Qualtra Geothermal Power Plant: Life Cycle, Exergo-Economic, and Exergo-Environmental Preliminary Assessment

Abstract

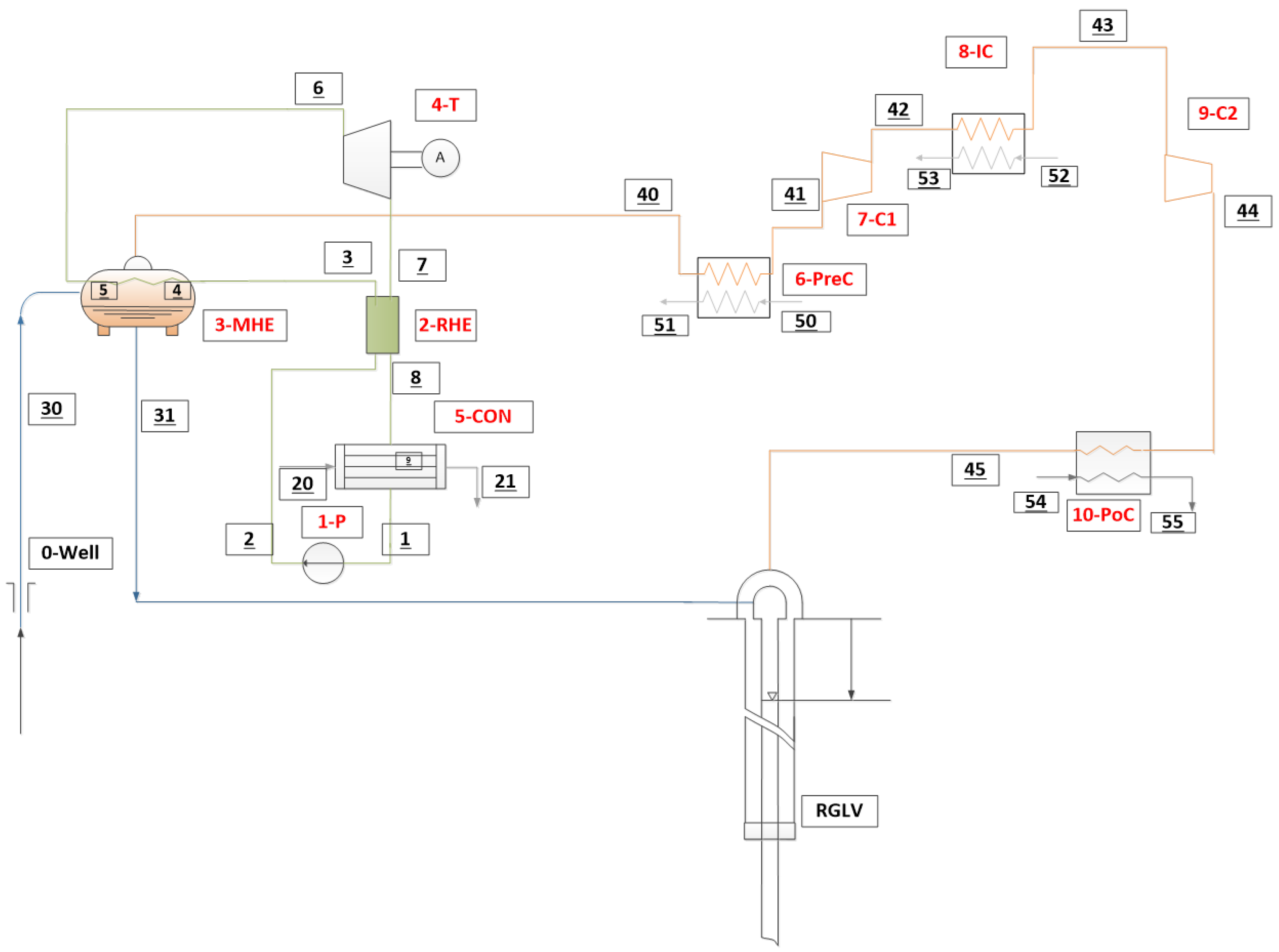

1. Description of the Qualtra Geothermal Project

2. Life Cycle Assessment

2.1. Life Cycle Assessment of Geothermal Power Plants

2.2. Life Cycle Inventory (LCI) for the Qualtra Plant

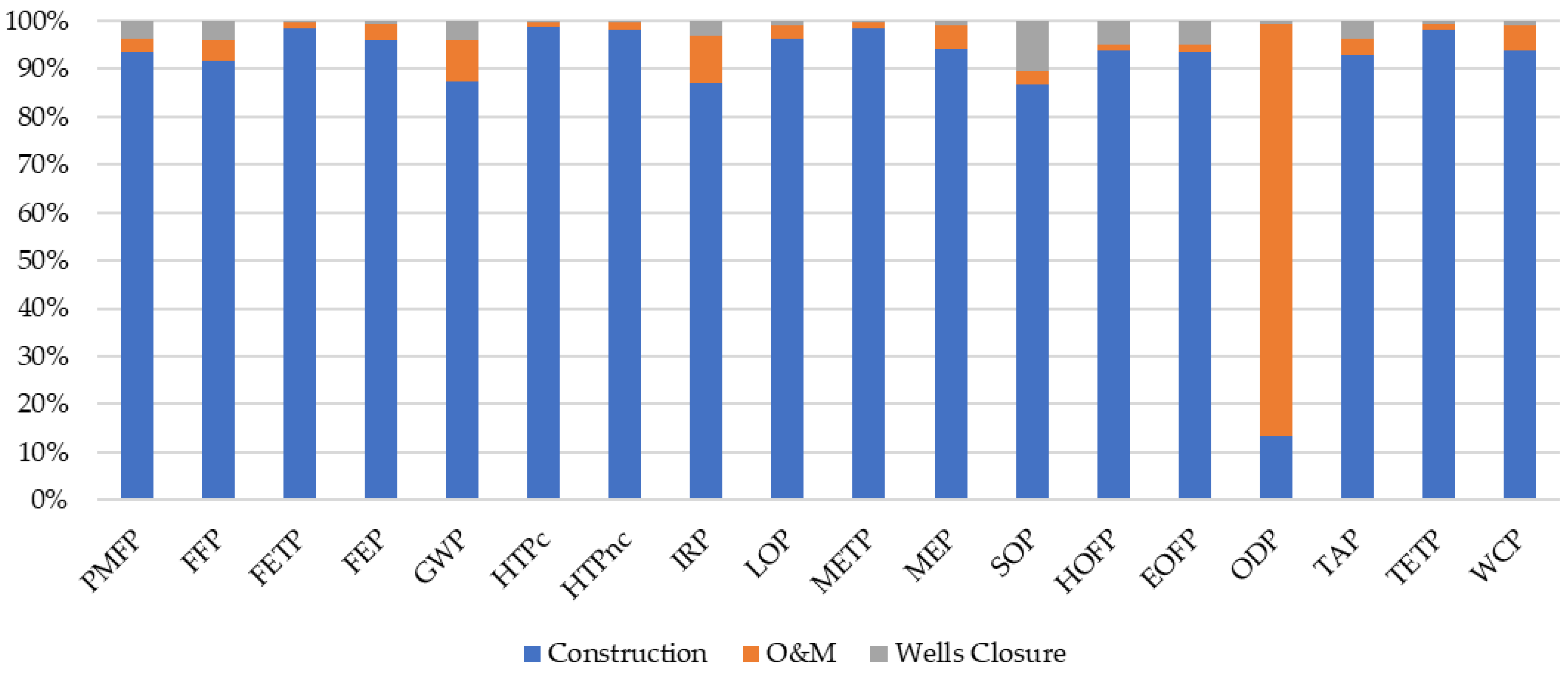

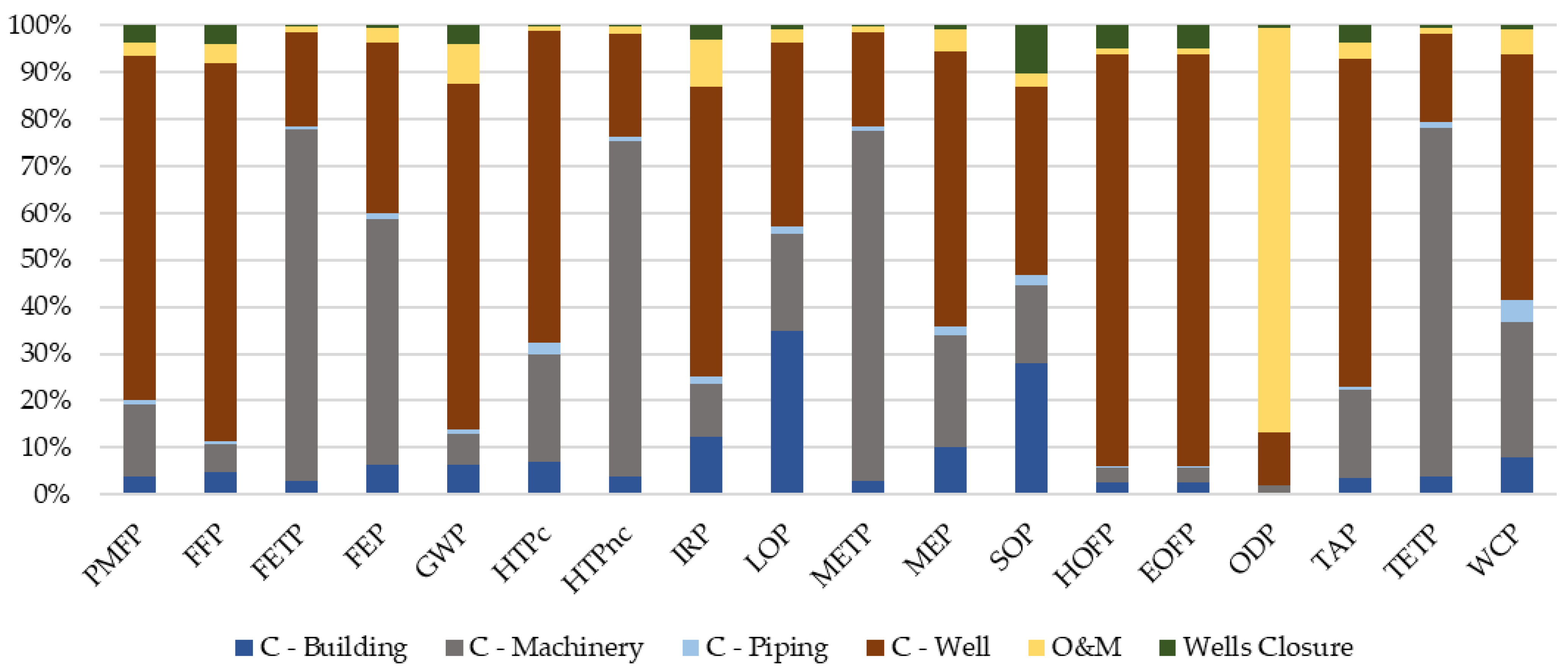

2.3. Midpoint Life Cycle Impact Analysis (LCIA) for the Qualtra Plant

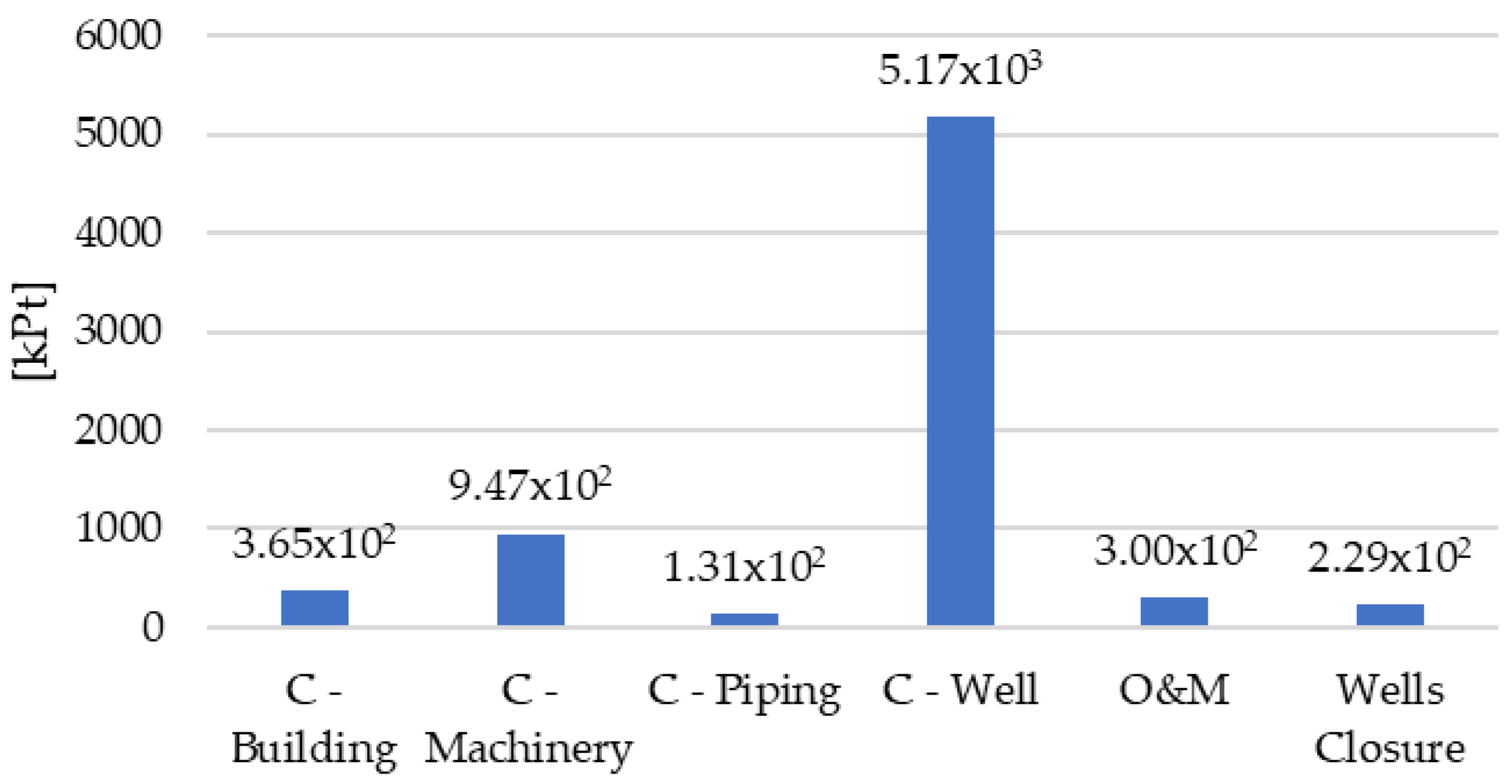

2.4. Building the Single Score—Qualtra

3. Exergy Analysis

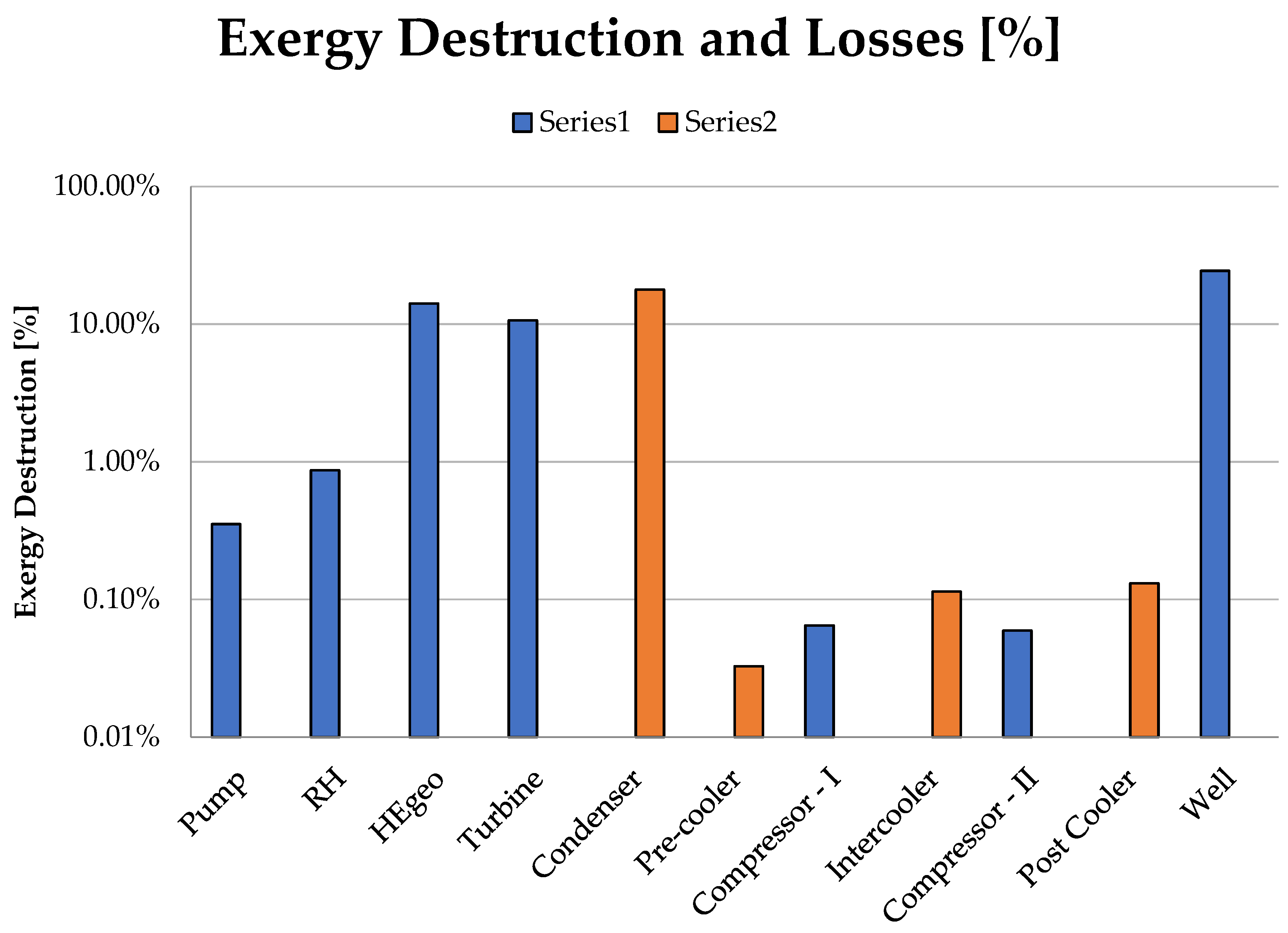

Exergy Analysis Qualtra

4. Exergo-Economic and Exergo-Environmental Analysis

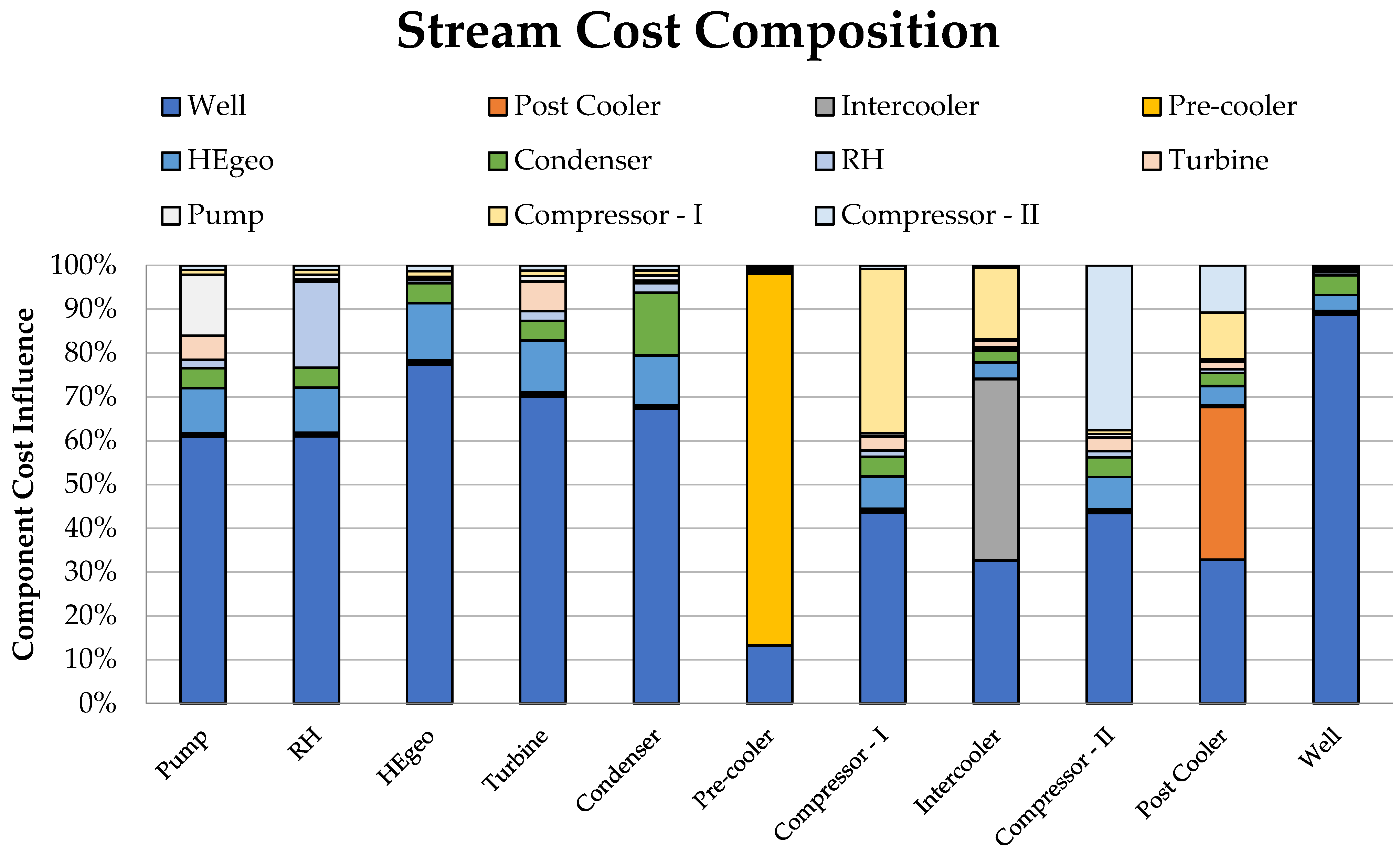

4.1. Exergo-Economic Results Qualtra

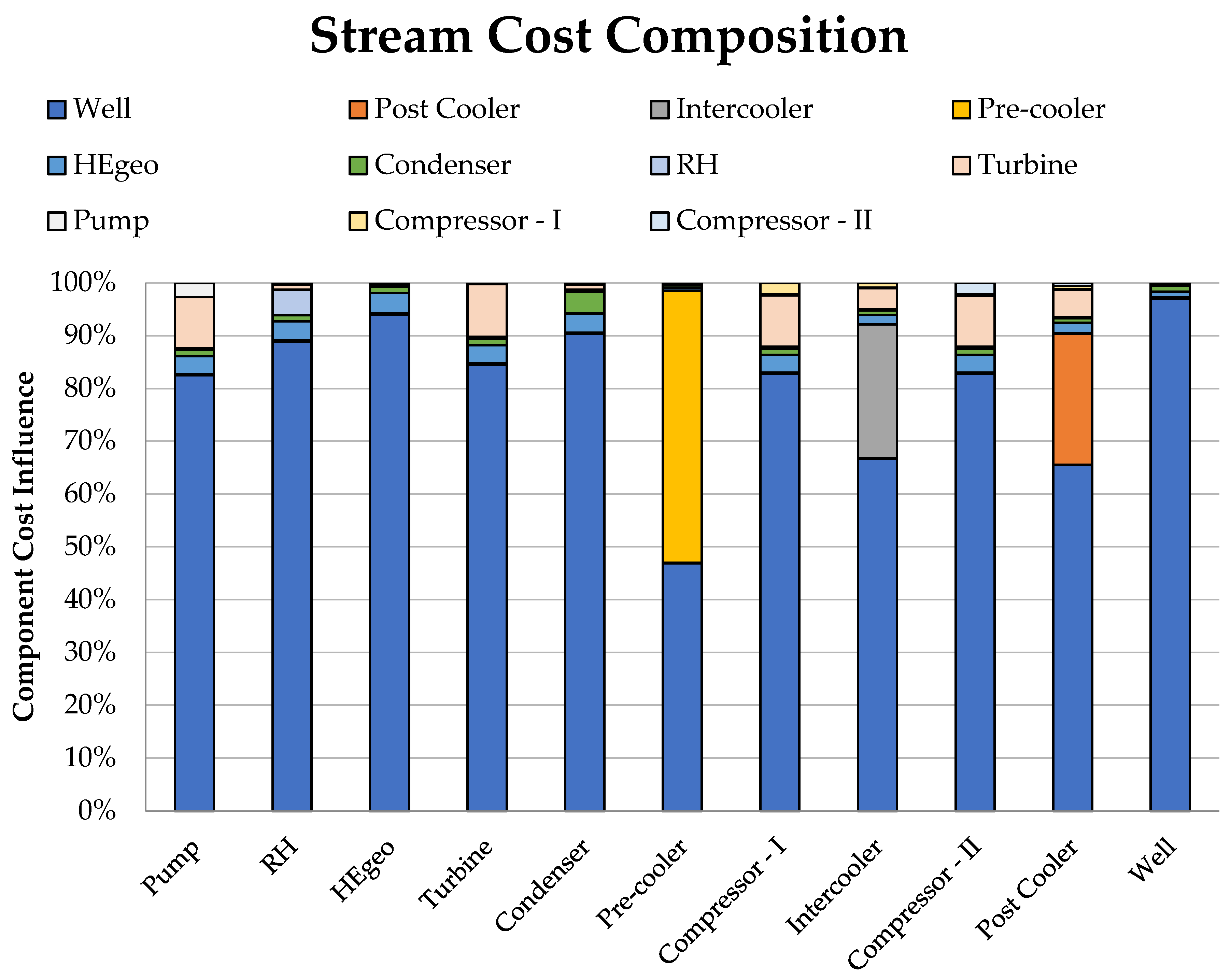

4.2. Exergo-Environmental Analysis Qualtra

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| b | specific environmental cost per unit exergy, EcoPoints/kJ |

| environmental cost per unit time, Ecopoints/s | |

| c | specific cost per unit exergy, €/kJ |

| cost rate, €/s | |

| e | specific exergy, kJ/kg |

| total exergy of a stream, kW | |

| f | capital intensity exergo-economic factor |

| fd | resource intensity exergo-environmental factor |

| h | specific enthalpy, kJ/kg |

| mass flow rate, kg/s | |

| r | cost increase exergo-economic factor |

| rd | impact increase exergo-environemntal factor |

| s | specific enthalpy, kJ/(kgK) |

| T | temperature, K |

| y | exergy destruction ratio |

| LCA impact rate of a component, Ecopoints/s | |

| Component Capital + Operation and Maintenance levelized cost rate, €/s | |

| ¦Å | component or system exergy efficiency |

| Subscripts: | |

| o | reference environment |

| d | direct |

| D | Destruction |

| e | outlet (exit) |

| F | Fuel |

| in | inlet |

| ind | indirect |

| k | k-th component |

| L | Loss |

| P | Product |

| Res | Resource |

| Rock | Hot Rock reference |

| Acronyms: | |

| GHG | Greenhouse Gases |

| GPP | Geothermal Power Plant |

References

- Leontidis, V.; Niknam, P.H.; Durgut, I.; Talluri, L.; Manfrida, G.; Fiaschi, D.; Akin, S.; Gainville, M. Modelling reinjection of two-phase non-condensable gases and water in geothermal wells. Appl. Therm. Eng. 2023, 223, 120018. [Google Scholar] [CrossRef]

- Marieni, C.; Voigt, M.; Clark, D.E.; Gíslason, S.R.; Oelkers, E.H. Mineralization potential of water-dissolved CO2 and H2S injected into basalts as function of temperature: Freshwater versus Seawater. Int. J. Greenh. Gas Control 2021, 109, 103357. [Google Scholar] [CrossRef]

- Karlsdóttir, M.R.; Palsson, O.P.; Pálsson, H.; Maya-Drysdale, L. Life cycle inventory of a flash geothermal combined heat and power plant located in Iceland. Int. J. Life Cycle Assess 2015, 20, 503–519. [Google Scholar] [CrossRef]

- Paulillo, A.; Striolo, A.; Lettieri, P. The environmental impacts and the carbon intensity of geothermal energy: A case study on the Hellisheiði plant. Environ. Int. 2019, 133, 105226. [Google Scholar] [CrossRef] [PubMed]

- Heberle, F.; Schifflechner, C.; Brüggemann, D. Life cycle assessment of Organic Rankine Cycles for geothermal power generation considering low-GWP working fluids. Geothermics 2016, 64, 392–400. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Pratiwi, A.; Ravier, G.; Genter, A. Life-cycle climate-change impact assessment of enhanced geothermal system plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

- Parisi, M.L.; Douziech, M.; Tosti, L.; Pérez-López, P.; Mendecka, B.; Ulgiati, S.; Fiaschi, D.; Manfrida, G.; Blanc, I. Definition of LCA Guidelines in the Geothermal Sector to Enhance Result Comparability. Energies 2020, 13, 3534. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Zuffi, C.; Manfrida, G.; Asdrubali, F.; Talluri, L. Life cycle assessment of geothermal power plants: A comparison with other energy conversion technologies. Geothermics 2022, 104, 102434. [Google Scholar] [CrossRef]

- OpenLCA 1.10, GreenDelta. Available online: https://www.openlca.org/download/ (accessed on 10 February 2021).

- Ecoinvent Database 3.6. 2020. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-36/ecoinvent-36.html (accessed on 1 December 2020).

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Butterworths: London, UK, 1985. [Google Scholar]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical and Metallurgical Processes; Hemisphere Publishing Corporation: New York, NY, USA, 1988. [Google Scholar]

- Di Pippo, R. Second Law assessment of binary plants generating power from low-temperature geothermal fluids. Geothermics 2004, 33, 565–586. [Google Scholar] [CrossRef]

- Bejan, A.; Moran, M.; Tsatsaronis, G. Thermal Design and Optimization; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Lazzaretto, A.; Tsatsaronis, G. SPECO: A systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 2006, 31, 1257–1289. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Czieszla, F. Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 659–680. ISBN 9780122274107. [Google Scholar] [CrossRef]

- Frangopoulos, C.; Caralis, Y.C. A method for taking into account environmental impacts in the economic evaluation of energy systems. Energy Convers. Manag. 1997, 38, 1751–1763. [Google Scholar] [CrossRef]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Ungar, P.; Talluri, L. Development of an exergo-economic and exergo-environmental tool for power plant assessment: Evaluation of a geothermal case study. In Proceedings of the 34th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2021), Taormina, Italy, 28 June–2 July 2021. [Google Scholar] [CrossRef]

| Site-Specific Parameter | Unit | Value for Qualtra |

|---|---|---|

| Reservoir | ||

| Number of wells drilled | - | 5 |

| Total meters drilled | m | 18,520 |

| Collection pipelines | m | 1750 |

| Power plant | ||

| Net installed capacity binary cycle | MW | 10 |

| Capacity factor | % | 0.92 |

| Useful life | y | 30 |

| Well Drilling | Provider | Amount | Unit |

|---|---|---|---|

| Input | |||

| activated bentonite | market for activated bentonite|activated bentonite|Cutoff, S—GLO | 7.23 | kg |

| barite | market for barite|barite|Cutoff, S—GLO | 38.55 | kg |

| chemical, inorganic | market for chemicals, inorganic|chemical, inorganic|Cutoff, S—GLO | 0.41 | kg |

| chemical, organic | market for chemical, organic|chemical, organic|Cutoff, S—GLO | 2.90 | kg |

| chemical, organic | market for chemical, organic|chemical, organic|Cutoff, S—GLO | 0.33 | kg |

| diesel, burned in building machine | diesel, burned in building machine|diesel, burned in building machine|Cutoff, S—GLO | 5534.10 | MJ |

| sodium hydroxide, without water, in 50% solution state | market for sodium hydroxide, without water, in 50% solution state|sodium hydroxide, without water, in 50% solution state|Cutoff, S—GLO | 0.37 | kg |

| steel, low-alloyed, hot rolled | market for steel, low-alloyed, hot rolled|steel, low-alloyed, hot rolled|Cutoff, S—GLO | 59.30 | kg |

| Water, well, RER | 0.01 | m3 | |

| Output | |||

| Drilling well | 1 | m |

| Machinery | Provider | Amount | Unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [1] | [2] | [3] | [4] | [5] | [6] | [7] | [8] | [9] | [10] | |||

| aluminum, cast alloy | market for copper|copper|Cutoff, S—GLO | 7645 | 1268 | 261 | 238 | kg | ||||||

| cast iron | market for steel, chromium steel 18/8|steel, chromium steel 18/8|Cutoff, S—GLO | 233 | 1904 | 4062 | 559 | 511 | kg | |||||

| copper | market for cast iron|cast iron|Cutoff, S—GLO | 328 | 2035 | 16,677 | 13,472 | kg | ||||||

| polyethylene, high density, granulate | market for steel, low-alloyed|steel, low-alloyed|Cutoff, S—GLO | 3371 | 6401 | kg | ||||||||

| reinforcing steel | market for aluminum, cast alloy|aluminum, cast alloy|Cutoff, S—GLO | 138,811 | kg | |||||||||

| steel, chromium steel 18/8 | market for polyethylene, high density, granulate|polyethylene, high density, granulate|Cutoff, S—GLO | 987 | 4984 | 2286 | 429 | 684 | 881 | kg | ||||

| steel, low-alloyed | market for reinforcing steel|reinforcing steel|Cutoff, S—GLO | 33 | 268 | 244,865 | 35,075 | 744 | 681 | kg | ||||

| wire drawing, copper | market for wire drawing, copper|wire drawing, copper|Cutoff, S—GLO | 372 | 341 | kg | ||||||||

| ReCiPe 2016 Midpoint | Impact Result | Unit (Refer to kWh) | |

|---|---|---|---|

| Fine particulate matter formation | PMFP | 1.80 × 10−5 | kg PM2.5 eq |

| Fossil resource scarcity | FFP | 1.86 × 10−3 | kg oil eq |

| Freshwater ecotoxicity | FETP | 1.10 × 10−3 | kg 1,4-DCB |

| Freshwater eutrophication | FEP | 2.10 × 10−6 | kg P eq |

| Global warming | GWP | 6.56 × 10−3 | kg CO2 eq |

| Human carcinogenic toxicity | HTPc | 1.09 × 10−3 | kg 1,4-DCB |

| Human non-carcinogenic toxicity | HTPnc | 1.14 × 10−2 | kg 1,4-DCB |

| Ionizing radiation | IRP | 1.40 × 10−4 | kBq Co-60 eq |

| Land use | LOP | 3.33 × 10−5 | m2a crop eq |

| Marine ecotoxicity | METP | 1.40 × 10−3 | kg 1,4-DCB |

| Marine eutrophication | MEP | 1.09 × 10−7 | kg N eq |

| Mineral resource scarcity | SOP | 2.65 × 10−6 | kg Cu eq |

| Ozone formation, human health | HOFP | 5.72 × 10−5 | kg NOx eq |

| Ozone formation, terrestrial ecosystems | EOFP | 5.84 × 10−5 | kg NOx eq |

| Stratospheric ozone depletion | ODP | 2.33 × 10−8 | kg CFC11 eq |

| Terrestrial acidification | TAP | 3.60 × 10−5 | kg SO2 eq |

| Terrestrial ecotoxicity | TETP | 5.71 × 10−2 | kg 1,4-DCB |

| Water consumption | WCP | 1.49 × 10−2 | m3 |

| Component Number | Component Name | Component Number | Component Name |

|---|---|---|---|

| 1 | Pump | 6 | Pre-cooler (or pc) |

| 2 | RHE | 7 | Compressor 1 (or comp-1) |

| 3 | MHE (Geo) | 8 | Intercooler (or ic) |

| 4 | Turbine | 9 | Compressor 2 (or comp-2) |

| 5 | Condenser | 10 | Post Cooler (or pc) |

| k | Component | PEC [€] | [€/s] | [€/s] | [€/s] | [€/kWh] | [€/kWh] | [%] | [-] |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Pump | 4.92 × 105 | 3.7 × 10−3 | 3.40 × 10−3 | 7.05 × 10−3 | 9.47 × 10−2 | 1.37 × 10−1 | 51.9 | 0.45 |

| 2 | RH | 9.00 × 105 | 6.7 × 10−3 | 5.82 × 10−3 | 1.25 × 10−2 | 6.58 × 10−2 | 1.13 × 10−1 | 53.5 | 0.71 |

| 3 | HEgeo | 4.82 × 106 | 3.6 × 10−2 | 6.15 × 10−2 | 9.73 × 10−2 | 4.28 × 10−2 | 6.10 × 10−2 | 36.8 | 0.43 |

| 4 | Turbine | 2.76 × 106 | 2.0 × 10−2 | 7.13 × 10−2 | 9.18 × 10−2 | 6.58 × 10−2 | 9.47 × 10−2 | 22.4 | 0.44 |

| 5 | Condenser | 1.84 × 106 | 1.4 × 10−2 | 1.19 × 10−1 | 1.33 × 10−1 | 6.58 × 10−2 | 0.00 × 100 | 10.3 | - |

| 6 | Pre-cooler | 1.06 × 105 | 7.9 × 10−4 | 1.40 × 10−4 | 9.30 × 10−4 | 4.28 × 10−2 | 0.00 × 100 | 84.7 | - |

| 7 | Compressor—I | 5.10 × 105 | 3.8 × 10−3 | 6.20 × 10−4 | 4.42 × 10−3 | 9.47 × 10−2 | 2.40 × 10−1 | 85.9 | 1.54 |

| 8 | Intercooler | 1.16 × 105 | 8.6 × 10−4 | 1.24 × 10−3 | 2.10 × 10−3 | 1.07 × 10−1 | 0.00 × 100 | 41.1 | - |

| 9 | Compressor—II | 4.71 × 105 | 3.5 × 10−3 | 5.70 × 10−4 | 4.07 × 10−3 | 9.47 × 10−2 | 2.42 × 10−1 | 86.0 | 1.55 |

| 10 | Post Cooler | 1.32 × 105 | 9.8 × 10−4 | 1.86 × 10−3 | 2.84 × 10−3 | 1.40 × 10−1 | 0.00 × 100 | 34.6 | - |

| 11 | Well | 4.63 × 107 | 2.1 × 10−1 | 0.00 × 100 | 2.12 × 10−1 | 0.00 × 100 | 4.09 × 10−2 | 100.0 | 0.00 |

| - | Total Plant | 5.84 × 107 | - | - | - | - | - | - | - |

| k | Component | Single Score [kPts] | [Pts/s] | [Pts/s] | [Pts/s] | [%] | [-] |

|---|---|---|---|---|---|---|---|

| 1 | Pump | 11.93 | 5.20 × 10−4 | 3.00 × 10−3 | 3.52 × 10−3 | 14.78 | 0.21 |

| 2 | RH | 25.63 | 1.12 × 10−3 | 4.93 × 10−3 | 6.05 × 10−3 | 18.46 | 0.35 |

| 3 | HEgeo | 210.0 | 9.15 × 10−3 | 6.00 × 10−2 | 6.91 × 10−2 | 13.24 | 0.28 |

| 4 | Turbine | 609.29 | 2.65 × 10−2 | 6.04 × 10−2 | 8.69 × 10−2 | 30.52 | 0.50 |

| 5 | Condenser | 70.23 | 3.06 × 10−3 | 1.01 × 10−1 | 1.04 × 10−1 | 2.93 | - |

| 6 | Pre-cooler | 3.40 | 1.48 × 10−4 | 1.39 × 10−4 | 2.87 × 10−4 | 51.54 | - |

| 7 | Compressor—I | 2.10 | 9.17 × 10−5 | 5.50 × 10−4 | 6.42 × 10−4 | 14.28 | 0.19 |

| 8 | Intercooler | 5.44 | 2.37 × 10−4 | 7.00 × 10−4 | 9.37 × 10−4 | 25.28 | - |

| 9 | Compressor—II | 1.94 | 8.43 × 10−5 | 5.05 × 10−4 | 5.89 × 10−4 | 14.32 | 0.19 |

| 10 | Post Cooler | 7.00 | 3.05 × 10−4 | 9.31 × 10−4 | 1.24 × 10−3 | 24.68 | - |

| 11 | Well | 5142 | 2.25 × 10−1 | 0.00 × 100 | 2.25 × 10−1 | 100.0 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuffi, C.; Ungar, P.; Fiaschi, D.; Manfrida, G.; Batini, F. Qualtra Geothermal Power Plant: Life Cycle, Exergo-Economic, and Exergo-Environmental Preliminary Assessment. Sustainability 2024, 16, 4622. https://doi.org/10.3390/su16114622

Zuffi C, Ungar P, Fiaschi D, Manfrida G, Batini F. Qualtra Geothermal Power Plant: Life Cycle, Exergo-Economic, and Exergo-Environmental Preliminary Assessment. Sustainability. 2024; 16(11):4622. https://doi.org/10.3390/su16114622

Chicago/Turabian StyleZuffi, Claudio, Pietro Ungar, Daniele Fiaschi, Giampaolo Manfrida, and Fausto Batini. 2024. "Qualtra Geothermal Power Plant: Life Cycle, Exergo-Economic, and Exergo-Environmental Preliminary Assessment" Sustainability 16, no. 11: 4622. https://doi.org/10.3390/su16114622

APA StyleZuffi, C., Ungar, P., Fiaschi, D., Manfrida, G., & Batini, F. (2024). Qualtra Geothermal Power Plant: Life Cycle, Exergo-Economic, and Exergo-Environmental Preliminary Assessment. Sustainability, 16(11), 4622. https://doi.org/10.3390/su16114622