Design, Technical Development, and Evaluation of an Autonomous Compost Turner: An Approach towards Smart Composting

Abstract

1. Introduction

1.1. Composting as an Integral Part of the Circular Economy

1.2. Robotics in Agriculture

1.3. Requirements and Needs in Industrial Composting

1.4. Key Contributions

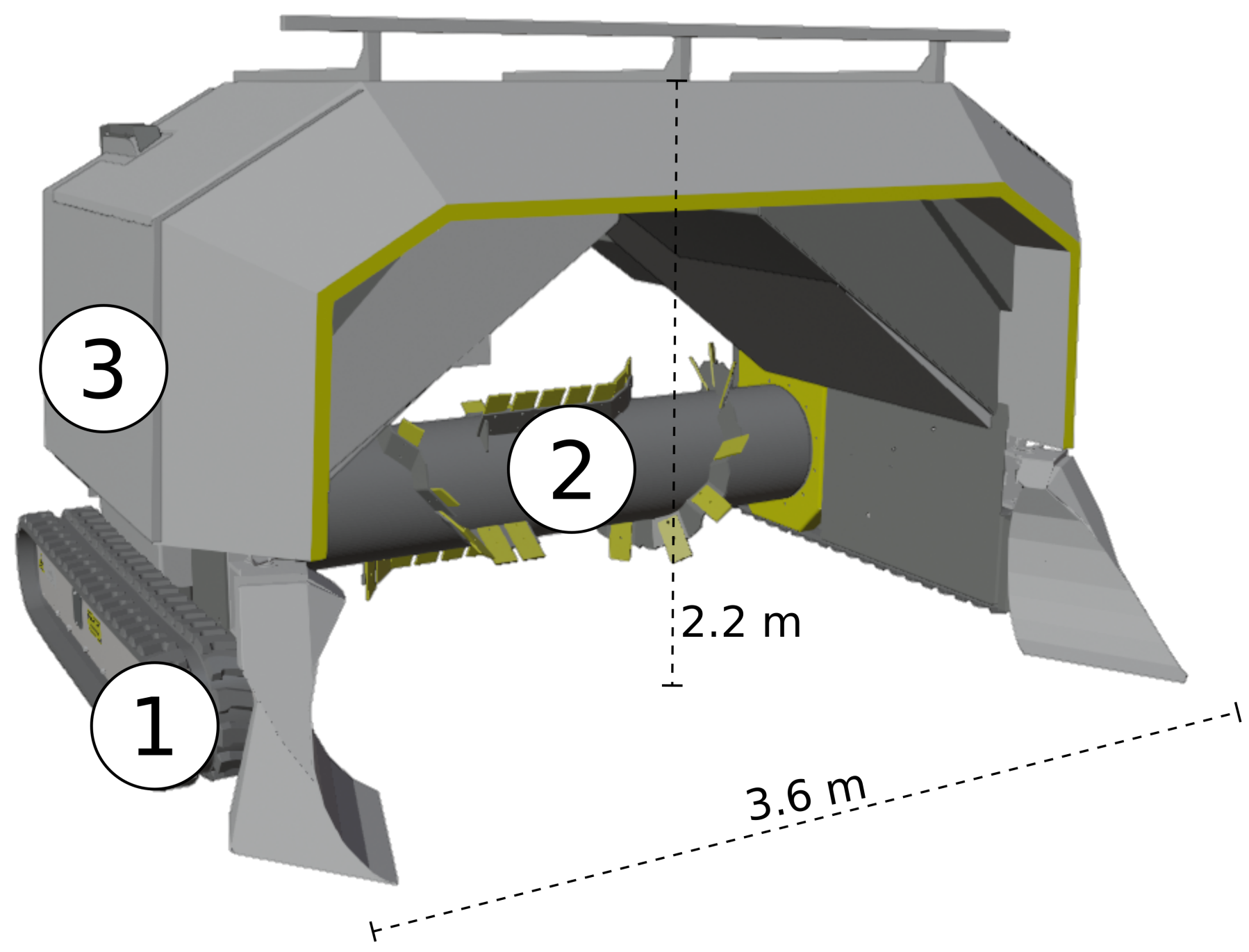

- We present the development of an electric, self-driving, autonomous compost turner as displayed in Figure 2.

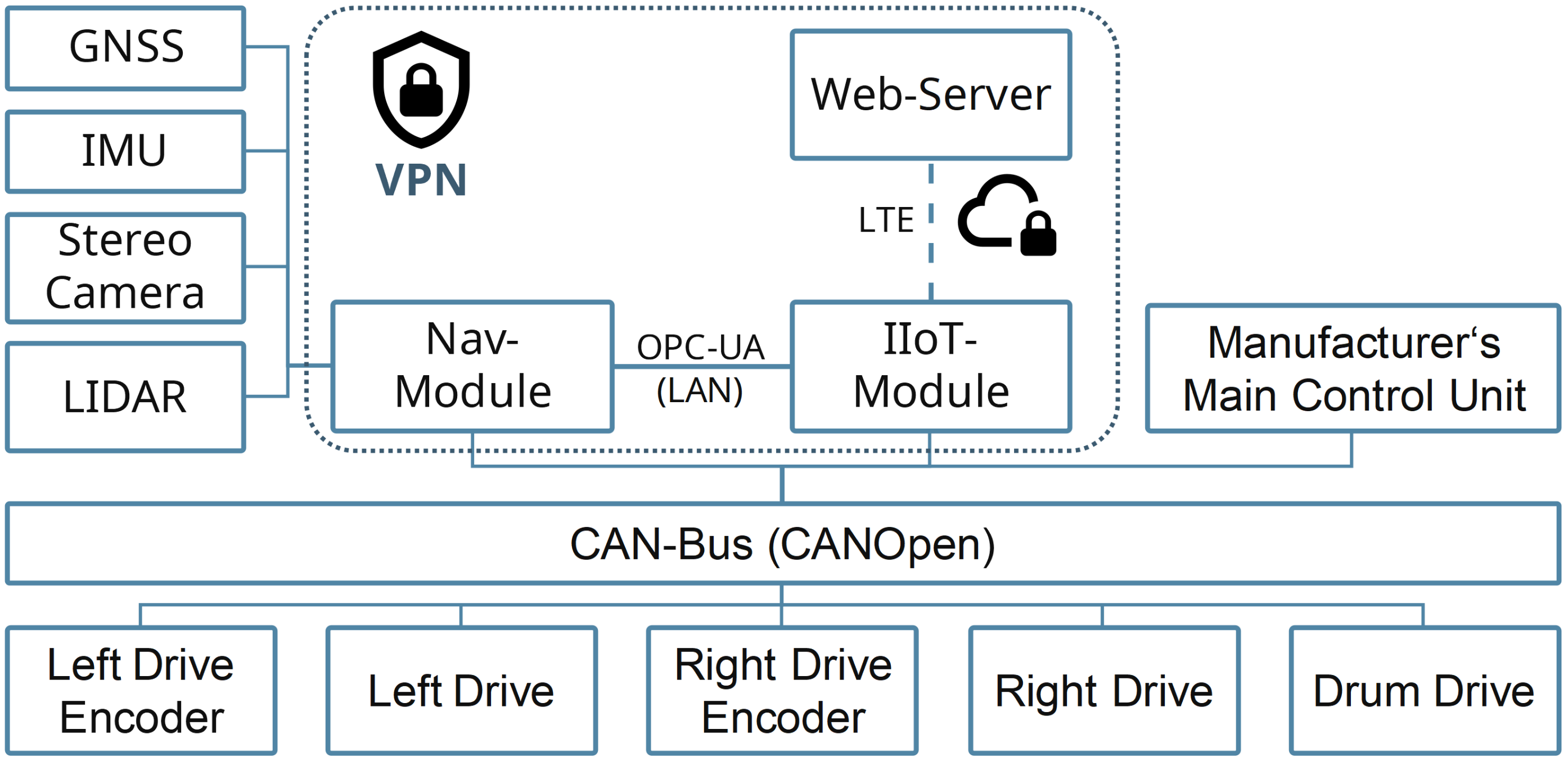

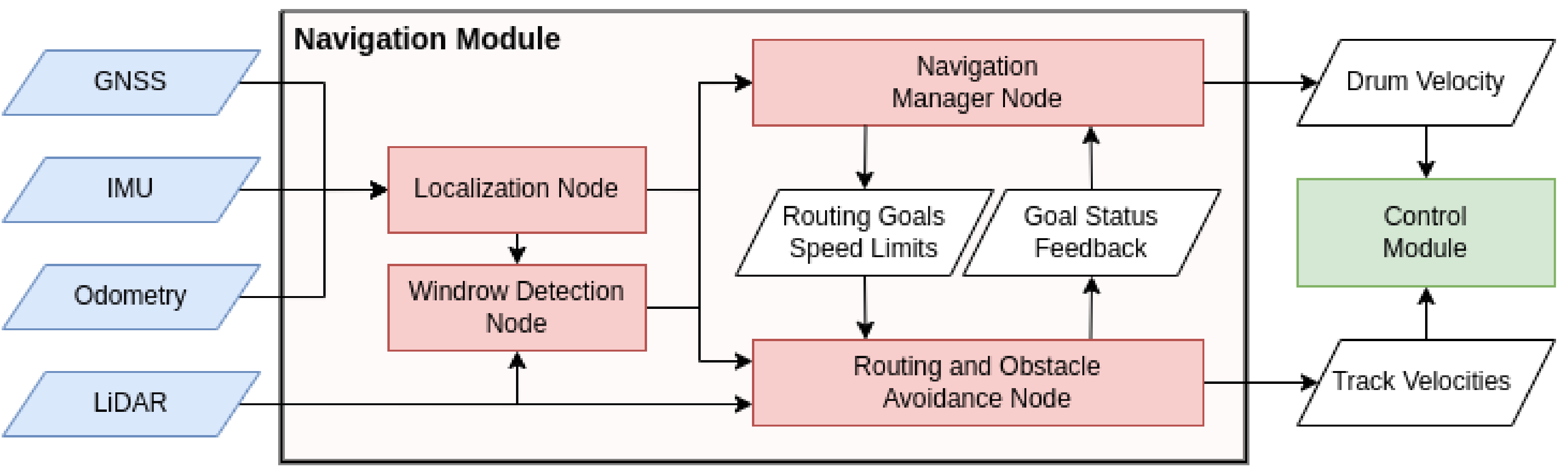

- We describe aspects of the hardware design, that is, sensor mounting and setup, a navigation module, and an IIoT module for control and data processing tasks. We also present the interfaces and interactions of components on a system-wide level.

- Furthermore, we describe the architecture of concepts, models, and software integration. In detail, the navigation tasks consisting of navigation filter and sensor fusion, compost windrow detection algorithm and route planning within the compost plant are presented. In addition to the control tasks, we describe the IIoT module’s real-time cloud-based processing tasks of compost data.

- The proposed concepts are validated by analyzing the performance of the autonomous compost turner in three path-following scenarios.

2. Materials and Methods

2.1. Setup of Hardware, Modules and Tools

2.1.1. The Electric Compost Turner

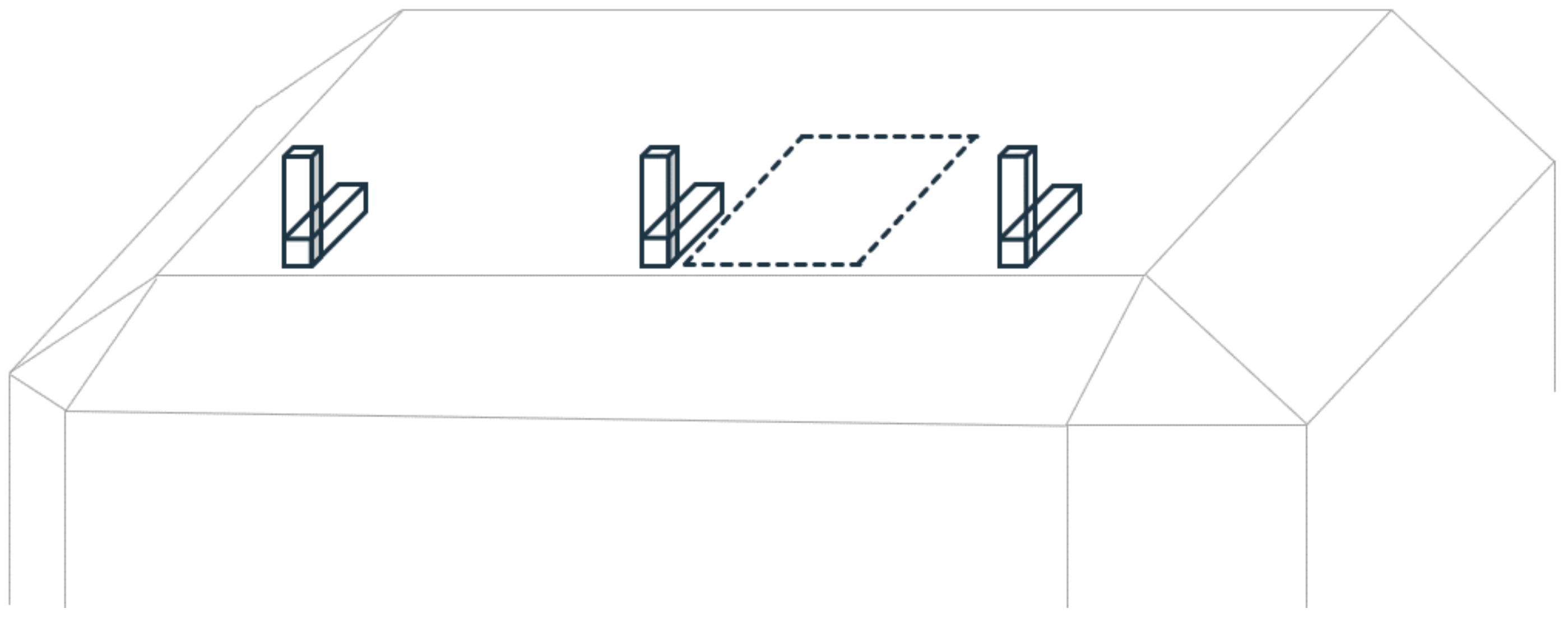

2.1.2. Navigation Sensors

2.1.3. The Navigation Module

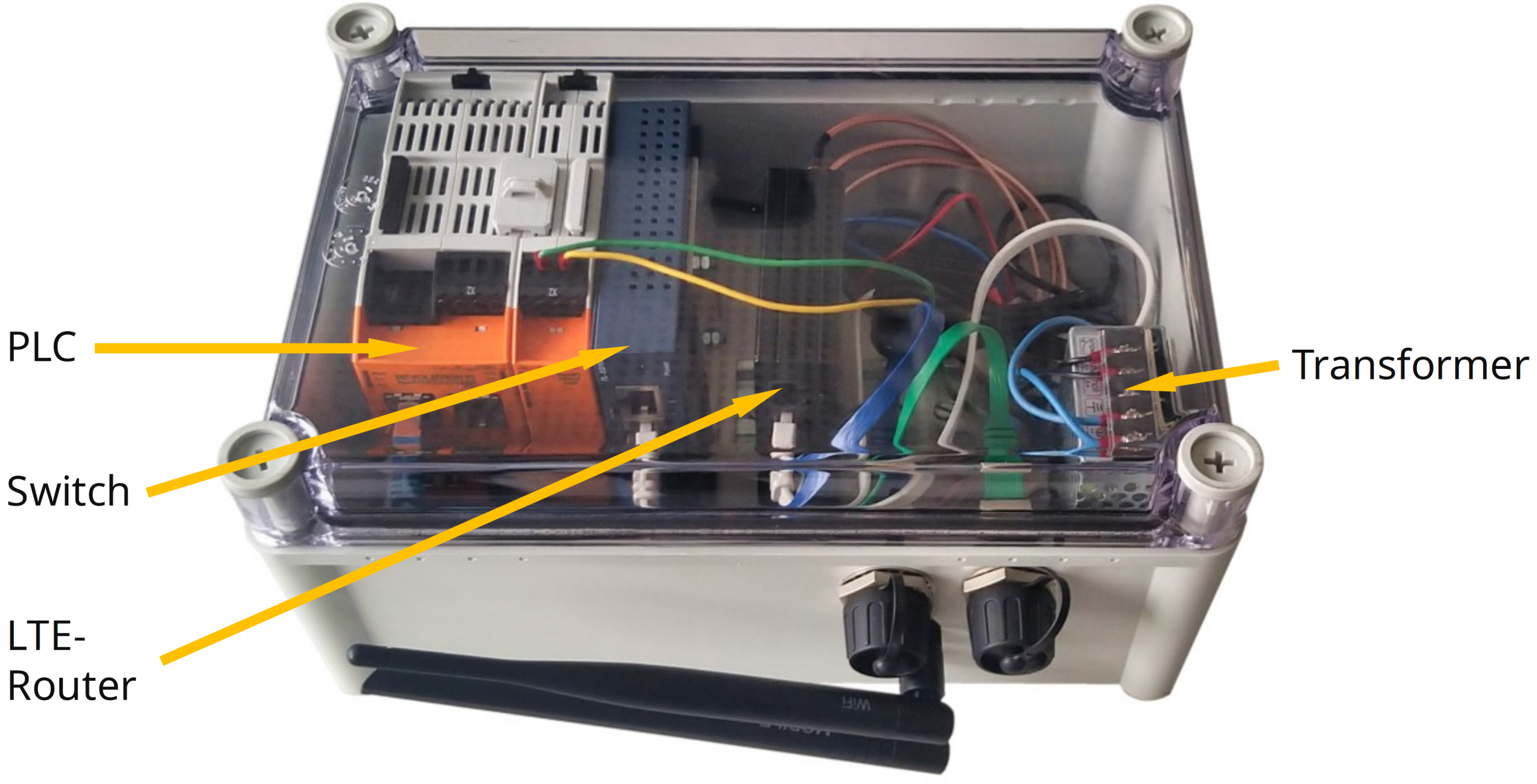

2.1.4. IIoT-Module for Control Tasks and Cloud-Based Data Visualization

2.2. System Architecture: Hardware Integration on the Industrial Compost Turner

2.3. Architecture of Concepts, Models and Software Integration

2.3.1. High-Level View on the Navigation Tasks

2.3.2. Navigation Filter (Localization Node)

2.3.3. Windrow Detection

2.3.4. Route Planning

2.3.5. Navigation Manager

- Idle: Basic state at the start and after finishing or canceling the navigation.

- Initialize: State when the manual initialization phase (see Section 2.3.3) is performed.

- On Site: State for normal driving on the composting site (e.g., after turning a windrow and moving to the start of the next one). Here, the detected windrow start and end points act as the routing goals, and the obstacle detection is active. The compost turner drives with the standard velocity limits, and the drum speed is zero.

- Local Correction: State in which deviations of the windrow detection results from the actual start point of the windrow are corrected. The navigation manager switches to this state after the windrow start point is reached. Here, the local LiDAR point cloud is used to detect the ridge of the windrow that is currently in front of the machine. If the across-track deviation of the robot compared to the locally detected windrow is too large, a correction maneuver is performed.

- Windrow Start: State after the local correction occurred. The compost turner is at the start of the windrow. In this state, the track speed limits are reduced to drive through the windrow slowly, and the drum is started. The obstacle detection is deactivated while moving through the windrow.

- In Windrow: State for the turning process of the windrow. The drum turns with the maximum allowed speed, and the local LiDAR point cloud is used to keep the compost turner centrally aligned to the windrow.

- Windrow End: State towards the end of the windrow. Here, the drum is stopped, and after reaching the windrow endpoint, the state is switched back to Idle or On Site, where the track speed limits are set back to normal, and the obstacle detection is set to active.

2.3.6. Control Tasks of the IIoT Module

2.3.7. Cloud-Based Data Processing Tasks of the IIoT Module

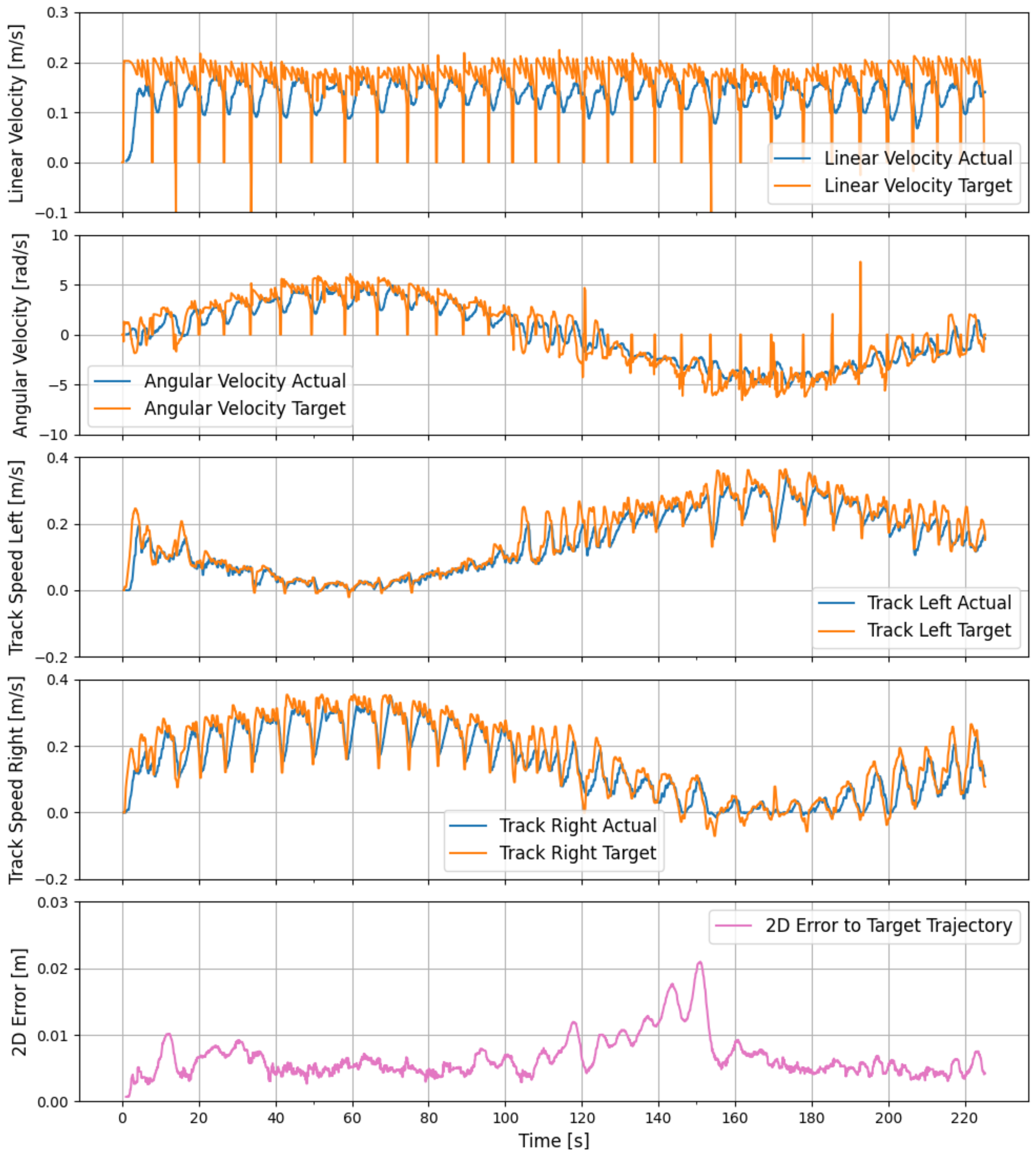

3. Results

3.1. Scenario 1: Validation of the Waypoint Navigation—Following a Circle

3.2. Scenario 2: Bernoulli Lemniscate—Infinity Shape

3.3. Scenario 3: Turning a Windrow

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Commission, E. Circular Economy Action Plan—For a Cleaner and More Competitive Europe; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Sulewski, P.; Kais, K.; Gołaś, M.; Rawa, G.; Urbańska, K.; Wąs, A. Home Bio-Waste Composting for the Circular Economy. Energies 2021, 14, 6164. [Google Scholar] [CrossRef]

- Adhikari, B.K.; Barrington, S.; Martinez, J.; King, S. Characterization of Food Waste and Bulking Agents for Composting. Waste Manag. 2008, 28, 795–804. [Google Scholar] [CrossRef] [PubMed]

- Dunst, G. Kompostierung und Erdenherstellung: Praxisbuch und Anleitung für Hausgarten, Landwirtschaft, Kommune und Profi, 1st ed.; Sonnenerde: Riedlingsdorf, Austria, 2015. [Google Scholar]

- Razza, F.; D’Avino, L.; L’Abate, G.; Lazzeri, L. The Role of Compost in Bio-waste Management and Circular Economy. In Designing Sustainable Technologies, Products and Policies: From Science to Innovation; Benetto, E., Gericke, K., Guiton, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 133–143. [Google Scholar] [CrossRef]

- Sweeten, J.M. Composting Manure and Sludge; Texas A&M AgriLife Extension: College Station, TX, USA, 2008; Available online: https://hdl.handle.net/1969.1/87650 (accessed on 21 July 2024).

- Van Der Linden, A.; Reichel, A. Bio-Waste in Europe: Turning Challenges into Opportunities; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Kuhlman, L.R. Windrow Composting of Agricultural and Municipal Wastes. Resour. Conserv. Recycl. 1990, 4, 151–160. [Google Scholar] [CrossRef]

- Moysiadis, V.; Sarigiannidis, P.; Vitsas, V.; Khelifi, A. Smart Farming in Europe. Comput. Sci. Rev. 2021, 39, 100345. [Google Scholar] [CrossRef]

- Kawasaki, H.; Murakami, S.; Kachi, H.; Ueki, S. Novel Climbing Method of Pruning Robot. In Proceedings of the 2008 SICE Annual Conference, Chofu, Japan, 20–22 August 2008; pp. 160–163. [Google Scholar] [CrossRef]

- Ishigure, Y.; Hirai, K.; Kawasaki, H. A Pruning Robot with a Power-Saving Chainsaw Drive. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; pp. 1223–1228. [Google Scholar] [CrossRef]

- Adamides, G.; Katsanos, C.; Parmet, Y.; Christou, G.; Xenos, M.; Hadzilacos, T.; Edan, Y. HRI Usability Evaluation of Interaction Modes for a Teleoperated Agricultural Robotic Sprayer. Appl. Ergon. 2017, 62, 237–246. [Google Scholar] [CrossRef] [PubMed]

- Oberti, R.; Marchi, M.; Tirelli, P.; Calcante, A.; Iriti, M.; Tona, E.; Hočevar, M.; Baur, J.; Pfaff, J.; Schütz, C.; et al. Selective Spraying of Grapevines for Disease Control Using a Modular Agricultural Robot. Biosyst. Eng. 2016, 146, 203–215. [Google Scholar] [CrossRef]

- Gonzalez-de Soto, M.; Emmi, L.; Perez-Ruiz, M.; Aguera, J.; Gonzalez-de Santos, P. Autonomous Systems for Precise Spraying – Evaluation of a Robotised Patch Sprayer. Biosyst. Eng. 2016, 146, 165–182. [Google Scholar] [CrossRef]

- Comba, L.; Gay, P.; Ricauda Aimonino, D. Robot Ensembles for Grafting Herbaceous Crops. Biosyst. Eng. 2016, 146, 227–239. [Google Scholar] [CrossRef]

- Bloch, V.; Degani, A.; Bechar, A. A Methodology of Orchard Architecture Design for an Optimal Harvesting Robot. Biosyst. Eng. 2018, 166, 126–137. [Google Scholar] [CrossRef]

- Eizicovits, D.; Tuijl, B.; Berman, S.; Edan, Y. Integration of Perception Capabilities in Gripper Design Using Graspability Maps. Biosyst. Eng. 2016, 146, 98–113. [Google Scholar] [CrossRef]

- Barth, R.; Hemming, J.; Henten, E.J. Design of an Eye-in-Hand Sensing and Servo Control Framework for Harvesting Robotics in Dense Vegetation. Biosyst. Eng. 2016, 146, 71–84. [Google Scholar] [CrossRef]

- Kurtser, P.; Edan, Y. Statistical Models for Fruit Detectability: Spatial and Temporal Analyses of Sweet Peppers. Biosyst. Eng. 2018, 171, 272–289. [Google Scholar] [CrossRef]

- Longo, D.; Muscato, G. Design and Simulation of Two Robotic Systems for Automatic Artichoke Harvesting. Robotics 2013, 2, 217–230. [Google Scholar] [CrossRef]

- AGCO GmbH. Project Xaver. 2024. Available online: https://www.fendt.com/de/2-fendt-xaver (accessed on 21 July 2024).

- Naio Technologies. 2024. Available online: www.naio-technologies.com (accessed on 21 July 2024).

- FarmDroid. 2024. Available online: www.farmdroid.dk (accessed on 21 July 2024).

- Shamshiri, R.R.; Weltzien, C.; Hameed, I.A.; Yule, I.J.; Grift, T.E.; Balasundram, S.K.; Pitonakova, L.; Ahmad, D.; Chowdhary, G. Research and Development in Agricultural Robotics: A Perspective of Digital Farming. Int. J. Agric. Biol. Eng. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Bac, C.W.; Roorda, T.; Reshef, R.; Berman, S.; Hemming, J.; van Henten, E.J. Analysis of a Motion Planning Problem for Sweet-Pepper Harvesting in a Dense Obstacle Environment. Biosyst. Eng. 2016, 146, 85–97. [Google Scholar] [CrossRef]

- Hameed, I.; Cour Harbo, A.; Osen, O. Side-to-Side 3D Coverage Path Planning Approach for Agricultural Robots to Minimize Skip/Overlap Areas between Swaths. Robot. Auton. Syst. 2016, 76, 36–45. [Google Scholar] [CrossRef]

- Barth, R. Vision Principles for Harvest Robotics: Sowing Artificial Intelligence in Agriculture. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 30 October 2018. [Google Scholar] [CrossRef]

- Pierzchała, M.; Giguère, P.; Astrup, R. Mapping Forests Using an Unmanned Ground Vehicle with 3D LiDAR and Graph-SLAM. Comput. Electron. Agric. 2018, 145, 217–225. [Google Scholar] [CrossRef]

- Das, J.; Cross, G.; Qu, C.; Makineni, A.; Tokekar, P.; Mulgaonkar, Y. Devices, Systems, and Methods for Automated Monitoring Enabling Precision Agriculture. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015. [Google Scholar] [CrossRef]

- Reitbauer, E.; Schmied, C.; Wieser, M. Autonomous Navigation Module for Tracked Compost Turners. In Proceedings of the 2020 European Navigation Conference (ENC), Dresden, Germany, 23–24 November 2020; p. 10. [Google Scholar] [CrossRef]

- Reitbauer, E.; Schmied, C.; Schedler, M. Integrated Navigation for Tracked Compost Turners Using GNSS, INS, Odometers, Stereo Camera and 3D Map. In Proceedings of the 33rd International Technical Meeting of the Satellite Division of the Institute of Navigation (ION GNSS+ 2020), Online, 21–25 September 2020. [Google Scholar] [CrossRef]

- Cichocki, M.; Reitbauer, E.; Theurl, F.; Schmied, C. Composting 4.0: From The Automatic Steering Of Compost Turners Towards An Autonomous Plant Management. In Proceedings of the 7th Central European Biomass Conference CEBC 2023, Graz, Austria, 18–20 January 2023. [Google Scholar] [CrossRef]

- Cichocki, M.; Landschützer, C. Leveraging Advanced Technologies in Industrial Composting Plants: Exploring Technical and Logistical Opportunities to Achieve Industry 4.0 Standards. Logist. J. 2023. [Google Scholar] [CrossRef]

- Cichocki, M.; Reitbauer, E.; Schmied, C.; Theurl, F. From Waste to Resource: Leveraging Simulation-based Technologies in the Development of an Autonomous Compost Turner. In Proceedings of the Logistikwerkstatt Graz, Graz, Austria, 8–9 May 2023. [Google Scholar] [CrossRef]

- Reitbauer, E.; Schmied, C. Performance Analysis of GNSS/INS/VO/Odometry Sensor Fusion Algorithms for Tracked Agricultural Vehicles. In Proceedings of the 34th International Technical Meeting of the Satellite Division of the Institute of Navigation (ION GNSS+ 2021), St. Louis, MO, USA, 20–24 September 2021; p. 3262. [Google Scholar] [CrossRef]

- Reitbauer, E.; Schmied, C. Bridging GNSS Outages with IMU and Odometry: A Case Study for Agricultural Vehicles. Sensors 2021, 21, 4467. [Google Scholar] [CrossRef] [PubMed]

- Reitbauer, E. Multi-Sensor Positioning for the Automatic Steering of Tracked Agricultural Vehicles. Verlag der Technischen Universität Graz: Graz, Austria, 2022; ISBN 978-3-85125-919-3. [Google Scholar] [CrossRef]

- Theurl, F.; Schmied, C.; Reitbauer, E.; Wieser, M. Automated Route Planning from LiDAR Point Clouds for Agricultural Applications. Eng. Proc. 2023, 54, 54. [Google Scholar] [CrossRef]

- Dijkstra, E.W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Roesmann, C.; Feiten, W.; Woesch, T.; Hoffmann, F.; Bertram, T. Trajectory modification considering dynamic constraints of autonomous robots. In Proceedings of the ROBOTIK 2012—7th German Conference on Robotics, Munich, Germany, 21–22 May 2012; pp. 1–6. [Google Scholar]

- Chitta, S.; Marder-Eppstein, E.; Meeussen, W.; Pradeep, V.; Tsouroukdissian, A.; Bohren, J.; Coleman, D.; Magyar, B.; Raiola, G.; Lüdtke, M.; et al. Ros_control: A Generic and Simple Control Framework for ROS. J. Open Source Softw. 2017, 2, 456. [Google Scholar] [CrossRef]

- Camacho, E.F. Model Predictive Control, 2nd ed.; Advanced Textbooks in Control and Signal Processing; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Fiedler, F.; Karg, B.; Lüken, L.; Brandner, D.; Heinlein, M.; Brabender, F.; Lucia, S. do-mpc: Towards FAIR nonlinear and robust model predictive control. Control Eng. Pract. 2023, 140, 105676. [Google Scholar] [CrossRef]

- Cichocki, M. Transforming the Composting Industry towards Industry 4.0 and Physical Internet Capabilities. Doctoral Thesis, Graz University of Technology, Graz, Austria, 2024. [Google Scholar] [CrossRef]

- Özdemir, M.N.; Kılıç, V.; Ünlüsoy, Y.S. Transient Tracked Vehicle Steering Model. In Proceedings of the ISTVS 8th Americas Regional Conference, Detroit, MI, USA, 12–14 September 2016; p. 20. [Google Scholar]

- Sabiha, A.D.; Kamel, M.A.; Said, E.; Hussein, W.M. ROS-based Trajectory Tracking Control for Autonomous Tracked Vehicle Using Optimized Backstepping and Sliding Mode Control. Robot. Auton. Syst. 2022, 152, 104058. [Google Scholar] [CrossRef]

- Endo, D.; Okada, Y.; Nagatani, K.; Yoshida, K. Path Following Control for Tracked Vehicles Based on Slip-Compensating Odometry. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 2871–2876. [Google Scholar] [CrossRef]

- Moosavian, S.; Kalantari, A. Experimental Slip Estimation for Exact Kinematics Modeling and Control of a Tracked Mobile Robot. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 95–100. [Google Scholar] [CrossRef]

- Lepej, P.; Maurer, J.; Uran, S.; Steinbauer, G. Dynamic Arc Fitting Path Follower for Skid-Steered Mobile Robots. Int. J. Adv. Robot. Syst. 2015, 12, 139. [Google Scholar] [CrossRef]

- CONCLUSION—CO2 Reduction on Industrial Composting Plants Using GNSS-based Cooperative Localization. Available online: https://projekte.ffg.at/projekt/4711800 (accessed on 21 July 2024).

- Cichocki, M.; Landschützer, C.; Hick, H. Development of a Sharing Concept for Industrial Compost Turners Using Model-Based Systems Engineering, under Consideration of Technical and Logistical Aspects. Sustainability 2022, 14, 10694. [Google Scholar] [CrossRef]

- Cichocki, M.; Landschützer, C.; Barenji, A.V.; Montreuil, B. Physical Internet Based Hyperconnected Logistics Platform Enabling Heavy-Duty Machinery Sharing in the Composting Industry: A Simulation-Based Scenario Investigation. In Proceedings of the 9th International Physical Internet Conference (IPIC 2023), Athens, Greece, 13–15 June 2023. [Google Scholar]

- Cichocki, M.; Barenji, A.V.; Montreuil, B.; Landschützer, C. Hyperconnected Logistic Platform for Heavy-Duty Machinery: Leveraging Physical Internet Principles to Drive the Composting Industry. Sustainability 2023, 15, 12898. [Google Scholar] [CrossRef]

| Type of Sensor | Quantity | Model | Description |

|---|---|---|---|

| GNSS | 1 | Alberding A12-RTK | Geodetic GNSS receiver with two antennas |

| IMU | 1 | XSens MTi-G-710 | MEMS IMU |

| Odometry | 2 | Atech AC-X | Wheel encoder on Compost Turner’s tracks |

| Optical Sensor | 1 | Velodyne Ultra Puck | LIDAR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cichocki, M.; Buchmayer, E.; Theurl, F.; Schmied, C. Design, Technical Development, and Evaluation of an Autonomous Compost Turner: An Approach towards Smart Composting. Sustainability 2024, 16, 6347. https://doi.org/10.3390/su16156347

Cichocki M, Buchmayer E, Theurl F, Schmied C. Design, Technical Development, and Evaluation of an Autonomous Compost Turner: An Approach towards Smart Composting. Sustainability. 2024; 16(15):6347. https://doi.org/10.3390/su16156347

Chicago/Turabian StyleCichocki, Max, Eva Buchmayer, Fabian Theurl, and Christoph Schmied. 2024. "Design, Technical Development, and Evaluation of an Autonomous Compost Turner: An Approach towards Smart Composting" Sustainability 16, no. 15: 6347. https://doi.org/10.3390/su16156347

APA StyleCichocki, M., Buchmayer, E., Theurl, F., & Schmied, C. (2024). Design, Technical Development, and Evaluation of an Autonomous Compost Turner: An Approach towards Smart Composting. Sustainability, 16(15), 6347. https://doi.org/10.3390/su16156347