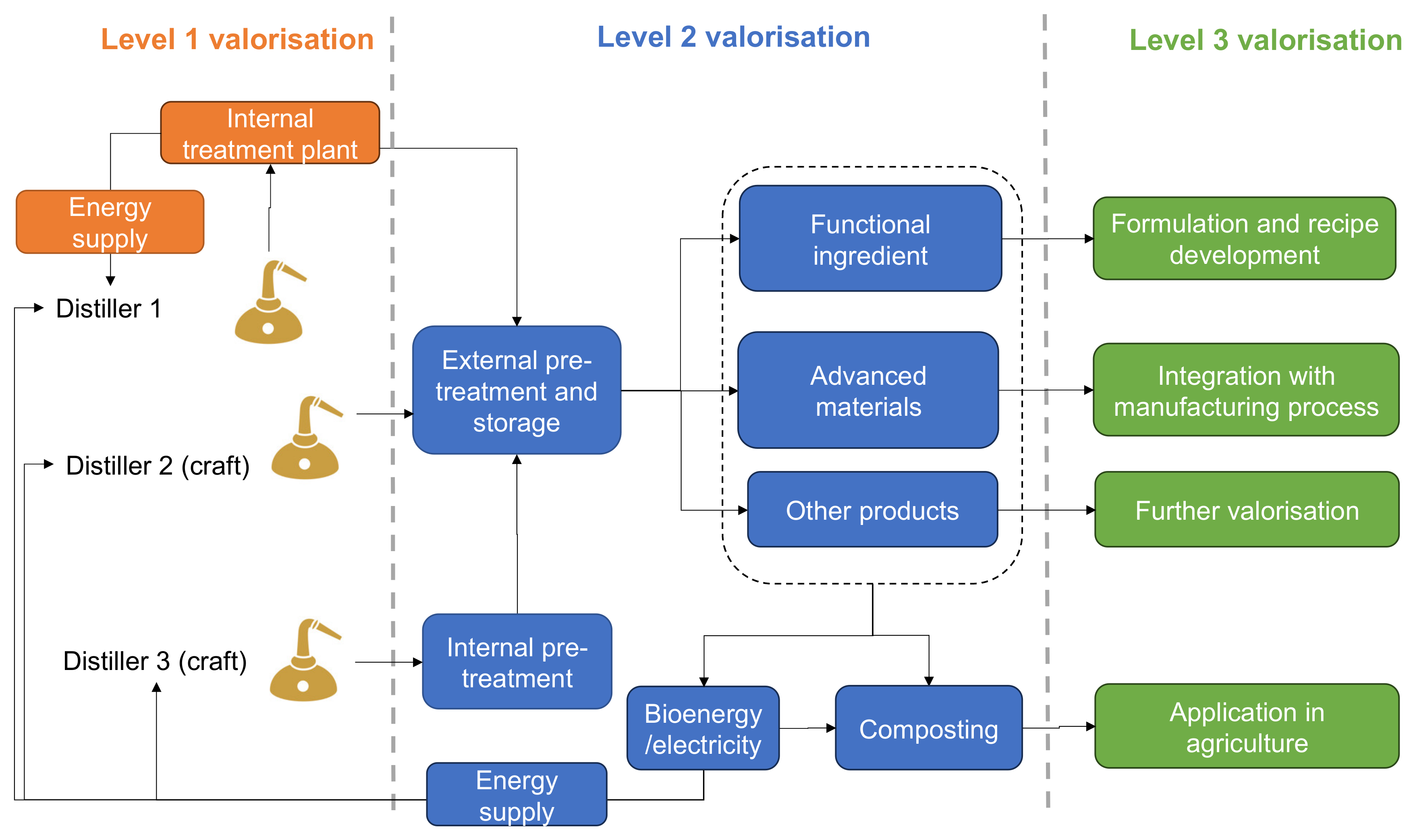

6. Proposal of a “Three-Level Valorisation System”

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scotch Whisky Association Facts & Figures. Available online: https://www.scotch-whisky.org.uk/insights/facts-figures/ (accessed on 13 March 2024).

- Spirits Global Market Report. 2024. Available online: https://www.thebusinessresearchcompany.com/report/spirits-global-market-report (accessed on 13 March 2024).

- White, J.S.; Stewart, K.L.; Maskell, D.L.; Diallo, A.; Traub-Modinger, J.E.; Willoughby, N.A. Characterization of Pot Ale from a Scottish Malt Whisky Distillery and Potential Applications. ACS Omega 2020, 5, 6429–6440. [Google Scholar] [CrossRef] [PubMed]

- Foltanyi, F.; Hawkins, J.E.; Panovic, I.; Bird, E.J.; Gloster, T.M.; Lancefield, C.S.; Westwood, N.J. Analysis of the Product Streams Obtained on Butanosolv Pretreatment of Draff. Biomass Bioenergy 2020, 141, 105680. [Google Scholar] [CrossRef]

- Gao, M.; Lin, Y.; Wang, P.; Jin, Y.; Wang, Q.; Ma, H.; Sheng, Y.; Van Le, Q.; Xia, C.; Lam, S.S. Production of Medium-Chain Fatty Acid Caproate from Chinese Liquor Distillers’ Grain Using Pit Mud as the Fermentation Microbes. J. Hazard. Mater. 2021, 417, 126037. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Liu, X.; Wu, Q.; Tian, H.; Ma, Y.; Cheng, S.; Fan, G.; Teng, C. Combining Autohydrolysis with Xylanase Hydrolysis for Producing Xylooligosaccharides from Jiuzao. Biochem. Eng. J. 2022, 187, 108678. [Google Scholar] [CrossRef]

- Production of Baijiu in China. Available online: https://www.statista.com/statistics/1222591/china-baijiu-production/ (accessed on 17 March 2024).

- Cheng, J.; Zhang, J.; Xiao, X.; Yuan, Y.; Liao, X.; Shi, B.; Zhang, S. Potassium Assisted Pyrolysis of Chinese Baijiu Distillers’ Grains to Prepare Biochar as Controlled-Release K Fertilizer. Sci. Total Environ. 2023, 884, 163814. [Google Scholar] [CrossRef]

- Wolstenholme, A. Distilled Spirits; Hill, A., Jack, F., Eds.; Elsevier: Edinburgh, UK, 2023. [Google Scholar]

- Zhang, J.; Chen, S.; Qian, Y.P.; Qian, M. Baijiu. In Distilled Spirits; Hill, A., Frances, J., Eds.; Elsevier: Edinburgh, UK, 2023. [Google Scholar]

- Spedding, G. Mezcal and Tequila. In Distilled Spirits; Hill, A., Jack, F., Eds.; Elsevier: Edinburgh, UK, 2023. [Google Scholar]

- Moda, I.; Sugimoto, T.; Wanikawa, A. Shochu. In Distilled Spirits; Hill, A., Jack, F., Eds.; Elsevier: Edinburgh, UK, 2023. [Google Scholar]

- De Pérez-Zavala, M.L.; Hernández-Arzaba, J.C.; Bideshi, D.K.; Barboza-Corona, J.E. Agave: A Natural Renewable Resource with Multiple Applications. J. Sci. Food Agric. 2020, 100, 5324–5333. [Google Scholar] [CrossRef] [PubMed]

- Iigatani, R.; Ito, T.; Watanabe, F.; Nagamine, M.; Suzuki, Y.; Inoue, K. Electricity Generation from Sweet Potato-Shochu Waste Using Microbial Fuel Cells. J. Biosci. Bioeng. 2019, 128, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Tang, Y.; Urakami, T.; Morimura, S.; Kida, K. Digestion Performance and Microbial Community in Full-Scale Methane Fermentation of Stillage from Sweet Potato-Shochu Production. J. Environ. Sci. 2014, 26, 423–431. [Google Scholar] [CrossRef] [PubMed]

- Circular Economy. Available online: https://environment.ec.europa.eu/topics/circular-economy_en (accessed on 13 March 2024).

- Kang, X.; Lin, R.; O’Shea, R.; Deng, C.; Li, L.; Sun, Y.; Murphy, J.D. A Perspective on Decarbonizing Whiskey Using Renewable Gaseous Biofuel in a Circular Bioeconomy Process. J. Clean. Prod. 2020, 255, 120211. [Google Scholar] [CrossRef]

- Alemán-Nava, G.S.; Gatti, I.A.; Parra-Saldivar, R.; Dallemand, J.F.; Rittmann, B.E.; Iqbal, H.M.N. Biotechnological Revalorization of Tequila Waste and By-Product Streams for Cleaner Production—A Review from Bio-Refinery Perspective. J. Clean. Prod. 2018, 172, 3713–3720. [Google Scholar] [CrossRef]

- Kumar, A.; Ram, C. Agave Biomass: A Potential Resource for Production of Value-Added Products. Environ. Sustain. 2021, 4, 245–259. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Spent Grain: A Functional Ingredient for Food Applications. Foods 2023, 12, 1533. [Google Scholar] [CrossRef] [PubMed]

- Dalton, C.; Okolie, J.A.; Davis, P.; Gunes, B. Design of a Pre-Treatment Integrated Anaerobic Digestion Treatment Facility for Decarbonising Whiskey Industry: A Circular Economy Perspective. Heliyon 2022, 8, e09522. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Liu, S.; Huang, C.; Ge, X.; Xi, B.; Mao, J. Chinese Baijiu Distiller’s Grains Resourcing: Current Progress and Future Prospects. Resour. Conserv. Recycl. 2022, 176, 105900. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Roberto, I.C. Chemical Characterization and Liberation of Pentose Sugars from Brewer’s Spent Grain. J. Chem. Technol. Biotechnol. 2006, 81, 268–274. [Google Scholar] [CrossRef]

- Palacios Hinestroza, H.; Hernández Diaz, J.A.; Esquivel Alfaro, M.; Toriz, G.; Rojas, O.J.; Sulbarán-Rangel, B.C. Isolation and Characterization of Nanofibrillar Cellulose from Agave tequilana Weber Bagasse. Adv. Mater. Sci. Eng. 2019, 2019, 1342547. [Google Scholar] [CrossRef]

- Yamamoto, M.; Saleh, F.; Hayashi, K. A Fermentation Method to Dry and Convert Shochu Distillery By-Product to a Source of Protein and Enzymes. J. Poult. Sci. 2004, 41, 275–280. [Google Scholar] [CrossRef]

- Russell, I.; Stewart, G. (Eds.) Whisky: Technology, Production and Marketing; Elsevier: Oxford, UK, 2014. [Google Scholar]

- O’Shea, R.; Yang, Y.; Kansagra, K.; Hickey, D.T.; Kohler, D.; Murphy, J.D. Decarbonising Distilled Spirits: An Assessment of the Potential Associated with Anaerobic Digestion of by-Products at Nine Operational Distilleries. J. Environ. Manag. 2023, 329, 116976. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.; Lin, R.; Wu, B.; Li, L.; Deng, C.; Rajendran, K.; Sun, Y.; O’Shea, R.; Murphy, J.D. Towards Green Whiskey Production: Anaerobic Digestion of Distillery by-Products and the Effects of Pretreatment. J. Clean. Prod. 2022, 357, 131844. [Google Scholar] [CrossRef]

- Jackson, S.A.; Kang, X.; O’Shea, R.; O’Leary, N.; Murphy, J.D.; Dobson, A.D.W. Anaerobic Digestion Performance and Microbial Community Structures in Biogas Production from Whiskey Distillers Organic By-Products. Bioresour. Technol. Rep. 2020, 12, 100565. [Google Scholar] [CrossRef]

- Hackula, A.; Shinde, R.; Hickey, D.; O’Shea, R.; Murphy, J.D.; Wall, D.M. Two-Phase Anaerobic Digestion for Enhanced Valorisation of Whiskey Distillery by-Products. Bioresour. Technol. 2023, 383, 129239. [Google Scholar] [CrossRef] [PubMed]

- Price, R.; MacDonald, L.; Gillies, N.; Day, A.; Brightman, E.; Li, J. Utilisation and Valorisation of Distillery Whisky Waste Streams via Biomass Electrolysis: Electrosynthesis of Hydrogen. Faraday Discuss. 2023, 247, 268–288. [Google Scholar] [CrossRef]

- Wehry, G.J.J.E.; Little, D.C.; Newton, R.W.; Bostock, J. The Feasibility of Underutilised Biomass Streams for the Production of Insect-Based Feed Ingredients: The Case for Whisky by-Products and Scottish Farmed Salmon. Clean. Eng. Technol. 2022, 9, 100520. [Google Scholar] [CrossRef]

- Jiang, Y.; Xing, M.; Kang, Q.; Sun, J.; Zeng, X.A.; Gao, W.; Li, H.; Gao, Y.; Li, A. Pulse Electric Field Assisted Process for Extraction of Jiuzao Glutelin Extract and Its Physicochemical Properties and Biological Activities Investigation. Food Chem. 2022, 383, 132304. [Google Scholar] [CrossRef] [PubMed]

- Xia, A.; Cheng, J.; Ding, L.; Lin, R.; Song, W.; Su, H.; Zhou, J.; Cen, K. Substrate Consumption and Hydrogen Production via Co-Fermentation of Monomers Derived from Carbohydrates and Proteins in Biomass Wastes. Appl. Energy 2015, 139, 9–16. [Google Scholar] [CrossRef]

- Galindo-Hernández, K.L.; Tapia-Rodríguez, A.; Alatriste-Mondragón, F.; Celis, L.B.; Arreola-Vargas, J.; Razo-Flores, E. Enhancing Saccharification of Agave tequilana Bagasse by Oxidative Delignification and Enzymatic Synergism for the Production of Hydrogen and Methane. Int. J. Hydrogen Energy 2018, 43, 22116–22125. [Google Scholar] [CrossRef]

- Valdez-Guzmán, B.E.; Rios-Del Toro, E.E.; Cardenas-López, R.L.; Méndez-Acosta, H.O.; González-Álvarez, V.; Arreola-Vargas, J. Enhancing Biohydrogen Production from Agave tequilana Bagasse: Detoxified vs. Undetoxified Acid Hydrolysates. Bioresour. Technol. 2019, 276, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Weber, B.; Estrada-Maya, A.; Sandoval-Moctezuma, A.C.; Martínez-Cienfuegos, I.G. Anaerobic Digestion of Extracts from Steam Exploded Agave tequilana Bagasse. J. Environ. Manag. 2019, 245, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Valdez-Vazquez, I.; Alatriste-Mondragón, F.; Arreola-Vargas, J.; Buitrón, G.; Carrillo-Reyes, J.; León-Becerril, E.; Mendez-Acosta, H.O.; Ortíz, I.; Weber, B. A Comparison of Biological, Enzymatic, Chemical and Hydrothermal Pretreatments for Producing Biomethane from Agave Bagasse. Ind. Crops Prod. 2020, 145, 112160. [Google Scholar] [CrossRef]

- Pérez-Pimienta, J.A.; Icaza-Herrera, J.P.A.; Méndez-Acosta, H.O.; González-Álvarez, V.; Méndoza-Pérez, J.A.; Arreola-Vargas, J. Bioderived Ionic Liquid-Based Pretreatment Enhances Methane Production from: Agave tequilana Bagasse. RSC Adv. 2020, 10, 14025–14032. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Vázquez, A.; Hernández, S.; Ortíz, I. Hydrothermal Pretreatment of Agave Bagasse for Biomethane Production: Operating Conditions and Energy Balance. Biomass Bioenergy 2020, 142, 105753. [Google Scholar] [CrossRef]

- Pérez-Pimienta, J.A.; García-López, R.M.; Méndez-Acosta, H.O.; González-Álvarez, V.; Simmons, B.A.; Méndoza-Pérez, J.A.; Arreola-Vargas, J. Ionic Liquid-Water Mixtures Enhance Pretreatment and Anaerobic Digestion of Agave Bagasse. Ind. Crops Prod. 2021, 171, 113924. [Google Scholar] [CrossRef]

- Aguirre-Fierro, A.; Ruiz, H.A.; Cerqueira, M.A.; Ramos-González, R.; Rodríguez-Jasso, R.M.; Marques, S.; Lukasik, R.M. Sustainable Approach of High-Pressure Agave Bagasse Pretreatment for Ethanol Production. Renew. Energy 2020, 155, 1347–1354. [Google Scholar] [CrossRef]

- Breton-Deval, L.; Méndez-Acosta, H.O.; González-Álvarez, V.; Snell-Castro, R.; Gutiérrez-Sánchez, D.; Arreola-Vargas, J. Agave tequilana Bagasse for Methane Production in Batch and Sequencing Batch Reactors: Acid Catalyst Effect, Batch Optimization and Stability of the Semi-Continuous Process. J. Environ. Manag. 2018, 224, 156–163. [Google Scholar] [CrossRef]

- Pérez Pimienta, J.A.; Papa, G.; Sun, J.; Stavila, V.; Sanchez, A.; Gladden, J.M.; Simmons, B.A. One-Pot Ethanol Production under Optimized Pretreatment Conditions Using Agave Bagasse at High Solids Loading with Low-Cost Biocompatible Protic Ionic Liquid. Green Chem. 2022, 24, 207–217. [Google Scholar] [CrossRef]

- Montiel Corona, V.; Razo-Flores, E. Continuous Hydrogen and Methane Production from Agave tequilana Bagasse Hydrolysate by Sequential Process to Maximize Energy Recovery Efficiency. Bioresour. Technol. 2018, 249, 334–341. [Google Scholar] [CrossRef] [PubMed]

- Calderón-Soto, L.F.; López-Gutiérrez, I.; Valencia-Ojeda, C.; Aguilar-López, R.; Alatriste-Mondragón, F.; Femat, R. Two-Stage Continuous Biomethane Production from Enzymatic Hydrolysate of Agave Bagasse: Modelling, Identification and Control. J. Process Control 2022, 120, 14–27. [Google Scholar] [CrossRef]

- López-Gutiérrez, I.; Montiel-Corona, V.; Calderón-Soto, L.F.; Palomo-Briones, R.; Méndez-Acosta, H.O.; Razo-Flores, E.; Ontiveros-Valencia, A.; Alatriste-Mondragón, F. Evaluation of the Continuous Methane Production from an Enzymatic Agave Bagasse Hydrolysate in Suspended (CSTR) and Granular Biomass Systems (UASB). Fuel 2021, 304, 121406. [Google Scholar] [CrossRef]

- Huerta-Cardoso, O.; Durazo-Cardenas, I.; Marchante-Rodriguez, V.; Longhurst, P.; Coulon, F.; Encinas-Oropesa, A. Up-Cycling of Agave tequilana Bagasse-Fibres: A Study on the Effect of Fibre-Surface Treatments on Interfacial Bonding and Mechanical Properties. Results Mater. 2020, 8, 100158. [Google Scholar] [CrossRef]

- Arreola-Vargas, J.; Xu, B.; Hu, C.; Meng, X.; Wang, Y.Y.; Ragauskas, A.J.; Méndez-Acosta, H.O.; Perez-Pimienta, J.A.; Dai, S.Y.; Yuan, J.S. Bioconversion of Agave Bagasse Lignin to Medium-Chain-Length Polyhydroxyalkanoates by Pseudomonas Putida. ACS Sustain. Chem. Eng. 2022, 10, 15670–15679. [Google Scholar] [CrossRef]

- Salvachúa, D.; Rydzak, T.; Auwae, R.; De Capite, A.; Black, B.A.; Bouvier, J.T.; Cleveland, N.S.; Elmore, J.R.; Huenemann, J.D.; Katahira, R.; et al. Metabolic Engineering of Pseudomonas Putida for Increased Polyhydroxyalkanoate Production from Lignin. Microb. Biotechnol. 2020, 13, 290–298. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Herrera, R.E.; Rutiaga-Quiñones, O.M.; Alemán-Huerta, M.E. Integration of Agave Plants into the Polyhydroxybutyrate (PHB) Production: A Gift of the Ancient Aztecs to the Current Bioworld. Ind. Crops Prod. 2021, 174, 114188. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, J.; Yin, Z.; Li, H.; Sun, X.; Zheng, F. Evaluation of Antioxidant Peptides Generated from Jiuzao (Residue after Baijiu Distillation) Protein Hydrolysates and Their Effect of Enhancing Healthy Value of Chinese Baijiu. J. Sci. Food Agric. 2020, 100, 59–73. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wang, R.; Yin, Z.; Sun, J.; Wang, B.; Zhao, D.; Zeng, X.A.; Li, H.; Huang, M.; Sun, B. Optimization of Jiuzao Protein Hydrolysis Conditions and Antioxidant Activity in Vivo of Jiuzao Tetrapeptide Asp-Arg-Glu-Leu by Elevating the Nrf2/Keap1-P38/PI3K-MafK Signaling Pathway. Food Funct. 2021, 12, 4808–4824. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zang, K.; Yan, R.; Sun, J.; Zeng, X.A.; Li, H.; Brennan, C.; Huang, M.; Xu, L. Modification of Jiuzao Glutelin with Pullulan through Maillard Reaction: Stability Effect in Nano-Emulsion, in Vitro Antioxidant Properties, and Interaction with Curcumin. Food Res. Int. 2022, 161, 111785. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zang, K.; Sun, J.; Zeng, X.A.; Li, H.; Brennan, C.; Huang, M.; Xu, L. Preparation of Modified Jiuzao Glutelin Isolate with Carboxymethyl Chitosan by Ultrasound-Stirring Assisted Maillard Reaction and Its Protective Effect of Loading Resveratrol/Quercetin in Nano-Emulsion. Ultrason. Sonochem. 2022, 88, 106094. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zang, K.; Xu, L.; Zeng, X.A.; Li, H.; Brennan, C.; Zhao, D.; Sun, J. Co-Delivery of Riboflavin and Rhein Based on Properties Improved Jiuzao Glutelin: Binding Mechanism, Stability, and Antioxidant Activities. J. Mol. Liq. 2022, 367, 120490. [Google Scholar] [CrossRef]

- Qin, L.; Ma, J.; Tian, H.; Ma, Y.; Wu, Q.; Cheng, S.; Fan, G. Production of Xylooligosaccharides from Jiuzao by Autohydrolysis Coupled with Enzymatic Hydrolysis Using a Thermostable Xylanase. Foods 2022, 11, 2663. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Xu, D.; Yang, J.; Yan, Z.; Zhang, Z.; Zhong, B.; Wang, X. Treatment of Distiller Grain with Wet-Process Phosphoric Acid Leads to Biochar for the Sustained Release of Nutrients and Adsorption of Cr(VI). J. Hazard. Mater. 2023, 441, 129949. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Feng, W.; Guo, L.; Huang, X.; Shi, B. Controlled Synthesis of Distiller’s Grains Biochar for Turbidity Removal in Baijiu. Sci. Total Environ. 2023, 867, 161382. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhao, J.; Zhang, X.; Xu, Y. An Eco-Friendly Biorefinery Strategy for Xylooligosaccharides Production from Sugarcane Bagasse Using Cellulosic Derived Gluconic Acid as Efficient Catalyst. Bioresour. Technol. 2019, 289, 121755. [Google Scholar] [CrossRef] [PubMed]

- Aachary, A.A.; Prapulla, S.G. Value Addition to Corncob: Production and Characterization of Xylooligosaccharides from Alkali Pretreated Lignin-Saccharide Complex Using Aspergillus Oryzae MTCC 5154. Bioresour. Technol. 2009, 100, 991–995. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, H.; Nishida, K.; Tamaki, H. Shochu Slop Is an Excellent Medium for Escherichia Coli K-12. Lett. Appl. Microbiol. 2019, 68, 505–508. [Google Scholar] [CrossRef] [PubMed]

- Koga, A.; Goto, M.; Morise, T.; Tran, H.T.D.; Kakimoto, T.; Kashiyama, K.; Yamauchi, N.; Nakayama, K.; Hayashi, S.; Yamamoto, S.; et al. Value-Added Recycling of Distillation Remnants of Kuma Shochu: A Local Traditional Japanese Spirit, with Photosynthetic Bacteria. Waste Biomass Valorization 2020, 11, 6717–6724. [Google Scholar] [CrossRef]

- Fujimura, S.; Kamitori, K.; Kamei, I.; Nagamine, M.; Miyoshi, K.; Inoue, K. Performance of Stacked Microbial Fuel Cells with Barley–Shochu Waste. J. Biosci. Bioeng. 2022, 133, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Khoa, T.N.D.; Waqalevu, V.; Honda, A.; Matsui, H.; Truong, N.X.; Sakaguchi, K.; Kawaji, H.; Ishikawa, M.; Shiozaki, K.; Kotani, T. Enrichment Effects of Fermented By-Product of Shochu Distillery on Brachionus Plicatilis Sp. Rotifer and Larviculture Performance in Japanese Flounder (Paralichthys olivaceus). Aquaculture 2021, 535, 736352. [Google Scholar] [CrossRef]

- Ano, Y.; Li, J.Y.; Jomoto, T.; Kurihara, D.; Nishimura, R.; Nakayama, H.; Kuwahara, M. Distillation Remnants of Shochu, a Traditional Japanese Liquor, Improve Pork Meat Quality by Reducing Stress. Food Chem. 2020, 318, 126488. [Google Scholar] [CrossRef] [PubMed]

- Eguchi, T.; Tashima, D.; Fukuma, M.; Kumagai, S. Activated Carbon Derived from Japanese Distilled Liquor Waste: Application as the Electrode Active Material of Electric Double-Layer Capacitors. J. Clean. Prod. 2020, 259, 120822. [Google Scholar] [CrossRef]

- Edwards, C.; McNerney, C.C.; Lawton, L.A.; Palmer, J.; Macgregor, K.; Jack, F.; Cockburn, P.; Plummer, A.; Lovegrove, A.; Wood, A. Recoverable Resources from Pot Ale & Spent Wash from Scotch Whisky Production. Resour. Conserv. Recycl. 2022, 179, 106114. [Google Scholar] [CrossRef] [PubMed]

- O’Shea, R.; Lin, R.; Wall, D.M.; Browne, J.D.; Murphy, J.D. Distillery Decarbonisation and Anaerobic Digestion: Balancing Benefits and Drawbacks Using a Compromise Programming Approach. Biofuel Res. J. 2021, 8, 1417–1432. [Google Scholar] [CrossRef]

| Spirit Type | Estimated Waste Discharge | References | |

|---|---|---|---|

| Discharge per Litre Spirit | Annual Discharge | ||

| Scotch whisky | 2.5 kg | 9 × 105 tons | [3] |

| Tequila | 3.6 kg | 1 × 106 tons | [13] |

| Baijiu | 3.0 kg | 2 × 107 tons | [5,6] |

| Shochu | 2.0 kg | 8 × 105 tons | [14,15] |

| Value-Added Products | Technologies/ Subjects | Key Findings | References |

|---|---|---|---|

| Bioenergy (Biomethane) | Anaerobic digestion | Four scenarios based on a whiskey plant size of 2 million L/a were assessed. The recommended scenario resulted in a biogas production containing 1.03 million m3 biomethane, corresponding to an energy yield of 10,300 MWh. It could cover 446% of the annual electricity demand and 25% of the heat demand of a traditional distillery. | [17] |

| Bioenergy (Biomethane) | Anaerobic digestion | A comprehensive assessment of biogas potential was reported at nine operational distilleries. Large variation was observed from different distilleries depending on the feedstocks and the processes employed. The theoretical methane yield obtained ranged from 288 to 521 L CH4 per kg volatile solids. | [27] |

| Bioenergy (Biomethane) | Anaerobic digestion | Methane production potential via anaerobic digestion was assessed, including specific methane yield, acid pretreatment and microbial analysis. The methane yield from the unprocessed by-products was 330 mL/g volatile solids from draff. | [28] |

| Bioenergy (Biomethane) | Anaerobic digestion | A novel anaerobic digestion plant integrated with a pretreatment stage was designed for a whisky distillery that produces 2 million litres whiskey per annum. Compared with the conventional digesters, the proposed method achieved a 20% increase in methane yield. | [21] |

| Bioenergy (Biomethane) | Anaerobic digestion | Acetoclastic methanogenesis and hydrogenotrophic methanogenesis are important pathways for biogas production under mesophilic and thermophilic anaerobic digestion plant. | [29] |

| Bioenergy (biomethane) and volatile fatty acids | Anaerobic digestion | The three systems studied delivered similar methane yields which could supply up to 44% of the thermal energy demand of a distillery that produces 50 million litre of whiskey per annum. The two-phase anaerobic digestion system could provide additional valorisation opportunity due to the production of volatile fatty acid. | [30] |

| Bioenergy (Biohydrogen) | Electrosynthesis | Draff and pot ale were identified as possible substrate for hydrogen production via digestion and electrolysis. | [31] |

| Feed | Feasibility study | Draff and pot ale were identified as the most promising biomass to produce Insect-based salmon feed ingredients. | [32] |

| Value-Added Products | Technologies/Subjects | Key Findings | References |

|---|---|---|---|

| Bioenergy (Biomethane and biohydrogen) | Oxidative delignification and enzymatic pretreatment | It resulted in yields 1.5 and 3.6 times (hydrogen and methane, respectively) superior to those obtained with hydrolysates of non-pretreated bagasse processed with a single enzyme. | [35] |

| Bioenergy (Biohydrogen) | Detoxification pretreatment | The detoxified hydrolysate produced 33% more biohydrogen than the un-detoxified one at the optimal condition. | [36] |

| Bioenergy (Biomethane) | Steam explosion pretreatment | It demonstrated steam explosion prior to anaerobic digestion could add on site output in energy recovery from agave bagasse. | [37] |

| Bioenergy (Biomethane) | Comparison of pretreatment method | Biological methane potential from most hydrolysates was the same whilst difference was observed in lag phase and the methane production rates. | [38] |

| Bioenergy (Biomethane) | Ionic liquid-based pretreatment | High methane generation was obtained using the hydrolysate from ionic liquid pretreated materials, 7.5 times higher when compared to that obtained without pretreatment. | [39] |

| Bioenergy (Biomethane) | Hydrothermal pretreatment | The operating condition of 154 °C and 15 min achieve the maximum solubilisation of total carbohydrates. | [40] |

| Bioenergy (Biomethane) | Ionic liquid pretreatment | Ionic liquid–water mixtures enhance pretreatment and anaerobic digestion of agave bagasse. | [41] |

| Bioenergy (Bioethanol) | High-pressure pretreatment | It demonstrated a sustainable high pressure treatment of lignocellulosic residual biomass for ethanol production. | [42] |

| Bioenergy (Biomethane) | Condition optimisation | Data reveal a acid catalyst effect, batch optimisation and stability of the semi-continuous process. | [43] |

| Bioenergy (Bioethanol) | Protic ionic liquid pretreatment | Pretreatment with a biocompatible low-cost protic ionic liquid was achieved, allowing one-pot ethanol production. | [44] |

| Bioenergy (Biomethane and biohydrogen) | Design of a two-stage system | The continuous hydrogen and methane production system was able to achieve equivalent to approx. 9 kJ/g bagasse, significantly increased energy recovery efficiency compared to one-stage methane production system. | [45] |

| Bioenergy (Biomethane) and volatile fatty acids | Process development | Two stage continuous production was modelled and demonstrated, where maximum volatile fatty acid production in the first stage and maximum biomethane production in the second stage were defined for the first time. | [46] |

| Bioenergy (Biomethane) | Continuous methane production in CSTR and UASB | The UASB reactor and the use of Cellulase 50XL can be advantageous features for future industrial application of methane production. | [47] |

| Nanofibers | Organosolv treatment followed by microfluidiser | The product has high resistance to pressure, and elasticity, with a potential to be used in the elaboration of advanced materials. | [24] |

| Green composites | Fibre-surface treatments | The fibre can be used as reinforcement fibres to manufacture polylactic acid-based green composites. | [48] |

| Chemical | Bioconversion of lignin to PHA | Increased PHA titre was achieved by a series of biological, fermentation configuration and condition optimisation. | [49] |

| Value-Added Products | Technologies/Subjects | Key Findings | References |

|---|---|---|---|

| Functional peptides | Extraction method development | Antioxidant peptides was obtained from Jiuzao protein hydrolysates. | [52] |

| Functional peptides | Method optimisation and mechanism investigation | The optimised yield of the tetrapeptide was obtained. It could improve antioxidant capacity in vivo by activating the Nrf2/Keap1-p38/PI3K-MafK signalling pathway. | [53] |

| Glutelin | Pulse electric field (PEF) assisted process | PEF can be a potential technique to extract high-quality glutelin extract from Jiuzao. | [33] |

| Glutelin | Grafting of Jiuzao glutelin with pullulan | Pullulan to Jiuzao glutelin ratio was optimised. A resulting product (PJC-2) can be a potential nanostabiliser for a range of food and non-food applications. | [54] |

| Glutelin | Ultrasound-stirring assisted Maillard reaction | Jiuzao glutelin conjugates was prepared and optimised between Jiuzao glutelin and carboxymethyl chitosan, leading to improved functional property of Jiuzao glutelin. | [55] |

| Glutelin | Maillard reaction | Jiuzao glutelin was grafted with dextran, gum arabic, and pectin via Maillard reaction, respectively, leading to improved stability. | [56] |

| Xylooligosaccharides | Autohydrolysis with a recombinant thermostable, xylanases (XynAS) | Combining autohydrolysis with the xylanases (XynAS) to produce xylooligosaccharides was achieved with maximum yield of 30.4%. | [6] |

| Xylooligosaccharides | Autohydrolysis with a recombinant thermostable, xylanases, namely XynAR | A similar to above process was developed to produce xylooligosaccharides, by autohydrolysis coupled with enzymatic hydrolysis (XynAR), with a yield of 34.2%. | [57] |

| Biochar | Potassium assisted pyrolysis | A novel potassium enriched biochar was developed as a controlled-release potassium fertiliser. | [8] |

| Biochar | Wet-process phosphoric acid and subsequent solid-phase pyrolysis | The biochar materials displayed dual functions including sustained release of multiple nutrients and potential to remove chromium. | [58] |

| Biochar | Controlled synthesis of biochar | A low-cost activated biochar was prepared from Jiuzao, used for turbidity removal in low alcoholic baijiu. | [59] |

| Chemical | Anaerobic fermentation | Jiuzao was used to produce ester of caproic acid using shallow pit mud as an inoculum in anaerobic fermentation. | [5] |

| Value-Added Products | Technologies/Subjects | Key Findings | References |

|---|---|---|---|

| Bacterial culture medium | Growing trials | Sweet potato based Shochu waste was an excellent culture medium for Escherichia coli K-12. | [62] |

| Bacterial culture medium | Growing trials | Rice based shochu waste could provide culture nutrient to selected photosynthetic bacteria. The resulting Kuma PSB promoted the growth of various vegetables. | [63] |

| Electricity | Cassette-electrode microbial fuel cells | Electricity generation from sweet potato based shochu waste was demonstrated. | [14] |

| Electricity | Stacked microbial fuel cells | Barley based shochu waste was utilised to generate electricity. | [64] |

| Electricity | Material treatment and characterisation | Shochu waste-derived activated carbon is a promising ingredient as the electrode active material of electric double-layer capacitors. | [67] |

| Functional feed | Feeding trials | Barley based Shochu waste improved pork meat quality by reducing stress. | [65] |

| Functional feed | Feeding trials | Sweet potato based Shochu waste could be used as a potential live feed enrichment media for larviculture of Japanese flounder. | [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stewart, K.; Willoughby, N.; Zhuang, S. Research Trends on Valorisation of Agricultural Waste Discharged from Production of Distilled Beverages and Their Implications for a “Three-Level Valorisation System”. Sustainability 2024, 16, 6847. https://doi.org/10.3390/su16166847

Stewart K, Willoughby N, Zhuang S. Research Trends on Valorisation of Agricultural Waste Discharged from Production of Distilled Beverages and Their Implications for a “Three-Level Valorisation System”. Sustainability. 2024; 16(16):6847. https://doi.org/10.3390/su16166847

Chicago/Turabian StyleStewart, Kelly, Nik Willoughby, and Shiwen Zhuang. 2024. "Research Trends on Valorisation of Agricultural Waste Discharged from Production of Distilled Beverages and Their Implications for a “Three-Level Valorisation System”" Sustainability 16, no. 16: 6847. https://doi.org/10.3390/su16166847

APA StyleStewart, K., Willoughby, N., & Zhuang, S. (2024). Research Trends on Valorisation of Agricultural Waste Discharged from Production of Distilled Beverages and Their Implications for a “Three-Level Valorisation System”. Sustainability, 16(16), 6847. https://doi.org/10.3390/su16166847